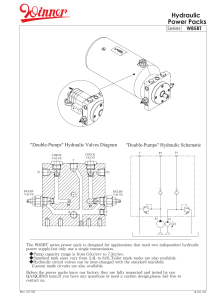

r 1 Jl o 4 01 I p 4 6 D L o o MANUAL AV C c i j L 1 J r f r L J r 1 f r L f J J 1 J J t QUICK DATSUN UP p CK SEftV CE tf AMUAl MODE ES 620 SER I I I 1 1 to 1 ISSAtlIA0101l 0KYO J Atl CO ENCE fEFEf INDEX FOREWORD prepared for the purpose of assisting service personnel of dealers fu providing effective service and maintenance of the This service manual has been authorized NISSAN DATSUN 1977 Datsun Pick up Since proper maintenance and service la1 should be inan owners this carefuny fu kept fu absolutely essential handy place for ready are a the Datsun satisfying reference and should be studied la1 fucludes man This procedures for ma futenance minor 1justrnents ac service operations remowl and installation and for disassembly and assembly of components operations require Some of these service effectiveperfonnance The special As you tools are read occasionally ofservice corne across gives the beginning At the of each on and Qr damage in for CAUTION supplemental of steps that must warns to some part of your DATSUN to user of each individual section is which each you will this service manual the first page enables the on a quickly table of contents which An index is major subject begins locate the placed at the within the section major subject All information illustrations and specifications contained in this manual latest product information available at the time of publication model differs from the especially designed CAUTION A NOTE is or particular procedure beginning page number procedures headed NOTE paragraphs prevent personal injury desired section Tools section the maintenance Reference Index The Quick SE in the infortl1ation that is important to B be fonowed to Special operations presented through the use of specifications approval are based on the If YOUT DATSUN consult your NlSSAN contained in this manual DATSUN dealer for information for alteratiohat any time of specifications and methods Rights liability for any la1 in man effecting M9tor Co maintenance or or reserved property damage occasioned by the repair of your Datsun is in no by anyone using a Nissan must fust service procedure completely satisfy vehicle s safety wi11be jeopardized by or N1SSAN by MOTOR CO LTD specifically himself that neither his Nissan safety w nor the the service method selected MOTOR TOKYO 1976 of this service way assumed tool which is not NISSAN @ use Ltd Accordingly mended personal injury are Printed in Japan CO JAPAN LTD I SECTION GI GENERAL INFORMATION DATSUN PICK UP MODEL 620 SERIES GENERAL INFORMATION I NISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN GI 3 General Informa ion Fig GI I Standord wheelbase model Fig GI 2 Delux Cob GI 2 L General Information GENERAL INFORMATION CONTENTS GI B MOOEL VARIATION GI 3 APPROXIMATE IDENTIFICATION NUMBERS GI 5 RECOMMENDED FUEL GI B LIFTING GI B RECOMMENDED GI 8 POINTS AND TOWING REFILL CAPACITIES LUBRICANTS LIFTING POINTS GI B RECOMMENDED SAE VISCOSITY SUPPORTABLE POINTS GI 7 NUMBER TOWING GI 7 LUBRICANT TIE GI 7 DOWN GI 8 GI g SPECIFICATIONS MODEL VARIATION Differential Destination Model Class Engine Transmission carrier model and gear ratio Standard wheelbase S E Ol 0 0 u E Long 0 E wheelbase 0 8 a Ol 0 0 u Ol u Deluxe Cab I I HL620TUV F4W7lB HL620FTUV FS5W71 B I HL620KTUV 3N7lB I I I I HLG620TUV F4W7lB HLG620FTUV FS5W71B HLG620KTUV 3N7lB KHL620TUV F4W7lB I KHL620FTUV FS5W7lB Hl90 KHL620KTUV L20B 3N7lB i u 0 Standard HL620TU F4W71 B HL620FTU FS5W7l B HL620KTU 3N7lB wheelbase U S 0 0 E 0 0 Long 8 wheelbase u Q 0 0 Z Q I I IHLG620KTU HLG620TU F4W7lB HLG620FTU FS5W7lB KHL620TU F4W71B KHL620FTU FS5W7l B KHL620KTU 3N7lB 3N7lB Deluxe Cab I GI 3 375 4 Pay load kg Ob 500 100 r General Information Differential Destination Class Model Transmission