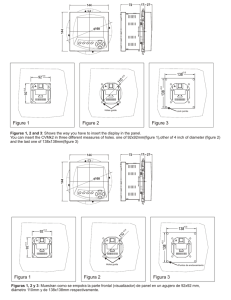

CBT INSTALLATION MANUAL FOR UH-1H HELICOPTER DOCUMENT NUMBER A726-005, REV. 0 Prepared by: W.R. DAVIS ENGINEERING LIMITED Ottawa, Ontario, Canada DAVIS File No. A726 DECEMBER 2008 The copyright in this document, which contains information of a proprietary nature, is vested in W.R. Davis Engineering Limited. The content of this document may not be used for purposes other than that for which it has been supplied and may not be reproduced, either wholly or in part, in any way whatsoever, nor may it be used by, or its content divulged to any other person whatsoever without the prior written permission of W.R. Davis Engineering Limited. A726-005, Rev 0.doc Document Number A726-005, Rev 0, December 2008 AMENDMENT RECORD ISSUE 0 DESCRIPTION CBT Installation Manual For UH-1H Helicopter Q-5 F Amendment Record (01/03/03) Document Number A726-005, Rev 0, December 2008 DATE December 2008 Davis REPORT DATA SHEET DAVIS NUMBER: SPONSOR'S NUMBER: A726 TITLE: CBT INSTALLATION MANUAL FOR UH-1H HELICOPTER DOCUMENT NUMBER A726-005, REV. 0 AUTHORS: SPONSOR'S REPRESENTATIVE: B. Brooking, P.Eng ORIGINAL SUBMISSION DATE: ORIGINAL APPROVED BY: December 2008 D. VanDam, P.Eng REVISIONS APPROVED BY: REVISIONS: Please ensure all previous revisions are marked obsolete. ABSTRACT: This document details the installation of the CBT IRSS device aboard the UH-1H helicopter including required cowling modifications. ISSUE DATE: COPY NUMBER: SECURITY CLASSIFICATION: December 5, 2008 UNCLASSIFIED DISTRIBUTION: DAVIS : File Q-5 D Report Data Sheet (15/05/00) Document Number A726-005, Rev 0, December 2008 NUMBER OF PAGES: 27 TABLE OF CONTENTS 1.0 INTRODUCTION .............................................................................................................. 1 1.1 1.2 1.3 2.0 PAGE PARTS DESCRIPTION ......................................................................................... 1 REFERENCES ....................................................................................................... 1 DEFINITIONS AND ABBREVIATIONS............................................................. 1 INSTALLATION PROCEDURES .................................................................................... 4 2.1 2.2 COWLING MODIFICATION KIT........................................................................ 4 CBT IRSS DEVICE.............................................................................................. 13 LIST OF FIGURES Figure 1 UH-1H OEM COWLING....................................................................................... 2 Figure 2 COWLING MODIFICATION KIT INSTALLED WITH CBT IRSS DEVICE ... 3 Figure 3 UPPER LOUVER TEMPLATE A02-02-001 ........................................................ 9 Figure 4 LOWER LOUVER TEMPLATE A02-02-002....................................................... 9 Figure 5 CUTTING TOP 3 AND TOP 4 LOUVER CUTOUTS........................................ 10 Figure 6 SAMPLE LOUVER-DOUBLER RIVET PATTERN.......................................... 10 Figure 7 COWLING LOUVER AND DOUBLER INSTALLATION............................... 11 Figure 8 TOP 4 LOUVER + TOP BACK DOUBLER INSTALLATION......................... 11 Figure 9 COWLING REINFORCING BAND AND CLOSURE SECTION..................... 12 LIST OF APPENDICES APPENDIX A APPENDIX B APPENDIX C ILLUSTRATED PARTS BREAKDOWN SCOPE OF SUPPLY INSTALLATION DRAWINGS Document Number A726-005, Rev 0, December 2008 1.0 INTRODUCTION This document describes the procedures for the installation of the DAVIS Centre Body Tailpipe (CBT) aboard the UH-1H helicopter. In order to retrofit the UH-1H for the CBT, the helicopter cowling must be modified to accommodate the new tailpipe. The installation personnel must be fully aware of the procedures described in this document prior to undertaking any of the installation procedures. Personnel must be fully qualified to work on this aircraft. 