Don`t Sit Still For Back Pain Chock and Block For Safety

Anuncio

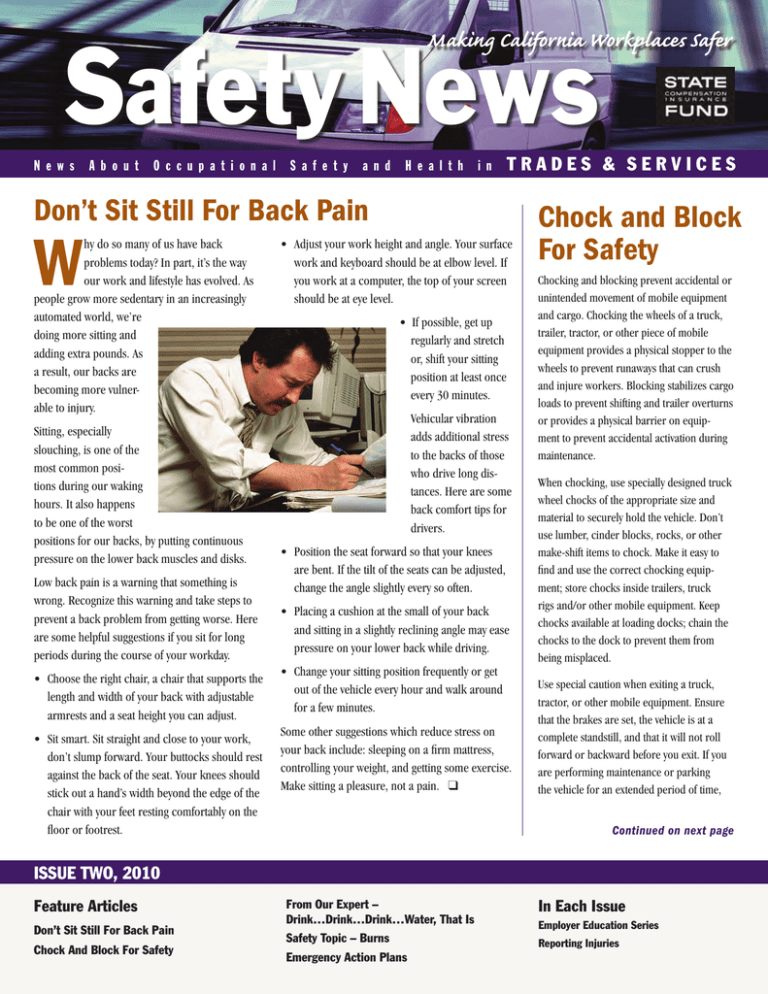

Safety News Making California Workplaces Safer N e w s A b o u t O c c u p a t i o n a l S a f e t y a n d H e a l t h i n Trades & Services Don’t Sit Still For Back Pain W hy do so many of us have back problems today? In part, it’s the way our work and lifestyle has evolved. As people grow more sedentary in an increasingly automated world, we’re doing more sitting and adding extra pounds. As a result, our backs are becoming more vulnerable to injury. Sitting, especially slouching, is one of the most common positions during our waking hours. It also happens to be one of the worst positions for our backs, by putting continuous pressure on the lower back muscles and disks. Low back pain is a warning that something is wrong. Recognize this warning and take steps to prevent a back problem from getting worse. Here are some helpful suggestions if you sit for long periods during the course of your workday. • Choose the right chair, a chair that supports the length and width of your back with adjustable armrests and a seat height you can adjust. • Sit smart. Sit straight and close to your work, don’t slump forward. Your buttocks should rest against the back of the seat. Your knees should stick out a hand’s width beyond the edge of the chair with your feet resting comfortably on the floor or footrest. • Adjust your work height and angle. Your surface work and keyboard should be at elbow level. If you work at a computer, the top of your screen should be at eye level. • If possible, get up regularly and stretch or, shift your sitting position at least once every 30 minutes. Vehicular vibration adds additional stress to the backs of those who drive long distances. Here are some back comfort tips for drivers. • Position the seat forward so that your knees are bent. If the tilt of the seats can be adjusted, change the angle slightly every so often. • Placing a cushion at the small of your back and sitting in a slightly reclining angle may ease pressure on your lower back while driving. • Change your sitting position frequently or get out of the vehicle every hour and walk around for a few minutes. Some other suggestions which reduce stress on your back include: sleeping on a firm mattress, controlling your weight, and getting some exercise. Make sitting a pleasure, not a pain. q Chock and Block For Safety Chocking and blocking prevent accidental or unintended movement of mobile equipment and cargo. Chocking the wheels of a truck, trailer, tractor, or other piece of mobile equipment provides a physical stopper to the wheels to prevent runaways that can crush and injure workers. Blocking stabilizes cargo loads to prevent shifting and trailer overturns or provides a physical barrier on equipment to prevent accidental activation during maintenance. When chocking, use specially designed truck wheel chocks of the appropriate size and material to securely hold the vehicle. Don’t use lumber, cinder blocks, rocks, or other make-shift items to chock. Make it easy to find and use the correct chocking equipment; store chocks inside trailers, truck rigs and/or other mobile equipment. Keep chocks available at loading docks; chain the chocks to the dock to prevent them from being misplaced. Use special caution when exiting a truck, tractor, or other mobile equipment. Ensure that the brakes are set, the vehicle is at a complete standstill, and that it will not roll forward or backward before you exit. If you are performing maintenance or parking the vehicle for an extended period of time, Continued on next page ISSUE TWO, 2010 Feature Articles Don’t Sit Still For Back Pain Chock And Block For Safety From Our Expert – Drink…Drink…Drink…Water, That Is Safety Topic – Burns Emergency Action Plans In Each Issue Employer Education Series Reporting Injuries S a f e t y N e w s S t a t e C o m p e n s a t i o n I n s u r a n c e F u n d I s s u e T w o, 2 0 1 0 F R O M O U R E X P ER T Drink… Drink… Drink… Water, That Is loss occurs in all environments – cold, mild, and hot. Drinking plenty of water throughout the day, even when there is a lack of thirst, replaces lost fluids. The body is designed to maintain an internal temperature of approximately 