Engine carrier model Pay load lb kg and gear ratio Standard wheelbase HL620TUN F4W71B HL620KTUN 3N71B 0 Long Canada wheelbase 2 0 Deluxe HLG620TUN E Z Cab F4W7IB I HLG620KTUN I I KHL620TUN F4W71B KHL620FTUN FS5W7IB L20B 3N71B I KHL620KTUN Hl90 375 4 3N7J B Model identification KHLG620KTUV I I LU Destined for V California model N Canada model T Floor shift vehicle K Automatic transmission F 5 Note 0 means no manual transmission 4 speed manual transmission 0 I speed s A and Canada U G Long wheelbase o Standard wheelbase and Deluxe Cab H Equipped K Deluxe Cab identification 4 GI with L20B engine 500 100 1 General Informa tion IDENTIFICATION NUMBERS Engine serllii The The unit and vehicle numbers are stamped and registered at the factory The engine and vehicle identifica tion numbers are used on legal docu These numbers ments factory are communications used for such as engine number serial number tW is the right hand side of the stamped cylinder block on I L20B XXXXXX 1 I Reports Warranty Claims Service Journals and other informa I Serial number j Technical Engine model tion Vehicle IdentHication plate The il SP031 Fig GI 7 M V S S certification k label location vehicle identification plate is located at the hood ledge in the engine compartment Vehicle emission control Information label The vehicle emission control infor mation label is stuck the hood on the insicre of panel SP029 GI 3 Fig Vehicle identification plat location Vehicle serial number Color code number The vehicle serial number is stamp ed on the upper face of the right side member The number is identified the follQwing flgUres as a by The stuck color on code the radiator number SP076 label is Fig GI B Vehicle emia ion control information label location support serial number Manual transmission number HL620 XXXXXX I The transmission serial number is stamped on the front upper face of Serial number transmission case Vehicle model Number system x X XXXXX GI326 Fig I Serial number 01 6 Color code number label location monthly Month of j manufacture e M VS S c rtlflcatlon label G1268 Fig 4 Vehicle serial number GI location The M V S S certification label is located at the driver side lock Gl 5 pillar 2 9 XY Z Line code of manufacture iGetneiraolnfonrml Apply parking brake block rear vehicle is firmly and wheels if the front of the to be raised Notes a YeDow mark Never get under the vehicle while it is supported only by the jack Always use safety stands to support frame WHOSO when you have to get beneath the vehicle b In no event should the jack be location When place number The attached a jacking up the jack under screw about 520 transmission serial number is the to case the applied to any points except following specified portions Fig GI 9 Manual trammiuion number Automatic transmission axle or rear front side at rear of front axle center Garage Jack right hand side of transmission case Note When carrying out operntions with Numbering system a garage jack be sure to support the vehicle withstands in a safe manner X XXXXX I Serial number jacking up the front end apply garage jack to front cross When monthly Month of member manufacture I 2 t ogai over stroke side frame 5 in 20 nun Fig GI 13 Warning WT012 9 X Y Z When Fig GI ll Front lifting point or portion of center sus pension member apply jacking the jack to the up rear end rear axle case last figure of year of manufacture When jacking up the rear side place jack under rear axle side of rear spring close a screw to the case J r uc I GI075 n9 Fig GI 14 Front lifting point AT344 WH077 Fig 01 10 Automatic trammision number location Fig GI 12 Reor lifting point LIFTING POINTS AND TOWING Notes a LIFTING POINTS When the the screw maximum Screw jack yellow mark appean on jack it indicates permissible height the Do not