1.1 PARTS DESCRIPTION A complete description of the CBT and the cowling modification is given in Ref. 1). Figure 1 shows the OEM tailpipe and cowling as installed aboard the UH-1H helicopter. Figure 2 shows the CBT installed within the modified cowling. For further details, see the Illustrated Parts Breakdown document (APPENDIX A). 1.2 REFERENCES 1) A726-002, CBT Structural Design Report 2) A726-004, Instructions For Continued Airworthiness (ICA) CBT IRSS Device 3) TM55-1520-210-23-1, Aviation Unit And Intermediate Maintenance Instructions Army Model UH-1H/V/EH-1H/X Utility Helicopters 1.3 DEFINITIONS AND ABBREVIATIONS CBT Centre Body Tailpipe CRES Corrosion-Resistant Steel DAVIS W.R. Davis Engineering Limited ICA Instructions for Continued Airworthiness IPB Illustrated Parts Breakdown IR Infrared IRSS Infrared Signature Suppressor LHS Left Hand Side OEM Original Equipment Manufacturer RHS Right Hand Side Document Number A726-005, Rev 0, December 2008 1 Figure 1 UH-1H OEM COWLING Document Number A726-005, Rev 0, December 2008 2 Figure 2 COWLING MODIFICATION KIT INSTALLED WITH CBT IRSS DEVICE Document Number A726-005, Rev 0, December 2008 3 2.0 INSTALLATION PROCEDURES Section 2.1 details the preparation and modification of the OEM UH-1H helicopter exhaust cowling to accommodate the CBT IRSS device. Section 2.2 details the installation of the CBT itself. Appendix B provides a list of parts supplied by DAVIS for the CBT IRSS installation and cowling modification. Note that rivets and tooling (with the exception of the louver templates) are not included. The cowling modifications use 1/8” solid aluminum 2117-T4 rivets. It is the responsibility of the installer to select the appropriate rivet grip length at installation. Installation drawings are provided in Appendix C. 2.1 COWLING MODIFICATION KIT The following instructions detail the steps required to modify the OEM cowling for adaption for use with the CBT IRSS device. 1. Unbolt and remove the OEM cowling from the helicopter. 2. De-rivet all eight (8) louvers on each side of the OEM cowling according to standard aerospace practices. 3. De-rivet the reinforcing ring that encircles the exit of the cowling. 4. Beginning with the upper louvers on either the RHS or LHS, locate the flexible Upper Louver Template (see Figure 3). Place the template on the outside of the cowling ensuring the template is oriented with the word ‘TOP’ toward the top of the cowling. 5. Align the forward two cutouts of the template with the existing forward two louver holes on the cowling. Trace the aft two cutouts onto the outside of the cowling with a non-scoring marking tool and remove the template. 6. Take the Top Front Doubler [18] and hand work the part to match the curvature of the cowling when the doubler is aligned with the existing forward two louver cutouts. Ensure the contoured edge of the doubler is oriented toward the top of the cowling. 7. When the doubler adequately conforms to the curvature of the cowling, align the forward two cutouts of the doubler with the existing forward two louver holes on the outside of the cowling and confirm that the third louver cutout aligns with that marked in step 5. Remove the doubler. Confirm that the Top 3 Louver ([5] on left side, [12] on right side) can be installed at this location. Trim louver flanges if necessary to accommodate equipment installed on top of the cowling. Document Number A726-005, Rev 0, December 2008 4 8. Take the Top 4 Louver ([6] on left side, [13] on right side) and fit it up against the cowling such that the louver flange aligns with the markings from step 5. Make any small adjustments in location that allow the louver to best fit the curvature of the cowling without deviating more than ¼” from the marked outline. Mark the new outline of the louver flange if necessary. 