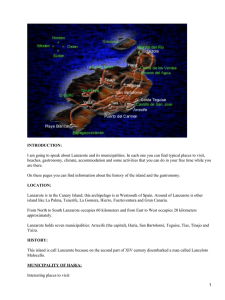

Geotextiles and Geomembranes 27 (2009) 162–166 Contents lists available at ScienceDirect Geotextiles and Geomembranes journal homepage: www.elsevier.com/locate/geotexmem Technical Note Effect of fiber reinforcement and distribution on unconfined compressive strength of fiber-reinforced cemented sand Sung-Sik Park* Division of Civil, Environmental and Urban Engineering, Wonkwang University, 344-2 Sinyongdong, Iksan, Jeonbuk 570-749, Republic of Korea a r t i c l e i n f o a b s t r a c t Article history: Received 31 March 2008 Received in revised form 8 September 2008 Accepted 9 September 2008 Available online 8 November 2008 A series of unconfined compression tests were carried out to examine the effect of fiber reinforcement and distribution on the strength of fiber-reinforced cemented sand (FRCS). Nakdong River sand, polyvinyl alcohol (PVA) fiber, cement and water were mixed and compacted into a cylindrical sample with five equal layers. PVA fibers were randomly distributed at a predetermined layer among the five compacted layers. The strength of the FRCS increases as the number of fiber inclusion layers increases. A fiberreinforced specimen, where fibers were evenly distributed throughout the five layers, was twice as strong as a non-fiber-reinforced specimen. Using the same amount of fibers to reinforce two different specimens, a specimen with five fiber inclusion layers was 1.5 times stronger than a specimen with one fiber inclusion layer at the middle of the specimen. The fiber reinforcement and distribution throughout the entire specimen resulted in a significant increase in the strength of the FRCS. Ó 2008 Elsevier Ltd. All rights reserved. Keywords: Fiber-reinforced sand Cemented sand Fiber distribution Unconfined compressive strength 1. Introduction Clay or granular soils are mixed with cement or gypsum to improve engineering properties such as cohesion and friction angle (Abdulla and Kiousis, 1997; Clough et al., 1981; Ismail et al., 2002; Kim et al., 2008; Liu et al., 2006; Saxena and Lastrico, 1978). Cemented soils can be used for the reinforcement of soft ground, the backfill materials of retaining walls, and for the sub-base of roads and railroads because cemented soils are less compressible and have an increased strength over that of natural soils. While such cemented soils can significantly increase compressive strength with an increasing cement ratio, this causes a brittle or sudden failure without plastic deformation to occur. Cemented sand that shows a brittle failure pattern can be reinforced with fiber to prevent such brittle failure. Several researchers (Consoli et al., 1998; Consoli et al., 2003; Kaniraj and Havanagi, 2001; Maher and Ho, 1993; Tang et al., 2007) have attempted to study the combined effect of fiber and cement on granular or clayey soils. Such fiberreinforced cemented specimens were prepared for laboratory testing by manually mixing sand, cement and fibers with water. For most of the experimental research that has been carried out on fiber-reinforced soils (Babu et al., 2008; Chauhan et al., 2008; Kaniraj and Gayathri, 2003), the fibers were considered to be uniformly distributed throughout a small specimen. However, in practice the fibers may be poorly distributed or may flow into one * Tel.: þ82 63 850 6716; fax: þ82 63 850 7140. E-mail address: [email protected] 0266-1144/$ – see front matter Ó 2008 Elsevier Ltd. All rights reserved. doi:10.1016/j.geotexmem.2008.09.001 place when fiber-reinforced samples are prepared in the laboratory. While applying such fiber-reinforced materials in the field, the fiber concentration or difficulties with fiber mixing could be significant and the anticipated strength increase of fiber-reinforced materials may not be achieved. The objective of this study is to examine the effect of fiber distribution and concentration on the strength of fiber-reinforced cemented sand. A series of unconfined compression tests were performed on artificially cemented samples with layered fiber reinforcement. The unconfined compressive strength (UCS) of the samples was evaluated to quantify the uncertainties associated with fiber distribution or concentration in the strength of fiberreinforced soils. The strength of fiber-reinforced soils could be factored to consider the uncertainty induced by non-uniform fiber distribution, which can be applied to a reliable design (e.g., limit state design) of soil reinforcement. 