IEEE Guide: Liquid-Immersed Power Transformer Installation & Maintenance

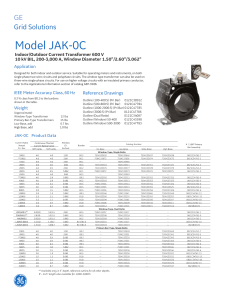

Anuncio