9. Locate and mark an offset inside the louver flange outline equal to the width of the louver flange (i.e. the theoretical profile of the louver flange). 10. Take the Top Back Doubler [20] and hand work the part to match the curvature of the cowling when the doubler is aligned with the inside profile of the louver flange. Trim the top and bottom of the doubler where necessary to accommodate the stiffening ribs on the inside of the cowling. Note the overlap with the existing rivet holes for the reinforcing band on the doubler. See Figure 8 to see the typical overlap between the doubler and the reinforcing band. If the edge of the doubler prevents rivets from being successfully installed, that region of the doubler may be trimmed away. 11. Using a step drill, drill out the radius corners of the two new louver cutouts marked in step 5. See Figure 5. 12. Cut the remainder of the louver cutouts using standard aerospace practices. The use of a reciprocating saw is recommended for cutting the cowling skin. 13. Apply a chromate primer to the cut edges before continuing. 14. Align the Top Front Doubler [18] as in step 7 to the inside of the cowling. Mark the locations of the existing cowling rivet holes around the front two louvers onto the doubler. Remove the doubler from the cowling. 15. Continue to mark the rivet pattern on the doubler, as started in step 14, around the louver cut outs (See Figure 6) with a pitch of approximately 1 inch while maintaining standard edge clearances (twice rivet diameter + 1/16”). Also mark a similar rivet pattern around the third (aft) louver cut out. Ensure all new rivet holes will not violate edge clearances with stiffening ribs or other assembly members. 16. Drill the marked rivet holes using standard aerospace practices. Be sure to deburr all drilled holes. 17. Align the doubler into place on the inside of the cowling and clamp into place. Match drill the rivet holes from step 16 through the cowling skin. 18. Align the Top 1, Top 2 and Top 3 Louvers ([3], [4], [5] on the left side; [10], [11], [12] on the right side) into place on the outside of the cowling. Ensure that the rivet holes will not violate edge clearance limits on the louver flanges by marking the locations onto the louver flanges and removing for inspection. Clamp the parts back in place when completed. Match drill all the doubler rivet holes through the louver flanges. Remove doubler and louvers. De-burr all rivet holes. Apply sealant (PR1422 or equivalent) to all faying surfaces, refit and Cleco in place. Document Number A726-005, Rev 0, December 2008 5 19. Complete the riveting of the Top 1, Top 2 and Top 3 Louvers into place along with the Top Front Doubler using standard aerospace practices in place as indicated by Figure 7 assembly. Do not rivet the Top 4 Louver and Top Back Doubler [20] at this time. 20. Repeat steps 4-19 for the top louvers on the other side of the cowling. When these steps have been completed, all Top 1, 2 and 3 Louvers and Top Front Doublers will have been riveted in place and the cutout for the Top 4 Louver will have been created. 21. Continue with the lower louvers on either the RHS or LHS. Locate the flexible Lower Louver Template (see Figure 4). Place the template on the outside of the cowling ensuring the template is oriented with the word ‘TOP’ toward the top of the cowling. 