ESTUDIO EXPERIMENTAL SOBRE LA RESISTENCIA TEMPRANA DEL RELLENO DE PASTA CEMENTADA

Anuncio

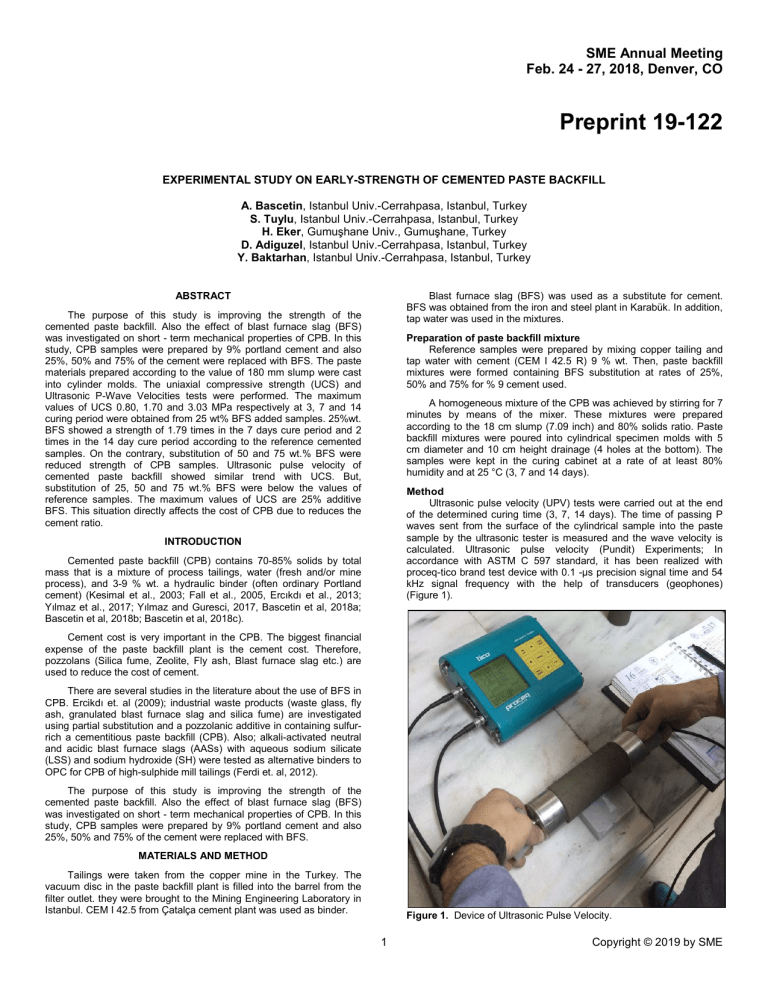

SME Annual Meeting Feb. 24 - 27, 2018, Denver, CO Preprint 19-122 EXPERIMENTAL STUDY ON EARLY-STRENGTH OF CEMENTED PASTE BACKFILL A. Bascetin, Istanbul Univ.-Cerrahpasa, Istanbul, Turkey S. Tuylu, Istanbul Univ.-Cerrahpasa, Istanbul, Turkey H. Eker, Gumuşhane Univ., Gumuşhane, Turkey D. Adiguzel, Istanbul Univ.-Cerrahpasa, Istanbul, Turkey Y. Baktarhan, Istanbul Univ.-Cerrahpasa, Istanbul, Turkey ABSTRACT Blast furnace slag (BFS) was used as a substitute for cement. BFS was obtained from the iron and steel plant in Karabük. In addition, tap water was used in the mixtures. The purpose of this study is improving the strength of the cemented paste backfill. Also the effect of blast furnace slag (BFS) was investigated on short - term mechanical properties of CPB. In this study, CPB samples were prepared by 9% portland cement and also 25%, 50% and 75% of the cement were replaced with BFS. The paste materials prepared according to the value of 180 mm slump were cast into cylinder molds. The uniaxial compressive strength (UCS) and Ultrasonic P-Wave Velocities tests were performed. The maximum values of UCS 0.80, 1.70 and 3.03 MPa respectively at 3, 7 and 14 curing period were obtained from 25 wt% BFS added samples. 25%wt. BFS showed a strength of 1.79 times in the 7 days cure period and 2 times in the 14 day cure period according to the reference cemented samples. On the contrary, substitution of 50 and 75 wt.% BFS were reduced strength of CPB samples. Ultrasonic pulse velocity of cemented paste backfill showed similar trend with UCS. But, substitution of 25, 50 and 75 wt.% BFS were below the values of reference samples. The maximum values of UCS are 25% additive BFS. This situation directly affects the cost of CPB due to reduces the cement ratio. Preparation of paste backfill mixture Reference samples were prepared by mixing copper tailing and tap water with cement (CEM I 42.5 R) 9 % wt. Then, paste backfill mixtures were formed containing BFS substitution at rates of 25%, 50% and 75% for % 9 cement used. A homogeneous mixture of the CPB was achieved by stirring for 7 minutes by means of the mixer. These mixtures were prepared according to the 18 cm slump (7.09 inch) and 80% solids ratio. Paste backfill mixtures were poured into cylindrical specimen molds with 5 cm diameter and 10 cm height drainage (4 holes at the bottom). The samples were kept in the curing cabinet at a rate of at least 80% humidity and at 25 °C (3, 7 and 14 days). Method Ultrasonic pulse velocity (UPV) tests were carried out at the end of the determined curing time (3, 7, 14 days). The time of passing P waves sent from the surface of the cylindrical sample into the paste sample by the ultrasonic tester is measured and the wave velocity is calculated. Ultrasonic pulse velocity (Pundit) Experiments; In accordance with ASTM C 597 standard, it has been realized with proceq-tico brand test device with 0.1 -µs precision signal time and 54 kHz signal frequency with the help of transducers (geophones) (Figure 1). INTRODUCTION Cemented paste backfill (CPB) contains 70-85% solids by total mass that is a mixture of process tailings, water (fresh and/or mine process), and 3-9 % wt. a hydraulic binder (often ordinary Portland cement) (Kesimal et al., 2003; Fall et al., 2005, Ercıkdı et al., 2013; Yılmaz et al., 2017; Yılmaz and Guresci, 2017, Bascetin et al, 2018a; Bascetin et al, 2018b; Bascetin et al, 2018c). Cement cost is very important in the CPB. The biggest