- Ninguna Categoria

Electrical Installation Engineering Specification N-242

Anuncio

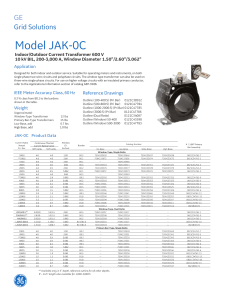

DESIGN ENGINEERING MANUAL VOLUME 4-I ENGINEERING SPECIFICATIONS TITLE N-242 ELECTRICAL INSTALLATIONS AND 1 GENERAL 1.1 Scope This specification covers the requirements established for the installation of the various electrical systems as defined in the drawings and in the Engineering Specification, "Electrical Works - Design Criteria". 1.2 Codes and Standards The codes and standards will be those mentioned in the Engineering Specification "Electrical Works" N-201. 1.3 Receiving and Handling of Equipment 1.3.1 Upon receipt and prior to unloading electrical equipment and/or material, it shall be checked to confirm the bill of lading and to determine possible damage in transit. Any evidence of nonconformity or damage shall be reported to the Project Engineer. 1.3.2 Electrical equipment and material shall be lifted according to the manufacturer's instructions, if included, using lugs or slings attached to or around the equipment. a. Temporary lifting lugs will not be permitted without the approval of the Project Engineer. b. No switchgear other than for lifting purposes shall be used to attach slings. 1.3.3 Electrical equipment shall be handled with sufficient care to prevent damage to the equipment. a. Slings shall have adequate protection to prevent damage to the surface of the equipment. b. Where necessary, sling spreaders will be used to prevent crushing or other damage to the equipment. 1.4 Storage 1.4.1 All equipment, accessories and electrical material shall be properly coded and identified before being placed in the warehouse. 1.4.2 Electrical equipment, accessories and materials shall be stored in designated areas as indicated below: a. Boards, control starters shall be stored in dry, warm, indoor areas, free of condensation or humidity. b. Transformers to be installed in outdoor areas may be stored outdoors without covers; transformers to be installed in indoor areas shall be stored indoors. c. Explosion-proof and totally enclosed motors can be stored outside without covers. d. other electric motors shall be stored in warm, dry rooms, free from condensation or moisture. 1.5 Field Procurement When authorized, field procurement of electrical equipment and/or material will comply with the area classification and requirements given in the drawings, design criteria and equipment specifications. 1.6 Field Engineering and/or Design When authorized, the engineering and/or field design will comply with Engineering Specification N-201, "Electrical Works". 2 INSTALLATION OF EQUIPMENT 2.1 General 2.1.1 The installation of electrical equipment shall comply with the location of the electrical equipment as shown on the electrical drawings and the manufacturer. 2.1.2 Electrical equipment shall be installed following specific instructions or practices recommended by the manufacturer. 2.1.3 Structural functions or requirements for the installation of electrical equipment shall be as shown on the structural and function drawings, except where these are specifically included on the electrical drawings or manufacturer's drawings. 2.1.4 The equipment shall be identified according to the one-line diagram. 2.2 Transformers 2.2.1 Power transformers will be installed on foundations and connected to the electrical system as identified on the electrical drawings. 2.2.2 Small dry type transformers shall be installed as shown on the drawings. 2.2.3 Transformers shall not be installed directly on the walls of the building; structural supports should be used for this purpose. 2.2.4 Transformers should preferably be located in outdoor areas. 2.2.5 Transformers should be located to minimize the length and bends in the secondary connections. 2.2.6 Throat-connected transformers are acceptable in outdoor type substations of standard construction. 2.2.7 Neutral grounding resistors shall be located in the transformer yard. Resistors shall be placed at ground level or individually butt-mounted or mounted on the sides of the transformer tank. Transformer mounted resistors shall be located so as not to physically or visually interfere with transformer accessories. Ground level resistors may be placed one on top of the other. 2.2.8 Transformers and ground level resistors shall be mounted on concrete bases. Bases shall project horizontally at least 75 mm in all directions from the base of the supported equipment. The top of the base shall be at least 450 mm above the finished level of crushed stone. 