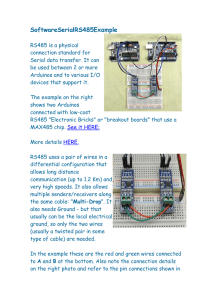

Index INTRODUCTION - The STEM disciplines and the Be Maker Basic Course Plan. Warnings Copyright Notes Preparing our Electronics and Robotics Lab. Installation of software on the PC Configuring the Arduino IDE Well begun is half done What is Arduino What is the Arduino IDE What is a Library and how to add it to the IDE LESSON 1 - Current, Voltage and Electrical Resistance. Ohm's law. What is an LED. Project 1 - Turning on an LED The Button: how it works and how to use it Project 2 - The use of a push button to turn on an LED. Curiosity: A bit of scientific history What is a Breadboard. Project 3 - Hello World Arduino's digital PINs Project 4 - Police cars with flashing lights LESSON 2 - Insights into Electrical Resistance How to read the value of a resistor Resistors with 4 colored circles Resistors with 5 colored circles Trivia: What is a Physical Magnitude and Uncertainty in Measurements Project 5 - The Traffic Light with Arduino Introduction to Coding The sketch Project 6 - The Stelliere Analysis of the sketch: The Stelliere Arduino Analog PINs Project 7 - Ohmeter. Using Arduino to measure a resistance Sketch Analysis: Ohmeter with Arduino LESSON 3 - Robotics with Arduino The photoresistor or also called Light Sensor Project 8 - Crepuscular Switch with Photoresistor Sketch Analysis: Twilight Switch with Photoresistor Curiosity: What is Light Project 9 - Luxmeter with Arduino Sketch Analysis: Luxmeter with Arduino The PWM signal - Pulse Width Modulation Relationship between Analog PINs and PWM Digital PINs Project 10 - Night and Day with PWM Signal Analysis of the Sketch: Night and Day with PWM signal Project 11 - The Return of the Cylons Analysis of the Sketch: Return of the Cylons LESSON 4 - THE RGB LEDS Project 12 - RGB LEDs with Arduino CURIOSITY: Stars shine and change color. Project 13 - Starlight Analysis of the sketch: Starlight Project 14 - Starlight 2 The Tilt Sensor or also called the Ball Tilt Sensor. Project 15 - Making an Electronic Hourglass. Analysis of the Sketch: The Electronic Hourglass LESSON 5 - THE SOUND CURIOSITY: What is sound? Project 16 - The Teresa wasp and the active buzzer. The Passive Buzzer Project 17 - The passive buzzer and the Piano-Man. Analysis of the Project 17 sketch - The passive buzzer and the Piano-Man. CURIOSITY: The Microphone and the Loudspeaker or Acoustic Speaker. Project 18 - What happens in that house? Let's use the microphone. LESSON 6 - THE ULTRASOUNDS Curiosity: what is Speed? HC-SR04 Ultrasonic Module. Obstacle Distance Detection Project 19 - Detect the distance to an obstacle. Analysis of Sketch: Project 19 - Obstacle Detection with Ultrasonic Module. CURIOSITY: What are Degrees of Freedom (DOF) and Electric Drives. The Servo Motor - Giving movement to things. Project 20 - Controlling a Servo Motor SG-90 Analysis of the Sketch: Project 20 - Controlling a Servo Motor. Project 21 - Radar System Ultrasound Project 22 - Ultrasonic Radar System with Processing LESSON 7 - Active and Passive Components and Elements in Series and in Parallel. The Active and Passive Components. Series and Parallel Connection of Components. The Series and Parallel Connection of Resistors. The Voltage Divider and the Potentiometer The Voltage divider The Potentiometer (for electronic applications it is called a Trimmer). Project 23 - The Use and Connection of the Potentiometer Fun facts: what is Temperature and what is Humidity LM35 Temperature Sensor Project 24-Detect the temperature of a body. Project 25 - Light thermometer. Analysis of the Sketch: Project 25 - Luminous Thermometer. The DHT11 Environmental Temperature and Humidity Sensing Sensor. What is a Library and how to add it to the IDE Project 26 - Ambient Temperature and Humidity. Sketch Analysis: Project 26-Environmental Temperature and Humidity. LESSON 8 - Magnetism and the Magnetic Field. Curiosity: The Hall Principle Project 27 - Magnetic Field Presence Detection - KY003 Analysis of Sketch: Project 27 - Use of LED on board Arduino. Project 28 - Analog Detection of a Magnetic Field - KY035 Curiosity: The Metal Detector Project 29 - Magnetic Detector with the Linear Magnetic Hall Sensor KY024. Analysis of the Sketch: Project 29 - Magnetic Detector. LESSON 9 - The Display for Arduino 7-segment LED display. Project 30 - Let's Make a Countdown. Analysis of the sketch: Project 30: Let's make a Countdown. 4-digit 7-segment LED display. Project 31 - Seconds counter. Project 32 - Counter of seconds and tenths of a second. Analysis of the sketch: Project 32 - Chronometer with use of the Library. Project 33 - Potentiometer Value Display with 4 Digit Display Project 34 - Insight for the millis() function. LED Matrix Display Project 35 - HELLO WORLD IN MATRIX ! Analysis of the Sketch: Hello World in the Matrix The LCD Display Curiosity: how the LCD display works Project 36 - HELLO WORLD WITH LCD DISPLAY. Sketch Analysis: Hello World with LCD Display LESSON 10 - Insight into Light: the Infrared Infrared Sensor Module KY-032 Comparison of HCSR04 Ultrasonic Module and KY032 Infrared Module. Project 37 - The use of KY032 Module with the EN PIN disabled Analysis of the Sketch: Project 37 - Form KY032. Project 38 - The use of KY032 Module with the EN PIN enabled KY-033 Infrared Sensor Module - Line Tracking Project 39 - The Use of KY033 Line Tracking Module. Sketch Analysis: Project 39 - KY033 Line Tracking Module. The Infrared Remote Control - IR Remote Controller Project 40 - Decoding the IR signal of a remote control Sketch Analysis: Project 40 - Decoding the IR signal of a remote control. Project 41 - Piloting Events with IR Remote Control Analysis of Sketch: Project 41 - Piloting events with IR Remote Control. INTRODUCTION - The STEM disciplines and the Be Maker Basic Course Plan. The Be Maker Course that I wanted to create fits perfectly into that new area of teaching that has been spreading lately, especially internationally, and in Italy we are just at the beginning. More and more resources are being invested in this, which has now even become a path of study that starts from elementary school up to the point where students reach graduation. This new area, which encompasses multiple disciplines, is called STEM and is also the origin of the Logo I wanted to give to the New Course. STEM is an acronym and stands for Science, Technology, Engineering and Mathematics. This acronym, of course, should be read in the broadest sense of its meaning, in fact, although the basic subjects are scientific, in this multidisciplinary area Art also quietly finds its place so much so that, again internationally, the new acronym STEAM has spread. Consequently, with the introduction of Art, all those associated humanities disciplines are also involved (History, Literature, Philosophy, etc...). The Be Maker Course represents, trying my best, the perfect synthesis of the new model of study, where all STEM disciplines are involved and called upon in a homogeneous and coordinated way. Obviously this is a first piece... The Course has been divided into Modules, the first Module which is the one we are about to begin, is the Basic Course. With this Course the foundations are created to deal with the subsequent Courses that will have more specialized features. The Basic Course Study Plan is rich and varied and is based on four main science topics: ELECTRICITY, LIGHT, SOUND and MAGNETISM. All projects, which are also created for fun purposes (in fact, if there is no fun there is no interest either), are nothing more than educational applications of the theoretical parts covered. The minimum suggested age is 12, but it depends a lot on the student's desire to learn new things. As for the maximum age, there is no limit...in fact, the Course creates the foundation of knowledge of the use of the development platform.... what will then limit the implementation of the projects, will only be the imagination and the desire to engage in learning new things...so there is no upper age limit for the students of the Course. Warnings Regarding safety aspects, since the projects are based on very low voltage power supply delivered from the pc's usb port or from supporting batteries or power supplies with maximum 9V output, there are no particular electrical risks. However, it should be pointed out that any short-circuits caused during the exercise could produce damage to the pc, furniture and in extreme cases even burns, for this reason whenever a circuit is assembled, or modifications are made on it, it will be necessary to do so in the absence of power supply and at the end of the exercise it will be necessary to disconnect the circuit by removing both the usb cable connecting to the pc and any batteries from the appropriate compartments or external power connectors. In addition, again for safety reasons, it is strongly recommended to carry out the projects on insulating and heat-resistant mats that can be purchased in any electronics store or even on specialized websites. At the end of the drills, hands should be washed, as electronic components may have processing residues that could cause harm if ingested or if in contact with eyes, mouth, skin, etc. Although the individual projects have been tested and safe, those who decide to follow what is stated in this document assume full responsibility for what might happen in the execution of the drills provided in it. For younger and/or first-time students in the field of Electronics, it is recommended that the exercises be performed with the help and in the presence of an adult. Copyright Notes All trademarks shown belong to their rightful owners; third party trademarks, product names, trade names, corporate names and company names mentioned may be trademarks of their respective owners or registered trademarks of other companies and have been used for explanatory purposes only and for the benefit of the owner, without any purpose of infringement of the Copyright rights in force. What is reported in this document is the property of Roberto Francavilla, Italian and European copyright laws are applicable to it - any texts taken from other sources are also protected by Copyright and owned by their respective Owners. All information and content (text, graphics and images, etc.) reported are, to the best of my knowledge, in the public domain. If, unintentionally, copyrighted or infringing material has been posted please notify me by email at [email protected] and I will promptly remove it. THE BOOK WAS TRANSLATED FROM ITALIAN INTO YOUR LANGUAGE BY ARTIFICIAL ITELLIGENCE. THE TRANSLATION IN SOME PLACES MAY NOT BE ACCURATE ESPECIALLY IN THE SOFTWARE CODE PARTS. FOR THIS REASON AFTER EACH TUTORIAL THERE IS A LINK FROM WHICH TO DOWNLOAD THE CORRECT SOFTWARE CODE. IN ADDITION THE BOOK IS SOLD AT AN EXTREMELY LOW PRICE AND IN THE OFFERS IT IS EVEN FREE. I HOPE YOU APPRECIATE THIS GESTURE OF MINE IN CHOOSING MY BOOK ANYWAY, BECAUSE I AM SURE YOU WILL FIND IT, IN SPITE OF EVERYTHING, VERY INTERESTING. FOR ANY INFORMATION: [email protected] Roberto Francavilla Preparing our Electronics and Robotics Lab. As the first activity of the Course, we need to prepare our Laboratory, and to do this we need to take all the materials from our Starter Kit out of the packaging. We check that all the materials that will be used in the various projects are present: We also need a PC (desktop or notebook is indifferent, but I suggest with Windows 10 installation): You also need to have a set of screwdrivers with magnetic Phillips and flat heads (preferably different sizes): and for the more daring a Digital Tester: Installation of software on the PC The entire Basic Course is based on the use of the Arduino UNO R3 development board, Arduino is actually a true open source platform, but it is also possible to use the many compatible versions of development boards made by the various manufacturers using the same platform. We now turn to the software installations on our PC. There are two pieces of software to be installed: - The chipset driver of the USB communication port of the development board. The "sketch" development environment called IDE As for the driver, if it is not installed you will notice it right away because when you first load the sketch (the program you need to run Arduino), it will give you an error. Normally the most popular development boards, even the compatible ones, make the drivers available on the Internet, so just do a search and download the driver and then run the executable. Since I cannot predict which boards you will buy, I will tell you that for the original board the driver is already included in the development environment, so no special configuration is needed, while for the compatible boards, the most common one (also because it is very cheap) is the one that has the chipset in SMD format, and normally in this case the driver to be installed is called CH341SER.zipper It can be downloaded from the Internet, unpacked, and then by running the executable, the driver will be installed. We mentioned that our development board is based on the open source Arduino platform, so we can use all the tools that the platform provides. Let's go to the Arduino website by typing the following address into our browser or clicking on the following link: https://www.arduino.cc The initial window appears, we click on "SOFTWARE" : then a page will be displayed where you can download the latest version of the IDE. Depending on which operating system you are using, on your right side you need to choose the relevant DOWNLOAD link [I suggest installing version 1.8.19, you can find it by scrolling down the page at the bottom]: As you can see from the picture on the web page above, there are the different versions of the IDE for: Windows, Mac, Linux,. What is shown below is the procedure for Windows; for other systems, the procedure is almost identical. Two ways of installing the IDE are possible, the automatic way by clicking on "Windows Win 7 and never" and the manual way, where you first need to download the ZIP package and then, once unpacked, you double-click on the executable. By clicking either option, the donation window appears in both cases: and in this regard, I strongly suggest, given the immense amount of work that the Arduino guys do, to carry it out, even a small amount. In case you decide not to make the donation, you can proceed with "JUST DOWNLOAD." Once you have launched the installer (by double-clicking on the .EXE executable file), following the prompts on the screen via dialog boxes, you will proceed to complete installation of both the IDE development environment and the driver for the Arduino development board. The windows that will appear to you will be: If the following dialog box appears, you should choose "Install." When the installation process is complete, an icon will appear on our Desktop: We now connect the Development Board to the PC using the USB cable that came with the board. If all went well, the PC, after a few seconds (necessary for driver installation), should be able to recognize the newly connected peripheral. It is possible to verify the correctness of the installation process by going to the START windows window located at the bottom left of the desktop: Click on Device Management: Look under Ports (COM and LPT) or other devices. A yellow exclamation mark indicates that the driver installation failed. In such a case, manual driver installation is required. Configuring the Arduino IDE After installing the driver correctly, it is time to configure the IDE, this is because the IDE can be used for different devices, we, on the other hand, want to use it for our Arduino or compatible Development Board. For either the original or compatible Arduino Development Board, you need to go to Tools ---> Board ----> and select Arduino Uno (as shown below). We then go on to select the correct COM port. Once the Development Board is connected, go to Windows START and right-click on it, then left-click on Device Manager Clicking on Ports (COM & LPT) shows which COM port the device is connected to. At this point we return to the Arduino IDE, go to Tools -- → COM Ports and select the port to which our device is connected. So we have finished the most boring part, don't worry from now on there will be lots of new things to learn and have fun. Well begun is half done Our ambitious goal is to become Makers ! That is, implementers of our electronic and robotic projects, and I am sure we will succeed. The following lessons, based on practical projects, are set up in such a way that theoretical topics are explained several times, even on different practical projects. In this way, even if a topic might at first be unclear or particularly difficult to understand, don't worry.... GO AHEAD!!! In fact you will surely find the same topic in another application, perhaps easier to learn.... And so you will find yourself saying.... ahh!...so that's how it works...that thing I didn't understand at project # ....... Also I want to remind you that through the email you will have the opportunity to get in touch with me, indeed I would be happy to, so don't delay when you need clarification, or even give me suggestions (which will always be welcome) and also to elaborate on some topic that needs clearer explanations.... Finally, since I do not want to bore you with all these premises, the last message is about the methodology of explaining the lectures; it is my intention to avoid using technical terms except those that are strictly necessary and to try to explain their meaning. Even for the theoretical parts, I will try to avoid going into details of physics and chemistry and will keep a suitable and congruous level of explanation with school bases for children 12 years old and up. At this point we begin to learn about the tools we will use in our Maker training. What is Arduino Arduino is a kind of small PC, it has a processor (a microcontroller to be exact), memory (like the RAM and Hard Disk of a PC), a motherboard, and connectors for signal inputs and outputs that go to external peripherals which can be sensors, actuator modules such as electric motors, etc. There are different types of boards, depending on certain features, for example, there are boards that already have WiFi module built in, those that have GPS, etc.. among the most popular is the Arduino UNO R.3, a basic development board that can be integrated with any type of module. Because the Arduino project is open source, many other manufacturers have made their own UNO R.3 board: Some manufacturers, seeing the potential of this board, have also developed it further by adding features and making it even easier to use. So many projects can be made with this Maker Development Board, the only limit is our imagination. Using the supplied USB cable, it is possible to connect the Development Board to the USB port of the PC from which the board itself draws the power necessary for its operation and interfaces with the PC to be programmed. What is the Arduino IDE First, let's start with the name: IDE which is an acronym and stands for Integrated Development Environment i .e., a set of applications that aggregates common development tools into a single graphical user interface. The IDE is an environment consisting essentially of: Editor: a text editor that facilitates the writing of software code that is called a sketch. The programming language used is based on C++. Monitor and Serial Plotter: where numeric variables can be represented, or textual, but also graphically and is also useful for debugger (searching for errors in sketches) Libraries: are a collection of functions and instructions that simplify the use of certain devices (sensors, modules, etc.) Clicking on the Arduino icon opens the window below: What are the indicated icons? A- It is used to verify written sketches by precompiling it and detects any errors. B- Load the sketch onto our Arduino board or Board. C- It is a shortcut to create a new editor window for a new sketch. D- It is used to directly open an example sketch. E- It is used to save the sketch. F- Used to send data from the board to the serial monitor. IMPORTANT: ALL PROJECTS SHOWN CAN BE REPRODUCED WITH ANY ARDUINO UNO R.3 COMPATIBLE BOARD, INCLUDING THE ORIGINAL OF COURSE !!! What is a Library and how to add it to the IDE The Internet, as you well know.... even better than I!, is a vast world where one can find anything. Even for the Arduino world.... surely there has been someone, in the vast global world, who has already solved technical problems and made his knowledge available for humble mortals so that they could improve (or even enhance what had been created!) by making complicated things become simple to understand and apply. Knowledge creators in the field of electronics and robotics, are called... MAKERS! (pronounced: meikers) and I hope that one day you will also become one with my little help! Well! The concept of a "Library" is basically this.... It is a repository in which you find instructions that simplify and make it easier to use things that would otherwise require complex operations that are difficult to apply. Let's take a practical example: the DHT11 sensor. The DHT11 sensor is a device that, thanks to the amount of water in the air or the ambient temperature, measures changes in the electrical resistance of certain elements. Basically, the DHT11 sensor is as if it were itself a mini Arduino to which elements are connected whose resistance varies according to the more or less presence of water in the environment and its temperature. This means that the sensor, already by itself, has a mini computer (you can see it in the picture above) that would already require software for its operation that would have to be written before the actual software that we would have to develop for its use. Then the creator of this sensor has given us a gift!, he has already developed all the software necessary for the internal workings of the sensor and has created a LIBRARY , that is, a set of simple instructions made available to us so that the DHT11 sensor is already properly programmed to return to us the values we need. There are several ways to insert a library into the Arduino IDE, the one we will use is the quickest and easiest, but be aware that it will not always be possible to use this method... but don't worry we will see them all when needed! Back to us: inserting a new library into the Arduino IDE and then allowing the IDE itself to load into Arduino the right instructions needed for Arduino and the add-ons that connect to it to work. First we open the software, double-click on the Arduino icon on the Desktop, and the IDE opens: Since when you open the IDE it usually loads the last sketch you wrote, let's start with a clean sketch to avoid confusion. To do this, you click on "File" and then on "New." as depicted above. At this point we can close the initial window where the previous sketch was. Now we click on "sketch" then on "#include library" and then on "Manage libraries..." After a few seconds, the following window appears and we go to type in the text box "DHT11" A list of libraries comes up, we select the one produced by Adafruit... ...and click on "Install." After a few seconds, the window that says "INSTALLED" appears. The library is now usable and when compiling the sketch for Arduino, the IDE will not give an error. This procedure applies to any new sensor that requires a library to be installed; all you need to do is change the name of the sensor. LESSON 1 - Current, Voltage and Electrical Resistance. Let's start with some theory, but don't worry I won't bore you. To give an intuitive explanation of what electric current and electric voltage is and how it works, it is useful to think of water. In fact, the current flowing in electric wires is quite similar to a flow of water. The major difference between current and water is that, while for water it is molecules (of water) that flow in the pipes, in electric wires, it is electrons (elements that make up the "atom"). Such flow of electrons is called "electric current." We can think of electrons as balls, and just as water can drive water mills, electrons can also drive similar objects, sort of electron mills. These mills, driven by electrons, can produce light, noise, sound or motion! So: current consists of electrons flowing in a wire and can drive electrical components, which we can imagine as small mills. Electric current is measured in "A" that is, in amperes (it is read "amper" because it comes from French). Let us now make the water analogy more specific, and think of a waterfall arising from a reservoir (i.e., made by means of a man-made dam). In a waterfall, water falls from the highest point and falls to the lowest point (due to gravity), where it collects, and there we suppose there is a system of pumps that bring back up into the reservoir the water that has just collected after falling from the waterfall. In this way the water is ready to make a new cycle of falling from the waterfall and rising through pumps. The highest point of the waterfall is the one with a "higher potential" (conventionally denoted by "+"), the lowest point is the one with a "lower potential" (conventionally denoted by "-"). So water goes from the + to the -, the same thing electric current conventionally does, that is, it goes from the + (higher potential point) to the " - " (lower potential point). This, in electrotechnical terms, is called potential difference (ddp), or also electrical voltage and is measured in "V" i.e. Volts. Water in its descent downstream surely encounters rocks, narrows, becomes a river and finds bends... such elements that oppose the intensity of water flow, in electrical engineering, are called "resistances" and they oppose the flow of electric current. Resistance is measured in Ohms, or also referred to as "☐." Ohm's law. At this point, we can already identify one of the earliest laws of electrical engineering, namely: for the same voltage (thus the jump in the waterfall's elevation), the higher the resistance (i.e., the more rocks and impediments to water flow), the lower the electric current (i.e., there is less water flow). This law of electrical engineering is called Ohm's law and is represented as follows: The inverse formulas are: and What is an LED. Although the shape is very reminiscent of an incandescent bulb, its operation is completely different. In the incandescent bulb, the current flows through a very thin filament of material with high electrical resistance, and thus by becoming incandescent, because precisely the electrical resistance tries to prevent the passage of current, incandescence generates light, but also a lot of heat, which is wasted energy because it is not used for the purpose of better brightness. In an LED, current flows through a semiconductor (i.e., a conductor that can conduct current only in a predefined direction), and the material that makes up the semiconductor, when current flows through it, emits light (i.e., photons). This method of producing light energy is much more economical, in fact, there is no waste of energy that turns into heat, and the LED is also more reliable as a light source because it is not subject to the temperature changes that cause incandescent filaments to break down, as is the case with regular light bulbs. Remember that the LED is a semiconductor, so the polarity with which we power it is important; the anode (i.e., the longest terminal) must be connected to the positive, otherwise it will not light, and if a reverse voltage (with swapped poles) is applied to it, which is higher than the permissible threshold voltage, we will surely burn out the LED. In reality, even powering the LED correctly risks burning it out, in fact you have to be careful not to exceed what is called "junction voltage," which is why in series with the LED in the previous project we put a 220 Ohm resistor (later I will explain how to determine the correct resistor value depending on the LEDs and the number of LEDs to be powered. The LED, as you can see from the figures above consists of two platelets between which is the semiconductor that when excited (i.e., run through by an electric current) emits photons (i.e., light!). The platelets end in "terminals" one longer (the anode) and the other shorter (the cathode). So the positive voltage, the one indicated by the "+," should be connected to the anode, the negative voltage, indicated by the "-," should be connected to the cathode. The two plates, with the semiconductor, are then covered with a light-transparent plastic capsule that protects the components and directs the same light outward. Project 1 - Turning on an LED The first project I would like to introduce is the power supply of an LED . For this project we need Arduino, the breadboard, an LED (any color), a 220-ohm resistor (Ohm, also referred to as " ☐ ", is the unit of measurement of electrical resistance), and Dupont jumper cables (male-male, i.e., those that have the silver tip on both sides): Arduino Uno Bread board 220 Ohm LED R3 or compatible resistance Dupont male USB - male cables connection cable Pay attention! The 220 Ohm resistor is identified by the colored rings, specifically if the resistor has 5 colored rings, it must have the rings colored as follows: red-red-black-brown. If the resistor has 4 colored rings, then the colors of the rings must be: red-red-brown and then a silver or gold colored ring. In the next lesson we will learn how to read the values of resistors through the use of the color chart. Resistance to 5 colored rings Resistance with 4 colored rings For the LED, you need to pay attention to the terminal pins, one is longer and one is shorter: The longer terminal (anode), in the connection diagrams is shown "bent" The connections to be made are: If everything has been connected well, when you plug one side of the USB cable into the USB port on the Arduino and the other side of the cable into the USB port on the PC, the LED should light up, because it is powered. At the bottom is the electrical symbol of the LED and the classical connection circuitry via resistor: In the electrical circuit the resistor can be placed before or after the LED, it does not matter because the two components have the same "I" current flowing through them (they belong to the same electrical branch), the voltage drop across the resistor is identical. Such a way of connecting the resistor to the LED is called, in electrotechnical terms, "in series" , the meaning will be better seen later. So with this project, you are beginning to have your first contacts with the world of electrical engineering and electronics, but let's take a closer look at what we did. Basically to a passive element, as the LED is, [passive element means it needs electricity to function], we have applied an electric voltage. The electric voltage is also called EMF (electromotive force), in fact it indicates how hard we push the electrons out of their orbits and create that flow called electric current. The electric current, thus generated, as it passes through the semiconductor material that makes up the LED, transfers this energy to the same material, which transforms it into "photons," that is, light. So Arduino functioned as a power supply, i.e., energy supplier, the electrical wires caused this energy to be transferred to what is called the user, i.e., the LED Some of this energy is dissipated in the resistor in series with the LED in the form of heat, this is to reduce the amount of energy that