2. Unconfined compression tests 2.1. Sand and cement Clean Nakdong River sand is used in this study and its gradation curve is shown in Fig. 1. As described in Table 1, an X-ray Fluorescence (XRF) analysis of Nakdong River sand shows that it consists of silica sand with more than 76% silica. A microphotograph of Nakdong River sand is shown in Fig. 2. The sand was sieved to a size ranging between 2 mm and 0.075 mm diameter and washed with a No. 200 sieve (0.075 mm in diameter) to remove fines. It was then oven-dried for testing. Ordinary Portland cement was used as S.-S. Park / Geotextiles and Geomembranes 27 (2009) 162–166 163 100 90 Percent finer (%) 80 70 60 50 40 30 20 10 0 10 1 0.1 0.01 Grain size (mm) Fig. 1. Grain size distribution of Nakdong River sand. a cementing agent for the preparation of artificially cemented samples. Fig. 2. Microphotograph of Nakdong River sand. 2.2. Fiber Polypropylene fiber is the most widely used inclusion in the laboratory testing of soil reinforcement (e.g., Khattak and Alrashidi, 2006; Santoni et al., 2001; Tang et al., 2007; Viswanadham et al., 2009; Yetimoglu and Salbas, 2003; Yetimoglu et al., 2005). This fiber is lighter than water, and weak in alkalis. Polyvinyl alcohol (PVA) fiber is a synthetic fiber that has recently been used in fiber-reinforced concrete, since its weather resistance, chemical resistance, and tensile strength are superior to that of polypropylene fiber. PVA fiber has a significantly lower shrinkage from heat than nylon or polyester. It has a specific gravity of 1.3, a good adhesive property to cement, and high anti-alkali characteristics. For this reason, it is suitable for mixing with cement and is widely used in concrete and cement reinforcement. The type of PVA fiber used in this study is RECS100L (produced by Kuraray in Japan) with a tensile strength of 1078 N/mm2. The PVA fiber shown in Fig. 3 is 12 mm in length and 0.1 mm in diameter, and is thicker than PVA fiber normally used for reinforced cement. three fiber-reinforced specimens (Case 1, Case 2, and Case 3) were prepared for testing, as illustrated in Fig. 4. The number of fiber inclusion layers for each specimen varied: zero (no fiber), one (middle layer only), three (middle, top and bottom layers), and five (all layers). Depending on the number of fiber inclusion layers, the degree of fiber reinforcement or distribution was determined as 0%, 20%, 60%, and 100%. One of the difficulties in preparing fiber-reinforced specimens is the method used to mix fibers into a non-plastic soil such as sand (Freitag, 1986). Cemented sand was prepared by mixing dry sand and cement with an optimum water content of 14%. The cemented sand was then divided into five portions and each portion was mixed by hand with a predetermined amount of fiber. Therefore, 2.3. Sample preparation The cement ratio is based on dry sand and defined as follows: rc ¼ Wc 100ð%Þ Ws (1) where Wc is the weight of cement and Ws is the weight of dry sand. The cement ratio used in this study is 4%. The fiber ratio is based on the amount of fiber used in each fiber inclusion layer. It is defined as follows: rf ¼ Wf 100ð%Þ Ws (2) where Wf is the weight of fiber used in each fiber inclusion layer, not in the entire specimen. One non-fiber-reinforced specimen and Table 1 X-ray Fluorescence analysis of Nakdong River sand. Classification Content (%) SiO2 76.62 Al2O 12.37 CaO 1.65 K2O 4.19 Na2O 2.88 Fe2O3 1.98 MgO – P2O5 – TiO2 0.28 Fig. 3. PVA fiber RECS100L (diameter 0.1 mm). 