2.2.9 The area around the bases of the equipment will be covered by a 100 mm layer of 20 mm crushed stone. The stone will be retained by a concrete coping. The top of the curbstone shall be 150 mm above the highest finished floor, inside or outside the transformer yard. 2.2.10 A cyclone mesh fence, with a minimum height of 2.4 m, will be installed around the entire perimeter of the transformer yard. Two access gates will be installed on opposite sides of the yard. The doors shall have provision for padlocks. This paragraph does not apply if the transformer does not have exposed energized or movable parts. 2.2.11 The use of fire walls between transformers is recommended. 2.2.12 The installation of captive transformers in substations will comply with the requirements mentioned above. 2.2.13 The installation of captive transformers near the motor or other device to which they supply power shall comply with the following requirements: a. Transformers shall be located in outdoor areas, at ground level. This may be in non-hazardous areas or in Class I, Division 2 areas. b. The location selected for the transformer shall be approved by the Project Engineer and shall meet the following conditions: – It shall be at least 7.5 m from pumps, compressors and similar machinery, with the exception of the equipment driven by the engine that powers it and at least 7.5 m from towers, drums, exchangers, air coolers and similar equipment. – It shall not be placed on or under compressor or similar platforms. Easy access shall be provided to the transformer, its associated motor and driven equipment. c. The area around the transformer shall meet the requirements described above and the following: – There shall be no exposed energized parts in the transformer yard. – A cyclone mesh fence will be installed around the area to keep personnel away from the transformer. d. 2.3 Wiring to and from the transformer will be subway. The primary feeder will exit at ground level within the transformer area. Boards 2.3.1 The panel sections should be connected according to the manufacturer's instructions, then installed on a concrete foundation and connected to the electrical system as shown on the drawings. 2.3.2 Leveling plates will be placed between the deck and the foundation for leveling and final installation. a. The location of the plates and the horizontal and elevation tolerances will follow the manufacturer's instructions. b. If the manufacturer's recommendations for the above item are not available, the equipment shall be leveled and reasonably placed vertically and brought to the specified elevation. 2.3.3 The above mentioned tolerances are to be kept to a minimum in reference to the board and the removable switches. 2.3.4 A concrete slurry shall be placed under the equipment in accordance with concrete specifications and manufacturer's recommendations. 2.3.5 In indoor type substations, the batteries will be located in a separate room, mounted on shelves against the wall. These batteries will be protected by a 150 mm high rim, in order to minimize the risk of collision when moving equipment inside the building. 2.3.6 In outdoor type substations with protected corridor, the batteries shall be located inside the covered area, against the wall. 2.3.7 The minimum safe spacing between switchboards and motor starters and sources of flame production, as shown on the area classification drawings, is detailed below: a. For main substations: 45 m. Spacing less than 45 m will be approved by the Project Engineer. b. The spaces for other facilities, other than substations, are detailed below according to the type of equipment, location of the flame production source and operation: 2.4 2.4.1 2.5 MCCs shall be installed in the same manner as the panels, in accordance with the manufacturer's engineering drawings and instructions. Engines 2.5.1 The motors will be located according to the manufacturer's recommendations. 2.5.2 Perform a visual inspection and remove any foreign matter in the motor. 2.5.3 Turn the motor manually to check that it is free before connecting it to the equipment to be driven. 2.5.4 Motors must be installed, leveled, aligned and connected to the driven equipment as indicated in the manufacturer's instructions. 2.6 3 Motor Control Center Battery Charger Boards, etc. 2.6.1 The panels, battery chargers, etc. shall be installed in accordance with the details in the manufacturer's drawings and instructions. 2.6.2 Do not install the board, loaders, etc., directly against the walls of the building. Structural shelves will be provided for this purpose. PIPING INSTALLATION 3.1 General The piping installation will comply with Engineering Specification N-201, Section 14, Piping. 3.2 Installation 3.2.1 The pipe shall be laid and supported in an orderly manner. 