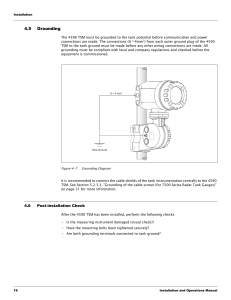

International Journal of Pressure Vessels and Piping 207 (2024) 105113 Contents lists available at ScienceDirect International Journal of Pressure Vessels and Piping journal homepage: www.elsevier.com/locate/ijpvp Analyzing joint efficiency in storage tanks: A comparative study of API 650 standard and API 579 using finite element analysis for enhanced reliability Deivi García-G a, *, J. Barco-Burgos b, c, Jaime Chaparro d, U. Eicker b, Joya Cárdenas D.R e, f, Alberto Saldaña-Robles f a Department of Mechanical Engineering, Universidad Nacional de Colombia, Bogotá, Colombia Department of Buildings, Civil and Environmental Engineering, Concordia University, 1455 Boulevard de Maisonneuve O., EV-6.111, Montréal, Canada I2E3 Institute of Innovations on Ecomaterials, Ecoproducts and Ecoenergies, Université du Québec à Trois-Rivières, Pavillon Y3351, Trois-Rivières, Québec, Canada d 3 Engineering Group SAS, Bogotá, Colombia e Facultad de Ingenierías y Tecnologías, Instituto Xerira, Universidad de Santander, Bucaramanga, 680003, Colombia f Department of Agricultural Engineering, Universidad de Guanajuato, Irapuato-Silao Km. 9, 36500 Ex-Hacienda El Copal, Irapuato, Guanajuato, Mexico b c A R T I C L E I N F O A B S T R A C T Keywords: Storage tank deformation Seismic analysis ASME/API fitness-for-service methodology Failure mode analysis Joint efficiency upgrade Finite element analysis techniques This study compares two renowned methodologies, API 650 and API 579, focusing on the analysis of joint ef­ ficiency at a value of 0.7. Using Finite Element Analysis (FEA), the research suggests that a 35 % increase in filling height might be achievable for a large tank that adhere to the stability criteria outlined by API 650. To support these findings, 337 simulations rigorously examined various parameters. These encompass the design factor (β), bottom constraint, geometric configuration, mesh size, and a newly introduced Local ASME criterion. The latter is specifically introduced to evaluate protection against plastic collapse for Maximum Fill Height (MFH). Additionally, the study advocates elevating the joint efficiency from 0.7 to a range of 0.8–0.87 in API 653. This recommendation is pertinent to storage tanks that are not susceptible to buckling failure mode and possess limited documentation. The outcomes of this research provide significant insights into tank design and have the potential to refine industry standards and practices. 1. Introduction Aboveground storage tanks (AST) have been essential in the oil and gas industry since the late 19th century. The industry has continuously evolved from initially utilizing wooden barrels to building larger welded storage tanks to meet storage demands [1,2]. However, containment loss has persisted as a critical problem, leading to advancements in welding technology and standards such as API 12C in 1935 [3,4]. This improvement was met with emerging challenges like brittle fracture and corrosion, necessitating ongoing research, codes, and regulations for issues such as corrosion control, environmental impact, safety structure design margin, and integrity assessment [1,2,4]. In examining the failures of storage tanks over the last 55 years, it has been concluded that adherence to good design, construction, mainte­ nance, and operation practices should have prevented most accidents [5][6]. Joint efforts by technical committees like ASME Boiler & Pres­ sure Vessel Code (B&PVC) and American Petroleum Institute (API) culminated in the release of the API RP 579 Fitness-for-Service (FFS) code in the early 21st century, offering guidance for operation suitability concerning damages like thickness metal loss, deformation, lamination, and cracks [7–10]. With 60 years of analytical and experimental research, failure modes in pressure vessels and tankage are now more understood and organized [11–19], guided by methodologies such as API 579/ASME FFS-1 [15]. Recent technological advancements in computation hardware have aided in achieving fidelity in Finite Element Analysis (FEA) models and experimental results [20–24][18,25–29]. Nevertheless, complex phe­ nomena like seismic events remain unresolved [30]. Various researchers have worked on mathematical formulations, defining safety margins, and creating standards like Eurocode 8 and API 650 [31–41]. In the past 15 years, the use of FEA in conjunction with risk proba­ bilistic methods like incremental dynamic analysis (IDA) has provided insights into buckling failure mode mechanisms, promoted mainly by excessive displacement and rotation of the shell-to-bottom joint, and other aspects of tank behavior under seismic loads [42–48]. These findings highlight the potential for simulation enhancement and reveal discrepancies between standards and simulation results [49–52]. * Corresponding author. E-mail address: [email protected] (D. García-G). https://doi.org/10.1016/j.ijpvp.2023.105113 Received 10 October 2023; Received in revised form 28 November 2023; Accepted 10 December 2023 Available online 21 December 2023 0308-0161/© 2023 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/bync-nd/4.0/). D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Nomenclature t_actual the actual thickness of the tank course, mm Vc = Design base shear due to the convective component, N V equivalent = Equivalent lateral seismic force, G-forces Vi = Design base shear due to impulsive component, N Vseismic = Total design base shear, N Wc = A practical convective portion of the liquid weight, N Wf = Weight of the tank bottom, N Wi = The practical impulsive portion of the liquid weight, N Wr = Weight of the fixed tank roof, N Ws = Total weight of the tank shell, N Y = Distance from the liquid surface to the analysis point, m z = The vertical distance from the bottom to the assessment point, m γ = Specific weight, N/m3 γ1 = Micro-strain region of the stress-strain curve γ2 = Macro-strain region of the stress-strain curve εL = Limiting triaxial strain, dimensionless εLU = Uniaxial strain limit, dimensionless εcf = Cold-forming strain, dimensionless αsl = The material factor for the multiaxial strain limit β new = β defined by experimental research - 1.67, dimensionless β old = β defined by table 2D.4 from API 579 - 2.5, dimensionless θ = Angle to the horizontal direction, radians ρ = Density of stored product, kg/m3 σ1 = Principal stress in the 1-direction σ2 = Principal stress in the 2-direction σ3 = Principal stress in the 3-direction σe = Von Mises stress, Mpa σh = Hydrostatic stress in tank shell, Mpa σs = Hydrodynamic stress in tank shell, Mpa σt = Hoop stress in tank shell, Mpa σUTS = Engineering ultimate tensile strength, Mpa σy = Engineering yield strength, Mpa a = Element size, mm a_gravity = increased acceleration for design factors, m/sg2 Ac = Convective spectral acceleration, G-forces Ai = Impulsive Spectral Acceleration, G-forces Cj(z) = dimensionless coefficient, dimensionless Co(r,z) = dimensionless coefficient, dimensionless D = nominal tank diameter, m E = dimensionless joint efficiency - 0.7 Ey = Modulus of elasticity, Mpa G = design-specific gravity, dimensionless g = acceleration of gravity, 9.81 m/sg2 H = Stress-strain curve fitting parameter h = height of liquid for hydro-static/dynamic calculation, m I1 = modified Bessel function of the first kind, dimensionless I’1 = the first derivative of I1, dimensionless index n = nth impulsive mode, dimensionless J = Anchorage ratio defined by API 650 J1 = Bessel function of the first kind, dimensionless MFH = Maximum Fill Height, m m2 = material constant used for local strain limit Nc = Convective hoop membrane force, N/mm Nh = Hydrostatic membrane force, N/mm Ni = Impulsive hoop membrane force, N/mm Pbc = Convective base pressure, Mpa Pbi = Impulsive base pressure, Mpa Phydrostatic = Hydrostatic pressure, Mpa Pwc = Convective wall pressure, Mpa Pwi = Impulsive wall pressure, Mpa R = Tank radius, m r = radial position, m RSFa = Allowable remaining strength factor, dimensionless t = Shell thickness, mm Researchers, such as Nadarajah et al. and Zheng Li et al., have con­ ducted experiments which suggest that design factors may be too con­ servative. As a result, they have proposed reducing design margins [53, 54]. With the industry’s increasing focus on reconditioning existing infrastructure for new technologies like hydrogen, methanol, ethanol, ammonia, and blended feedstock [55–57], it has become economically viable to evaluate and update the efficiencies of existing storage tanks in order to increase the capacity of this growing market. However, no research has yet addressed the simultaneous use of the β factor and joint efficiency, E, in finite element analysis models, nor have the limitations on filling height in aboveground storage tanks been studied [58–60]. This study aims to fill this gap by investigating the impact of design factors β and E on filling height limitation for storage tanks subjected to earthquakes. Utilizing FEA, this research compares load models and geometries to identify restrictions on Fitness-for-Service assessment. The results will contribute to a better understanding of boundary conditions, geometry, and seismic load model in contrast to the existing formulation in API 650, ultimately proposing a revised joint efficiency value. 2. Materials and methods In the current investigation, a specified tank model is rigorously analyzed. The study employs an integrated approach, incorporating API 650/653 standards for tank construction and maintenance and API 579 code for Fitness-for-Service assessments through Finite Element Analysis (FEA). Material behavior characteristics, calibrated element size, in­ cremental time steps, and geometric configuration are meticulously delineated. Boundary conditions and seismic load models are also sys­ tematically defined to emulate realistic constraints and operational re­ quirements. These parameters offer a robust framework for evaluating the tank model’s structural integrity and functional suitability under diverse conditions. To estimate possible over conservatism imposed by design standards on the maximum fill height for storage tanks, an analysis was conducted on a storage tank with the following attributes. 1. Tank with minimal documentation, which lack of design and main­ tenance records, requires a treatment with a joint efficiency of 0.7. Table 1 Tank overview with minimal documentation. Nominal Capacity (m3) Diameter (m) Height (m) Product Specific Gravity Tank anchorage 8.640 Pressure Design (mbar) Atmos. 27.432 Temperature Design (◦ C) 49 14.630 Material Unknown Water Tank type Fixed Roof 1 N◦ of Columns 7 No anchors N◦ of Rafters 24 inner side 48 outer side 2 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 2. The studied tank evidenced overall shell deformation, and exceeded the plumbness tolerance referenced by API 653. There is no docu­ mented research which addresses limitation in maximum fill height due to shell deformation. 3. Location of the tank in a region susceptible to seismic activities, re­ quires that the tank owner evaluate the suitability to operate under seismic loads and limit the fill height of the tank. 4. The stored product of the tank will change from crude oil to water. The integrity assessment will be based on a heavier product than design. Shell imperfections is a characteristic encouraged by other re­ searchers to be investigated [46,61]. Further details related to the tank configuration can be found in Table 1 and Fig. 1 and appendix A. The studied tank presented a U-type channel reinforcement at the sixth course to prevent additional shell deformation, as depicted in Fig. 1. Additional details related to thicknesses and reinforcement are presented in Table 2. Two primary methodologies were proposed for evaluating the maximum fill height (MFH) in storage tanks: the API 653/650 standard approach described in Fig. 2 and the Finite Element Analysis (FEA) Fig. 1. Reinforcement details and schematic tank configuration in front view. Table 2 Tank configuration and thicknesses. Thicknesses (mm) Bottom Course 1 6.35 12.45 Course Height 1 to 6 (m) 2.438 Course 2 9.78 U-channel Reinforcement (mm) Course 3 7.67 Web Thickness (mm) Course 4 6.48 Flange Thickness (mm) 150 × 50 7.95 8.7 Course 5 Course 6 6.58 6.50 Distance from reinforcement to TopAngle (mm) 600 Fig. 2. API 653/API 650 methodology for tank assessment [60]. 