Wall Hung Back Outlet Gravity Tank

Anuncio

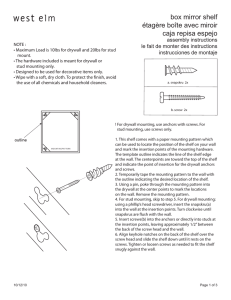

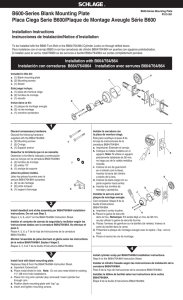

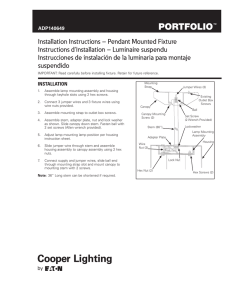

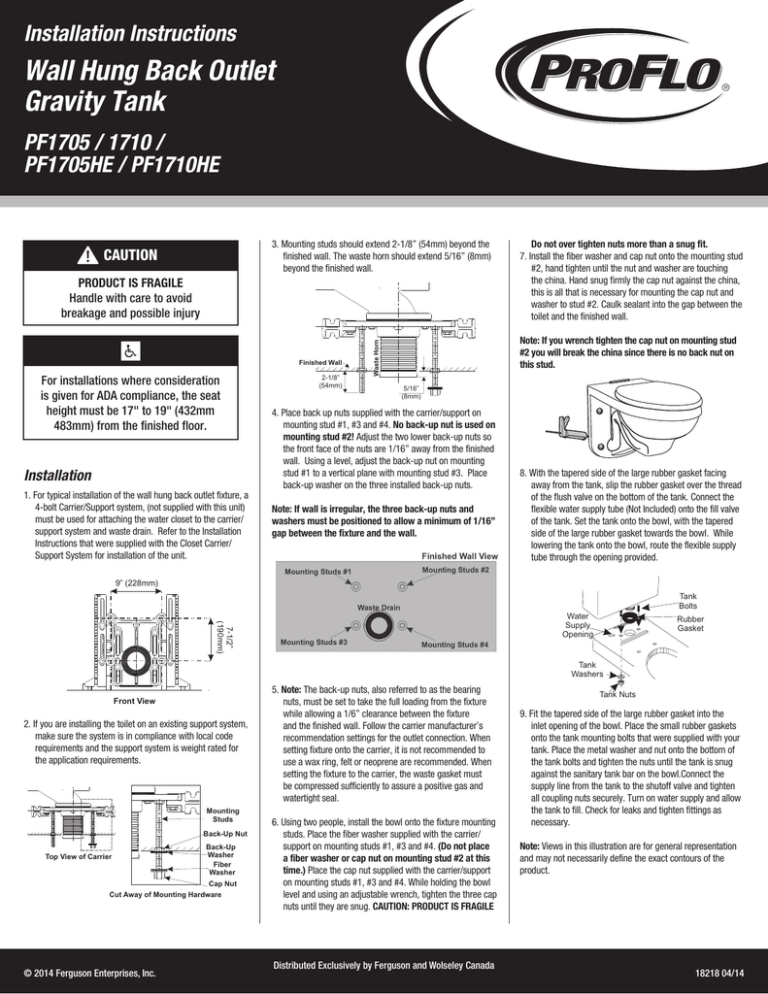

(H) Flexible Supply Tube (Not Included) (I) Closet Carrier/Support (Not Included) F D CAUTION: PRODUCT IS FRAGILE Handle with care to avoid breakage and possible injury! Installation Instructions Wall Hung Back Outlet Gravity Tank Wall Hung Back Outlet Toilet with Tank Installation SINK INSTALLATION: 1 5 For typical installation of the wall hung back outlet fixture, a 4-bolt Carrier/Support system, (not supplied with this unit) must be used for attaching the water closet to the carrier/support system and waste drain. Refer to the Installation Instructions that were supplied with the Closet Carrier/Support System for installation of the unit. 9” (228mm) Back-Up Nut Back-Up WhenTop setting fixture onto the carrier,Washer it is not View of Carrier Fiber recommended to use a wax ring, feltWasher or neoprene are recommended. Cap Nut Cut Away of Mounting Hardware When setting thetighten fixture tomore the carrier, thefit.waste Doback notupover nuts than a snug 4 Place nuts supplied with the carrier/support on mounting gasket must be to assure stud #1, #3the and #4.compressed No back-up nutcap is sufficiently used mounting 7. Install fiber washer and nut on onto the mounting stud stud #2! gas Adjustand the twowatertight lower back-up nuts so the front face of a positive seal. #2, hand tighten until thefixture nut and washer are touching install the bowl onto the mounting 3. Mounting studs should extendextend 2-1/8” (54mm) the Mounting studs should 2-1/8” (54mm)beyond beyond the 3 finished wall. finished wall. The waste horn should extend 5/16” (8mm) Thefinished waste horn should extend 5/16” (8mm) the beyond the wall. Using twobeyond people, CAUTION 6 Note: The back-up nuts, also referred to as thefinished wall. PRODUCT IS FRAGILE bearing nuts, must be set to take the full loading Handle with care to avoid from the fixture while allowing a 1/6” clearance between the fixture injury and the finished wall. breakage and possible studs. 7 the nuts are 1/16” away from the finished wall. Using a level, adjust back-up nut on mounting to anut vertical planethe china, thethe china. Hand snug firmlystud the#1cap against with mounting stud #3. Place back-up washer on the three this isback-up all that is necessary for mounting the cap nut and installed nuts. Note; If the wall is irregular, the three back-up nuts and washer to stud #2. Caulk sealant into the gap between the washers must be positioned to allow a minimum of 1/16” gaptoilet between and wall. the wall. andthe thefixture finished Install the fiber washer and cap nut onto the mounting stud #2, hand tighten the nut and washer are Place the fiber washer supplied with theuntil carrier/support on Hand snug mounting studs #1,touching #3 and the #4. china. (Do not place a firmly fiber the cap nut agains Finished Wall View this is all that#2 is at necessary for mounting the washer or cap nutthe onchina, mounting stud this time.) Mounting #2 Note: If youStuds wrench tighten the cap nut Studs on mounting stud Mounting #1 Waste Horn Follow the carrier manufacturer’s recommendation ® 2 If you are back-up installing the toilet on analso existingreferred support system, Note: The nuts, to as the make sure the system is in compliance with local code bearing nuts,and must be set tois take theforfull loading requirements the support system weight rated application requirements. fromthe the fixture while allowing a 1/6” clearance between the fixture and the finished wall. Mounting Follow the carrier manufacturer’s recommendation Studs settings for the outlet connection. Front View 5 Note: Views in this illustrations are for general representation and may not necessarily define the exact contours of the product. If replacing an existing toilet be certain to shut off water supply before removing old toilet. 7-1/2” (190mm) PF1705 / 1710 / PF1705HE / PF1710HE For installations where consideration is given for ADA compliance, the seat height must be 17” to 19” (432 to 483) from the finished floor. cap nut and washer to stud #2. Recommended Tools & Materials (A) Regular Screwdriver #2 you will break the china since there is no back nut on settings for the outlet connection. (B) Adjustable Wrench . Place the cap nut supplied with the carrier/support on Finished Wall A When performance matters. this stud. (C) Marker Wastegap Drain between the toilet and Caulk sealant into the mounting studs #1, #3 and #4. While holding the bowl 2-1/8” G (D) TapeFor Measure When setting fixture onto the carrier, E it is not installations where consideration finished wall.wrench, tighten the three (54mm) I B level and using an adjustable 5/16” (E) Level recommended to use a wax ring, felt or neoprene (8mm) Mounting Studs #3 is given for ADA compliance, the seat (F) Silicone Sealant Mounting Studs #4 cap nuts until they are snug. are recommended. C (G) Putty Knife height must be 17" to 19" (432mm H 4. Place back up nuts supplied with the carrier/support on F (H) Flexible Supply Tube (Not Included) 7730/7730HE D mounting stud #1, #3 and #4. NoCAUTION: back-up nut PRODUCT is used on IS FRAGILE REV 10/2013 483mm) from the finished floor. (I) Closet Carrier/Support (Not Included) When setting the fixture to the carrier, the waste the mounting stud #2! Adjust the two nuts so nuts more than a snug fit. Dolower not back-up over tighten CAUTION: PRODUCT gasket must IS beFRAGILE compressed sufficiently to theassure front face of the nuts are 1/16” away from the finished -1Handle with care to avoid breakage and possible this illustrations representation WhenViews matters. a positive gas and watertight seal. injury! wall. Note: Using aperformance level,inadjust the back-uparenutforongeneral mounting If you wrench tighten the cap nut on mounting and may not necessarily define the exact contours of Note: the product. For installations where consideration is given for stud #1 to a vertical plane with mounting stud #3. Place stud8.#2 With the tapered side ofthe the large rubber gasketthere facing is no Installation you will break china since ADA compliance, the seat height must be 17” to If replacing an existing toilet be certain to shut off back-up washer on the three installed back-up nuts. away from therubber tank, slip gasket the rubberfacing gasket over the thread Install fiber washer and cap nut onto the mounting With the tapered side of the large 19” (432 to 483)the from the finished floor. back nut on this stud. water supply before 8 removing old toilet. 