3.2.2 Pipe bends equal to and greater than 1-1/4" shall be factory made, except when construction conditions necessitate a field made bend. Bends equal to and less than 1" may be field made. 3.2.3 In no case shall a pipe be bent, or an elbow used, smaller than the allowable bend radius for the conductor to be installed. 3.2.4 When it is necessary to make curves in the field, these will be made with tools designed to make such curves. 3.2.5 Pipe cuts in the field shall be made with a hand or power saw or approved machine and shall be made at right angles. a. Cuts will be limited to remove the burr. b. The rocks will be painted red or white before the collars are placed. c. Pipe ends shall be threaded with a minimum of five full threads. d. The use of insulated threads is not permitted. 3.2.6 Bends and deflections shall be avoided as much as possible; pipe that has been crushed or wrinkled in making the bend shall not be used. 3.2.7 PVC jacketed pipe shall be installed with protected taps. 3.2.8 Pipe joints shall be watertight. 3.2.9 Tighten the pipe securely to all metal boxes and pull boxes and junction boxes, using watertight connectors. 3.2.10 The boxes shall be rigidly anchored by means of piping or mounting lugs. 3.2.11 Openings in piping into which water, plaster, mortar or foreign particles may fall shall be closed with watertight caps or plugs during the construction period. 3.2.12 Connections to cast iron fittings and boxes shall be threaded. a. Connections or steel plate boxes shall be made by means of locknuts on both sides of the box and nipples. b. If watertight construction is required, a neoprene gasket with steel reinforcing ring shall be installed between the outer casing wall and the locknut. 3.2.13 Unused connectors in box and accessories will be capped. 3.2.14 The open holes in the boxes will be closed. 3.3 Reserve Piping 3.3.1 The reserve piping shall conform to N-201 Engineering Specification, Section 14, Piping, as a minimum. For Refineries the standby piping detailed below shall be supplied: 3.3.2 For 13.8 kV ducts between manholes, provide a minimum of 50% reserve ducts; at least two in each case. 4 3.3.3 For control ducts between manholes or pulling points, provide for a minimum of 50%; at least 6 in each case. 3.3.4 Provide 100% in control ducts, reserve, between the power station and the first manhole. The same applies to the process control house. 3.3.5 Provide two (2) 13.8 kV conduits between each panel section at the main station and the first manhole. 3.3.6 Floor space will be provided for future 13, 8 kV panel sections and two (2) ducts with covers at the power station and extending to the first manhole. 3.3.7 In all manholes provide projections, for future connections, in all directions. 3.3.8 Provide 50 percent reserve conductors in cables between the control house and terminal boxes for alarm control and instrumentation. Backup conductors will be connected to terminal strips. CABLE TRAY INSTALLATION 4.1 Supports The installation of the cable trays shall comply with the Engineering Specification N-201, Section 14, Conduits. 5 CABLE INSTALLATION 5.1 General The cables shall be placed inside the pipes or trays indicated on the drawings. 5.2 Pipeline Installation See Engineering Specification N-241 "Installation of Conductors and Cables in Pipes and Cable Trays". 5.3 Installation in trays See Engineering Specification N-241 for Cables in Pipe and Cable Trays". 5.4 5.4.1 "Installation of Conductors and Splices and Terminations Splicing of cables or conductors in pipes or trays shall not be permitted. a. Splicing in boxes designed for this purpose is permitted, however, the use of boxes in cable trays will not be allowed. 5.4.2 For splicing power cables (greater than 600 V), the manufacturer's recommendations shall be strictly followed. 5.4.3 The termination of power cables (over 600 V) in the equipment shall be done by means of stress cones. The shields shall be terminated in the stress cones and grounded. 5.4.4 Cable splices (below 600 V) shall be made with press-fit or bolted connectors. 5.4.5 connections or motors shall be made with bolted terminals. 5.4.6 The sharp points on the terminals shall be rounded to prevent puncturing of the splice tapes. 5.4.7 The splices of conductor 2 AWG or larger, in 400 V circuit, shall be made with 3 layers of tapes in 1/2 overlap of scotch filler tape and 3 layers of 1/2 overlap of scotch 33 tape. 5.4.8 Splices in conductors smaller than 2 AWG shall be insulated with vinyl electrical tape. 5.4.9 Power circuits that have a high short-circuit rating and are located in a common enclosure shall be covered with fireproof tape, as shall adjacent circuits. 