3 Roof 4.78 Aspect ratio (H/R) 1 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 convective design response spectrum acceleration parameter (%g), D is nominal tank diameter (m), and H is maximum design product level (m). The parameters shown in Table 4 are considered in assessing earth­ quake load. The dynamic hoop tensile stress is directly combined with the hy­ drostatic design stress, as described in API 650 and shown in Eq. (4). √̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅ Nh ± N 2i + N 2c σt = σh ± σs = (4) t Table 3 Anchorage ratio criteria [60]. Anchorage Ratio, J Criteria J ≤ 0.785 0.785 ≤ J ≤ 1.54 J > 1.54 The tank is self-anchored The tank is uplifting but stable. The tank is not stable Table 4 Seismic parameters are to be considered in the assessment. Peak Ground Acceleration, Sp Seismic Group Scaling Factor Site Class Impulsive Spectral Acceleration, Ai Convective spectral acceleration, Ac 0.3 g III 0.75 D 0.23 g 0.05 g Nh is the product hydrostatic membrane force (N/mm) and is calculated according to Eq. (5), computed using SI units. σ t is the total combined hoop stress in the shell (MPa) σ h is the hydrostatic hoop stress in the shell (MPa) Nh = 4.9(MFH − 0.3)DG API 650 – E.6.2.4 defines the maximum allowable hoop tension membrane stress for the hydrostatic plus the hydrodynamic effect. This calculation considers allowable stress material and joint efficiency. As the fill height decreases, so does the hoop stress in the shell. Specialized in-house software aids in the API 650 calculations for structural strength, stability criteria, and the maximum allowable hoop stress according to API 650 E.6.2.4, defining the tank’s maximum fill height and anchorage requirement [60]. simulation described in Fig. 3. 2.1. API 650/653 standard methodology API 653/API 650 traditional approach defined in Fig. 2 assumes a perfect cylindrical form, which focuses on the elastic behavior of the tank under two main operational scenarios. Hydrostatic assessment defines the Maximum Fill Height (MFH) as the deterministic parameter for safe operation, and the liquid level must not exceed its value and the allowable stresses of the material. The hydro­ static load is assessed using the 1-foot method from the API 650/653 standard, a straightforward hand calculation defined in Equation (1). MFHAPI653 = S.E.tactual + 0.3 4.9 DG 2.2. API 579 code – FEA methodology According to API 579 general guidelines, a systematic analysis using finite element approach is adopted to evaluate the maximum fill height, as depicted in Fig. 3. This approach encompasses material behavior, element size, incremental time step, geometry configuration, boundary conditions, and seismic load model. To enhance the credibility of the simulations and establish a reliable MFH for the tank, a sensitivity analysis is conducted based on β design factor. The FE software package ANSYS Workbench version 2020 R1 [62] is used to carry out 337 simulations, where the first load step from 0 to 1 corresponds to hydrostatic load and gravity loads, and the second load step from time 1 to 2 is designated to seismic load, both load steps are simulated using an incremental non-linear static analysis. It is essential to clarify that load step time is not directly related to loads dependent on time but establishes the sequence in which loads are applied in the model. The influence of joint efficiency of 0.7 is introduced in the FEA model using a global approach. In other words, the applied load is increased by multiplying by the inverse of the governing weld joint ef­ ficiency before determining the hydrostatic and hydrodynamic load. Firstly, a nonlinear material behavior such as elastic-plastic with isotropic hardening is considered in the FEA, and this choice is moti­ vated by its enhanced capability to identify the plastic-buckling failure mode [63][64,65]. Distinct element sizes for the model are considered in the assessment to identify discrepancies in the results, and incre­ mental time steps are analyzed to overcome non-convergence issues. See section 2.2.1 and 2.2.2 for more information. Secondly, a comparative analysis, detailed in section 2.2.3, is con­ ducted among four different shell configurations to determine if overall shell deformation influenced the maximum fill height of the tank (Per­ fect cylinder, geometry from topological measurements, GMNIA_I and GMNIA_II). Thirdly, four types of boundary conditions described in section 2.2.4 are considered in the assessment: Fully fixed, MPC (Multi-point constraint), Elastic-support, and Frictional contact; the first two condi­ tions do not permit any rotation of the shell-to-bottom joint. Subsequently, three distinct seismic models further discussed in section 2.2.5 are included to facilitate a comprehensive comparison, using two different methods of load application within FEA simulation (Pressure distribution models and equivalent lateral seismic force). These previous models are consistently utilized throughout this work (1) where MFHAPI653 is the maximum fill height defined by API 653 standard (m), S is the maximum allowable stress for the material of the shell (MPa), E is the joint efficiency for the tank, tactual is the actual thickness of the tank course, D is the nominal diameter of the tank (m), and G is the specific gravity of the stored product (dimensionless). Conversely, in hydrodynamic scenarios such as seismic events, it becomes imperative to assess the tank’s stability through the anchorage ratio criteria, denoted as J and defined in the API 650 standard and presented in Table 3. When the anchorage ratio is not satisfied, installing mechanical anchorage or reducing the fill height of the tank is necessary. Hydrodynamic assessment per Appendix E of API 650 defined how dynamic hoop tensile stress was induced by seismic motion and, there­ fore, defined the maximum fill height. This approach involves two in­ dependent response modes exhibited by the tank: impulsive and convective. The impulsive mode primarily contributes to higher stress levels at the tank’s base, whereas the convective mode contributes to stresses more importantly at the top of the tank [60,61]. Eqs. (2) and (3), extracted from Appendix E of API 650, provides a formulation for impulsive and convective hoop membrane forces acting on the tank shell using SI units. [ ( ( )2 ] ) MFH MFH D Ni = 8.48Ai GDH tanh 0.866 − 0.5 (2) H H H [ ] 1.85Ac GD2 cosh 3.68(H−D MFH) [ ] Nc = cosh 3.68(H) D (5) (3) where Ni is the impulsive hoop membrane force (N/mm), Nc is the convective hoop membrane force (N/mm), MFH is the maximum fill height from the liquid surface to the analysis point (m), considering positive down, G is design-specific gravity (dimensionless), Ai is impulsive design response spectrum acceleration coefficient (%g), Ac is 4 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 3. API 579, numerical analysis methodology for tank assessment [16]. as benchmarks for evaluating other parameters like geometry, element size, and boundary conditions. In addition, the API 579 code method­ ology introduces design factors known as penalty factors, which are used in the present study, with necessary modifications as indicated in Table 5. Where: Phydrostatic : design or operating static head from liquid or bulk materials. D: deadweight of the tank, appurtenances, platforms, transportation loads. Eq: earthquake loads. β: elastic-plastic load factor defined by Table 2D.4 from API 579, which corresponds to 2.5. The previous design factor, β, is examined by a sensitivity analysis in the limitation imposed in the FEA models and maximum fill height for three different values, using the existing value of 2.5 as referenced in API 579 code, the newly suggested value of 1.67 when buckling is a relevant failure mode, and the combination approach of 2.5 for hydrostatic load and 1.67 for seismic load. Finally, the plastic collapse load which is a function of the fill height is determined from 3 different perspectives: Load-displacement diagram to identify the nonlinear behavior of the phenomenon, the lack of convergence in FEA models as referenced by the ASME code [15], and a newly proposed acceptance criterion used so far by ASME code to esti­ mate local failure. This local ASME criterion is derived from the local strain limit established by the ASME code, wherein each point of the equivalent plastic strain, εpeq within the tank is compared against the limiting triaxial strain, εL . This latter was previously solved using Eq-6. ( ( )( )) αsl σ1 + σ2 + σ3 1 εL = εLU × exp − − 3 1 + m2 3σ e (6) where εL corresponds to the limiting triaxial strain, εLU is the uniaxial strain limit, αsl , correspond to a material factor for the multiaxial strain limit, m2, correspond to a material constant, σ1, corresponds to prin­ cipal stress in the 1-direction, σ2, corresponds to principal stress in the 2direction, σ3, corresponds to principal stress in the 3-direction and σe, correspond to von Mises stress. For enhanced reliability and ease of interpretation of FEA results, Equation 5.7 from ASME BPVC Section VIII-Division 2 part 5 is rear­ ranged in Eq-7 to identify if values higher than one are expected in the solution and correlate it with the maximum fill height for the tank. ( ) εpeq + εcf ≤1 (7) εL Where, εL , is the limiting triaxial strain εpeq , is the equivalent plastic strain at each point εcf , is the forming strain based on material and fabrication method The following section provides an in-depth examination of each component in the API 579 methodology employed for the present study. 2.2.1. Material behavior Material: ASTM A283 Grade C steel is the material specification used to model shell, bottom, and reinforcement at course N◦ 6, using the procedure outlined in ASME Section VIII, Division 2, Annex 3- D [15], it employs an engineering yield strength of 206 MPa, an engineering ul­ timate strength of 379 MPa, a modulus of elasticity of 199,575 MPa and considering the micro-strain and macro-strain region of the stress-strain curve, γ1 and γ2, and the stress-strain curve fitting parameter, H, defined in equations (8)–(11). Table 5 Load case for elastic-plastic FFS assessment. Required factored load combination 0.88β(Phydrostatic + D) + 0.71βEq 5 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Furthermore, various element sizes are introduced in the analysis, such as 101 mm, 165 mm, and 305 mm, to find any discrepancies in the results. Mesh quality is measured through the skewness parameter with the maximum acceptable value of 0.65. Additionally, to determine buckling, significant rotation, and considerable strain of the storage tank, quadrilateral dominant ele­ ments, SHELL181, are used for the assessment. It entails a four-node element with six degrees of freedom at each node. This element can handle surface loads and incorporates reduced integration with hour­ glass control. It is worth noting that hourglass problems can be mitigated when refined meshes are used [67][68]. The elements and nodes range from a minimum of 43,744 to a maximum of 355,545. Incremental Time Step: It defines how quickly a load is applied to a model; from an FEA perspective, defining a load increment within a “sub-step” step is essential. It is also noteworthy that nonlinear problems require sub-steps small enough to capture the moment transfer from one surface to another for contact simulation to follow nonlinearities of the material, geometry, or loads [67][68]. ANSYS recommends an incre­ mental time step according to Eq. (13). Fig. 4. Strain hardening behavior curve for ASTM A283 grade C. εt = γ1 = γ2 = H= σt Ey ε1 2 ε2 2 ITS = + γ1 + γ2 (8) (1 − tanh[H]) (9) (1 + tanh[H]) (10) ))] [ ( ( 2 σt − σys + K σ UTS − σ ys ( ) K σUTS − σys 1 N × fnatural (13) where ITS is the incremental time step dimensionless, N is a recom­ mended number of points per cycle for this case is 20 [67][68],and fnatural corresponds to the lowest mode of the structure’s natural fre­ quency. An initial value of 6.25E-3 is used in the assessment. 