© MIS Corporation. All Rights Reserved.

Our Research is Your Success...

Published in:

March

2010

IN

Revista Cubana de

T I G A C I O N E

S

V E S

Interaction between osteoblasts and titanium

surfaces: application in dental implants”

*

Juan Carlos Vanegas Acosta, Diego Garzón-Alvarado, Martín Casale

*Juan Carlos Vanegas Acosta, Diego Garzón-Alvarado, Martín Casale, Interaction

between osteoblasts and titanium surfaces: application in dental implants. Rev. Cubana.

Invest. Bioméd. 2010, 29(1): 51-68.

2010

MC-RL011 Rev. 1

Juan Carlos Vanegas Acosta

Diego Garzón-Alvarado

3

Martín Casale

1

2

“Interaction between osteoblasts and titanium

surfaces: application in dental implants”

ABSTRACT.

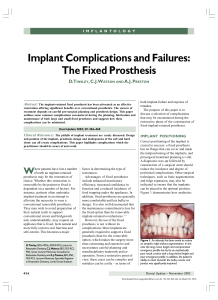

Pictures of stereo zoom and SEM of the

four types of surfaces used in this study.

Left, microscopy zoom stereo (4X ,

bar=0.5mm). Right, SEM microscope

(2500X, bar=10m). (A) and (B) machined

surface, (C) and (D) SBAE surface, (E)

and (F) TCP surface, (G) and (H) TCP+

acid surface.

The bone integration of dental implants is dependent of type of material of implant, its superficial

topography and also by the type of coating. Although there are many the materials used for

the manufacture of dental implants, currently the titanium is the choice material by its inert

behavior when it contact with biological tissues. As the superficial topography influenced on

cellular adhesion and proliferation, the dental implants underwent treatments creating superficial

irregularities in the micro and sub-micrometric scale. Likewise, the coats based on organic-origin

minerals are used to improve the bone deposition on implant.

The aim of present paper is to carry out the osteoblasts cells culture on Ti-6AI-4V substrates

using four different types surfaces typically used in dental implants to determine which of them

have the better behavior in terms of cellular adhesion, cellular proliferation and biomineralization.

The osteoblasts cells were cultivated during 24 hr for the adhesion assay and during 1, 2, 5, 6

and 7 days for the proliferation assay. The biomineralization was assessed by characterization

with estereozoom and SEM of the mineral depots colored using dying technique with red alizarin.

The quantization of these mineralization depots was performed using a tool of images processing.

The results obtained showed that the rough surfaces and coated have a better behavior. None

of the study surfaces had a toxic character for cells and all showed cellular adhesion profiles,

cellular proliferation and biomineralization.

SE M images of the process of

biomineralization on TCP and TCP+Acid

surfaces after 5 days (left) and 15 days of

cultivation (right). Bar=10m. (A) and (B) TCP

surface, (C) and (D) TCP+Ácido surface.

Authors’ affiliations

1

Group of Modeling and Numerical Methods

in Engineering-GNUM, National University of

Colombia, Bogota, Colombia.

2

Faculty of Engineering, National University

of Colombia, Bogota, Colombia.

3

School of Dentistry, National University of

Colombia, Bogota, Colombia.