would otherwise be too high and risk burning out the LED. [For the video related to the project click here]. The Button: how it works and how to use it Before moving on to the next project, it is good to see how a very important component works and how it is used: the button. The principle of operation of a button is very simple, and the animated gif below visually summarizes that operation. The button consists of a movable part and a fixed part, the movable part consists of a metal blade attached to a plastic holder that is the button of the button that will be pressed, below that blade is a spring that keeps the movable part pushed upward. The fixed part, on the other hand, consists of two separate blades that continue forming the button feet. The whole is enclosed in a plastic case. When the button is pressed, the spring compresses and the moving blade brings the two fixed blades into contact. If an electrical voltage (denoted by "+") is applied to one of the two blades, that voltage is also transferred to the other blade, so we have what is called in electrical engineering jargon "closing an electrical circuit." The buttons we use are characterized by having 4 pins (or also called terminals) of which are two by two metallically connected to each other. So connecting either pin A or C is the same thing, as is also pin B with respect to D. The pins that are separated metallically, as the figure above also shows, are those that are closest to each other, that is, pin A is separated from B, just as C is separated from D. Another type of push button, but whose functionality is identical to that seen above, is the two-terminal push button: However, now let's execute a project that better than anything else illustrates how the button works. Project 2 - The use of a push button to turn on an LED. In this project I would like to show you how to power an LED through the use of a Button that will allow us to turn the LED on and off at will. The materials needed for this project are identical to the previous one, but in addition we need a micro button. Arduino Uno R3 or compatible Bread board 220 Ohm resistance LED Dupont male USB - male cables connection cable Button We proceed with the connections as per the diagram below keeping the USB cable disconnected from the Arduino. In particular, attention should be paid to the longer terminal of the LED which should be connected in series with the 220 Ohm resistor. The resistor in turn is in series with the button terminal. The red dupont cable, which carries the 5V, should be connected to the other terminal of the button and the yellow dupont cable should be connected to the Arduino's GND and the LED's cathode. If everything has been connected well, when you plug the cable to the USB port of your PC, the LED should be off and pressing the button will turn it on, because only by pressing the button is the LED powered, that is, the button closes the circuit and gives electrical continuity. [For the video related to the project click here]. Now we try to understand what we have done. Let us remember the flow of water from a waterfall, or a river. With the insertion of the button, all we have done is to interpose a dam, that is, an obstacle that cannot be crossed by the water, and only when the pipes are opened does the water flow out for the waterfall. So the button interrupts the flow of current with a circuit interruption, only when it is pressed the circuit is restored and current can flow through it. Another example to make people understand the function of the button, is to imagine that you have a faucet, only when you open the faucet you create the pressure difference such that the water comes out (and thus circulate the power). IMPORTANT: I would like to point out to you that I have used the term conventional direction of current, this is because in the days of the studies of this phenomenon it was thought that it was the positive charges that moved from the + to the - (because they were attracted by the opposite sign), actually later it was discovered that it is the electrons that generate the current flow and since they have a negative charge, they are attracted to the positive pole, so the current actually goes from the negative pole to the positive pole, but conventionally we have continued to maintain the convention that the current goes from the + to the -. Curiosity: A bit of scientific history In 1799, Italian scientist Alessandro Volta (hence the name Volt to the unit of voltage measurement), who had been studying the then mysterious phenomena of electromagnetism for years, succeeded in building an early, rudimentary but effective electric battery. In the early 1800s Charles Augustin de Coulomb discovered that electrons, sub-atomic particles with a negative electric charge, are naturally attracted to areas where electric charges are of lesser intensity, and thus can be seen as 'gaps,' with positive valence. In the mid-1800s, around 1860, the unit for measuring electric current was named after the French physicist André-Marie Ampère, a leading scholar of electromagnetism. The Ohm (symbol: Ω) is the unit of measurement of electrical resistance, its name derived from that of the German physicist Georg Simon Ohm discoverer of Ohm's law of the same name. In fact, in 1827, his main discovery was that the electric current flowing through a conductor is directly proportional to the voltage applied to its ends. Of course, I have mentioned only a few physicists, actually between the early and late 1800s, there were 100 years of outstanding scientific discoveries in the fields of electrical engineering, electronics and electromagnetism. In 1889 the International System was born in Paris, after the agreement of several states, i.e., fundamental physical quantities such as: length, mass and time were given the units of measurement "meter [m]," "kilogram [kg]" and "second [s]," then over time were added: kelvin degrees [K] for temperature, ampere [A] for current, candle [cd] for brightness and mole [mol] for the amount of substance. These are the units of measurement that all scientists use to exchange information and scientific research around the world. What is a Breadboard. The Breadboard is to the maker like the blank canvas to a painter [Roberto Francavilla]. Breadboard is a board made of insulating material with many small holes. There are commercially available of different sizes, the most common one being the 400-hole one. The various small holes are electrically connected to each other in a special way that I will show you later. Basically, in these small holes the terminals of the various electronic components are inserted and without soldering, thus saving considerable time and especially reuse of components, it allows the connection between the various electronic components. In fact, the Breadboard is used to experiment with the functionality of the circuits that makers develop with the possibility of reusing components and the speed of modifying and trying out different circuit solutions. As can be seen from the photo, metal strips arranged horizontally and vertically allow connections between holes in the same horizontal and vertical row. Breadboard columns are identified by numbers, rows by uppercase letters. The only rows whose holes are all electrically connected to each other are those identified with "+" and " -." The holes in the other rows (A, B, C, D, E, F, G, H, J), as can be seen from the picture above and from the lines in the figure, are not connected to each other horizontally, but they are connected vertically, that is, in columns. This means that inserting a pin in column 6 to any line in the group between A and E, is the same thing. The Breadboard, as you can always see from the figure, is divided into two parts that are isolated from each other. Project 3 - Hello World With this project we begin to use Arduino in its true functionality, in fact in projects 1 and 2 our Maker board was used as a simple battery (power supply), now we will use it for what it is, which is a development board with a powerful and flexible microcontroller. For the project we will only need an Arduino development board and a USB cable. This project is not only a test of communication between our Arduino board and PC, but also a basic project in the Arduino world that introduces programming. Arduino Uno R3 or compatible USB connection cable And as a matter of practice, when starting to learn a new programming language, one of the first things to learn is to make our system we are programming write the phrase "Hello Word." Then we connect our development board to the PC via the USB cable and launch the Arduino IDE application by double-clicking on its icon. An empty window opens, or a new empty window must be opened: We type the sketch below into the window: /* Be Maker - STEM - Project 3 - Hello World */ int val; //we define the variable named "val" void setup() { Serial.begin(9600); // Let's initialize the port with a baud rate of 9600 } void loop() { val = Serial.read(); // Reads what is entered into the bar as input to the Serial Monitor and // assigns it to the variable val. if(val=='R') // Checks if what was entered is equal to the letter "R" { // if it is = "R", Serial.println ("Hello World!"); // show the string message "Hello World!" }} Once you have written the sketch, first proceed to click on the "V" (check mark), if there are no errors*, then upload it to Arduino by clicking on "->" and finally, once uploaded click on the lens (top right). The Serial Monitor window appears to you: Whenever we type in R (uppercase) and then on Send (or Send), the Serial Monitor displays the words: Hello World ! * In case clicking on the check mark brings up an error, then there are three possible causes: 1) Incorrect typing of the sketch, so double-check the individual lines paying attention to the ";" at the end of the instructions or the double lines for comments...we will discuss this at length later anyway. 2) Incorrect configuration of the serial port on the PC, about which I invite you to see the procedure provided in the initial activities at the Course 3) Incorrect installation of the development board driver, in fact some compatible Arduino install microcontrollers that require special drivers to be installed on your PC in order to be seen by the serial port. Also for this problem see the procedure provided in the initial activities at the Course. [For the video related to the project click here]. [For the sketch related to the project click here]. Arduino's digital PINs Before proceeding with the next project, it is helpful to know what digital PINs are and how they work on our development board. The Arduino board has 14 digital PINs. Digital PINs are particular PINs that can function as an input for Arduino or also as an output (the same PIN cannot function as an input and an output at the same time) and is characterized by the fact that it can take only two values: state High - High i.e. 5 V and state Low - Low i.e. 0 V. Some digital PINs (6 to be exact) are indicated with a wavelet " ⁓ ", these digital PINs are characterized by the fact that they can produce a PWM-type signal, but we will discuss this later. In the next project we begin to look at the use of Digital PINs. Project 4 - Police cars with flashing lights This is a simple project showing the use of Arduino's digital PINs. Arduino Uno R3 or compatible Bread board 2 x 220 Ohm resistor Red LED Blue LED USB connection cable Dupont male male cables - Printed cardboard With this project we also learn the use of wiring diagrams and the symbols to be used to represent the various components. The wiring diagram to be made is as follows: Instead, refer connections: to the assembly diagram below for After the connections we move on to writing the sketch. Connect Arduino to the PC via the USB cable and launch the Arduino IDE application by double-clicking on its icon. An empty window opens, or a new empty window must be opened: Type the sketch below: /* Be Maker - STEM - Project 4 - Police Car */ void setup() { pinMode(4, OUTPUT); //we declare digital PIN 4 as the output pinMode(6, OUTPUT); //we declare digital PIN 6 as the output } void loop() { digitalWrite(4, HIGH); //Put PIN 4 in high state = at 5V i.e. on digitalWrite(6, LOW); //Put PIN 6 in low state = at 0V i.e., off delay(1000); // we wait for 1000 milliseconds i.e. 1 second digitalWrite(4, LOW); //Put PIN 4 in low state = at 0V i.e., off digitalWrite(6, HIGH); //Put PIN 6 in high state = at 5V i.e. on delay(1000); // we wait for 1000 milliseconds i.e. 1 second } Once you have written the code launch the verification precompilation (check mark), it will ask you to save the sketch (you can change its name) and then click on the arrow to load: As a result, the two red and blue LEDs will alternately turn on and off after every second. If you place the police car, previously printed and cut out, in such a way that the two LEDs protrude from the car's upper beacon, drilling two holes at appropriate distances for how the LEDs are positioned, you will achieve a nice effect. [For the video related to the project click here]. [For the sketch related to the project click here]. (print and cut out) LESSON 2 - Insights into Electrical Resistance We saw in the previous lesson, referring to a watercourse, that electrical resistance can be defined as the "obstacle" that water, i.e., electric current, encounters during its natural path in the riverbed, i.e., electric cables. Of course, it is easy to see how such difficulty of the water current (but also of the electric current) depends on several factors, namely, the length of the route (length of the electric cables), the width of the riverbed (cross section of the cables), and the type of soil that makes up the riverbed (the material used for the electric conductors, whether copper, aluminum, or other material). In fact, the longer the course of the river, the higher the resistance; the larger the cross-section of the riverbed (of electric cables), the more easily water flows through it, so the resistance is lower; if the riverbed is made up of fine, compact sand or a well-smoothed surface, it will offer less resistance to water than a riverbed made up of irregular rocks; likewise, there are materials that have properties such that electric current will flow through them better than others. For example, gold is an excellent electrical conductor, as are silver, copper, aluminum... (all metals are good conductors), while there are materials that hinder the passage of electric current to such an extent that they are called "insulators" such as plastic, rubber,... Another way to visualize electrical resistance in order to fully understand its physical principle is as depicted in the figure below: The amount of water in the two reservoirs is initially the same, and the water level represents the electrical potential, that is, the force by which the water is pushed out of the pipe. The narrower the outlet pipe is, the more difficulty the water will have in exiting. Taking this to an extreme, if we were to have such a small pipe (imagine a hair's width), it is intuitable that water will have great difficulty escaping. The tube representing the electrical conductor, in the case of it being a hair, will obviously almost totally prevent water from escaping, in which case the material constituting the conductor is called an insulator and therefore the current flowing through that conductor is practically zero. The electrical resistor, the symbol of which is a zig-zag line, is indicated by a capital letter " R " , then a subscript "1", "2",... especially when there are several electrical resistors of different values, the electric current flowing through it is indicated by "I", while the electric voltage at the ends of the electrical resistor is indicated by a "V" (remember the waterfall seen in Lesson 1.... the water falls from the highest point "+" to the lowest point "-") . Observe that the voltage V conventionally is indicated by an arrow opposite to the direction of the current, and the arrowhead of the voltage corresponds to the "+." Current, again conventionally, goes from the positive "+" pole to the negative "-" pole. Commercially available electrical resistors are readily available components and can be found in different types depending also on the currents they must be able to withstand. Actually, the seller should be told the value of the resistor you want and the electrical power (the current is not given). Electrical power is another important electrical quantity in electrical engineering and in the case of DC-fed circuits, as in our case, it is denoted by P and is measured in watts (electrical symbol "W"). Electrical power is calculated by making the product of the value of the voltage applied to the resistor and that of the current flowing through it, but it is also equal to the product of electrical resistance and the value of current flowing through it raised to the square, i.e: For our projects, we will generally refer to electrical resistance values ranging from a few hundred Ohms up to a few tens of miles of Ohms, and we will use the resistance to properly distribute the electrical voltage generated by the Arduino, i.e., the 5 V, so that our components will work best in the various electronic circuits we develop. Even for Ohms, as for other units of physical quantities, there are multiples and submultiples. We will, however, always stay in the range of multiples, that is, we will often use "kOhm" (read kiloOhm) [it is a multiple of Ohm, i.e., 1 kOhm corresponds to 1000 Ohms]. So when I talk about tens of miles of Ohms, I am talking about tens of kOhms. The values of current circulating in the circuits we normally make are very low, on the order of milli-amperes (mA). From this you understand very well that the electrical powers involved are very low on the order of 0.25 W or at most 0.5 W (in the trade, electrical resistors capable of withstanding such powers are referred to as ¼ watt or ½ watt). The figure below shows what the resistor we use in our circuits looks like. There is a ceramic substrate on which is wound a wire of a particular conducting material that has its own electrical resistance; the number of turns represents its length and thus its total resistance. The conducting wire terminates at the ends on two plates with two metal terminals that are the output connectors. The whole is then covered with another ceramic material. The ceramic material is insulating, so in addition to mechanically protecting the resistor, it prevents short circuits from occurring. How to read the value of a resistor The resistance value is indicated on the outer casing by colored circles or colored bands. Let's say right away that there are different ways used to indicate the resistance value, among the most popular ones, of which standards have been created, are the value indication with 4 circles in total and the one with 5 colored circles in total, the one with 6 circles is less common, but still used mainly for laboratory components. The table below shows the correlation between circle colors and resistor values. I would like to immediately and still point out that one of the circles is always more spaced than the others (in the case of 6-circle resistor, the most spaced circles are 2). The furthest circle indicates tolerance , for color reading we start from the first circle on the side opposite the spaced circle. Resistors with 4 colored circles The first circle indicates the value of the first digit, the second circle indicates the value of the second digit and the third circle indicates the multiplier, and finally the fourth circle indicates the tolerance. Let's give an example to get a good understanding of how to apply the criterion of resistance enhancement. Suppose we have a resistance like the one in the figure below: The first thing we need to identify is the most spaced circle that is "gold" in color, this circle represents the tolerance on the resistance value of the component, in this case the tolerance, that is, the uncertainty on the value, is +/- 5%. After that we go to see the color of the first circle on the opposite side of the most spaced, the color is "brown," that is, the first digit has a value of "1," the second circle is "black," so the second digit has a value of "0," and the third circle is "red," that is, a multiplicative factor " x 100." At this point we know the value of the resistance, in fact: R = 1 , 0, x 100, +/- 5% i.e. 10 x 100 +/- 5% and thus R = 1,000 Ohm +/- 5% Our resistance is 1,000 Ohms, which is one kilo Ohm with a tolerance of 5%. Because we Makers like math we also go and calculate for ourselves, in terms of values, what it means to have a 5 percent tolerance: We calculate 5% of 1,000, i.e., 5 x 1,000 and then divide by 100, so we get 50, so: R = 1,000 +/- 5% Ohm means that the value of R is definitely somewhere between (1,000-50) 950 and (1,000+50) 1,050 Ohms. Resistors with 5 colored circles The first circle indicates the value of the first digit, the second circle indicates the value of the second digit, the third circle indicates the value of the third digit and the fourth circle indicates the multiplier, and finally the fifth circle indicates the tolerance. Again, let us give an example to get a good understanding of how to apply the criterion of resistance enhancement. Suppose we have a resistance like the one in the figure below: Again, the first thing we need to identify is the most spaced circle that is "brown," this circle represents the tolerance on the resistance value of the component, in this case the tolerance, that is, the uncertainty on the value, is +/- 1%. After that we go to see the color of the first circle on the opposite side of the most spaced, the color is "red," that is, the first digit has a value of "2," the second circle is "purple," so the second digit has a value of "7," the third circle is "black," so the third digit is "0," and finally the fourth circle is "orange" , i.e. a multiplicative factor " 1 K " i.e. "x 1000". At this point we know the value of the resistance, in fact: R = "2", "7", "0", x 1,000 +/- 1%, and that is R = 270,000 Ohms or even R=270 kOhm (kilo Ohms), with a tolerance of 1%, i.e.: 1 x 270,000 : 100 = 2,700 Ohms. So the true value of the resistance is a number between 267,300 Ohms and 272,700 Ohms. Since we are not making space shuttles, for our designs having tolerances of 1%, 5%, and even 10% does not involve committing significant errors, then from now on we will consider tolerance only a component qualifier (i.e., we will say that a component with a tighter tolerance is better than one with a wider tolerance), but we will not take it into account in our calculations. One last example: The first circle is red, so 2, the second circle is still red and so another 2, the third circle is black, so the third digit is 0 and finally the fourth circle is black, so the multiplier is for 1. So the R = 220 x 1 that is 220 Ohms. Trivia: What is a Physical Magnitude and Uncertainty in Measurements A physical quantity is a property of a body (or phenomenon) that can be measured. To specify the physical quantity requires a number (which indicates its value) and a unit of measurement. The unit of measurement is a reference quantity of a quantity, which is assigned a value of 1. Let's take an example to better understand what I wrote: One of the fundamental quantities is length to which the meter [m] has been assigned as the unit of measurement. But what is the meter? In Sèvres, France, a rod is preserved that has a length of 1 in 10 million of the length of the arc of the Earth's meridian that starts at the North Pole and passes through Paris, stopping at the Equator. This rod, thus determined, represents the length of 1 m. Obviously then for comparison the "meters" used when we want to take measurements of an object were reproduced. In fact, to measure a length, all we do is to see how many times the meter is contained in the length to be measured. Obviously when measurements of quantities are made, there are also errors, which can be instrumental errors due to the instruments not being perfectly calibrated, errors in the reading of the instrument (the so-called parallax error)... we are obviously talking about small errors that are related to the measurement of the quantity. These errors then introduce a small indeterminacy into the measurement, and then you have the so-called tolerance in the measurement. Project 5 - The Traffic Light with Arduino Let's continue with the use of Arduino's digital PINs and make a simple project that will give us lots of fun. Let's make a traffic light with Arduino. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male - USB connection cable male cables 3 x 220 Ohm 3 x LEDs (red, resistor yellow and green) Printed Cardboard The wiring diagram is: Instead, follow the diagram below for assembly: After the connections we move on to writing the sketch. Connect Arduino to the PC via the USB cable and launch the Arduino IDE application by double-clicking on its icon. An empty window opens, or a new empty window must be opened: Type the sketch below: /* Be Maker - STEM - Project 5 - Traffic Light */ void setup() { pinMode(4, OUTPUT); pinMode(5, OUTPUT); pinMode(6, OUTPUT); } void loop() { digitalWrite(4, HIGH); //Red lit. digitalWrite(5, LOW); //Yellow off digitalWrite(6, LOW); //Green off delay(6000); // 6 sec wait. digitalWrite(4, LOW); //Red off digitalWrite(5, LOW); //Yellow off digitalWrite(6, HIGH); //Green on delay(4000); // 4 sec wait. digitalWrite(4, LOW); //Red off digitalWrite(5, HIGH); //Yellow on digitalWrite(6, HIGH); //Green on delay(2000); // Waiting for 2 sec. } Once you have written the code launch the verification precompilation (check mark), it will ask you to save the sketch (you can change its name) and then click on the arrow to load: The result will be: the red LED turns on and stays on for 6 sec, after which the red LED turns off and the green LED turns on. After another 4 sec, the yellow LED also turns on and stays on for 2 sec. After that, the yellow and green LEDs are turned off and the red LED is turned on again. If you place the card with the traffic light, previously printed and cut out, it will surely give you a nice effect. [For the video related to the project click here]. [For the sketch related to the project click here]. Introduction to Coding The time has come to enter the world of Coding, and the first thing I would like to introduce is sketching. But first let's take a little step back to understand what we mean by Coding. The term Coding has been around for a very few years and as the name suggests comes from "coding" or generating codes, which in turn, in computer terms, refers to Programming Computers (or more generally: electronic devices) using a particular programming language. So, summarizing, the term coding refers to computer programming and thus to the design and development of software. Saying that...you'll tell me, bravo you copied the definition from the first-year high school book of computer science.... .... but really: what does it mean to Program a Computer or Electronic Device???? So I try to explain better--and to explain, I don't want to start from the birth of Computers, but from a concrete example. Suppose we have an industrial process that we wish to automate, for example, the production of corks from wine bottles... The first thing we do is to identify in detail the entire production process: taking the cork sheet, transferring it to the press, etc..... so we define a well-defined ordered sequence of actions.... The various actions, although in a well-defined sequence, are linked together, and the link is called an algorithm. For example: before operating the press check that the cork sheet is positioned correctly, if yes, then proceed to pressing, otherwise stop.... The one described above is an algorithm of the logical type.... But there are also mathematical ones... Once the individual steps of the process and the algorithms that govern them have been determined, then it is translated into the programming language, and then you have the production of the software that installed on the control machines and PCs, realize the desired automated process. Coding -- that's what it means! Well! After this introduction, let's move on to our Arduino development platform and look at the sketch... The sketch You have surely understood, at least from the last few projects you have done, that Arduino, since it is nothing more than a minicomputer, needs to be programmed to do what we want it to do, and this is done in its development environment called IDE. In fact, it is in the sketch that we will write, in a particular, step-by-step language, what Arduino is to do for us. The programming language we will use for the sketches is basically C++ The sketch is made up of two parts, one beginning with "void setup() { ...... }" and the other with "void loop() { ...... }" both parts enclose within curly brackets the instructions that Arduino will execute. And in particular, in the part enclosed by "void setup()..." as also the name "setup" says, you define the "variables," "set" the Arduino PINs, call libraries, etc... , however you write all those instructions and/or all those operations that need to be executed at least once. While in the "void loop ()..." part you enter all those instructions that Arduino will execute in an infinite loop (cycle). Project 6 - The Stelliere With this project we learn how to trigger an event on the Arduino by simply pressing a button. The event, in this particular case, is turning on an LED, but it could also be an entire starry sky! Arduino Uno R3 or compatible USB cable connection Breadboard Resistance 1kOhm + 220Ohm resistor Dupont male male cables Button Yellow LED Printed Cardboard The wiring diagram is as follows: Instead, the assembly diagram is this: After the connections, let's move on to writing the sketch. Connect Arduino to the PC via the USB cable and launch the Arduino IDE application and write the following code... /* Be Maker School - STEM - Project 6 - The Stelliere */ int val; // we define a variable named "val" of type integer void setup() { pinMode (3, OUTPUT); // we set digital PIN 3 as the "output" pinMode (1, INPUT); // we set digital PIN 1 as the "input" } void loop() { val = digitalRead (1); // reads the value taken on digital PIN 1 if (val == LOW ) // check if val has assumed the low state (button NOT pressed) { digitalWrite(3,LOW); // if the button is NOT pressed then digital PIN 3 is set to LOW } // the LED is kept off. else { digitalWrite(3,HIGH); // if the button is pressed then digital PIN 3 is set to HIGH } // the LED is turned on } Once you have written the code launch the verification precompilation (check mark), it will ask you to save the sketch (you can change its name) and then click on the arrow to load. Once you start the sketch, whenever you press the button, Arduino commands the LED to turn on. Position the printed card so that the yellow LED comes out of the star and you have become a Stellier ! From this project onward, in order to learn the programming language for making skatches, we also begin to do sketch analysis of the projects we will gradually make. [For the video related to the project click here]. [For the sketch related to the project click here]. Analysis of the sketch: The Stelliere Analyzing the sketch, we can observe several interesting things, first of all the usefulness of inserting comments. Comments (which will be ignored by Arduino) can be entered in two different ways. The first is with the use of the split "/" and the asterisk " * " , specifically they are put at the beginning and end of anything that Arduino should ignore as a comment: /* [comment] */ . This method is used when the comment occupies multiple lines. The second method is to put the double divided "//", this way everything to the right of the // and for the entire line is ignored by Arduino and not executed because it is seen as a comment. This mode is used when the comment is on the same line as an instruction to describe what the specific instruction does. Another interesting thing I want to point out to you about the sketch is the definition of the digital PINs in the void setup() , we said that the digital PINs can take two values: HIGH and LOW (or even 0 and 1) and we said that the Arduino digital PINs ranging from No. 0 to No. 13 can be INPUT and OUTPUT PINs. In this project digital PIN 1 is of INPUT, in fact when the button is pressed it carries voltage to the PIN, so it receives a signal that we read with the digitalRead instruction. Digital PIN 3, on the other hand, provides a LOW or HIGH signal with the digitalWrite instruction, so it is an OUTPUT PIN. This functionality of digital PINs in the sketch, whether of INPUT or OUTPUT must be declared in the void setup(). Arduino Analog PINs Arduino has 6 Analog PINs named A0, A1, A2,...A5. Analog PINs, like Digital PINs, can be configured as inputs or outputs depending on their use. A clarification needs to be made: an analog quantity can actually take on infinite values, since Arduino is in essence a minicomputer and is therefore characterized by digital quantities, it cannot reproduce the infinite values required by an analog quantity, but the quantity is "discretized" and brought back to a value between 0 and 1023 , that is, in a range of 1024 possible values. Since the quantities read or reproduced by the Analog PINs are actually electrical voltages, and knowing that the Arduino has a maximum voltage of 5V output from its PINs (whether digital or analog), it is readily understood that the value 0 is associated with 0 V and the value of 1023 with 5V. At this point by applying a simple proportion, we can derive the value of the magnitude (if the value of the analog PIN is known), or the value of the analog PIN if what is known is the value of the magnitude. Let us see the application of this concept in a Project. Project 7 - Ohmeter. Using Arduino to measure a resistance Suppose we have a resistor whose bands are not readable or have erased, the question is, how do we determine the resistance value of an unknown resistor? This project shows the use of Arduino when we want to know the value of a resistor whose colored bands above the component are not shown for whatever reason. We need: Arduino Uno R3 or compatible USB cable connection Breadboard Resistance 1kOhm Dupont male - male cables Unknown resistor or alternatively. 