2.2.3. Geometry configuration Nonlinear-geometry: A VISUAL BASIC application using VLISP and AUTOCAD is programmed to automate the drawing; the model uses splines for every circumferential measurement at different heights, and more than 1400 data points are used in the geometry built with smooth curves and non-uniform rational B-splines (NURBS) to refine kinks and deviations from longitudinal and circumferential measurements. The use of NURBS allows to describe complex geometries and their incor­ poration has been recently addressed by researchers more extensively [69–71]. The referenced datapoints from topological measurements are provided in table A1 from appendix A. A reinforcement with a U channel is connected to course N◦ 6 as shown in Fig. 5, located at 600 mm from top-edge of the shell. The simulation does not consider the tank’s roof and columns because failure mode is expected to be more relevant at the shell-to-bottom joint or shell; besides, it reduces the computational time. Geometrically and materially nonlinear analyses with imperfections (11) The resulting proper stress-strain curve is shown in Fig. 4. 2.2.2. Element size and incremental time step Element size: The initial element size is obtained from a geometrical correlation of the tank [66], defined by Eq. (12). √̅̅̅̅̅̅ D a = 0.5 t (12) 2 where "a" corresponds to element size, D is the nominal diameter of the tank, and t is the thickness for the bottom course of the shell, units need to be consistent [66]. Fig. 5. Shell courses from topological measurements. 6 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 6. a. Eigenvalue buckling from hydrodynamic load. b. Geometrical imperfection in tank model with shell deviation of 114 mm – GNMIA II. c. Eigenvalue buckling from hydrostatic load. d. Geometrical imperfection in tank model with shell deviation of 50 mm – GNMIA I. included (GMNIA_II): the eigenvalue buckling mode from a seismic load produces general deformation of the cylinder at the upper part of the shell, as shown in Fig. 6a. An outward shell displacement of approxi­ mately 114 mm is introduced as imperfections for GMNIA-II based on the plumbness reference from API 653 which recommends a limiting value of 127 mm, as depicted in Fig. 6b. Geometrically and materially nonlinear analyses with imperfections included (GMNIA_I): The eigenvalue buckling mode from a hydrostatic load produces general deformation of the cylinder at the base, as shown in Fig. 6c An outward shell displacement of approximately 50 mm at lower courses are introduced, as shown in Fig. 6d, considering that de­ viations are not as high as upper part of the shell (approximately 45 % deviations from GMNIA_II) and shell-to-bottom joint offers stiffness re­ strictions, therefore it is not expected to have deviations higher than roundness reference from API 653 which recommends a limiting value of 57 mm. 2.2.4. Boundary conditions (BC) Many storage tank buckling behavior researchers have used fixed, pinned, spring-stiffness, and non-linear contact boundary conditions for the bottom. It is improbable to have any movement at the center of the tank, and therefore the assumption of 60 % of the nominal diameter of the tank to be fixed is used [13,50,51,61,72]. This study uses four types of boundary conditions for the bottom. • Fully fixed. • Elastic-support. • Frictional contact (Pure penalty formulation). • MPC (Multi point constraint). Fully fixed support requires all degrees of freedom (DOF) from the bottom elements to be restrained in displacement and rotation. The bottom projection upon the shell must also be restrained to avoid non7 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 7. Impulsive (left) and convective (right) pressure distribution in AST produced by seismic load, figures extracted from Spritzer’s work [46]. convergence problems, even at a low liquid level. Elastic support: previous publication [12,61,66] worked with one portion of the bottom as a spring-like model. This constraint uses a constant elastic stiffness to simulate soil-to-tank bottom interaction with a subgrade modulus of 68.000 kN/m3. Frictional contact: different authors and standards have recom­ mended values between 0.2 and 0.4 for the frictional coefficient [51,60]. This type of boundary condition works with contact and target sur­ faces and penalty equations for penetration between elements; further information may be found in Ref. [68]. MPC contact – No separation: This type of contact does not use penalty equations based on penetration; this formulation simplifies the problem and promotes convergence more easily than frictional. This work focuses on the critical failure modes expected to occur in the tank. Since the primary interest is in plastic collapse at the lower courses and buckling at higher courses of the tank’s shell, the tank’s roof and supporting members (such as columns and rafters) are not included in the model. To account for the stiffened structure without explicitly modeling the roof, a rotation restraint is considered at the highest edge of the shell, allowing movement in the up-and-down direction. Pwc = Pbc = ( ) √̅̅ sinh h3r (√̅̅ ) cosh h3R 15 (cos θ)2 (sin θ)2 ρAc R cos θ 1 − − 16 3 2 ) cosh 27 8 z R ( √̅̅̅̅ cosh ) ( 15 r r2 (cos θ)2 r2 (sin θ)2 − ρAc R cos θ − 16 R 3R2 2R2 27 8 ) (16) h R 1 ( ) √̅̅̅̅ 27 h cosh 8 R (17) Where, Pwi is the impulsive wall pressure in (Mpa), Pbi is the impulsive base pressure in (Mpa), Pwc is the convective wall pressure in (Mpa), Pbc is the convective bottom pressure in (Mpa), ρ is the density of stored product in (1000 kg/m3), θ is the angle concerning the horizontal di­ rection of ground motion (radians), R is the tank radius in (m), z is the vertical distance from the base in (m), r is the radial position in (m), h is the height of surface liquid in (m). Jacobsen-Veletsos’ model is based on a shell rigid model, and the analytical solution involves an infinite series of Bessel and modified Bessel functions. The formulation for impulsive pressure distribution for the tank wall and bottom is described in Eq. (18) and (19). 2.2.5. Seismic load models The incremental non-linear static analysis for horizontal hydrody­ namic loading is applied using large deflection capabilities provided by the FE software. This work compares the static pushover analysis extensively used by other researchers [73][43,46,48,53,65] and the static equivalent lateral body force also implemented by previous re­ searchers [41,51]. Pressure distribution: This seismic load follows Jacobsen-Veletsos’ model [32] and Housner’s model [33,34]. Their mathematical calcula­ tion is extracted from the research presented by Bohra, Azzuni, and Guzey [53], and presented herein in Equations (10)–(20). Housner’s model assumes a rigid bottom and shell. Impulsive pres­ sure on the wall and bottom is presented in Eq. (14) and (15), and the formulation of convective pressure distribution along the tank wall and bottom is detailed in Equations (16) and (17). ( ( )2 ) √̅̅̅ (h − z) 1 h − z Pwi = ρAi h 3cos θ (14) − 2 h h √̅̅̅ 3 Pbi = ρAi h cos θ 2 ) ( √̅̅̅̅ ( Pwi = Co (R, z)ρAi Rcosθ (18) Pbi = Co (r, 0)ρAi Rcosθ (19) Where Co(r,z) is a dimensionless coefficient defined in Eq. (20), where index n represents the nth impulsive mode, only the 1st impulsive mode is used in this assessment. [ ] (2n− 1)π r ) ( I 1 n+1 ∞ 2h 8 h ∑ (− 1) (2n − 1)π z [ ] cos Co (r, z) = 2 (20) 2 2h π R n=1 (2n − 1) ′ (2n− 1)πR I1 2h where Pwi is the impulsive wall pressure in (Mpa), Pbi is the impulsive base pressure in (Mpa), I1 the first kind for the modified Bessel function (dimensionless), I′1 is the first derivative concerning radial position r of modified Bessel function of the first kind (dimensionless), ρ, θ, R, z, h, r are the same parameters defined for Eq. (14)–(17). The formulation for convective pressure distribution for the tank wall and bottom is presented according to Eq. (21) and (22). (15) Pwc = Cj (z)Aj (t)ρRcosθ (21) Pbc = Cj (r)Aj (t)ρRcosθ (22) Cj(z) and Cj(r) are dimensionless coefficients defined in Eq. (23) and (24). 8 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 pressure in (Mpa), Pbc is the convective base pressure in (Mpa), ρ, θ, R, z, h, r are the same parameters defined for Eq. (14)–(17). The previous models produce a pressure distribution on the tank wall, as shown in Fig. 7. The equivalent lateral seismic force (ELSF) model is the other type of seismic load considered in this study. Impulsive and convective weights define this lateral force; both are calculated per Appendix E of API 650 standard. The total force is defined as the square root of the sum of the squares (SRSS) according to Eq. (25)–(27) [51,60]. ( ) Vi = Ai Ws + Wr + Wf + Wi (25) Table 6 Maximum Fill Height, MFH, according to API 653 hydrostatic loads for different joint efficiencies. Course N◦ MFH (m) – E = 1 MFH (m) – E = 0.85 MFH (m) – E = 0.7 Course 6 Course 5 Course 4 Course 3 Course 2 Course 1 >14.63 >14.63 >14.63 >14.63 14.26 >14.63 >14.63 >14.63 >14.63 13.59 12.53 12.83 >14.63 >14.63 13.44 12.10 10.82 10.63 Table 7 Maximum Fill Height (MFH) based on hoop stresses calculation – API 650 – hydrostatic and hydrodynamic loads. Course N◦ MFH (m) – E = 1 MFH (m) – E = 0.85 MFH (m) – E = 0.7 Course 6 Course 5 Course 4 Course 3 Course 2 Course 1 >14.63 >14.63 <14.14 13.05 <13.14 <14.23 >14.63 >14.63 <13.11 <11.89 11.61 <12.04 >14.63 >14.63 <12.19 <10.61 <9.91 9.72 Cj (z) = ( λj z R ) λj 2 − 1 cosh ( ) λj h R (23) Cj (r) = ( λj r R ) ( ) λj − 1 J1 λj 2 (27) Vequivalent = ( ) 2J1 (26) √̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅̅ Vseismic = V 2i + Vc 2 where Vi is the design base shear due to the impulsive component in (N), Vc is the design base shear due to the convective component in (N), Ws is the total weight of the tank shell in (N), Wr is the weight of the fixed tank roof in (N), Wf is the weight of the tank bottom in (N), Wi is the practical impulsive portion of liquid weight in (N), Wc is the practical convective portion of liquid weight in (N) and Vseismic is the total design base shear in (N). An equivalent lateral seismic force in G-force units can be deter­ mined from Eq. (28) using the tank’s weight [51]. ( ) 2 cosh Vc = Ac Wc Vseismic Weighttank (28) 3. Results (24) 3.1. API 650/653 assessment where subscripts j corresponds to jth convective mode, only the 1st convective mode is used in this assessment. J1 is the first kind of Bessel function and first order (dimensionless), λj are values where the first derivative of J1 is zero (dimensionless). Pwc is the convective wall Hydrostatic per API 653 defined in sections 4.3.3.1 and 4.3.3.2 the limitation imposed in the fill height for a storage tank according to the 1foot method. Table 6 presents the limitation imposed for three joint Fig. 8. Equivalent von Mises Stress distribution and fill height of the tank. 9 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 9. aEQVMS values in psi. J-V Model with frictional contact, fill height 13.18 m b. EQVMS values in psi. J-V Model with frictional contact, fill height 13.18 m. c. Equivalent plastic strain. J-V Model with frictional contact, fill height 13.18 m d. Equivalent plastic strain. H Model with elastic support, fill height 13.25 m – Element size 203 mm – non-convergence results. efficiencies commonly used in the industry: 1, 0.85, and 0.7. Hydrodynamic per Appendix E of API 650 defined the lower fill height limit in the storage tank. It can be seen in Table 7. Stability criteria were satisfied through the anchorage ratio, J, whose calculation gave 1.23. This value was below the maximum threshold of API 650, as 1.54. 3.2.1. Failure mode and stress distribution Pressure distribution and equivalent lateral seismic model, both seismic models revealed that the governing failure mode for the old existing design factor β and the old-new β combination, with a joint efficiency of 0.7, was identified as plastic collapse. The tank’s fill height was limited by von Mises stress, reaching a critical state at 379 MPa predominantly due to hydrostatic load. The maximum filling heights corresponding to the reviewed seismic models were determined. 3.2. FEA assessment The results from 337 simulations to identify failure mode and maximum fill height are described below. It considered design factor influence, bottom constraint, local ASME criterion, mesh sensitivity, and geometry configuration. 