Presentación de PowerPoint

Anuncio

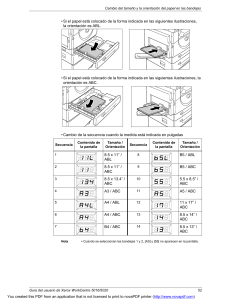

Architect, Professor tutor in UNED, Master in design engineering and researcher in architecture 3D printing and design engineering 1 1. PRESENT SITUATION 1. ANALYSIS ANÁLISISOF DETHE LA SITUACIÓN ACTUAL 2. STUDY OF THE CHANCES AND LIMITATIONS 3. CONCLUSIONS AND IMPROVEMENTS 2 1. ANALYSIS OF THE PRESENT SITUATION TYPES OF MODELS USED IN ARCHITECTURE 3 1. ANALYSIS OF THE PRESENT SITUATION TYPES OF MODELS USED IN ARCHITECTURE 4 1. ANALYSIS OF THE PRESENT SITUATION 3D PRINTING DEVELOPMENT 5 1. ANALYSIS OF THE PRESENT SITUATION HOW CAN THE ARCHITECTURE OFFICES USE THIS TECHNOLOGY IN THEIR WORK? FIRST OF ALL, WE MUST THINK ABOUT THE 3D PRINTER FEATURES REMIND! YOU CAN BUY A PRINTER, OR JUST ORDER A MODEL TO A SPECIALIZED COMPANY 6 1. ANALYSIS OF THE PRESENT SITUATION 3D PRINTER FEATURES - Costs (from 600 to 40.000 €) - Weight and size (build volume) 7 1. ANALYSIS OF THE PRESENT SITUATION 3D PRINTER FEATURES - Layer resolution: from 0,250 mm to 0,015 mm EnvisionTEC Digital Dental Printer Layers 25 - 100 microns Photosensitive resin Concept Laser MLAB 90 Layers 20 - 100 microns Metal Alloy Cobalt Chromium 8 1. ANALYSIS OF THE PRESENT SITUATION 3D PRINTER FEATURES - Working material ABS Metal PLA Nylon Concrete Many others: resins, chocolat, flour… Wood Salt Ceramic Sugar 9 1. ANALYSIS OF THE PRESENT SITUATION THEN, WE MUST THINK ABOUT THE CURRENT EQUIPMENT AND PERSONAL SKILLS: - ENOUGH POWERFUL COMPUTER - WORKERS WHO KNOW HOW TO USE IT - TIME TO DEVELOP THE VIRTUAL MODELS 10 1. ANALYSIS OF THE PRESENT SITUATION FROM VIRTUAL TO REAL MODELS Phases: - Modeling (according to the scale and joints) - Conversion from virtual model to printing format (layers) - Printing - Post-production 11 1. ANALYSIS OF THE PRESENT SITUATION FROM VIRTUAL TO REAL MODELS Modeling Adapting the model: scale and unnecessary elements Adapting the model: joints 12 1. ANALYSIS OF THE PRESENT SITUATION FROM VIRTUAL TO REAL MODELS Post-production Remove the “staircase effect” 13 1. ANALYSIS OF THE PRESENT SITUATION FROM VIRTUAL TO REAL MODELS Post-production Painting, enamelling, varnishing or polishing 14 1. ANALYSIS OF THE PRESENT SITUATION THE ARCHITECTURE OFFICES ARE ALSO PRINTING AT 1:1 SCALE 15 1. ANALYSIS OF THE PRESENT SITUATION 1:1 SCALE DUS Architects: plastics 16 1. ANALYSIS OF THE PRESENT SITUATION 1:1 SCALE Bioplastics Softkill Design + Lab Stuart-Smith's + Materialise 17 1. ANALYSIS OF THE PRESENT SITUATION 1:1 SCALE Sand + magnesium oxide + chlorine Enrico Dini + Shiro Studio 18 1. ANALYSIS OF THE PRESENT SITUATION 1:1 SCALE Lunar soil UK Monolite + Enrico Dini + Foster and Partners + ESA 19 1. ANALYSIS OF THE PRESENT SITUATION 1:1 SCALE Concrete + composite fibres Khoshnevis Behrokh - University of Southern California 20 1. ANALYSIS OF THE PRESENT SITUATION 2. STUDY OF THE CHANCES AND LIMITATIONS 3. CONCLUSIONS AND IMPROVEMENTS 21 2. FUTURE: CHANCES AND LIMITATIONS WHAT IS IT FOR, THE MODEL I WANT TO PRINT? AESTHETICS FUNCTIONALITY 22 2. FUTURE: CHANCES AND LIMITATIONS STUDY CASES Industrial building V-Flash. 