220 Ohm resistor The wiring diagram is as follows. We use a 220-ohm resistor as the Rx: Instead, the assembly diagram is this: Note: A 220-ohm resistor was used as the unknown resistor. Now we double-click on the Arduino icon on the Desktop and the IDE opens and we copy the following sketch, be sure to follow each step indicated: /* Be Maker- STEM - Project 7 - Ohmeter */ void setup() { Serial.begin(9600); //serial port initialization } void loop() { int read=analogRead(A0); //read the value from pin A0 // I apply Proportion: // x : reading = 5 : 1023 -> x = (5*reading)/1023 float Vout=(reading*5)/1023.0; //With the proportion I calculate the voltage float current=(5-Vout)/1000; //Apply Ohm law and calculate current float ResIncognita=Vout/current; //calculate the unknown resistance Serial.print("Voltage output: "); //print the results Serial.print(Vout); Serial.print(" Resistance value: "); Serial.println(ResIncognita); delay(1000); //cycle restarts after 1 sec. } Once you have written the code launch the verification precompilation (check mark), it will ask you to save the sketch (you can change its name) and then click on the arrow to load and then on the lens to access the serial monitor. Started the Serial Monitor, the result is this: If you remember the tolerance.... whereby the measured value (214.71 Ohms) will always be slightly different from the theoretical value of 220 OhmsCOPY00 in fact, if you apply the formula of percentages [(220-214.72)/220]*100 = 2.4, you then get an error of about 2.4%, that is, within the allowable tolerance which is that stated by the resistor manufacturer (+/- 5%), otherwise you could have asked for a refund... Tip ! : When using Arduino to make measurements, always check the correct functionality of the components, otherwise you risk going crazy... for example I happened to use a 1 kOhm resistor that was actually 10 kOhm! So I was getting values ten times smaller than expected. I solved the problem by checking the actual value of the resistor with a tester and then realized that a batch of resistors bought and sold for 1 kOhm, were actually 10 kOhm. Sketch Arduino Analysis: Ohmeter with Analyzing the Ohmeter sketch, we observe the following: In the "void setup() { ...... }" enclosed by the two curly brackets is the following instruction: Serial.begin (9600); this instruction sets the communication speed between the Arduino and the PC to 9600 bits per second, which is the maximum communication speed on the COM port between the PC and the Arduino. This instruction is entered when you want to display the values of variables on the serial monitor in the IDE. Variables are empty containers that are filled during sketch execution (we will see more about this topic in a later lesson). The instruction "analogRead(...)" is one of the most important instructions in the Arduino language, in fact through this instruction it is possible to read the values of the analog PINs present on the Arduino. The correct syntax is as follows ("read" is an arbitrary name assigned to a variable): int read = analogRead(A0); At the end of each instruction is the ";" , the semicolon indicates that the instruction is finished and Arduino will move on to the next one. After this instruction, the sketch running on Arduino reads the value on the PIN and gives it a number from 0 to 1023 (i.e., 1024 values), where "0" if the value of the voltage read at PIN A0 is 0 V and "1023," if the voltage read is 5 V (i.e., the maximum voltage that can be produced on the PIN by Arduino). For intermediate numbers at these two extremes, and thus to have intermediate values of voltage read at the PIN, proportions must be made..... holy Math!!! In fact, for example, suppose the value read on the PIN is "184," at which point we apply the proportion: 1024 : 5 = 184 : x (reads 1024 stands for 5 volts as 184 stands for X volts, where X is the unknown) The formula for solving this proportion tells us that to derive the unknown value X, we must multiply the inner members of the proportion and divide by the (known) outer member, so: X = 5 * 184 /1024 = 0.898 V So the voltage measured by Arduino at PIN A0 is about 0.9 V. Noting the voltage, applying Ohm's Law, seen in the previous Lesson, we derive the value of the unknown resistance. I will stop here with the explanation of the formulas used, because I do not want to bore you with further calculations, which we will see in other projects anyway. At this point we see the last two instructions: Serial.print("Output voltage: "); Serial.println(Vout); The Serial.print Instruction ("....") prints on the screen, on the Serial Monitor, the content between the " " (quotation marks) and printing occurs on the same line. To access the Serial Monitor, as mentioned earlier, you click on the lens. The Serial.println (...) instruction prints and then goes to the carriage return line for the next print. The instruction Serial.println(Vout); prints the value contained in the variable Vout (and then goes to the next line). [For the video related to the project click here]. [For the sketch related to the project click here]. (print and cut out) LESSON 3 - Robotics with Arduino With this lesson we begin to explore the world of sensors that we can connect to Arduino, and so with that we also begin to talk about robotics. Did you know that with Arduino you can build real robots? Nooo! And instead Yes!!! It all depends on your imagination. The word "robot" is assumed to come from the Czech language meaning "slave" and was a word used in ancient Europe to refer to people who did the heavy and repetitive work, but the best use of the word Robot is, in my opinion, by the great writer Asimov who also set the laws of it: First Law: "A robot cannot harm a human being nor can it allow a human being to receive harm because of its failure to do so." Second law: "A robot must obey orders given by humans as long as those orders do not contravene the first law." Third law: "A robot must protect its own existence as long as this does not conflict with the first and second laws." Obviously, today by the word robot we denote anything that performs operations mechanically in an automatic way thanks to an electronic controller, with particular reference to programmable devices used in some sectors of industry, but also for domestic uses (see for example kitchen robots, robot vacuum cleaners..). What enables a machine to have reactions, and thus a certain behavior, are the SENSORS, which are those electronic devices that detect the values of a physical quantity and transmit its changes. Sensors are also called TRANSDUCERS which can be classified as active if the transducers generate a current or voltage signal or passive if the transducers produce a change in an electrical parameter such as resitance, capacitance etc. at the output. Another classification criterion refers to the type of signal produced at the output. Analog transducers have an output signal that continuously follows changes in the input physical quantity. Digital transducers output the value of the magnitude inn numerical terms with discrete values. However, don't worry, by the end of the course you will be very good at understanding the operation of lots of sensors. The photoresistor or also called Light Sensor In this lecture we will discuss the light sensor. In particular we will talk about photoresistors its commercial English name is LDR that is Light Dependent Resistor, which is that electronic component that as the brightness of the environment in which it is placed changes its electrical resistance, and then with that change we can establish different behaviors for Arduino to perform. The operating principle of an LDR is based on special characteristics possessed by certain substances that when subjected to the action of light (photons), change their resistivity characteristics. Electrical resistivity, also called specific electrical resistance, is the ability of a material to resist the passage of electrical charges. In the International System, resistivity is measured in ohms per meter (Ω-m). Resistivity differs from resistance in that it is a specific property of the material in question and depends primarily on the microscopic structure of the medium; in contrast, resistance R is a property of the entire conductor under consideration (macroscopic property). The animated figure above shows how some materials when hit by photons (light) absorb energy and are able to conduct more electric current when subjected to an electric voltage (electrons are released from their bond). These materials, therefore, change their resistivity, lowering it, when affected by light. In the absence of light, photoresistors act as materials with high resistivity. For our projects we will refer to the GL 5528 photoresistor: As we have said there is a link between amount of light striking the photoresistor and the value of Resistance that the sensor takes on, this link is expressed by means of a graph (logarithmic-based) shown below: On the x-axis (x-axis), there are Lux (i.e., light intensity); on the y-axis (y-axis) there are kOhm (i.e., Resistance). As can be seen from the graph, the greater the light, the smaller the Resistance. The gray band represents the uncertainty (tolerance) range of the LDR - GL5528 sensor. The circuit in which a photoresistor is inserted is called a voltage divider and is the same circuit used to measure the unknown resistance in the ohmmeter seen in the previous lesson, i.e., you put two resistors in series of which one is known and measure the voltage value (Vm) at the junction point of the two resistors. Knowing the voltage applied to the circuit (5 V), one can determine the value of the unknown resistance of the photoresistor and thus measure the brightness: We have the voltage Vm measured by Arduino by taking the signal to one of its analog PINs, e.g., A0, at this point, knowing the voltage Vm, we know the voltage applied on the known resistor, which is obtained by deduction, i.e.: 5 V - Vm, consequently we can calculate the electric current "I" which by Ohm's law (V = R x I) is equal to (using the inverse formula): and finally we can calculate the value of the unknown resistance: If we also have the correspondence table between the degree of brightness (which is measured in lux) and the resistance value, we also know how much light is hitting the photoresistor moment by moment. For example, photoresistor manufacturers release what are called datasheets (i.e., data sheets) of components (an example is the figure below referring to the GL5528 photoresistor): which tells us that with 10-15 lux of brightness, a resistance value of about 10-15 kOhm corresponds. Since I believe that I have reached and exceeded the attention curve... and therefore I am sure that from this moment on you will not receive anything more..., let us move on to practical things and therefore let us carry out the following project. Project 8 - Crepuscular Switch with Photoresistor For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male - male cables USB connection cable 220 Ohm resistance Yellow LED Resistance 1 kOhm Photoresistor GL5528 The wiring diagram is: The diagram below should be followed for assembly: After the connections we move on to writing the sketch. Connect Arduino to the PC via the USB cable and launch the Arduino IDE application by double-clicking on its icon. A blank window opens, or a new blank window needs to be opened and we write the sketch below: /* Be Maker - STEM - Project 8 - Twilight. */ void setup() { pinMode(2,OUTPUT); //we set PIN 2 as the output Serial.begin(9600); //we set the serial port } void loop() { int read=analogRead(A0); //reads the PIN A0 float Vout=(reading*5)/1024.0; //determines the Vout on the base //of the value read at PIN A0 float Rnota=1000.0; //value of the known Resistance i.e. 1000 Ohm float current=(5-Vout)/Rote; //calculates current float ResIncognita=Vout/current; //calculates unknown resistance Serial.print("Voltage output: "); //print on the screen the sentence between "" Serial.print(Vout); //print the Vout value on the screen //println means it then goes to head //to the next line Serial.print(" Resistance value: "); //print on the screen the sentence between "" Serial.println(ResIncognita); //print the resistance value on the screen if (ResIncognita>10000) { digitalWrite(2,HIGH); //puts PIN 2 in high state [5 V]. } else { digitalWrite(2,LOW); //puts PIN 2 in a low state [0 V]. } delay(1000); //waits one second before starting again } Once you have written the code launch the verification precompilation (check mark), it will ask you to save the sketch (you can change its name) and then click on the arrow for loading and the lens for the Serial Monitor: Once you start the sketch, do some testing by lowering the brightness of your room and raising it, when the room gets dark then Arduino commands an LED to turn on (the reference value you can lower or raise depending on the brightness conditions of your room). Sketch Analysis: Twilight Switch with Photoresistor Analyzing the sketch we see that it is basically similar to the previous one on the Ohmeter, so there would be nothing to highlight except the use of the "if" control structure. The control structure works like this: if the condition in the if brackets is true, then Arduino will execute the instructions contained in the if brackets, otherwise it means that the condition is not verified and everything enclosed in the else brackets will be executed. The syntax is as follows: if (condition) { //statement(s) } else ) { //statement(s) } [For the video related to the project click here]. [For the sketch related to the project click here]. Curiosity: What is Light Until the early 1900s, Light was thought to consist of electromagnetic waves and as such followed the laws of classical electromagnetism; the waves consisted of two sinusoidal components perpendicular to each other (see animated gif: blue-colored magnetic field and red-colored electric field): The frequency of these waves, that is, the periodicity with which the waves repeat, if it was in the range of 400 to 700 nanometers wavelength (this is called the spectrum, the range of frequencies), could be visible to the human eye (spectrum of visible light). Each frequency, of this spectrum, also defines the color of light, and the sum of all the frequencies of visible light form the so-called White Light, which is then that emitted by the sun. In the early 1900s, particularly between 1900 and 1905, Max Planck and Albert Einstein, with the theories and experiments of quantum neo-physics, introduced the concept of the photon, and thus defined light as being composed of photons i.e. particles of zero mass, but made of energy alone. This particle, the photon, also has the properties of being an electromagnetic wave. Project 9 - Luxmeter with Arduino Also in this project with Arduino we will make a measuring instrument, namely the Luxmeter. What is the Luxmeter used for? It is used to measure the intensity of light present in a given environment or how much light is hitting an object...you know the instruments that photographers used? well! those were basically luxmeters; once they measured the light, they gave indications of the shutter aperture time and aperture. For this project we need: Arduino Uno R3 or compatible USB cable connection Breadboard Resistance 1kOhm Dupont male male cables LDR GL5528 Photoresistor 220 Ohm resistor LED The wiring diagram is as follows and is identical to the one above: As also the assembly scheme is identical to that of the previous project: Before we pass are to the sketch, a little explanation is needed on how to derive the lux value of the brightness by measuring the value of the photoresistor resistance, in essence we will use the table already described previously, namely: the table refers to GL5528, obviously if another type of photoresistor were to be used, the table would have to be rebuilt in the same way as I did above. For the association of values in the table we will use what in computer jargon is called the method of "nested ifs" , this method is generally avoided, but for educational reasons I propose it. Now we double-click on the Arduino icon on the Desktop and the IDE opens and we copy the following sketch, be sure to follow each step indicated: /* Be Maker - STEM - Project 9 - Luxmeter */ void setup() { pinMode(2,OUTPUT); //we set PIN 2 as the output Serial.begin(9600); //we set the serial port } void loop() { int read=analogRead(A0); //reads the PIN A0 float Vout=(reading*5)/1024.0; //determines the Vout on the base //of the value read at PIN A0 float Rnota=1000.0; //value of the known Resistance i.e. 1000 Ohm float current=(5-Vout)/Rote; //calculates current float ResIncognita=Vout/current; //calculates the resistance of the photoresistor Serial.print(" Photoresistor value [kOhm]: "); //print on the screen the sentence between "" Serial.print(ResIncognita); //print the value of the resistance Serial.print (" Value Illuminance [lux]: "); //print on the screen the sentence between "" if (ResIncognita<=2000) { Serial.println (" over 100 lux "); digitalWrite(2,LOW); //puts PIN 2 in a low state [0 V]. } else { if (ResIncognita>2000 && ResIncognita<3500) { Serial.println (" about 80 lux "); digitalWrite(2,LOW); } else { if (ResIncognita>=3500 && ResIncognita<4500) { Serial.println (" about 40 lux "); digitalWrite(2,LOW); } else { if (ResIncognita>=4500 && ResIncognita<5500) { Serial.println (" about 30 lux "); digitalWrite(2,LOW); } else { if (ResIncognita>=5500 && ResIncognita<9500) { Serial.println (" about 20 lux "); digitalWrite(2,LOW); } else { if (ResIncognita>=9500 && ResIncognita<29500) { Serial.println (" about 5 lux "); digitalWrite(2,LOW); } else { if (ResIncognita>=29500) { Serial.println (" about 1 lux "); digitalWrite(2,HIGH); //puts PIN 2 in high state [5 V]. } }}}}}} delay(1000); //waits one second before starting again } Once you have written the code launch the verification precompilation (check mark), it will ask you to save the sketch (you can change its name) and then click on the arrow to load and then on the lens to access the serial monitor. Started the Serial Monitor, the result is this: Sketch Analysis: Arduino Luxmeter with The particularity of the sketch of this project is to have created ranges of correspondence of resistance values to illuminance values and then depending on the resistance value the most appropriate illuminance value is chosen, this was done using nested ifs, that is, after the if that theoretically establishes the alternative to a condition and closes the verification (as happens to the sketch of the previous project), a new condition is immediately reinserted to be verified with a new "if" and this happens as many as 6 times. As I said at the beginning, this programming methodology has only a didactic purpose, generally we try to avoid nested ifs and C++ also provides other solutions that we will see in other projects. [For the video related to the project click here]. [For the sketch related to the project click here]. The PWM signal - Pulse Width Modulation We know that Arduino has 14 digital PINs, that is, they are capable of receiving input, or giving an output signal with only two states, HIGH and LOW. Digital PINs are indicated by numbers ranging from 0 to 13, but paying attention some of them also have in addition to the number a ripple symbol " ᷉ ". Those PINs are Digital PINs with the capability of giving an output voltage of the PWM type, in English Pulse Width Modulation, that is, a Pulse Width Modulated Electric Voltage. The Digital PINs with such functionality are the: 3, 5, 6, 9, 10 and 11. Let's see what we can do with these PINs with a ripple (slang for "tilde"). The PWM signal is a signal that is always based on the principle of on or off (so it retains the characteristics of the two states HIGH and LOW), but if we consider a period of time (called: cycle) and in this period we go to change the holding duration of the high state, rather than the low state, and repeat it for all cycles, the average value of the signal that we have at the PIN is no longer 0V or 5V, but will be a value between 0 and 5V. The adjacent figure explains this concept, but let's look at it even better with the next figure. In the first case, we have that the value of 5 V is not maintained in the cycle time, so the signal is 0% of the 5 V voltage, that is, the digital PIN has an average value of 0 V at its output. In the second case, 5 V is maintained for 25 percent of the cycle time, that is, 25 percent of 5V, so the voltage at the digital PIN output has an average value of 1.25 V. In the third case, 5V is maintained for 50% of the cycle time, that is, 50% of 5V, so the voltage at the digital PIN output has an average value of 2.5 V. In the fourth case, 5V is maintained for 75% of the cycle time, that is, 75% of 5V, so the voltage at the digital PIN output has an average value of 3.75 V. In the fifth case, 5V is maintained for 100% of the cycle time, that is, 100% of 5V, so the voltage at the digital PIN output has an average value of 5V. A PWM digital PIN can be given values between 0 and 255 (where 0 indicates 0 V and 255 indicates 5 V-essentially 256 values). The instruction, with its syntax, for assigning a PWM signal to a digital PIN is as follows: So summarizing the above in a schematic, and assuming that PIN No. 11 is used for a PWM-type signal, we have: Of course, we can also use the intermediate values and not just the ones given. The next project shows in a practical way an interesting application of the PWM signal to digital PINs. In fact, it is enough to think of an Arduino function that allows us to adjust the brightness of an LED (but it could be anything else, e.g., the lights in our house, the rotational speed of a motor, ....) by acting on the PWM digital PINs, but I will say more, we can adjust such variation to other external phenomena as well. The following project links the measurement of external brightness detected by a photoresistor to the brightness that we wish to give in a room, however, before we delve into the project I would still like to highlight one thing that will be very useful in so many applications. Relationship between and PWM Digital PINs Analog PINs As explained earlier an Analog PIN takes values between 0 and 1023 (where 0 indicates 0V and 1023 indicates 5Vessentially 1024 values ), while a PWM digital PIN takes values between 0 and 255 (where 0 indicates 0V and 255 indicates 5V-essentially 256 values). At this point, thanks to a simple proportion of our holy Mathematics, we are able to write a formula that defines the voltage of a PWM digital PIN as a function of the value detected by the analog PIN (for example: A0). In fact, the proportion is as follows: 256 : 1024 = X : reading at PIN A0 (reads: 256 stands for 1024 as the unknown value to be derived and sent to the digital PWM PIN stands for the reading at Pin A0) When the unknown is in the proportional means, we know that to derive it we do the multiplication between the proportional extremes and divide by the known term between the proportional means. Therefore: but 256/1024 = 1/4, so to get the corresponding PWM signal value by having an analog signal, just divide the latter value by 4. Project 10 - Night and Day with PWM Signal Suppose we want to keep the light in a room constant at all times, so as the sun goes down, gradually artificial lighting goes to supplement the sunlight to keep the same level of brightness in the room at all times. Well the project I present allows precisely this functionality. For this project we need: Arduino Uno R3 or compatible Breadboard Resistance 1kOhm Dupont male male cables USB cable connection LDR GL5528 Photoresistor 220 Ohm resistor The wiring diagram is as follows: While below is the assembly diagram: LED Now we double-click on the Arduino icon on the Desktop and the IDE opens and we copy the following sketch, be sure to follow each step indicated: /* Be Maker School - STEM - Project 10 - Night and Day */ void setup() { pinMode(11,OUTPUT); //we set PIN 11 as the output Serial.begin(9600); //we set the serial port } void loop() { int read=analogRead(A0); //reads the PIN A0 int valuepwm=reading/4; //converts the reading into the PWM signal float Vout=(reading*5)/1024.0; //determines the Vout on the base //of the value read at PIN A0 float Rnota=1000.0; //value of the known Resistance i.e. 1000 Ohm float current=(5-Vout)/Rote; //calculates current float ResIncognita=Vout/current; //calculates unknown resistance Serial.print("Photoresistor resistance [Ohm]: "); Serial.print(ResIncognita); Serial.print(" A0 read value: "); Serial.print(reading); Serial.print(" PWM value before map: "); Serial.print(valuepwm); valuepwm = map(valuepwm, 200, 255, 0, 255); //map value according to new scale Serial.print(" PWM value after of map: "); Serial.println(valuepwm); if (valuepwm<0) {valuepwm=0;} analogWrite(11,valuepwm); //sets PIN 11 to a variable voltage between 0 and 5V delay(200); //holds 200 ms before starting again } Once you have written the code launch the verification precompilation (check mark), it will ask you to save the sketch (you can change its name) and then click on the arrow to load and then on the lens to access the serial monitor. Starting the sketch on Arduino, if everything has been done correctly, you have that by shading the photoresistor sensor (even with a pen cover), the brightness of the LED increases, while on the contrary, by getting more light to the sensor, the LED tends to go out, all with a FADE-type effect i.e., with a gradual change. Analysis of the Sketch: Night and Day with PWM signal There are so many interesting things to analyze in this sketch. Let's go through them all starting with the main things: 1) You can see how the PWM signal is applied to the digital PIN, in fact the analogWrite instruction is used for a PWM digital PIN instead of the classic digitalWrite instruction. You can see this in the line where there is: analogWrite(11,valuepwm); 2) We have seen how to convert a value from an Analog PIN to a corresponding value from a Digital PWM PIN, just divide the reading on the Analog PIN by 4, this can be seen on the line: int valuepwm = reading/4; 3) Since at the time of the execution of the project it was night and in my room at most I could get 50 lux and no more, you understand very well that the LED always started from an on condition. So I used a function called map, which basically just calculates proportions, and then what was my possible range of PWM signal values (unable to run the project in full sunlight) ranging from a minimum of 200 to a maximum of 255, I remapped it to a new scale of 0 to 255. The syntax for the map function is: map(value, fromLow, fromHigh, toLow, toHigh) you see it applied to the sketch at line: valuepwm = map(valuepwm, 200, 255, 0, 255); where the variable valuepwm is assigned the new remapped value of the value that the same variable had before. Since in remapping it could happen to have negative values that are considered by the PWM digital PIN as a HIGH value, then I also had to enter in control with an if to the line: if (valuepwm<0) {valuepwm=0;} [For the video related to the project click here]. [For the sketch related to the project click here]. Project 11 - The Return of the Cylons I have always been a fan of the Battlestar Galactica TV series, and the thing I was curious about was how they gave the light movement that was somehow supposed to represent the Cylon robots' visuals. Well! with the project we are going to develop you too can make a Cylon head and why not, use it for carnival. For this project we need: Arduino Uno R3 or compatible Breadboard No. 5 220 Ohm Resistors No. 5 Red LEDs USB connection cable The wiring diagram is as follows: The assembly diagram is as below: Dupont male male cables Now open a new sketch window by double-clicking on the Arduino application and write the code below and save the file: /* Be Maker - STEM - Project 11 - Cylon */ int delay=100; int delay2=1; void setup() { //configure PWM PINs at the output pinMode(5, OUTPUT); pinMode(6, OUTPUT); pinMode(9, OUTPUT); pinMode(10, OUTPUT); } void loop() { analogWrite(9, 255); //cycle of for with i decreasing to make //gradual switching off of the LED for (int i = 255; i >= 0; i--) { analogWrite(10, i); delay(delay2); } delay(delay); analogWrite(6, 255); for (int i = 255; i >= 