financial expense of the paste backfill plant is the cement cost. Therefore, pozzolans (Silica fume, Zeolite, Fly ash, Blast furnace slag etc.) are used to reduce the cost of cement. There are several studies in the literature about the use of BFS in CPB. Ercikdı et. al (2009); industrial waste products (waste glass, fly ash, granulated blast furnace slag and silica fume) are investigated using partial substitution and a pozzolanic additive in containing sulfurrich a cementitious paste backfill (CPB). Also; alkali-activated neutral and acidic blast furnace slags (AASs) with aqueous sodium silicate (LSS) and sodium hydroxide (SH) were tested as alternative binders to OPC for CPB of high-sulphide mill tailings (Ferdi et. al, 2012). The purpose of this study is improving the strength of the cemented paste backfill. Also the effect of blast furnace slag (BFS) was investigated on short - term mechanical properties of CPB. In this study, CPB samples were prepared by 9% portland cement and also 25%, 50% and 75% of the cement were replaced with BFS. MATERIALS AND METHOD Tailings were taken from the copper mine in the Turkey. The vacuum disc in the paste backfill plant is filled into the barrel from the filter outlet. they were brought to the Mining Engineering Laboratory in Istanbul. CEM I 42.5 from Çatalça cement plant was used as binder. Figure 1. Device of Ultrasonic Pulse Velocity. 1 Copyright © 2019 by SME SME Annual Meeting Feb. 24 - 27, 2018, Denver, CO BFS containing samples (50% and 75%) were not increased the strength to reference specimens. The roughness of the upper and lower surfaces of the samples was corrected prior to the experiment. In addition, the length is measured with an electronic caliper gage with a precision of 0.1 mm. Length values obtained from the caliper gage are entered to the device in length. To ensure a smooth connection between the transducers and the upper and lower surfaces of the sample, gel was coated on both surfaces and UPV values were obtained for each sample. 3 samples were tested for each curing time and the values obtained in the results were averaged. Figure 3. UPV of 9% cemented and blast furnace slag substituted samples. Figure 4. UCS of 9% cemented and blast furnace slag substituted samples. In the 14 days cure period, the paste backfill limit value of ≥ 0.7 MPa was exceeded in the mixture ratio of 25% and 50%. Also, the highest UCS strength in 14 days is 3.03 MPa (25% BFS). As a roof support, no mixing ratio exceeds the desired limit value ≥ 4 MPa. Furthermore, all mixing ratios of ≥ 0.15 MPa, which are the limit of liquefaction risk, are provided. Figure 2. The Press Used in the Uniaxial Compressive Strength Test. Cemented Paste Backfill (CPB); The uniaxial compressive strength test was performed on cylindrical samples prepared in 50 × 100 mm dimensions in accordance with ASTM C 39 standard. Samples which reached the determined cure times were calculated separately for the 3, 7 and 14 days cure periods by breaking the automatic controlled press at a constant loading speed of 1 mm / min with a loading capacity of 50 kN (Figure 2). The length/diameter ratio of the cylindrical CPB samples is at least 2 cm and the upper and lower surfaces of the samples are corrected before the test. For each cure period, 3 samples were tested in the experiment and the mean values were obtained as a result. CONCLUSION In this study, CPB samples were prepared by 9% portland cement and also 25%, 50% and 75% of the cement were replaced with BFS. 25%wt. BFS showed a strength of 1.79 times in the 7 days cure period and 2 times in the 14 day cure period according to the reference cemented samples. On the contrary, substitution of 50 and 75 wt.