Risk Mitigation for IM/PMM Engines with CILA2S Equipment

Anuncio

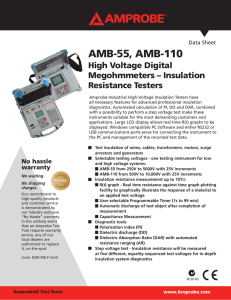

MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S® SURFACE EQUIPMENT This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 CONTENT 1. PURPOSE 3 2. SCOPE 3 3. DEFINITIONS 3 4. GENERAL CONDITIONS 5 4.1 HERRAMIENTAS Y EQUIPOS 5 4.2 HAZARDS, RISKS AND SECURITY CONTROLS: 5 4.3 OCCUPATIONAL SAFETY AND HEALTH PRECAUTIONS (SST) 10 4.4 ENVIRONMENTAL ASPECTS 12 5. RELATED DOCUMENTS 15 6. DEVELOPMENT 15 6.1 PROTOCOL FOR RISK MITIGATION IN ESP IM-PMMM OPERATION 15 This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 1. PURPOSE The purpose of this manual is to establish the proper safety conditions for operating CILA2S® surface equipment that controls artificial lift systems with permanent magnet motors. 2. SCOPE This procedure applies to all SLA COL S.A.S. personnel who must execute or delegate tasks involving the operation of CILA2S® surface equipment controlling artificial lift systems with permanent magnet motors. 3. DEFINITIONS CONNECTION: Derivation of the local network of the respective service, which goes up to the registry of court of the property. In buildings of horizontal property or condominiums, the attack arrives up to the registry of general court. In those cases in which the cutting device is upstream of the meter, for the purposes of these regulations, the connection shall be understood as the set of conductors and accessories between the electrical connection point to the general use system (STN, STR or SDL) and the output terminals of the measuring equipment. RISK ANALYSIS: A set of techniques for identifying, classifying and evaluating risk factors. It is the study of harmful or prejudicial consequences, linked to actual or potential exposures. ELECTRIC ARC: Light beam produced by the flow of electric current through an insulating medium, which produces radiation and hot gases. CABLE: Set of wires without insulation between them and twisted by means of concentric layers. CALIBRATION: Diagnosis of the operating conditions of a measurement equipment and adjustments, if necessary, to ensure the precision and accuracy of the measurements generated with it. QUALITY: The totality of the characteristics of an entity that gives it the aptitude to satisfy explicit and implicit needs. It is a set of qualities or attributes, such as availability, price, reliability, durability, security, continuity, consistency, support and perception. ELECTRIC POWER QUALITY (CPE): It is defined as the set of qualifiers of phenomena inherent to the voltage waveform, which allow judging the value of the deviations of the instantaneous voltage with respect to its standard shape and frequency, as well as the effect that such deviations may have on electrical equipment or other systems. CHARGE: The electrical power required for the operation of one or more electrical equipment or the power carried by a circuit. ELECTRICAL CURRENT: It is the movement of electrical charges between two points that are not at the same potential, because one of them has an excess of electrons with respect to the other. ELECTRICITY: Electricity is a physical phenomenon whose origin is electrical charges and whose energy manifests itself in mechanical, thermal, luminous and chemical phenomena, among others. ELECTROCUTION: The passage of electric current through the human body, the consequence of which is death. This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT TECHNICAL SPECIFICATION: Document characteristics of a product or service. that establishes CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 the minimum technical PHASE: Designation of a conductor, a group of conductors, a terminal, a winding or any other element of a multi-phase system that will be energized during normal service. VOLTAGE FLUCTUATION: Phenomenon that causes transient distortion of the voltage waveform, with respect to its standard form. It is said that there is a service discontinuity when the voltage does not follow the standard waveform. GENERATOR: A natural or legal person who produces electrical energy, who has at least one power plant or generating unit. It also means electrical power generation equipment including generating sets. INSTRUMENTS: Can be defined as the device for determining the value or magnitude of a quantity or variable. LIVE LINE: Term applied to a line with voltage or energized line. INSULATING MATERIAL: Material that prevents the propagation of any physical phenomenon, (Electrical insulator, dielectric material used to prevent the passage of electrical charges. Thermal insulator, material that prevents the passage of heat). ELECTRICAL MEASUREMENTS: To measure means to compare a magnitude of unknown value with a previously chosen unit of measurement. The measurement process usually requires the use of an instrument as a physical medium to determine the magnitude of a variable. Standard measurements are preferably used in laboratories and the units of measurement used are adopted internationally. VOLTAGE LEVELS: Regional Transmission and/or Local Distribution systems are classified by levels, depending on the nominal operating voltage, according