1. Housner’s model: 13.106 m (43 ft) 2. Jacobsen-Veletsos’ model: 13.335 m (43.75 ft) 3. Equivalent Lateral Seismic Force (ELSF) model: 13.030 m (42.75 ft) It was observed that as the filling heights approached the failure 10 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 10. aMembrane Stress distribution and fill height of the tank b Membrane stress values in psi. J-V Model, elastic support, fill height 13.25 m c. Membrane stress values in psi. J-V Model, elastic support, fill height 13.33 m (converged result at the limit of numerical stability). threshold, the equivalent von Mises stress (EQVMS) for shell elements located within a range of fill height (between 10 % and 55 %) presented values around 92 % of the stress limit, as it is presented in Figs. 8, 9a, and 9b. Plastic strain above 10 % were found in shell elements with equiv­ alent von Mises stress close to the limit of 379 Mpa, as presented in Fig. 9c. Numerical instability outputs with non-convergence results were presented in models close to fill height of failure and unrealistic local­ ized plastic strain values, as shown in Fig. 9d. Membrane stress distribution presented consistent results for all the models reviewed herein, as depicted in Fig. 10a. The increasing fill height toward failure indicated that numerical instability led to distur­ bances in the uniformity of stresses as presented in Fig-10b and Fig-10c. Furthermore, stabilization energy exhibited abrupt increments at loca­ tions where numerical instability occurred, as shown in Fig-11a-11b. On the other hand, maximum axial compression stress value for shell of the tank indicated higher values than allowable values of API 650 and a remarkable consistency in the increasing values of fill height for models that considered movement of the shell-to-bottom joint (uplift), such as frictional or elastic boundary conditions, as presented in Fig-12. However, unusual high values of compression stresses were found for low fill heights specially for equivalent lateral seismic force, and models that did not consider rotation of the shell-to-bottom joint, for example fully fixed and MPC support as presented in Fig. 13. 3.2.2. Design factor influence 3.2.2.1. Pressure distribution model. The new design factor of 1.67 increased the fill height to 14.63 m (48 ft), a 9 % increment compared to old β factor. Figs. 14 and 15 show the maximum outward deformation 11 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 11. aStabilization energy BTU (to convert to joules multiply by 1055), J-V Model, elastic support, fill height 13.18 m b. Stabilization energy BTU (to convert to joules multiply by 1055), J-V Model, elastic support, fill height 13.25 m (non-convergence result). Fig. 12. Axial compression stress for models that consider uplift. Fig. 13. Axial compression stress distribution and fill height of the tank. for different fill heights for Jacobsen-Veletsos’ model (J-V model) and Housner’s model (H model) for both β factors and a joint efficiency of 0.7. To achieve convergence in the models with the old β factor and oldnew β factor combination, it was necessary to reduce the incremental time step load to values as low as 1.54E-4, especially for frictional contact. Nonlinear stabilization techniques like damping factors or en­ ergy dissipation were introduced to improve convergence. Notably, relying only on the ITS recommended by Eq. (8) was insufficient to capture buckling and moment transfer in the models. Furthermore, large incremental time steps that produced nonconvergence results had the potential to be misinterpreted as a buckling-induced failure mode, considering that Newton-Raphson Re­ siduals (NRR) locations, agreed with the proximity between maximum and minimum peak normal stresses as it is exemplified in Fig. 16a and b, where the fill height is 10.97 m, the ITS is 2.85E-3, and the model did not reach convergence. There was an increase between 34 % and 36 % in the fill height of the tank based on the old β design factor of 2.5 with FEA methodology compared to API 650 calculation. However, when the MFH is compared between both factors, the old β and the old-new β combination refer­ enced as 2nd LS β (1.67) in Figs. 17 and 18, differences were lower than 1 %. 3.2.3. Equivalent lateral seismic force According to the new β factor, it is possible to fill the tank to 14.630 m (48 ft). Load-displacement diagram for both β factors, revealed that several fill heights had difficulties in achieving convergence at second load step, for example, between 3.0 m and 9.75 m for the new β factor and 9.68 m–11.89 m for the old β factor, as shown in Fig. 19. Reduction in design factor, as proposed for the old-new β factor combination denominated as 2nd LS β (1.67) in Fig. 20. It increased the MFH by less than 1 % to a new maximum of 13.106 m (43 ft). It is also observed that the old-new β factor combination had problems reaching convergence for fill heights between 6 and 10 m, this zone agreed with the unexpected high compressive stresses values identified in Fig. 13. 12 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 at the bottom could not reach convergence for this specific seismic model. There was uncertainty for the proposed old-new β factor combina­ tion model, as shown in Fig. 20, due to non-convergence outcomes for all boundary conditions at fill heights between 6.0 m and 10.36 m—for example, Fig. 21. Illustrates premature termination at 80 % of the sec­ ond load step for an ELSF model with a fill height of 7.62 m and old-new β factor combination, and NRR provides a visual indication where there is numerical instability. Conversely, Fig. 22a and b presents a contrasting scenario for both ELSF and Housner models, employing the old β factor with completion of the simulation at a fill height of 7.62 m. Von Mises stress distribution is displayed for both models for comparison purposes. 3.2.4.1. Local ASME criterion. During the filling heights between 8.53 m and 12.5 m in the AST, the maximum value of the ASME criterion was less than 0.625. Pressure distribution and equivalent lateral seismic force model were consistently located at the first course (approximately 0.381 m–1.016 m) above the shell-to-bottom joint or at the shell-tobottom joint itself. As shown in Fig. 23a, b, 23c and 23d. In contrast to the previous observations regarding the maximum values of the ASME criterion, a different pattern emerged. It was iden­ tified that for all three seismic models reviewed herein, their respective ASME criterion values followed a nonlinear tendency to converge to­ ward one or above as the models approached failure. This trend also seemed to outline a tentative maximum fill height. This shift in behavior was accompanied by a substantial change in the location of these values, as is presented in b.Figure 24, 25, 26 and 27a and 27b Local ASME criteria for all the seismic models and bottom constraints reviewed in this investigation were presented in Fig. 27a and b. It revealed values above one for ELSF models at 12.5 m of fill height and above; for Housner’s model corresponded to 12.8 m of fill height, and for Jacobsen-Veletsos’ model the threshold of 1 was reached at 13.25 m of fill height and above. These results provided a 5 % tolerance in deviation of the MFH defined from the FE simulation. As models were simulated to reach failure, it was identified that a unique MFH proved to be elusive, and it was discerned that too much numerical aid through stabilization techniques might promote conver­ gence results. Notably, relying only on convergence criteria without limiting stabilization techniques could be risky for equipment with minimal documentation. However, when the Local ASME criterion was introduced, unrealistic values too much higher than one was identified, as presented in Fig. 28. Furthermore, the local ASME criterion could track singularities in the processing of the solution, as presented in Fig. 29. It revealed that values higher than one were reached for this criterion in Load steps 0 to 1, corresponding to hydrostatic load. This observation underscores the remarkable influence of hydrostatic load in the governing failure mode. Fig. 14. Fill height for old and new β factor with Jacobsen-Veletsos’ model. Fig. 15. Fill height for old and new β factors with Housner’s model. 3.2.5. Mesh size sensitivity All three seismic models were analyzed for four different element sizes: 101 mm, 165 mm, 203 mm, and 305 mm. Elastic support was employed for pressure distribution models, while fully fixed was used for the equivalent lateral seismic force model. Fig. 30 shows the differ­ ence in the MFH for the old β design factor and the old-new β factor combination introduced in this study. Differences in the MFH between β factors are not higher than 1.5 %. In other words, reducing the design factor for seismic load did not produce significant changes in the maximum fill height. This outcome confirms that plastic collapse is the governing failure mode and that the reviewed mesh size models offered a 3 % tolerance between the maximum and minimum value for MFH. These irregularities in the results disappeared in models with quadratic elements. It is the author’s belief that models experienced shear locking which is a phenomenon commonly observed in lower-order elements [74]. 3.2.4. Bottom constraint Pressure Distribution Model: Figs. 17 and 18 illustrate the loaddisplacement diagram where the nonlinear behavior is observed. The tank’s shell displacement is quickly increased by low load increments, approximately from 9.753 m (32 ft) and above. Notably, frictional contact models compared to either fully fixed, MPC, or elastic-support increased the solution time, ranging from 2 to 5 times. In addition, comparing the maximum uplift value from frictional contact and elastic support was within a 25 % tolerance, and MFH de­ viation between models was within a 2 % range. Equivalent Lateral Seismic Force: It was identified that elastic support 3.2.6. Geometry configuration Housner’s seismic model was used as the benchmark to plot the loaddisplacement diagram for three different geometry configurations 13 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 16. aNewton-Raphson Residuals indicate where there is numerical instability. b. Unaveraged Z-normal peak stresses in psi. Maximum and minimum values close to each other. Fig. 17. Fill height for different boundary conditions with the J-V model. Fig. 18. Fill height for different boundary conditions with the H model. (topological measurements, perfect cylinder, and GMNIA I). These models were simulated with an old-new β factor combination and an elastic support condition for the bottom. It is observed in Fig. 31 that the geometry derived from topological measurements had the maximum fill height defined at 13.18 m, which is around 2 % higher than the perfect cylinder model. From a general perspective, deviations in the results remained within a limited 3 % range for all geometries reviewed herein, as shown in Fig. 32. It is outstanding that utilization of B-splines surfaces from to­ pological measurements yielded higher MFH values in comparison to the perfect cylinder or imperfections induced geometries. and joint efficiency of 0.7 for equipment with minimal documentation, two methodologies were compared in detail based on API 650/653 standard approach and API 579 incorporating finite element analysis. The discussion of previous results is presented in the following section. The maximum fill height determined per API 650/653 standards primarily relies on stress calculations and stability criteria. However, these calculations did not account for the failure mode for the studied broad tank: plastic collapse, driven by the hydrostatic load in approxi­ mately 98 %. Sensitivity analysis of design factor β underscored that a reduction of 33 % in seismic design load for the reviewed seismic models did not increase the MFH by more than 2 %. In other words, API 579 and FEA methodology revealed that it was possible to increase the MFH by at least 34 % in contrast to API 650/653 standard calculation because the aboveground storage tank is not susceptible to seismic load. The lack of sensitivity to seismic load identified for this tank relates to its aspect ratio, considered a broad tank, which complies with 4. Discussion In order to identify if there is over-restraint in API 650/653 calcu­ lations for maximum fill height in a broad tank subjected to seismic load 14 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 579 produce a liquid fill level higher than the closed-form solution equations given by API 650, have been observed by Prueter et al. [51] and Kummari et al. [52] for ammonia tank. Other researchers have observed significant discrepancies in allowable buckling stress values from standards and FEA solutions [46,49,50,78]. These deviations are mainly related to the lack of experimental tests for storage tanks. Ex­ periments so far of storage tanks under seismic load are prone to mimic either fluid motion or structure vibration in the elastic zone, and from then propose a mathematical formulation [34,47] [79,80,81,82]. A unique solution to identify either the MFH in a storage tank or the critical seismic parameter defining structural instability seems to be unsolved in the short term [30,43]. However, it is possible from a nu­ merical analysis perspective to incorporate tracking parameters to identify if failure is close [15,51,83,84] as it is described as follows. 