5.4.10 No splicing of control circuits shall be permitted. Terminal strips shall be used at convenient locations for such purpose. 5.4.11 The control and power conductors will be identified at both ends and in the junction and terminal boxes with the number of the cable conductor by means of plastic rings. a. Labels should have white letters superimposed on a black background. 5.4.12 Splices and branches. Cables shall be laid in full lengths between terminations, where possible. Where splices and taps are required, the following requirements shall be met: a. Straight splices or taps are preferred on circuits operating at over 600 volts. Coiled splices at any voltage shall be made only on unscreened, above-ground cables. b. Splices and branches on subway cables when permitted by the separate a. Buried splices shall be protected within cast iron sheaths or be made of suitable cast resin, approved by the inspecting engineer. For armored cables, clamps shall be used. The shield, sheath and armor of the cables shall be connected through the splice. Splice boxes will be supported by concrete bases. The cable will be left on each side of the splice to prevent stresses when the cable settles. c. Connectors shall be used to join conductors at splices and taps. Connectors shall be of the solderless type, except solder type sleeve connectors which may be used in straight splices or taps. d. In shielded cable systems, splices and branches will be inside junction boxes. e. In rigid cable ducts and supports, splices and branches shall be supported in the ducts, trays or ladders, shall be accessible for repair and shall be protected against physical damage in the same manner as the cables. f. The use of more than one splice in subway circuits shall be approved by the Project Engineer. 5.4.13 In pipe installations, the cable shall be pulled inside the conduit, in one piece between splice or termination points, as follows: a. The recommended pulling tension should be determined and followed. For long cable lengths, pulling lugs are preferred. b. Cables with neoprene or other non-metallic outer jacket shall not be used. 5.4.14 6 Stranded conductors connecting to terminal strips or boards with screw-type terminals shall be connected by means of lug terminals. INSTALLATION - MISCELLANEOUS 6.1 Cuts and Patches 6.1.1 The cuts, patching, repairs, etc., required in electrical work installations will be carried out by specialized personnel in the corresponding area. a. Rocks, sleeves, hanger fittings, brackets and fasteners shall be accurately positioned prior to new construction to avoid unnecessary cutting. b. 6.1.2 Welded or damaged galvanized steel shall be painted with Galvoweld. 6.1.3 All PVC pipe will be touched up with PVC patching compound where it has been removed during threading or damaged during the job. 6.2 7 For existing works that are cut, relocated or otherwise damaged during these operations, they shall be patched or replaced, as required by the project engineer, to match the existing works. The conductor connections to the switchboards and control centers will maintain the same physical phasing arrangement throughout the system. The phase sequence at the inputs shall be ABC (or RST, RYB) with phase b (S, Y) in the center and phase A on the left, front or top, viewing the equipment from the operating side. INSTALLATION TESTS 7.1 General 7.1.1 Installation tests shall be witnessed by the project engineer. 7.1.2 Test reports will be prepared for equipment and cables. 7.1.3 If defective equipment or cables are detected, they will be repaired and retested. 7.1.4 Electrical equipment and wiring shall be inspected, mechanically and electrically tested before being energized or placed in service. 7.1.5 Engineering Specification N-201, "Electrical Works", will be used in conjunction with this specification. 7.1.6 Final acceptance of the electrical works will depend on the satisfactory operation of the system as designed and specified. 7.1.7 Safety precautions shall be taken to protect personnel and equipment before applying the megger or any other voltage during the test. 7.1.8 Insulation resistance tests performed with a megger shall be done as follows: – Use a 500 volt megger on systems up to 600 volts with a minimum acceptable insulation resistance of 1 megohm. – Use a 2,500-volt megger on systems between 2,000 and 4,160 volts with a minimum acceptable insulation resistance of one megohm for each 1,000 volts. – Use a 5000 megger on systems greater than 4160 volts, with a minimum acceptable resistance of one megohm per 1000 volts. 