jack up further Before using the follows jack proceed a b When the jack is at lower llinit do not add large force downward 6 GI GI076 Fig GI 15 Rear lifting point General Information To tow another SUPPORTABLE POINTS rope to The front supportable points under rear connect t1ie Before towing make are rear axle case a rope should not be con nected to any position other than A as the trans sure mission is in neutral gear Notes supportable points Manual transmission leaf spring shackle are under frame side member The rear car towing described above b Avoid applying towing rope as load suddenly to a it may cause dam age If the axle rear the inoperative towed with its ground the or transmission is or vehicle should be wheels off the rear propeller shaft must be l1oved re Automatic transmission When the vehicle is towed wheels rear make N mission is in MPH distance of Hi kin 6 miles axle or if the exceed speed and a Ifthe rear inoperative transmission is its trans position Neutral Don t exceed 30 km h 20 Fig GI 16 Front supportable points on the sure or the above condi tions the vehicle must be towed with ground its rear wheels off the propeller the or shaft must be removed WH131 Fig Gl 18 Fronttowing point Note When the vehicle is towed with its front wheels on the steering maintain v the ground wheel shouId be secured to a straight ahead position TIE DOWN GI078 Fig GI 17 Rear supportable points The front two tie down hooks are located under the 1st crosSInember The hook is available TOWING When the vehicle is to be hook towed connect a rope securely to the hook under the 1st CrosSIn ember Before towing make brake is released sure rear spring shackle be used forward the For down tie also used parking Fig 01 19 Rear towing point GI 7 as a as the a towing rear leaf lIDs point is towing point General Information APPROXIMATE REFILL CAPACITIES I I 45 ManUal transmission I 8 0J Automatic tr I 7 8J Fuel tank Cooling system with heater Engine lubrication system Manual transmission I I smission us 8Y qt 6Jiqt I 4Ji qt 3 without oil f1lter I 3 8J I 1 7J I I I 5 speed transmission I I 2 s J 5 I box 4 I 10 J qt qt 3Xqt ql 3Xpl 3 4Y pt 3Mpt 5Uqt 4Uqt pt pt I 33J 0 I Differential carrier 0 9 Ji gal 7 3J I measure 8Jiqt 4 speed transmission Imper I I I 4 measure IUi gal J with oil f1lter Automatic transmission Steering gear Uter 2M pI pI I pt RECOMMENDED FUEL Use an gasoline with unleaded a or low lead of 91 RON Research Octane For California models Nuniber minimum octane rating use only unleaded gasoline catalytic tion RECOMMENDED LUBRICANTS RECOMMENDED SAE VISCOSITY NUMBER C ENGINE on IIO 10Vt4ll 10Wf 12O I ao 40 2 ICWII J SAE 5W 20 oils ate not lecom mended for sustained high speed drivin GEAR On I J w c 30 20 0 20 40 60 Temperature Range Anticipated Next Oil Change OF 8 GI 80 100 Before converter to from protect the contamina General Information LUBRICANT SPECIFICATIONS Specifications Item SAE Classification Gasoline engine oil SD or SE Remarks Furthermore refer to SAE recommended viscosity table See Poge GI B Transmission and 0 API 4 GL steering Differential Automatic TIM fluid Multipurpose grea Brake and clutch fluid API GL S Type DEXRON lithium soap base NLGI2 DOT 3 Permanent anti freeze Antifreeze Ethylene glycol ba GI 9 e SECTION ET ENGINE TUNE UP DATSUN PICK UP MODEL 620 SERIES I NISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN ENGINE TUNE UP ET 2 BASIC MECHANICAL SySTEM ET 7 IGNITION AND FUEL SYSTEM ET EMISSION CONTROL SYSTEM ET 13 SERVICE DATA AND SPECIFICATIONS ET 25 TROUBLE DIAGNOSES AND CORRECTIONS H 27 9 Engine Tune up ENGINE TUNE UP CONTENTS LOCATION OF EMISSION CONTROL EMISSION CONTROL SYSTEM PIPING SYSTEM COMPONENTS lNon California models INon California models ET 2 EMISSION CONTROL SYSTEM PIPING ET 3 EMISSION