Identification of Strategic Supplies for Leading Mining Companies in

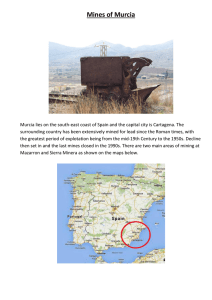

Anuncio