3D Systems resin polymerisation layers 0,11 mm Scale 1:850 23 2. FUTURE: CHANCES AND LIMITATIONS STUDY CASES Museum V-Flash. 3D Systems resin polymerisation layers 0,11 mm Scale 1:700 24 2. FUTURE: CHANCES AND LIMITATIONS STUDY CASES Arts Centre RepRap Prusa (+ waspmod) Fused Filament Fabrication. ABS layers 0,25 mm Scales 1:1000 and 1:250 25 2. FUTURE: CHANCES AND LIMITATIONS STUDY CASES Market and vegetable garden Dimension. Stratasys Fused Deposition Modelling. ABS layers 0,33 mm Scale 1:225 26 2. FUTURE: CHANCES AND LIMITATIONS STUDY CASES Market and vegetable garden 27 2. FUTURE: CHANCES AND LIMITATIONS STUDY CASES Single-family house Z Printer. 3D Systems cianocrilate adhesive + powder plaster Layers 0,1 mm Scale 1:150 28 2. FUTURE: CHANCES AND LIMITATIONS STUDY CASES Single-family house V-Flash. 3D Systems resin polymerisation layers 0,11 mm Scale 1:150 29 2. FUTURE: CHANCES AND LIMITATIONS STUDY CASES Single-family house Dimension. Stratasys Fused Deposition Modelling. ABS layers 0,33 mm Scale 1:100 30 2. FUTURE: CHANCES AND LIMITATIONS STUDY CASES Presentation models Z Printer. 3D Systems cianocrilate adhesive + powder plaster Layers 0,1 mm 31 1. ANALYSIS OF THE PRESENT SITUATION 2. STUDY OF THE CHANCES AND LIMITATIONS 3. CONCLUSIONS AND IMPROVEMENTS 32 3. CONCLUSIONS - ADAPTING THE DIGITAL MODEL THE SCALE IS NOT UNIFORM (REMOVE ELEMENTS, ENLARGE OTHERS…) - TRY TO ELIMINATE THE POST-PRODUCTION PHASE (IT CAN BE VERY TIME-CONSUMING) - REUSE THE MATERIALS (MONEY, TIME, SPACE IN THE STUDIO) 33 3. CONCLUSIONS - PRINTING WITH MORE THAN TWO MATERIALS (IT DEPENDS ON THE TECHNOLOGY) - ADDING OTHER ELEMENTS WHILE PRINTING (USING A ROBOT ARM OR SIMILAR) - PRINTING ON MODELS THAT ALREADY EXIST (TO DEVELOP MORE COMPLEX PROJECTS) 34 THANK YOU 35 1. ANÁLISIS DE LA SITUACIÓN ACTUAL DESARROLLO DE LA IMPRESIÓN 3D 1976 Estereolitografía. Charles Hull (3D Systems) – comercialización en 1988 1980 Sinterización selectiva por láser. Carl Deckard y Joseph Beaman 1980 Modelado por deposición fundida. S. Crump Scott (Stratasys) 1993 Impresión 3D con aglutinante. Jim Bredt y Tim Anderson (Z Corporation ) 2004 Proyecto RepRap. Adrian Bowyer 2009 Makerbot Industries. Bre Pettis, Adam Mayer, y Zach “Hoeken” Smith 2008 Prótesis de pierna a medida, impresa en 3D 2009 Bio-impresión de tejidos orgánicos: vaso sanguíneo (Organovo) 2011 Impresión 3D de oro de 14 kilates y plata de ley (Materialise) 36 1. ANÁLISIS DE LA SITUACIÓN ACTUAL CARACTERÍSTICAS DE UNA MÁQUINA DE IMPRESIÓN 3D O DE PROTOTIPADO RÁPIDO Material de trabajo: investigaciones en el MIT Densidad variable 4D 37 1. ANÁLISIS DE LA SITUACIÓN ACTUAL ANÁLISIS DE MATERIALES Y PROCESOS Comparación de equipos y tecnologías 38 1. ANÁLISIS DE LA SITUACIÓN ACTUAL PASOS PARA LA CONSTRUCCIÓN DE LOS MODELOS Impresión 3D Comparación entre dos posiciones de cara a la optimización en la construcción Posicionado en origen del eje Y Paralelo al eje Z Tiempo estimado: 3h 55min Posicionado al final del eje Y Paralelo al eje X Tiempo estimado: 1 h 11min 39 2. FUTURO: POSIBILIDADES Y LIMITACIONES LOCALIZACIÓN DE DIFICULTADES Prestaciones de la maqueta en función del uso final 40