0; i--) { analogWrite(9, i); delay(delay2); } delay(delay); analogWrite(5, 255); for (int i = 255; i >= 0; i--) { analogWrite(6, i); delay(delay2); } delay(delay); analogWrite(3, 255); for (int i = 255; i >= 0; i--) { analogWrite(5, i); delay(delay2); } delay(delay); analogWrite(5, 255); for (int i = 255; i >= 0; i--) { analogWrite(3, i); delay(delay2); } delay(delay); analogWrite(6, 255); for (int i = 255; i >= 0; i--) { analogWrite(5, i); delay(delay2); } delay(delay); analogWrite(9, 255); for (int i = 255; i >= 0; i--) { analogWrite(6, i); delay(delay2); } delay(delay); analogWrite(10, 255); for (int i = 255; i >= 0; i--) { analogWrite(9, i); delay(delay2); } delay(delay); } Important: The sketch above was written in that form to account for the still limited knowledge of the programming language for Arduino, but by using arrays the code can be greatly simplified: /* Be Maker School - STEM - Project 11 - Cylon array version */ int delay1=100; int delay2=1; int myLED[] = {3,5,6,9,10}; int count=0; void setup() { //configure output PWM PINs with for loop for (count=0; count<6; count++) { pinMode(myLED[count], OUTPUT); } } void loop() { for (count=0; count<5; count++) { analogWrite(myLED[count], 255); if (count>0) { for (int i = 255; i >= 0; i--) { analogWrite(myLED[count-1], i); delay(delay2); } } delay(delay1); } for (count=4; count>0; count--) { if (count>0) { analogWrite(myLED[count-1], 255); } for (int i = 255; i >= 0; i--) { analogWrite(myLED[count], i); delay(delay2); } delay(delay1); } } Load the sketch and you get a nice effect of a peering robotic eye, especially if you cut out the cardboard and create the slit in which to insert the LEDs.... The famous KITT car from Supercar also had a similar effect... Analysis of the Sketch: Return of the Cylons Not considering the second transcribed sketch because the topics covered will be seen later, from the first sketch we can observe that the only new topic introduced is the for loop. The for loop is used when we need, within the body of the program , to have repetitive operations performed a certain number of times. In fact in this case it was using to drive the LED shutdown in a gradual way using the variable i that starting from the maximum value of 255, at each cycle it would decrease and the LED light intensity accordingly also. The syntax for the for loop is: for (initialization; condition; increment) { // statement(s); } In our sketch it was using for example: for (int i = 255; i >= 0; i--) { analogWrite(10, i); delay(delay2); } The integer variable "i" starts at a value of 255 and decrements down to zero; as long as this condition is true, the for loop repeats and in particular performs what is between the curly brackets, that is, it goes to write into the PWM digital PIN a value equal to the variable i (which is decreasing) and then goes to gradually turn off the LED connected to PIN 10. [For the video related to the project click here]. [For the sketch related to the NORMAL project click here]. [For the sketch related to the CON ARRAY project click here]. (print and cut out) LESSON 4 - THE RGB LEDS We saw in Lesson No. 1 that the LED is made of a special semiconductor material that when a current is passed through it emits light. It is called a semiconductor because it conducts and therefore emits light only if the voltage is applied properly, that is, the anode (the longer terminal) must be connected to the positive voltage, while the cathode (the shorter terminal) is connected to ground. The semiconductor part occupies less than a millimeter, so what we see is the outer part of the lens that scatters the light. We have seen that LEDs can be of different colors, the RGB LED is basically composed of three LEDs, so it emits three different wavelengths of light, one red, one green and one blue (hence the acronym RGB: Red, Green and Blue). The emission of light with a different wave frequency depends on the type of substance used as a semiconductor in the LED. The table above shows, depending on the color of the LED, the substances used, the wavelength and also the threshold voltage, which also represents the maximum voltage that can be applied to the LED otherwise the LED will be ruined or may even burn out. For this reason, as mentioned in Be Maker Module 01, the LED should be protected, and thanks to the table above we can also calculate what is the most appropriate resistor value to use. In fact, it can be seen that the threshold voltage is generally, for various LEDs, about 2 V. Considering that the maximum current for an LED is about 15 mA, or 0.015 A, applying Ohm's Law: Once the value is calculated, we need to take the "commercial" resistance value closest to the calculated value. Commercial values are the standard resistance values that we can find commercially, which are summarized (the main ones) in the table below: The RGB LED can look different: as a regular 5-mm LED with four terminals, or in strips of the SMD type (with four wires), or even mounted on a board (RGB module) with four PINs. The three main colors mixed together, in different intensities, produce virtually infinite color combinations: There are two types of RGB LEDs, one is with COMMON CATODE (common negative that is connected to GND) and the other is with COMMON ANODE (common positive and then connects to 5V). In the common anode (+) type, there will be three negative terminals each representing the single color of light emitted; in the common cathode (-) type, there will be the three positive terminals and each representing the single color of light. In series with each LED (and thus each terminal excluding the common anode or common cathode) a resistor is inserted that will allow the current circulating in the diode to be regulated, so three 220 Ohm resistors will be needed (red, red, brown circles). The internal circuit of an RGB LED can be represented as below. Instead, the wiring diagram with the three protective resistors is: Project 12 - RGB LEDs with Arduino For this project we need: Arduino Uno R3 or compatible Breadboard No. 3 Resistors 220 Ohm LED RGB The wiring diagram is: Dupont male male cables USB connection cable The diagram below should be followed for assembly: Once the circuit is assembled, the sketch to be written and uploaded to Arduino is: /* Be Maker - STEM - Project 12 - LED RGB */ int redpin = 11; // we assign the name redpin the value 11 int bluepin =10; // we assign the name bluepin the value 10 int greenpin =9; // let's assign the name greenpin the value 9 int val; void setup() { pinMode(redpin, OUTPUT); // we set in OUTPUT the 11 pinMode(bluepin, OUTPUT); // we set in OUTPUT the 10 pinMode(greenpin, OUTPUT); // we set in OUTPUT the 9 Serial.begin(9600); } void loop() { for(val=255; val>0; val--) { analogWrite(11, val); analogWrite(10, 255-val); analogWrite(9, 128-val); delay(10); } for(val=0; val<255; val++) { analogWrite(11, val); analogWrite(10, 255-val); analogWrite(9, 128-val); delay(10); } Serial.println(val, DEC); } Once the sketch is loaded on the Arduino and the serial monitor is opened, the RGB LED shows the RGB color combinations according to the values represented on the monitor. [For the video related to the project click here]. [For the sketch related to the project click here]. CURIOSITY: Stars shine and change color. Stars "shine" and change color because it is a phenomenon that depends on the fact that starlight, before reaching your eyes, must pass through the atmosphere. The atmosphere is made up of many small cells of air. Each cellette moves in random motion, rising or falling due to thermal convection: this is called atmospheric turbulence. When the star's light passes through these air cells, the path of its rays is randomly deflected, which causes you to see the star apparently blink and sometimes change color. The lower the star is on the horizon or the brighter it is, the more intense the phenomenon. Of course, if we were observing the starry sky from the Moon, since there is no atmosphere on the Moon, this optical phenomenon would not be there. . Project 13 - Starlight For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables USB connection cable No. 3 Resistors 220 Ohm LED RGB Button Resistance 1kOhm Potentiometer 1 KOhm The wiring diagram is: The diagram below should be followed for assembly: After the connections we move on to writing the sketch. Connect Arduino to the PC via the USB cable and launch the Arduino IDE application by double-clicking on its icon. A blank window opens, or a new blank window needs to be opened and we write the sketch below: /* Be Maker School - STEM - Project 13 - Starlight */ int redRGB = 11; //select the pin for the red LED of RGB int bluRGB =9; // select the pin for the blue LED of RGB int greenRGB =10; // select the pin for the green LED of RGB int pinBut=4; // select pin for digital input from button int val; //variable intensity for the color of RGB int color; //1=red, 2=blue, 3=green int pushbutton; //variable that tells me if button pressed void setup() { Serial.begin(9600); pinMode(redRGB, OUTPUT); pinMode(bluRGB, OUTPUT); pinMode(greenRGB, OUTPUT); pinMode(pinBut, INPUT_PULLUP); color=1; analogWrite(redRGB, 255); analogWrite(bluRGB, 255); analogWrite(greenRGB, 255); } void loop(){ pushbutton=digitalRead(pinBut); if(pushbutton==0){ color=color; } else { color++; if (color>3){ color=1; } } intensity_color(color); } void intensity_color(int state){ val = analogRead(A0); val = map(val,0,1023,0,255); switch (status) { case 1: Serial.print("Color Red "); analogWrite(redRGB, val); break; case 2: Serial.print("Blue Color "); analogWrite(bluRGB, val); break; case 3: Serial.print("Green Color "); analogWrite(greenRGB, val); break; } Serial.print("- Intensity'= "); Serial.println(val); delay(200); } Once you have written the code launch the verification precompilation (click on the check mark), it will ask you to save the sketch (you can change its name) and then click on the arrow for loading and the lens for the Serial Monitor: /* Be Maker - STEM - Project 13 - Starlight */ int redRGB = 11; //select the pin for the red LED of RGB int bluRGB =9; // select the pin for the blue LED of RGB int greenRGB =10; // select the pin for the green LED of RGB int pinBut=4; // select pin for digital input from button int val; //variable intensity for RGB color int color; //1=red, 2=blue, 3=green int pushbutton; //variable that tells me if button pressed void setup() { Serial.begin(9600); pinMode(redRGB, OUTPUT); pinMode(bluRGB, OUTPUT); pinMode(greenRGB, OUTPUT); pinMode(pinBut, INPUT_PULLUP); color=1; analogWrite(redRGB, 255); analogWrite(bluRGB, 255); analogWrite(greenRGB, 255); } void loop(){ pushbutton=digitalRead(pinBut); if(pushbutton==0){ color=color; } else { color++; if (color>3){ color=1; } } intensity_color(color); } void intensity_color(int state){ val = analogRead(A0); val = map(val,0,1023,0,255); switch (status) { case 1: Serial.print("Color Red "); analogWrite(redRGB, val); break; case 2: Serial.print("Blue Color "); analogWrite(bluRGB, val); break; case 3: Serial.print("Green Color "); analogWrite(greenRGB, val); break; } Serial.print("- Intensity'= "); Serial.println(val); delay(200); } Once you start the sketch and open the serial monitor, you can see on the screen which color of the RGB LED is active and its intensity value, at which point acting on the potentiometer will change the color of the RGB LED because you are changing the intensity of the active color. To change the active color and thus the color to be changed, you can press the button, again on the screen you will be shown the new active color and so on. In this way you can mix the three RGB colors at will and get the desired color by simulating the color change of the stars. Analysis of the sketch: Starlight There are so many new and interesting things to learn in this sketch, let's start with the simplest one: a) Use of "INPUT_PULLUP"; as you can see in the void setup, the digital input pin that controls whether or not the button has been pressed has been set as INPUT_PULLUP. This statement allows Arduino to set itself up to receive an unstable signal such as that from pressing a button. Then Arduino will attempt to stabilize the input signal. b) Use of the control structure switch(...) ..... case ... ; in one of the previous projects we had seen the use of the "nested" if structure, but I had also said that this way of making the processor make decisions, was not very suggested especially when there are so many cases to examine. The use of the switch...case... simplifies the structure, in fact we only need to define for each individual case what to do and then have the switch function do the case selection directly.. The general syntax of the control structure is: switch (var) { case label1: // statements break; case label2: // statements break; default: // statements break; } Where var is a variable of type int or char and indicates the number of the "case" you want to process, and label1 is the label, also a variable of type int or char. In the syntax example there are only three cases of which one is the default. The last case, the default case is selected when you have none of the previous cases. The structure can also have more cases than those represented. c) Use of calling an external "procedure"; in the sketch you can see that in the void seup, in the final part, there is: " intensity_color(color); " so we are going to call an external procedure to the void setup that performs a particular process. As you can see the external procedure was defined with the "void" also since in the procedure there is the control structure switch...case... to the same procedure, through its call, we are also passing it a parameter (put in round brackets) that it will use in its process. In fact, the procedure is called by putting procedure_name(eventual_parameter); , the definition of the procedure is: void process_name(int eventual_parameter) { process} [For the video related to the project click here]. [For the sketch related to the project click here]. Project 14 - Starlight 2 This project is the natural continuation of the previous one, in fact with this project I wish to visually highlight, instead of reporting it on the serial monitor, what color we are acting on with the potentiometer adjustment. And this can be done by integrating three LEDs with their protective resistors to the previous project. For this project, therefore, we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables USB connection cable No. 6 Resistors 220 Ohm LED RGB Button Resistance 1kOhm Potentiometer 1 KOhm Blue LED Red LED Green LED The wiring diagram is: The diagram below should be followed for assembly: After the connections we move on to writing the sketch. Connect Arduino to the PC via the USB cable and launch the Arduino IDE application by double-clicking on its icon. A blank window opens, or a new blank window needs to be opened and we write the sketch below: /* Be Maker - STEM - Project 14 - STARLIGHT_2 */ int redRGB = 11; //select the pin for the red LED of RGB int bluRGB =9; // select the pin for the blue LED of RGB int greenRGB =10; // select the pin for the green LED of RGB int redLED = 7; //select the pin for the red LED int bluLED =5; // select the pin for the blue LED int greenLED =6; // select the pin for the green LED int pinBut=4; // select pin for digital input from button int val; //variable intensity for RGB color int color; //0=red, 1=blue, 2=green int pushbutton; //variable that tells me if button pressed void setup() { Serial.begin(9600); pinMode(redRGB, OUTPUT); pinMode(bluRGB, OUTPUT); pinMode(greenRGB, OUTPUT); pinMode(redLED, OUTPUT); pinMode(bluLED, OUTPUT); pinMode(greenLED, OUTPUT); pinMode(pinBut, INPUT_PULLUP); color=1; analogWrite(redRGB, 255); analogWrite(bluRGB, 255); analogWrite(greenRGB, 255); } void loop(){ pushbutton=digitalRead(pinBut); if(pushbutton==0){ color=color; } else { color++; if (color>3){ color=1; } } choice_color(color); intensity_color(color); delay(200); } void choice_color(int state){ Serial.print(" status="); Serial.print(state); switch (status) { case 1: digitalWrite(redLED, HIGH); digitalWrite(bluLED, LOW); digitalWrite(greenLED, LOW); break; case 2: digitalWrite(redLED, LOW); digitalWrite(bluLED, HIGH); digitalWrite(greenLED, LOW); break; case 3: digitalWrite(redLED, LOW); digitalWrite(bluLED, LOW); digitalWrite(greenLED, HIGH); break; } } void intensity_color(int state){ val = analogRead(A0); val = map(val,0,1023,0,255); Serial.print(" intensity="); Serial.println(val); switch (status) { case 1: analogWrite(redRGB, val); break; case 2: analogWrite(bluRGB, val); break; case 3: analogWrite(greenRGB, val); break; } } Once the sketch is started, in addition to the RGB LED turning on, the LED whose intensity can be changed via the potentiometer will also turn on. By pressing on the button you can change the modifiable active color and this will be represented by the corresponding colored LED. [For the video related to the project click here]. [For the sketch related to the project click here]. The Tilt Sensor or also called the Ball Tilt Sensor. This sensor can be found commercially as a simple sensor or even as a pre-assembled module. The operating principle is the same, and it is basically a digital signal that tells us whether the sensor has tripped or not. The working principle is represented by the animated GIF image I made: inside an involocro there are two end plates and a metal ball, when the casing, which has the cylindrical shape is moved, the ball touches the two end plates and closes the electrical contact between the terminals. Basically, it behaves like a button, except that the contact closure occurs because the ball rolls inside the cylinder. By appropriately positioning the terminals and sizing the enclosure, it is also possible to choose with what minimum degree of tilt the ball contacts the two terminals. In the following project we see an application of this and how to connect it to Arduino. Project 15 - Making an Electronic Hourglass. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables USB connection cable No.6 220Ohm Resistors No. 3 Red LEDs Tilt sensor Resistance 1kOhm No. 3 Yellow LEDs The wiring diagram is: While the assembly diagram is: Be careful when positioning the tilt sensor, it should be positioned so that in the initial position it causes contact and by rotating it 180° it does not, otherwise the desired effect will not be achieved. Now we double-click on the Arduino icon on the Desktop and the IDE opens and we copy the following sketch, be sure to follow each step indicated: /* Be Maker - STEM - Project 15 - Electronic Hourglass */ const byte SWITCH_PIN = 7; // digital PIN for reading the tilt sensor byte switch_state = 0; void setup(){ //using the for loop set PINs in Output for(int i=8;i<14;i++){ pinMode(i, OUTPUT); } pinMode(SWITCH_PIN, INPUT_PULLUP); for(int i=8;i<11;i++){ digitalWrite(i,0); } for(int i=11;i<14;i++){ digitalWrite(i,1); } Serial.begin(9600); } void loop() { switch_state = digitalRead(SWITCH_PIN); Serial.println(switch_state); if (switch_state == 0){ delay(1000); //after one sec. digitalWrite(13,0); digitalWrite(8,1); delay(1000); digitalWrite(12,0); digitalWrite(9,1); delay(1000); digitalWrite(11,0); digitalWrite(10,1); } if (switch_state == 1){ delay(1000); digitalWrite(8,0); digitalWrite(13,1); delay(1000); digitalWrite(9,0); digitalWrite(12,1); delay(1000); digitalWrite(10,0); digitalWrite(11,1); } } Once the sketch is loaded, Arduino will check the status of the Tilt Sensor, and will appropriately orient the "sand in the hourglass," that is, it will turn on the appropriate LEDs, of course once this step is completed, that is, the LEDs are all on one side, then to restart the hourglass, it will be necessary to flip the tilt sensor to start the hourglass in reverse. Analysis of the Sketch: The Electronic Hourglass As can be seen from the sketch, a "for" loop is used in the setup part to set the PINs to which the LEDs are connected , of course they are all set in OUTPU because they generate a signal that can be either high state (LED on) or low state (LED off). The PIN to which the Tilt Sensor is connected is set as INPU_PULLUP to prepare Arduino to better stabilize the signal coming to it on that PIN. The delay instruction, which in its classical syntax is : delay (milliseconds); is used to scan time and thus to simulate sand falling from the hourglass. In fact, as you can see from the sketch , in the design it is set for a time equal to one second (i.e., 1,000 milliseconds), the time it takes for an LED at the top of the hourglass to turn off and for it to turn on at the bottom (transfer of sand from top to bottom). [For the video related to the project click here]. [For the sketch related to the project click here]. (print and cut out) LESSON 5 - THE SOUND We devote this Lesson to the study of Sound, or rather the generation and propagation of sound waves and the related Arduino sensors and modules that exploit this phenomenon to handle events. CURIOSITY: What is sound? Suppose you drop a stone into the water of a pond, you will see that waves expand from the point where the stone falls, these waves move away from the point of fall and propagate in concentric circles. If we make a body vibrate, these vibrations of the body are transferred to what surrounds the body (e.g.: air, water, etc. ) and this phenomenon occurs due to the expansion/compression action of the molecules of the air or water in which the body that is vibrating is immersed. This results in the generation of sound. The sound produced by the vibration of a body propagates through waves, and to give visibility to this phenomenon, we gave the example of a stone dropped into the water of a pond. Instead, in the animated image above, the compression/expansion phenomenon is shown with the example of a foil vibrating in the air; the light blue-colored arrows indicate the air sucked into the area of depression created by the movement of the foil. The blue-colored arrows, on the other hand, indicate the overpressure created by the same movement in the opposite direction. The vibration, then, compresses and expands the air surrounding the body; this compression and expansion is transmitted to the surrounding air, thus producing waves called "sound waves" (sound: because at certain frequencies, to simplify--at a certain speed of vibration, such waves can also be heard). In fact, these vibrations are then picked up by the ear, which inside the ear, thanks to the presence of the "eardrum" and due to the presence of "ossicles," transfer and transform the vibrations picked up into electrical impulses that our brain translates into a sensation called sound. So sound is a sensation that we receive and comes from a vibration of a body. If such sensation is pleasant, then we call it "sound," otherwise it is classified as "noise." Very important in the propagation of sound is the medium in which it propagates, which also determines its speed. In water, the In air, because In iron, the speed is 1480 m/s. That is, in one second the sound wave travels about 1.5 km. the molecules are more rarefied (they are farther apart) the speed of sound propagation is about 340 m/s, that is, in one second sound travels 340 m. propagation speed is 5130 m/s, that is, in one second sound travels about 5 km. This is because the crystallines are much closer together and therefore the transmission of vibration induced by the action of compression/expansi on is more immediate. Is it in a vacuum? Obviously in a vacuum, since there is no compression/expansion of molecules, no sound is propagated. The sound wave in its path may encounter an obstacle, usually a "denser" body. For example, a sound wave that is propagating in the air, when it encounters a rock wall, reflects off it and a "reflected wave" is generated and some of the sound is also reproduced in the rock. When the reflected wave returns in the same direction as the source, the phenomenon we call "echo" occurs. Frequency, which is measured in Hz (pronounced erz), which is the closeness between the sound waves produced (or rather: the number of sound waves transmitted in one second), classifies sound into: low sounds (what we call "bass") or high sounds (what we call "treble"). Only certain frequencies of sound are audible to the human ear, those that have a frequency between 20 Hz and 20,000 Hz (or even written 20 kHz). Elephants can perceive sounds even below 20 Hz, while bats can perceive sounds as low as 120 kHz. After the theoretical part, which gave us a better understanding of sound, we move on to the practical part with a nice project, which was a lot of fun. Project 16 - The Teresa wasp and the active buzzer. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables USB connection cable Buzzer active Print drawing Before moving on to circuit assembly, it is good to know that the active buzzer has two PINs, one of which is longer. The longer one is the positive PIN " + " , the shorter one is the negative " - ". Generally, the passive buzzer also has a sticker where the positive PIN is indicated. The electrical symbol of the active buzzer is: The wiring diagram to be made is as follows: The assembly scheme to be carried out is as follows: Note: The positive PIN of the active buzzer is connected to digital PIN 8 of the Arduino, and the negative PIN to GND. Once the circuit is assembled (and the design placed on the buzzer), the sketch to be written and uploaded to Arduino is: /* BE MAKER - STEM - Project No. 16 - Vespa Teresa */ int buzzerPin = 8; //I assign PIN 8 the positive PIN of the buzzer void setup () { pinMode (buzzerPin, OUTPUT); //declare in OUTPUT the PIN 8 } void loop () { digitalWrite(buzzerPin, HIGH); //enable PIN 8 to 5 V delay (500); //leaving PIN 8 powered for half a second digitalWrite(buzzerPin, LOW); ///put out PIN 8 delay (500); //I leave PIN 8 off for half a second } When the sketch is loaded, the buzzer will sound intermittently; you can change the on/off time of the buzzer by going to the time indicated in the delay of the sketch. [For the video related to the project click here]. [For the sketch related to the project click here]. The Passive Buzzer The Buzzer is a piezoelectric device. Piezoelectricity is the property of certain crystalline materials to polarize by generating a potential difference when subjected to mechanical deformation and at the same time to deform elastically when subjected to an electrical voltage. The GIF above shows how a Deformation of the piezoelectric material generates a Voltage The GIF above shows how a Voltage applied to the piezoelectric generates a Deformation Buzzers can be active, if they have within them an oscillator (a quartz with a predetermined and fixed frequency) that when energized with electrical voltage stresses the piezoelectric material at a certain frequency and then, this vibration of the piezoelectric material (usually a membrane), produces sound at a fixed frequency (this is the so-called Monotone Sound). Passive Buzzers, not having an oscillator, need a timevarying supply voltage in order to produce sound. So the variable voltage with a given frequency is given from the outside. To do this, we can take advantage of our Arduino's ability to produce a time-varying voltage through PWM (Pulse Width Modulation), i.e., a Pulse Width Modulated Voltage. But at this point the question arises, what if we vary the frequency? You will get different sounds and at certain frequencies, you can even reproduce musical notes. So, the conclusion is that with an Arduino and a passive Buzzer we can play melodies . The buzzer is used in alarms, countdowns, keyboard input confirmation, etc. The passive buzzer is the one shown in the photo below: In the table is the correspondence between the main notes and the frequency. Project 17 - The passive buzzer and the Piano-Man. For this project we need: Arduino Uno R3 or compatible Breadboard Passive buzzer 220 Ohm resistor Dupont male male cables USB connection cable Before moving on to the assembly of the circuit, it is good to know that the passive buzzer has a low resistance, which is why it is used to put a 220 Ohm resistor in series with the passive buzzer.In addition, since we will be feeding the buzzer with a "square half-wave," in order to have a cleaner emitted sound, it would be useful to couple a filter (basically a capacitor) to the buzzer.But these aspects, concerning applied electronics, we will see in a dedicated course.For the moment, let us just insert a resistor and for our teaching purposes. The electrical symbol of the passive buzzer is: The wiring diagram to be made is as follows: The assembly scheme to be carried out is as follows: Once the circuit is assembled, the sketch to be written and uploaded to Arduino is: /* Be Maker STEM - Project 17 Plan_Man Passive Buzzer */ #define BUZZER_PIN 9 //we connect to PIN 9 the Buzzer #define NOTE_C5 523 #define NOTE_D5 587 #define NOTE_E5 659 #define NOTE_F5 698 #define NOTE_G5 784 #define NOTE_A5 880 #define NOTE_B5 988 #define NOTE_C6 1047 //She builds a vector (variable containing multiple values) with the Notes: unsigned int melody[] = { NOTE_C5, NOTE_D5, NOTE_E5, NOTE_F5, NOTE_G5, NOTE_A5, NOTE_B5, NOTE_C6}; unsigned int duration = 500; //Duration of the note in milliseconds void setup() { pinMode(BUZZER_PIN, OUTPUT); //Let's output PIN 9 } void loop() { for (int thisNote = 0; thisNote < 8; thisNote++) { tone(BUZZER_PIN, melody[thisNote], duration); //see more delay(1000);//It changes note after one second } delay(2000);//After two seconds the cycle starts again } When the sketch is loaded, the buzzer will play a melody formed by the scale of Notes. Analysis of the Project 17 sketch The passive buzzer and the PianoMan. In the sketch, it can be seen that to activate the passive buzzer, the instruction to be given is "tone" with the following syntax: tone (num_pin, frequency_note, duration_note); With this instruction, a PWM signal is generated with specified frequency and holding the same frequency equal to the value also specified. While for active Buzzer activation it was sufficient to put the Buzzer PIN in the high state with a simple instruction of digitalWrite (buzzerPin, HIGH); And to turn it off, of course: digitalWrite (buzzerPin, LOW); Another thing I would like to point out is the definition of the vector, that is, that particular variable we have called "melody," which as you can observe contains multiple values. The individual values are placed in an orderly fashion from position 0 to position "n-1." They can be called by writing in the sketch the name of the variable and inside the square brackets, the position of the value we wish to read: melody [thisNote] [For the video related to the project click here]. [For the sketch related to the project click here]. It is possible to experiment with new melodies and practice with the Tone instruction, using the examples in the IDE. To open them: You can also try this tune I found on the Internet (just copypaste): /* Be Maker STEM - Project 17a_Buzzer Passive */ #define NOTE_B0 31 #define NOTES_C1 33 #define NOTES_CS1 35 #define NOTE_D1 37 #define NOTE_DS1 39 #define NOTE_E1 41 #define NOTE_F1 44 #define NOTE_FS1 46 #define NOTE_G1 49 #define NOTE_GS1 52 #define NOTE_A1 55 #define NOTE_AS1 58 #define NOTES_B1 62 #define NOTE_C2 65 #define NOTE_CS2 69 #define NOTE_D2 73 #define NOTE_DS2 78 #define NOTE_E2 82 #define NOTE_F2 87 #define NOTE_FS2 93 #define NOTE_G2 98 #define NOTE_GS2 104 #define NOTE_A2 110 #define NOTE_AS2 117 #define