22. Align the forward two cutouts of the template with the existing forward two louver cutouts in the OEM cowling. Trace the aft two cutouts onto the outside of the cowling with a non-scoring marking tool and remove the template. 23. Take the Bottom Front Doubler [19] and hand work the part to match the curvature of the cowling when the doubler is aligned with the existing forward two louver cutouts. 24. When the doubler adequately conforms to the curvature of the cowling, mark the existing rivet hole locations onto the doubler and remove from the cowling. 25. Continue to mark the rivet pattern on the doubler, as started in step 24, around the louver cut out (See Figure 6) with a pitch of approximately 1 inch while maintaining standard edge clearances (twice rivet diameter + 1/16”). Ensure all new rivet holes will not violate edge clearances with stiffening ribs or other assembly members. 26. Drill the marked rivet holes into the doubler. De-burr all holes. 27. Align the doubler into place on the inside of the cowling and clamp into place. Match drill the rivet holes from step 26 through the cowling skin. 28. Align the Bottom Front Louvers [7] at these two locations. Mark the rivet holes onto the louver flanges and inspect rivet edge clearances. Trim the louver flanges if necessary to clear items such as the reinforcing rib on side of the cowling. 29. Clamp the louvers into place and match drill all rivet holes through the louver flanges. Remove parts and de-burr all drilled holes. Apply sealant to faying surfaces, reinstall and Cleco into place. 30. Take the Bottom 3 Louver ([8] on left side, [14] on right side) and fit it up against the cowling such that the outside of the louver flange aligns with the markings from step 22. Make any small adjustments in location that allow the louver to best fit the curvature of the cowling without deviating more than ¼” from the marked outline. Trim louver flanges if necessary to accommodate the stiffening rib on the side of the cowling. Mark the new outline of the louver flange if necessary. Document Number A726-005, Rev 0, December 2008 6 31. Locate and mark an offset inside the Bottom 3 Louver flange outline equal to the width of the louver flange (i.e. the theoretical profile of the louver flange) 32. Repeat steps 30 and 31 for the Bottom 4 Louver ([9] on left side, [15] on right side). 33. Take the Bottom Back Doubler [21] and hand work the part to match the curvature of the cowling when the doubler is aligned with the inside outline of the louver flanges as marked in step 31. Trim the top and bottom of the doubler where necessary to accommodate the stiffening ribs in this area. 34. Using a step drill, drill out the radius corners of the two new louver cutouts (per side). See Figure 5. 35. Cut the remainder of the louver cutouts using standard aerospace practices. The use of a reciprocating saw is recommended for cutting the cowling skin. 36. Apply a chromate primer to the cut edges before continuing. 37. Mark a rivet hole pattern on the doubler [21] around the louver cutouts using an approximate pitch of 1 inch, maintaining standard edge clearances (twice rivet diameter + 1/16”). Figure 6 illustrates what the doubler rivet pattern should look like. Move holes if edge clearances will be interfered with by stiffening ribs or other assembly members. Drill and de-burr the marked rivet holes. 38. Fit the doubler [21] to the inside of the cowling. Match drill the doubler rivet holes including those through the cowling skin, maintaining standard edge clearances (twice rivet diameter + 1/16”). 