CONTROL DEVICES LOCATION OF EMISSION CONTROL SYSTEM COMPONENTS California models California models 4 ET ET 5 ET 6 LOCATION OF EMISSION CONTROL SYSTEM COMPONENTS Non California models 6 7 @ 9 I 2 3 4 5 Thermal vacuum valve Check valve Air gallery pipe Auto choke 6 Automatic temperature control air cleaner Anti Backfire valve A B valve 7 Bo05t Controlled 8 Deceleration Device P C V valve 9 Air 10 j D relief valve E 12 G R control valve Air pump air cleaner Carbon canister 13 Air 14 Spark delay 11 8C D pump valve AfT models ET365 Fig ET l Location of emaion control sy tern component Non California mod I ET 2 Engine Tune up LOCATION OF EMISSION CONTROL SYSTEM COMPONENTS California models 8 7 8 cv @ valve 1 Thennal 2 Check valve 3 Altitude compensator in air cleaner 4 Air vacuum gallery pipe 5 qj choke Auto 6 Automatic temperature control air cleaner 7 Anti Backfire valve 8 Boost Controlled Deceleration Device B C D O 9 P C V valve A B valve relief valve E G R control valve 10 Air 11 12 6 C D D control valve and solenoid valve relief valve 13 Emergency air 14 IS Air pump air cleaner Carbon canister 16 Air control valve 17 Air pump ET366 Fig ET 2 Location 01 emiuion control sydem component California mod a ET3 r Engine Tune up EMISSION CONTROL SYSTEM PIPING 1 2 3 4 5 6 Vacuum tube to distributor yellow Vacuum tube to carbon canister yeUow Vacuum tube to thermaJ vaCuum valve white Vacuum tube Vacuum tube to carburetor yellow Thermal vacuum valve to E G R control valve white 7 Vacuum tube to carburetor white 8 A 9 Vacuum tube 10 11 Non California models B valve to vacuum to connector green carbon canister yellow S D V to distributor yellow Vacuum tube to S D V yellow ET367 Fig ET 3 Emi8ion 4 ET stem piping control8 Non California models Engine Tune up EMISSION CONTROL SYSTEM PIPING 1 2 3 Vacuum tube to distributor yellow Vacuum tube to carbon canister yellow Thermal Vacuum valve to E G R control valve 4 California models white Vacuum tube to thermal vacuum valve white 5 Vacuum tube 6 Vacuum tube to 7 Vacuum 8 Vacuum tube to 9 Air carburetor yellow hose connector to intake manifold green carburetor white valve to vacuum hose tro con connector green 10 A B to vacuum 11 D C D D 12 B valve to connector control valve green white C D D control valve to intake manifold green 13 Vacuum hose connector to E A R control valve 14 green D C D D control valve to air pump air cleaner ET368 Fig ET 4 Emission control system piping California models ET5 lIIIII mJ Cr l l c Jl x X X X I I X X alvc X alvc I X I X I X I I I X I j I X X X X X X X X X X X I I T M X X X X X X X X X I X AHmjcL X X X X X X X X vl ve I I I I I I I I I I I I I I B X X I X I X I X X X X X X X X X X X X X X X X I X I sy tem X I I X X X T X DEVICS X X X X X X X X X X X I I I I I I X X X X X X I I I I I I I I I I I I I I I X X X X X X X I I I I contrled T gu vacum exhausl valve mlu delay ulI preure TransmlS Back Vacum X X I X X X X X X X I I I X 0 S V C C DC T I X X X X X X X I I X X X I I X M X X X X X I I I I I I I I I I I I i l alor compcn ilt udc wflh body at ched I valve rv rclifva lUiprCn relicI numn PUlnt air ulidc air 4t air l wilh with 1er C T e e comDenlatr TT fuclvporatYe hlle due air lh Early F I olck onlrol aulchnk pipe with without with o OO T c C P a 8 D c vlcuum a AIR ENGI E PROER valve svtem tem acum cleaner eonlro all T sv P Ive fAir mainte c no r mile 5Vlcm with 500 R ry l e G E cut rler ln lvr V V t DV A Air TS T I Airconlt Rcliervac R R J C A C 1 v R E G E LG T r AlT Ch T PT A Availbe avNotilabe X h e unit equiped m1917odels orCanud CARBUETO IGNTO SYTEM ml c I A G E SY TEM CATLYZER Newly control oLir mocratue Wamin lavIC Fluor I R V temprau vacum Automaic Positve Thermal Combined t S c B valve waminl Remark 12 I Thermal AlP valve valve valve VUI lD