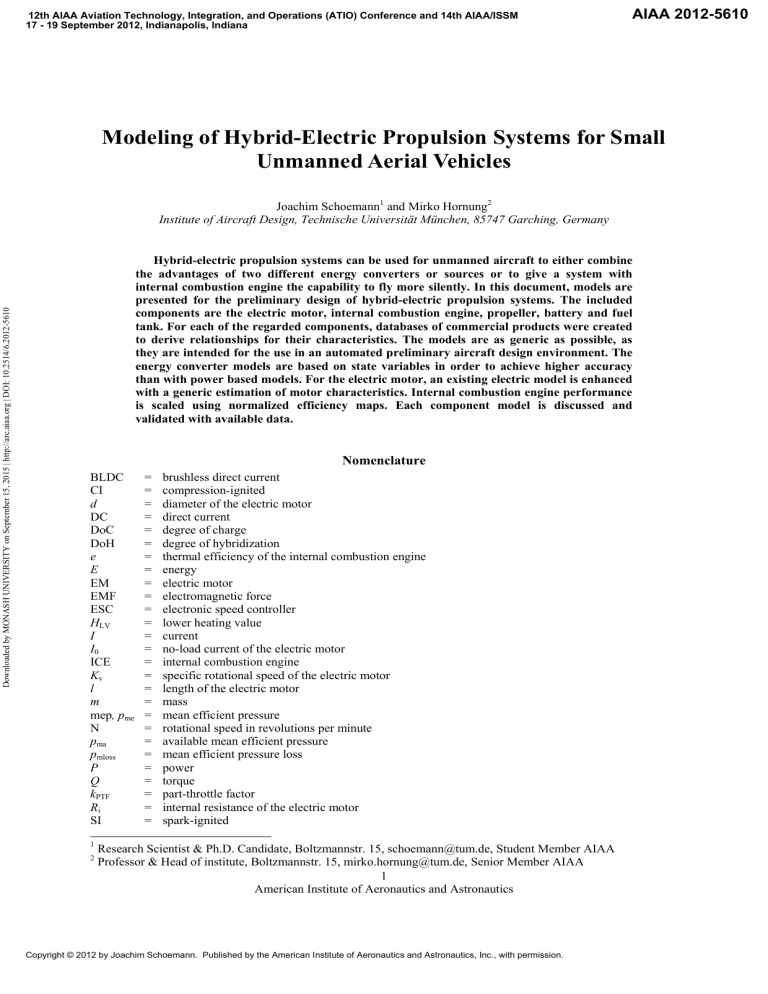

12th AIAA Aviation Technology, Integration, and Operations (ATIO) Conference and 14th AIAA/ISSM 17 - 19 September 2012, Indianapolis, Indiana AIAA 2012-5610 Modeling of Hybrid-Electric Propulsion Systems for Small Unmanned Aerial Vehicles Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 Joachim Schoemann1 and Mirko Hornung2 Institute of Aircraft Design, Technische Universität München, 85747 Garching, Germany Hybrid-electric propulsion systems can be used for unmanned aircraft to either combine the advantages of two different energy converters or sources or to give a system with internal combustion engine the capability to fly more silently. In this document, models are presented for the preliminary design of hybrid-electric propulsion systems. The included components are the electric motor, internal combustion engine, propeller, battery and fuel tank. For each of the regarded components, databases of commercial products were created to derive relationships for their characteristics. The models are as generic as possible, as they are intended for the use in an automated preliminary aircraft design environment. The energy converter models are based on state variables in order to achieve higher accuracy than with power based models. For the electric motor, an existing electric model is enhanced with a generic estimation of motor characteristics. Internal combustion engine performance is scaled using normalized efficiency maps. Each component model is discussed and validated with available data. Nomenclature BLDC CI d DC DoC DoH e E EM EMF ESC HLV I I0 ICE Kv l m mep, pme N pma pmloss P Q kPTF Ri SI 1 2 = = = = = = = = = = = = = = = = = = = = = = = = = = = brushless direct current compression-ignited diameter of the electric motor direct current degree of charge degree of hybridization thermal efficiency of the internal combustion engine energy electric motor electromagnetic force electronic speed controller lower heating value current no-load current of the electric motor internal combustion engine specific rotational speed of the electric motor length of the electric motor mass mean efficient pressure rotational speed in revolutions per minute available mean efficient pressure mean efficient pressure loss power torque part-throttle factor internal resistance of the electric motor spark-ignited Research Scientist & Ph.D. Candidate, Boltzmannstr. 15, [email protected], Student Member AIAA Professor & Head of institute, Boltzmannstr. 15, [email protected], Senior Member AIAA 1 American Institute of Aeronautics and Astronautics Copyright © 2012 by Joachim Schoemann. Published by the American Institute of Aeronautics and Astronautics, Inc., with permission. t T UAV v V Vfuel WOT ω Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 H = = = = = = = = endurance thrust unmanned aerial vehicle velocity voltage fuel volume wide-open throttle rotational speed in radians per second I. Introduction YBRID-ELECTRIC propulsion systems were driven into public attention by the development in the automotive industry. There, the combination of internal combustion engines and electric motors is used to reduce fuel consumption. The basic measure to do so is to recover energy during braking, to propel the vehicle electrically at low speeds and to have the internal combustion engine run in its optimum point of operation most of the time and hence downsize it. As cost and weight increase, hybrid-electric systems are not a per se solution to reduce fuel consumption but need to be designed very carefully. The advantages mentioned cannot be transferred to unmanned aircraft applications one-to-one, as a flight profile is much more static than a driving cycle and hence the aspects of recovering energy and frequent low speed phases have to be discarded. The primary objective of hybrid-electric propulsion systems for unmanned aircraft is not to lower energy consumption. There are two main types of hybridizations with different objectives. Combustion engines are hybridized to give aircraft the capability to fly more silently. This implies the assumption that electric propulsion systems are more silent than those based on internal combustion systems, which must not be the case for all conditions. When electric propulsion systems are hybridized, the objective is to combine the characteristics of two power sources or converters, e.g. one with high specific power for takeoff and climb, and one with high specific energy for cruise flight. Nonetheless hybrid propulsion systems should be as efficient as possible. As another advantage, they may easily be designed to provide complete propulsion redundancy. One primary field of application of unmanned aerial vehicles (UAV) is surveillance. Depending on the mission task, it may be required to operate secretly. In order to use smaller and hence cheaper low and medium altitude aircraft for this task, silent flight is a key capability. A small UAV within this document shall be defined as one with a maximum takeoff mass below 150 kg, as this is one certification limit in Germany1. The focus in this document is on the hybridized internal combustion engines. Generally, three potential types of hybrid-electric propulsion systems are considered for the class of small propeller driven UAV: • Hybrid fuel cell system: An electric motor powered by a fuel cell and a battery • Hybrid photovoltaic system: An electric motor powered by solar cells and a battery • Hybrid internal combustion engine: The combination of an internal combustion engine and a battery-powered electric motor in parallel, serial or series-parallel configuration. In the further course of this document, this system is generally referred to as ‘hybrid-electric’. II. Problem Statement & State-of-the-Art A. State-of-the-art The first two of the configurations stated above and their components have been widely treated in previous publications. A summary of activities in the field of solar powered aviation and a conceptual design method can be found in Ref. 2. The conceptual design of unmanned aircraft with stand-alone and hybrid fuel cell propulsion system is described in Ref. 3, including an overview of research activities. Results explicitly referring to the hybridization of fuel cells are given in Ref. 4. Pioneering work on hybrid-electric systems was done by Frederick Harmon and his students at the Air Force Institute of Technology. After simulation and control concepts were treated first5, a conceptual design method was developed6,7, the propulsion system and control tested8 and a prototype prepared9. A team at the Queensland University of Technology realized a prototype of a hybrid powerplant and derived performance prediction rules from the measured results10,11. In the very recent past, several reports on projects including designing and testing of hybrid-electric systems were published12,13,14. The components used in a hybrid-electric powerplant are the propeller, the electric motor (EM) with electronic speed controller (ESC), the internal combustion engine (ICE), the battery and the fuel tank. In a parallel configuration, mechanical couplings are necessary, but will not be discussed in detail within the scope of this 2 American Institute of Aeronautics and Astronautics Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 document. An overview of propeller modeling and optimization is given in Ref. 15 and 16. The same model for electric motors, based on a simplified equivalent electric circuit, is presented in Ref. 3, Ref. 8, Ref. 16 and Ref. 17, of which two validate the generated data3,17. The influence of high-altitude operation on the electric motor is presented in Ref. 18. Scalable unified models of both the electric motor and the internal combustion engine with the Willans Line approach are described in Ref. 19. The effect of scaling of automotive engines on their efficiency is reported in Ref. 20 and Ref. 21, and with focus on the stroke-to-bore ratio in Ref. 22. A team of the University of Maryland described the difficulties in performance prediction23, testing24 and scaling25 of small internal combustion engines. B. Problem Statement The motivation for the creation of the models described in this document is to compare different hybrid systems over a wide range of requirements. In doing so, it shall be quantified where the advantages of the different systems lie. The models developed are intended to be