7 1. For typical installation of the wall hung back outlet fixture, a the flush valve on the bottom of the tank. Connect the away from the tank, slip ofthe rubber gasket over the stud #2, hand tighten until the nut and washer are Carrier/Support system, (not supplied with this unit) Note: If wall is irregular, the three back-up nuts and water supply tube (Not Included) onto the fill valve Wall4-bolt Hung Back Outlet Toilet with Tank Installation 9 flushvalve flexible SINK INSTALLATION: touching the the china. Hand snug firmly the cap nut against thread of the on the bottom of the tank. oftank the large into the must be used for attaching water closet to the carrier/ washers must be positioned to allow a minimum of 1/16”Fit the tapered of the tank.side Set the onto the rubber bowl, withgasket the tapered the china, this ishung all that isInstallation necessary forgap the 1 Forsupport typicalsystem installation of the wall back outlet fixture, a 2mounting inlet opening of the bowl. The tank should level and and waste drain. Refer to the If you are installing the toilet on an existing support system, between the fixture and the wall. side of the large rubber gasket towards the bowl.sitWhile 4-bolt Carrier/Support (not supplied withCarrier/ this unit) make sure the system is in compliance with local cap and washer stud #2. Connect the code flexible water tube (Not Included) Instructions thatnut weresystem, supplied with thetoCloset parallel to supply the the finished wall. lowering tank onto the bowl, route the flexible supply must be used for attaching the water closet to the carrier/support .waste for Support System installation theInstallation unit. system and drain. Refer toofthe Instructions that were supplied the Closet Carrier/Support System for the Caulkwith sealant into the gap between of the unit. Tools &installation Materials finished wall. 9” (228mm) requirements and the support system is weight rated for onto the fill valve the application requirements. toilet and the When performance matters. G E Bolts large rubber gasket towards Mounting Water Secure the by placing the metal Rubber washer and nut the bowl. WhileStuds lowering thetank Supply onto the bottom of the tank bolts and Gasket tighten by hand Nut tank onto the Back-Up bowl, route Opening both nuts while holding the tank level. the flexible supply tube Back-Up Washer provided. through the opening Tank I 7-1/2” (190mm) F H Top View of Carrier ble injury! of the tank. tube through the opening provided. Place the small rubber gaskets onto the tank mounting that were supplied with your tank. Slide both bolts Set the tank ontobolts the bowl, into the mounting holes from inside the tank. with the tapered side of the Tank Fiber With the tank level and sitting parallel to the wall, begin Note: If you wrench tighten the cap nut on mounting Washers Washer to tight the nuts alternating between the two nuts to stud #2 you will break the china since there is no Nut the tank even. Tighten the nuts until the tank is 5. Note: The back-up nuts, also referred to as the bearing Capkeep Tank Nuts back nut on stud. If replacing an existing toilet this be certain to shut off Note: Views in this illustrations are for general representation and may not necessarily define the exact contours of the product. of Mounting nuts, must be set to takeCut the Away full loading from theHardware fixture snug against the sanitary tank bar on the bowl. while allowing a 1/6” clearance between the fixture 9. Fit the tapered side of the large rubber gasket into the 4andPlace Connect the flexible waterinlet supply the to rubber gaskets 3 2. If you are installing lation toilet on an existing support system, Fit the the tapered side of the large rubber gasket backthe upwall. nutsFollow supplied the manufacturer’s carrier/support on CAUTION: mounting theinto finished thewith carrier openingline of thefrom bowl. Placetank the small PRODUCT IS FRAGILE finished wall. studlevel #1, #3 and andsettings #4. Nofor back-up nut is usedvalve. onWhen mounting the shutoff Tighten all coupling nuts securely. make sureinlet the system is in compliance with local codetank should opening of the bowl. The sit recommendation the outlet connection. onto the tank mounting bolts that were supplied Do not over tighten nuts more than a snug fit. with your 2 requirements If you are installing the toilet on an existing support system, stud #2! Adjust the two lower back-up nuts so the front face of and the system is(8mm) weight rated for The sure waste should extend 5/16” beyond the setting fixture theaway carrier, is not recommended to a level, tank. Place the metal washer and nut onto the bottom of parallel to finished wall. make thehorn system issupport inthe compliance with local code the nuts areonto 1/16” fromit the finished wall. Using pport finished wall. requirements and the support system is weight rated for the application requirements. Turn on #1 water at the supply and thenuts tank useadjust a waxthe ring, felt or nut neoprene are recommended. When the valve tank bolts and allow tighten the untilto thefill. tank is snug back-up on mounting stud to a vertical plane s the application requirements. with the mounting Placethe back-up on the three setting fixture stud to the#3.carrier, wastewasher gasket must against the sanitary tank bar on the bowl.Connect the r Place the small rubber gaskets onto the tank mounting installed back-up nuts. be Note; compressed sufficiently to assure positive gas and supply line from the tank to the shutoffthat valve and tighten Check all fittings and tighten any fittings If thebolts wall is irregular, the a three back-up nutsfor andleakage bolts that were supplied with your tank. Slide both watertight seal. all coupling nuts securely. Turn on water supply and allow washers must be positioned to allow a minimum of 1/16” are leaking. into the mounting holes from inside the tank. gap between the fixture and the wall. the tank to fill. Check for leaks and tighten fittings as Mounting Studs 6. Using two people, install the bowl onto the fixture mounting necessary. Finished Wall View Secure the tank by placingBack-Up the metal washer nut Nut studs.and Place the fiber washer supplied with Mounting the carrier/ Studs #2 Mounting Studs #1 onto the bottom of the tankBack-Up bolts and tighten byonhand support mounting studs #1, #3 and #4. (Do not place Note: Views in this illustration are for general representation both nuts while holding theWasher tank level. Top View of Carrier a fiber washer or cap nut on mounting stud #2 at this and may not necessarily define the exact contours of the Fiber Finished Wall time.) Place the cap nut supplied with the carrier/support product. Washer Waste Drain parallel to the wall, begin on mounting studs #1, #3 and #4. While holding the bowl 2-1/8”With the tank level and sitting Cap Nut (54mm)to tight the Cut Away of5/16” Mounting Hardware level nuts and using nuts alternating between the two to an adjustable wrench, tighten the three cap When performance matters. (8mm) Tighten the nuts until Mounting Studs #3 CAUTION: PRODUCT nuts they is are snug. IS FRAGILE keep the tank even. theuntil tank Mounting Studs #4 e Front View water supply before removing old toilet. 