98.6°F. The body releases excessive heat by circulating blood to the capillaries in the upper layers of the skin thus increasing heat transfer and perspiration. When the body heats up faster than it can cool itself down, mild to severe heat-related illnesses may develop. N o matter what the time of year; no matter what the temperature; no matter where you live or work – indoors or outdoors – staying hydrated is important to overall health and performance. Dehydration occurs when the body takes in substantially less fluid than what is lost through its normal body processes. The body is nearly 60% water by weight; the loss of just 2.5 liters (0.66 gallons) per day can adversely affect it, if not replaced. This natural process of fluid Heat stress occurs when the body is unable to release heat and cool itself. According to the National Institute for Occupational Safety and Health (NIOSH), when air temperature is equal to or warmer than the skin, blood brought to the skin’s surface cannot efficiently release heat. The body’s main cooling mechanism is the evaporation of perspiration (or sweat) and if evaporation cannot occur, the body is unable to rid itself of excess heat and this natural cooling process becomes impaired. If the body cannot release excess heat, it stores it and this increases the body’s core temperature and heart rate. Prolonged heat stress can lead to death. Increased air temperature, high humidity, radiant heat, and minimal air circulation can increase the risk of developing heat-related illnesses. Other risk factors include: increased age; body weight/body build; level of physical fitness; lack of acclimatization; poor nutrition; fatigue; alcohol or drug use; certain medical conditions, such as diabetes; wearing personal protective equipment (PPE), such as nonbreathable protective clothing, hoods, and/or respirators, as they can increase workload and/or restrict movement; and, inadequate water/fluid replacement. For more information on preventing heat stress, go to http://www.dir.ca.gov/DOSH/ HeatIllnessInfo.html. ❑ R.J. Banks, MS, CIE is the Senior Ergonomist for State Fund. Chock And Block For Safety continued from page 1 chock the wheels. To properly chock a free-standing vehicle, place chocks on the left and right rear axle wheels. It is safest to chock both the front and back wheels on both sides of a vehicle. Some vehicle wheels may also need to be chocked at the front and back of each tire. Ensure that trailers are firmly placed against the loading dock edges and prevent rollaways by using chocks. Place chocks on the left and right wheels that are closest to the loading dock. This placement allows a forklift to push down on the trailer wheels and seat them more firmly against the chock. If only the front axle is chocked, a forklift could push the trailer forward and loosen the chock or cause the wheel to jump the chock. The driver, dock workers, and forklift drivers share the responsibility to ensure that the truck and trailer wheels are properly chocked. Never drive a forklift into a trailer until you ensure that the wheels are properly chocked. Ensure that the trailer floor is in good condition and that it can support the weight of the forklift and its load. Block or secure trailer cargo to prevent the load from shifting during transit and unloading. Shift- ing loads can strike, injure, and engulf workers while a sudden shift in center of gravity can overturn a trailer. Securely block all cargo, not just wheeled equipment and round items (e.g., wire reels). Block items separately and on all four sides using lumber thick enough to prevent cargo movement. Don’t use other freight or cargo as a block. When performing maintenance on equipment that could pose a pinch hazard, block it to prevent accidental activation. ❑ S a f e t y N e w s S t a t e C o m p e n s a t i o n I n s u r a n c e F u n d Safety Topic / Temas de Seguridad Burns Burns can be caused by a number of sources: heat, electricity, chemicals or radiation. Stay alert to the potential burn hazards on your job, wear personal protective equipment when necessary, and learn the basics for burn first aid. Quick action and proper first aid can lessen the effects of a burn and, in some cases, save a life. Contact with extreme heat in any form causes