used in an automated preliminary aircraft design environment, so they need to be as generic as possible. Fitted functions are used instead of interpolations where possible in order to keep computation time down for a possibly applied optimization process. Power based models, in which an energy converter’s characteristics are determined merely based on its power requirement, are not suitable for the use in an automated process over a wide range of requirements. The reason for this is that the converters’ efficiencies almost always depend on state variables. State variables within this document shall be the term for the variables whose product is power. For the mechanical domain this is rotational speed and torque or force and translational speed. Voltage and current are the state variables in the electrical domain and in the chemical domain they are the lower heating value and mass flow19. Within a power based design process efficiencies have to be manually estimated and hence inaccuracies might flaw the quality of the results. If the design methodology is only applied to one set of requirements at a time, as done in the Airforce Institute of Technology’s work7, an experienced designer is able to keep the fidelity high enough by manually readjusting the results. The aforementioned publications offer solutions for the optimization of the three hybrid systems suitable for small unmanned aircraft. Battery-electric16 and fuel cell powered3 systems are modeled based on state variables, but the relationships for the electric motor are either discrete3 or derived from a very wide spectrum of commercial models and hence not as accurate as desired16. For hybrid-electric systems, only power based design methodologies are known to the authors. The models presented in this document shall enable a design process for hybrid-electric propulsion systems based on state variables and hence increase its accuracy. III. Hybrid Design Process Parallel Configuration Series Configuration Combustion Engine Tank Fuel Tank Combustion Engine Generator Mechanical Coupling Charger Electric Motor Battery Electric Motor Electrical Connection Mechanical Connection Propeller Battery Propeller Charger Electrical Connection Mechanical Connection a) b) Figure 1. Series (a) and parallel (b) hybrid-electric propulsion system configuration There are three common configurations of hybrid-electric propulsion systems. In a series configuration, as shown in Fig. 1a, the internal combustion engine is not directly driving the propeller, its shaft power is transformed into electrical power by a generator and then used either by an electric motor to drive the propeller or stored in batteries. The drawback of this concept and the reason why it is seldom considered for aviation purposes is the fact that the electric motor needs to be sized for maximum power and together with the necessary generator creates additional weight compared to the parallel configuration shown in Fig. 1b. In the parallel configuration, both the engine and the motor may drive the propeller and hence, if in dual use during phase of maximum power, may be sized for lower powers than as single systems. In parallel systems, mainly torque–coupling devices are used, for 3 American Institute of Aeronautics and Astronautics Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 example a pulley assembly9. They should provide for a possibility to disconnect the combustion engine in electric flight mode as well as for the internal combustion engine to drive the propeller and charge the battery using the electric motor as a generator at the same time. Commercial electronic speed controllers for brushless direct current (BLDC) motors are not generally capable of a generator mode, but this fact is neglected in this preliminary stage. More details on the actual realization of a parallel hybrid-electric propulsion system can be found in Ref. 9. The series-parallel concept allows both series and parallel operation by using a planetary gear with propeller, electric motor, generator and internal combustion engine connected to it. Due to the additional generator and gear, a seriesparallel configuration is typically heavier than the parallel system, but offers high efficiency. For all configurations it has to be assessed, whether the internal combustion engine can be restarted with the electric motor or an additional electric starter is necessary. A typical surveillance mission for an unmanned aerial vehicle with hybrid-electric propulsion system contains three main relevant phases: Takeoff and climb with maximum power, a cruise flight to and back from the target area and a silent electric flight over the target area. Optionally a number of cruise flight segments during which the batteries are re-charged and further electric flight phases may be added to the profile. The descent and landing phases are assumed not to require propulsion energy at the preliminary stage. If a rule-based propulsion control is applied, it leads to four design points for a parallel system: 1. Regular cruise flight: The internal combustion engine drives the propeller. 2. Charging cruise flight: The internal combustion engine drives the propeller and the electric motor to charge the batteries. 3. Electric flight: The electric motor drives the propeller. The internal combustion engine is disconnected from the drive train in order not to cause an additional torque demand. 4. Maximum power: Both the internal combustion engine and the electric motor drive the propeller. The power levels of the internal combustion engine 1. Regular Cruise 2. Charging Cruise 3. Electric Flight 4. Maximum Power and the electric motor for the Flight Flight four design points are visualized in Fig. 2 in relation to the propulsion power P. for PICE = P PICE = 0 PICE = (1-DoH)P PICE = (1+DoC)P each design point. The fraction of the propulsion power delivered by the PEM = 0 P = P P =DoH·P PEM = -DoC·P EM EM electric motor during dual use (design point 4) PEM/P is defined as the degree of Figure 2. Power supplied by the internal combustion engine PICE and the hybridization DoH. During electric motor PEM relative to the propulsion power P for each design point charge (design point 2), the in a parallel hybrid-electric propulsion system. fraction of power applied to the electric motor’s shaft in generator mode and propulsion power -PEM/P is defined as degree of charge DoC. Within a simplified aircraft design process, as shown in Fig. 3, the essential input for the propulsion system design is the required thrust. Furthermore the design velocity and endurance for all design points need to be given. In order to show general tendencies and the functionality of the models, within this document, required only a stand-alone propulsion system design process Aeropropulsion thrust system Propulsion dynamics is regarded in detail. When ignoring packing in mass (untrimmed) preliminary design, the single decisive parameter to evaluate the propulsion system, and hence cost function for its optimization, is its mass. Within a Geometry RequireWeight & complete aircraft design process, a change in Sizing ments Balance propulsion system mass will change the required thrust and the process needs to be re-run until convergence. AeroPerfordynamics Required thrust, velocity and endurance for each mance (trimmed) of the design points are the input for the propulsion Figure 3. Propulsion system design within the overall design methodology presented in this document. aircraft design process Figure 4 exemplary shows it for the parallel 4 American Institute of Aeronautics and Astronautics Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 configuration. As to be seen there, the process is quasi-static and backwards-facing. The starting point is the required propulsion power, which is used to size first the propeller, then the energy converters and last the energy sources. For each component, the mass and the properties necessary to size the connected components are determined. The goal of a possible optimization is to determine each component’s characteristics, represented in the design variables, so that the system mass is minimized. A parallel hybrid-electric propulsion system includes the following components: Propeller, coupling, internal combustion engine with fuel tank and electric motor with electronic speed controller and battery. A brief description of the models describing these components is