10 Waste Horn 9Mounting studs should extend 2-1/8” (54mm) beyond the 4 © Place back up nuts supplied with the carrier/support on mounting stud #1, #3 and #4. No back-up nut is used on mounting stud #2! Adjust the two lower back-up nuts so the front face of the nuts are 1/16” away from the finished wall. Using a level, PRODUCT adjust theCAUTION: back-up nut on mounting stud #1IS to aFRAGILE vertical plane with mounting stud #3. Place back-upnuts washer on the than three a snug Do not over tighten more installed back-up nuts. Note;Ferguson If the wallEnterprises, is irregular, the three 2014 Inc. back-up nuts and washers must be positioned When performance matters. to allow a minimum of 1/16” gap between the fixture and the wall. snug against the sanitary tank bar on the bowl. 7730/7730HE REV 10/2013 fit. Distributed Exclusively by Ferguson and Wolseley Canada -1WARNING: Do not use plumbers putty, pipe dope or any other sealant on the 18218 04/14 Troubleshooting Troubleshooting Wall Hung Back Outlet WallTank Hung Back Outlet Gravity ® Gravity Tank PF1705 / 1710 / PF1705HE PF1705/ PF1710HE / 1710 Difficulties Difficulties These parts must be used as illustrated to ensure a water tight connection Reason Water level is too high Fill valve adjusted or too low incorrectly Fill not fully open Fill valve can’t fill Leaking Solution METAL/COPPER METAL FLANGED METAL SPIRAL VINYL/BRAIDED FLARED TUBING TUBING TUBING CONNECTOR Adjust water level Filter clogged Float cup is stuck by tank wall Free fill valve from tank wall LOCK NUT LOCK NUT LOCK NUT CONE WASHER EXISTING WASHER EXISTING CONE WASHER COUPLING NUT COUPLING NUT Open shut-off valve Remove and clean filter LOCK NUT WATER SHUTOFF EXISTING COUPLING NUT WATER SHUTOFF COUPLING NUT WATER SHUTOFF WATER SHUTOFF Captive cone washers already included Use the existing washers and coupling nut Water supply tube or pipe must extend at least 1/2” inside threaded shank of valve Caution: CLAMP NUT could result in breakage and potential DAMAGE DO NOT use cone washer with plastic supply line DO NOT use plumber’s putty to seal these fittings Hexagonal nut is loose Tighten hexagonal nut IF WATER CONTINUES TO RUN, CLEAN THE SEAL AS DESCRIBED IN FIGURES 1-6 BELOW IF FILL VALVE SHUTS OFF BUT CONTINUES TO LEAK Follow the How to clean Seal instructions below. 1 refill tube 2 3 IF FILL VALVE TURNS OFF AND ON DURING PERIODS OF NON-USE, it is a signal you are wasting water. Check to see if the lowest portion of the refill tube is inserted into overflow pipe, below the water level in the tank. Check to see if the fill valve float is stuck. Make sure it moves freely. Check to see if the flapper is worn, dirty or misaligned. Replace the flapper with a original replacement flapper. Disconnect the adjustment screw from the fill valve arm 4 5 Turn 1/8 counter clockwise to loosen fill valve head Cover the fill valve head and slowly turn on the water to remove any debris Check to see if the flush valve nut is tight. IF FILL VALVE WON’T TURN ON OR SHUT OFF or REFILL OF TANK WATER IS SLOW A Replacement Seal may be needed. caution: .CLAMP NUT could result in breakage and potential DAMAGEDO NOT use cone washer with plastic supply line. DO NOT use plumber’s putty to seal these fittings. Captive cone washers already included. Use the existing washers and coupling nut. Check the angle stop and insure the water is on. IF WATER IS LEAKING FROM THE TANK Refer to the supply line hook up diagram. Check the fill valve clamp nut to insure it is tight. Confirm the tank is securely fastened to the bowl. Check to see if the flapper is worn, dirty or misaligned. Replace the flapper with a original replacement flapper. Check to see if the flush valve is nut is tight. Remove fill valve cap and disconnect refill tube Turn off water supply 6a Rinse the seal and head with water 6b WARNING DO NOT USE IN-TANK TOILET BOWL CLEANERS CONTAINING BLEACH OR CHLORINE Use of such products will: 1. Result in damage to tank components and may cause flooding and property damage 2. Void warranty Reassemble in reverse order to assure functioning © 2010 Ferguson Enterprises, Inc. All Rights Reserved © 2014 Ferguson Enterprises, Inc. Distributed Exclusively by Ferguson and Wolseley Canada Distributed Exclusively by Ferguson and Wolseley Canada 6635 12/10 18218 04/14 CAUTION: PRODUCT IS FRAGILE Handle with care to avoid breakage and possible injury! Note: Views in this illustrations are for general representation and may not necessarily define the exact contours of the product. For installations where consideration is given for ADA compliance, the seat height must be 17” to 19” (432 to 483) from the finished floor. Instructions d’installation If replacing an existing toilet be certain to shut off water supply before removing old toilet. Wall Hung Back Outlet Toilet with Tank Installation SINK INSTALLATION: Sortie arrière de type mural Réservoir de gravité 1 For typical installation of the wall hung back outlet fixture, a 4-bolt Carrier/Support system, (not supplied with this unit) must be used for attaching the water closet to the carrier/support system and waste drain. Refer to the Installation Instructions that were supplied with the Closet Carrier/Support System for installation of the unit. 9” (228mm) 5 ® Note: The back-up nuts, also referred to as the bearing nuts, must be set to take the full loading from the fixture while allowing a 1/6” clearance between the fixture and the finished Goujonswall. de Écrou de Follow the carrier manufacturer’srenfort recommendation Rondelle de settings for the outlet connection. renfort Vue de dessus du support Rondelle en fibre Vue de face 3 5 If you are installing the toilet on an existing support system, make sure the system is in compliance with local code requirements and the support system is weight rated for the application requirements. fixation 7-1/2” (190mm) PF1705 / 1710 / PF1705HE / PF1710HE 2 Mounting studs should extend 2-1/8” (54mm) beyond the finished wall. 6 When setting fixture onto the carrier, it is not Écrou borgne coupé éléments de montage recommendedModèle to use ades wax ring, felt or neoprene are recommended. 4 Place back up nuts supplied with the carrier/support on mounting stud #1, #3 and #4. No back-up nut is used on mounting stud #2! Adjust the two lower back-up nuts so the front face of When setting thefrom fixture to wall. theUsing carrier, the nuts are 1/16” away the finished level, the waste Using two people, install the la bowl onto the 7. Installez rondelle en fibre etfixture l’écrou àa mounting chapeau sur adjust the back-up nut on mounting stud #1 to a vertical plane gasket be compressed sufficiently to assure with mounting stud de #3. fixation Place back-up onàthe three jusqu’à ce lemust goujon no 2,washer serrez la main studs. installed back-up nuts. a positive gasis irregular, and watertight seal. l’écrou et la rondelle la porcelaine. Serrer Note; Ifque the wall the threetouchent back-up nuts and The waste horn should extend 5/16” (8mm) beyond the finished wall. dépasser de 8 mm (5/16 po) du mur fini. Note: The back-up nuts, also referred devrait to as the MISE GARDE bearingEN nuts, must be set to take the full loading from the fixture while allowing a 1/6” clearance fermement à with laand main l’écrou à chapeau contre la porcelaine, Place the fiber washer supplied the gap between the fixture the wall.carrier/support on c’estfiber tout cewasher qu’il faut and pour monter à chapeau cap onto the mounting Vue dunut mur fini mounting 7 studs Install #1, #3the and #4. (Do not place al’écrou fiber et de la fixation rondelle sur le goujon no 2. Appliquez du produit Écrou denut fixation no 2 washer are Écrouhand no 1 stud #2, tighten until the and washer or cap nut on d’étanchéité mounting stud #2entre at this time.) dans l’espace la toilette et le mur fini. touching the china. Hand snug firmly the cap nut agains outlet connection. Mur fini Recommended Tools & Materials A) Regular Screwdriversettings for the thesupplied china, this isDrain alldethat isl’écrou necessary foràmounting vidange Place the cap nut with the carrier/support on Remarque : Si vous serrez à chapeau l’aide d’une the B) Adjustable Wrench 2-1/8” cap nut andle#4. washer to stud #2. A When performance matters. clé sur goujon de fixation no 2, vous risquez de briser la mounting studs #1, #3 and While holding the bowl (54mm) C) Marker 5/16” When setting fixture onto the carrier, it is not . adjustable porcelaine de contre-écrou sur ce (8mm)level and using an G D) Tape Measure Écrou de fixationétant no 3 donné l’absence wrench, tighten the three Écrou de fixation no 