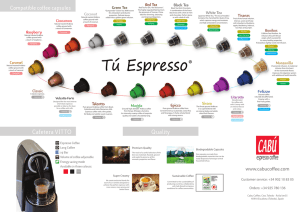

The present project shows an evaluation of the technical, legal, financial, and environmental aspects of a prefeasibility study of an automated green coffee bean processing plant for the production of roasted coffee, either ground or in beans. The roasting process is what produces the characteristic flavor of coffee by causing the green coffee beans to change in taste. Unroasted beans contain similar if not higher levels of acids, protein, sugars, and caffeine as those that have been roasted, but lack the taste of roasted coffee beans due to the chemical reactions that occur during roasting. The information presented in this study was compiled from different sources depending on both public and private entities, which allowed a market study, where the product to be processed was defined, its supply and demand, product marketing channels and purchase prices. Domestic coffee market in Argentina has varied over time and consumers are always in search of innovative and environmentally friendly products. This is why we not only look for quality raw materials, but also implement cutting edge technology to meet the needs of this growing market. Regarding the supplier market, it was determined that the raw material we needed to meet market expectations had to be imported from Brazil to ensure year-round availability. For the competing market, a register of all coffee processing companies and a field analysis were carried out to determine the best location for our project. The automated process is divided into several sectors, all connected by mechanical transport and conveyor belts. It begins with the roasting of the grains, which are then ground and packaged for shipment. The selected technology allows to have and annual production of 1.029.420 kg of roasted coffee beans, working in eight-hour shifts, with a production line adapted to achieve the best possible performance with the acquired technology.