4.1. Local ASME criterion The investigation highlighted that unresolved outcomes could arise in FEA models characterized by factors such as excessive loads, meshing issues, substantial incremental time steps, poorly defined contact properties or boundary conditions, and relying on convergence alone for elastic-plastic analysis may lead to misinterpreted conclusions. It is highlighted that the local ASME criterion, defined in Eq. (7) [15,83], emerged as a simple and effective parameter to estimate unrealistic re­ sults for values exceeding 1 when plastic collapse is the dominant failure mode. It offered valuable insights into instability within the load path and exhibited an asymptotic trend for non-convergence results attrib­ utable to excessive load or proximity to failure, as exemplified in Fig. 27a and b, and 29. However, it is necessary to estimate in further research if this local strain limit criterion for elastic-plastic analysis is consistent for models where buckling is a dominant failure mode and non-convergence results might be expected, for example, for tall tanks or more critical seismic parameters as peak ground acceleration above 0.65. In addition, the recommended upgrade of joint efficiency provided in this investigation should be only addressed for broad tanks (with aspect ratio close to 1), which are compliant with stability criteria as defined per API 650 standard, where vertical seams for the lower courses of the shell do not provide any discontinuity that promotes a different failure mode for the tank. The joint efficiency upgrade suggested for the tank studied with minimal records may be the first step towards improving the current 0.7 value set for unknown tanks [85]. Tank storage companies are increasingly adapting their existing infrastructure to support their ef­ forts towards achieving carbon neutrality by 2050. They are also restructuring their business models to ensure stable supply chains for emerging roles of storage tanks such as ammonia, methanol, advanced non-food-based biofuels, flow batteries, bio-kerosene, and other such fuels, while keeping the storing fossil fuels demand [86][87,88][55] [89–92]. This work highlights the need for further discussions on assessing the resilience of existing storage tanks that were originally designed for specific liquids, but are now being tasked to work with heavier liquids, more corrosive products or induced embrittlement of steel such as biofuels, carbon storage gases, hydrogen, and non-liquid electricity storage. This can be done using engineering principles, developed methodologies for integrity assessment, and simulation through Finite Element Analysis (FEA) as the key backbone. Fig. 19. Fill height for old and new β factor with ELSF model. Fig. 20. Fill height for different boundary conditions with equivalent lateral seismic force model (ELSF) using old β factor and old-new β factor combination. stability criteria defined by API 650 standard [46]. Second, base uplift was limited by amplification factors introduced in hydrostatic load, restraining the failure mechanism at the base to initiate [75–77] and third, the adjustment of design factor β and joint efficiency E within FEA simulations, takes precedence over the refinement of the mathematical foundations of the existing seismic models. Both design factors β and E offered a variation in the MFH between 34 % and 45 %. Conversely, the three seismic models reviewed in this investigation demonstrated a disparity in the MFH, not exceeding 5 %. The proposed increase in the fill height to 14.63 m, for a new β factor of 1.67, could produce non-conservative values and introduce height­ ened risk for equipment with minimal documentation. In addition to the overestimated fill height of around 17.2 m for the new β factor, when load displacement is projected with the same slope and maximum shell displacement. These discrepancies in the maximum fill height, where FEA and API 5. Conclusions From the results reviewed herein, their analysis, and discussion, it is possible to conclude the following. • Aboveground storage tanks with minimal documentation, subjected to seismic load, and limited by the API 650 stability criteria can benefit from an improved mechanical integrity assessment. This 15 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 21. Newton-Raphson residuals for non-convergence results, ELSF model at 7.62 m (25 ft)- using old-new β factor combination. Fig. 22. aEquivalent Von Mises stress in psi for old β factor at 7.62 m - using ELSF model. b. Equivalent Von Mises stress in psi for old β factor at 7.62 m - Housner’s model. enhancement can be achieved using FEA methodology according to API 579 code or by joint efficiency upgrade. • A broad storage tank following API 653’s joint efficiency require­ ment of 0.7 exhibits the potential to increase the maximum fill height between 34 % and 36 %. Findings derived from FEA simulations indicated that this tank, which complies with the API 650 stability criteria, displayed robust resistance to buckling failure mode. A comprehensive assessment encompassing diverse parameters, such as design factor β, seismic load model, geometry configuration, boundary conditions, and element sizes, revealed that plastic collapse was the dominant failure mode. It is triggered mainly by hydrostatic load. In addition, differences between the MFH for the reviewed parameters in this study are within a range of 5 % value. As a result, the maximum fill height recommended is between 12.801 m (42 ft) and 13.106 m (43 ft). • The extensive investigation of the studied tank suggests that analo­ gous outcomes to API 653 calculations could be achieved by enhancing joint efficiency. This enhancement might involve elevating the joint efficiency from its value of 0.7 to a range spanning from 0.8 to 0.87. • The novel local ASME criteria introduced to estimate overall stability promoted by plastic collapse exhibited remarkable consistency in the results across the seismic models reviewed herein and the range of boundary conditions employed. This criterion exhibited an asymp­ totic nonlinear behavior, progressively trending toward one or higher values for models approaching failure. It provides three notable advantages. 16 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 23. Local ASME Criterion (a) ELSF model at 12.26 m of fill height – MPC bottom constraint (b) ELSF model at 12.04 m of fill height – Frictional bottom constraint (c) J-V model at 8.53 m of fill height – Elastic support (d) H model at 10.36 m of fill height – Frictional bottom constraint. Fig. 24. Local ASME Criteria for J-V model at 13.18 m fill height with frictional BC. 17 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 25. Local ASME Criteria for H model at 13.10 m of fill height with elastic support BC. Fig. 26. Local ASME Criteria for ELSF model at 13.25 m of fill height with fixed BC. Fig. 27. aLocal ASME Criteria for all seismic models. b. Local ASME Criteria for seismic models range from 0 to 5. Firstly, when the maximum value obtained is significantly below 1, it becomes viable to identify if unresolved FEA models lack adjustments in their settings, such as lower incremental time steps. Secondly, thanks to its sensitivity to software numerical enhancement like stabilization techniques, it is possible to identify un­ realistic results for values surpassing 1. This presents an alternative to relying uniquely on the conventional convergence/non-convergence criteria defined by ASME when performing plastic collapse analysis. 18 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Fig. 28. Local ASME Criteria for J-V model at 13.33 m - converged solution. Fig. 29. Local ASME Criterion for ELSF model at 13.25 m – non-convergence result. Fig. 30. MFH for seismic models for different element sizes. Finally, the overall threshold defined by this criterion may be further integrated into reliability calculation or statistics analysis to estimate MFH for tanks or MAWP for pressure vessels [84]. Fig. 31. Load-displacement diagram for Housner’s model and different geom­ etry configurations (topological measurements, cylinder, and GMNIA I). 19 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 CRediT authorship contribution statement Deivi García-G: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Validation, Visualization, Writing - original draft, Writing - review & editing. J. Barco-Burgos: Conceptualization, Methodology, Resources, Software, Supervision, Validation, Writing original draft, Writing - review & editing. Jaime Chaparro: Funding acquisition, Investigation, Methodology, Resources, Supervision, Writing - review & editing. U. Eicker: Methodology, Resources, Su­ pervision. Joya Cárdenas D.R: Investigation, Project administration, Resources, Software, Supervision, Validation, Visualization. Alberto Saldaña-Robles: Formal analysis, Investigation, Methodology, Re­ sources, Software, Supervision, Writing - review & editing. Declaration of competing interest Fig. 32. MFH for seismic models for different geometrical configurations. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. • Additional exploration of storage tank configurations, aligned with API 650 stability criteria and seismic considerations, is recom­ mended to validate the feasibility of a safe and dependable upgrade of joint efficiency from the existing 0.7 to a suggested ranged be­ tween 0.8 and 0.87. • The joint efficiency upgrade offers a faster and more cost-effective solution for reconditioning existing storage tanks compared to FEA models. This is particularly beneficial for repurposing existing infrastructure for fossil fuel markets or in case of a global food ca­ tastrophe scenario, as suggested by Throup et al., where equipment design and organization can be completed within 4 weeks [57]. However, it is important to take a holistic approach focused on resilience and reliability, while refining FEA models to provide guidance on adapting infrastructure for safely storing hazardous substances. Data availability Data will be made available on request. Acknowledgment The authors would like to thank Chithranjan Nadarajah for guiding the assessment of this research, Eyas Azzuni for giving general advice on the subject, and Edisson Garcia for providing the necessary information to deploy this research. The authors express their gratitude to 3 Engineering Group and Corporacion CIMA for funding this research. APPENDIX A Table A.1 Topological measurements for the tank (Part I) RADII MEASUREMENTS IN INCHES FOR CIRCUMFERENTIAL DIRECTION (DEGREES) Height 0 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 1 ft 2 ft 3 ft 4 ft 5 ft 6 ft 7 ft 8 ft 9 ft 10 ft 11 ft 12 ft 13 ft 14 ft 15 ft 16 ft 17 ft 18 ft 19 ft 20 ft 21 ft 22 ft 23 ft 24 ft 25 ft 26 ft 27 ft 28 ft 29 ft 540.00 540.24 540.47 540.49 540.51 540.47 540.43 540.41 540.39 540.20 540.00 539.82 539.65 539.49 539.33 539.15 538.98 539.04 539.09 539.21 539.33 539.43 539.53 539.61 539.69 539.57 539.45 539.31 539.17 540.00 540.08 540.16 540.16 540.16 540.06 539.96 539.84 539.72 539.57 539.41 539.29 539.17 539.06 538.94 538.80 538.66 538.62 538.58 538.50 538.43 538.37 538.31 538.23 538.15 538.01 537.87 537.85 537.83 540.00 540.10 540.20 540.24 540.28 540.18 540.08 540.00 539.92 540.00 540.08 540.26 540.43 540.57 540.71 540.85 540.98 540.94 540.91 540.81 540.71 540.63 540.55 540.39 540.24 540.14 540.04 540.04 540.04 540.00 540.08 540.16 540.24 540.31 540.30 540.28 540.06 539.84 539.88 539.92 539.80 539.69 539.51 539.33 539.09 538.86 539.07 539.29 539.47 539.65 539.82 540.00 540.10 540.20 540.16 540.12 540.08 540.04 540.00 540.04 540.08 540.10 540.12 540.02 539.92 539.76 539.61 539.61 539.61 539.70 539.80 539.86 539.92 539.86 539.80 539.72 539.65 539.45 