4 E recommended B to use a wax ring, felt or neoprene I Caulk sealant into the gap between the toilet and the goujon. E) Level cap nuts until they are snug. are recommended. F) Silicone Sealant 4. Placez les écrous de renfort fournis avec le support/soutienfinished wall. 7730/7730HE Pour les installations où l’on accorde de C G) Putty Knife l’importance à(Not la conformité avec l’ADA, H) Flexible Supply Tube Included) When setting the fixture toD the I) Closet Carrier/Support Included) la hauteur du(Not siège doit se situer entre washers must be positioned to allow a minimum of 1/16” Waste Horn LE PRODUIT betweenEST theFRAGILE. fixture and the finished wall. Manipuler avec soin pour carrierpossible. manufacturer’s recommendation éviter toutFollow bris etthe blessure sur le goujon no 4. Aucun écrou H de fixation no 1, no 3 et CAUTION: renfort n’est utilisé sur le goujon de fixation PRODUCT no 2! carrier,Fde the waste REV 10/2013 IS FRAGILE -1-nuts more than a snug fit. Do not over tighten Ajustez les deux écrous de renfort de façon à ce que le gasket must be compressed sufficiently to assure When performance matters. CAUTION: PRODUCT 432 et 483 mm (17IS et FRAGILE 19 po) duwatertight sol fini. seal. devant des écrous se trouve à 1,6 mm (1/16 po) du mur a positive gas and À l’aide d’uninniveau, ajustez l’écrou renfortrepresentation sur le Handle with care to avoid breakage and possible injury! fini.Note: Views this illustrations are forde general and may not necessarily the exact contours of the product. goujon de fixation no 1 sur ledefine plan vertical avec le goujon For installations where consideration is given for Installation de Iffixation no 3. une rondelle deWith renfort suroff les trois Note: the height fiber washer and the mounting the tapered sideIfofyou thewrench large rubber gasket facing ADA compliance, the seat must be 17” to cap nut onto 8be certain replacing anPlacez existing toilet to shut 7 Install tighten the cap nut on mounting renfort installés. 483) from thehand finished floor. until the nut and écrous waterdesupply removing old toilet. stud #2, tighten washer are before away from the tank, slipyou the will rubber gasket over the stud #2 break the china since there is no 1.19” Pour(432 une to installation traditionnelle de l’appareil à sortie 8. Avecon le côté effilé du grand en touching the china. Hand snug firmly the cap nut against thread of the flushvalve bottom of joint the d’étanchéité tank. arrière de type mural, un système de support/soutien à back nut onthe this stud. Wall Hung Back Outlet Toilet with Tank Installation Remarque: Si le mur est irrégulier, les trois écrous de caoutchouc faisant dos au réservoir, glissez le joint SINK INSTALLATION: 4 boulons (nonthe fourni avec cetthis appareil) être is utilisé china, is alldoit that necessaryrenfort for mounting the doivent être positionnés pour et les rondelles d’étanchéité en caoutchouc sur les filets du robinet de 9system, pour fixer la toilette système deback porteur/soutien et aau 1 For typical installation of au the wall hung outlet cap nut and washer tofixture, stud #2. 2permettre Connect tube Included) If you areun installing the toilet on support écart minimum de an 1,6existing mm (1/16 po) the entreflexible laFit thewater chassesupply surside la partie du réservoir. gasket Connectezinto le the tapered of inférieure the(Not large rubber 4-boltdrain Carrier/Support system, (not supplied with this unit) de vidange. Se reporter aux instructions d’installation make sure the system is in compliance with local code . onto the fill valve of the tank. fixation et le mur. tuyau d’alimentation en eau flexible (non inclus) au robinet mustfournies be usedavec for attaching thede water closet to thede carrier/support requirements and the support system is weight rated for inlet opening of the bowl. The tank should sit level and le système support/soutien toilette CaulkRefer sealant into theInstructions gap between the andrequirements. the system and waste drain. to the Installation thetoilet application parallel to the finished wall. pour l’installation de l’appareil. that were supplied with the Closet Carrier/Support System for finished wall. installation of the unit. Tools & Materials Boulons du Place the small rubber gaskets onto the tank mounting réservoir bolts that were supplied with your tank.Joint Slide both bolts Ouverture de Goujonsinto de the mounting d'étanchéité holes from inside the tank. l'alimentation en eau 9” (228mm) When performance matters. G E ble injury! fixation 7-1/2” (190mm) F I H en caoutchouc Écrou de renfortSecure onto Rondelle de Note: If you wrench tighten the cap nut on mounting 5. Remarque: Les écrous de renfort, également appelés renfort both Vue de dessus du support Rondelle en stud #2 you will break the china since there is no doivent être réglés pour accepter écrous de roulement, Note: Views in this illustrations are for general representation fibre the tank by placing the metal washer and nut the bottom of the tank bolts and tighten by hand Rondelles du nuts while holding réservoirthe tank level. l’ensemble de la charge de la fixation tout en permettant With the tank level Écrous du réservoir and sitting parallel to the wall, begin un jeu de 0,2 mm (1/6 po) entre la fixation et le murÉcrou borgne to tight the nuts alternating between the two nuts to Modèle coupé des éléments de montage fini. Veuillez suivre les recommandations du fabricant de remplissage du réservoir. Placez le réservoir sur la keepwater the tank even. Tighten thetank nuts until the tank is the flexible supply Fit the tapered side of the large rubberconcernant gasket into thede la connexionConnect le réglage de sortie. Au moment cuvette, avec leline côté from effilé duthe grand joint to d’étanchéité en 2. Si vous installer la toilette sur un système de support snug against sanitary tank barTout onenthe bowl. lation Mounting studs should extend 2-1/8” (54mm) beyond the the shutoff valve. Tighten all the coupling nuts securely. 3 inlet opening of the bowl. The tank4should sitlalevel Place back up nutsand supplied with the carrier/support on mounting de régler fixation sur le support, il n’est pas recommandé caoutchouc tourné vers la cuvette. abaissant le finished wall. assurez-vous que le système respecte les déjà existant, stud #1, #3 and #4. de Nocire, back-up nut is used on mounting d’utiliser un anneau il est recommandé d’utiliser réservoir sur la cuvette, acheminez le tuyau d’alimentation parallel to the finished wall. 2 exigences If you are installing on an existing support system,et du codethe dutoilet bâtiment pertinent à sa région stud #2! Adjust the two lower back-up nuts so the front face of PRODUCT IS allow FRAGILE plutôt du feutre ou du néoprène. Au moment de régler la atCAUTION: flexible à traversand l’ouverture fournie. Turn on water the supply valve the tank to fill. make surehorn the system in compliance localbeyond code the The waste shouldis extend 5/16” with (8mm) the nuts are 1/16” away from the finished wall. Using a level, que la capacité pondérale du système de soutien pport Do not over tighten nuts more than a snug fit. requirements and the support system is weight rated forest finished wall. fixation au support, le joint d’étanchéité de vidange doit être adjust the back-up nut on mounting stud #1 to a vertical plane Place thedesmall rubber gaskets onto the tank mounting s the application correspond auxrequirements. exigences l’application. suffisamment une bonne 9. Placez lesand