39. Align the Bottom 3 and Bottom 4 Louvers to the outside of the cowling. Mark the rivet holes from step 38 onto the louver flanges. Remove and inspect for edge clearance violations. Clamp back into place. Match drill through the louver flanges. Remove parts, de-burr all rivet holes and apply sealant to all faying surfaces. Cleco the louvers and doubler into place. 40. Complete the riveting of the Bottom 3 and Bottom 4 Louvers into place along with the Bottom Back Doubler [21] using standard aerospace practices in the locations indicated in Figure 7 assembly. 41. Repeat steps 21-40 for the louvers on the other side of the cowling. 42. At this point all louvers have been installed except for the Top 4 Louvers ([6] on left side, [13] on right side) 43. Test fit the cowling over the CBT device to ensure clearance at the cowling exit. Ensure there will be sufficient space for the largest diameter portion of the CBT to pass through the cowling exit with the reinforcing ring installed. When the cowling is installed, the gap between the cowling and the tailpipe should be consistent around the entire circumference. The cowling may be trimmed if necessary to allow for installation over the CBT. Remove the cowling and continue modifications. Document Number A726-005, Rev 0, December 2008 7 44. Locate the new Cowling Reinforcing Band [16] and fit it into place on the inside of the cowling. The band must be flexed slightly in a spring type action to allow it to fit into place. The band must fit between the reinforcing ribs and the cowling skin with the gap in the band located toward the bottom. 45. Fit the Cowling Closure Section [17] into place at the bottom of the cowling to complete the reinforcing band. See Figure 9. The cowling closure section ends are joggled to allow the cowling reinforcing band to sit underneath it when the band is installed Measure how much of the band must be trimmed to fully accommodate the closure section. Remove the reinforcing band and trim. 46. Fit the band back into place along with closure section. Locate the closure section toward the bottom of the cowling. Drill the rivet holes in the overlap section through the band and Cleco into place. See Figure 9. 47. Align the Top Back Doublers [20] on each side of the cowling. These doublers were trimmed to fit in step 10. The reinforcing band should lie between the doubler and the cowling skin. 48. Joggle the doublers [20] as necessary where they overlap the reinforcing band to ensure best fit up. Clamp into place. 49. Match drill the reinforcing band [16] and doublers [20] through the existing reinforcing band rivet holes. Remove the doublers. 50. Continue the rivet pattern on the doublers [20], as started in step 49, around the louver cut out with a pitch of approximately 1 inch while maintaining standard edge clearances (twice rivet diameter + 1/16”). Figure 6 illustrates what the doubler rivet pattern should look like. Move holes if edge clearances are interfered with by other assembly members. 51. Fit doublers [20] back into place and align the Top 4 Louvers [6] and [13] and clamp into place, trimming the louver flanges as necessary. 52. Match drill louvers and cowling skin to the holes drilled in the doubler in step 50. 53. Remove the louvers, doublers and reinforcing band. De-burr all drilled holes. Apply sealant to all faying surfaces, reinstall and Cleco into place. 