burns. The first action in a burn situation is to stop the heat source or break contact between the heat source and the skin. Because the body holds heat and continues to burn until the skin cools, even with a minor burn, a person can go into shock. For most burns, cool the burn with water. Unless told to by a medical professional, never use butter or ointments, which may seal in heat and cause infection. Never break a burn blister; it protects the burn area from infection. For burns caused by electricity, turn off the electric El contacto con el calor extremo en cualquier forma puede causar quemaduras. Lo primero que se debe hacer en una situación de quemadura es eliminar la fuente de calor o romper el contacto entre la fuente de calor y la piel de la víctima. Debido a que el cuerpo retiene el calor y continúa quemándose hasta que la piel se enfríe, aun con una quemadura leve, la víctima puede caer en estado de shock. Para la mayoría de las quemaduras, se debe enfriar la piel con agua. A no ser que lo indique un profesional médico, nunca se deben usar mantequilla ni ungüentos, los cuales pueden retener el calor y causar una infección. Nunca rompa la ampolla de una quemadura, ya que ésta protege el área contra infecciones. Para las quemaduras causadas por la electricidad, T w o, 2 0 1 0 Topic Review/ Revisión Del Tema Instructor _________________________ power at the source. Don’t touch the victim until all wires are clear. Make sure the victim’s breathing and heartbeat are regular and seek medical attention immediately. If the burn is from a chemical, locate the chemical container and follow the label directions for treatment, consult the Material Safety Data Sheets (MSDS) or call the Poison Control Center. Remove any contaminated clothing. If the eyes are affected, flush for 15-30 minutes. For acid chemicals, immediately flush the area for 15-20 minutes. For dry chemicals, brush the chemical off the skin – but not with bare hands – and then flush it for 15-20 minutes. Get professional medical attention as soon as possible. Stay alert to possible burn hazards, use all recommended protection devices, know the location of wash stations, and know where emergency phone numbers are posted. ❑ ❑ Quemaduras Las quemaduras pueden ser causadas por varias razones: calor, electricidad, sustancias químicas o radiación. Manténgase alerta a los peligros potenciales de quemaduras en su trabajo, use los equipos de protección personal cuando sean necesarios y aprenda los conocimientos básicos de primeros auxilios para quemaduras. Una acción rápida y los primeros auxilios apropiados pueden disminuir los efectos de la quemadura y, en algunos casos, hasta salvar una vida. I s s u e Date / Fecha_______________________ Location / Ubicación_________________ Attended by / Asistente(s) __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ desconecte el suministro eléctrico en su fuente. No toque a la víctima hasta que todos los conductores eléctricos queden libres. Asegúrese de que la respiración y el ritmo cardíaco de la víctima se hayan normalizado y busque atención médica de inmediato. Si la quemadura ha sido causada por una sustancia química, busque el envase de la sustancia y siga las indicaciones de tratamiento contenidas en la etiqueta, consulte la Hoja de Datos de Seguridad de Materiales (MSDS, por sus siglas en inglés), o llame a un centro de control de envenenamiento (Poison Control Center). Quítele a la víctima la ropa contaminada. Si han sido afectados los ojos, lávelos con agua durante 15 a 30 minutos. En caso de ácidos, lave con agua el área afectada de inmediato durante 15 a 20 minutos. Para sustancias químicas en polvo, quite la sustancia de la piel con una brocha o cepillo suave – nunca con las manos – y luego lave el área durante 15 a 20 minutos. Obtenga atención médica lo más pronto posible. Manténgase alerta a los posibles peligros de quemadura, use todos los dispositivos de protección recomendados, conozca la ubicación de las estaciones de lavado y sepa dónde están escritos los números de teléfono para emergencias.