given in this section, details are given in the next one. The propeller model determines the shaft torque the propeller requires to generate a given thrust at a given velocity and the propeller mass. The design variables are the rotational speed and the propeller diameter and thrust coefficient. In the coupling model, the distribution of propeller torque and rotational speed on the two energy converters’ shafts is determined. In a simple pulley assembly, as it will be assumed for preliminary design, the coupling constant, which is defined by the ratio of the pulley radii, is used as the design variable. The internal combustion engine model computes the required chemical power for given torque and rotational speed, and the engine mass. Design variables are the displacement volume, the stroke-to-bore ratio, the number of cylinders and whether a two-stroke or a four-stroke cycle and a compression-ignited (CI, Diesel cycle) or spark-ignited (SI, Otto cycle) machine is used. The fuel tank model contains the determination of fuel and fuel tank mass, basing on the used fuel type. On the electric propulsion path, the electric motor model returns its required input voltage and current to deliver the given shaft torque for the given rotational speed and gives the motor mass. The electric motor design variables are its diameter and length as well as its specific rotational speed. The battery model delivers the mass of a battery pack providing energy for all design points and the arrangement of battery cells in parallel and series. The design variable is the capacity of one battery cell. Requirements: For each Design Point i: -Thrust Ti -Velocity vi -Flight Time ti Ti, vi Propeller: Qi = f(Ti,vi, Design variables) mprop = f(f(Ti,vi, Design Variables) ti ti Qi, ωi QICE,i, ωICE,i Internal Combustion Engine Pchem,i = f(Qi, ωi, Design Variables) mICE = f(Design Variables) Pchem,i Fuel Tank Ereq = Σ Pchem,i · ti mtank = f(Ereq) mfuel = f(Ereq) Coupling QICE,i, ωICE,i = f(Qi, ωi, Design variable) QEM,i, ωEM,i = f(Qi, ωi, Design variable) Design variables Electric Motor System Diameter, Length, Rot. Speed ω Spec. rot speed Propeller IC Engine Diameter, thrust Displacement, coeff. Stroke-to-bore Coupling ratio, cycle, Coupling const. number of Battery cylinders Cell Capacity QEM,i, ωEM,i Electric Motor Vin,i, Iin,i = f(Qi, ωi, Design Variables) mEM = f(Design Variables) Vin, Iin Battery & Electr. Speed Controller Ereq = Σ Vin,i · Iin,i · ti m batt = f(Ereq, Iin, Design Variables) Figure 4. Overview of the proposed propulsion system design process IV. Modeling of Propulsion components A. Propeller For the modeling of the propeller, the application XROTOR26 was used. XROTOR uses a blade-element/vortex implementation27 and optimizes the blade’s twist and chord distribution to minimize induced loss for given operational requirements, airfoil data and basic geometry. Contrary to the philosophy of avoiding look-up tables stated above, for the propeller modeling it was decided to use interpolation from previously created data sets, as an in-the-loop use of the tool would be too time consuming. For expected ranges of thrust, rotational speed, diameters, thrust coefficients and velocity, torque and efficiency were computed. In order to simplify data handling for the chosen use case, only two blade propellers and only one blade airfoil were regarded. The chord and twist distribution of the blade are optimized for each combination of the five properties design velocity, rotational speed 5 American Institute of Aeronautics and Astronautics Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 and thrust, diameter and thrust coefficient. As the propeller will be run in four design points, off-design data were computed for each blade geometry. Off-Design data here means the behavior of thrust and torque for velocities and rotational speeds other than those the blade geometry was optimized for in XROTOR. For the modeling of the propeller, the design points of regular cruise flight and charging cruise flight are considered the same, as the energy path for charging does not include the propeller. Within the propulsion system design process, one of the three design points has to be chosen to be the one to define the blade geometry. It is reasonable to choose the one with longest endurance. Interpolation using required thrust and velocity as well as the design variables rotational speed, diameter and thrust coefficient, yields the required torque for this point. Using the off-design data, the rotational speed is found, for which the required thrust at the given velocity for the other two design points is obtained. Torque is computed accordingly. As the blade geometry is previously optimized in XROTOR for one of the three design points, the model will not return the absolute optimum propeller geometry. To change this, the model would need to be implemented in the design loop. B. Electric Motor The electric motor can be modeled using a simplified equivalent circuit that is shown in Fig. 5. It was originally developed for brushed DC motors but may be used for brushless types with reasonable accuracy3. The + Q,ω Ri + model is also used in several more publications8,16,28,29 Iin Imot ∗ † and the applications Motocalc and Electricalc . Vemf Vin I0 The losses modeled are the resistive losses, represented by the internal resistance Ri, and the friction and iron losses, represented by the no-load current I0, i.e. the current that is drawn when no load Figure 5. Equivalent circuit for the electric motor is connected. Capacitive losses are neglected assuming that the motor is running always at full power. Another motor characteristic, introduced in Eq. (5), is the specific rotational speed Kv, which is the rotational speed per back-electromotive force Vemf induced. Pin = Vin I in (1) Pout = Vemf I mot = Qω (2) Vemf = Vin − R i I in (3) I mot = I in − I 0 (4) Kv = ω 30 N = π Vemf Vemf (5) From the definitions of input and output power in Eq. (1) and Eq. (2), and the relationships derived from the circuit in Eq. (3) and Eq. (4), the input voltage and current can be determined as function of required torque and rotational speed as given in Eq. (6) and Eq. (7) I in (Q, ω) = QK v Vin (Q, ω) = ∗ † π 30 ω K π v 30 + I0 + (QK v (6) π 30 + I0 ) R i Available at http://www.motocalc.com/ [Retrieved 13 August 2012] Available at http://www.slkelectronics.com/ecalc/index.htm [Retrieved 13 August 2012] 6 American Institute of Aeronautics and Astronautics (7) Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 Application of Eq.(6) and Eq. (7) in the preliminary design process requires knowledge of the three motor specific parameters no-load current I0, internal resistance Ri and specific rotational speed Kv. In manufacturer data sheets, the no-load current I0 is usually given only for one specific input voltage. The specific rotational speed Kv is commonly given for the no-load condition. Both parameters and the internal resistance Ri are assumed to be constant over the operational range with acceptable results3. A more sophisticated model would include rising internal resistance with increasing current drawn and hence increased temperature29, as well as the decrease of specific rotational speed under higher load. One possibility to determine the parameters is to discretely take them from a list of existing motors2,3, but this limits the range of applicable optimization algorithms and requires relatively high computation time. In a generic model, suitable for optimization, either relationships between the three parameters have to be given or they have to be related to other motor characteristics. In Ref. 16, linear relationships between specific rotational speed and inverse motor mass, internal resistance and inverse specific rotational speed squared and no-load current and internal resistance to the power of 0.6 are given. Unfortunately these simple functions lack accuracy when compared to data of commercial off-the-shelf aeromodeling components, as they were derived over a very wide range of different motor types. To derive more accurate relationships for this use case, data of over 700 electric motors were collected. The database consists almost exclusively of aeromodeling motors, of which all are brushless DC models, due to their advantages in efficiency, specific power and electromagnetic compatibility. An attempt to create a model for all the motors has resulted in accuracies too