% BFS were reduced strength of CPB samples. Ultrasonic pulse velocity of cemented paste backfill showed similar trend with UCS. But, substitution of 25, 50 and 75 wt.% BFS were below the values of reference samples. The maximum values of UCS are 25% additive BFS. This situation directly affects the cost of CPB due to reduces the cement ratio. RESULTS In Figure 3; Samples of %25 BFS compared to reference samples received higher UPV values. In addition, UPV values show a similar tendency with uniaxial compressive strength results (9% cement and BFS substituted samples). UPV values; depending on the curing time, it varies from 493 to 1700 µ / s. A decline in values is observed with 14. days cure time (for %25 BFS). Also; in other examples, the UPV value was increased depending on the cure time. UPV value of 1 MPa <UCS< 4 MPa are 1440-1700 µ / s. The further researches; UCS and UPV values at different cement rates and at different cure rates should be examined. ACKNOWLEDGEMENT This study was funded by Istanbul University with the project number FDK-2018-24707. REFERENCES In Figure 4; addition of BFS in paste backfill mixture containing 9% cement increased compressive strength. 25% BFS containing samples increased the strength to reference specimens. But, another 1. 2 Bascetin, A, Eker, H, Tuylu, S, D, Adiguzel, (2018a), Effect of Substitution of Zeolite on the Mechanical Properties of Cemented Copyright © 2019 by SME SME Annual Meeting Feb. 24 - 27, 2018, Denver, CO Paste Backfill, Proceedings of the 4 th International Underground excavations symposium, 13-14 September 2018, Istanbul, p 575581. 2. Bascetin, A. Eker, H. Tüylü, S. Adigüzel, D. (2018b), Determination of strength properties of copper mine tailings, ROCKMEC’2018-12th Regional Rock Mechanics Symposium, 3-5 October 2018, Trabzon, Turkey, s. 162-167, 2018. 3. Bascetin, A. Eker, H. Tüylü, S. Adigüzel, D. Odabas, E. (2018c), Effect of Fly Ash on The Mechanical Strength of Cemented Paste Backfill, Cappadocia Earth Sciences Symposium, 24-26 October 2018, Niğde, Turkey. 4. Ercikdi, B, Cihangir, F, Kesimal, A, Deveci, ˙ H, Alp, I, (2009), Utilization of industrial waste products as pozzolanic material in cemented paste backfill of high sulphide mill tailings, Journal of Hazardous Materials 168 (2009) 848–856. 5. Ercikdi B, Baki H, İzki M (2013) Effect of desliming of sulphiderich mill tailings onthe long-term strength of cemented paste backfill, J Environ Manage 115:5–13 6. Fall M, Benzaazoua M, Ouellet S (2005) Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill, Miner Eng 18(1):41–44. 7. Cihangir, F, Ercikdi, B, Kesimal, A, Alp, T, Deveci, ˙ H, (2012), Utilisation of alkali-activated blast furnace slag in paste backfill of high-sulphide mill tailings: Effect of binder type and dosage, Minerals Engineering 30 (2012) 33–43. 9. Kesimal A, Ercikdi B, Yılmaz E (2003) The effect of desliming by sedimentation on paste backfill performance, Miner Eng 16(10):1009–1011 10. Yılmaz T, Erçıkdı, B, Cihangir, F, (2017), Effect of the Partial Replacement of Blast Furnace Slag and Perlite on the Mechanical and Microstructural Properties of Cemented Paste Backfill, Çukurova University Journal of the Faculty of Engineering and Architecture, 32(2), pp. 239-251, June 2017. 11. Yılmaz, E, Guresci, M, (2017), Design and Characterization of Underground Paste Backfill", in: Paste Tailings Management, Yilmaz, E, Mamadou, F, Eds,, Springer, London/Berlin/Switzerland , Cham, pp,111-144. 3 Copyright © 2019 by SME