- Ninguna Categoria

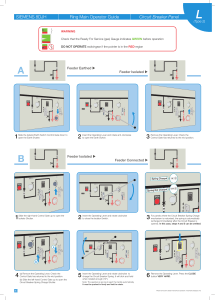

DSII & DSLII Low Voltage Circuit Breaker Installation Guide

Anuncio