54. Complete the riveting of [6] ([13]), [20], [16] and [17] using standard aerospace practices. Document Number A726-005, Rev 0, December 2008 8 Figure 3 UPPER LOUVER TEMPLATE A02-02-001 Figure 4 LOWER LOUVER TEMPLATE A02-02-002 Document Number A726-005, Rev 0, December 2008 9 Figure 5 CUTTING TOP 3 AND TOP 4 LOUVER CUTOUTS Figure 6 SAMPLE LOUVER-DOUBLER RIVET PATTERN Document Number A726-005, Rev 0, December 2008 10 Figure 7 COWLING LOUVER AND DOUBLER INSTALLATION Figure 8 TOP 4 LOUVER + TOP BACK DOUBLER INSTALLATION Document Number A726-005, Rev 0, December 2008 11 Figure 9 COWLING REINFORCING BAND AND CLOSURE SECTION Document Number A726-005, Rev 0, December 2008 12 2.2 CBT IRSS DEVICE Install the CBT IRSS device [2] according to the following procedure: 1. If in place, unfasten and remove the cowling. 2. Remove the OEM tailpipe starting with disconnecting the fuel drain from the OEM tailpipe. 3. Support the tailpipe and loosen the bolt on the existing v-band clamp until the clamp may be removed. 4. Lift the OEM tailpipe off of the engine flange and remove. 5. Lift the CBT into place, locating the alignment pins and aligning with the holes on the engine mounting flange. The CBT should angle upwards when located correctly. 6. Seat the CBT mounting flange against the engine flange securely. 7. Install the band clamp around both flanges and hand-tighten the bolt. Lightly tap around the clamp (while still supporting the tailpipe) with a wooden or rubber mallet to ensure the tailpipe is seated. Torque to the installation value indicated in the UH-1H manual. 8. Connect the fuel drain to the fitting on the bottom of the CBT. 9. Replace the cowling, sliding the exit over the CBT, and bolt into place. Document Number A726-005, Rev 0, December 2008 13 APPENDIX A ILLUSTRATED PARTS BREAKDOWN Document Number A726-005, Rev 0, December 2008 ITEM 1 PART NO. A02-E0-900-0 2 A02-F0-900-0 DESCRIPTION COWLING MODIFICATION KIT CENTRE BODY TAILPIPE; IRSS ASSEMBLY ITEM 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 PART NO. A02-E0-001-0 A02-E0-002-0 A02-E0-003-0 A02-E0-004-0 A02-E0-005-0 A02-E0-006-0 A02-E0-007-0 A02-E0-008-0 A02-E0-009-0 A02-E0-010-0 A02-E0-011-0 A02-E0-012-0 A02-E0-013-0 A02-E0-017-0 A02-E0-018-0 A02-E0-019-0 A02-E0-020-0 A02-E0-021-0 A02-E0-022-0 DESCRIPTION LOUVER; CBT COWLING; LEFT TOP 1 LOUVER; CBT COWLING LEFT TOP 2 LOUVER; CBT COWLING LEFT TOP 3 LOUVER; CBT COWLING LEFT TOP 4 LOUVER; CBT COWLING BOTTOM FRONT LOUVER; CBT COWLING LEFT BOTTOM 3 LOUVER; CBT COWLING LEFT BOTTOM 4 LOUVER; CBT COWLING RIGHT TOP 1 LOUVER; CBT COWLING RIGHT TOP 2 LOUVER; CBT COWLING RIGHT TOP 3 LOUVER; CBT COWLING RIGHT TOP 4 LOUVER; CBT COWLING RIGHT BOTTOM 3 LOUVER; CBT COWLING RIGHT BOTTOM 4 REINFORCING BAND; COWLING CLOSURE SECTION; COWLING TOP FRONT DOUBLER BOTTOM FRONT DOUBLER TOP BACK DOUBLER BOTTOM BACK DOUBLER ITEM 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 PART NO. A02-00-001-0 A02-CA-800-0 A02-C0-001-0 A02-C0-002-0 A02-CB-800-0 A02-CC-800-0 A02-CD-800-0 A02-CE-800-0 A02-C0-003-0 A02-C0-004-0 A02-C0-005-0 A02-C0-006-1 A02-C0-006-2 A02-DE-800-0 A02-D0-002-0 A02-D0-003-0 A02-D0-004-0 A02-DA-800-0 A02-DB-800-0 A02-DC-800-0 A02-DD-800-0 A02-D0-006-1 A02-D0-006-2 A02-D0-006-3 A02-D0-008-0 A02-AA-800-0 A02-AB-800-0 A02-AA-006-L A02-AA-006-R A02-B0-001-0 A02-BB-800-0 A02-BA-800-0 A02-B0-003-1 A02-B0-003-2 A02-B0-003-3 DE5340-1 DESCRIPTION LABEL - CBT IDENTIFIER OUTER BODY RING 2 OUTER BODY RING 3 OUTER BODY RING 4 OUTER BODY RING 5 OUTER BODY RING 3 DOUBLER OUTER BODY RING 4 DOUBLER OUTER BODY RING 5 DOUBLER R1 - R2 STANDOFF R1-R2 STANDOFF DOUBLER R2 - R3 STANDOFF R3 - R4 STANDOFF R4 - R5 STANDOFF OUTER BODY RING 6 OUTER BODY RING 7 OUTER BODY RING 8 OUTER BODY RING 9 OUTER BODY RING 7 DOUBLER OUTER BODY RING 8 DOUBLER OUTER BODY RING 9 DOUBLER OUTER BODY RING 9 DOUBLER STANDOFF; OUTER BODY; R6-R7 STANDOFF; OUTER BODY; R7-R8 STANDOFF; OUTER BODY; R8-R9 STANDOFF; OUTER BODY; R5-R6 OUTER BODY RING1 INNER BODY RING1 STRUT COLLAR; SLIDING - LEFT STRUT COLLAR; SLIDING - RIGHT INNER BODY RING 2 INNER BODY RING 3 INNER BODY RING 4 STANDOFF; INNER BODY; R1-R2 STANDOFF; INNER BODY; R2-R3 STANDOFF; INNER BODY; R3-R4 INSTALLATION KIT; FUEL DRAIN APPENDIX B SCOPE OF SUPPLY Document Number A726-005, Rev 0, December 2008 No. QTY./SHIP SET CUSTOMER PART # DAVIS PART # PART DESCRIPTION DRAWING NO. SERIAL NO. CRATE# PACKED BY CHECKED BY COWLING MODIFICATION KIT 1 1 A02-E0-001-0 LOUVER, CBT COWLING, LEFT TOP 1 A02-E0-001 2 1 A02-E0-002-0 LOUVER, CBT COWLING, LEFT TOP 2 A02-E0-002 3 1 A02-E0-003-0 LOUVER, CBT COWLING, LEFT TOP 3 A02-E0-003 4 1 A02-E0-004-0 LOUVER, CBT COWLING, LEFT TOP 4 A02-E0-004 5 4 A02-E0-005-0 LOUVER, CBT COWLING, BOTTOM FRONT A02-E0-005 6 1 A02-E0-006-0 LOUVER, CBT COWLING, LEFT BOTTOM 3 A02-E0-006 7 1 A02-E0-007-0 LOUVER, CBT COWLING, LEFT BOTTOM 4 A02-E0-007 8 1 A02-E0-008-0 LOUVER, CBT COWLING, RIGHT TOP 1 A02-E0-008 9 1 A02-E0-009-0 LOUVER, CBT COWLING, RIGHT TOP 2 A02-E0-009 10 1 A02-E0-010-0 LOUVER, CBT COWLING, RIGHT TOP 3 A02-E0-010 11 1 A02-E0-011-0 LOUVER, CBT COWLING, RIGHT TOP 4 A02-E0-011 12 1 A02-E0-012-0 LOUVER, CBT COWLING, RIGHT BOTTOM 3 A02-E0-012 13 1 A02-E0-013-0 LOUVER, CBT COWLING, RIGHT BOTTOM 4 A02-E0-013 14 1 A02-E0-017-0 REINFORCING BAND, COWLING A02-E0-017 15 1 A02-E0-018-0 CLOSURE SECTION, COWLING A02-E0-018 16 2 A02-E0-019-0 TOP FRONT DOUBLER A02-E0-019 17 2 A02-E0-020-0 BOTTOM FRONT DOUBLER A02-E0-020 18 2 A02-E0-021-0 TOP BACK DOUBLER A02-E0-021 19 2 A02-E0-022-0 BOTTOM BACK DOUBLER A02-E0-022 20 1 A02-02-001-0 UPPER LOUVER TEMPLATE A02-002-001 21 1 A02-02-002-0 LOWER LOUVER TEMPLATE A02-002-002 IRSS ASSEMBLY 20 1 A02-F0-900-0 SUPPRESSOR ASSEMBLY A02-F0-900 B UPDATED AS PER DAVIS ECC #08-213; ADDED LOUVER INSTALLATION TEMPLATES T.PREM 26/11/2008 A INITIAL RELEASE T.PREM 05/11/2008 B.CHANTER 11/07/2008 W.HUMPHRIES 11/06/2008 DATE CHECKED APPROVED DESCRIPTION REV. DESIGNED BY T.PREM DRAWN BY T.PREM CHECKED BY B.CHANTER APPROVED BY W.HUMPHRIES DESIGNED DATE 05/11/2008 DRAWN DATE DAVIS W.R. DAVIS ENGINEERING LTD. OTTAWA CANADA TITLE 05/11/2008 CBT ASSEMBLY SCOPE OF SUPPLY CHECKED DATE 05/11/2008 APPROVED DATE 05/11/2008 DRAWN CONT. NO. A726 CONT.NAME CAGE CODE CBT DRAWING NO. 3AB25 A02-06-000 REV. B This document unless otherwise noted, remains the property of W.R. Davis Engineering Limited. It shall not be reproduced or used for manufacture, design, or construction without the express authorization of the owner. The recipient, by accepting this document assumes the custody thereof and under the above terms, agrees not to allow its use by unauthorized persons without incurring liability for penalities imposed by law. APPENDIX C INSTALLATION DRAWINGS Document Number A726-005, Rev 0, December 2008 1 2 3 4 5 6 7 8 9 10 11 12 13 14 A 15 16 17 18 19 20 21 ITEM QTY PART NUMBER DESCRIPTION 1 1 A02-E0-900-0 COWLING MODIFICATION KIT ALUMINUM 2 1 A02-F0-900-0 IRSS ASSEMBLY SST / INCONEL / TITANIUM 22 23 MATERIAL DESCRIPTION 24 MANUFACTURER A B B 1 C C D D E E 2 F F G G H H J J K K L L M M N N P P Q B UPDATED AS PER DAVIS ECC #08-190; ORIGINAL A02-00-000 RENAMED TO A02-F0-900 T.PREM 08/11/04 A INITIAL PRODUCTION RELEASE T.PREM 08/05/27 S.REINISCH 08/06/12 W.HUMPHRIES 08/06/12 DRAWN DATE CHECKED APPROVED REV. DESCRIPTION Q REVISIONS This drawing unless otherwise noted, remains the property of W.R. Davis Engineering Limited. It shall not be reproduced or used for manufacture, design or construction without the express authorization of the owner. The recipient, by accepting this drawing assumes the custody thereof and under the above terms, agrees not to allow its use by unauthorized persons without incurring liability for penalties imposed by law. R UNLESS OTHERWISE