to the following definition: Leve IV: Systems with a rated voltage greater than or equal to 62 Kv. Level III: Systems with a rated voltage greater than or equal to 30 kV and less than 62 kV. Level II: Systems with a rated voltage greater than or equal to 1 kV and less than 30 kV. Level I: Systems with nominal voltage less than 1 kV. QUALIFIED PERSON: A natural person who demonstrates his or her education (training and coaching) in the knowledge of electrical engineering and the risks associated with electricity. SUT (STEP UP TRANSFORMER): Voltage Booster Transformer TABLE: Metallic or non-metallic enclosure where elements such as cutting, control, measurement, protection devices, busbars are housed; for the purposes of this regulation, it is equivalent to a panel, cabinet or panel. VOLTAGE: The difference in electrical potential between two conductors, which causes electrons to flow through a resistor. Voltage is a magnitude, the unit of which is volt; a frequent error is to speak of "voltage". This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 TRANSFORMER: The transformer is a device that converts electrical energy of a certain voltage level into electrical energy of another voltage level by means of the action of a magnetic field. It is made up of two or more coils of wire, usually electrically isolated from each other and wound around the same ferromagnetic core. VARIABLES: A variable is that which varies or can vary. It is something unstable, inconstant and changeable. In other words, a variable is a symbol that represents an unspecified element of a given set. This set is called the universal set of the variable or universe of the variable, and each element of the set is a value of the variable. FREQUENCY VARIATOR: Electronic power equipment that modulates the energy received by the motor. They are devices that allow the speed of an AC motor to be varied, converting the fixed magnitudes of frequency and mains voltage into variable magnitudes. PMM ENGINE: These are electric motors whose operation is based on permanent magnets. 4. GENERAL CONDITIONS 4.1 HERRAMIENTAS Y EQUIPOS FLUKE 434 / 435 brand dual-channel dynamic signal analyser Multimeter, FLUKE brand, model 87, series III. Voltage divider. DC / AC amperimetric clamp. FLUKE 381 Non-contact voltage detector. (optional ) 4.2 HAZARDS, RISKS AND SECURITY CONTROLS: Check all your tools before starting work. Deteriorated tools should be removed from service and replaced immediately with tools in good condition. Shocks, cuts, and electric shocks may result. Before starting work at the customer's site, verify that a Risk Analysis has been performed for the activity to be performed. When applicable, request a work permit from the supervisor. Report all unsafe conditions to the supervisor in writing and request that they be corrected before operations begin. If conditions are unsafe, no operation should be performed. Read and follow all warnings, cautions, notes, and instructions contained in this document. This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 THE USE OF: WATCHES, RINGS, BRACELETS, SLAVES, CHAINS, EARRINGS, PIERCING, METAL PROSTHESES, PACEMAKERS, FERULES OR ANY OTHER ELECTRICALLY CONDUCTIVE METALLIC MATERIAL FOR THE EXECUTION OF ELECTRICAL WORKS IS "PROHIBITED". THE ELECTRICAL WORKS WILL BE CARRIED OUT BY A MINIMUM OF 2 WORKERS, UNDER NO CIRCUMSTANCES OR WORK ORDER WILL BE CARRIED OUT INDIVIDUALLY. A warning identifies an immediate danger that poses a probability of causing death or serious injury. DANGER: Exposure to high voltage during operation. Do not touch exposed surfaces during testing. **ELECTRICAL RISK** A precaution identifies potential conditions and actions that are likely to result in death or severe injury. CAUTION: Preview the physical conditions of the measuring equipment to be used, as well as the conditions of the location where the work will be performed.. **CAUTION** This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 SAFETY DISTANCE: Minimum distance around electrical equipment or energized conductors, necessary to guarantee that there will be no accident due to the approach of people, animals, structures, buildings or other equipment. All unsafe conditions you encounter must be reported and requested to be repaired before operations begin. Maintain Order and Cleanliness in the workplace at all times. Do not walk or stand in areas unrelated to your work, or handle equipment, tools, or devices unrelated to your work. If in doubt, consult your supervisor. You could cause or suffer an accident. Wear a helmet, goggles, safety boots, hearing protection, dielectric mask, and dielectric gloves when taking no-voltage measurements. Wear precision gloves and/or cowhide when handling equipment and tools. You may experience cuts with sharp surfaces and skin conditions. This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT DANGERS RISK Biomechanical: Dynamic Charge: Repeated movements of the upper extremities. Application of forces, Overexertions Muscle injuries, tiredness, lumbago, musculoskeletal injuries, hernias, varicose veins, muscle spasms CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 CONTROLS PREVENTIVE. Mechanical