petitstighten joints d’étanchéité en caoutchouc mounting comprimé stud #3. Place back-up washer onétanchéité the three for leakage r Check all fittings any fittings that sur les bolts that were supplied with your tank.with Slide both boltspour assurer installed au gaz etback-up à l’eau. nuts. boulons de montage du réservoir qui sont fournis avec are leaking. into the mounting holes from inside theNote; tank. If the wall is irregular, the three back-up nuts and votre réservoir. Placez la rondelle en métal et l’écrou sur washers must be positioned to allow a minimum of 1/16” 6. Deux personnes sont nécessaires la partie inférieure des boulons du réservoir et serrez les Goujons de gap between the fixture and thepour wall.installer la cuvette fixation Secure the tank by placing the metal washer and de nut sur les goujons fixation de la fixation. Placez la rondelle écrous jusqu’à ce que le réservoir soit bien serré contre Vue du mur fini de en fibre fournie avec le support/soutien sur le goujon de la barre du réservoir sanitaire sur la cuvette. Connectez onto the bottom of the Écrou tank bolts and tighten by hand renfort Écrou de fixation no 2 Écrou de fixation no 14. (Ne pas placer fixation no 1, no 3 et no de rondelle en la conduite d’eau du réservoir au robinet d’arrêt et both nuts while holdingRondelle the tank level. de fibre ou d’écrou à chapeau sur le goujon de fixation no bien serrez tous les écrous de raccordement. Ouvrir renfort Vue de dessus du support Rondelle en 2 à ce moment précis.) Placez l’écrou à chapeau fourni l’alimentation en eau et laissez le réservoir se remplir. Mur fini With the tank level and sitting parallel to the wall, begin fibre Drain avec le support/soutien surdelevidange goujon de fixation no 1, no 3 Vérifiez l’absence de fuites et serrez les raccords au to tight the nuts alternating between the two nutsento Écrou borgne 2-1/8” et no 4. Tout tenant la cuvette au niveau et en utilisant besoin. Modèle des éléments de montage (54mm) keep thecoupé tank tank serrez is les trois écrous à chapeau jusqu’à une cléthe ajustable, 5/16” even. Tighten the nuts until (8mm)the sanitary tank bar on the snug against bowl. ce Écrou qu’ils soient biennoajustés. MISE EN Écrou GARDE Remarque: Les vues de cette illustration servent de de fixation 3 e 4 Les de:fixation no 4 Place back up supplied with thedépasser carrier/support mounting 3. goujons denuts fixation devraient de 54onmm performancegénérale matters.et peuvent ne pas définir LE PRODUIT EST FRAGILE. Serrer les écrous jusqu’à ce Whenreprésentation stud #1, #3 and #4. No back-up nut is used on mounting (2-1/8 po) du mur fini. La tubulure denuts sortie defront vidange stud #2! Adjust the two lower back-up so the face of qu’ils soient bien serrés et non pas davantage. nécessairement les contours exacts du produit. CAUTION: PRODUCT IS FRAGILE 7730/7730HE the nuts are 1/16” away from the finished wall. Using a level, Donut not tighten more than a snug fit. REV 10/2013 adjust the back-up onover mounting stud #1nuts to a vertical plane back nut on this stud. and may not necessarily define the exact contours of the product. 10 If replacing an existing toilet be certain to shut off Vueremoving de faceold toilet. water supply before Waste Horn 9 with mounting stud #3. Place back-up washer on the three installed back-up nuts. Note; If the wall is irregular, the three back-up nuts and washers must be positioned to allow a minimum of 1/16” When performance matters. gap between the fixture and the wall. © 2014 Ferguson Enterprises, Inc. Vue du mur fini Écrou de fixation no 2 -1- WARNING: Do not use plumbers putty, pipe dope or any other sealant on the water supply connections to this tank. WARRANTY is voidCanada if any type of sealant is used on the water supply connection. Distributed Exclusively by Ferguson and Wolseley 18218 04/14 Dépannage Dépannage Réservoir de gravité Réservoir dedegravité à à sortie arrière type mural ® sortie arrière de type mural PF1705 / 1710 / PF1705HE PF1705/ /PF1710HE 1710 Dépannage Difficultés Raisons Le robinet de Le niveau de l’eau est remplissage n’est pas trop élevé ou trop bas correctement ajusté. Le robinet de remplissage ne se remplit pas. Fuite Solution Ajuster le niveau de l’eau Le robinet de sectionnement n’est pas complètement ouvert. Ouvrir le robinet de sectionnement. Le filtre est obstrué. Enlever et nettoyer le filtre. Le flotteur de la cuvette est coincé par la paroi du réservoir. Libérer le robinet de remplissage de la paroi du réservoir. L’écrou hexagonal est desserré. Serrer l’écrou hexagonal. SI LE ROBINET DE REMPLISSAGE EST FERMÉ, MAIS QU’IL CONTINUE À FUIR Ces pièces doivent être utilisées telles qu’illustrées pour assurer une connexion d’eau étanche. MÉTAL/CUIVRE À BRIDE EN MÉTAL SPIRALE EN MÉTAL VINYLE / TRESSÉ TUBAGE MANDRINÉ TUBAGE TUBAGE CONNECTEUR CONTREÉCROU CONTREÉCROU CONTREÉCROU CONTREÉCROU RONDELLE CONIQUE RONDELLE EXISTANTE ÉCROU D’ACCOUPLEMENT ÉCROU D’ACCOUPLEMENT ÉCROU D’ACCOUPLEMENT EXISTANT RONDELLE CONIQUE EXISTANTE ÉCROU D’ACCOUPLEMENT FERMETURE DE L’EAU FERMETURE DE L’EAU FERMETURE DE L’EAU FERMETURE DE L’EAU Utiliser les rondelles et l’écrou d’accouplement existants. Rondelles coniques imperdables déjà incluses Le tuyau ou le flexible d’alimentation en eau doit excéder d’au moins 1/2 po à l’intérieur de la queue filetée du robinet. L’ÉCROU DE SERRAGE DE COLLIER pourrait entraîner un bris ou Mise en garde: des DOMMAGES potentiels. NE PAS utiliser de rondelle conique avec une conduite d’alimentation en plastique. NE PAS utiliser de mastic à plombier pour assurer l’étanchéité de ces raccords. SI L’EAU CONTINUE DE COULER, NETTOYER LE DISPOSITIF D’ÉTANCHÉITÉ TEL QUE DÉCRIT DANS LES FIGURES 1 À 6 CI-DESSOUS. Suivre les instructions Comment nettoyer le dispositif d’étanchéité ci-dessous. 1 2 3 SI LE ROBINET DE REMPLISSAGE S’OUVRE PUIS SE FERME DURANT DES PÉRIODES D’INUTILISATION, C’est une indication que vous gaspillez de l’eau. Vérifier si la portion inférieure du tuyau de remplissage est insérée dans le tuyau de trop-plein, sous le niveau d’eau dans le réservoir. Vérifier si le flotteur du robinet de remplissage est coincé. S’assurer qu’il bouge librement. Fermer l’alimentation en eau. Vérifier si le clapet est usé, sale ou désaligné. Remplacer le clapet avec un clapet de remplacement d’origine. 4 Enlever le capuchon du robinet de remplissage et déconnecter le tuyau de remplissage. Déconnecter la vis d’ajustement du bras du robinet de remplissage. 5 6a Couvrir la tête du robinet de remplissage et ouvrir lentement l’eau pour enlever tout débris. Rincer le dispositif d’étanchéité et la tête avec de l’eau. Vérifier si l’écrou du robinet de la chasse est bien serré. SI LE ROBINET DE REMPLISSAGE NE SE FERME PAS ET NE S’OUVRE PAS ou si LE REMPLISSAGE DU RÉSERVOIR D’EAU EST LENT, le remplacement du dispositif d’étanchéité peut s’avérer nécessaire. Mise en garde : L’ÉCROU DE SERRAGE DE COLLIER pourrait entraîner un bris et des DOMMAGES POTENTIELS. NE PAS utiliser du mastic à plombier pour assurer l’étanchéité de ces raccords. Rondelles coniques imperdables déjà incluses. Utiliser les rondelles et l’écrou d’accouplement existants. Vérifier l’arrêt d’équerre et s’assurer que l’alimentation d’eau est ouverte. SI LA FUITE D’EAU PROVIENT DU RÉSERVOIR, se reporter au diagramme de branchement de la conduite d’alimentation. Vérifier l’écrou de serrage de collier du robinet de remplissage afin de s’assurer qu’il est bien serré. Confirmer que le réservoir est bien attaché à la cuvette. Vérifier si le clapet est usé, sale ou désaligné. Remplacer le clapet avec un clapet de remplacement d’origine. Vérifier si l’écrou du robinet de la chasse est bien serré. © 2010 Ferguson Enterprises, Inc. All Rights Reserved © 2014 Ferguson Enterprises, Inc. Tourner de 1/8 dans le sens inverse des aiguilles d’une montre pour desserrer la tête du robinet de remplissage. 