NOTE_B2 123 #define NOTE_C3 131 #define NOTE_CS3 139 #define NOTE_D3 147 #define NOTE_DS3 156 #define NOTE_E3 165 #define NOTE_F3 175 #define NOTE_FS3 185 #define NOTE_G3 196 #define NOTE_GS3 208 #define NOTE_A3 220 #define NOTE_AS3 233 #define NOTES_B3 247 #define NOTES_C4 262 #define NOTES_CS4 277 #define NOTE_D4 294 #define NOTE_DS4 311 #define NOTE_E4 330 #define NOTE_F4 349 #define NOTE_FS4 370 #define NOTE_G4 392 #define NOTE_GS4 415 #define NOTE_A4 440 #define NOTE_AS4 466 #define NOTES_B4 494 #define NOTE_C5 523 #define NOTES_CS5 554 #define NOTE_D5 587 #define NOTE_DS5 622 #define NOTE_E5 659 #define NOTE_F5 698 #define NOTE_FS5 740 #define NOTE_G5 784 #define NOTE_GS5 831 #define NOTE_A5 880 #define NOTE_AS5 932 #define NOTE_B5 988 #define NOTE_C6 1047 #define NOTE_CS6 1109 #define NOTE_D6 1175 #define NOTE_DS6 1245 #define NOTE_E6 1319 #define NOTE_F6 1397 #define NOTE_FS6 1480 #define NOTE_G6 1568 #define NOTE_GS6 1661 #define NOTE_A6 1760 #define NOTE_AS6 1865 #define NOTE_B6 1976 #define NOTE_C7 2093 #define NOTE_CS7 2217 #define NOTE_D7 2349 #define NOTE_DS7 2489 #define NOTE_E7 2637 #define NOTE_F7 2794 #define NOTE_FS7 2960 #define NOTE_G7 3136 #define NOTE_GS7 3322 #define NOTE_A7 3520 #define NOTE_AS7 3729 #define NOTE_B7 3951 #define NOTE_C8 4186 #define NOTE_CS8 4435 #define NOTE_D8 4699 #define NOTE_DS8 4978 #define REST 0 int tempo=114; // change this to make the song slower or faster int buzzer = 9;// change this to whichever pin you want to use // notes of the moledy followed by the duration. // a 4 means a quarter note, 8 an eighteenth , 16 sixteenth, so on // !!negative numbers are used to represent dotted notes, // so -4 means a dotted quarter note, that is, a quarter Plus an eighteenth!!! int melody[] = { NOTE_E4,4, NOTE_E4,4, NOTE_F4,4, NOTE_G4,4,//1 NOTE_G4,4, NOTE_F4,4, NOTE_E4,4, NOTE_D4,4, NOTE_C4,4, NOTE_C4,4, NOTE_D4,4, NOTE_E4,4, NOTE_E4,-4, NOTE_D4,8, NOTE_D4,2, NOTE_E4,4, NOTE_E4,4, NOTE_F4,4, NOTE_G4,4,//4 NOTE_G4,4, NOTE_F4,4, NOTE_E4,4, NOTE_D4,4, NOTE_C4,4, NOTE_C4,4, NOTE_D4,4, NOTE_E4,4, NOTE_D4,-4, NOTE_C4,8, NOTE_C4,2, NOTE_D4,4, NOTE_D4,4, NOTE_E4,4, NOTE_C4,4,//8 NOTE_D4,4, NOTE_E4,8, NOTE_F4,8, NOTE_E4,4, NOTE_C4,4, NOTE_D4,4, NOTE_E4,8, NOTE_F4,8, NOTE_E4,4, NOTE_D4,4, NOTE_C4,4, NOTE_D4,4, NOTE_G3,2, NOTE_E4,4, NOTE_E4,4, NOTE_F4,4, NOTE_G4,4,//12 NOTE_G4,4, NOTE_F4,4, NOTE_E4,4, NOTE_D4,4, NOTE_C4,4, NOTE_C4,4, NOTE_D4,4, NOTE_E4,4, NOTE_D4,-4, NOTE_C4,8, NOTE_C4,2 }; // sizeof gives the number of bytes, each int value is composed of two bytes (16 bits) // there are two values per note (pitch and duration), so for each note there are four bytes int notes=sizeof(melody)/sizeof(melody[0])/2; // this calculates the duration of a whole note in ms (60s/time)*4 beats int wholenote = (60000 * 4) / time; int divider = 0, noteDuration = 0; void setup() { // iterate over the notes of the melody. // Remember, the array is twice the number of notes (notes + durations) for (int thisNote = 0; thisNote < notes * 2; thisNote = thisNote + 2) { // calculates the duration of each note divider = melody[thisNote + 1]; if (divider > 0) { noteDuration = (wholenote) / divider; // regular note, just proceed } else if (divider < 0) { // dotted notes are represented with negative durations!!! noteDuration = (wholenote) / abs(divider); noteDuration *= 1.5; // increases the duration in half for dotted notes } // we only play the note for 90% of the duration, leaving 10% as a pause tone(buzzer, melody[thisNote], noteDuration*0.9); // Wait for the specief duration before playing the next note. delay(noteDuration); noTone(buzzer); // stop the waveform generation before the next note. } } void loop() { // if you want to repeat the song forever, paste the setup code here . } [For the sketch related to the MELODIA project click here] CURIOSITY: The Microphone and the Loudspeaker or Acoustic Speaker. At this point, with the knowledge we have gained about Sound and Piezoelectric materials, we are able to understand quite well how the microphone works. The microphone is nothing more than a "Transducer" of the pressure that sound waves exert on a membrane, into electrical impulses. This "transduction" (or more simply, this translation of a vibration into a sequence of electrical impulses) takes place with the help of a special material called piezoelectric. In fact, the piezoelectric material as we have seen is capable of producing a voltage when it is stressed to a compression or expansion, that is, when it undergoes a deformation. In the loudspeaker there is basically the reverse process to the microphone, that is, the electrical impulse, suitably amplified, activates an electromagnet that attracts to itself a permanent magnet attached to a taut membrane. In this way, the movement of the magnet generates the vibrations of the membrane and thus reproduces sound waves with the same frequency induced by the movement of the magnets. So with the use of microphones and speakers we are able to equip our Robot with hearing and speech. Project 18 - What happens in that house? Let's use the microphone. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables Microphone module 220 Ohm resistor Led of any color USB connection cable Before moving on to the assembly of the circuit, it is good to know more about the Sound Sensor Module or microphone that we will be using for educational purposes, in fact, there are different types of Sound Sensor Modules on the market, from the more sophisticated ones that also have an amplification circuit and very sensitive microphones, and those that are purely for educational purposes, less sensitive but equally functional. However, the operation is basically the same. We will use the Sensor Modules that are commercially found with the abbreviation KY-037 and with the abbreviation KY038 which is the older brother (slightly more sensitive), these in turn can have 4 PINs because they make both a digital and analog output signal available, those with 3 PINs make only the digital signal available. In addition they may have one or two LEDs, at least one LED is used to verify the correct sensitivity setting, while the second one, precisely not always present, indicates the power supply to the Module. Finally, these Modules always have a trimmer (i.e., a small potentiometer) that by adjusting it using a screwdriver, it is possible to establish the threshold sensitivity that the microphone must have in order to make the digital signal available in the output state of LOW or HIGH at the relevant PIN indicated by D0 or by OUT (in the case of a 3-PIN Module). At this point we turn to the wiring diagram: (Note: Use the digital PIN of the D0 Sound Sensor Module or also indicated with OUT for the 3 PIN Module). The mounting diagram is instead: After the connections we move on to writing the sketch. Connect Arduino to the PC via the USB cable and launch the Arduino IDE application by double-clicking on its icon. A blank window opens, or a new blank window needs to be opened and we write the sketch below: /* Be Maker STEM - Project 18-Sensor_Digital_Room. */ int digitalPin = 9; //PIN digital signal of Sound Sensor Module int digitalValue = 0; // Variable that retains the value 0 or 1 if it exceeds the threshold //Takes sensor calibration to create threshold value. int ledPIN= 3; // PIN to which the LED is connected void setup () { pinMode (digitalPin, INPUT); //We set PIN 9 as the INPUT pinMode (ledPIN, OUTPUT); //We set PIN 3 as the OUTPUT Serial.begin (9600); //We set the serial communication port. } void loop () { digitalValue = digitalRead(digitalPin); //read the value at PIN 9 if (digitalValue > 0) { digitalWrite (ledPIN, HIGH); delay(3000); //keeps the LED active for 3 sec. } else { digitalWrite (ledPIN, LOW); } } Warning: once the sketch is loaded on Arduino, the sensor module must be calibrated according to the background noise present in your environment. So if the LED connected to PIN 3 remains on, it means that the background noise is exceeding the calibration threshold, turn the screw present on the module's trimmer, using a flathead screwdriver, until the LED goes off. Conversely, in case the LED is off even with loud noise, adjust until it turns on. Position the screw just at the limit so that the LED is off and turns on at the slightest noise slightly louder than in the environment. [For the video related to the project click here]. [For the sketch related to the project click here]. LESSON 6 - THE ULTRASOUNDS In the previous Lesson we saw what sound is and how it is generated, a vibrating body produces sound waves, the vibration, that is, the oscillation in time of the body, establishes what is called frequency. So Frequency can be defined as the number of complete oscillations of the body in the unit of time (which is the second and is denoted by "s"). The unit of measurement of frequency is the Hertz (Hz). Sounds that have frequencies above 20,000 Hz, or 20 kHz, are called "ultrasounds," and these sounds are used in electronics in so many applications, such as in detecting the distance of a body from the sound source. To best understand the principle used in distance detection using an ultrasonic signal, it is necessary to learn some Physics. Curiosity: what is Speed? The speed of an object is the distance traveled by that same object in the unit of time. So the speed of a sound wave is the distance (which is measured in meters) traveled by that same sound wave, in the unit of time (expressed in seconds, "s"). Of course, there are also multiples and submultiples of the meter and the second. Did you know that a hare runs at an average speed of about 60 kilometers per hour (km/h), that is, in one hour the hare covers a distance of 60 km. A Sound Wave travels through the air at a speed of 343 m per second (m/s), or 0.0343 cm per microsecond (cm/☐s). HC-SR04 Ultrasonic Module. Obstacle Distance Detection The ultrasonic module that we will use in our projects is the HC-SR04. The HC-SR04 is a very convenient distance sensing sensor that is mainly used for object avoidance in various robotics projects. In early cars with parking sensors, it was also used in detecting obstacles when parking and even to detect the water level. The HC-SR04 ultrasonic sensor uses an ultrasonic generator to determine the distance to an object as bats do. It is a module that offers excellent non-contact detection with high accuracy, and readings are stable. Operation is not affected by sunlight or black objects as is the case with laser detectors. It is presented to consist of a base plate (which can be blue, but I have also seen some in yellow, red, or orange), two cylinders, which look like two eyes, an oscillator that seems to give the two eyes a mono-eyelash, and four PINs that look like a mustache...in fact, this module is often used in a position that looks like a head.... For example in robot cars... The two cylinders are for: emitting the ultrasonic signal (cylinder indicated by "T") and receiving the signal (cylinder indicated by "R"). For the 4 pins: to one you connect the 5V power supply (Vcc) directly from Arduino, then there is the ground (GND) pin and then the two pins "Trig" and "Echo" which should be connected to two analog or even digital pins of Arduino. One pin is for sending the sound pulse and the other is for detecting the time the signal is received. To explain how the module works I have to go back to the previous physics lesson, but it is also useful for school....so read it... The operating principle of the Ultrasonic Module is simple: the module emits an ultrasonic signal and calculates the travel time (in microseconds) between the instant of emission and the instant of reception after the same signal bounces off the obstacle. Once the time is measured, the distance traveled by the signal is calculated accordingly. In fact, for example, if the travel time of the sound wave in going to the obstacle and then returning once it has bounced off the obstacle itself was 300 microseconds, by making the necessary equivalences, we have that the distance traveled by the outward and return signal is: distance (in centimeters) = 0.0343 x time (in microseconds) or 0.0343 x 300 = 10 cm Since the time is the "going" and "returning" time, obviously the distance of the obstacle is half, so it is 5 cm. Let us see with a graphic representation what has been explained: The emitter Tx sends the ultrasonic pulse, the receiver Rx receives the pulse bounced off the obstacle. The module calculates the elapsed time between the outward and return, so the distance the signal travels is twice the distance there is between the module and the obstacle, which is why in the calculation to determine the distance value of the obstacle must be divided by two. So the "algorithm" to be used to determine the distance is: Obstacle distance (in centimeters) = [0.0343 x t (in microseconds)]: 2 After the theoretical part, we then move on to our project. Project 19 - Detect the distance to an obstacle. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables HC-SR04 The wiring diagram for connection is: USB connection cable While the assembly diagram is: Trig and Echo are connected to digital PINs 10 and 9, respectively. Although these PINs have tilde, that is, they can be used for sending PWM signals, we will use them as normal digital PINs. We click on the Arduino icon and after opening a new file we copy the sketch below: /* Be Maker - STEM - Project 19 - Obstacle Detection with Ultrasonic Module. */ const int PortaTrig = 10; const int PortaEcho = 9; void setup() { pinMode(PortaTrig, OUTPUT); pinMode(PortaEcho, INPUT); Serial.begin(9600); Serial.print( "Ultrasonic Sensor: "); } void loop() { digitalWrite ( PortaTrig, LOW ); //sets the trigger output to a low value digitalWrite ( PortaTrig, HIGH ); //sets the trigger output to a high value, i.e., sends a pulse delayMicroseconds ( 10 ); // the high value is held for 10 microseconds digitalWrite( PortaTrig, LOW ); //makes the pulse end i.e. puts the trigger output at LOW long duration = pulseIn( PortaEcho, HIGH ); //measures time long distance = 0.0343 * duration / 2; //calculates the distance in cm Serial.print("distance: "); Serial.print(distance); Serial.println(" cm "); delay(100); //Wait 100 milliseconds before starting again } Once the sketch is loaded and the serial plotter is activated, the distances of the objects in front of the sensor will be detected Analysis of Sketch: Project 19 Obstacle Detection with Ultrasonic Module. In the distance measurement sketch we find two new functions. First: delayMicroseconds ( 10 ); this instruction introduces a delay that this time is expressed in microseconds (classical delay, remember, introduces delays in the sketch of milliseconds). Second: long duration = pulseIn(PortaEcho, HIGH ); tells Arduino to load into the variable named "duration" defined as a variable of type "long," that is, a variable that has many decimal places, the time value calculated from the time the pulse starts from the Tx to the time the signal is received by the Rx bringing the PIN state to a high state (HIGH). [For the video related to the project click here]. [For the sketch related to the project click here]. CURIOSITY: What are Degrees of Freedom (DOF) and Electric Drives. Movements, limb movements, torso rotation.... are the movements that enable a robot to perform those activities that we want it to do to accomplish the assigned (programmed) task. Let us give an example to better understand the concept of motion by analyzing one of the most widely used robots in industrial processes for mass production: the Puma Robot. This robot, which is nothing more than a mechanical arm, is widely used in the automotive industry for welding, painting, moving heavy components, placing components in precise locations in assemblies and storage, etc. From this we understand how the first question we must ask ourselves in designing a Robot is: what should our Robot do ? The complexity in designing a Robot lies in the number of motions to be given and consequently the number of "motion joints" to be inserted; in the particular case of the figure, there are six. But how do we determine how many joints to insert? The answer lies in determining whether our working point should be able to move in space, or on a plane, or a line. Suppose a rigid body can only translate along its axis (straight line), this possibility of motion is called in Mechanics "degree of freedom," obviously the other motions that cannot be made are said to be constrained. Thus, in this case the motion is characterized by only one degree of freedom. In the case represented by the figure on the right, however, we have that the body can translate along the abscissae and along the ordinates, that is, it can move in a plane, so the body is characterized by having two degrees of freedom. In this other case (see figure at left) the body moves rigidly in space, so it is characterized by having three degrees of freedom. In Physics, but also and particularly in Mechanics, the position in space of a rigid (solid) body can be identified by six variables (three of translation and three of rotation) called degrees of freedom. Obviously reproducing by means of a single piece of equipment the position in space of a body is impossible (...at least with current technological knowledge), because there are "constraints" imposed by the equipment that generates the motion, which are normally electrical drives. This is why the Puma Robot has six pivot joints (six electric drives), because the movement that enables each pivot joint, as shown in the figure, in turn enables the working point that is at the end of the arm, to reach "any" point in space and its relative position is always known. Electric drive (or also called Power Drive System: PDS) is defined as a system that converts electrical energy into mechanical energy with the help of power and control electronic equipment. The motors used for electric drives are shown in the diagram below.Obviously, I do not wish to teach a course in Electric Machinery, but I just wish to show you the significant number of electric motors we have available to us in order to give the mechanical motion we want. After this challenging but necessary first theoretical part to understand what and how many motors we need to make particular movements, we move on to more practical matters. For our purposes and applications with Arduino we will use two types of motors: Stepper motors and servo motors. The Servo Motor - Giving movement to things. With the Servo Motor it is possible to give motion to objects, such as a robotic arm, a lever, etc. Again, for its use, just follow the following lesson carefully. The servo motor is composed of an electro-mechanical part and an electronic part, the electro-mechanical part creates the motion, the electronic part controls it. However outwardly the servo motor looks like a plastic shell, a gear that rotates a pin, and a three-pin cable. The servo motor we will use in the next project is the SG-90, which can be powered directly from Arduino and is used for moving light objects. As shown in the figure below, the colored cable has three poles: one pole is connected to Arduino's 5V Vcc voltage, another to ground (GND), and the third pole is to be connected to an Arduino digital PIN and is used for control. For "heavier" applications we can use servomotors with the commercial designation MG996R or the TD-8120MG, but in this case, especially if they are more than one servomotor, power must be supplied by an external power supply. Project 20 - Controlling a Servo Motor SG-90 For this project we need: Arduino Uno R3 or compatible Micro-servo SG90 Dupont male male cables USB connection cable First we take our Arduino, servo motor, and wires and connect them as shown in the figure below. The wiring diagram is: For assembly, follow the diagram below: The Servo Motor usually has three colored leads: orange (control lead), red (5 V) and brown (GND), in other cases, depending on the manufacturer, the control lead is white. We click on the Arduino icon and after opening the IDE we create a new file and copy the sketch below: /* Be Maker - STEM - SG90 Servo Motor Control */ #include <Servo.h>//Recalls the Motor Control Library. //Variables and functions Servo ServoMotor; //Creates an object called ServoMotor void setup() { Serial.begin(9600); ServoMotor.attach(9); //We declare that the ServoMotor is attached to PIN 9 Serial.print("SERVO MOTOR - ROTATION - "); } void loop() { // Let's rotate the Servo Motor by an angle ranging from 10° to 160°. for(int i=10;i<=160;i++) { ServoMotor.write(i); Serial.print("Angle: "); Serial.print(i); //print the value of the angle Serial.println(" °"); //print the unit of measurement, i.e. degrees delay(30); } // Let's rotate the Servo Motor by an angle ranging from 160° to 10°. for(int i=160;i>=10;i--) { ServoMotor.write(i); Serial.print("Angle: "); Serial.print(i); //print the value of the angle Serial.println(" °"); //print the unit of measurement, i.e. degrees delay(30); } } After checking the sketch let's upload it to Arduino in the usual way and open the serial monitor, we will see the moving part of the motor (called the rotor) rotate from 10° to 160° and then back again, and the rotation in degrees is shown on the monitor. Analysis of the Sketch: Project 20 Controlling a Servo Motor. Analyzing the sketch above we can observe the following instruction: #include <Servo.h> That is, it calls up the library to drive the servo motor. This library should already be installed in the Arduino IDE, in case it is not, you can use the procedure described in the preparatory activities for the Course. Among the instructions that the <Servo.h> library provides, we have the most commonly used ones: [objectname].attach(PIN) : allows you to specify on which pin our servo is connected and bind it to the ServoMotor object; [objectname].detach(PIN) : removes the link between the ServoMotor object and the pin it was bound to; [objectname].read(x) : reads the angular position of our servo, returns the last value passed with write(); [objectname].write(x) : tells the servo the angle at which to position itself; Continuing with the analysis of the sketch...let's look at the individual instructions in the SETUP area: Servo ServoMotor; // .....è used to create an object named ServoMotor ServoMotor.attach(9); // ...we specify to the IDE that the ServoMotor is attached to PIN 9 Turning to the LOOP part: ServoMotor.write(i); // ....the variable "i" is the one incremented by one by the for loop, so in this way the rotor will turn one degree at a time. It can be seen from the "for" loops that the first one increments from 10 to 160 and the second one decrements from 160 to 10. The rest are instructions already seen in previous projects. [For the video related to the project click here]. [For the sketch related to the project click here]. Project 21 - Radar System Ultrasound For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables USB connection cable Micro-servo SG90 Bracket support Module HC-SR04 Since we will be using both the HC-SR04 ultrasonic module and the SG-90 servomotor for this project, the ultrasonic module should be attached to the servomotor before proceeding. Any kind of "craft" methods can be used to do this, or you can purchase the appropriate mounting brackets that can be found on major market places such as Ebay, Amazon, Aliexpress, or others.. In the case of a homemade solution, be careful not to create a metal bracket that could short-circuit the tracks on the ultrasonic module. I personally suggest that you purchase the appropriate brackets for a few euros including shipping costs. First we take the bracket and attach, with screws, the HCSR04 sensor to it, and then the whole thing we attach, with more screws, to the servo motor on which we have mounted the intended bracket. We take double-sided tape and make the servo motor stand with the bracket (and sensor) mounted on it. See photo below for assembly: 1 ) + = 2 ) + = The wiring diagram is as follows: We make the connections as shown in the assembly diagram: Now let's go to the sketch, click on the Arduino icon and after opening the IDE create a new file and copy the sketch below: /* Be Maker - STEM - Project 21- Ultrasonic Radar System. */ #include <Servo.h>//Recalls the Motor Control Library. Servo ServoMotor; //Creates an object called ServoMotor //ULTRASOUND MODULE int triggerPort = 11; //PIN to which the Trigger signal is connected int echoPort = 10; //PIN to which the Echo signal is connected //long s=0.0; //long d=0.0; void setup() { Serial.begin(9600); ServoMotor.attach(6); //The ServoMotor is declared to be attached to PIN 6 pinMode( triggerPort, OUTPUT ); pinMode( echoPort, INPUT ); Serial.print("MOTOR SERVO - ROTATION - "); } void loop() { // Let's rotate the Servo Motor by an angle ranging from 10° to 160°. for(int i=10;i<=160;i++) { ServoMotor.write(i); digitalWrite( triggerPort, LOW ); //ports the trigger output to a low value digitalWrite( triggerPort, HIGH ); //enable trigger delayMicroseconds( 10 ); //holds trigger active for 10 microsec (generates pulse) digitalWrite( triggerPort, LOW ); //deactivate the trigger long d = pulseIn( echoPort, HIGH ); //calculates the duration of the bounce time long s = 0.0343 * d / 2; //calculates the distance if (s<100){ for (int t=1;t<s;t++){ Serial.print("."); } for (int j=s;j<100;j++){ Serial.print("X"); } Serial.print (" Obstacle to: "); Serial.print(s); Serial.print(" cm "); Serial.print("Angle: "); Serial.print(i); Serial.println(" °"); } else { for (int t=1;t<100;t++){ Serial.print("."); } Serial.println(" °"); } } // Let's rotate the Servo Motor by an angle ranging from 160° to 10°. for(int i=160;i>=10;i--) { ServoMotor.write(i); digitalWrite( triggerPort, LOW ); //ports the trigger output to a low value digitalWrite( triggerPort, HIGH ); //enable trigger delayMicroseconds( 10 ); //holds trigger active for 10 microsec (generates pulse) digitalWrite( triggerPort, LOW ); //deactivate the trigger long d = pulseIn( echoPort, HIGH ); //calculates the duration of the bounce time long s = 0.0343 * d / 2; //calculates the distance if (s<100){ for (int t=1;t<s;t++){ Serial.print("."); } for (int j=s;j<100;j++){ Serial.print("X"); } Serial.print (" Obstacle to: "); Serial.print(s); Serial.print(" cm "); Serial.print("Angle: "); Serial.print(i); Serial.println(" °"); } else { for (int t=1;t<100;t++){ Serial.print("."); } Serial.println(" "); } } } As for the analysis of the sketch, as can be observed from the listing above, it is nothing more than a combination of the sketches made to control the sensor and the Servo Motor. Now all that remains is to load the sketch and activate the Serial Monitor and try interposing obstacles in front of the radar to see its detection. [For the video related to the project click here]. [For the sketch related to the project click here]. Project 22 - Ultrasonic Radar System with Processing For the more daring, without modifying what has been achieved in terms of hardware, there is also a version of the same project with more attractive graphics. For this version I had to modify a project already found on the net that uses, in addition to the Arduino IDE, another Open Source software called Processing. Without going into the technical details of Processing because there will be a Course dedicated to this other programming environment, if you want, you can try your hand at this project too (it is a tad more complicated than the usual projects, but it is worth it!). Go to the site : https://processing.org/ The page appears to you: Click on Download Processing and the page is accessed: Choose the version according to your operating system (in my case it is 64-bit Windows): It is downloaded Processing in its latest version (in this case, 3). Processing is an Open Source program and is therefore free, but if you wish you can make a donation, which I recommend, to keep it updated with new features. The version I downloaded is processing-3.5.3windows64.zipper, unzip it and run the installer. Click twice consecutively on the "processing" file and the installation starts: A message appears after installation saying that files created with processing version 2 may not work, continue and click Get Start. At this point the Processing window opens. You can close it. Download the files (just click on the name): Radar_with_Processing.zipper (file to unzip and upload to Arduino) Radar_Processing_ino.zipper(file to unzip and run on PC with Processing) The first thing to do is to check that the settings provided on the Radar_Processing_ino file are correct, so connect Arduino to the PC and open the Radar_with_Processing sketch , check which port Arduino is connected to (look at the bottom right), in my case Arduino is connected to COM3 (see below): Now double-click on the file: Radar_Processing_ino , obviously after unpacking it. The following window opens: Go to line #21 and check that the port number is correct, if so change the port number (NUMBER ONLY!). Then go to your desktop and right-click to select screen resolution. In my case it is set to 1280 x 720 (see figure below): At this point return to Processing and check that the resolution reported on line 19 is correct, if so change it, however do not put resolutions lower than 1280 x 720! In case your resolution is lower adjust it to that reported on Processing. Now load the sketch on your Arduino and after a few seconds launch processing, clicking on the "play" button: A real RADAR appears to you!!! Since I think I have already stressed you enough, I'll end it here! And see you at the next class. [For the sketch to upload to Arduino click here]. [For the sketch to be uploaded to the PC with Processing click here] LESSON 7 - Active and Passive Components and Elements in Series and in Parallel. With this Lesson we delve into some very important aspects of electrical engineering that will help us understand so many things about the electrical circuits we have already made so far. The Active and Passive Components. Components are the basis of electronic devices. They can be divided into active components and passive components. The definition of active component, or passive component, in the bibliography (i.e., how it is described in books) is not always clear, indeed sometimes it is even contradictory. As far as we are concerned, the definition that I am familiar with and find most relevant refers to the ability to input or use energy in a given circuit, namely: A component is said to be ACTIVE if it feeds energy into a circuit, while it is PASSIVE if the component uses the energy fed into the circuit. To give some examples: a battery is an active component (because it inputs electricity), on the other hand, an LED (uses electricity to emit light, but also produces heat), a resistor (uses electricity and produces heat), a servomotor (uses electricity and produces motion, but also produces heat),... so, these, are all passive components. Series and Parallel Connection of Components. A component is normally identified by two terminals, one indicated by "+" and the other indicated by "-" or even "GND," these terminals identify the conventional direction of the current, entering from the + and exiting from the - . The component with two terminals is called a "bipole." Component If we connect several bipoles together in such a way that the incoming terminal of one connects to the outgoing terminal of the other, we have a Series Connection. Series