Aids PREVENTIVE. Implementation of campaigns on ergonomic habits, training in handling loads, checking and evaluating the weight and frequency with which the load is lifted, storing the load at hip height and keeping it close to the possible body, avoiding lifting the load over the shoulders, calisthenics day at the beginning of the activities. PREVENTIVE. Avoid prolonged standing, squatting or sitting positions, repetitive movements and unnecessary movements. PREVENTIVE. Verify the weight is adequate (Max 25kg), if you are going to lift greater loads, ask for help without exceeding the maximum weight per worker and if possible use mechanical assistance, for the transport of loads under 50Kg, use mechanical assistance or wheelbarrow. PROTECTIVE. Use of Dielectric equipment and EPP, helmet class E, Gloves Class 2, Carpet, Boots high cane, Mask and clothes of work. PROTECTIVE. Periodic breaks (active breaks). Mechanical: Manipulation of tools and equipment REACTIVE. In case of back or limb injury, inform the resident, evaluate conditions, transfer to the nearest health care center and/or Activate Medevac. Cuts, bruises, PREVENTIVE. Carry out the activity with caution and finger entrapment, coordinate the activity among the executors following Improper use of the indications of the leader. tools PREVENTIVE. Verify through pre-operational the state of the tools and equipment. PROTECTIVE. Use dielectric PPE: E class helmet, Class 2 gloves, mat, and high cane boots, mask and work clothes. Biomechanical: Inadequate ergonomic positions REACTIVE. Provide first aid, report and request support from Ecopetrol and/or Activate Medevac . Back pain / PREVENTIVE. Disseminate the AR in a five-minute talk, ensuring the knowledge and commitment of all circulatory disorders / cramps staff. / repetitive strain injuries / PROTECTIVE. Ergonomically correct postures and inflammation of active pauses. tendons and PROTECTIVE. Maintain concentration during the lymph nodes / activity. spinal injuries. This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT Electric: Indirect electrical contact Electric arc, short circuit, burns CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 PREVENTIVE. Apply SAES. PREVENTIVE. Identify energized electrical systems and perform activity with caution following supervisor's instructions. PREVENTIVE. Verify that the tools are adequate, perform pre-operational. PROTECTIVE. Use dielectric PPE, class E helmet, class 2 gloves, mat, high cane boots, mask and work clothes. Electric: Presence electrical voltage of Electrocution, burns, amputation REACTIVE. Provide first aid, report and request support from Ecopetrol and / or Activate Medevac. PREVENTIVE. Apply SAES. PREVENTIVE. Dissemination and application of the eight golden rules of all electrical work. PREVENTIVE. To inform the execution of the tests to the Head of electrical area on the part of Ecopetrol and to verify its authorization. PREVENTIVE. To signal the area to isolate personnel alien to the activity and to identify those of transit of personnel. PROTECTIVE. Use dielectric PPE: class E helmet, class 2 gloves, mat, high cane boots, mask and work clothes. REACTIVE. Provide first aid, report and request support from Ecopetrol and / or Activate Medevac. This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 4.3 OCCUPATIONAL SAFETY AND HEALTH PRECAUTIONS (SST) The risks that may arise in the activity, related to OSH aspects, classified as ergonomic, physical, mechanical, biological, psychosocial, electrical and locative; they will be analyzed in detail for the execution of the task in the Risk Analysis (RA) annexed to the work permit, which carries out in its assessment a safety analysis for the execution of the work, evaluating and valuing the risks and applying the necessary controls. The work must comply with a planning, risk analysis and work permit must be disclosed to all personnel involved in the task before starting the work. If it is considered that there are not enough controls, the work should be stopped by the activity leader. Do not run in the workplace and always hold on to the handrails when climbing or descending stairs and the like. You may suffer falls that could cause severe trauma and fractures. Be careful not to place fingers, hands, or feet on or between moving parts or parts that can move and jam them. You may suffer contusions and even loss of fingers or parts of hands and feet. Do not exceed your physical exertion. If you feel that the force you must exert is greater than your capacity, ask for help. You may suffer physical injuries such as abdominal hernias and disc hernias. When moving to work site and sites within the field do not exceed speed limits and comply with the established according to customer requirements. The activity must be performed with a minimum of two people. Maintain Order and Cleanliness in the workplace at all times. Do not walk or stand in areas unrelated to your work, or handle equipment, tools, or devices unrelated to your work. If in doubt, consult your supervisor. You could cause or suffer an accident. While equipment is energized: Do not connect or disconnect cables, do not remove covers, do not