164 S.-S. Park / Geotextiles and Geomembranes 27 (2009) 162–166 a b c 1000 140 mm Layer 4 Cemented sand Layer 3 Fiber-reinforced cemented sand Layer 2 Layer 1 70 mm Case 1 Case 2 Case 3 Fig. 4. Fiber-reinforced specimen. a uniform distribution of fibers throughout the specimen was achieved for laboratory testing. However, the hand mixing method will not be applicable to large-scale work in the field. After mixing, each portion was compacted directly into a small-sized mold by applying 55 blows per layer via a metal rammer that has a 65 mm diameter circular face with a weight of 22 N. The metal mold was separated and then the specimen was cured for 7 days. Each specimen was 70 mm in diameter and 140 mm in height. Unconfined compression tests were carried out at a shearing rate of 1%/ min (1.4 mm/min). 3. Results of unconfined compression tests Two series of unconfined compression tests were carried out to investigate the strength of fiber-reinforced cemented sand (FRCS). Each series consisted of three fiber-reinforced cases (Case 1, Case 2, and Case 3), as shown in Table 2. The aim of the first series, the L series, was to evaluate the effect of fiber reinforcement on an UCS. In the L series, the fiber ratio of rf is constant at 0.2%. Fig. 5 shows the results of the L series where the number of fiber inclusion layers varied when using the same amount of fibers. As the degree of fiber reinforcement increases, the UCS significantly increases, as summarized in Table 3. The 100% (fully reinforced) fiber-reinforced specimen was twice as strong as the 0% fiber-reinforced specimen, as shown in Fig. 6 and Table 3. The aim of the second series, the T series, was to evaluate the effect of fiber distribution on an UCS. The effect of fiber distribution or concentration on the UCS was accessed by increasing the fiber inclusion layer and by using the same amount of fibers in the entire specimen. In the T series, the rf of Case 1, Case 2, and Case 3 is 1%, 0.33%, and 0.2%, respectively. However, the total amount of fibers used in the entire specimen is 1% of the weight of dry sand and constant in all cases. L-3 and T-3 are essentially the same conditions and their results show repeatability of test results. Fig. 7 shows the results of the T series. As the degree of fiber distribution increases, Table 2 Summary of unconfined compression tests. Specimen Reinforced layer Fiber ratio, rf Strength (kPa) Secant elastic modulus (MPa) No fiber No fiber No fiber 440 37 L series L-1 L-2 L-3 Layer 3 Layer 1, 3, 5 All layers 0.2% 0.2% 0.2% 530 696 857 47 35 41 T series T-1 T-2 T-3 Layer 3 Layer 1, 3, 5 All layers 1% 0.33% 0.2% 609 741 894 31 35 40 Unconfined compressive stress (kPa) Layer 5 800 600 400 No fiber 200 L-1 L-2 L-3 0 0 1 2 3 4 5 Axial strain (%) Fig. 5. Results of L series. the UCS significantly increases, as summarized in Table 4. The 100% (fully distributed) fiber-distributed specimen was 1.5 times stronger than the 20% fiber-distributed specimen, as shown in Fig. 8 and Table 4. The same cases in each series (L-1 and T-1, L-2 and T-2, L-3 and T-3) have the same degree of fiber reinforcement and distribution of 20%, 60%, and 100%. With the exception of Case 3, the rf of the T series is greater than that of the L series. By making a comparison between the same cases in each series, it was confirmed that, for the effect of the amount of fiber on the UCS, its strength increased with an increase in fiber content (Ang and Loehr, 2003; Kaniraj and Havanagi, 2001; Santoni et al., 2001; Tang et al., 2007). The secant elastic modulus of each specimen was calculated from one half of the axial strain at peak strength. As shown in Table 2, the comparison shows that it does not seem to be influenced by the fiber reinforcement and distribution. Park et