6b AVERTISSEMENT NE PAS UTILISER DE NETTOYEURS À CUVETTE CONTENANT DU JAVELLISANT OU DU CHLORE DANS LE RÉSERVOIR. L’utilisation de tels produits aura pour effet de : 1. Causer des dommages aux composants du réservoir et pourrait causer un débordement et des dommages à la propriété. Réassembler dans l’ordre inverse pour assurer un bon fonctionnement. Distributed Exclusively by Ferguson and Wolseley Canada Distributed Exclusively by Ferguson and Wolseley Canada 2. Annuler la garantie. 6635 01/11 18218 04/14 CAUTION: PRODUCT IS FRAGILE Handle with care to avoid breakage and possible injury! Instrucciones de instalación For installations where consideration is given for ADA compliance, the seat height must be 17” to 19” (432 to 483) from the finished floor. Note: Views in this illustrations are for general representation and may not necessarily define the exact contours of the product. If replacing an existing toilet be certain to shut off water supply before removing old toilet. Wall Hung Back Outlet Toilet with Tank Installation Recommended Tools & Materials gular Screwdriver SINK INSTALLATION: justable Wrench 1 For typical installation of the wall hung back outlet fixture,Whena performance2matters.If you are installing the toilet on an existing support system, A arker 4-bolt Carrier/Support system, (not supplied with this unit) make sure the system is in compliance with local code ® The back-up nuts, also referred G must be used for attaching the water closet to the carrier/support Note: requirements and the support system is weight rated for to as the pe Measure E system and waste I drain. Refer to the Installation Instructions the application requirements. B vel bearing nuts, must be set to take the full loading that were supplied with the Closet Carrier/Support System for cone Sealant installation of the unit. from the fixture while allowing a 1/6” clearance 9” (228mm) C utty Knife H between the fixture and the finished wall. F exible Supply Tube (Not Included) pernos de D set Carrier/Support (Not Included) montaje Tanque con descarga por gravedad AUTION: PRODUCT IS FRAGILE andle with care to avoid breakage and possible injury! For installations where consideration is given for ADA compliance, the seat height must be 17” to 19” (432 to 483) from the finished floor. 7-1/2” (190mm) PF1705 / 1710 / PF1705HE / PF1710HE 5 Follow the carrier manufacturer’s recommendation tuerca de settings for the outlet connection. respaldo Note: Views in this illustrations are for general representation and may not necessarily define the exact contours of the product.vista superior If replacing an existing toilet be certain to shut off water supply before removing old toilet. Vista frontal tuerca de respaldo arandela de fibra tapa de la tuerca Corte de los accesorios de montaje When setting fixture onto the carrier, it is not recommended to use a wax ring, felt or neoprene are recommended. del transportador Back Outlet Toilet with Tank Installation Kl Hung INSTALLATION: Mounting studs should extend 2-1/8” (54mm) beyond the 4 Place back up nuts supplied with the carrier/support on mounting 3 finished wall. When setting theNofixture to the the waste stud #1, #3 and #4. back-up nut usedcarrier, on mounting 3. Los vástagos de montura deben sobresalir 5/16" (8mm) de 7. Instale la arandela de back-up fibra yisel tapón la face tuerca el stud #2! Adjust the two lower nuts so thede front of en or typical installation of the wall hung back outlet fixture, a 2 If you are installing gasket must be compressed sufficiently to assure an existing support The wastethe horntoilet shouldon extend 5/16” (8mm) beyondsystem, the the nuts are 1/16” away from theajuste finishedmanualmente wall. Using a level, la sure paredthe terminada. perno de montaje #2, hasta que ADVERTENCIA -bolt Carrier/Support system, (not supplied with this unit) make system finished wall. is in compliance with local code a positive gas and adjust the back-up nut on watertight mounting stud #1seal. to a vertical plane must be used for attaching the water closet to the carrier/support la tuercastud y la#3.arandela toquen la porcelana. requirements and the support system is weight rated for with mounting Place back-up washer on the threeAjuste ystem and waste5 drain. Refer to the Installation Instructions installed back-up nuts. the application requirements. manualmente el tapón dethe tuerca firmemente contra la 6 Using two people, install the bowl onto fixture mounting EL PRODUCTO ESback-up FRÁGIL. The nuts, Note; If the wall is irregular, the three back-up nuts and hat were supplied with the Note: Closet Carrier/Support System foralso referred to as the porcelana. Eso es tolotoand loallow quecap necesita montar la Install the fiberbewasher nut onto mounting washers must positioned ase minimum of para 1/16”the studs. 7 nstallation of the unit. bearing nuts, must be set to take the full loading Manéjese con cuidado para evitar fixture anden theel wall. tuerca ythe latighten arandela perno #2. and Selle con siliconaare de 9” (228mm) studgap #2,between hand until the nut washer fromy posibles the fixture while allowing a 1/6” clearance vista de el la inodoro pared terminada la separación entre y la the paredcap terminada. su ruptura daños. touchingcaucho the china. Hand snug firmly nut agains Place the fiber washer supplied with thePernos carrier/support on de montaje N.º 2 Pernos de montaje N.º 1 pernos de the china, this is all that is necessary for mounting the cabezal de desague between the fixture and the finished wall. 7-1/2” (190mm) mountingmontaje studs #1, Nota: #3 and #4. con (Do not place a fiber Recommended Tools & Materials Si ajusta llave el tapón de tuerca en el perno de (A) Regular Screwdriver cap nut and washer to stud #2. pared terminada washertuerca or cap nut on mounting stud #2 at this time.) montaje #2, romperá la porcelana debido a que no hay (B) Adjustable Wrench Follow the carrier manufacturer’s recommendation de Drenaje residual A When performance matters. (C) Marker respaldo. tuerca de respaldo en este perno. 2-1/8” settings for the outlet connection. Caulk sealantwith into the the carrier/support gap between the G (54mm) (D) Tape Measure E tuerca de Place the cap nut supplied ontoilet and the 5/16” I B (E) Level respaldo finished wall. (8mm) Pernos de montaje N.º 3 vista superior Para la instalación en donde se considera Pernos de montaje N.