touch cards. When the VSD is energized, it may start unexpectedly. It is recommended that personnel be removed from the inverter and wellhead area. As well as the acrylic protector where applicable, secure the cabinet doors and SUT. Before handling, disconnect all power to the equipment. After power is turned off, the internal capacitor remains charged for some time. The load indicator LED will go out when the Direct Current Bus detects less than 50 VDC. To prevent electric shock wait at least 5 minutes after the indicators are turned off and measure the voltage on the DC bus to confirm the voltage level. This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 4.4 PERSONAL PROTECTIVE EQUIPMENT Wear a helmet, goggles, and safety boots, hearing protection, dielectric mask and dielectric gloves when taking de-energized measurements. Wear precision gloves and/or cowhide when handling equipment and tools. You may experience cuts with sharp surfaces and skin conditions. At the beginning of the working day, check the state of the personal protection elements necessary for the safe execution of activities. Feet: Safety footwear, dielectric boots high cane minimum 15 kv Feet: Class 2 dielectric mat. Eyes: Outdoor dielectric safety goggles with dark lens, indoor dielectric safety goggles with light lens. Ears: Dielectric insertion hearing protection or cup with attenuation according to environmental studies. Head: Dielectric helmet class E zafarí type. Facial: Anti-arc dielectric mask with a minimum of 8 cal/cm 3. Body: Adequate dielectric work clothing resistant to fire. Hands: Class 1 dielectric gloves, with their respective mechanical protection (flesh gloves, anti-sweat gloves). Characteristics of dielectric gloves: This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 4.4 ENVIRONMENTAL ASPECTS ASPECTS IMPACTS AND CONTROLS Identify and report sources of high temperature or high pressure product release to supervisors. Activate emergency plan in the event of an event. In case of spill or leakage of fluids, report to the shift operator or area supervisor to activate a contingency plan. When starting work in workplaces, always safeguard the flora, fauna and community, report to the COE any novelties that imply relocation of the fauna. 4.6 SOLID WASTE MANAGEMENT To establish responsibilities for the integral management of waste generated in all areas or fields worked by the company SLACOL SAS, in order to carry out a proper management of them, in accordance with current legal regulations and without causing impact on people and the environment. In order to ensure good management of solid waste generated in the activities of the company and comply with existing national regulations we must follow the guide GHS-G-002 on the management of solid waste for projects of the client ECOPETROL or that another client requires us. Blue Grey Green Grey Red Black Cream Glass and Plastic and metal food containers Paper and Cardboard Waste Ordinary Single Cups Carton Cups without liquid content Hospital Waste Hydrocarbon impregnated elements Laboratory Chemical Residues Selection and Separation The executors of the field activities must separate and select the waste at the source to guarantee the quality of the recyclable waste and avoid transferring dangerous characteristics to a waste that is not; in this sense, they must make good use of the buckets and/or bags arranged in the work points, using the colour code already established in the guide GHS-G002. For the collection and transport of non-hazardous waste, the executor of the activity must guarantee the following conditions: At the time of removing the waste from the point of work and/or storage ready for accumulation, it must be ensured that the place is in perfect condition, when applied must be removed leachate from the place and other substances and / or elements that may generate pollution. This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 The collection frequencies will be agreed with the technical agency of each contract; however, it must be guaranteed that the time that these remain in the collection point is not excessive, to avoid the generation of bad odors, the generation of pests or other possible negative impacts on the environment. Separate collection by type of waste (glass, paper, etc.); in this aspect it is key that the collector knows the color code so that the different types of waste are not mixed. The development of this work must be done in compliance with the safety measures deemed appropriate for their execution in the respective risk analysis. Identification of the type of waste; these will be stacked in each collection point in bags of a different color according to their classification (glass, paper, organic, etc.), it is the obligation of the executor of the activities of transport and collection to know the color code for the identification of the procedure to follow with each type of material. IDENTIFICATION OF ENVIRONMENTAL ASPECTS AND IMPACTS ASPECTO ACTIVITY DESCRIPTION ENVIRO NMENTA L ELEMEN T CHARACT ER (+/-) IMPACT Energy Consumption Negative Pressure on resources used to produce energy Sugar Cane Paper Consumption Positive Preservation of the