7.2 Cable Testing 7.2.1 7.3 See inspection procedure PI-13-02-01, for "Electrical Conductors". Transformer Testing 7.3.1 The transformer tests shall comply with the Engineering Specification N-201, "Electrical Works", Section 7. Power Transformers. 7.3.2 Insulation resistance tests (megado) of oil-immersed transformers shall be performed according to the above mentioned specification. 7.3.3 Testing and oil filling as well as electrical testing of the transformer shall be performed by a specialist in the field. 7.3.4 The following steps shall be performed before connecting any transformer to the electrical system. a. Mechanically inspect the tap-changing equipment and attach or connect it to the rated tap unless otherwise specified. b. Inspect the transformer for physical damage. c. Inspect the transformer to verify the specified ratings. d. Perform insulation resistance tests by taking megger readings of both the transformer and the power system feeders prior to connection. 7.3.5 Small dry type transformers shall be subjected to insulation resistance tests with a megger. a. The primary and secondary windings of the transformer shall be disconnected from the system prior to the megger test. b. Insulation resistance readings will be taken as follows: – Connect the high voltage winding with the low voltage winding to ground. – Connect the low voltage winding with the high voltage winding ground. – Megar, connecting the instrument between the primary and secondary windings. 7.3.6 Insulation resistance tests will be performed on the transformer after the primary and secondary connections are completed and the terminal boxes are covered. a. This test will be performed after having successfully performed separately the insulation resistance test on transformers and on the primary and secondary feeders. b. Additionally, this test shall be performed with the primary and secondary circuit breakers open or the fuses removed. c. Perform insulation resistance tests on transformers and primary feeders with readings taken from each line-to-ground conductor. 7.3.7 Perform the following tests, after successful completion of the combined transformer and primary feeder insulation resistance tests. The tests shall be performed with the secondary circuit breaker open or the fuse removed and the primary feeder energized at rated voltage. a. Take voltage readings on the secondary and note them in the report. b. Verify phase rotation on the secondary and note in the report. 7.3.8 Testing and verification of current and potential transformers will be performed in accordance with the testing of the panels. 7.3.9 Perform tests to verify the operation of the transformer alarms. 7.4 Power Panel Tests 7.4.1 Board testing will commence after all necessary safety precautions have been taken, which should include the placement of ropes and caution signs around the area. 7.4.2 Boards or components shall not be energized until the following tests have been performed and defects corrected: a. Inspection and testing of circuit breakers. b. Insulation resistance tests. c. Functional tests of the control circuits on the board. d. Calibration and adjustment of protection relays. 7.4.3 Defects found in panel tests shall be corrected according to the manufacturer's instructions, or under the direct supervision of the manufacturer. 7.4.4 Remove each switch from the board and check the following points: – – – – Examine the switch for physical damage. Examine the contact surfaces. Check that the contact bolts are tight. Close the switch manually and observe: Contact alignment and sweeps. Check the tension of the opening springs. – Perform insulation resistance tests of the breaker with the megger and note the resistance between each phase-to-phase and phase-to-ground conductor with the breaker closed. – Repeat the insulation resistance test on the two switch terminals, with the switch open. – Examine the switchgear cell in the panel for physical damage and proper sealing of the safety windows. – Insert the breaker into the panel and leave it in the pulled-out position until the insulation resistance test is completed. 7.4.5 For functional testing of the panels, only AC or DC control voltage shall be present throughout the system. 