low to correctly describe the dependencies. This is due to the different motor architectures various manufactures use and the fact that data on several characteristics affecting the results are seldom published. Those unknown characteristics include the number of stator coils, the number of magnet poles and the wire gauge for example. It was hence decided, that for preliminary aircraft design, it is sufficiently accurate to develop exemplary models for the two main types of used electric motors, the inrunner and the outrunner, based only on the data of one manufacturer each. An inrunner motor is characterized by the rotor running inside of the stator, whereas in an outrunner architecture it is the other way round. For the inrunner motors the manufacturer Lehner‡ was chosen and for the outrunners Scorpion§. Both offer a wide range of different motors and group their products into series which makes fitting much easier. Nominal power levels for electric motors are difficult to define because of their dependence on supply voltage and unpublished data, but the estimated maximum continuous power of the included inrunners ranges from 250 W to around 4000 W, whereas the included outrunners provide power between around 70 W and 2800 W. An approach using idealized textbook methods30 yields the inverse proportionality of the specific rotational speed to the number of coil windings, the rotor radius, the air gap flux density and the axial motor length. Internal resistance is proportional to the fraction of wire length and gauge. Non-resistive losses, namely friction, hysteresis and eddy current losses, are proportional to the rotational speed, magnet field properties and friction and material coefficients, which are unknown for commercial motors. The only values available of those mentioned above are the motor diameter and length as well as the number of windings. The motors used in the database are divided into series with equal diameter. Within each diameter series, there exist several motor lengths. For each pair of diameter and length, several models are available, distinguished by different specific rotational speeds. Modification of the specific rotational speed is done, in case of the chosen manufacturers, by changing the number of coil windings and pole pairs. During the design of a propulsion system, the specific rotational speed is a parameter of more practical use than the number of coil windings. This is why it is used as an independent variable together with diameter and length for a regression using the database. When plotting internal resistance and no-load current over the specific rotational speed, as done in Fig. 6, each of the single curves represents one motor series with equal diameter and length. Equal markers in the figure mark series with equal diameter. The behavior of internal resistance is inverse quadratic over the specific rotational speed, as the latter decreases with increasing number of windings and hence increasing wire length. Furthermore, the bigger the series’ diameter and length are, the lower the internal resistance levels get. This may be explained by the fact, that more space within the motor case allows bigger wire gauges for the coil windings. No-load current rises when either one of the independent variables is increased. An increase with size of the motor can be explained with the increased air friction, higher eddy current losses and a possibly increased number of bearings. As no-load currents are indicated for the same voltage, higher specific rotational speeds lead to higher noload rotational speeds hence more no-load current is drawn. Furthermore it is obvious, that higher currents flow for reduced internal resistances. ‡ § Data available at http://www.lehner-motoren.de/ [Retrieved 13 August 2012] Data available at http://www.scorpionsystem.com/ [Retrieved 13 August 2012] 7 American Institute of Aeronautics and Astronautics Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 a) b) Figure 6. Behavior of internal Resistance Ri (a) and no-load current I0 (b) over specific rotational speed Kv for all included inrunner motors. Each single curve represents one motor series with equal diameter and length Polynomial fits for the internal resistance and the no-load current with the independent variables specific rotational speed, diameter and length led to either low coefficients of determination for low degrees or instable behavior of the functions for degrees higher than three. Furthermore visualization and hence handling of data with three independent variables is very difficult. Polynomial fits neither returned any reasonable results when diameter and length were merged into one variable by multiplication, division or exponentiation. As the behavior of both dependent variables can be perfectly fitted over specific rotational speed with power functions, a custom equation of the form given in Eq. (8) was found to return very good results for fitting the internal resistance and no-load current to the product of diameter d and length l and specific rotational speed Kv. c c I 0 , R i = c1 (dl)c2 K v 3 + c 4 (dl) c5 + c 6 K v 7 + c8 (dl) + c 9 K v + c10 (dl) K v + c11 (8) Coefficients of determination for the resulting unrestrained fits are R2Ri=0.974 and R2I0=0.933 for the inrunner internal resistance and no-load current and respectively R2Ri=0.949 and R2I0=0.682 for the outrunners. The worse outrunner values can be explained with the number of magnet poles, one of the decisive design characteristics of electric motors that could not be included due to the lack of data, and which is constant for the inrunners, whereas varying for the outrunner motors. b) a) Figure 7. Limits of specific rotational speed for inrunner (a) and outrunner (b) electric motors. Limits derived from the database are drawn as solid lines, the maximum implied by the minimum internal resistance is drawn as dashed line. In case of an optimization, the product of diameter and length and the specific rotational speed are the design variables for the electric motor. For the fitted functions to return reasonable values, the relations between the design variables have to be carefully set. Using the database, the minimum and maximum specific rotational speed of each 8 American Institute of Aeronautics and Astronautics Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 motor series can be fitted to the product of diameter and length with power functions. Furthermore, the areas where internal resistance and no-load current fall below the minima given in the database are restrained to keep the model conservative. For each product of diameter and length, high specific rotational speeds are limited by the lower value of the database maximum or the point where the minimum resistance Ri,min is underrun. Low values are limited respectively by the higher one of the database minimum or the value at which the minimum no-load current I0,min is underrun. The limits are shown with the distribution of the database motors in Fig. 7. The limit for minimum noload current is missing due to reasons explained below. a) b) Figure 8. Minimum internal resistance (a) and no-load current (b) as function of the product of motor diameter and length for inrunner motors. The minimum value for each motor series with the same diameter and length is taken from the database. a) b) Figure 9. Internal resistance (a) and no-load current (b) of inrunner motors as function of the product of motor diameter and length d·l and the specific rotational speed Kv To generically determine the minimum internal resistance Ri,min and no-load current I0,min, that may not be underrun, the minimum value of both for each motor series in the database were fit to the product of diameter and length. A motor series here is a group of motors with the same diameter and length. The power fit for the internal resistance, shown in Fig. 8a, can be done with a high coefficient of determination of R² = 0.963. A reasonable fit for the minimum no-load current is not possible based on the database. Because of that, in Fig. 8b, the no-load currents computed for the minimum specific rotational speed limit Kv,min from the database, are plotted against the database minimum no-load currents. As the curve runs within the scatter of database values for all motor series except the biggest one, it is accepted to neglect restraining minimum allowed specific rotational speeds with the minimum noload current