al. (2008) conducted unconfined compression tests on fully reinforced or distributed (Case 3 in this study) cemented specimens using four different cement ratios. Test results demonstrated that a secant elastic modulus depended on a cement ratio. Fig. 9 shows photographs of the non-fiber-reinforced specimen and other specimens in the L series after failure. In the non-fiber-reinforced specimen, a vertical crack throughout the entire specimen appeared after failure, as shown in Fig. 9(a). In the fiber-reinforced specimens, cracks began to appear in the non-fiber inclusion layer and spread to the fiber inclusion layers, as shown in Fig. 9(b)–(d). The top plate slightly penetrated into the specimen at the end of the tests. This may not have significantly influenced the UCS of the specimen because it occurred after peak stress. Such penetration of the plate may be Table 3 Results of L series. Specimen Degree of fiber reinforcement (%) Strength (kPa) Ratio of strength increase (%) No Fiber L-1 L-2 L-3 0 20 60 100 440 530 696 857 100 120 158 195 200 200 180 180 Strength Increase (%) Strength Increase (%) S.-S. Park / Geotextiles and Geomembranes 27 (2009) 162–166 160 140 120 100 160 140 120 0 20 40 60 80 100 100 0 20 40 60 Degree of Fiber Reinforcement (%) Degree of Fiber Distribution (%) Fig. 6. Effect of fiber reinforcement in L series. Fig. 8. Effect of fiber distribution in T series. 1000 Unconfined compressive stress (kPa) 165 80 100 concentrated fibers. From a practical point of view, a fiber mixing method, which can control the uniformity of fiber distribution throughout the specimen, is very important especially when applying fiber-reinforced soils in the field. 800 600 400 No fiber 200 T-1 T-2 T-3 0 0 1 2 3 4 5 Axial strain (%) Fig. 7. Results of T series. related to the ductile behavior of fiber-reinforced soils. It could be partially attributed to the non-confinement of a specimen in an unconfined compression test. The effect of confinement due to rough plates may be insignificant especially in unconfined compression tests because there is no confinement in the horizontal direction. In summary, the strength of the FRCS depends on the degree of fiber reinforcement and distribution. The UCS of cemented sands reinforced with evenly distributed fibers can be up to 1.5 times greater than those reinforced with poorly distributed or Table 4 Results of T series. Specimen Degree of fiber distribution (%) Strength (kPa) Ratio of strength increase (%) T-1 T-2 T-3 20 60 100 609 741 894 100 122 147 Fig. 9. Specimens after failure: (a) non-fiber-reinforced specimen; (b) L-1 specimen; (c) L-2 specimen; (d) L-3 specimen. 166 S.-S. Park / Geotextiles and Geomembranes 27 (2009) 162–166 4. Conclusions The effect of fiber reinforcement and distribution on the strength of the FRCS was investigated in terms of an UCS. PVA fibers were randomly reinforced at a predetermined layer among five compacted layers. The UCS of fiber-reinforced cemented specimens gradually increases as the number of fiber inclusion layers increases. The specimen where fibers were evenly distributed at five layers was twice as strong as the non-fiber-reinforced specimen. When the same amount of fibers was reinforced in the entire specimen, the specimen with five fiber inclusion layers was 1.5 times stronger than the specimen with one layer at the middle. The strength ratio of 1.5 is a factor that can consider the strength reduction of the FRCS induced by non-uniform fiber distribution. The strength of fiber-reinforced cemented soils depends not only on the degree of fiber reinforcement and distribution but also on the amount of fiber used in the specimen. These results can be used to quantify the uncertainties associated with fiber distribution or concentration in the strength of fiber-reinforced soils. Using fiber-reinforced soils does not necessarily guarantee an anticipated strength increase or a safe design unless