7.4.6 Functional tests on the board shall be performed according to the following: – With the power switches on the cells, operate each up and down mechanism (if any) and observe if it functions properly. – Verify the control circuits, opening and closing of the circuit breaker, operating the local control suiche and remote devices, as applicable. – Observe if the pilot lights are working properly. – Arrange each switch with electric trip, with its mechanical trip. – Trip each breaker that is electrically operated, manually, by applying current or voltage to each of its associated protection relays. – Test the operation of the lockout relays in the breaker open/close control circuits, simulating the conditions for lockout. – Close and trip each breaker by operating manually. – Check the space heater control circuits by operating each control component in the circuit. 7.4.7 Perform continuity tests on all current transformers. - Unconnected current transformers will short circuit the secondary terminals. 7.4.8 Check the voltage of the potential transformers. 7.4.9 Once the protective relays have been set, insulation resistance tests and functional tests of the control circuits and circuit breaker (if applicable) have been performed, energize the main busbar of the panel and test the following: – Sequence of phases in the main bar. – Operation of voltmeters and their selectors. 7.4.10 After applying the load, the instruments mentioned below will be tested: – – – – 7.5 Ammeters and their selectors. KWh meters. KVA meters kW meters Electrical System Protection Devices - Testing, Calibration and Adjustment 7.5.1 Testing, calibration and adjustment will be performed on the following protection devices: – – – – Adjustable circuit breaker trip elements. Protection relays. Electrical measuring equipment. Timer devices. In addition, the following will be verified: – Wiring and its identification. – Type and characteristics of each relay. 7.5.2 Each adjustable relay shall be installed, calibrated and tested using a cycle counter, variable load, ammeters and voltmeters as required, using relay test equipment having a waveform with minimum distortion. Settings, calibration points and verification points shall be in accordance with written instructions or curves supplied by the Project Engineer. 7.5.3 Verify the proper functioning of the alarms. 7.6 7.6.1 Transfer Suiche Testing Disconnect supply, load and other cables as necessary and perform insulation resistance tests on the transfer suiches with a megger and note the results of the measurements. a. Avoid the feedback to through from small transformers , by disconnecting the secondary terminals. b. Measure the alternating system and the phase-to-phase and phase-to-ground transfer suiche. c. 7.6.2 Repeat the above with the suiche in the closed position. Perform functional tests on the transfer suiche simulating no-load low voltage conditions. a. Measure the transfer time with a cycle meter. b. Operate the transfer suiche manually in each direction. c. Observe if pilot lights and other devices are working properly. 7.6.3 Test if the transfer alarms are working properly. 7.6.4 Once the supply and load feeders have undergone insulation resistance tests, reconnect them to the transfer socket and the phases between the normal and emergency supply conductors. 7.7 Engine Control Center Tests 7.7.1 With the input switch open, output switches or suiches open and the disconnecting elements of the starters open, measure the busbars and note the results. a. Megar between phase-to-phase and phase-to-ground. b. Repeat the measurements with the disconnecting elements of the starters closed but with the rest of the switches open. 7.7.2 Verify and adjust the contact alignment and sweep of each of the medium voltage motor control center suiches, following the manufacturer's instructions. 7.7.3 Tighten bolts, clean magnetic core faces, check fuses, magnetic switches and overload relay heaters according to type and capacity. 7.7.4 Calibrate relays and direct trip devices in the medium voltage motor control center, following the project engineer's instructions. 7.7.5 Verify the operation of the starters or contactors from the remote stations to ensure the proper functioning of the control circuits. 7.7.6 Verify the alarms, to ensure their proper functioning. 7.8 Testing of Engines Consult Engineering Specifications N-251 "Technical Specification for TEFC Squirrel Cage Induction Motors 500 HP and Below", for motor testing, N-268 "General Purpose Application of API 541 Form-wound Squirrel-cage Induction Motors 250 Horsepower and Larger" or N-269 "Special Purpose Application of API 541 Form-wound Squirrel-cage Induction Motors 250 Horsepower and Larger". 7.8.1 Before connecting the power cables to the motors, perform insulation resistance tests on the motor windings using the megger and record the results. a. On TEFC type motors, remove the drain plugs prior to the test to allow drainage and then replace the plugs. b. Take the measurement at each of the terminals and ground. 