limit. The restrained plots for the internal resistance and no-load current of the inrunner motors can be seen in Fig. 9. The model is intended for use within the limits of the original data only. This limits the product of diameter and length to values between 1000 mm² and 8500 mm² for inrunner motors and 800 mm² to 5500 mm² for outrunners. The restraint, not to allow motors with internal resistances below the minimum for their size, cuts a significant number of models with high specific rotational speed from the design space. Another drawback of the model is that, due to the low number and the narrow specific rotational speed range of available aeromodeling motors bigger than 9 American Institute of Aeronautics and Astronautics Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 those by the chosen manufacturers, no model can be derived for them and hence existing high power motors cannot be represented in the design space. Brushless DC motors with even higher power for other applications than aeromodeling cannot be included in this model, as commonly the three motor characteristics specific rotational speed, no-load power and internal resistance are not published. A reasonable approach to the determination of the electric motor mass is to assume that its components’ masses are proportional to either the motor length, surface or volume. Discarding the influence of surface and length results in the linear functions given in Fig. 10 for both inrunner and outrunner motors. As the coefficients of determination of R²=0.984 for the inrunners and R²=0.976 for the outrunners are only slightly below those obtained with the fit to three independent variables, it was preferred to use the simpler equation. When deriving a linear fit for all the motors in the database, the coefficient of Figure 10. Linear fits for the electric motor mass. determination goes down to R²=0.722. Peculiar Coefficient of determination for inrunners is R2 = 0.984, outliers are either non-aeromodeling motors, when for outrunners R2 = 0.976 heavier, and more expensive models for aeromodeling competitions, when lighter. C. Electronic Speed Controller The electronic speed controller was shown to be responsible for significant losses in an electric power train, especially, when the system is run at partial load3,17. Nevertheless, only one model is known to the author that covers this issue3. It is given in Eq. (9). η ESC = Vin,ESC − R i,ESC I Vin,ESC − k PTF Vin,ESC ⎛ ⎞ P ⎜1 − in,ESC ⎟ ⎜ P ⎟ max,ESC ⎠ ⎝ (9) For full load the second term in Eq. (9) becomes zero as the input power Pin,ESC equals maximum power Pmax,ESC. Thus the losses are only depending on the controllers internal resistance Ri,ESC. For part load, the second term, depending on the power fraction and the part throttle factor kPTF is dominating. To use the model both the internal resistance of electronic speed controllers Ri,ESC as well as a part throttle factor kPTF are required. The author of the model determined them experimentally for some models. As the part throttle factor is first and yet only used in the model and the internal resistance is almost never provided by the manufacturers, the model unfortunately cannot be implemented in an automated process yet. As neither the losses at full nor at part load can be quantified, one alternative could be to derive a representative function for the controller efficiency over the duty cycle from experimental data3,17, but due to the lack of a sufficient number of experiments and coverage of input parameters this is inaccurate. Figure 11. Mass of electronic speed controllers In order to derive a law for the mass of electronic speed controllers, data of 50 models was collected in a database. All models are in a similar price range and all do provide the battery eliminator circuit that can be used as energy supply for the command and control system. The four regarded manufacturers offer versions for low voltage levels up to 22.2 V (6 Lithium Polymer cells in series) and for high voltage levels up to 51.8 V (14 lithium Polymer cells in series). The maximum voltage level of the electronic speed controller is a restraint for a possible optimization, if the design is to be based on commercial components. For some manufacturers it is possible to create 10 American Institute of Aeronautics and Astronautics Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 a linear fit over maximum input current for both the low and the high voltage models’ mass with a high coefficient of determination, but as for some the behavior of the two series is completely different, it was decided to describe the controllers’ mass depending on their maximum input power. The results, to be seen in Fig. 11, correlate very well with previously published work2. The coefficient of determination of the linear fit is R²=0.802. D. Battery The battery model presented here aims to make results for the mass of a required battery more accurate for the common case that not a bespoke model is used, but commercially available units. Because of their superior specific energy and their wide commercial availability, only Lithium-Polymer batteries are regarded. It is sufficiently accurate to assume a constant specific energy for Lithium Polymer batteries2, but it is very unlikely that batteries storing exactly the required amount of energy are available. In the presented model it is hence determined how the single cells are arranged in parallel and series. The number of cells in series is computed, as given in Eq. (10), from the maximum voltage requested by the electric motor. The voltage a cell can provide decreases when more current is drawn or the state of charge is Figure 12. Mass of batteries as function of stored decreasing. For simplification of the model it is energy and maximum current acceptable to assume the nominal voltage per cell of Vcell = 3.7 V (Ref. 3). ⎡V ⎤ n s = ⎢ max ⎥ ⎢ Vcell ⎥ (10) The number of cells in parallel is set by the capacity of the single cell, which is used as the design variable for the battery and the required capacity. In an aeromodeling context, capacity, contrary to textbook definition, is used as a value defining for how long a current can be provided. Its unit hence is Ampere hours. Both the parallel number of cells, given in Eq. (11), and the number of cells in series are rounded up, as they need to be integer of course. For Lithium Polymer it is assumed that only 80% of the battery’s capacity may be discharged as otherwise it might be harmed. ⎡ ∑ 1.2 I i t i ⎤ np = ⎢ ⎥ ⎢ C cell ⎥ (11) The mass of a battery cell depends on the energy and maximum continuous current it is able to deliver. A function was fitted from a database of over 400 aeromodeling batteries. With a double linear approach a high coefficient of determination of R²=0.982 can be reached. As expected and to be seen in Fig. 12, the mass of the batteries increases for both higher stored energy Ecell and higher maximum discharge current Imax,cell. They can be computed from the design variable of the battery, the capacity per cell Ccell, and the maximum current drawn by the electric motor Imax using Eq. (12) and Eq. (13). E cell = C cell Vcell I max,cell = (12) I max np (13) 11 American Institute of Aeronautics and Astronautics Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 For the use in an optimization, the design space has to be restrained in order to prevent unreasonable results. A relationship was established between the two variables that the battery mass is computed from, stored energy and maximum current. From the database, linear restraints can be derived. They are plotted in Fig. 12. A plain maximum for the maximum current is set at 500 A. E. Internal Combustion Engine Although internal combustion engines are a part of aviation since the very first powered flight, it is surprisingly challenging to create a model for their preliminary design. Modeling of the thermodynamic and combustion processes is both too time-consuming for preliminary design and inaccurate for small engines23. A scaling procedure for engine performance is hence required. A usual representation of engine performance data is the efficiency map, in which the overall efficiency or the brake specific fuel consumption is given over torque and rotational speed. The maximum torque for each rotational speed is indicated with the wide-open throttle (WOT) curve. Scaling of engine performance might only be done for similar