539.25 539.15 539.06 538.72 538.39 538.44 538.50 538.60 538.70 540.00 540.24 540.47 540.63 540.79 540.89 540.98 540.96 540.94 540.87 540.79 540.85 540.91 540.98 541.06 541.10 541.14 541.20 541.26 541.38 541.50 541.67 541.85 541.87 541.89 541.89 541.89 541.75 541.61 540.00 540.10 540.20 540.28 540.35 540.37 540.39 540.35 540.31 540.31 540.31 540.30 540.28 540.28 540.28 540.26 540.24 540.39 540.55 540.89 541.22 541.42 541.61 541.75 541.89 541.81 541.73 541.83 541.93 540.00 539.90 539.80 539.92 540.04 540.04 540.04 539.96 539.88 539.96 540.04 540.10 540.16 540.22 540.28 540.33 540.39 540.30 540.20 540.00 539.80 539.55 539.29 539.04 538.78 538.82 538.86 538.84 538.82 540.00 539.96 539.92 539.88 539.84 539.74 539.65 539.53 539.41 539.29 539.17 539.04 538.90 538.80 538.70 538.60 538.50 538.62 538.74 538.84 538.94 538.98 539.02 539.04 539.06 538.96 538.86 538.60 538.35 540.00 540.04 540.08 540.18 540.28 540.30 540.31 540.30 540.28 540.16 540.04 539.92 539.80 539.69 539.57 539.49 539.41 539.33 539.25 539.17 539.09 538.94 538.78 538.76 538.74 538.56 538.39 538.70 539.02 540.00 540.20 540.39 540.55 540.71 540.73 540.75 540.69 540.63 540.75 540.87 541.08 541.30 541.48 541.65 541.75 541.85 541.95 542.05 542.07 542.09 542.05 542.01 542.07 542.13 542.15 542.17 542.19 542.20 540.00 539.98 539.96 540.10 540.24 540.18 540.12 540.04 539.96 539.80 539.65 539.45 539.25 539.04 538.82 538.66 538.50 538.66 538.82 538.98 539.13 539.27 539.41 539.51 539.61 539.55 539.49 539.51 539.53 540.00 540.00 540.00 540.10 540.20 540.20 540.20 540.10 540.00 539.98 539.96 539.88 539.80 539.76 539.72 539.69 539.65 539.55 539.45 539.33 539.21 539.04 538.86 538.82 538.78 538.72 538.66 538.58 538.50 540.00 540.16 540.31 540.30 540.28 540.20 540.12 539.98 539.84 539.88 539.92 540.06 540.20 540.31 540.43 540.47 540.51 540.51 540.51 540.53 540.55 540.55 540.55 540.53 540.51 540.43 540.35 540.16 539.96 540.00 540.16 540.31 540.37 540.43 540.31 540.20 540.16 540.12 539.88 539.65 539.33 539.02 539.07 539.13 538.66 538.19 538.29 538.39 538.44 538.50 538.46 538.43 538.46 538.50 538.39 538.27 538.21 538.15 540.00 540.24 540.47 540.43 540.39 540.24 540.08 539.92 539.76 539.76 539.76 539.84 539.92 540.00 540.08 540.10 540.12 540.04 539.96 539.84 539.72 539.61 539.49 539.39 539.29 539.39 539.49 539.31 539.13 (continued on next page) 20 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Table A.1 (continued ) RADII MEASUREMENTS IN INCHES FOR CIRCUMFERENTIAL DIRECTION (DEGREES) Height 0 12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 30 ft 31 ft 32 ft 33 ft 34 ft 35 ft 36 ft 37 ft 38 ft 39 ft 40 ft 41 ft 42 ft 43 ft 44 ft 45 ft 46 ft 47 ft 48 ft 539.11 539.06 538.92 538.78 538.72 538.66 538.52 538.39 538.31 538.23 537.62 537.01 538.82 538.58 538.35 538.64 538.94 539.06 539.17 537.81 537.80 537.74 537.68 537.50 537.32 537.22 537.13 537.26 537.40 537.01 536.61 536.50 536.38 536.26 536.48 536.69 536.85 537.01 540.02 540.00 539.90 539.80 539.90 540.00 540.02 540.04 540.00 539.96 539.98 540.00 540.59 540.57 540.55 540.65 540.75 540.71 540.67 540.02 540.00 539.92 539.84 539.51 539.17 538.96 538.74 538.78 538.82 538.84 538.86 538.50 538.54 538.58 538.82 539.06 539.09 539.13 538.74 538.78 538.60 538.43 538.54 538.66 538.37 538.07 538.48 538.90 538.68 538.46 538.19 538.09 537.99 537.91 537.83 537.72 537.60 541.56 541.50 541.40 541.30 541.04 540.79 540.94 541.10 541.36 541.61 541.30 540.98 540.91 540.93 540.94 541.16 541.38 541.16 540.94 542.03 542.13 542.17 542.20 542.24 542.28 542.22 542.17 542.20 542.24 541.95 541.65 541.50 541.24 540.98 540.69 540.39 540.18 539.96 538.82 538.82 539.13 539.45 539.51 539.57 539.65 539.72 539.65 539.57 539.59 539.61 539.65 539.72 539.80 539.98 540.16 540.28 540.39 538.13 537.91 537.58 537.24 537.32 537.40 537.01 536.61 536.36 536.10 535.69 535.28 535.87 535.47 535.08 535.22 535.35 535.51 535.67 539.02 539.02 539.06 539.09 539.09 539.09 538.92 538.74 538.84 538.94 538.39 537.83 538.66 538.39 538.11 538.05 537.99 538.21 538.43 542.07 541.93 541.87 541.81 541.91 542.01 541.99 541.97 542.17 542.36 542.15 541.93 541.57 541.42 541.26 541.16 541.06 540.77 540.47 539.51 539.49 539.45 539.41 539.31 539.21 538.86 538.50 538.48 538.46 537.85 537.24 538.23 538.92 539.61 539.11 538.62 538.13 537.64 538.44 538.39 538.37 538.35 538.39 538.43 538.33 538.23 538.31 538.39 537.91 537.44 538.50 538.58 538.66 538.94 539.21 538.78 538.35 539.72 539.49 539.61 539.72 539.74 539.76 539.63 539.49 539.67 539.84 539.55 539.25 539.53 539.61 539.69 540.08 540.47 540.59 540.71 538.05 537.95 537.93 537.91 537.78 537.64 537.36 537.09 536.93 536.77 536.14 535.51 535.87 536.22 536.57 537.01 537.44 537.89 538.35 539.11 539.09 538.96 538.82 538.86 538.90 538.88 538.86 538.64 538.43 537.81 537.20 537.64 537.99 538.35 538.62 538.90 539.15 539.41 RADII MEASUREMENTS IN INCHES FOR CIRCUMFERENTIAL DIRECTION (DEGREES) Height 192 204 216 228 240 252 264 276 288 300 312 324 336 348 1 ft 2 ft 3 ft 4 ft 5 ft 6 ft 7 ft 8 ft 9 ft 10 ft 11 ft 12 ft 13 ft 14 ft 15 ft 16 ft 17 ft 18 ft 19 ft 20 ft 21 ft 22 ft 23 ft 24 ft 25 ft 26 ft 27 ft 28 ft 29 ft 30 ft 31 ft 32 ft 33 ft 34 ft 35 ft 36 ft 37 ft 38 ft 39 ft 40 ft 41 ft 42 ft 43 ft 44 ft 45 ft 46 ft 47 ft 48 ft 540.00 540.20 540.39 540.57 540.75 540.87 540.98 540.96 540.94 540.83 540.71 540.73 540.75 540.75 540.75 540.77 540.79 540.83 540.87 540.85 540.83 540.87 540.91 541.04 541.18 541.14 541.10 541.02 540.94 540.71 540.47 540.41 540.35 540.51 540.67 540.81 540.94 541.12 541.30 540.85 540.39 540.47 540.71 540.94 541.10 541.26 541.42 541.57 540.00 540.26 540.51 540.71 540.91 541.00 541.10 541.12 541.14 541.08 541.02 540.98 540.94 540.93 540.91 540.81 540.71 540.75 540.79 540.77 540.75 540.77 540.79 540.77 540.75 540.75 540.75 540.53 540.31 540.24 540.16 540.28 540.39 540.53 540.67 540.61 540.55 540.61 540.67 539.92 539.17 539.45 539.57 539.69 539.37 539.06 539.23 539.41 540.00 540.31 540.63 540.75 540.87 540.79 540.71 540.67 540.63 540.63 540.63 540.73 540.83 540.85 540.87 540.87 540.87 541.00 541.14 541.18 541.22 541.30 541.38 541.40 541.42 541.50 541.57 541.28 540.98 540.83 540.67 540.51 540.35 540.33 540.31 540.16 540.00 540.20 540.39 539.92 539.45 539.53 539.61 539.69 539.27 538.86 539.13 539.41 540.00 540.14 540.28 540.31 540.35 540.31 540.28 540.31 540.35 540.51 540.67 540.53 540.39 540.35 540.31 540.30 540.28 540.30 540.31 540.30 540.28 540.30 540.31 540.16 540.00 539.72 539.45 539.70 539.96 539.98 540.00 540.08 540.16 540.45 540.75 540.79 540.83 540.71 540.59 539.78 538.98 540.28 540.33 540.39 540.47 540.55 540.69 540.83 540.00 539.96 539.92 540.12 540.31 540.37 540.43 540.43 540.43 540.59 540.75 540.85 540.94 541.00 541.06 541.02 540.98 540.94 540.91 540.77 540.63 540.45 540.28 540.12 539.96 539.80 539.65 539.47 539.29 539.07 538.86 538.60 538.35 538.82 539.29 539.19 539.09 539.00 538.90 538.56 538.23 538.62 538.76 538.90 538.76 538.62 538.50 538.39 540.00 540.02 540.04 539.96 539.88 539.82 539.76 539.67 539.57 539.37 539.17 538.88 538.58 538.27 537.95 537.64 537.32 537.32 537.32 537.26 537.20 537.17 537.13 536.91 536.69 536.54 536.38 536.20 536.02 535.63 535.24 536.87 538.50 536.59 534.69 534.17 533.66 533.80 533.94 533.44 532.95 535.87 535.49 535.12 535.30 535.47 535.18 534.88 540.00 540.00 540.00 539.94 539.88 539.72 539.57 539.35 539.13 538.98 538.82 538.64 538.46 538.17 537.87 537.68 537.48 537.22 536.97 536.61 536.26 535.98 535.71 535.10 534.49 534.45 534.41 534.84 535.28 535.59 535.91 536.08 536.26 536.28 536.30 536.18 536.06 536.16 536.26 535.87 535.47 535.87 535.55 535.24 534.96 534.69 534.90 535.12 540.00 540.12 540.24 540.33 540.43 540.47 540.51 540.47 540.43 540.43 540.43 540.51 540.59 540.67 540.75 540.83 540.91 540.85 540.79 540.61 540.43 540.37 540.31 540.24 540.16 539.59 539.02 539.11 539.21 539.06 538.90 538.56 538.23 538.11 537.99 537.81 537.64 537.72 537.80 537.46 537.13 538.11 538.46 538.82 539.11 539.41 539.94 540.47 540.00 540.12 540.24 540.16 540.08 540.02 539.96 539.84 539.72 539.57 539.41 539.31 539.21 539.11 539.02 538.86 538.70 538.76 538.82 538.90 538.98 539.06 539.13 539.19 539.25 539.17 539.09 539.04 538.98 538.88 538.78 538.64 538.50 538.35 538.19 537.74 537.28 537.11 536.93 536.14 535.35 535.83 536.91 537.99 537.44 536.89 536.36 535.83 540.00 540.14 540.28 540.37 540.47 540.31 540.16 540.20 540.24 540.12 540.00 539.90 539.80 539.67 539.53 539.43 539.33 539.23 539.13 539.04 538.94 538.80 538.66 538.54 538.43 538.44 538.46 538.64 538.82 538.92 539.02 539.06 539.09 539.23 539.37 539.27 539.17 539.17 539.17 538.72 538.27 538.19 538.31 538.43 538.44 538.46 538.41 538.35 540.00 540.20 540.39 540.63 540.87 540.91 540.94 540.96 540.98 540.94 540.91 541.04 541.18 541.24 541.30 541.30 541.30 541.50 541.69 541.65 541.61 541.73 541.85 541.99 542.13 541.91 541.69 541.71 541.73 541.75 541.77 541.75 541.73 541.69 541.65 541.42 541.18 541.28 541.38 541.04 540.71 540.83 540.85 540.87 540.75 540.63 540.73 540.83 540.00 540.14 540.28 540.35 540.43 540.39 540.35 540.30 540.24 540.10 539.96 539.76 539.57 539.43 539.29 539.09 538.90 539.15 539.41 539.35 539.29 539.47 539.65 539.70 539.76 539.80 539.84 539.98 540.12 540.24 540.35 540.51 540.67 540.43 540.20 540.04 539.88 539.92 539.96 539.55 539.13 539.29 539.49 539.69 539.59 539.49 539.51 539.53 540.00 540.18 540.35 540.49 540.63 540.67 540.71 540.69 540.67 540.71 540.75 541.00 541.26 541.24 541.22 541.26 541.30 541.20 541.10 540.96 540.83 540.63 540.43 540.33 540.24 540.37 540.51 540.51 540.51 540.65 540.79 540.81 540.83 540.73 540.63 540.73 540.83 541.02 541.22 540.87 540.51 541.10 541.18 541.26 541.38 541.50 541.42 541.34 540.00 540.18 540.35 540.37 540.39 540.51 540.63 540.59 540.55 540.53 540.51 540.71 540.91 541.02 541.14 541.26 541.38 541.40 541.42 541.42 541.42 541.34 541.26 541.18 541.10 540.94 540.79 540.65 540.51 540.33 540.16 540.06 539.96 540.00 540.04 540.06 540.08 540.31 540.55 540.12 539.69 540.24 540.02 539.80 540.10 540.39 540.16 539.92 21 International Journal of Pressure Vessels and Piping 207 (2024) 105113 D. García-G et al. Table A.2 Converged results for Jacobsen-Veletsos Model (Part I) JACOBSEN-VELETSOS MODEL OLD - ELASTIC FULLY FIXED - 2ND LS B (1.67) H (m) # Nodes # Energy Elements Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria H (m) # Nodes # Energy Elements Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria 6.096 7.620 8.534 9.144 9.754 10.363 10.973 11.278 11.430 11.735 12.192 12.497 12.649 12.725 12.802 13.106 13.183 13.183 13.259 13.335 97812 56057 56057 56057 56057 56057 56057 56054 56054 56054 56054 56054 56054 56054 65760 65760 65760 178198 43766 43766 59868 56699 56699 56699 56699 56699 56699 56696 56696 56696 56696 56696 56696 56696 66435 66435 66435 179526 44640 44640 8 8 8 8 8 8 8 8 8 8 8 8 8 8 6.5 6.5 6.5 4 12 12 0.129 0.089 0.121 0.159 0.227 0.223 0.512 0.641 0.705 0.848 1.076 1.216 1.291 1.318 1.366 1.522 1.593 1.572 1.640 1.744 248 233 251 262 270 277 323 337 343 357 379 389 394 408 401 407 415 421 424 501 20 65 36 28 25 68 78 86 86 67 43 43 44 120 115 163 182 388 205 335 0.09 0.09 0.09 0.10 0.11 0.13 0.24 0.27 0.30 0.38 0.49 0.50 0.52 0.61 0.55 0.70 0.93 2.36 0.99 13.46 9.754 10.363 10.973 11.582 11.887 12.192 12.497 12.802 12.878 56054 56054 56054 56054 56054 56054 56054 56054 56054 56696 56696 56696 56696 56696 56696 56696 56696 56696 8 8 8 8 8 8 8 8 8 0.205 0.318 0.510 0.777 0.921 1.077 1.215 1.366 1.405 271 290 315 343 357 371 392 402 403 91 98 102 89 70 53 45 55 62 0.13 0.17 0.24 0.32 0.40 0.64 0.73 0.76 0.77 0.67 0.42 0.72 1.06 1.56 1.74 4.77 5.91 6.35 9.75 10.61 11.12 12.60 10.11 12.17 14.51 5.53 39.51 273.00 1.44 2.49 4.29 6.61 7.92 9.38 10.62 12.17 12.70 JACOBSEN-VELETSOS MODEL ELASTIC SUPPORT - 2ND LS B (1.67) MPC - 2ND LS B (1.67) H (m) # Nodes # Energy Elements Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria H (m) # Nodes # Energy Elements Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria 9.754 10.363 10.973 11.735 12.192 12.497 12.802 12.954 12.954 13.106 13.183 13.259 13.259 13.335 56054 56054 56054 56054 56054 56054 56054 60842 56054 60842 60842 60842 58104 43758 56696 56696 56696 56696 56696 56696 56696 61299 56696 61299 61299 61299 58744 44637 8 8 8 8 8 8 8 6.5 8 6.5 6.5 6.5 8 12 0.215 0.325 0.511 0.851 1.078 1.214 1.367 1.447 1.447 1.524 1.600 1.776 1.729 1.739 270 289 315 351 372 392 402 398 405 400 404 422 421 428 32 31 37 33 34 46 58 171 68 223 225 225 202 223 0.11 0.16 0.22 0.34 0.51 0.51 0.55 0.58 0.62 0.61 0.666 1.2259 1.1474 1.22 7.620 9.754 10.363 10.973 11.735 12.192 12.802 12.954 12.954 13.030 13.106 