����❑ ❑ Safety Recommendations / Recomendaciones de seguridad __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ __________________________________ Safety News News About Occupational Safety and Health in ISSUE TWO 2010 Trades & Services Prsrt Std US Postage Paid Permit 803 Zip Code 92887 Loss Control Services P.O. BOX 420807 SAN FRANCISCO, CA 94142-0807 Please forward to the person responsible for your safety program Remember To Recycle This Newsletter Emergency Action Plans Employer Education Series Workplace emergencies can happen unexpectedly, but with an action plan in place and workers trained to respond quickly and appropriately, efficiency can be optimized, damage and injuries can be minimized, and, in some cases, lives can be saved. An Emergency Action Plan details what actions will be taken to ensure personal safety in an emergency. Review your company’s Plan, train all workers in its elements, and update the plan periodically or whenever the plan, personnel, equipment or worksite changes. State Fund continues to promote community educational outreach by increasing the quantity and frequency of employer seminars. These seminars are produced and sponsored by State Fund and are open to State Fund policyholders. The seminar topics cover all aspects of worker’s compensation and are offered statewide. Your Plan should describe in detail what actions would be taken by whom for emergencies likely to occur in your workplace. It should include procedures for reporting emergencies, activating alarms, equipment shutdown, rescue, escape, first aid, and employee accounting. Make sure workers know and understand their role in the Plan for various emergency scenarios. Training and random emergency drills should be held at least annually to allow workers to practice the response procedures. The program venues provide the opportunity for attendees to have their workplace safety questions immediately and personally answered by industry experts. The typically half-day seminars are usually held at regional State Fund offices. To learn what programs are scheduled in your area, visit www.scif.com and click on Seminars. q For help with your Plan, visit State Fund at www.statefundca.com, California’s Office of Emergency Services at www.oes.ca.gov/, or the Federal Emergency Management Agency at www.fema.gov/. q As part of State Fund’s Employer Education Series, the local State Fund Loss Control departments offer safety seminars dedicated to loss prevention. They feature safety training targeted to specific industries and safety topics of interest to California employers. Various programs in the series are developed in conjunction with State Fund insured GroupPrograms and external affiliates and partners. Some of these partners are occupational safety and health providers such as Cal/OSHA Consultation Service, the Department of Health Services, and the University of California. The goal of State Fund’s Employer Education Series is to present valuable information from recognized safety and health experts to enable employers to reduce the frequency and severity of workplace injuries, facilitate regulatory compliance, and increase business profits. Reporting Work-Related Injuries State Fund’s Claims Reporting Center (1-888-222-3211) is available 24 hours a day, 7 days a week for policyholders to report injuries as soon as they occur. Agents will do the necessary paperwork to get the claim started and refer the injured to the designated physician or provider. Within 8 hours of any serious illness or injury (requiring hospitalization over 24 hours, other than for medical observation or where there is permanent employee disfiguration) or death occurring in the workplace or in connection with employment, employers must report the incident to the Division of Occupational Safety and Health. q This Trades & Services Safety News is produced by the Safety and Health Services Department of State Fund to assist clients in their loss control efforts. Information or recommendations contained in this publication were obtained from sources believed to be reliable at the date of publication. Information is only advisory and does not presume to be exhaustive or inclusive of all workplace hazards or situations. Permission to reprint articles subject to approval by State Compensation Insurance Fund. Published by State Compensation Insurance Fund’s Safety and Health Services Department. Editor: Judy Kerry © State Compensation Insurance Fund 2010 PRINTED ON RECYCLED PAPER