engines and hence the more efficiency maps of existing engines are used for calibration of a scaling model, the more accurate it can be used. While for automotive engines efficiency maps are available31, to obtain data for small engines is very difficult. The reason for this is that small internal combustion engines serve the niche markets of model aircraft, gardening tools, scooters, boats, snowmobiles or generators, where very general statements on fuel consumption are accepted by the customer. Creating efficiency maps from experiments is an expensive and time-consuming way to obtain the data. From the experiments published8,24, it is known that problems occur for single cylinder models due to the rough running and that a fine carburetor adjustment has big influence on the results. Automotive reference efficiencies for naturally aspirated engines range from 20 % to 42 %31. In a measuring campaign for two- and four stroke engines with displacements of below 15 cm³ efficiencies of around 8 % are obtained24. For a 35 cm³ multi-purpose four-stroke engine 20% are exceeded8. A 28.1 cm³ four-stroke engine specifically designed for the use in unmanned aircraft reaches up to 34% efficiency at the same power level and rotational speed than the previous one32. The Willans line model19 is a commonly used method33,34 to scale engine performance. Variables defining the target engine are its displacement volume Vd and the cylinder stroke S. The model does not reflect the influences of air-to-fuel ratio, ignition dynamics, fuel injection and thermal effects. It assumes a formally linear relationship between engine input and output power. Losses are divided into thermal losses, represented by the energy conversion efficiency or thermal efficiency e, and friction and auxiliary losses represented by the power loss Ploss and respectively the torque loss Qloss. The power formulation is given in Eq. (14), the torque formulation in Eq. (15). & fuel H LV ) − Ploss Pout = ωQ out = ePin − Ploss = e(m Q out = e & H LV m − Q loss ω (14) (15) In order to use the model for scaling, normalized mean values are used. As can be seen in Eq. (16), torque is normalized by the engine displacement Vd to obtain the mean effective pressure (mep) pme for the shaft torque, the fuel’s available mep pma and pmloss for the torque loss. The rotational speed is normalized by the cylinder stroke S and used as mean piston speed cm, as given in Eq. (17). & H LV ⎛ 4 π ⎞ ⎛4π⎞ ⎛4π⎞ m ⎟⎟ = e ⎜⎜ ⎟⎟ − Q loss ⎜⎜ ⎟⎟ Q out ⎜⎜ V ω V V d ⎠ d ⎠ d ⎠ ⎝ 4 ⎝ 43 142 3 142 4 ⎝43 4 142 p me cm = p ma (16) p mloss S ω π (17) Using the normalized mean values with Eq. (14) leads to the function given in Eq. (18). The proposed parameters19 for the thermodynamic efficiency and the loss have to be calibrated from existing efficiency maps. As both the thermal efficiency and the losses are functions of the mean piston speed, it becomes clear, that the relation of output and input power is not really linear and hence efficiency is not constant. 12 American Institute of Aeronautics and Astronautics p me = ep ma − p mloss = ((e 00 + e 01c m + e 02 c 2m ) − (e10 + e11c m ) p ma ) p ma − (p mloss,0 + p mloss,2c 2m ) (18) The resulting definition for the internal combustion engine’s overall efficiency is given in Eq. (19). Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 η= Pout ePin − Ploss P p p = = e− loss = e− mloss = me Pin Pin Pin p ma p ma (19) To use the model, a generic wide-open throttle curve needs be determined in order to choose realistic combinations of the state variables torque and rotational speed or respectively mean efficient pressure and mean piston speed. How it can be obtained is described within the next paragraphs. One issue in using the Willans line method is that it was originally derived for forward-facing use, i.e. determining shaft torque from available fuel energy. When re-organizing Eq. (18) and Eq. (19) into the form η = f(pme, cm) given in Eq. (20), in which it could be used for fitting from an efficiency map, the parameterization is disadvantageous. η= (e 2 00 + e 01c m + e 02 c m ) ± 2(e10 + e11c m ) (e p me 2 p +p +p c2 00 + e 01c m + e 02 c m ) − me mloss,0 mloss,2 m 2(e10 + e11c m ) e10 + e11c m (20) As an alternative, the possibility of linear scaling35 of the efficiency map was investigated. As the performance should only be scaled for similar motors, baseline efficiency maps need to be provided for two-stroke and fourstroke SI and four-stroke CI motors. If enough data were available, ideally various ranges of displacement would be represented by various baseline efficiency maps. To use the efficiency map of an internal combustion engine as baseline for scaling, it has to be normalized. The wide-open throttle curve is normalized by the maximum overall mean efficient pressure of the engine, as shown in Eq. (21). The mean effective pressures at lower throttle levels are normalized by the value of the wide-open throttle curve at the corresponding mean piston speed, as in (22). p me,WOT (c m ) = p me (c m ) = p me,WOT (c m ) p me,max p me (c m ) p me,WOT (c m ) (21) (22) Two basic assumptions are prerequisite for the linear scaling: 1. The normalized wide-open throttle curve’s behavior over the mean piston speed is unchanged over the range of engines regarded. 2. The efficiency of all the engines regarded is the same for equal normalized mean effective pressure and mean piston speed, if the stroke-to-bore ratio is the same. Assumption 1 can be validated later on in this chapter, for the validation of assumption 2 not enough data on small engine fuel consumption are available. Naturally, maximum power and torque of an internal combustion engine increase with its size. In order to establish a relationship, a database with over 250 engines below 30 kW shaft power was assembled. The biggest part of the included engines is for aeromodeling, small percentages are ultralight aircraft or multi-purpose engines. For most of them neither wide-open throttle curves are given nor are data about fuel consumption. Hence a relationship between displacement, as design variable of the internal combustion engine, and net power is established, a value that is widely indicated. From the operation of research aircraft at the institute it is anyhow known, that manufacturer indications on power may be too optimistic. Net power can be described as linear function of the displacement volume with a coefficient of determination of R²=0.975. Both the original data and the fit can be seen in Fig. 13a. The peculiar outlier is a Wankel engine with unusually high specific power. As only very few Wankel engines in this power range are available, no reliable general 13 American Institute of Aeronautics and Astronautics conclusions about their capabilities can be drawn. It can nevertheless be stated that the Wankel engine would be very interesting for application in aircraft, if high specific power was provided with a high level of reliability. The first step of scaling engine performance to other displacements is to determine the maximum power related to it. From the assumption that the wide-open throttle curve’s behavior over mean piston speed is not concerned by the change in displacement volume, the mean piston speed for which maximum power is reached and the normalized WOT mep at that point stays the same. The overall maximum mep pme,max can then be computed as shown in Eq. (23). Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 p me,max Pmax ⎛ 4 S ⎞ ⎜ ⎟ Q p me,WOT (c m,Pmax ) c m,Pmax ⎜⎝ Vd ⎟⎠ = = = p me,WOT (c m,Pmax ) p me,WOT (c m,Pmax ) p me,WOT (c m,Pmax ) ( ) 4π Pmax Vd (23) With the maximum mep the absolute values of the WOT curve can be computed using Eq. (21) and from there, using Eq. (22), the normalized mep which can be used to interpolate the efficiency from the normalized efficiency map. b) a) Figure 13. Net power (a) and rotational speed range (b) as function of the internal combustion engines’ displacement volume The second design variable of the internal combustion engine is the stroke-to-bore ratio. It is a parameter of essential importance to the engine design, as it not only defines its basic geometry but also has a major influence on the combustion process and hence performance20,21,22. The resulting change of the brake specific fuel consumption is quantified in Ref. 22 relative to a stroke-to-bore ratio of 0.7 and for two absolute values of the mean effective pressure (262 kPa and 500 kPa) and over a range of rotational speeds. From the data, a function for the relative efficiency change is derived with linear dependencies on mean piston speed and mean effective pressure and quadratic dependency on stroke-to-bore ratio. While for constant mean efficient pressure levels high accuracy is reached, the minimum number of two supporting points does not allow a statement on the accuracy of the engine load formulation. In Figure 14 it can be seen that efficiency rises with Figure 14. Internal combustion engine overall increasing stroke-to-bore ratio as thermal efficiency rises. efficiency for varying stroke-to-bore ratio and With higher rotational speeds, the negative influence of mean piston speed normalized by the efficiency the stroke-to-bore ratio on friction losses increases, so that with stroke-to-bore ratio 0.7 for pme=262kPa the overall improvement is reduced22. For higher mean efficient pressure, the effect of increasing friction becomes more dominant. The maximum mean efficient pressures 14 American Institute of Aeronautics and Astronautics Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 of the engines in the database, for which net torque is given, ranges from 500 kPa to 2000 kPa. This means that even at partial load, for most of the applications, the value for efficiency change due to the influence of the stroke-to-bore ratio would have to be extrapolated, which, given only two points of support, flaws the quality of the model. From the engine database, maximum and minimum rotational speeds of the engines are plotted over displacement volume in Fig. 13b. A very general observation is that smaller engines operate at higher rotational speeds. For engines with displacement volumes bigger than 50cm³, the range usually extends from minima of 1000 rpm to 2000 rpm to maxima of 5000 rpm to 8000 rpm. For smaller engines, minimum speeds only increase slightly, whereas the maximum speeds rise to 20,000 rpm. While generally the normalization of the rotational speeds reduces these big differences in the speed range, the engine that is scaled from and to should operate in a similar speed range. The Honda GX Series engines¶, for which WOT torque data is provided, is used to determine whether scaling using a normalized WOT curve leads to reasonable results. The series includes four-stroke engines with displacement volumes from 25 cm³ to 390 cm³ and similar stroke-to-bore ratio. The resulting relative error for the WOT curves, when Figure 15. Relative error for scaling of Honda GX applying the normalized curve of the 160 cm³ engine to series WOT curves in percent. The normalized all models can be seen in Fig. 15. Scaling down leads to WOT curve for the 160cm³ model was applied on all acceptable relative errors of up to 14% for mean piston models with displacements from 25cm³ to 390cm³. speeds lower than 4 m/s or higher than 7.5 m/s. When scaling up, relative errors are generally lower. Scaling an engine with smaller displacement volume reduces the errors for the small engines but increases those for the larger engines and the maximum error significantly. Two-stroke engines have higher specific power compared to four-stroked engines, which is explained with their simplicity and the fact that a power cycle is completed within two strokes compared to four for the four-stroke engine. This tendency is also to be found in the database, for which the distribution of mass is given in Fig. 16. Below a displacement of 50 cm³, both engine types have similar mass, above the two-stroke models are significantly lighter. The outlying two-stroke models are heavier because a belt drive is included in the manufacturer mass data. These engines are neglected for the fitted functions. For the four-stroke engines, a linear function yields a coefficient of determination of R²=0.967, for the two-stroke engines a power function with a coefficient of determination of R²=0.950 is used as with a linear fit the values for engines with very low displacement would become too high. Figure 16. Mass of internal combustion engines. Twostroke engines are represented with crosses and a solid line for the fit, four-stroke engines are represented with squares and a dashed line. Wankel engines are represented with circles and not included for the fit. ¶ Figure 17. Mass of fuel tanks as function of volume. A conservative cubic function for transport canister is plotted with a solid line, a linear function for industrial canisters is plotted with a dashed line. Data available at http://engines.honda.com/models/series/gx [Retrieved 13 August 2012] 15 American Institute of Aeronautics and Astronautics F. Fuel Tank The mass and volume of the necessary fuel can be computed, as given in Eq. (24) and Eq. (25) using the chemical power required by the internal combustion engine and the fuel’s lower heating value HLV and density ρfuel. m fuel = Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 Vfuel = ∑P t chem,i i (24) H LV m fuel ρ fuel (25) The only property of interest for the fuel tank is its mass. A data base was created with 40 tanks from 0.1 L to 31 L volume. Aeromodeling tanks usually have volumes below 2 L. Larger tanks are for industrial use or for the transport of fuel. As can be seen in Fig. 17, a linear function can be fitted for the industrial tanks, which are generally lighter. The mass of the heavier transport canisters can be described with a cubic polynomial function. As safety upon impacts may be an important issue for an aircraft, it was decided to use the more conservative function for the robust transport canisters. V. Conclusion and Outlook This document describes an applicable approach to the design of hybrid-electric propulsion systems. For the parallel configuration the design process is shown and the used models are presented in detail. The models were created with the intention to allow an automated use in the preliminary design process of unmanned aerial vehicles over a wide range of requirements. They are based on the use of the state variables, the variables whose product is power, for the energy converters. For each component of the propulsion system, a database of existing components is created in order to derive or validate dependencies and models. The propeller model is a re-arrangement of data created with an implementation of the blade-element theory and previously optimized in terms of minimum induced loss. For the electric motor a well established electrical model is used. The component characteristics necessary for its use, internal resistance and no-load current, are derived from the motor geometry and specific rotational speed. A universal model, applicable to all types of electric aeromodeling motors could not be created due to unavailable data. Instead, models with high accuracy are created based on the product range of one manufacturer each for the two main architectures, inrunner and outrunner motors. In order to keep the model conservative, the design space is slightly restrained for very big motors and high specific rotational speeds, where otherwise the minimum lowest database values would be underrun. A model for electronic speed controllers, which implements losses at partial load, is identified. For its application in an automated process more experimentation is necessary, as relevant data is not yet available. The battery model accounts for commercial sizes of batteries and includes the architecture of the battery pack. For the modeling of the internal combustion engine, two scaling models are derived from automotive applications. Both require the scaling of the wide-open throttle curve, which can be done with an acceptable relative error of below 15%. The influence of the stroke-to-bore ratio was modeled, but due to a narrow range of loads in the original data, extrapolation has to be applied and hence the accuracy is unclear. For all components, as the electric motor, the battery pack, the electronic speed controller, the internal combustion engine and the fuel tank, mass prediction laws have been derived from the databases of commercial products. Further work will be on the implementation of the models into a preliminary propulsion system design framework including stand-alone optimization, followed by the integration into a conception aircraft design environment. It has to be practically assessed if the models offer an advantage over discrete interpolation models in terms of computation time. Enhancements of the electric motor model may include the behavior of the three characteristics no-load current, specific rotational speed and internal resistance during different phases of operation. The model for the generic determination of those three characteristics could be applied to a wider range of motors if more data was published by the manufacturers. Useful data would be wire gauge, number of magnet poles, number of coils and limits of input voltage and current as well as rotational speed. The model for the electronic speed controller may be applied with more experimental data on partial load operation. The battery model can be enhanced with the representation of losses and voltage dependency on current and state of charge. For the further validation and refinement of the internal combustion engine model it is of crucial importance to obtain more data on the fuel consumption of small engines. 