Connection In series connection, all components are passed through by the same "I" current. If we connect multiple bipoles by joining the "+" and "-" terminals together, we have Parallel Connection. Parallel Connection In parallel connection, all components are subjected to the same "V" voltage. The Series and Parallel Connection of Resistors. For the moment let us focus on passive components, and among them let us see in detail what happens if we connect resistors in series or in parallel. The linking principle is the one already described in the previous paragraphs, so let's start right away by giving some examples for better understanding. First, let us review what happens if we apply a voltage V to a resistor R: Applying a voltage to Resistance R creates an electric current I, which is calculated by Ohm's Law: Suppose we now have two 100-ohm resistors connected in series and a voltage of 5V is applied to them: When two resistors are in series, they behave as if there is only one "Equivalent Resistance" which is given by the sum of the two resistances, so Req = 200 Ohm. At this point, again using Ohm's Law, we can calculate the current delivered by the 5V battery by applying the formula: Going to replace the letters the numerical values: Thus the current circulating in the circuit thus made is 0.025 A, or 25 mA. Let us now calculate the voltage applied to the first resistor, again using Ohm's Law: from which: The voltage applied to the second resistor, is calculated by doing the difference between the total voltage applied to both resistors, minus the voltage that is created on the first resistor. From the calculation it turns out that there is also a voltage of 2.5V on the second resistor. So a voltage of 2.5 V is applied on the individual resistors, which is half the voltage delivered by our battery. Now suppose instead that we have the two resistors in parallel: In this case, the equivalent resistance of two resistors in parallel is calculated by the formula: from which, calculating the least common multiple and solving the sum of two fractions: going to replace the numerical values: Hence: Let us now go on to calculate the current "I" with Ohm's Law: So putting two equal resistors in parallel means having an equivalent resistance equal to half the value of the single resistor you connect in parallel. While the current will be I = 0.1 A , i.e. 100 mA ( and that is 4 times higher than in the previous circuit). So be careful putting resistors in parallel, you risk burning out the components and our Arduino! What if the resistors were different, for example, with value R1 and R2 ? Applying the previous rule, we obtain: However, the value that results for the equivalent resistance is smaller than the smaller resistance value between the two resistances. In fact, if, for example, R1 is 100 Ohms and R2 is 10 Ohms, the Req = 9.09 Ohms. I wanted to insist on this theoretical part, which is somewhat tedious because of the presence of so many calculations, to make you understand two important concepts: 1) If we put two resistors in series, the current circulating in the circuit is reduced and a lower voltage is applied to each resistor than it generated (in technical terms, when current flows through a resistor, it is said to cause a voltage drop). In fact, the principle by which we put a resistor in series to an LED (considering the LED as if it were a resistor, because it has its own internal resistance) is just that, that is, to reduce the voltage applied to the LED and thus reduce the current flowing through it. 2) If we instead put two resistors in parallel, the voltage applied to the resistors is still the same, i.e., that of the battery, the value of the equivalent resistance decreases and consequently the value of the current delivered by the battery increases. So with Arduino we are very careful about putting resistors in parallel, because beyond certain current values it cannot withstand and thus burns out. The Voltage Divider and the Potentiometer In the previous Lessons we have already used both the divider and the potentiometer, they have been used in specific applications such as, for example, in sensing the voltage at the ends of a photoresistor (use of the voltage divider) or to vary the light intensity of an RGB LED (use of the potentiometer), but we have not yet seen in detail their actual operation and their field of use, in this Lesson, after seeing what it means to put resistors in series and parallel, we will delve into these aspects. The Voltage divider Sometimes it happens that we need to create reference voltages for electrical measurements, as was the case with the photoresistor. To do this we need only apply two very important laws of electrical engineering, one you know well by now and that is Ohm's law, which tells us that by applying an electric voltage to a resistor, it is passed through by an electric current given by the formula : Or, interpreting the law in reverse: a current "I" flowing through a Resistance "R" produces a "voltage drop V" , that is: This principle of producing a voltage drop is used to create a reference voltage in electrical measurements. For example, suppose we want to create a reference voltage of 2.5 V from a Voltage of 5 V, then (without going through all the calculations we have seen before), all we need to do is to put two resistors in series of equal value (e.g., 100 Ohm) and the reference voltage at the ends of one of the resistors is exactly 2.5 V. The voltage at the ends of R remains constant at 2.5 V only if we read it with an instrument called a voltmeter or with Arduino (for example: by means of one of its analog PINs), but if we want to use this voltage to supply a 2.5 V load, the value at the ends of R will change, depending on the load we are going to connect (in parallel with R!). The Potentiometer (for electronic applications it is called a Trimmer). The working principle of a potentiometer is equivalent to a voltage divider, with the special feature that thanks to a knob it is possible to change the resistance and thus change the voltage at the central point. - Black Element = wire of definite characteristics and resistivity wrapped on insulating material and is called Fixed Resistance. Green element = slider made of conductive material and is the sliding contact that rotates due to the knob. Basically, by varying the position of the center slider with the knob, all we are doing is increasing the length of the wire over which the current circulates and thus the resistance of the conducting material, which is given by the following formula: Where R is the resistance," r " (pronounced "ro' ") is the resistivity of the material that makes up the wire wrapped on the insulating material," l " is the length and " s " is the cross section of the wire wrapped on the insulating material. The potentiometer when applied in low-power circuits, such as those we have made, takes the name of Trimmer, so between Trimmer and Potentiometer there are no substantial differences in their principle of operation, but only constructive ones and thus in the ability to be able to be traversed by currents with higher values, for the potentiometer, than lower ones for the trimmer. Thus the potentiometer is used in higher power circuits than those for which the trimmer is used. example of Trimmer Project 23 - The Use and Connection of the Potentiometer To understand in detail how a Potentiometer works and one of its most usual applications, let us carry out the following project. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables 2x 220 Ohm LEDs of any color 10 KOhm USB connection cable Resistors potentiometer The purpose is to change the voltage applied to an LED, thanks to the potentiometer, and then vary the brightness manually by acting on the knob of the same potentiometer. To realize this effect, based on the knowledge we have gained so far, we can make the following circuit: As can be easily observed from the wiring diagram, in this case Arduino is used as a simple 5 V battery. The assembly diagram is as follows: Pin one of the potentiometer is connected to the Arduino's 5V, from pin two we go to connect the anode of the LED (yellow) to which the classic 220 Ohm resistor has been connected in series. Finally, the third pin of the potentiometer is connected to ground (GND) through a 220 Ohm resistor. By varying the resistor, that is, by turning the knob on the potentiometer, you will be able to see the brightness of the LED vary; in fact, in this way, we have placed another resistor of varying value in series with the LED resistor; the higher the resistor the higher the voltage drop across the resistors and thus the lower the voltage applied to the LED and thus the lower the brightness. I would like to point out that in series with the third pin of the potentiometer, before connecting the same to ground, I have inserted a 220 Ohm resistor, this is because the Potentiometer having a variable resistance (theoretically from 0 to 10 kOhm, or from 0 to 1 kOhm, depending on the type of potentiometer we use), for low values of resistance Arduino would deliver high currents with the risk of burning it out, instead, by putting a resistor in series, however even when the potentiometer takes low values, we are limiting the current delivery. [For the video related to the project click here]. Fun facts: what is Temperature and what is Humidity Temperature is that quantity that indicates the thermal state of a body or environment, that is, how hot or how cold that particular body or environment is. The unit of measurement is the degree Celsius [°C] or rather, in the International System, it is measured in degrees Kelvin [°K]. Humidity is that quantity that indicates how much water vapor is present in a given environment and is measured in percentage terms. At 0% humidity, one has a dry and ascetic environment. A '100% humidity , in practice, you are immersed in water vapor. LM35 Temperature Sensor For the following project we will use the LM35 temperature sensor, let's give a brief description of it: The sensor is calibrated to give results in °C , so if we want °K we need to convert it with the formula that says: 0 °K = -273.1 °C, that is, if we have 27.9 °C, these correspond to 300 °K. The applicable voltage ranges from 4 V to 30 V, but we will obviously use it at 5V. For every 10 mV measured, we have 1 °C. Since the function is linear, as can be seen from the data-sheet graph, we only need to measure the output voltage Vout with Arduino and apply the simple formula: Project 24-Detect the temperature of a body. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables LM35 The wiring diagram for connection is: While the assembly diagram is: USB connection cable We click on the Arduino icon and after opening a new file we copy the sketch below: /* Be Maker - STEM - Body Temperature Sensing with LM35 */ #define sensorPin A0 //define which Analog PIN I connected the sensor to. void setup() { Serial.begin(9600); //We set the port speed to 9600 } void loop() { int reading = analogRead(sensorPin); // Get a reading from the temperature sensor float voltage = reading * (5000 / 1024.0); // Convert the reading into voltage float temperature = voltage / 10; // Convert the voltage into the temperature in degree Celsius Serial.print(temperature); // Print the temperature in the Serial Monitor Serial.println(" °C"); delay(1000); // wait a second between readings } Once the sketch is loaded and the serial monitor is activated, the temperatures of the objects that are in contact with the sensor will be detected. As far as the sketch is concerned, since there are no special things to highlight, no analysis is done. [For the video related to the project click here]. [For the sketch related to the project click here]. Project 25 - Light thermometer. Based on the previous project, let's make a fun light thermometer where we will use a decision-making algorithm based on the "switch-case" function to determine whether a body is: cold, room temperature, hot, or burning hot. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables LM35 No. 4 LEDs: Blue, Red, Green and Yellow No. 4 220 Ohm resistor The wiring diagram for connection is: USB connection cable While the assembly diagram is: We click on the Arduino icon and after opening a new file, we copy the sketch below: /* Be Maker - STEM - Luminous Thermometer */ #define sensorPin A0 //define which Analog PIN I connected the sensor to. #define scottaPin 3 //define at which PIN Digital LED Red #define warmPin 4 //define at which PIN Digital LED Yellow #define environmentPin 5 //define at which PIN Digital LED Green #define coldPin 6 //define at which PIN Digital Blue LED. int ignitionLED; void setup() { pinMode(scottaPin, OUTPUT); pinMode(hotPin, OUTPUT); pinMode(environmentPin, OUTPUT); pinMode(coldPin, OUTPUT); Serial.begin(9600); //We set the port speed to 9600 } void loop() { int reading = analogRead(sensorPin); // Get a reading from the temperature sensor float voltage = reading * (5000 / 1024.0); // Convert the reading into voltage float temperature = voltage / 10; // Convert the voltage into the temperature in degree Celsius Serial.print(temperature); // Print the temperature in the Serial Monitor Serial.println(" °C"); delay(1000); // wait a second between readings if (temperature<=10){lightingLED=0;} if (temperature>10 && temperature<=27){lightingLED=1;} if (temperature>27 && temperature<=36){lightingLED=2;} if (temperature>36){lightingLED=3;} switch (ignitionLED) { case 0: digitalWrite(scottaPin, LOW); digitalWrite(hotPin, LOW); digitalWrite(environmentPin, LOW); digitalWrite(coldPin, HIGH); break; case 1: digitalWrite(scottaPin, LOW); digitalWrite (hotPin, LOW); digitalWrite(environmentPin, HIGH); digitalWrite(coldPin, LOW); break; case 2: digitalWrite(scottaPin, LOW); digitalWrite(hotPin, HIGH); digitalWrite(environmentPin, LOW); digitalWrite(coldPin, LOW); break; case 3: digitalWrite(scottaPin, HIGH); digitalWrite(hotPin, LOW); digitalWrite(environmentPin, LOW); digitalWrite(coldPin, LOW); break; } } At this point we load the sketch on Arduino and with the tip of the sensor touch the different bodies to measure their temperature. Depending on the measured temperature range, a particular colored Led will light up: Blue Led = cold, Green Led = room temperature, Yellow Led = hot, or Red Led = hot. We can enrich the design by also putting a card with holes for the LED head and on the card write the measured temperature range. Analysis of the Sketch: Project 25 Luminous Thermometer. Also used for this sketch was the control structure switch(..) ..... case ... ; which we review as being a very important structure. This way of having the processor make decisions is used especially when there are many cases to examine and decide on which actions to take. The use of the switch...case... simplifies the structure, in fact it is enough to define for each case what to do and then we have the switch function do the case selection directly. The general syntax of the control structure according to the Arduino Reference Book is: switch (var) { case label1: // statements break; case label2: // statements break; default: // statements break; } Where var is a variable of type int or char and indicates the number of the "case" you want to process, and label1 is the label, also a variable of type int or char. In the syntax example there are only three cases of which one is the default. The last case, the default case is selected when you have none of the previous cases. The structure can also have more than the represented number of cases. [For the video related to the project click here]. [For the sketch related to the project click here]. The DHT11 Environmental Temperature and Humidity Sensing Sensor. Sometimes there is a need to detect the Temperature and Humidity present in a room and according to these values it is possible to adjust the heating or air conditioning so that what is called the "optimal thermal comfort" of the room is achieved. The DHT11 sensor is nothing more than a mini-arduino where thanks to its sensors and the presence of a processor it is able to provide, in digital format, the value of temperature and humidity. Why did I want to specify this aspect? The reason is that, like Arduino, the DHT11 having a processor and sensors, in turn, would require specific programming and also in a particularly complicated language effectively making the use of the DHT11 only for a select few. Instead, thanks to the presence of millions of makers like you, the use of the DHT11 sensor module is very simple as there are "Libraries" of instructions thanks to which we are able to interrogate the sensor module without worrying about writing hundreds of lines of program code in a complex language. Let us now see how to connect the DHT11 Sensor Module: As you can see, the Module has the third pin from the left that has no function and therefore should not be connected to anything. A 4.7 kOhm resistor is normally connected between the Vcc pins and Data: Be aware that there are commercially available DHT11 Sensor Modules, mounted on a baseplate, with the 4.7 kOhm resistor already connected and, most importantly, with only the 3 PINs needed. Before moving on to the hands-on project, let's review how to add in the Arduino IDE a library, although it is already explained in the preparatory activities for the Course I still think it is useful to refresh the memory. What is a Library and how to add it to the IDE The concept of a "library" is basically this.... It is a repository in which you find instructions that simplify and make it easier to use modules and sensors that would otherwise require complex operations and instructions that are difficult to apply. Let's see how to add the DHT11 Sensor Library; there are several ways to insert a library into the Arduino IDE, the one we will use is the easiest and quickest, but be aware that it will not always be possible to use this method... but don't worry we will see them all when needed! Back to us: inserting a new library into the Arduino IDE and then allowing the IDE itself to load into Arduino the right instructions needed for Arduino and the add-ons that connect to it to work. First we open the application, double-click on the Arduino icon on the Desktop, and the IDE opens: Since when you open the IDE generally the last sketch you wrote is loaded, let's start with a clean sketch so there is no confusion.To do this we click on "File" and then on "New," as depicted above. At this point we can close the initial window where the previous sketch was. Now we click on "sketch" then on "#include library" and then on "Manage libraries..." After a few seconds, the following window appears and we go to type in the text box "DHT11" A list of libraries comes up, we select the one produced by Adafruit... ...and click on "Install." After a few seconds, the window that says "INSTALLED" appears. The library is now usable and when compiling the sketch for Arduino, the IDE will not give an error. Project 26 - Ambient Temperature and Humidity. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male - male cables USB connection cable DHT11 Sensor Module The wiring diagram for connection, in the case of using the sensor, is: In the case of using the Sensor Module: For the mounting diagram in the case of using the 4 PIN sensor: In the case of using the Sensor Module with 3 PINs): Caution: Since there is no standard, pay attention to which PIN is assigned the "S" or "DATA" symbol, as well as the one with the "+" or "Vcc" symbol where they will connect to Digital PIN 4 and Arduino's 5V, respectively. The sketch to be written (directly taken from the example in the Library): // Example testing sketch for various DHT humidity/temperature sensors #include "DHT.h" #define DHTPIN 4 // Digital pin connected to the DHT sensor #define DHTTYPE DHT11 // DHT 11 DHT dht(DHTPIN, DHTTYPE); void setup() { Serial.begin(9600); Serial.println(F("DHT11 Start")); dht.begin(); } void loop() { delay(2000); // Wait a few seconds between measurements. float h = dht.readHumidity(); float t = dht.readTemperature(); // Read temperature as Celsius (the default) Serial.print(F("Humidity: ")); Serial.print(h); Serial.print(F("% Temperature: ")); Serial.print(t); Serial.print(F("°C ")); } Then, once the sketch is loaded and waiting a couple of seconds, the Serial Monitor prints the values. Sketch Analysis: Project Environmental Temperature Humidity. 26and It is worth highlighting, because it is very important, the inclusion of the Library with the command "#include" #include "DHT.h" You also need to specify which sensor you are using because the same library contains multiple types of sensors, so you need the instruction: #define DHTTYPE DHT11 // DHT 11 and then the creation of an object called dht is needed: DHT dht(DHTPIN, DHTTYPE); from that moment in the void loop(), we can put the instructions that go to read the digital values of temperature and humidity. [For the video related to the project click here]. [For the sketch related to the project click here]. LESSON 8 - Magnetism and the Magnetic Field. We dedicate this Lesson to the study of the Magnetic Field. This is an important and challenging subject, so I realize that it may be a difficult topic for younger people. I will try to explain it as simply as possible, but if I fail to do so--don't worry! Just go ahead anyway. Let us first define what magnetism is: that is, that property that some bodies possess in attracting objects of a ferrous nature to themselves. Bodies with this property are called magnets or magnets. Magnetite, an iron ore, is an example of a natural magnet. A magnet attracts ferrous bodies at its ends, which are called magnetic poles. These two poles are not equal and are distinguished into north pole (N) and south pole (S). Poles of the same type (N-N and S-S) repel each other and poles of the opposite type (N-S and S-N) attract each other. The poles of a magnet can never be separated; if you split a magnet it will restore the poles as they were in the original dimension. The magnetic field, in physics, is defined as follows: the magnetic field is a vector field, capable of passing through bodies, generated in space by the motion of an electric charge or a time-varying electric field. Let us try to decipher what physics says in simpler terms. So, we have materials that are normally magnetized and materials that can become magnets if a current flows through them. First, let us see why physics speaks of a "vector field." The magnetic field is called "vector" because its lines of force, that is, the areas of influence, have a definite direction. In the case of a magnet made by the circulation of current, the magnetic field produced depends on the direction in which the electric current is circulating. In the case of permanent magnets, on the other hand, the lines of force go from the North Pole to the South Pole of the magnet. In the field of electronics and electrical engineering, the magnetic field generated by an electric current is that phenomenon most widely used for a wide variety of purposes. The area of influence of the magnetic field is the space in which we can observe the phenomenon of magnetism. Obviously, the closer we are to what produces the magnetic field, whether it is a material through which the current flows or a permanent magnet, the greater the effect of that field. It is also possible to do a very simple experiment to visualize the force lines of the magnetic field produced by a permanent magnet. Just take a smooth, white cardboard and cover (dust) it with iron filings (iron filings are the waste from ironworking; they are very small iron needles, they look like many straws). When a magnet is placed, a magnet is placed under the card; by giving gentle shakes to the card, the iron filings, magnetized, are arranged along the lines of force of the magnetic field, composing the pattern of the projection on the plane of the same lines of force. The Earth also has its own Magnetic Field, and several physicists and scholars think it is due to the large amount of iron and nickel in the core (other theories, however, say that the magnetic field generated by the Earth is electrical in nature). However, you have surely had occasion to see a compass whose needle aligns with the lines of force of the Earth's magnetic field indicating its magnetic North Pole, which is slightly different from the geographic North Pole. As I mentioned earlier, in electrical engineering and electronics the phenomenon of magnetism is widely used, in fact in this Lesson we will look at some projects that use this phenomenon to regulate certain events. The principle used is the so-called "Hall effect." Curiosity: The Hall Principle To measure the Magnetic Field, the so-called Principle of Edwin Hall, an American physicist, is used, who noted that if we run a metal (or semiconductor) foil through a direct current between the " + " and " - " terminals and this foil is immersed in a magnetic field, the flow of the current (or rather electrons) is deflected and thus a buildup of charges is created toward the outer edges of the foil, such that a measurable potential difference (Hall voltage) is created between the "a" and "b" terminals. This buildup is the greater, the larger the magnetic field and consequently the voltage at the ends of terminals "a" and "b" will be higher. The signs of Hall voltage depend on the magnetic polarization and the voltage applied to the foil. This principle has several applications especially in mechatronics, in fact exploiting the principle that the magnetic field is influenced by the type of material in which it is applied, we can, thanks to the Hall probe, measure its variations. Thanks to these variations we can check whether a ferrous product (e.g. from a rolling mill) has been made correctly (no field variation), or count the number of revolutions of a crankshaft, etc. For example, the figure above shows a measuring system, without contact with the moving part, for measuring the speed of a rotating disk or the number of revolutions of a gear, even when these moving parts are inside plastic or metal enclosures Another example of a Hall probe application is shown in the figure below: Current measurement system without contact with the live part. This method takes advantage of the principle that an electric current produces a magnetic field, so by measuring the magnetic field we can measure electric current without making contact with the live part. Project 27 - Magnetic Field Presence Detection KY003 For this project we need: Arduino Uno R3 or compatible Hall Effect Sensor Breadboard Dupont male male cables USB connection cable Module - KY003 Hall Effect Sensor Module - KY003 consists of a component that is sensitive to the effects of the magnetic field (whose name is unspeakable! a series of meaningless numbers and letters... ) and the characteristics indicated by the manufacturer, works well even at high temperatures. There is a 680-ohm resistor on the module and an LED that activates when a magnetic field is present. At the PIN indicated with S the signal is available that will go to a digital PIN of Arduino, at the PIN indicated with "-" the GND of Arduino needs to be connected and at the PIN with "+" or nothing is indicated, or even indicated with Vcc, the 5V power supply from Arduino needs to be given. The wiring diagram for connection is: First we take our Arduino, some Dupont male-female leads, and the sensor, which in English is called the Hall Magnetic Sensor. We connect everything as per the assembly diagram below: Signal PIN "S" is connected to digital PIN 3 of Arduino, and for the rest just connect the power supply to 5V and ground to GND of Arduino. We open the IDE and after opening a "New" window, copy the sketch below: /* Be Maker - STEM - Magnetic Field Detection Switch Sensor */ int Led = 13; //LED present on Arduino int sensor = 3; //PIN to which the sensor signal is connected int val; //numeric variable void setup() { pinMode(Led, OUTPUT); //set the LED as the OUTPUT pinMode(sensor, INPUT); //set sensor PIN as INPUT } void loop() { val = digitalRead(sensor); //The sensor output is read. if(val == LOW) //If the value of the sensor signal is "LOW" //then the magnetic field is present and the LED //on Arduino is turned on { digitalWrite(Led, HIGH); } else { digitalWrite(Led, LOW); } } You upload the sketch to Arduino and at this point, by moving a magnet near the sensor you can observe that the LED at PIN13 turns on and off, this depending of course on the distance between magnet and sensor. When the magnetic field is strong enough to be detected by the sensor the LED at PIN 13 on the Arduino will turn on, the LED located on the module will also turn on (but not all modules report such an LED). Analysis of Sketch: Project 27 - Use of LED on board Arduino. Sometimes in order not to stand around mounting an LED and a resistor to check the functionality of a particular circuit or module, it is possible to use an LED that Arduino makes available to users. Such an LED is connected to digital PIN 13, and to be used it must be configured as if there were an external LED connected to PIN 13. So it must be defined to which PIN the LED is connected: int Led = 13; //LED present on Arduino In the void setup, it should be specified that it is a PIN output: pinMode(Led, OUTPUT); //set the LED as the OUTPUT And finally it should be turned on or off with any LED: digitalWrite(Led, HIGH); Most Arduino clones also carry such an LED. [For the video related to the project click here]. [For the sketch related to the project click here]. Project 28 - Analog Detection of a Magnetic Field KY035 With the KY-035 Analog Hall magnetic sensor module, it is possible to continuously detect the magnetic field since it is a sensor module that has an analog output. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables USB connection cable Hall Effect Sensor Module - KY035 Module KY035 has the same pinout as KY003, the only difference being that at the PIN marked "S" is the analog signal and not just the ON/OFF of KY003. The wiring diagram for connection is: We take our Arduino, some Dupont male-female leads, and the sensor, For this project we assemble the circuit as the previous one with the only difference being that the signal output is taken to an analog PIN, specifically, in our case, to PIN number A5. We open the IDE and write the sketch below. /* Be Maker - STEM - Analog Magnetic Field Measurement */ int sensorPin = A5; // The sensor signal is connected to the analog PIN A5 int sensorValue = 0; // variable in which we store the value received from the sensor void setup () { Serial.begin (9600); } void loop () { sensorValue = analogRead(sensorPin); delay(sensorValue); Serial.println (sensorValue, DEC); // you can graph the results using the serial plotter } Again, once the sketch is uploaded to Arduino, moving a magnet near the sensor allows us to observe the change in magnetic field strength, and thanks to the "Serial Plotter" feature of the IDE, we can also get a plot of the value of the same magnetic field it has as a function of distance. To activate the Serial Plotter, go to "Tools" and then click on "Serial Plotter." [For the video related to the project click here]. [For the sketch related to the project click here]. Curiosity: The Metal Detector The operating principle of a Metal Detector is very simple; we have said that a current produces a magnetic field, and if this current varies over time, the magnetic field produced will also vary over time. In 1834 the Russian physicist Emil Lenz discovered that by subjecting a conducting material (such as metals are, for example) to a time-varying magnetic field, an electric current is produced on it, which in turn produces a magnetic field that goes against the one generating the current (the so-called Lenz's Law). Thus, a metal detector, thanks to a coil run through by a varying current, produces a varying magnetic field, consequently on the metal that is perhaps in the ground, a counter magnetic field is produced, and then it is enough to detect that counter magnetic field that the metal we are looking for is found. The more time-varying the magnetic field, the greater the strength of the magnetic field induced in the metal we are searching for, and thus the greater the depth of investigation in the ground we can perform. In this way metal objects are found, remediation of ordnance is carried out,.... TREASURES are found! With the knowledge gained in this lesson we are able to build ourselves a seeker...magnets! Project 29 - Magnetic Detector with the Linear Magnetic Hall Sensor KY024. For this project we will use neither sensor module KY003 nor KY035, but sensor module KY024, which is the Linear Magnetic Hall Sensor. This module differs from the first two because it has both functionalities, that is, it has an analog output and a digital output: The PIN labeled A0 is the analog output, the PIN labeled D0, on the other hand, is the digital output, while the PIN labeled G stands for Ground and the PIN labeled "+" stands for the power supply (at 5 V). The module also has a trimmer that can be adjusted to adjust the sensitivity of the sensor and thus the threshold value for turning on the LED. There are two LEDs on the module, one is lit when the module is powered and the other when there is the presence of a magnetic field. For this project we need: Arduino Uno R3 or compatible Breadboard Hall effect linear sensor module KY024 Active buzzer The wiring diagram is as follows: Dupont male - male cables USB connection cable So we proceed to the connections as shown in the diagram below: We open the IDE and write the sketch below. The following Arduino sketch will read values from both the digital and analog sensor interfaces. The digital interface will turn on the LED at Arduino PIN 13 when a magnetic field is detected and will emit a sound from Buzzer. The analog interface starts from an initial value determined by the input voltage (adjusted by the trimmer), this value will increase or decrease depending on the strength and polarity of the magnetic field. For better graphical representation, the initial value is set to zero. Try moving the magnetic detector near a magnet to see its effect and through the trimmer adjust it accordingly. We always use the Serial Plotter to get the graphical representation of the values. /* Be Maker - STEM - Linear Analog-Digital Magnetic Field Sensor */ int ledPin = 13 ; // at PIN 13 the LED on the Arduino int digitalPin = 3; // at PIN 3 of the Arduino there is the digital signal int buzPin = 8; // at PIN 8 of Arduino there is active buzzer int analogPin = A0; // at PIN A0 of Arduino there is the analog signal int digitalVal ; // reading the digital value int analogVal = 0; // reading the analog value void setup () { pinMode (ledPin, OUTPUT); pinMode (buzPin, OUTPUT); pinMode (digitalPin, INPUT); pinMode(analogPin, INPUT); Serial.begin(9600); } void loop () { digitalWrite (ledPin, LOW); //holds off the LED at PIN 13 on Arduino digitalWrite(buzPin, LOW); //keeps the buzzer off digitalVal = digitalRead(digitalPin) ; // Reads the digital interface if(digitalVal == HIGH) //If the value of the sensor signal is "HIGH" //then the magnetic field is present and the LED //on the Arduino is turned on and the Active Buzzer is powered //then the value of A0 is read and printed { digitalWrite(ledPin, HIGH); digitalWrite (buzPin, HIGH); analogVal = analogRead(analogPin); Serial.println (analogVal, DEC); delay (analogVal); } else { digitalWrite(ledPin, LOW); digitalWrite(buzPin, LOW); analogVal = 0; Serial.println (analogVal, DEC); delay (300); } } Analysis of the Sketch: Project 29 Magnetic Detector. The only observation, worthy of the name, to the sketch concerns the analogRead () instruction, which will automatically set analog PIN A0 as INPUT , so the instruction pinMode(analogPIN, INPUT) can also be omitted, but for teaching reasons I have reported it anyway, that instruction, to avoid confusion. In addition, as you can see from the decision logic set with the if and else, if the magnetic field value is low (less than the threshold level adjusted with the trimmer), I forcibly set the analog signal readout variable to 0 and keep Led and Buzzer off. Of course, this logic can be modified at will. [For the video related to the project click here]. [For the sketch related to the project click here]. LESSON 9 - The Display for Arduino This Lesson we devote it to the immense world of displays that can be used with Arduino, obviously we will focus on those that actually turn out to be important to know from the point of view of the number of possible applications and we will leave out, at least for the moment, those that instead have specific uses or those that are particularly expensive. First, let's figure out when we need a display: the answer is simple! all those times when we need immediate return information, from the Arduino, that would otherwise require: connection with a USB cable, the availability of a PC, etc. For example, when we are monitoring a quantity, or when we want a status of a PIN... of course, I am not referring to the debugging phase, because in that case I can safely use the Serial Monitor or Serial Plotter that the IDE provides us with, but for example, when to have constantly under control the temperature of an environment, the voltage at the ends of a component, etc.... 7-segment LED display. As the name also implies, the display consists of 7 LED segments that are individually activated to dial the digit (i.e., single number) we wish to show. This type of display is used for countdown (starting with 9, of course), to indicate the status of a PIN, to indicate whether or not a process has been successful, etc. Since the segments are LEDs in their own right, they follow the normal LED rules when powered by Arduino, that is, they should be protected with 220 W resistors. Remember also that inserting resistors in series with the LEDs reduces the current delivered by the Arduino while preserving their functionality. The Display features the following corresponding segment identification: pinout with the The display can be of the "common cathode" type, then GND will go to the common (DC) and the individual PINs must be placed in the HIGH state to make the relevant LEDs light up, or, on the contrary, for the common anode version, voltage to 5V must be brought to the common (AC) PIN and the individual PINs, must be placed in the LOW state to make the relevant LEDs light up. Project 30 - Let's Make a Countdown. For this project we need: Arduino Uno R3 or compatible Breadboard 7segment LED display (common cathode) No. 8 220 W resistors Dupont male male cables USB connection cable The wiring diagram is as follows: R resistors are 220 W . The assembly scheme to be carried out is as follows: Note: The common PIN is connected to the Arduino GND because a "common cathode display" is being used. Once the circuit is assembled, the sketch to be written and uploaded to Arduino is: /* BE MAKER - STEM - Project No. 30 - Countdown with 7-segment led display */ // set the IO pin for each segment int a=11;// set digital pin 7 for segment a int b=10;// set digital pin 6 for segment b int c=5;// set digital pin 5 for segment c int d=6;// set digital pin 10 for segment d int e=7;// set digital pin 11 for segment e int f=8;// set digital pin 8 for segment f int g=9;// set digital pin 9 for segment g int dp=4;// set digital pin 4 for segment dp void digital_0(void) // display number 0 { digitalWrite(a,HIGH); digitalWrite(b,HIGH); digitalWrite(c,HIGH); digitalWrite(d,HIGH); digitalWrite(e,HIGH); digitalWrite(f,HIGH); digitalWrite(g,LOW); digitalWrite(dp,LOW); } void digital_1(void) // display number 1 { digitalWrite(a,LOW); digitalWrite(b,HIGH); digitalWrite(c,HIGH); digitalWrite(d,LOW); digitalWrite(e,LOW); digitalWrite(f,LOW); digitalWrite(g,LOW); digitalWrite(dp,LOW); } void digital_2(void) // display number 2 { digitalWrite(a,HIGH); digitalWrite(b,HIGH); digitalWrite(c,LOW); digitalWrite(d,HIGH); digitalWrite(e,HIGH); digitalWrite(f,LOW); digitalWrite(g,HIGH); digitalWrite(dp,LOW); } void digital_3(void) // display number 3 { digitalWrite(a,HIGH); digitalWrite(b,HIGH); digitalWrite(c,HIGH); digitalWrite(d,HIGH); digitalWrite(e,LOW); digitalWrite(f,LOW); digitalWrite(g,HIGH); digitalWrite(dp,LOW); } void digital_4(void) // display number 4 { digitalWrite(a,LOW); digitalWrite(b,HIGH); digitalWrite(c,HIGH); digitalWrite(d,LOW); digitalWrite(e,LOW); digitalWrite(f,HIGH); digitalWrite(g,HIGH); digitalWrite(dp,LOW); } void digital_5(void) // display number 5 { digitalWrite(a,HIGH); digitalWrite(b, LOW); digitalWrite(c,HIGH); digitalWrite(d,HIGH); digitalWrite(e, LOW); digitalWrite(f,HIGH); digitalWrite(g,HIGH); digitalWrite(dp,LOW); } void digital_6(void) // display number 6 { digitalWrite(a,HIGH); digitalWrite(b, LOW); digitalWrite(c,HIGH); digitalWrite(d,HIGH); digitalWrite(e,HIGH); digitalWrite(f,HIGH); digitalWrite(g,HIGH); digitalWrite(dp,LOW); } void digital_7(void) // display number 7 { digitalWrite(a,HIGH); digitalWrite(b,HIGH); digitalWrite(c,HIGH); digitalWrite(d,LOW); digitalWrite(e,LOW); digitalWrite(f,LOW); digitalWrite(g,LOW); digitalWrite(dp,LOW); } void digital_8(void) // display number 8 { digitalWrite(a,HIGH); digitalWrite(b,HIGH); digitalWrite(c,HIGH); digitalWrite(d,HIGH); digitalWrite(e,HIGH); digitalWrite(f,HIGH); digitalWrite(g,HIGH); digitalWrite(dp,LOW); } void digital_9(void) // display number 9 { digitalWrite(a,HIGH); digitalWrite(b,HIGH); digitalWrite(c,HIGH); digitalWrite(d,HIGH); digitalWrite(e,LOW); digitalWrite(f,HIGH); digitalWrite(g,HIGH); digitalWrite(dp,LOW); } void setup() { int i;// set variable for(i=4;i<=11;i++) pinMode(i,OUTPUT);// set pin from 4 to 11 as "output" } void loop() { while(1) { digital_9();// display number 9 delay(1000); // wait for 1s digital_8();// display number 8 delay(1000); // wait for 1s digital_7();// display number 7 delay(1000); // wait for 1s digital_6();// display number 6 delay(1000); // wait for 1s digital_5();// display number 5 delay(1000); // wait for 1s digital_4();// display number 4 delay(1000); // wait for 1s digital_3();// display number 3 delay(1000); // wait for 1s digital_2();// display number 2 delay(1000); // wait for 1s digital_1();// display number 1 delay(1000);// wait for 1s digital_0();// display number 0 delay(1000);// wait for 1s } } Starting the sketch, the display will illuminate the digit nine and after every second, it will decrease by one until it reaches zero and start again. Analysis of the sketch: Project 30: Let's make a Countdown. There are no special things to report in this sketch even though it is very long. In fact, the many sketch lines written are only to drive the 7 LED dialing seeds individually and nothing else. It should be remembered that in case we had a Common Anode display, then those that are PINs with HIGH status would be PINs with LOW status and vice versa. [For the video related to the project click here]. [For the sketch related to the project click here]. 4-digit 7-segment LED display. The 4-digit 7-segment LED display functions quite similarly to the one seen in single digits, the only difference being that in addition to the PINs that turn on the individual LED segments, there are an additional 4 PINs to the display that are used to enable the reference digit. The diagram of the display with the various PINs is as follows: The PINs named A, B, C, D, E ,F and G are the ones that turn on the segment LEDs, the PIN named dp is the one that turns on the dot LED, and the ones named D1, D2, D3 and D4, are the ones that turn on the single digit. Obviously, since we could only drive one digit at a time in this way, in case we wanted to represent a two-digit or multi-digit number, we would always have the individual digits light up one at a time, but at such a speed that to our eyes it would appear to be the two, or three, or four digits lit up at the same time...cartoon style made by quickly scrolling through the pages of individual drawings. These displays can also be found in the market in the Common Cathode type, or Common Anode type. In the case of the Common Cathode display, then D1, D2, D3, and D4 are placed in the state of LOW (one at a time) and PINs A, B, C, D, E ,F, and G (and dp, if dot is to be used), are placed in the state of HIGH. In the case of Common Anode displays, exactly the opposite occurs. Project 31 - Seconds counter. For this project we need: Arduino Uno R3 or compatible Breadboard 4 digit 7 segment LED display (common cathode) No. 8 220 W resistors Dupont male male cables USB connection cable The wiring diagram is as follows: The diagram below should be followed for assembly: After the connections we move on to writing the sketch. Connect Arduino to the PC via the USB cable and launch the Arduino IDE application by double-clicking on its icon. A blank window opens, or a new blank window needs to be opened and we write the sketch below: /* BE MAKER - STEM - Project 31 - SECONDS COUNTER. */ // If the Display is Common Cathode #define DIGIT_ON LOW #define DIGIT_OFF HIGH #define SEGMENT_ON HIGH #define SEGMENT_OFF LOW // If the Display is Common Anode // #define DIGIT_ON HIGH // #define DIGIT_OFF LOW // #define SEGMENT_ON LOW // #define SEGMENT_OFF HIGH // PIN variables definition second link int segE = 8; int segD = 7; int segDP = 5; int segC = 6; int segG = 12; int digit4 = 1; int digit1 = 4; int segA = 10; int segF = 11; int digit2 = 3; int digit3 = 2; int segB = 9; #define DISPLAY_BRIGHTNESS 20000 #define OFF 10 //Case no. 10 all segments off. void setup() { // Set all PINs to OUTPUT pinMode(segA, OUTPUT); pinMode(segB, OUTPUT); pinMode(segC, OUTPUT); pinMode(segD, OUTPUT); pinMode(segE, OUTPUT); pinMode(segF, OUTPUT); pinMode(segG, OUTPUT); pinMode(segDP, OUTPUT); pinMode(digit1, OUTPUT); pinMode(digit2, OUTPUT); pinMode(digit3, OUTPUT); pinMode(digit4, OUTPUT); // All digits set to off digitalWrite(digit1, DIGIT_OFF); digitalWrite(digit2, DIGIT_OFF); digitalWrite(digit3, DIGIT_OFF); digitalWrite(digit4, DIGIT_OFF); } void loop() { displayNumber(millis()/1000); } void displayNumber(int toDisplay) { for (int digit = 4 ; digit > 0 ; digit--) { if (digit==4) digitalWrite(digit4, DIGIT_ON); else if (digit==3) digitalWrite(digit3, DIGIT_ON); else if (digit==2) digitalWrite(digit2, DIGIT_ON); else if (digit==1) digitalWrite(digit1, DIGIT_ON); ShowNumber(toDisplay % 10); delayMicroseconds(DISPLAY_BRIGHTNESS); ShowNumber(OFF); toDisplay /= 10; digitalWrite(digit1, DIGIT_OFF); digitalWrite(digit2, DIGIT_OFF); digitalWrite(digit3, DIGIT_OFF); digitalWrite(digit4, DIGIT_OFF); } } // Segment management by number dialing void ShowNumber(int n) { switch (n) { case 0: digitalWrite(segA, SEGMENT_ON); digitalWrite(segB, SEGMENT_ON); digitalWrite(segC, SEGMENT_ON); digitalWrite(segD, SEGMENT_ON); digitalWrite(segE, SEGMENT_ON); digitalWrite(segF, SEGMENT_ON); digitalWrite(segG, SEGMENT_OFF); break; case 1: digitalWrite(segA, SEGMENT_OFF); digitalWrite(segB, SEGMENT_ON); digitalWrite(segC, SEGMENT_ON); digitalWrite(segD, SEGMENT_OFF); digitalWrite(segE, SEGMENT_OFF); digitalWrite(segF, SEGMENT_OFF); digitalWrite(segG, SEGMENT_OFF); break; case 2: digitalWrite(segA, SEGMENT_ON); digitalWrite(segB, SEGMENT_ON); digitalWrite(segC, SEGMENT_OFF); digitalWrite(segD, SEGMENT_ON); digitalWrite(segE, SEGMENT_ON); digitalWrite(segF, SEGMENT_OFF); digitalWrite(segG, SEGMENT_ON); break; case 3: digitalWrite(segA, SEGMENT_ON); digitalWrite(segB, SEGMENT_ON); digitalWrite(segC, SEGMENT_ON); digitalWrite(segD, SEGMENT_ON); digitalWrite(segE, SEGMENT_OFF); digitalWrite(segF, SEGMENT_OFF); digitalWrite(segG, SEGMENT_ON); break; case 4: digitalWrite(segA, SEGMENT_OFF); digitalWrite(segB, SEGMENT_ON); digitalWrite(segC, SEGMENT_ON); digitalWrite(segD, SEGMENT_OFF); digitalWrite(segE, SEGMENT_OFF); digitalWrite(segF, SEGMENT_ON); digitalWrite(segG, SEGMENT_ON); break; case 5: digitalWrite(segA, SEGMENT_ON); digitalWrite(segB, SEGMENT_OFF); digitalWrite(segC, SEGMENT_ON); digitalWrite(segD, SEGMENT_ON); digitalWrite(segE, SEGMENT_OFF); digitalWrite(segF, SEGMENT_ON); digitalWrite(segG, SEGMENT_ON); break; case 6: digitalWrite(segA, SEGMENT_ON); digitalWrite(segB, SEGMENT_OFF); digitalWrite(segC, SEGMENT_ON); digitalWrite(segD, SEGMENT_ON); digitalWrite(segE, SEGMENT_ON); digitalWrite(segF, SEGMENT_ON); digitalWrite(segG, SEGMENT_ON); break; case 7: digitalWrite(segA, SEGMENT_ON); digitalWrite(segB, SEGMENT_ON); digitalWrite(segC, SEGMENT_ON); digitalWrite(segD, SEGMENT_OFF); digitalWrite(segE, SEGMENT_OFF); digitalWrite(segF, SEGMENT_OFF); digitalWrite(segG, SEGMENT_OFF); break; case 8: digitalWrite(segA, SEGMENT_ON); digitalWrite(segB, SEGMENT_ON); digitalWrite(segC, SEGMENT_ON); digitalWrite(segD, SEGMENT_ON); digitalWrite(segE, SEGMENT_ON); digitalWrite(segF, SEGMENT_ON); digitalWrite(segG, SEGMENT_ON); break; case 9: digitalWrite(segA, SEGMENT_ON); digitalWrite(segB, SEGMENT_ON); digitalWrite(segC, SEGMENT_ON); digitalWrite(segD, SEGMENT_ON); digitalWrite(segE, SEGMENT_OFF); digitalWrite(segF, SEGMENT_ON); digitalWrite(segG, SEGMENT_ON); break; case 10: digitalWrite(segA, SEGMENT_OFF); digitalWrite(segB, SEGMENT_OFF); digitalWrite(segC, SEGMENT_OFF); digitalWrite(segD, SEGMENT_OFF); digitalWrite(segE, SEGMENT_OFF); digitalWrite(segF, SEGMENT_OFF); digitalWrite(segG, SEGMENT_OFF); break; } } Once the sketch is started the display will show the seconds elapsed since you started the sketch on Arduino. [For the video related to the project click here]. [For the sketch related to the project click here]. Project 32 - Counter of seconds and tenths of a second. Keep the same wiring and assembly diagram as in the previous project. Install the new SevSeg Library in the IDE: Go to Sketch, click on #include library and click on Manage Library and type in the dialog box the name of the library of interest which is called SevSeg and then once found, click on install and the library will be installed. Once the Library is installed, copy the code below into a new sketch: /* BE MAKER - STEM - Project 32: Stopwatch with use of the Library. EXTRACTED FROM THE LIBRARY EXAMPLES DISPLAY PIN CONNECTION CONFIGURATION TO ARDUINO Diital pins D1=4, D2=3, D3=2, D4=1 Segment pins A=10, B=9, C=6, D=7, E=8, F=11, G=12 and dp=5 */ #include "SevSeg.h" SevSeg sevseg; //Instantiate a seven segment controller object void setup() { byte numDigits = 4; byte digitPins[] = {4, 3, 2, 1}; byte segmentPins[] = {10, 9, 6, 7, 8, 11, 12,5}; bool resistorsOnSegments = false; // 'false' means resistors are on digit pins byte hardwareConfig = COMMON_CATHODE; // See README.md for options bool updateWithDelays = false; // Default 'false' is Recommended bool leadingZeros = false; // Use 'true' if you'd like to keep the leading zeros bool disableDecPoint = false; // Use 'true' if your decimal point doesn't exist or isn't connected sevseg.begin(hardwareConfig, numDigits, digitPins, segmentPins, resistorsOnSegments, updateWithDelays, leadingZeros, disableDecPoint); sevseg.setBrightness(90); } void loop() { static unsigned long timer = millis(); static int deciSeconds = 0; if (millis() - timer >= 100) { timer += 100; deciSeconds++; // 100 milliSeconds is equal to 1 deciSecond if (deciSeconds == 10000) { // Reset to 0 after counting for 1000 seconds. deciSeconds=0; } sevseg.setNumber(deciSeconds, 1); } sevseg.refreshDisplay(); // Must run repeatedly } Load the sketch on Arduino you will see that when the loading is complete the display will start counting the time elapsed since the program was launched on Arduino (seconds and tenths of a second will be indicated) Analysis of the sketch: Project 32 Chronometer with use of the Library. There are many interesting things in this sketch, let's look at the most interesting ones. First of all you can see that the use of the SevSeg Library drastically reduces the code instructions to be written since special functions are used to handle the 4-digit seven-segment LED Display. Among these instructions we find: byte hardwareConfig = COMMON_CATHODE; which tells Arduino what type of display we are using whether common cathode or common anode (in which case we would write COMMON_ANODE) . With instructions: byte digitPins[] = {4, 3, 2, 1}; byte segmentPins[] = {10, 9, 6, 7, 8, 11, 12,5}; we tell Arduino how our display is connected to its pins. In our particular case: Diital pins D1=4, D2=3, D3=2, D4=1 Segment pins A=10, B=9, C=6, D=7, E=8, F=11, G=12 and dp=5 . With education: bool leadingZeros = false; we tell Arduino whether there should be zeros in front of the digit we want to show on the display (in which case we needed to write "true" or not). With education: bool disableDecPoint = false; we tell Arduino that we plan to use the decimal point of the display (otherwise we would have written "true") With education: sevseg.setNumber(deciSeconds, 1); we tell Arduino that the numbers it needs to show on the display, are numbers with only one decimal place. Let's look at the millis() function instead: when it is called it returns the elapsed time, in milliseconds, since the sketch started running on the Arduino. Since we want tenths of a second, and after ten tenths of a second must trigger the second, the form to get this is: if (millis() - timer >= 100) { timer += 100; deciSeconds++; // 100 milliSeconds is equal to 1 deciSecond if (deciSeconds == 10000) { // Reset to 0 after counting for 1000 seconds. deciSeconds=0; } Also after 999.9 seconds, it resets the counter to zero and restarts from zero. Please note, the Arduino Reference Book says that the type of value returned by the millis() function is "unsigned long", also to make the variable fixed for the millis() function call, which is updated from time to time, it must also be defined as "static" type. So the correct form is: static unsigned long timer = millis(); For more details on the use of the library and instructions in C++ you can refer to the Readme file that accompanies the library, and for other instructions, to the Arduino Reference Book [Refence Book click here], while for the mills() function there is a project, also in this lesson, for further discussion. [For the video related to the project click here]. [For the sketch related to the project click here]. Project 33 - Potentiometer Value Display with 4 Digit Display The applications of a 4-digit display are really countless, in this project it is used to numerically represent the value that the potentiometer takes at that moment. The schematic to be made, for the display part is identical to the previous one so you can use the same wiring: For assembly, follow the diagram below: It is basically the same schematic as the previous project with the addition of the 10K potentiometer. Now open the Arduino IDE and write the following sketch: /* BE MAKER - STEM - Project 33: Potentiometer Value Display. EXTRACTED FROM THE LIBRARY EXAMPLES DISPLAY PIN CONNECTION CONFIGURATION TO ARDUINO Diital pins D1=4, D2=3, D3=2, D4=1 Segment pins A=10, B=9, C=6, D=7, E=8, F=11, G=12 and dp=5 */ #include "SevSeg.h" SevSeg sevseg; //Instantiate a seven segment controller object #define pot A0 void setup() { byte numDigits = 4; byte digitPins[] = {4, 3, 2, 1}; byte segmentPins[] = {10, 9, 6, 7, 8, 11, 12,5}; bool resistorsOnSegments = false; // 'false' means resistors are on digit pins byte hardwareConfig = COMMON_CATHODE; // See README.md for options bool updateWithDelays = false; // Default 'false' is Recommended bool leadingZeros = false; // Use 'true' if you'd like to keep the leading zeros bool disableDecPoint = true; // Use 'true' if your decimal point doesn't exist or isn't connected sevseg.begin(hardwareConfig, numDigits, digitPins, segmentPins, resistorsOnSegments, updateWithDelays, leadingZeros, disableDecPoint); sevseg.setBrightness(90); } void loop() { int val = analogRead(pot); int scale = map(val, 0, 1023, 0, 10000); //potentiometer from 10K if (scale > 9999 || scale < 1) { // if value > 9999 or < 0 then value to 0 scale = 0; } sevseg.setNumber(scale); sevseg.refreshDisplay(); // Must run repeatedly } [For the video related to the project click here]. [For the sketch related to the project click here]. Project 34 - Insight for the millis() function. The millis() function, as mentioned paragraph, once called in the form: in the previous unsigned long timer = millis(); returns the elapsed time, in milliseconds, since the start of the sketch loaded on the Arduino, but this definition does not give it the proper importance. First of all, we can observe that the variable that contains it is of the type "unsigned long" and that is, it can take a maximum value of 4,294,967,294, so if we divide by 1,000 and then by 60 and again by 60 and then by 24, it turns out that the millisecond counter, before it resets to zero, needs 49.7 days to elapse with the Arduino always on and running the same sketch. Only after the 50 days or so does the variable reset and start counting from zero again. This function has multiple uses, all of which are interesting and all to be discovered by doing several trials. Among the uses I find most interesting about this feature is that it gives you the ability to have actions occur at certain time intervals, so let's look at one application of it right away with a specific project. For this project we only need our Arduino connected to the PC via its USB cable The purpose of the project is to make writings appear on the Serial Monitor at certain time intervals (but it could be turning on one LED, turning off another, etc... the sketch can be easily adapted to our purposes). Copy the code below into a new Arduino sketch after launching the application: /* BE MAKER - STEM - Project 34: Deepening mills() */ #define INTERVAL_1 3000 #define INTERVAL_2 5000 #define INTERVAL_3 7000 #define INTERVAL_4 15000 unsigned long time_1 = 0; unsigned long time_2 = 0; unsigned long time_3 = 0; unsigned long time_4 = 0; void print_tempo(unsigned long tempo_millis); void setup() { Serial.begin(9600); } void loop() { if(millis() > time_1 + INTERVAL_1){ time_1 = millis(); print_time(time_1); Serial.println("I am"); } if(millis() > time_2 + INTERVAL_2){ time_2 = millis(); print_time(time_2); Serial.println("A message"); } if(millis() > time_3 + INTERVAL_3){ time_3 = millis(); print_time(time_3); Serial.println("Of"); } if(millis() > time_4 + INTERVAL_4){ time_4 = millis(); print_time(time_4); Serial.println("Greetings"); } } void print_tempo(unsigned long tempo_millis){ Serial.print("Time: "); Serial.print(time_millis/1000); Serial.print("s - "); } [For the video related to the project click here]. [For the sketch related to the project click here]. LED Matrix Display As the name implies, the module we will see consists of 24 LEDs arranged in 8 columns and 8 rows. There are several 8x8 LED displays on the market, the one we will analyze is the classic 16 PIN version. In fact, the number of pins this mudule has are 16, 8 pins, or PINs, are used to drive the columns and 8 PINs are used to drive the rows. Since Arduino has 14 digital PINs, the question arises: how do we drive the 16 PINs digitally if we only have 14 digital PINs with Arduino UNO? The answer is equally simple: by using two of the 5 analog PINs of Arduino, in fact an analog PIN can be used for all intents and purposes as a if it were a digital PIN of Arduino, as long as the same instructions as the digital PIN are used. But we will see this better in the sketch, now let's move on to a better understanding of how the 8x8 LED matrix works. LED arrays can also be Common Anode or Common Cathode, the latter being the most common. As you have undoubtedly already learned, in the case of the Common Cathode, the PIN must be placed in a low LOW state in order to make the individual PINs light up.So referring to the figure above, the rows, to which all the cathodes are connected, must be placed in a LOW state, while the columns must be placed in a HIGH state in order to make the LEDs light up. So as if we were at the game of naval battle, in order to make the LEDwhich is in column 4 and row 2 light up, we have to put column 4 in the state of HIGH and row 2 in the state of LOW and titte the other rows and columns have to be in the state of LOW. Having figured out how to make the individual LEDs light up, it is simple at this point to be able to dial in both letters and numbers with the matrix. Let us now turn to the project. Project 35 - HELLO WORLD IN MATRIX ! For this project we need: Arduino Uno R3 or compatible Breadboard 8x8 LED Matrix Display No. 8 220 W resistors Dupont male male cables USB connection cable (common cathode) The wiring diagram is as follows: Pay attention to the connections in the wiring diagram, you need to consider the following pin-out of the display (in my case), obviously in your case I suggest you retrieve the datasheet from the internet by googling the serial number of your display, if it matches mine, then follow the same connections, otherwise you will have to adjust them. Personally, thanks to the datasheet of the LED matrix I purchased, I constructed this little table that helped me: DISPLAY PIN. ROW/COLUMN DISPLAY RESISTANCE ARDUIN PIN 1 R5 220 W 4 2 3 4 R7 220 W 6 A0 12 5 6 R8 220 W 7 11 7 R6 220 W 5 8 R3 220 W 2 9 10 11 R1 220 W 0 13 10 12 13 14 R4 220 W 3 A1 1 C2 C3 C5 C4 C6 C1 R2 220 W 15 16 C7 C8 9 8 At this point the assembly diagram turns out to be much easier to make even though there is a considerable number of dupont wires. Now we double-click on the Arduino icon on the Desktop and the IDE opens and we copy the following sketch, be sure to follow each step indicated: /* Be Maker School - STEM - Project 3 - Hello World in Matrix */ #define r8 0 #define r7 1 #define r6 2 #define r5 3 #define r4 4 #define r3 5 #define r2 6 #define r1 7 #define c1 8 #define c2 9 #define c3 10 #define c4 11 #define c5 12 #define c6 13 #define c7 19 #define c8 18 #define initr HIGH #define initc LOW int analoginit= 0; #define pause 100 #define screenTime 50 int vRows[8]={r1,r2,r3,r4,r5,r6,r7,r8}; int vCols[8]={c1,c2,c3,c4,c5,c6,c7,c8}; byte A[8][8] = {{0,0,0,1,1,0,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0}, {0,0,1,1,1,1,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0}, {0,0,1,0,0,1,0,0}}; byte B[8][8] = {{0,0,1,1,1,0,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0}, {0,0,1,1,1,0,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0}, {0,0,1,1,1,0,0,0}}; byte C[8][8] = {{0,0,0,0,0,0,0,0},{0,0,0,1,1,1,1,0},{0,0,1,0,0,0,0,0}, {0,1,0,0,0,0,0,0},{0,1,0,0,0,0,0,0},{0,0,1,0,0,0,0,0},{0,0,0,1,1,1,1,0}, {0,0,0,0,0,0,0,0}}; byte D[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,1,1,0,0,0},{0,0,1,0,0,1,0,0}, {0,0,1,0,0,0,1,0},{0,0,1,0,0,0,1,0},{0,0,1,0,0,1,0,0},{0,0,1,1,1,0,0,0}, {0,0,0,0,0,0,0,0}}; byte E[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,1,1,1,0,0},{0,0,1,0,0,0,0,0}, {0,0,1,1,1,0,0,0},{0,0,1,0,0,0,0,0},{0,0,1,0,0,0,0,0},{0,0,1,1,1,1,0,0}, {0,0,0,0,0,0,0,0}}; byte