º 4 mounting studs #1, #3 and #4. While holding the bowl (F) Silicone Sealant When setting fixture onto the carrier, is not arandela de del it transportador C level and using an adjustable wrench, tighten the three cumplimiento con la ADA, la altura del (G) PuttyelKnife fibra recommended to use a wax ring, felt or neoprene 4. Colocar las H tuercas de seguridad que se entregaron con el 7730/7730HE F (H) Flexible Supplydebe Tubeser (Notde Included) cap nuts until they are snug. tapa de la REV 10/2013 asiento 17’’ y 19’’ (432mmD soporte o el apoyo en el perno prisionero de la montura (I) Closet Carrier/Supportare (Notrecommended. Included) tuerca 483mm) desde elISpiso terminado. Corte de los accesorios de montaje -1CAUTION: PRODUCT FRAGILE PRODUCT IS FRAGILE delthe perno prisionero # 2. Ajustar las dosCAUTION: tuercas inferiores When setting the fixture to the injury! carrier, waste When performance matters. Handlestuds withshould careextend to avoid breakage and the possible not over tighten nuts more than a snug fit. Mounting 2-1/8” (54mm) beyond Note: Views this separadas illustrations1/16" areDo for representation 4 de tal forma que inestén degeneral la pared # 1, # 3 y # 4. No se usa tuerca de seguridad en la montura Vista frontal Place back nuts supplied with the carrier/support on mounting sufficiently toupassure and not exacton contours of the product. nivel, define ajustar tuerca demounting respaldo studterminada. #1, #3may andUsando #4. necessarily Nounback-up nut the islaused Note: If you wrench tighten the cap nut on mounting a positive gas and watertight seal. ADA compliance, the seat height must be 17” to studdel #2! Adjust the lower back-up nutsvertical so thecon front of Ifperno replacing antwo existing toilet beplano certain to shut offel facestud de montaje # 1 hasta un 8.#2 Colocando la parte estrecha empaque grande de goma you will break thedel china since there is no TheInstalación waste horn should extend 5/16” (8mm) beyond the the nuts are 1/16” away from the finished wall. Using a level, 19” (432 to 483) from the finished floor. water supply de before removing perno prisionero montaje N.º 3.old toilet. de cara al tanque, deslice el empaque de goma finished wall. back nut on contraria this stud. adjust the back-up nut on mounting stud #1 to a vertical plane sobre la rosca de la válvula de desagüe al fondo del tanque. Para la instalación convencional dewith la montura para la salida Install the fiber washer and cap nutwith onto the mounting With tapered side of the large rubber gasket facing mounting stud #3. Place back-up onthe the three Wall1.Hung Back Toilet Tank Installation 8 washer 7 Outlet SINK INSTALLATION: Nota: Si back-up la parednuts. está irregular, las tres tuercas y 9 el tubo flexible de suministro de agua (no incluido) posterior colgablestud en la #2, pared,hand se deberá usar ununtil sistema installed tighten the nut and washer are away from the tank, Conecte slip the rubber gasket over thegasketel into the ofde the large arandelas respaldo se deberán colocar de talnuts forma dentro de laside válvula llenado delrubber tanque. Coloque If thede wall is irregular, the three back-up and Fit the tapered de soporte de 4 pernos el tanque de aguaaal 1 For typical installation of thepara walladaptar hung back outletHand fixture, 2Note; Ifthe you are installing the toilet on an existing supportofsystem, touching the china. snug firmly cap nut against thread the flushvalve on the bottom oflado the tank. washers must be positioned to allow a minimum of 1/16” que quede un espacio mínimo de 1/16" entre la montura tanque sobre la taza, con el estrecho del empaque de and inlet opening of the bowl. The tank should sit level 4-bolt Carrier/Support (not supplied this unit) sistema de soportesystem, y al drenaje. Consultewith las instrucciones make sure the system is in compliance with local code gap between theand fixture and thesystem wall. is weight rated for the china, this is toallthethat is necessary for mounting thesupport mustde beinstalación used for attaching the water closet carrier/support y larequirements pared. grande viendo wall. hacia la taza. Al mismo tiempo que the parallelgoma to the finished que se incluyen con el sistema de anclaje del system and waste drain. Installation to Instructions capRefer nutdeto and washer stud #2. the application requirements. Connect the flexible coloca waterel supply tube (Not Included) vista de la pared terminada tanque sobre la taza, dirija el tubo de suministro tanque para la instalación lathe unidad. that were supplied with the Closet Carrier/Support System for flexible a través de la apertura queonto se proporciona. . onto the fill ofthe the tank. Pernos de montaje N.º valve 2 Place Pernos de montaje N.º 1 small rubber gaskets the tank mounting of the unit. Toolsinstallation & Materials 9” (228mm) Caulk sealant into the gap between the toilet and the bolts that were supplied with your tank. Slide both bolts finished wall. ared terminada into the mounting holes from inside the tank. G cabezal de desague gasket must be compressed finished wall. For installations where consideration is given for When performance matters. pernos de pernos del montaje tanque the tank by placing the metal washer tuerca Secure de empaqueand nut respaldo H 5/16” de huleby hand onto the bottom of the apertura deltank bolts and tighten F de agua the tank level. (8mm) de nutssuministro Pernos de montaje N.º 3 while holding Pernos de montajetuerca N.º 4 both respaldo vista superior arandela de del Las transportador 5. Nota: tuercas de respaldo también conocidas como ble injury! Note: Views in this illustrations are for general representation 7730/7730HE fibraWith the tank level and sitting parallel to the wall, begin arandelas del between the two nuts to tuercas se deben colocar de tal10/2013 forma que Note: If you tighten the cap nut de onconexión, mounting and may not necessarily define the wrench exact contours of the product. REV tapa deto la tight the nuts alternating tanque lleven toda la carga de la montura, dejando un espaciotuercakeep the tank even. Tighten the nuts until the tank is #2 you will break the china since there is no If replacing an stud existing toilet be certain to shut off Vista frontal Corte determinada. los accesorios de montaje water supply before removing old toilet. de 1/6" entre la montura y la pared Siga las back nut on this stud. tuercas del tanque snug against the sanitary tank bar on the bowl. del fabricante para la conexión de salida Mounting studs should extend 2-1/8” (54mm) beyond the 4 recomendaciones 3When performance lation Place back up nuts supplied with the carrier/support on mounting matters. del portador. Al colocar la montura en el portador no se 9. Coloque el empaque pequeño de goma sobre los pernos de finished wall. el inodoro sobre un sistema de anclaje 2. Si va a instalar stud #1, #3 and #4. No back-up nut is used on mounting E e 7-1/2” (190mm) -1- 10 9 CAUTION: PRODUCTline IS FRAGILE Connect the flexible water the tank to Coloque Fit the side ofcon the gasket into recomienda usar un anillo de cera, se recomienda usar monturasupply del tanque quefrom se incluyen en el tanque. 