SPECIFIED: 1. DIMENSIONS ARE IN: mm 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 DECIMALS 3. SURFACE FINISH: -- SHTA0 101606 1 5. TOLERANCES: 2. SCALE: 1:2 4. REMOVE ALL BURRS AND SHARP EDGES 18 DESIGNED .X ± 0.5 .XX ± -- .XXX ± -- A. PREM DRAWN 08/11/04 DATE A. PREM 08/11/04 DATE CHECKED S. REINISCH WHOLE NUMBERS ± 1.0 ANGLES ± 0.5° APPROVED HOLE SIZES ± 0.5 HOLE CENTERS ± 0.5 19 DATE W.HUMPHRIES 20 08/11/04 CONT. NO . A726 21 R CBT ASSEMBLY 08/11/04 DATE W. R. DAVIS ENGINEERING LTD. OTTAWA CANADA Davis TITLE CONTRACT NAME CAGE CODE CBT 3AB25 22 USED ON DRAWING NO. REV. A02-00-000 B -- A0 23 SHT 1 OF 1 24 1 2 3 4 5 6 7 8 9 10 12 11 13 14 MS20470AD | 4N 21 A 15 16 17 18 19 20 21 DESCRIPTION 22 23 ITEM QTY PART NUMBER MATERIAL DESCRIPTION 1 1 A02-E0-001-0 LOUVER, CBT COWLING, LEFT TOP 1 ALUMINUM ALLOY, TYPE 2024 2 1 A02-E0-002-0 LOUVER, CBT COWLING, LEFT TOP 2 ALUMINUM ALLOY, TYPE 2024 3 1 A02-E0-003-0 LOUVER, CBT COWLING, LEFT TOP 3 ALUMINUM ALLOY, TYPE 2024 4 1 A02-E0-004-0 LOUVER, CBT COWLING, LEFT TOP 4 ALUMINUM ALLOY, TYPE 2024 5 4 A02-E0-005-0 LOUVER, CBT COWLING, BOTTOM FRONT ALUMINUM ALLOY, TYPE 2024 6 1 A02-E0-006-0 LOUVER, CBT COWLING, LEFT BOTTOM 3 ALUMINUM ALLOY, TYPE 2024 7 1 A02-E0-007-0 LOUVER, CBT COWLING, LEFT BOTTOM 4 ALUMINUM ALLOY, TYPE 2024 8 1 A02-E0-008-0 LOUVER, CBT COWLING, RIGHT TOP 1 ALUMINUM ALLOY, TYPE 2024 9 1 A02-E0-009-0 LOUVER, CBT COWLING, RIGHT TOP 2 ALUMINUM ALLOY, TYPE 2024 10 1 A02-E0-010-0 LOUVER, CBT COWLING, RIGHT TOP 3 ALUMINUM ALLOY, TYPE 2024 11 1 A02-E0-011-0 LOUVER, CBT COWLING, RIGHT TOP 4 ALUMINUM ALLOY, TYPE 2024 12 1 A02-E0-012-0 LOUVER, CBT COWLING, RIGHT BOTTOM 3 ALUMINUM ALLOY, TYPE 2024 13 1 A02-E0-013-0 LOUVER, CBT COWLING, RIGHT BOTTOM 4 ALUMINUM ALLOY, TYPE 2024 ALUMINUM, 2024-0 24 MANUFACTURER A B B C C D D E F 14 1 A02-E0-017-0 REINFORCING BAND, COWLING 15 1 A02-E0-018-0 CLOSURE SECTION, COWLING ALUMINUM, 2024-0 16 2 A02-E0-019-0 TOP FRONT DOUBLER ALUMINUM ALLOY, TYPE 2024 ALUMINUM ALLOY, TYPE 2024 17 2 A02-E0-020-0 BOTTOM FRONT DOUBLER 18 2 A02-E0-021-0 TOP BACK DOUBLER ALUMINUM ALLOY, TYPE 2024 19 2 A02-E0-022-0 BOTTOM BACK DOUBLER ALUMINUM ALLOY, TYPE 2024 20 A/R MS20426AD4 RIVET, 0.125" DIA. COUNTERSUNK HEAD, SOLID ALUMINUM 2117-T4 21 A/R MS20470AD4 RIVET, 0.125" DIA. UNIVERSAL HEAD, SOLID ALUMINUM 2117-T4 E F G G 16 16 8 9 1 2 3 H 10 11 4 H J J 14 K K 18 18 L L 19 19 M M N N 15 REF 17 17 P P 5 5 5 5 12 13 6 7 Q Q A INTIAL PRODUCTION RELEASE K.WONG 08/09/12 REV. DESCRIPTION DRAWN DATE CHECKED APPROVED REVISIONS This drawing unless otherwise noted, remains the property of W.R. Davis Engineering Limited. It shall not be reproduced or used for manufacture, design or construction without the express authorization of the owner. The recipient, by accepting this drawing assumes the custody thereof and under the above terms, agrees not to allow its use by unauthorized persons without incurring liability for penalties imposed by law. R NOTES: 1) FOR INSTALLATION PROCEDURE, REFER TO A726-005 - "CBT INSTALLATION MANUAL". 1 2 3 4 5 6 UNLESS OTHERWISE SPECIFIED: 1. DIMENSIONS ARE IN: mm 8 9 10 11 12 13 14 15 16 17 DECIMALS 3. SURFACE FINISH: -- SHTA0 101606 7 5. TOLERANCES: 2. SCALE: 1:2.5 4. REMOVE ALL BURRS AND SHARP EDGES 18 DESIGNED .X ± T.PREM 0.75 DRAWN .XX ± -- .XXX ± -- WHOLE NUMBERS ± 1.5 ANGLES ± 1.0 HOLE SIZES ± -- HOLE CENTERS ± -- 19 DATE 08/09/12 DATE K.WONG 08/09/12 CHECKED DATE APPROVED DATE T.PREM W.HUMPHRIES Q.A. APPROVED -- 20 08/09/12 08/09/12 DATE -- W. R. DAVIS ENGINEERING LTD. OTTAWA CANADA Davis TITLE CONT. NO . A726 21 R COWLING MODIFICATION KIT CONTRACT NAME CAGE CODE USED ON DRAWING NO. 3AB25 A02-00-000 CBT 22 23 REV. A02-E0-900 A A0 SHT 1 OF 1 24