16 American Institute of Aeronautics and Astronautics Acknowledgments The work done in this study is done by Technische Universität München as subcontractor of Cassidian within the project DemUEB Phase 3 (Demonstration of the use of UAV in Bavaria) funded by the Bavarian Ministry of Economic Affairs, Infrastructure, Transport and Technology (German: Bayerisches Staatsministerium für Wirtschaft, Infrastruktur, Verkehr und Technologie). The authors would like to thank their colleagues Bastian Figlar, Benedikt Mohr, Daniel Paulus, Christian Rößler and Sebastian Speck for their useful comments on the work. Furthermore the authors would like to thank Sebastian Wohlgemuth and Daniel Engelsmann from Technische Universität München’s Institute of Internal Combustion Engines for their comments on engine scaling and the people at Bauhaus Luftfahrt e.V. for discussing the electric motor model. References 1 Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 Anon., “Entwurf eines Vierzehnten Gesetzes zur Änderung des Luftverkehrsgesetzes“ [in German], Deutscher Bundestag, Drucksache 17/8098, 2011 2 Noth, A., “Design of Solar Powered Airplanes for Continuous Flight,” Ph.D. Dissertation, ETH Zürich, Zürich, 2008. 3 Rößler, C. O., “Conceptual Design of Unmanned Aircraft with Fuel Cell Propulsion System,” Ph.D. Dissertation, Lehrstuhl für Luftfahrtsysteme, Technische Universität München, München, 2011. 4 Bradley, T. H., Moffit, B. A., Parekh, D. E., Fuller, T. F, Mavris, D. N., “Energy Management for Fuel Cell Powered Hybrid-Electric Aircraft,” Seventh International Energy Conversion Engineering Conference, AIAA, Denver, CO, 2009. 5 Harmon, F. G., Frank, A. A., Joshi, S. S., “The control of a parallel hybrid-electric propulsion system for a small unmanned aerial vehicle using CMAC neural network”, Neural Networks, Vol. 18, 2005, pp. 772-780. 6 Harmon, F. G., Frank, A. A., Chattot, J.-J., “Conceptual Design and Simulation of a Small Hybrid-Electric Unmanned Aerial Vehicle,” Journal of Aircraft, Vol. 43, No. 5, 2006, pp. 1490-1498. 7 Hiserote, R., Harmon, F. G., “Analysis of Hybrid-Electric Propulsion System Design for Small Unmanned Aircraft Systems,“ Eighth Annual International Energy Conversion Engineering Conference, AIAA, Nashville, TN, 2010. 8 Greiser, C. M., Mengistu, I. H., Rotramel, T. A., Harmon, F. G.,”Testing of a Parallel Hybrid-Electric Propulsion System for use in a Small Remotely-Piloted Aircraft,“ Ninth Annual International Energy Conversion Engineering Conference, AIAA, San Diego, CA, 2011. 9 Ausserer, J. K., Harmon, F. G., “Integration, Validation, and Testing of a Hybrid-Electric Propulsion System for a Small Remotely-Piloted Aircraft,“ Tenth International Energy Conversion Engineering Conference, AIAA, Atlanta, GA, 2012 10 Glassock, R., Hung, J. Y., Gonzalez, L. F., Walker, R. A., “Design, Modelling and Measurement of Hybrid Powerplant for Unmanned Aerial Systems (UAS),” Fifth Australasian Congress on Applied Mechanics, Brisbane, Australia, 2007. 11 Glassock, R., Hung, J. Y., Gonzalez, L. F., Walker, R. A., “Multimodal Hybrid Powerplant for Unmanned Aerial Systems (UAS) Robotics”, Twenty-Fourth Bristol International Unmanned Air Vehicle Systems Conference, Bristol, United Kingdom, 2009. 12 Koster, J. et al., “Hybrid Electric Integrated Optimized System (HELIOS) – Design of a Hybrid Propulsion System for Aircraft,” Forty-Ninth AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exhibition, Orlando, FL, 2011. 13 Lieh, J., Spahr, E., Behbahani, A., Hoying, J., “Design of Hybrid Propulsion Systems for Unamnned Aerial Vehicles,“ Forty-Seventh AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diega, CA, 2011. 14 Deschenes, A., Brown, K., Sobin, A., West, G., “Design, Construction, and Testing of RC Aircraft for a Hybrid Propulsion System,“ Forty-Ninth AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exhibition, Orlando, FL, 2011. 15 Gur, O., Rosen, A., “Optimization of Propeller Based Propulsion System,” Journal of Aircraft, Vol. 46, No. 1, 2009, pp. 95-106. 17 American Institute of Aeronautics and Astronautics 16 Gur, O., Rosen, A., “Optimization of Electric Propulsion Systems for Unmanned Aerial Vehicles,” Journal of Aircraft, Vol. 46, No. 4, 2009, pp. 1340-1353. 17 Lundström, D., Amadori, K., Krus, P., “Validation of Models for Small Scale Electric Propulsion Systems,” Forty-Eighth AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exhibition, Orlando, FL, 2010. 18 McElroy, T., Landrum, D. B., “Simulated High-Altitude Testing of a COTS Electric UAV Motor“, Fiftieth AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exhibition, Nashville, TN, 2012. 19 Rizzoni, G., Guzzella, L., “Unified Modeling of Hybrid Electric Vehicle Drivetrains”, IEEE/ASME Transaction on Mechatronics, Vol. 4, No. 3, 1999, pp. 246-256. 20 Downloaded by MONASH UNIVERSITY on September 15, 2015 | http://arc.aiaa.org | DOI: 10.2514/6.2012-5610 Huß, M., Hübner, W., Wachtmeister, G., “Scaling Functions for the Simulation of Different SI-Engine Concepts in Conventional and Electrified Power Trains,“ GT-Suite Users Conference, Frankfurt, Germany, 2010. 21 Weinowski, R. et al, “Future downsizing of SI engines – potentials and limits of 2- and 3-cylinder concepts“, 30. Internationales Wiener Motorensymposium, Vienna, Austria, 2009. 22 Filipi, Z. S., Assanis, D. N., “The effect of the stroke-to-bore ratio on combustion, heat transfer and efficiency of a homogeneous charge spark ignition engine of given displacement”, International Journal of Engine Research, Vol. 1, No. 2, 2000, pp. 191-208. 23 Menon, S., Cadou, C., “Experimental and computational investigations of small internal combustion engine performance,” Fifth US Combustion Meeting, San Diego, CA, 2007 24 Menon, S., Moulton, N., Cadou, C., “Development of a Dynamometer for Measuring Small Internal Engine Combustion Engine Performance,” Journal of Propulsion and Power, Vol. 23, No. 1, 2007, pp. 194-202. 25 Cadou, C., Menon, S., “Scaling of Losses in Small IC Aero Engines with Engine Size,” Forty-Second AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, 2004 26 XROTOR, Software Package, Ver. 7.55, Drela, M., Youngren, H., Cambridge, MA, 2011 27 Larrabee E. E., French S. E., “Minimum induced loss windmills and propellers,” Journal of Wind Engineering and Industrial Aerodynamics, Vol. 15, No. 1-3, 1983, pp. 317-327. 28 Drela, M., “First-Order DC Electric Motor Model,”, MIT Aero & Astro, 2007. 29 Drela, M., “Second-Order DC Electric Motor Model,”, MIT Aero & Astro, 2006. 30 Hanselmann, D., Brushless Permanent Magnet Motor Design, 2nd ed., Magna Physics Publishing, Lebanon, 2006 31 Heywood, J. B., Internal Combustion Engine Fundamentals, McGraw-Hill Book Company, New York, 1988 32 Hendrickson, S. P., McGeer, T. “A Miniature Powerplant for Very Small, Very Long Range Autonomous Aircraft,” Final Report to the United States Department of Energy under contract number DE-FG03-96ER82187, 1999, Bingen, WA 33 Rajagopalan, A., Washington, G., Rizzoni, G., Guezennec, Y., “Development of Fuzzy Logic and Neural Network Control and Advanced Emissions Modeling for Parallel Hybrid Vehicles”, NREL/SR-540-32919, 2003 34 Wei, X., “Modeling and Control of a Hybrid-Electric Drivetrain for Optimum Fuel Economy, Performance and Driveability,” Ph.D. Dissertation, Ohio State University, Columbus, OH, 2004 35 Gao, D. W., Mi, C., Emadi, A., „Modeling and Simulation of Electric and Hybrid Vehicles,“ Proceedings of the IEEE, Vol. 95, No. 4, 2007, pp. 729-745 18 American Institute of Aeronautics and Astronautics