13.183 93626 93626 93626 93626 93626 93626 93626 93626 124182 124182 124182 124182 94308 94308 94308 94308 94308 94308 94308 94308 124777 124777 124777 124777 8 8 8 8 8 8 8 8 6.5 6.5 6.5 6.5 0.085 0.205 0.319 0.509 0.847 1.075 1.363 1.442 1.449 1.489 1.531 1.624 223 271 290 315 350 371 402 405 399 400 403 413 52 88 93 94 79 51 62 66 166 162 157 150 0.09 0.13 0.17 0.23 0.35 0.62 0.72 0.74 2.92 3.39 3.87 4.35 1.47 2.52 4.32 7.32 9.48 10.73 12.14 10.05 13.25 10.84 11.76 16.60 18.90 45.00 0.3 1.5 2.5 4.3 7.2 9.4 12.2 13.4 10.3 10.9 11.7 14.4 JACOBSEN-VELETSOS MODEL FRICTIONAL PURE PENALTY - 2ND LS B (1.67) H (m) # Nodes # Elements Energy Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) EQVM Stress (Mpa) Axial Stress (Mpa) Local ASME criteria 10.363 10.973 11.735 12.192 12.802 13.106 13.183 124172 124172 124172 124172 124172 124172 124172 124770 124770 124770 124770 124770 124770 124770 2.1 3.7 6.1 8.1 9.5 10.3 11.0 6.5 6.5 6.5 6.5 6.5 6.5 6.5 0.340 0.518 0.865 1.070 1.370 1.525 1.600 290 316 350 378 393 401 406 283 305 338 362 378 379 379 25 29 28 57 101 124 137 0.17 0.24 0.44 0.52 0.54 0.59 0.72 Table A.3 Converged results for Housner’s Model (Part I) HOUSNER MODEL OLD - ELASTIC FULLY FIXED - 2ND LS B (1.67) H (m) # Nodes # Energy Elements Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria H (m) 6.096 7.620 56937 56937 57438 57438 6.5 6.5 0.055 0.084 197 232 64 59 0.081 0.090 9.754 65075 10.363 65075 0.14 0.30 # Nodes # Energy Elements Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria 65655 65655 8 8 0.202 0.310 268 286 91 103 0.135 0.167 1.3 2.3 (continued on next page) 22 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Table A.3 (continued ) HOUSNER MODEL OLD - ELASTIC FULLY FIXED - 2ND LS B (1.67) H (m) # Nodes # Energy Elements Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria H (m) # Nodes # Energy Elements Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria 8.534 9.144 9.754 10.363 10.439 10.973 11.582 11.887 12.192 12.344 12.421 12.802 13.106 13.106 13.106 13.106 56937 56937 56937 116483 83780 125283 125283 125283 125283 125283 125283 125283 178198 58113 43766 125283 57438 57438 57438 117927 84575 126066 126066 126066 126066 126066 126066 126066 179526 58753 44644 126066 6.5 6.5 6.5 4.5 6 6.5 6.5 6.5 6.5 6.5 6.5 6.5 4 8 12 6.5 0.115 0.150 0.211 0.328 0.334 0.497 0.765 0.913 1.068 1.135 1.171 2.281 1.510 1.517 1.518 1.526 248 257 269 284 289 335 362 376 390 396 399 369 435 424 428 420 36 37 38 51 61 138 140 123 103 122 118 101 367 196 177 221 0.095 0.100 0.111 0.153 0.160 0.258 0.345 0.455 0.500 0.500 0.497 0.606 1.328 0.998 0.995 1.049 10.973 11.582 11.918 12.497 12.802 13.106 65075 65075 65075 103858 60842 60842 65655 65655 65655 104481 60842 60842 8 8 8 8 6.5 6.5 0.509 0.780 0.935 1.269 1.369 1.529 306 328 351 395 401 415 106 95 73 124 157 147 0.219 0.304 0.395 0.966 3.048 7.942 0.48 0.69 1.10 0.94 1.87 4.62 6.52 7.63 8.92 9.38 9.58 11.22 10.08 17.25 35.39 15.51 3.9 6.1 7.7 – 348.0 501.0 HOUSNER MODEL ELASTIC SUPPORT - 2ND LS B (1.67) MPC - 2ND LS B (1.67) H (m) # Nodes # Energy Elements Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria H (m) # Nodes # Energy Elements Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria 6.096 7.620 10.363 10.973 11.582 11.887 11.887 11.979 12.040 12.101 12.192 12.497 12.573 12.802 13.106 13.106 13.183 13.183 13.183 13.259 125283 65985 103935 103935 103935 103858 103935 103935 103935 103935 103858 103858 103858 125283 65760 125283 58118 178218 60842 43755 126066 66688 104671 104671 104671 104481 104671 104671 104671 104671 104481 104481 104481 126066 66435 126066 58758 179543 60842 44634 6.5 6.5 8 8 8 8 8 8 8 8 8 8 8 6.5 6.5 6.5 8 4 6.5 12 0.058 0.121 0.336 0.517 0.794 0.996 0.931 0.972 0.999 1.027 1.125 1.255 1.295 1.361 1.519 1.526 1.587 1.575 1.597 1.639 198 253 287 306 331 351 350 354 356 359 363 375 379 406 417 420 419 424 412 425 14 30 38 34 21 34 38 37 37 42 55 88 94 101 171 221 204 326 273 203 0.083 0.103 0.166 0.213 0.346 0.441 0.429 0.429 0.433 0.437 0.454 0.490 9.754 10.363 10.973 10.973 11.278 11.735 11.887 11.887 11.918 11.918 12.497 12.573 103935 104051 109358 103935 129062 104051 125283 104051 129062 105916 125283 125283 104671 104789 110010 104671 129695 104789 126066 104789 129695 106615 126066 126066 8 8 8 8 6.5 8 6.5 8 6.5 8 6.5 6.5 0.201 0.309 0.542 0.509 0.669 0.845 0.917 0.917 1.283 0.932 1.411 1.612 274 289 309 307 322 343 365 351 376 354 388 401 84 97 109 107 101 76 69 69 150 144 42 163 0.142 0.171 0.219 0.217 0.260 0.344 0.440 0.390 2.100 0.412 0.727 0.714 0.1 0.6 2.5 4.2 6.5 7.9 8.3 8.1 8.4 8.6 8.7 9.9 11.2 14.7 15.5 17844.0 5.9 12.9 39.6 1.36 2.33 3.99 3.93 3.81 6.84 29.24 7.58 8148.00 7.28 33.01 12.28 0.606 0.966 1.049 1.035 2.597 0.823 1.018 HOUSNER MODEL FRICTIONAL PURE PENALTY - 2ND LS B (1.67) H (m) # Nodes # Elements Energy Potential [BTU] Mesh size [in] Displace. X (m) Membr. Stress (Mpa) EQVM Stress (Mpa) Axial Stress (Mpa) Local ASME criteria 7.620 10.363 10.973 11.125 11.125 11.582 11.582 11.582 11.735 11.887 11.887 11.887 11.887 12.040 12.116 12.192 12.497 12.497 12.802 13.106 103858 103858 267718 267718 125283 65075 104051 65075 125283 124172 125283 103935 103935 124172 124172 124172 103935 124172 124172 124172 104481 104481 269023 269023 126066 65655 104789 65655 126066 124770 126066 104671 104671 124770 124770 124770 104671 124770 124770 124770 0.51 51.42 – 47.99 29.34 4.49 6.81 4.49 41.81 6.57 46.56 5.02 5.02 7.04 7.26 7.50 6.36 8.46 9.47 10.59 8 8 4.5 4.5 6.5 8 8 8 6.5 6.5 6.5 8 8 8 6.5 6.5 8 6.5 6.5 6.5 0.052 0.329 0.519 0.583 0.581 0.436 0.791 0.436 0.861 0.931 0.931 0.493 0.506 0.999 1.034 1.070 0.666 1.215 1.368 1.523 233 290 325 332 332 329 334 329 360 366 366 338 338 372 375 378 358 389 401 406 241 36 45 58 48 50 53 20 53 76 36 78 47 47 43 49 57 55 81 103 126 0.1 0.178 0.488 0.337 0.301 0.651 0.377 0.241 0.526 0.475 0.654 0.266 0.266 0.491 0.505 0.521 0.319 0.494 0.538 0.675 23 350 353 356 367 379 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 Table A.4 Converged results for Equivalent Lateral Seismic Force Model (Part I) ELSF MODEL OLD - FIXED H (m) # Nodes FULLY FIXED - 2ND LS B (1.67) # Energy Elements Potential [BTU] 3.048 76717 53001 6.096 76717 53001 7.62 76717 53001 8.5344 76717 53001 9.144 76717 53001 9.4488 76717 53001 9.525 59423 60030 9.6012 71193 71778 9.6012 38419 39275 9.6012 205303 206675 10.9728 178187 179517 11.8872 178187 179517 12.4968 178187 179517 12.8016 178187 179517 13.0302 178187 179517 13.1064 58116 58756 13.1826 65990 66695 13.1826 58118 58758 13.1826 43756 44638 Mesh Displace. Membr. size X (m) Stress [in] (Mpa) 23.63 10 0.15 10 0.37 10 0.66 10 1.02 10 1.28 10 1.09 8 0.93 6.5 3.06 12 0,324/342 4 1.08 4 2.04 4 2.73 4 3.10 4 3.41 4 14.21 8 12.45 6.5 14.22 8 37.79 12 0.022 0.057 0.085 0.112 0.145 0.170 0.177 0.186 0.185 0.187 0.513 0.925 1.219 1.371 1.490 1.529 1.618 1.606 1.582 83 180 218 237 250 257 259 261 261 261 308 349 374 387 396 401 402 401 410 EQVM Stress (Mpa) Axial Local H (m) Stress ASME (Mpa) criteria 121 139 41 261 61 69 291 292 294 292 305 84 26 30 33 37 55 52 56 89 227 240 258 261 260 265 301 363 379 379 379 379 379 379 379 0.077 0.081 0.0909 0.101 0.1128 0.121 0.1237 0.126 0.126 0.15 0.281 0.542 1.1543 1.053 1.0143 0.754 0.756 0,754 0.762 # Nodes # Energy Elements Potential [BTU] 6.096 76717 53001 7.62 124781 69639 8.5344 65985 66688 8.5344 164130 55151 10.9728 205303 206675 10.9728 76717 53001 11.7348 76717 53001 11.8872 76717 53001 12.0396 76717 53001 12.192 76717 53001 12.4968 748017 201649 12.4968 178209 179528 12.8016 178209 179528 13.1064 178209 179528 13.1064 58116 58756 13.1826 43744 44624 13.1826 65990 66695 13.2588 43744 44624 0.14 0.24 0.42 0.59 1.09 5.45 9.27 10.22 11.48 9.38 2.67 2.69 3.06 3.96 13.21 36.90 12.02 40.80 Mesh Displace. Membr. size X (m) Stress [in] (Mpa) Axial Local Stress ASME (Mpa) criteria 10 6.5 6.5 10 4 10 10 10 10 10 4 4 4 4 8 12 6.5 12 179 217 236 238 307 307 342 349 357 352 372 372 385 401 399 403 400 417 229 51 63 87 327 308 305 296 247 303 28 28 31 47 48 101 46 92 0.0815 0.09 0.101 0.127 0.281 0.222 0.354 0.406 0.566 0.334 3.0714 1.1483 1.063 1.0363 0.748 0.757 0.755 0.806 0.057 0.085 0.113 0.113 0.575 0.580 0.935 1.015 1.107 1.005 1.218 1.219 1.371 1.531 1.529 1.583 1.619 1.667 ELSF MODEL MPC - 2ND LS B (1.67) H (m) # Nodes # Energy Elements Potential [BTU] 10.9728 76717 53001 11.8872 76717 53001 12.192 76717 53001 12.2682 128302 128807 12.3444 354322 355545 5.45 10.22 12.03 6.39 4.84 FRICTIONAL PURE PENALTY - 2ND LS B (1.67) Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria H (m) 10 10 10 6.5 4 0.573 1.005 1.166 0.991 1.020 307 349 362 355 357 308 296 246 302 329 0.222 0.405 0.706 0.342 0.467 10.9728 68335 69328 11.7348 68335 69328 11.8872 124781 125644 12.0396 124781 125644 12.192 124781 125644 12.3444 124781 125644 12.4968 124781 125644 12.6492 124781 125644 12.8016 124781 125644 12.954 124781 125644 13.1064 124781 125644 References # Nodes # Energy Elements Potential [BTU] 7.9 16.0 6.0 6.5 7.1 7.6 8.1 8.7 9.2 9.7 10.6 Mesh size [in] Displace. X (m) Membr. Stress (Mpa) Axial Stress (Mpa) Local ASME criteria 12 12 6.5 6.5 6.5 6.5 6.5 6.5 6.5 6.5 6.5 0.520 0.867 0.936 1.004 1.074 1.145 1.218 1.294 1.372 1.450 1.527 308 341 347 353 361 367 374 380 386 392 397 40 38 22 29 46 59 72 82 97 111 125 0.216 0.518 0.431 0.461 0.496 0.508 0.519 0.53 0.54 0.577 0.605 [14] W. Reinhardt, «Investigation of the elastic-plastic design method in section VIII div. 2. » Proceedings of the ASME 2009 Pressure Vessels and Piping Division Conference, 2009. [15] ASME Boiler & Pressure Vessel Code, Section VIII- Division 2 - Alternative Rules, New York, 2021. [16] American Petroleum Institute, API, fitness for service API 579-1, ASME FFS 1 (2016). [17] A. Rondon y, S. Guzey, Failure pressure of the API specification 12F shop welded, flat bottom tanks, J. Pressure Vessel Technol. 139 (2017). [18] J. MacKay y F. Keulen, Partial safety factor approach to the design of submarine pressure hulls using nonlinear finite element analysis, Finite Elem. Anal. Des. 65 (2013) 1–16. [19] ASME Boiler & Pressure Vessel Code, Section VIII-Division 2 -Alternative Rules, New York, 2004. [20] B. Wang, S. Zhu, P. Hao, X. Bi, K. Du, B. Chen, X. ma y, Y. Chao, Buckling of Quasiperfect cylindrical shell under axial compression: a combined experimental and numerical investigation, Int. J. Solid Struct. (2017) 130–131. [21] E. Skukis, O. Ozolins, K. Kalnins y, M. Arbelo, Experimental test for estimation of buckling load on Unstiffened cylindrical shells by vibration correlation technique, Procedia Eng. 172 (2017) 1023–1030. [22] M. Rastgar y, H. Showkati, Buckling of cylindrical steel tanks with Oblique body imperfection under uniform external pressure, J. Pressure Vessel Technol. 139 (2017). [23] S.-R. Cho, T. Muttaqie, Q. Do, S. Kim, S. Kim y, D.-H. Han, Experimental investigations on the failure modes of ring-stiffened cylinders under external hydrostatic pressure, Int. J. Nav. Archit. Ocean Eng. (2018). [24] K. Athiannan y R. Palaninathan, Experimental investigations on buckling of cylindrical shells under axial compression and transverse shear, Sadhana-Academy Proceedings in Engineering Sciences 29 (2004) 93–115. [1] B. Long y, B. Garner, Guide to Storage Tanks & Equipment, Roles and Associates Limited, Great Britain, 2003. [2] P.E. Myers, Aboveground Storage Tanks, McGraw-Hill, New York, 1997. [3] J.R.C. A Baker, «Catastrophic Tank Failures: Highlights of Past Failures along with Proactive Tanks Designs, de The US EPA Fourth Biennial Freshwater Spills Symposium, Cleveland, Ohio, USA, 2002. [4] J.M. Lieb, «Recent Developments in API Storage Tank Standards to Improve Spill Prevention and Leak Detection/Prevention, » Tank Industry Consultants, 2001. [5] C.-C.L. James I Chang, A study of storage tank accidents, J. Loss Prev. Process. Ind. 19 (2006) 51–59. [6] J.I. Chang y, C.-C. Lin, A study of storage tank accidents, J. Loss Prev. Process. Ind. 19 (1) (2006) 51–59. [7] American Petroleum Institute, API, Damage Mechanisms Affecting Fixed Equipment in the Refining Industry, third ed., 2020. [8] W.R.C. Welding Research Council, Damage mechanisms affecting fixed equipment in the refining industry -, Bulletin 489 (2004). [9] W.R.C. Welding Research Council, Damage mechanisms affecting fixed equipment in the pulp and paper industry -, Bulletin 488 (2004). [10] Welding Research Institute, WRC, Damage mechanisms affecting fixed equipment in fossil electric power industry -, Bulletin 490 (2004). [11] F. Ahmad, M. Hossain y R. Seshadri, Fitness-for-Service assessment of hydrocarbon storage tanks, J. Pressure Vessel Technol. 