Forest Resource Paper Consumption Negative Decrease in Forest Resources Generation of solid waste Ordinary, Organic Negative Soil contamination TYPE WATER Administrative activities such as preparation of reports, proposals, daily work on computer equipment, etc.. (Use of electrical and electronic equipment) Forestal Forestal Soil CONTROL MEASURES Energy Efficient Environment al Managemen t Programme Use of electronic media, reuse of paper, recycling Use of electronic media, reuse of paper, recycling Integral Solid Waste Managemen t Plan This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT Soil Soil Water Air Soil Puesta en Marcha de Equipos Soil Generation of recyclable waste Generation of hazardous waste (RAES, Toners, Cartridges, Luminaires, Expired Drugs, Correctors, Markers) Energy Consumption Emission of ozonedepleting substances (Aerosol Paint) Generation of solid waste Organic, Ordinary or recyclable Generation of hazardous waste (RAES, Bulbs, fuses, lamps, ballasts, absorbents contaminated by hazardous substances, solvents, Chemicals, Radio Communicati on, aerosol bottles, Freon 12 Refrigerant, EPP, Equipment). CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 Reuse of resources Positive Soil contamination Continue to reuse paper and separate waste for recycling. Integral Solid Waste Managemen t Plan Negative Negative Pressure on resources used to produce energy Energy Efficient Environment al Managemen t Programme Green Shopping Negative Ozone depletion Negative Soil contamination Integral Solid Waste Managemen t Plan Negative Landfill overpressure Integral Solid Waste Managemen t Plan This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT Soil Air Fire (Contingency)) Water Chemical spillage Generation of gases, fumes, particulate matter and vapours by combustion Water consumption CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 Soil contamination Negative Negative Deterioration Quality of Sources Chemical spill contingency plan of the Emergency Water and Contingency Plans Air pollution Negative 5. RELATED DOCUMENTS EPP inspection format. Format pre inspection of equipment and tool. Work permit. 6. DEVELOPMENT 6.1 PROTOCOL FOR RISK MITIGATION IN ESP IM-PMMM OPERATION 1. Verification of electrical measuring equipment (4.1 Tools and equipment) and personal protective equipment (4.2 safety precautions). This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 2. Use personal protective equipment when taking electrical measurements. (4.2 Safety precautions). Permanent magnet motors or permanent magnets require the following care when performing operation and maintenance activities: 1. During the down-hole run, always keep the motor tips shorted through a mechanism that drains any voltage induced by motor movement. 2. Before carrying out resistance and insulation measurements during electrical integrity tests, the existence of voltage should be checked. 1. Before carrying out resistance and insulation measurements during electrical integrity tests, the existence of voltage between the cable ends of the PMM motor should be checked, making use of EPPs and appropriate equipment for measuring voltages above 1000 Volts. This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 2. Depending on the depth, conditions and characteristics of the reservoir, it is advisable to install check valves at the end of the ESP. 3. The PMM motor will behave like a generator when the pump spins the rotor when the ESP system is turned off. The magnitude of the subsequent FEM is important in all three phases. 4. Before carrying out resistance and insulation measurements in the vent box or in the SUT, during the electrical integrity tests, the existence of voltage between the ends of the PMM motor cable should be checked, making use of the EPPs and the appropriate equipment for measuring voltages above 1000 Volts. If necessary the FEM must be drained by the appropriate device. 5. Personnel training is mandatory and the installation of labels on the junction boxes (vent box) and SUT transformer should be verified IN ORDER TO ENSURE LIFE DURING OPERATIONS WITH PERMANENT MAGNET MOTORS OR PERMANENT MAGNETS WE MUST FULLY FOLLOW THE FOLLOWING RULES: GOLD RULES Stop of the well (Activate anti Back-Spin CILA2S) Standing Valve Release or ESP Check valve / PCP BackSpin Release / Machine Weight Brake Mandatory 600V BT & 10KV AT Gloves Disconnection. Effective cut. Prevent any possible feedback. Blocking and signalling. Check absence of voltage. Grounding and short circuit. Signalling of the work area This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S. INTEGRATED MANAGEMENT SYSTEM MANUAL FOR RISK MITIGATION IN OPERATION OF IM/PMM ENGINES WITH CILA2S SURFACE EQUIPMENT VERSION Date 000 11-07-2019 CODE: MPM-PD-006 VERSION: 001 DATE: 18-07-2019 REASON FOR THE UPDATE Elaboración de documento. Vbº. HSE APPROVED Name: Henry Rincon Position: Supervisor HSEQ Date: 11-07-2019 Name: Carlos Martinez Position: Director of Engineering Date: 11-07-2019 This document is the property of SLA COL S.A.S. This document is not intended for general circulation and should not be reproduced or distributed without the written approval of SLA COL S.A.S.