the uncertainties associated with the fiber distribution or concentration are adequately considered. Acknowledgement This paper was supported by Wonkwang University in 2008. References Abdulla, A.A., Kiousis, P.D., 1997. Behavior of cemented sands – I. Testing. International Journal for Numerical and Analytical Methods in Geomechanics 21 (8), 533–547. Ang, E.C., Loehr, J.E., 2003. Specimen size effects for fiber-reinforced silty clay in unconfined compression. Geotechnical Testing Journal 26 (2), 1–10. Babu, G.L.S., Vasudevan, A.K., Haldar, S., 2008. Numerical simulation of fiber-reinforced sand behavior. Geotextiles and Geomembranes 26 (2), 181–188. Chauhan, M.S., Mittal, S., Mohanty, B., 2008. Performance evaluation of silty sand subgrade reinforced with fly ash and fibre. Geotextiles and Geomembranes 26 (5), 429–435. Clough, G.W., Sitar, N., Bachus, R.C., Rad, N.S., 1981. Cemented sands under static loading. Journal of the Geotechnical Engineering Division 107 (GT6), 799–817. Consoli, N.C., Prietto, P.D.M., Ulbrich, L.A., 1998. Influence of fiber and cement addition on behavior of sandy soil. Journal of Geotechnical and Geoenvironmental Engineering 124 (12), 1211–1214. Consoli, N.C., Vendruscolo, M.A., Prietto, P.D.M., 2003. Behavior of plate load tests on soil layers improved with cement and fiber. Journal of Geotechnical and Geoenvironmental Engineering 129 (1), 96–101. Freitag, D.R., 1986. Soil randomly reinforced with fibers. Journal of Geotechnical Engineering 112 (8), 823–826. Ismail, M.A., Joer, H.A., Sim, W.H., Randolph, M.F., 2002. Effect of cement type on shear behavior of cemented calcareous soil. Journal of Geotechnical and Geoenvironmental Engineering 128 (6), 520–529. Kaniraj, S.R., Gayathri, V., 2003. Geotechnical behavior of fly ash mixed with randomly oriented fiber inclusions. Geotextiles and Geomembranes 21 (3), 123–149. Kaniraj, S.R., Havanagi, V.G., 2001. Behavior of cement-stabilized fiber-reinforced fly ash–soil mixtures. Journal of Geotechnical and Geoenvironmental Engineering 127 (7), 574–584. Kim, Y.T., Kim, H.J., Lee, G.H., 2008. Mechanical behavior of lightweight soil reinforced with waste fishing net. Geotextiles and Geomembranes 26 (6), 512–518. Khattak, M.J., Alrashidi, M., 2006. Durability and mechanistic characteristics of fiber reinforced soil–cement mixtures. International Journal of Pavement Engineering 7 (1), 53–62. Liu, H., Deng, A., Chu, J., 2006. Effect of different mixing ratios of polystyrene prepuff beads and cement on the mechanical behaviour of lightweight fill. Geotextiles and Geomembranes 24 (6), 331–338. Maher, M.H., Ho, Y.C., 1993. Behavior of fiber-reinforced cemented sand under static and cyclic loads. Geotechnical Testing Journal 16 (3), 330–338. Park, S.-S., Kim, Y.-S., Choi, S.-G., Shin, S.-E., 2008. Unconfined compressive strength of cemented sand reinforced with short fibers. Journal of the Korean Society of Civil Engineers 28 (4C), 213–220. Santoni, R.L., Tingle, J.S., Webster, S.L., 2001. Engineering properties of sand–fiber mixtures for road construction. Journal of Geotechnical and Geoenvironmental Engineering 127 (3), 258–268. Saxena, S.K., Lastrico, R.M., 1978. Static properties of lightly cemented sand. Journal of the Geotechnical Engineering Division 104 (GT12), 1449–1464. Tang, C., Shi, B., Gao, W., Chen, F., Cai, Y., 2007. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotextiles and Geomembranes 25 (3), 194–202. Viswanadham, B.V.S., Phanikumar, B.R., Mukherjee, R.V., 2009. Swelling behaviour of a geofiber-reinforced expansive soil. Geotextiles and Geomembranes 27 (1), 73–76. Yetimoglu, T., Salbas, O., 2003. A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotextiles and Geomembranes 21 (2), 103–110. Yetimoglu, T., Inanir, M., Inanir, O.E., 2005. A study on bearing capacity of randomly distributed fiber-reinforced sand fills overlying soft clay. Geotextiles and Geomembranes 23 (2), 174–183.