132 (2010). [12] E. Azunni y, S. Guzey, Failure Modes of American Petroleum Institute 12F Tanks with a Rectangular Cleanout and Stepped Shell Design, ASME J. Pressure Vessel Technology, 2018, 2018. [13] E.a.G.S. Azzuni, «Stability of open top cylindrical steel storage tanks: design of top wind girder,» ASME, J. Pressure Vessel Technology (2017). 24 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 [56] Tank Storage Association, Insight - Issue 5, Letchworth Garden City, Tank Storage Association, Spring, 2021. [57] J. Throup, J.B.G. Martínez, B. Bals, J. Cates, J.M. Pearce y, D.C. Denkenberger, Rapid repurposing of pulp and paper mills, biorefineries, and breweries for lignocellulosic sugar production in global food catastrophes, Food Bioprod. Process. 131 (2022) 22–39. ISSN 0960-3085. [58] American Petroleum Institute, A.P.I, Specifications on All-Welded Oil Storage Tanks 12-C, July, Dallas, Texas, 1936. [59] American Petroleum Institute, API 653 Tank Inspection, Repair, Alteration, and Reconstruction, first ed., 1991. [60] American Petroleum Institute, API, welded tanks for oil storage - API 650, 12va Edición, Errata 1 (2021). Errata 3. [61] H. Bohra, E. Azzuni y, S. Guzey, Seismic analysis of Open-top storage tanks with flexible foundation, ASME Journal Pressure Vessel Technology 141 (4) (2019). [62] ANSYS, Ansys Workbench Products Release Notes, 2005. Canonsburg, Pennsylvania. [63] S. Trevor, Weld joint efficiency in design by analysis, Proceedings of the ASME 2016 Pressure Vessels and Piping Conference 3 (2016) 17–21. Design and Analysis. [64] M, S. T.K, S, M.S. Stonehouse, A novel comparison of design-by-analysis methods, J. Pressure Vessel Technol. 134 (2010). [65] J. Rotter, M. Cai y, M. Holst, Buckling of thin cylindrical shells under locally elevated compressive stresses, J. Pressure Vessel Technol. 133 (2011), 11204, https://doi.org/10.1115/1.4002771. [66] H. Wanshi, H. Bohra, E. Azzuni y, S. Guzey, The uplift effect of bottom plate of aboveground storage tanks subjected to wind loading, Thin-Walled Struct. 144 (2019). Noviembre. [67] ANSYS, Mechanical User’s Guide, Canonsburg, Pennsylvania, 2020. [68] ANSYS, «Mechanical User’s Guide,» Ansys Inc. https://ansyshelp.ansys.com/, 2021. [69] M.-J. Kazemzadeh-Parsi, A. Pasquale, D.D. Lorenzo, V. Champaney, A. Ammar y F. Chinesta, NURBS-based shape parametrization enabling PGD-based space separability: methodology and application, Finite Elem. Anal. Des. 227 (2023) nº ISSN 0168-874X. [70] Kazemzadeh-Parsi, Mohammad-Javad, A. Amine, D. Jean y, C. Francisco, Enhanced parametric shape descriptions in PGD-based space separated representations, Advanced Modeling and Simulation in Engineering Sciences 8 (2021), https://doi.org/10.1186/s40323-021-00208-2. [71] D. Hoover y, A.V. Kumar, Immersed boundary thin shell analysis using 3D B-Spline background mesh, Finite Elem. Anal. Des. 195 (2021). ISSN 0168-874X. [72] K. Bakalis y, S.A. Karamanos, Uplift Mechanics of Unanchored Liquid Storage Tanks Subjected to Lateral Earthquake Loading, 158, Thin-Walled Structures, 2021. [73] K. Bakalis, A. Kazantzi, D. Vamvatsikos y, M. Fragiadakis, Seismic performance evaluation of liquid storage tanks using nonlinear static procedures, J. Pressure Vessel Technol. (2018). [74] A.B. Harish y, M.K. Matikainen, Alleviation techniques for volumetric locking in elements based on the absolute nodal coordinate formulation, Finite Elem. Anal. Des. 24 (2023). ISSN 0168-874X. [75] J.H. Lee, S.-H. Lee y, S.-W. Han, Nonlinear earthquake responses of unanchored cylindrical liquid storage tanks on flexible soil, Structures 54 (2352–0124) (2023) 1465–1490. [76] K. Bakalis y, S.A. Karamanos, Uplift mechanics of unanchored liquid storage tanks subjected to lateral earthquake loading, Thin-Walled Struct. 158 (0263–8231) (2021), 107145. [77] V. M y K. S. A, «Modeling of uplifting mechanism in unanchored liquid storage tanks subjected to seismic loading,» de Second European Conference on Earthquake Engineering and Seismology, Istanbul, 2014. [78] M. Moreno, J. Colombo, J. Wilches, S. Reyes y J. Almazán, Buckling of steel tanks under earthquake loading: code provisions vs FEM comparison, Journal of Constructional Steel Research 209 (nº 0143–974X) (2023), 108042. [79] T. Sina, S.A. Shahrouz y, B. Ali, Shaking table test for assessing the seismic performance of semi-anchored steel water tanks, Thin-Walled Struct. 176 (0263–8231) (2022), 109311. [80] D. Hernandez-Hernandez y, N.C. Tam Larkin, Shake table investigation of nonlinear soil–structure–fluid interaction of a thin-walled storage tank under earthquake load, Thin-Walled Struct. 167 (0263–8231) (2021), 108143. [81] K. Nam-Sik y, L. Dong-Guen, Pseudodynamic test for evaluation of seismic performance of base-isolated liquid storage tanks, Eng. Struct. 17 (3) (1995) 198–208. [82] F. Mayumi, N. Masaki, I. Kiyoshi, H. Yutaka, T. Yukihiro y, A. Hiroshi, Dynamic buckling experiments of fluid-structure-coupled co-axial thin cylinder, Nucl. Eng. Des. 188 (1) (1999) 13–26. [83] ASME boiler and pressure vessel code, PTB-1 Section VIII - Division 2 Criteria and Commentary, 2014. [84] E. Patelli, H.M. Panayirci, M. Broggi, B. Goller, P. Beaurepaire, H.J. Pradlwarter y, G.I. Schuëller, General purpose software for efficient uncertainty management of large finite element models, Finite Elem. Anal. Des. 51 (2012) 31–48. ISSN 0168874X. [85] American Petroleum Institute, API, tank Inspection, Repair, alteration, and Reconstruction - API 653, 5ta Edición, Adendo 2 (2020). [86] Ministerio de minas y, energia de Colombia, Colombia’s Hydrogen Roadmap, Ministerio de minas y energia de Colombia, 2022. [25] K, P.R. Athiannan, Experimental investigations on buckling of cylindrical shells under axial compression and transverse shear, Proceedings in Engineering Sciences 29 (2004) 93–115. [26] S. Abduljauwad, H. Al-Ghamedy, J. Siddiqui, I. Asi y, N. Al-Shayea, Stability of vertically bent pipelines buried in sand, J. Pressure Vessel Technol. (2004). [27] A. Nazari, Experimental and numerical study on the nonlinear response of notched cylinders under compressive loading, Sci. Iran. 19 (2012) 355–365. [28] O. Ozolins y, K. Kalnins, An experimental buckling study of column-supported cylinder, Procedia Eng. 172 (2017) 823–830. [29] M. Graßmann, F. Schleich y, M. Stammler, Validation of a finite-element model of a wind turbine blade bearing, Finite Elem. Anal. Des. 221 (2023) nº ISSN 0168-874X. [30] J. Rotter, «The New Framework for Shell Buckling Design and the European Shell Buckling Recommendations, fifth ed., » ASME J. Pressure Vessel Technology, 2011. [31] L.S.J. Leander, M. Hoskins, Water pressure in a tank caused by a simulated earthquake, Bull. Seismol. Soc. Am. 24 (1) (1934) 1–32. [32] L.S. Jacobsen, Impulsive Hydrodynamics of Fluid inside a Cylindrical Tank and of Fluid Surrounding a Cylindrical Pier, 39, Bulletin of the Seismological Society of America, 1949, pp. 189–204. [33] G.W. Housner, Dynamic Pressures on Accelerated Fluid Containers, 47, Bulletin of the Seismological Society of America, 1957. [34] G.W. Housner, The Dynamic Behavior of Water Tanks, Bulletin of the Seismological Society of America, 1963. [35] A.S. Veletsos, Seismic Effects in Flexible Liquid Storage Tanks, Proceedings of the International Association for Earthquake Engineering Fifth World Conference, Rome, 1974, pp. 630–639. [36] V. A, Seismic response and design of liquid storage tanks, in: Guidelines for the Seismic Design of Oil and Gas Pipeline Systems, American Society of Civil Engineers (ASCE), 1984. [37] Y.J, « Dynamic Behavior of Fluid-Tank Systems, » Doctoral dissertation, Houston, Texas, 1976. [38] P.K. Malhotra y, A.S. Veletsos, Seismic Response of Unanchored and Partially Anchored Liquid-Storage Tanks Final Report, 1995. United States. [39] C.-C. Yu y, A.S. Whittaker, Review of analytical studies on seismic fluid-structure interaction of base-supported, Eng. Struct. 233 (2021) nº ISSN 0141-0296. [40] Department of Advanced Technology Brookhaven National Laboratory, Associated Universities, Inc, Seismic design and evaluation guidelines for the Department of Energy High-Level Waste Storage Tanks and Appurtenances, » United States, 1995. [41] P.K. Malhotra, T. Wenk y M. Wieland, Simple procedure for seismic analysis of liquid-storage tanks, Struct. Eng. Int. 10 (2000) 197–201. [42] L.G. Virella, Dynamic buckling of anchored steel tanks subjected to horizontal earthquake excitation 62 (6) (2006) 521–531. [43] M. Sobhan, F.R. Rofooei y, N.K.A. Attari, Buckling behavior of the anchored steel tanks under horizontal and vertical ground motions using static pushover and incremental dynamic analyses, Thin-Walled Struct. 112 (2017) 173–183, nº ISSN 0263-8231. [44] H.N. Phan, F. Paolacci y, S. Alessandri, Enhanced seismic fragility analysis of unanchored steel storage tanks accounting for Uncertain modeling parameters, J. Pressure Vessel Technol. (2018). [45] S. Miladi y, M.S. Razzaghi, Failure analysis of an un-anchored steel oil tank damaged during the Silakhor earthquake of 2006 in Iran, Eng. Fail. Anal. 96 (2019) 31–43. [46] J. Spritzer y, S. Guzey, Nonlinear Numerical Evaluation of Large Open-Top Aboveground Steel Welded Liquid Storage Tanks Excited by Seismic Loads, 119, Thin-Walled Structures, 2017, pp. 662–676. [47] S. Natsiavas, Response and Failure of Fluid-Filled Tanks under Base Excitation, 1987. California. [48] M. Vathi, S. Karamanos, I. Kapogiannis y K. Spiliopoulos, «Performance Criteria for Liquid Storage Tanks and Piping Systems Subjected to Seismic Loading,» ASME, J. Pressure Vessel Technology, 2015. [49] N. Hosseinzadeh, H. Kazem, M. Ghahremannejad, E. Ahmadi y, N. Kazem, Comparison of API650-2008 provisions with FEM analyses for seismic assessment of existing steel oil storage tanks, J. Loss Prev. Process. Ind. 26 (4) (2013) 666–675. [50] D.Z. Djermane, Dynamic buckling of steel tanks under seismic excitation: numerical evaluation of code provisions, Eng. Struct. 70 (2014) 181–196, nº ISSN 0141-0296. [51] P. Prueter y, S. Kummari, Evaluating large aboveground storage tanks subject to seismic loading: Part I — closed-form solutions and equivalent static analysis, Prague, Czech Republic, in: Proceedings of the ASME 2018 Pressure Vessels and Piping Conference, 8, Seismic Engineering, 2018. [52] S. Kummari, P. Prueter y, M. Bifano, «Evaluating Large Aboveground Storage Tanks Subject to Seismic Loading: Part II — Explicit Dynamic Analysis with Liquid Sloshing Effects,» Proceedings of the ASME, in: Pressure Vessels and Piping Conference, 8, 2018. Seismic Engineering, 2018. [53] C. Nadarajah, B. Hantz y S. Krishnamurthy, Buckling of Cylinders Due to External Pressure: Experimental Work Compared with Finite Element Stress Analysis, Virtual, Online: Proceedings of the ASME 2020 Pressure Vessels & Piping Conference, 2020. [54] Z. Li, H. Pasternak y, A. Jäger-Cañás, Buckling of Ring-Stiffened Cylindrical Shell under Axial Compression Experiment and Numerical Simulation, 164, Thin-Walled Structures, 2021. [55] J. Su, S.v. Dyk y, J. Saddler, Repurposing oil refineries to “stand-alone units” that refine lipids/oleochemicals to produce low-carbon intensive, drop-in biofuels, J. Clean. Prod. 376 (2022). ISSN 0959-6526. 25 D. García-G et al. International Journal of Pressure Vessels and Piping 207 (2024) 105113 [87] R. Cardinale, From natural gas to green hydrogen: developing and repurposing transnational energy infrastructure connecting North Africa to Europe, Energy Pol. 181 (2023). ISSN 0301-4215. [88] T. Peter Davidson - Executive Director, F. Ravi Bhatiani - Executive Director, y U. Johan Deleu - President, Interviewees, Tank Talk | Repurposing and Re-using Existing Infrastructure for the Future, 20 July 2023 [Entrevista]. [89] HCSS Geo-economics, The European Tank Storage Sector and the Global Energy Landscape, The Hague Centre for Strategic Studies, June 2021. [90] HCSS Geo-economics, The European Tank Storage Sector 2050 and beyond, The Hague Centre for Strategic Studies, May 2022. [91] S.&P. Global, «INTERVIEW, Vopak Singapore looks to repurpose tanks amid renewables push, Commodity Insights (31 08 2023). [92] M.a.S.H. Rastgar, Buckling of cylindrical steel tanks with Oblique body imperfection under uniform external pressure, ASME. J. Pressure Vessel Technology (2017). 26