7.8.2 a. 7.8.3 Connect and terminate the cable terminations on each motor. Place the covers, carry out the megado and note the results. Make measurements from MCC between each of the conductors and ground. After completing the megado, with the motor uncoupled check: – Free to rotate. – That the rotation is adequate. – That the lubrication is working properly. 7.8.4 7.9 Verify the temperature indication system, its alarms and tripping. Lighting System Test 7.9.1 Disconnect the output of the transformer feeding the distribution board, open the output switches, perform the measurement and note the results. a. Take measurements at the busbars of each panel phase to phase and phase to ground. b. Once the insulation resistance tests have been satisfactorily performed on the panel, reconnect the feeder to the transformer. c. Check the ground continuity of the transformer neutral and the panel. 7.9.2 Once the lighting panel has been energized, check the phase to neutral voltage; if the result is satisfactory energize the lighting circuits and check the following: – Proper operation of the components of each circuit. – Once the panel is installed, a table is prepared containing the breaker number and the zones it feeds. This table will be placed on the inside or cover of the panel. 7.9.3 Perform functional tests of photocells, lighting contactors and bypass suiches. 7.9.4 Verify operation of emergency lighting systems or units by simulating loss of power. Keep the emergency or standby system energized as long as necessary to verify capacity. 7.9.5 7.10 Testing for Batteries and Chargers 7.10.1 Batteries for substations and instruments will receive a booster charge according to the manufacturer's instructions. 7.10.2 Battery chargers will be tested to verify their operation and that they can deliver their maximum rated power. 7.10.3 The chargers shall be set at float for regular service. The float voltage shall be given by the battery manufacturer. 7.10.4 Verify the correct operation of the alarms. 7.10.5 Verify and make the required corrections in the following points: 7.11 8 Check and make corrections as required in the following points: – Luminaires complete with glass, protectors and reflectors. – Broken glass, broken reflectors, etc. – Burned out lamps, ballasts, etc. – Boxes and pipe fittings with lids and their gaskets. – All openings in pipes that are not in use shall be plugged. – Transformers, boards, etc., shall have manufacturer and service identification plates. a. All openings in pipe that are not in use will be plugged. b. Boxes and pipe fittings with lids and their gaskets. c. The equipment shall have manufacturer's and service identification plates. Testing of the grounding system. 7.11.1 The grounding system will follow Engineering Specification N-201, Section 17. 7.11.2 The resistance of the grounding system shall be measured with a three or four electrode ground meter. 7.11.3 The resistance of any grounding electrode shall not exceed 5 ohms. 7.11.4 Verify the electrical continuity of the grounding system circuits. CONCLUSION OF THE INSTALLATION 8.1 General The electrical installation will be considered completed once the different electrical systems have been installed, tested, commissioned as required, with quality finish and the installation has been accepted by the project engineer. 8.2 Termination 8.2.1 Electrical systems will function as required and with protective devices in place and operating properly. 8.2.2 Electrical equipment shall have manufacturer's and service nameplates. 8.2.3 Clean the equipment, especially the insulators. 8.2.4 Paint retouching in the required parts. 8.2.5 The table identifying the circuits will be placed in an appropriate location on the board. 8.2.6 The lighting system shall be free of defective lamps, broken glass, shields, reflectors or other damaged components. 8.2.7 Openings in unused pipes will be plugged. 8.2.8 The finished piping systems will have the cables installed, and the covers with their gaskets will be in place in the boxes. 8.2.9 Seals in the pipe shall be filled with Chicco or other material approved by the project engineer. 8.2.10 The connections to the equipment grounding system and the neutrals to the transformers have been connected. 8.2.11 Caps have been provided and placed in the grounding wells.

Anuncio

Documentos relacionados

Descargar

Anuncio

Añadir este documento a la recogida (s)

Puede agregar este documento a su colección de estudio (s)

Iniciar sesión Disponible sólo para usuarios autorizadosAñadir a este documento guardado

Puede agregar este documento a su lista guardada

Iniciar sesión Disponible sólo para usuarios autorizados