2 existente, asegúrese quetapered los large rubber If you are installing thede toilet onelanmismo existingcumpla support system, stud #2! Adjust thethe two lower back-up nuts so the front face Doofnot over tighten nuts more than a snug fit. The waste horn should extend 5/16” with (8mm) beyond the make surelocales the system isque in compliance local coderesista the shutoff all coupling fieltro o neopreno. colocar montura enwall. el portador, la arandela metálica y lanuts tuercasecurely. en el fondo de las tuercas the nuts are level 1/16” Al away fromlathe finished Usingvalve. aellevel, Tighten inlet opening of the bowl. The tank should sit and requisitos y de el sistema de soporte finished wall. and the support system is weight rated for requirements adjust thedel back-up mounting stud #1 a vertical plane empaque drenajenut seon deberá comprimir lo to suficiente del tanque, y ajustarlas hasta que el tanque esté ceñido elthepeso para losrequirements. requisitos aplicación. paralleldetola the finished wall. application with asegurar mountingun stud #3. Place back-up washer on the three para sellado positivo del gas y un on sellado contra la valve barra deland tanque sanitario tanque. Turn water at the supply allow thedeltank to Conecte fill. installed back-up nuts. impermeable. la línea de suminstro del tanque a la llave de paso y ajuste Note; If the wall is irregular, the three back-up nuts and Place the small rubber gaskets onto the tank mounting firmemente todas las tuercas de acoplamiento. Abra washers must be positioned to allow a minimum of 1/16” Check all fittings for leakage and tighten any fittings that bolts that were supplied with your tank. Slide boltsand gapayuda between thepersonas, fixture the la wall. 6. Con deboth dos instale taza sobre los pernos elsuministro de agua y permita que se llene el tanque. pernos de are leaking. montaje into the mounting holes from inside the tank. del montaje. Coloque prisioneros la arandela de fibra que se Revise que no haya fugas y ajuste la montura como sea vista de la pared terminada cabezal de desague pport s r Drenaje residual I 2-1/8” (54mm) tuerca de respaldo incluye con la montura del portador, sobre losdepernos #1,N.º 2 Pernos montaje Pernos de montaje N.º 1 y #4. Coloque tapón de la tuerca que se incluye en el Secure the tank by placing the metal #3 washer and elnut tuerca de los pernos prisioneros de montaje #1, #3 vista superioronto the bottom of therespaldo tank bolts andportador, tightensobre by hand pared terminada arandela de sostiene la taza nivelada y usa una del transportador both nuts while holding fibra the tank level.y #4. Mientras que se Drenaje residual 2-1/8” (54mm) tapa de la tuerca llave ajustable, ajuste las tres tapas de las tuercas hasta que estén ceñidas. ADVERTENCIA: EL PRODUCTO ES necesario. Nota: La perspectiva de esta ilustración es una representación general y puede no necesariamente definir los contornos exactos del producto. With the tank anddesitting to theNowall, Corte5/16” de los level accesorios montaje parallelFRÁGIL ajustebegin demasiado. Solo debe quedar ceñido. When performance matters. (8mm) Pernos de montaje to tight the nuts alternating between the two nuts to N.º 3 Pernos de montaje N.º 4 4 Place back up nuts supplied with the carrier/support on mounting keep the tank Tighten the nuts until the tank is stud #1, #3 and #4. No back-up nut iseven. used on mounting stud #2! Adjust the two lower back-upthe nuts sanitary so the front face of bar on the bowl. snug against tank 7730/7730HE the nuts are 1/16” away from the finished wall. Using a level, adjust the back-up nut on mounting stud #1 to a vertical plane with mounting stud #3. Place back-up washer on the CAUTION: PRODUCT IS three FRAGILE installed back-up nuts. not over tighten nutsnuts more Note; If the wall Do is irregular, the three back-up and than a washers must be positioned to allow a minimum of 1/16” performance matters. ©When 2014 Ferguson Enterprises, Inc. gap between the fixture and the wall. vista de la pared terminada REV 10/2013 -1snug fit. Distributed Exclusively by Ferguson and Wolseley Canada WARNING: Do not use plumbers putty, pipe dope or any other sealant on the 18218 04/14 Solucion de problemas Solución de problemas Tanque de gravedad de descarga Tanque de gravedad de descarga trasera para colgar en pared ® trasera para colgar en pared PF1705 / 1710 / PF1705//PF1710HE 1710 PF1705HE Solución de problemas Estas partes deben usarse conforme se ilustra para garantizar una conexión de sellado hermético Dificultades Razones La válvula de llenado El nivel de agua está no está ajustada muy alto o muy bajo correctamente Solución Ajuste el nivel de agua Quite y limpie el filtro El cono de flotación se Libere la válvula de atora con la pared del llenado de la pared del tanquel tanque Fugas de agua La tuerca hexagonal está floja ESPIRAL METÁLICA METAL SPIRAL VINIL/ENTRELAZADA TUBING TUBING CONECTOR CONTRATUERCA ARANDELA CÓNICA La válvula de cierre no Abra la válvula de está totalmente abierta cierre La válvula de llenado Filtro obstruido no se puede llenar METAL/COBER CAÑERÍA ACAMPANADA Ajuste la tuerca hexagonal SI LA VÁLVULA DE LLENADO SE CIERRA PERO CONTINÚA LA FUGA Siga las instrucciones sobre cómo limpiar el sello que se muestran a continuación. CONTRATUERCA CONTRATUERCA CONTRATUERCA ARANDELA EXISTENTE ARANDELA CÓNICA EXISTENTE TUERCA DE ACOPLAMIENTO TUERCA DE ACOPLAMIENTO TUERCA DE ACOPLAMIENTO EXISTENTE VÁLVULA DE CIERRE DE AGUA VÁLVULA DE CIERRE DE AGUA TUERCA DE ACOPLAMIENTO VÁLVULA DE CIERRE DE AGUA Use las arandelas y la tuerca de acoplamiento existentes VÁLVULA DE CIERRE DE AGUA Use las roldanas existentes y la tuerca de acoplamiento La tubería de suministro o el tubo deben extenderse al menos 1/2” dentro del vástago de cuerda de la válvula LA TUERCA DE LA ABRAZADERA puede provocar roturas y DAÑO potencial. Precaución: NO use una arandela cónica con la tubería plástica de abastecimiento. NO use masilla de plomería para sellar estas válvulas. SI EL AGUA CONTINÚA CORRIENDO, LIMPIE EL SELLO COMO SE INDICA EN LAS FIGURAS 1-6 A CONTINUACIÓN 1 SI LA VÁLVULA ARRANCA Y SE PARA DURANTE PERÍODOS EN QUE NO 2 3 SE ESTÁ UTILIZANDO. Es señal de que está desperdiciando agua Compruebe si la parte más baja del tubo de relleno está insertada dentro de la tubería de desagüe, por debajo del nivel de agua en el tanque. Compruebe si el flotador de la válvula de llenado está atorado. Asegúrese de que se mueva libremente. Quite el tapón de la válvula de llenado, y desconecte el tubo de relleno Desconecte el suministro de agua 4 Desconecte el tornillo de ajuste del brazo de la válvula de llenado 6a 5 Compruebe si la clapeta está desgastada, sucia o desalineada. Reemplace la clapeta con una original de repuesto. Compruebe si la tucera de la válvula de descarga está adjustada. SI LA VÁLVULA DE LLENADO NO ARRANCA O SE APAGA, o EL LLENADO DEL TANQUE DE AGUA ES LENTO puede ser que se requiera reemplazar el sello. Precaución: LA TUERCA DE LA ABRAZADERA puede provocar roturas y DAÑO potencial, NO utilice una arandela cónica con una tubería de suministro de plástico. No use masilla de plomería para sellar estos ajustes. Se incluyen las arandelas cónicas esclavas. Use las arandelas existentes y la tuerca de acoplamiento. Compruebe el ángulo de parada y asegúrese de que esté corriendo el agua. SI ESCURRE AGUA DEL TANQUE, consulte el diagrama de acoplamiento de la tubería de suministro. Compruebe que la tuerca de la abrazadera de la válvula de llenado esté apretada. Confirme que el tanque esté ajustado con seguridad a la taza. Compruebe si la clapeta está desgastada, sucia o desalineada. Reemplace la clapeta con una original de repuesto. Verifique que la tuerca de la válvula de descarga esté apretada. © 2010 Ferguson Enterprises, Inc. All Rights Reserved © 2014 Ferguson Enterprises, Inc. Gire 1/8 en sentido invertido a las agujas del reloj para aflojar la cabeza de la válvula de llenado Cubra la cabeza de la válvula de llenado y suelte el agua lentamente para eliminar cualquier rebaba Enjuague el sello y la cabeza con agua 6b ADVERTENCIA NO UTILICE LIMPIADORES DENTRO DEL TANQUE DEL INODORO, QUE CONTENGAN CLORO O BLANQUEADORES El uso de tales productos: 1. Provocará daños a los componentes del tanque y puede provocar inundación y daño a la propiedad 2. Puede invalidar la garantía Vuelva a ensamblar las piezas en orden invertido para garantizar su funcionamiento Distributed Exclusively by Ferguson and Wolseley Canada Distributed Exclusively by Ferguson and Wolseley Canada 6635 01/11 18218 04/14