F[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,1,1,1,0,0},{0,0,1,0,0,0,0,0}, {0,0,1,1,1,0,0,0},{0,0,1,0,0,0,0,0},{0,0,1,0,0,0,0,0},{0,0,1,0,0,0,0,0}, {0,0,0,0,0,0,0,0}}; byte G[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,1,1,1,1,0},{0,0,1,0,0,0,0,0}, {0,0,1,0,0,0,0,0},{0,0,1,0,1,1,1,0},{0,0,1,0,0,0,1,0},{0,0,1,1,1,1,1,0}, {0,0,0,0,0,0,0,0}}; byte H[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0}, {0,0,1,1,1,1,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0}, {0,0,0,0,0,0,0,0}}; byte I[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,1,1,0,0,0},{0,0,0,1,0,0,0,0}, {0,0,0,1,0,0,0,0},{0,0,0,1,0,0,0,0},{0,0,0,1,0,0,0,0},{0,0,1,1,1,0,0,0}, {0,0,0,0,0,0,0,0}}; byte J[8][8] = {{0,0,0,0,0,0,0,0},{0,0,0,1,1,1,0,0},{0,0,0,0,1,0,0,0}, {0,0,0,0,1,0,0,0},{0,0,0,0,1,0,0,0},{0,0,1,0,1,0,0,0},{0,0,1,1,1,0,0,0}, {0,0,0,0,0,0,0,0}}; byte K[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,1,0,0,0}, {0,0,1,1,0,0,0,0},{0,0,1,0,1,0,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0}, {0,0,0,0,0,0,0,0}}; byte L[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,0,0,0,0,0},{0,0,1,0,0,0,0,0}, {0,0,1,0,0,0,0,0},{0,0,1,0,0,0,0,0},{0,0,1,0,0,0,0,0},{0,0,1,1,1,1,0,0}, {0,0,0,0,0,0,0,0}}; byte M[8][8] = {{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,1,0,0,0,1,0,0}, {1,0,1,0,1,0,1,0},{1,0,0,1,0,0,1,0},{1,0,0,0,0,0,1,0},{1,0,0,0,0,0,1,0}, {0,0,0,0,0,0,0,0}}; byte N[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,0,0,0,1,0},{0,0,1,1,0,0,1,0}, {0,0,1,0,1,0,1,0},{0,0,1,0,0,1,1,0},{0,0,1,0,0,0,1,0},{0,0,0,0,0,0,0,0}, {0,0,0,0,0,0,0,0}}; byte O[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,1,1,1,0,0},{0,1,0,0,0,0,1,0}, {0,1,0,0,0,0,1,0},{0,1,0,0,0,0,1,0},{0,1,0,0,0,0,1,0},{0,0,1,1,1,1,0,0}, {0,0,0,0,0,0,0,0}}; byte P[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,1,1,0,0,0},{0,0,1,0,0,1,0,0}, {0,0,1,0,0,1,0,0},{0,0,1,1,1,0,0,0},{0,0,1,0,0,0,0,0},{0,0,1,0,0,0,0,0}, {0,0,0,0,0,0,0,0}}; byte Q[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,1,1,1,0,0},{0,1,0,0,0,0,1,0}, {0,1,0,0,0,0,1,0},{0,1,0,0,0,0,1,0},{0,1,0,0,0,1,1,0},{0,0,1,1,1,1,1,0}, {0,0,0,0,0,0,0,1}}; byte R[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,1,1,0,0,0},{0,0,1,0,0,1,0,0}, {0,0,1,0,0,1,0,0},{0,0,1,1,1,0,0,0},{0,0,1,0,0,1,0,0},{0,0,1,0,0,1,0,0}, {0,0,0,0,0,0,0,0}}; byte S[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,1,1,1,0,0},{0,0,1,0,0,0,0,0}, {0,0,1,1,1,1,0,0},{0,0,0,0,0,1,0,0},{0,0,0,0,0,1,0,0},{0,0,1,1,1,1,0,0}, {0,0,0,0,0,0,0,0}}; byte T[8][8] = {{0,0,0,0,0,0,0,0},{0,1,1,1,1,1,0,0},{0,0,0,1,0,0,0,0}, {0,0,0,1,0,0,0,0},{0,0,0,1,0,0,0,0},{0,0,0,1,0,0,0,0},{0,0,0,1,0,0,0,0}, {0,0,0,0,0,0,0,0}}; byte U[8][8] = {{0,0,0,0,0,0,0,0},{0,1,0,0,0,0,1,0},{0,1,0,0,0,0,1,0}, {0,1,0,0,0,0,1,0},{0,1,0,0,0,0,1,0},{0,0,1,0,0,1,0,0},{0,0,0,1,1,0,0,0}, {0,0,0,0,0,0,0,0}}; byte V[8][8] = {{0,0,0,0,0,0,0,0},{0,0,1,0,0,0,1,0},{0,0,1,0,0,0,1,0}, {0,0,1,0,0,0,1,0},{0,0,0,1,0,1,0,0},{0,0,0,1,0,1,0,0},{0,0,0,0,1,0,0,0}, {0,0,0,0,0,0,0,0}}; byte W[8][8] = {{0,0,0,0,0,0,0,0},{1,0,0,0,0,0,1,0},{1,0,0,1,0,0,1,0}, {0,1,0,1,0,1,0,0},{0,1,0,1,0,1,0,0},{0,0,1,0,1,0,0,0},{0,0,0,0,0,0,0,0}, {0,0,0,0,0,0,0,0}}; byte X[8][8] = {{0,0,0,0,0,0,0,0},{0,1,0,0,0,0,1,0},{0,0,1,0,0,1,0,0}, {0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,0,0,1,0,0},{0,1,0,0,0,0,1,0}, {0,0,0,0,0,0,0,0}}; byte Y[8][8] = {{0,1,0,0,0,0,1,0},{0,1,0,0,0,0,1,0},{0,0,1,0,0,1,0,0}, {0,0,1,0,0,1,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0}, {0,0,0,1,1,0,0,0}}; byte Z[8][8] = {{0,1,1,1,1,1,1,0},{0,0,0,0,0,0,1,0},{0,0,0,0,0,1,0,0}, {0,0,0,0,1,0,0,0},{0,0,0,1,0,0,0,0},{0,0,1,0,0,0,0,0},{0,1,0,0,0,0,0,0}, {0,1,1,1,1,1,1,0}}; byte space[8][8]= {{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0}, {0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0}, {0,0,0,0,0,0,0,0}}; byte escl[8][8]= {{0,0,0,0,0,0,0,0},{0,0,0,1,0,0,0,0},{0,0,0,1,0,0,0,0}, {0,0,0,1,0,0,0,0},{0,0,0,1,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,0,0,0,0}, {0,0,0,0,0,0,0,0}}; void resetRows(){ for(int i=0;i<8;i++) digitalWrite(vRows[i],initr); } void resetCols(){ for(int i=0;i<8;i++) digitalWrite(vCols[i],initc); } void setup() { pinMode(r1,OUTPUT); pinMode(r2,OUTPUT); pinMode(r3,OUTPUT); pinMode(r4,OUTPUT); pinMode(r5,OUTPUT); pinMode(r6,OUTPUT); pinMode(r7,OUTPUT); pinMode(r8,OUTPUT); pinMode(c1,OUTPUT); pinMode(c2,OUTPUT); pinMode(c3,OUTPUT); pinMode(c4,OUTPUT); pinMode(c5,OUTPUT); pinMode(c6,OUTPUT); pinMode(c7,OUTPUT); pinMode(c8,OUTPUT); resetRows(); resetCols(); } void lightRows(){ for(int i=0;i<8;i++) digitalWrite(vRows[i],!initr); } void lightCols(){ for(int i=0;i<8;i++) digitalWrite(vCols[i],!initc); } void counter1(){ for(int i=0;i<8;i++){ resetCols(); resetRows(); digitalWrite(vCols[i],HIGH); delay(pause); for(int j=0;j<8;j++){ resetRows(); digitalWrite(vRows[j],LOW); delay(pause); } } } void counter2(){ for(int i=0;i<8;i++){ resetCols(); resetRows(); digitalWrite(vRows[i],LOW); delay(pause); for(int j=0;j<8;j++){ resetCols(); digitalWrite(vCols[j],HIGH); delay(pause); } } } void blinking(){ for(int i=0;i<3;i++){ lightCols(); lightRows(); delay(pause*10); resetRows(); resetCols(); delay(pause*10); } } void drawSymbols(byte m[8][8]){ for(int k=0;k<screenTime;k++){ for(int i=0;i<8;i++){ digitalWrite(vCols[i],!initc); for(int j=0;j<8;j++) digitalWrite(vRows[j],!m[i][j]); delay(2); resetRows(); resetCols(); } } } void writeLetter(String wordIn){ for(int i=0;wordIn[i]!=0;i++){ switch(wordIn[i]){ case 'A':drawSymbols(A); break; case 'B':drawSymbols(B); break; case 'C':drawSymbols(C); break; case 'D':drawSymbols(D); break; case 'E':drawSymbols(E); break; case 'F':drawSymbols(F); break; case 'G':drawSymbols(G); break; case 'H':drawSymbols(H); break; case 'I':drawSymbols(I); break; case 'J':drawSymbols(J); break; case 'K':drawSymbols(K); break; case 'L':drawSymbols(L); break; case 'M':drawSymbols(M); break; case 'N':drawSymbols(N); break; case 'O':drawSymbols(O); break; case 'P':drawSymbols(P); break; case 'Q':drawSymbols(Q); break; case 'R':drawSymbols(R); break; case 'S':drawSymbols(S); break; case 'T':drawSymbols(T); break; case 'U':drawSymbols(U); break; case 'V':drawSymbols(V); break; case 'W':drawSymbols(W); break; case 'X':drawSymbols(X); break; case 'Y':drawSymbols(Y); break; case 'Z':drawSymbols(Z); break; case '!':drawSymbols(excl); break; default:drawSymbols(space); break; } } } void loop() { counter1(); counter2(); blinking(); String a="HELLO WORLD!" writeLetter(a); } Once the sketch is loaded, the letter-by-letter Hello World appears illuminated on the LED array. Analysis of the Sketch: Hello World in the Matrix As you can see from the sketch, we introduced a new type of variable. We had already seen what arrays were, that is, variables that could contain multiple values and were identified with an index. In this sketch we see the array variable (always called array) being defined in this way: byte A[8][8] = {{{0,0,0,1,0,0,0},....., {.....}}; where "bytes" indicates the type of variable and how much memory it occupies, "A[8][8]" indicates the name of the variable and the size of the array, i.e., 8 rows and 8 columns, and then after the "=" in curly brackets, the individual values are entered, which in our case represent the LEDs that must be turned on to make up the letter "A," in fact if you notice, zero is set for the LED to be kept off and 1 for the LED to be turned on, so for the variable A: 1 2 3 4 5 6 7 8 1 0 0 0 0 0 0 0 0 2 0 0 0 0 0 0 0 0 3 0 1 1 1 1 1 1 1 4 1 0 0 1 0 0 0 0 5 1 0 0 1 0 0 0 0 6 0 1 1 1 1 1 1 1 7 0 0 0 0 0 0 0 0 8 0 0 0 0 0 0 0 0 In this way you can dial what you want and assign it a variable name. Alternatively, it is possible to activate individual LEDs, again in the sketch you can observe the functions "counter1()", "counter2()" and "blinking()" which thanks to "for" cycles drive the individual LEDs in the matrix by acting directly in the variables vCols and vRows. Returning to the representation on the LED array of the phrase "Hello World", we can observe the function writeLetter(...) that for each letter of the string we enter to it, thanks to the switch... case... structure, calls the variable of the single letter that makes up the word Hello Word and represents it on the LED array. [For the sketch related to the project click here]. The LCD Display Also using the LCD display represents a good way to immediately represent some values that we find useful to keep track of in an ongoing process in Arduino. Liquid crystal displays (LCDs) consist of liquid crystals activated by electric current. Curiosity: how the LCD display works The process of operation is not the easiest to explain in detail, so a very simplified description is given here; for any further study, plenty of material can be found on the Internet. As far as we are concerned, it is enough to know about the LCD display which is made thanks to the presence of liquid crystals i.e., a particular substance that at the same temperature can coexist both in the liquid and solid state at the same time, this substance subjected to polarization, i.e., a low-power electric current, has a different behavior that we are able to drive. Certain parts of the substance, polarized, orient themselves in a precise configuration, thus forming the figure of our interest. There are several types that differ substantially in the number of lines of alphanumeric information they can display, normally they are 16 characters and are two-, three- or four-line (for those used with Arduino). The liquid crystal display has the distinct advantage of having low power consumption compared to LED displays. Its other advantages are its low cost and ease of finding it on the market. The main disadvantages of LCDs are: a light source must be added to make the information visible, and when there is low ambient light, a backlight must also be added. Other disadvantages are: it can work in a very limited temperature range (i.e., between 0°C and 60° C), also it has a short operating life compared to LED displays. Project 36 - HELLO WORLD WITH LCD DISPLAY. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables LCD display 16 x 2 lines No. 2 220 W resistors 10 KOhm potentiometer USB connection cable The wiring diagram is as follows: For better visibility of PINs, I partially reproduce the photo of the display: The assembly scheme is as follows: Once the circuit is assembled, the sketch to be written and uploaded to Arduino is: /* Be Maker School - STEM - Project 36 - Hello World LCD */ #include <LiquidCrystal.h> const int rs = 12, en = 11, d4 = 5, d5 = 4, d6 = 3, d7 = 2; //define variables associated with link PINs LiquidCrystal lcd(rs, en, d4, d5, d6, d7); //associating display PINs to Arduino PINs void setup() { lcd.begin(16, 2); //set the display as a 2-line, 16-character display lcd.print("hello, world!"); //let me play the inscription only once } int foo = 0; //set a variable that will act as my seconds counter void loop() { lcd.setCursor(0, 1); //position the cursor on the first line down to the position lcd.print(foo); //print the seconds counter delay(1000); foo++; } Sketch Analysis: Hello World with LCD Display As you can see from the sketch for the operation of the display we introduce a new library called <LiquidCrystal.h>. This library significantly simplifies our use of the display, in fact it only takes a few lines of program code to achieve the desired result. Let's see what instructions help us manage our LCD display. First we need to call the Dedicated Library with #include <LiquidCrystal.h> , in the void setup part, I can set the title of the information that is shown, it is printed once on the display lcd.print("hello, world!");. In the void loop part instead when the information needs to be updated lcd.print(foo); The positioning of the cursor from which to start the writing is done with the instruction: lcd.setCursor(0, 1); at this point have fun making changes and see the results. [For the video related to the project click here]. [For the sketch related to the project click here]. LESSON 10 - Insight into Light: the Infrared The sun is the source of life for the earth, thanks to it we have the light and heat we need for our survival. Light is produced by a transformation of energy; in fact, due to the high temperatures of the sun's constituent mass, its incandescence is transferred not only as heat, but also as light. The same principle applies to candles, to incandescent light bulbs, which have a tungsten filament that heats up, due to the circulation of current, in addition to producing heat, emits light. There are other ways to produce light, such as by passing electrical discharges through a gas (neon lights, or mercury vapor lights), or by exploiting the electroluminescent characteristics of particular materials as is the case with LEDs. Leaving aside the Quantum Physics of the great scientist Albert Einstein, let's try to understand a little bit more than what we learned in Lesson No. 3. We have already seen that light propagates in waves, however, unlike sound, it does not need a "material" medium because they are special electromagnetic waves (photon waves). Basically, light propagates even in a vacuum (just think of the light that comes to us from stars, but also from the sun itself). The propagation of light occurs on straight trajectories called "rays," and they, too, may encounter obstacles on their path. The propagation speed of light, is much higher than that of Sound. The demonstration of this is when there is a thunderstorm... lightning generates both light and at the same time, noise, but we get the lightning first... and after a few seconds the thunder. Light travels at about 300,000 kilometers per second , that is, in one second light travels about 300,000 kilometers! When light meets a transparent body, it manages to pass through it, only a very small part is reflected. If the body is opaque, then diffuse reflection occurs. If the body is a mirror, then the reflection is said to be specular. Through reflection we are able to see even objects that do not emit light of their own. Just to complete the topic of "light" of our interest, I would like to say that infrared is that particular light whose spectrum (i.e., wavelength) is below the color red (hence "infrared"), i.e., a frequency whose wavelength is greater than 700 nano-meter is of the order of tera-Hertz. Infrared has countless applications in electronics and robotics, we will look at some of them. Infrared Sensor Module KY-032 This sensor module is used as an alternative method to the HC-SR04 sensor module for obstacle detection. The operating principle of the sensor is very similar to the ultrasonic module, in fact it is based on the emission of infrared signals that are then reflected by any bodies that are in the path of the incident signal beam and then, once reflected, are picked up by the receiver: Comparison of HCSR04 Ultrasonic Module and KY032 Infrared Module. For the comparison between Ultrasonic Module HCSR04 and Infrared Module KY032 for obstacle detection, we construct a small table to highlight the major differences between the two modules for the purpose of obstacle detection: Main Features Ultrasonic Module (Sound) Spectrum Propagation Frequencies above 20 kHz (20 kilo-hertz, or 20 thousand hetz). Ultrasound is at the high end of the sound spectrum. Infrared Module (Light) Frequency on the order of THz (tera-hertz, or trillion hertz). Infrared is at the lower end of the light spectrum. The maximum propagation speed of light is in vacuum: 300,000 km/s (300,000 kilometers per second). Compared with solid bodies, sound in air propagates at a slower speed and does not propagate in a vacuum. In air, the speed of sound is about 340 m/s (340 meters per second) Ability of the Optimal for solid At the same angle reflected wave surfaces that are to the sound, with to return in the same direction as the generator. perpendicular to the direction of the sound wave, as these surfaces tilt, relative to the direction of the wave, the dispersion of reflected sound increases. For particular inclinations, the sound wave does not return in the direction of the generator, so the reflection causes the sound to scatter. light there is a very good reflection in the direction of the generator--even for very inclined surfaces. Light is not reflected from very dark-colored bodies (in which case light is absorbed) and in the case of transparent materials (where light passes through the material). It is clear from the comparison that the two obstacle detection modules, although they serve the same purpose, function differently and the two systems almost complement each other to form a single system that is safer in obstacle detection. Project 37 - The use of KY032 Module with the EN PIN disabled For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables IR module KY032 with jumper inserted on EN The scheme to be carried out is as follows: USB connection cable The assembly scheme is as follows: We click on the Arduino icon and after opening a new file we copy the sketch below: /* Be Maker - STEM - PROJECT 37 INFRARED MODULE KY-032 FOR OBSTACLE DETECTION. With EN disabled */ int Obstacle = 0; //LOW status means obstacle found! #define ObstaclePin 8 // selects the pin for sensor KY-032 void setup() { pinMode(ObstaclePin, INPUT); //setting PIN 8 as INPUT Serial.begin(9600); //setting the serial port } void loop() { Obstacle = digitalRead(ObstaclePin); //read the status of PIN 8 if (Obstacle == 0) { Serial.println(" Obstruction eye!!!"); //if PIN 8 status is low //then the obstacle is present } else { Serial.println (" Street Free"); //otherwise, the street is free } delay(50); //cycle repeats after 300 msec. } Once the sketch is loaded and the serial monitor is activated, pass your hand in front of the sensor module at different distances and verify the detection by the LED on board the module lighting up and the writing appearing on the serial monitor. The switching point of the sensor can be adjusted using the trimmers located on the module. Analysis of the Sketch: Project 37 Form KY032. Since the Module functions as a switch, i.e., if it finds the obstacle within the distance calibrated by the trimmers the module puts the signal PIN in the LOW state, it is suggested to proceed , before its use, to calibration. This is done with the help of a ruler and by placing an obstacle at the desired distance. It will be necessary to adjust the two trimmers until the obstacle, at that precise distance, is detected. [For the video related to the project click here]. [For the sketch related to the project click here]. Project 38 - The use of KY032 Module with the EN PIN enabled For this project we need: Arduino Uno R3 or compatible IR module KY032 with jumper removed on EN Breadboard Dupont male male cables USB connection cable The scheme to be carried out is as follows: The assembly scheme is as follows: We click on the Arduino icon and after opening a new file we copy the sketch below: /* Be Maker - STEM - DRAFT 38 INFRARED MODULE KY-032 FOR OBSTACLE DETECTION. With EN enabled */ int ObstaclePin = 8; //Pin to which the sensor is connected int EnPin = 7; //Pin to which the EN PIN of the module is connected. int Obstacle = LOW; //LOW status means obstacle not found void setup() { pinMode(ObstaclePin, INPUT); //setting PIN 8 as INPUT pinMode(EnPin, OUTPUT); //setting PIN 7 as OUTPUT Serial.begin(9600); //setting the serial port } void loop() { digitalWrite(EnPin, HIGH); //enable module operation Obstacle = digitalRead(ObstaclePin); //read the status of PIN 8 if (Obstacle == LOW) { Serial.println("Obstruction eye!!!"); //If the status of PIN 8 is low then the obstacle is present } else { Serial.println ("Street Clear"); //otherwise, the street is clear } delay(30); //cycle repeats after 300 msec. } Once the sketch is loaded and the serial monitor is activated, pass your hand in front of the sensor module at different distances and verify the detection by the LED on board the module lighting up and the writing appearing on the serial monitor. The switching point of the sensor can be adjusted using the trimmers located on the module. Basically, in this design, as you can see, you only have the special feature that the operation of the module can be enabled or disabled as needed. To enable it, the EN PIN must be put in the high state (HIGH). With the presence of the jumper the EN turns out to be always enabled. [For the video related to the project click here]. [For the sketch related to the project click here]. KY-033 Infrared Sensor Module - Line Tracking We have seen, in the previous paragraphs, that infrared when hitting surfaces with particular very dark colors, they fail to be reflected and therefore not picked up by the receiving sensor. So, some fellow Makers of yours rightly thought of exploiting this phenomenon to make a sensor that could identify a dark-colored line from other colors. Such a module was called a Line Tracking Module (English: Line Tracking) and its abbreviation under which it is commercially sold is KY-033, we will call it a line-tracking sensor or module. The operation of such a sensor is simple, and the module is similar to the previous one: Basically, when the receiving LED does not pick up the infrared emitted by the emitting LED, it means that the sensor is positioned on the BLACK color Line (obviously, very dark colors must be used to draw the lines, BLACK being the optimum). The module has three PINs, one for ground (indicated by G or GND), one for power supply (indicated by Vcc or V+), and one for output signal (indicated by S or OUT). The location is not always as shown in the figure so watch for the indications on the module. In addition, the module has a trimmer that is used to adjust the intensity of the emitting signal, so depending on the distance between the emitter and the line to be tracked, a small adjustment has to be made (usually in the middle position, which is the one shown in the figure above, it already works very well). It should be noted that the output signal is analog, so you will need to connect the signal PIN of the module to an Analog PIN of the Arduino. But let's take a closer look at the operation of the module in the following project. Project 39 - The Use of KY033 Line Tracking Module. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables IR Module KY033 Line Tracking The scheme to be carried out is as follows: USB connection cable The assembly scheme is as follows: We click on the Arduino icon and after opening a new file we copy the sketch below: /* Be Maker - STEM - Project 39 - Line Chase Module -KY033 */ int sensorPin = A5; // The sensor is connected to the A5 pin. int ledPin = 13; // selected PIN 13 for the LED on the Arduino int sensorValue = 0; // Variable that takes the value from the sensor void setup () { pinMode (ledPin, OUTPUT); Serial.begin (9600); } void loop () { sensorValue = analogRead(sensorPin); if (sensorValue > 500) { digitalWrite(ledPin,HIGH); //PIN on Arduino turned on Serial.println ("ON LINE"); } else { digitalWrite(ledPin,LOW); //PIN on Arduino off Serial.println ("OUT OF LINE"); } delay (200); } Once the sketch is loaded and the serial monitor is activated, pass the sensor over a Line at least a couple of cm thick and observe the output signal. Sketch Analysis: Project 39 - KY033 Line Tracking Module. Analyzing the sketch above we can observe the following instruction: int ledPin = 13; With this instruction we say that the Integer Variable named LED has a value of 13. The same can be said about education: int sensorPin = A5; Where A5 is the number of the Analog PIN of Arduino where we connected the "OUT" signal of the sensor. The Variable named "sensorValue," is assigned a value of 0 initially, with the instruction: int sensorValue = 0; Related to the SETUP section, we can observe the instructions: pinMode(ledPin, OUTPUT); which defines as OUTPUT the LED that is on the Arduino (and is connected right to PIN 13). In the LOOP section we have the interesting part: first we have the analogRead(sensorPIN) instruction read; the value present on PIN A5 and assign it to the variable sensorValue. At this point when the sensor is above a clear surface, the module returns a low voltage value (about 83 mV - milliVolts), so remembering that the analog PIN goes from 0 to 1023, we calibrate the sensor to a value of 500, i.e.: 5 V/1024*500 = 2.44 V. That is, when the sensor returns a value greater than 2.44 V (i.e., greater than 500) it is on a dark surface and for us the sensor is in the correct position is therefore "ON LINE." I carried out several tests, also using the adjustment granted by the trimmer, and observed that, placing the sensor about 4 to 5 cm from the surface, with the color brown the sensor returns values between 500 and 600, while with black it goes between 800 and 1000. The best sensor functionality, however, is when you put two of them paired together. They are better able to detect their relative positioning with respect to the line to be tracked. [For the video related to the project click here]. [For the sketch related to the project click here]. The Infrared Remote Control - IR Remote Controller In addition to being used for sensors in detecting obstacles or tracking lines, infrared light is also used to transmit information from one device to another. An example of this is our TV remote control. In this part of the Lesson we will concentrate on learning the operation of an infrared remote control (information transmitter) and its corresponding information receiving device (which in our case is an infrared receiver called KY022). Information from one device to another is transmitted via Infrared signals (we use the abbreviation IR for short) of an encoded type. Normally when one buys the remote control, the manufacturer of the remote control also indicates in the manual the encoding with which the remote control transmits information about IR signal, but we will dispense with this information, because we will also see how to get this information from our remote control. So we will perform two practical projects, one to retrieve the encoding information (thus decoding the signal) and the other to use the transmitted encoded information to make Arduino perform operations. Project 40 - Decoding the IR signal of a remote control For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables USB connection cable IR remote control to be decoded IR Receiver KY022 220 W resistor The scheme to be carried out is as follows: For assembly, refer to the diagram below: Green LED After the connections we move on to writing the sketch. Connect Arduino to the PC via the USB cable and launch the Arduino IDE application by double-clicking on its icon. Open a new empty window and write the sketch below: /* Be Maker - STEM - Project 40 - Decoding IR Remote Control */ #include <IRremote.h> int pinIRremote = 5; //PIN of Arduino to which the receiver signal is connected IRrecv receiver(pinIRremote); //instance for object creation decode_results results; int ledPin=9; void setup() { Serial.begin(9600); //set the serial port receiver.enableIRIn(); //enables reception pinMode(ledPin, OUTPUT); } void loop() { if (receiver.decode(&results)) { digitalWrite(ledPin, HIGH); //turns on the LED when it receives the signal Serial.println(results.value); delay(1000); digitalWrite(ledPin, LOW); //shuts down the LED after decoding receiver.resume(); //ready to receive the next signal } } At this point, once you have loaded the sketch on the Arduino, open the Serial Monitor of the IDE , point the remote control at the receiver, and press each button on the remote control once. With each press, the green light turns on when the signal is captured and turns off when the decoding is done. The code of the button pressed appears on the Serial Monitor. Now all that remains is to write down the codes corresponding to each button on the remote control. In my case: - Power off button: 16580863 Volume +: 16613503 Volume -: 16617583 1 : 16582903 2 : 16615543 3 : 16599223 4 : 16591063 Etc... Sketch Analysis: Project 40 Decoding the IR signal of a remote control. As you can see from the sketch, we have introduced a new library: #include <IRremote.h> that makes it very easy to use the IR Receiver. In fact, you only have to read the comment lines at the individual command lines that you can immediately guess what function the individual instruction performs. Be careful, it is quite normal for the IR Receiver to also capture other infrared signals, such as those generated by artificial lighting or even from other remote commands. [For the video related to the project click here]. [For the sketch related to the project click here]. Project 41 - Piloting Events with IR Remote Control Thanks to the KY-022 Module, we can drive events with an Infrared remote control, in fact, once we have stored the codes corresponding to the individual keys of the remote control, with the if instruction that establishes which key has been pressed, we can make a certain event take place. An example is the following project. For this project we need: Arduino Uno R3 or compatible Breadboard Dupont male male cables USB connection cable IR remote control to be decoded IR Receiver KY022 No. 4 220 W resistor No. 4 LEDs of different colors The scheme to be carried out is as follows: For assembly, refer to the diagram below: After the connections we move on to writing the sketch. Connect Arduino to the PC via the USB cable and launch the Arduino IDE application by double-clicking on its icon. Open a new empty window and write the sketch below: /* Be Maker - STEM - Project 41 - Piloting Events with IR Remote Control */ #include <IRremote.h> int pinIRremote = 5; int pinLEDgreen = 9; int pinLEDyellow = 10; int pinLEDred = 11; int pinLEDblu = 12; IRrecv receiver(pinIRremote); decode_results results; void setup() { pinMode(pinLEDgreen, OUTPUT); pinMode(pinLEDyellow, OUTPUT); pinMode(pinLEDred, OUTPUT); pinMode(pinLEDblu, OUTPUT); Serial.begin(9600); receiver.enableIRIn(); digitalWrite(pinLEDyellow,LOW); digitalWrite(pinLEDred,LOW); digitalWrite(pinLEDblu,LOW); } void loop() { if (receiver.decode(&results)) { digitalWrite(pinLEDgreen,HIGH); Serial.println(results.value); if(results.value==16582903){digitalWrite(pinLEDyellow,HIGH);} if(results.value==16615543){digitalWrite(pinLEDred,HIGH);} if(results.value==16599223){digitalWrite(pinLEDblu,HIGH);} if(results.value==16580863){ digitalWrite(pinLEDyellow,LOW); digitalWrite(pinLEDred,LOW); digitalWrite(pinLEDblu,LOW); } delay(1000); digitalWrite(pinLEDgreen,LOW); receiver.resume(); } } At this point, once you have loaded the sketch on Arduino, open the Serial Monitor of the IDE , point the remote control at the receiver and press the "1" key to turn on the yellow LED, the "2" key to turn on the red LED and the "3" key for the blue LED. To turn everything off, press the red power off key . Analysis of Sketch: Project 41 Piloting events with IR Remote Control. Analyzing the sketch above, we can see that in order to get the IR receiver to work easily, the IRremote.h library must be loaded: #include <IRremote.h> As you can observe the code, with this library, is very simple: To create the "receiver" object IRrecv xxxxxxx (pinIRremote); To enable the IR receiver xxxxx.enableIRIn(); To decode the IR signal xxxxxxx.decode Once the signal is decoded, the value is entered into the results variable results.value To prepare to receive more IR signal xxxxxxxx.resume(); [For the video related to the project click here]. [For the sketch related to the project click here].