fThermal ITon device pump arkdelayvalvc Sn I CLEANR Ched valve valve C C E vc m S R A E r c Throlte Onlhot Altiude valve s I 0n ICnlor R d Jmpcalor tranmlor ISwilchn ncr 0 C Oiltrbuo unIt with l A lI1OfCuiol M valve B II val vl vc l C fo control control I A I A I A I deaner dl lliT air in l valve lIve sYltem fo UD I Jtrc1anr dualvQe introducinl exhaust control 1J1 air IC U I l1r wllh hcalm valve ble d Rcliefva l TO P icll cod C l wilh Automalcns temprau T to I Jc tlitlji I Enj I Jn I m1JC I ilUde Maoulrmn valvel ill T nt control I T I E 8 TS I I I I X I X I X I X I X I I I I X I X I X X I AlT I X I I 1 I X I I X X I X I I X I X M I C C D T lifomla model E recnultO advam Bo lt Tran Spark I I I I I I I I I I 1 lIodch forC X I I X I X I I I I X I aNonUfon anada X I AlT lPI L EJ X I I I I I I I I X X X I X X I X M 1 210 I I I I I I I I I I I T I AI4 I Can da V declration contrled contrled nasduce A I CONTRL EMISON X X CO E V 1 dov I R A A E I I I I X V R lIem I X Jlvc X I X I I I I X I X X I X X I X X I I X I models C X I I Califor models Except Can da X I I T M X I X I X I I I X AJ I Cilnad X E E I S I G b I X I X I X I X I X I X I I I X I X I I X X I X I X I X I X 1 X I I I I CalifornIa modcb X I l H I I I 1 I hfor R dclay cncy Anu Emer dll u Vacu m Tup ktiu M 620 FlU NOll r r X AfT I ula 11Ie relief T Non L20H I CalifJl rlodet X I I AfT I c0 epl l l E V C V T A C Engine Tune up BASIC MECHANICAL SYSTEM CONTENTS ADJUSTING INTAKE AND EXHAUST VALVE CLEARANCE ET 7 CHECKING AND ADJUSTING DRIVE BELT ET B AND CONNECTIONS ET B INSPECTION OF ET 7 RETIGHTENING CYLINDER PERMANENT ANTI FREEZE COOLANT CHECKING COOLING SYSTEM HOSES COOLING HEAD BOLTS CHECKING MANIFOLD NUTS AND CARBURETOR RADIATOR CAP PRESSURE TEST VACUUM FITTINGS HOSES SECURING NUTS ET7 AND CONNECTIONS CHECKING ENGINE OIL ET B CHECKING ENGINE REPLACING OIL FILTER ET B COMPRESSION CHANGING ET B TEST RESULT ENGINE COOLANT ADJUSTING INTAKE AND EXHAUST VALVE CLEARANCE Note bolts adjust intake and exhaust 1 Check for cracks or ET B ET B ET 9 COMPRESSION ET 9 TEST PRESSURE CHECKING AND ADJUSTING DRIVE BELT After tightening cylinder head ET B SYSTEM ET 9 2 to Normal drive belt deflection is 8 12 mm 0 315 to 0 472 in moderate thumb pressure is when applied midway between pulleys damage Re place if necessary valve clearances clearance Valve is adjustment impossible when the engine is in oper Compressor pulley ation 1 Loosen pivot turn pivot locking screw until the nu t and 8 to 12 specified mm 0 315 Idler clearance is obtained while cold up engine for at pulley 8 to 12 and recheck the clearance Warm in 472 0 Water pump Using service tool tighten pivot locking nut securely after adjustment 2 to mm pulley 0 315 to 0 472 in least several minutes and stop it Measure valve clearance while hot If out of specifications adjust Air Unit mm pump pulley in Alternator Intake 0 20 0 008 Exhaust 0 25 Intake 0 25 OmO Cold 0 010 AC456 Fig ET 6 Driue belt tension Wann I Exhaust 30 0 0 012 RETIGHTENING CYLINDER HEAD BOLTS MANIFOLD NUTS AND CARBURETOR SECURING NUTS Tightening torque Cylinder head bolts 1st turn 4 0 kg 6 0 kg ET009 Fig ET 5 Adjusting valve clearance Refer to the following tightening torque specifications ET 7 29 ft Ib m 43 ft Ib 3rd turn 5 to 6 STl 064000 I m 2nd turn 5 8 kg m 47 to 61 ft lb r Tune up Engine ManifolJ I 2 to 16 8 7 5 0 10 kg to Do not overtighten oil Note Carburelor nuls 3 6 tighlen filter by hand m kg oil installing I 6 ft lb to to When 2 nuts lest m leakage should flIt occur 7 2 fl tb CHANGING ENGINE Fig fJ ET l rod ioto Teltill cop COOLANT COOLNG SYSTEM PRESSURE TEST PERMANENT ANTI FREEZE COOLANT Fig ET 7 Tightening s quence Permanent anti freeze coolant is an base producl conlain ethylene glycol ing chemical inhibilors 10 protect the cooling system against corrosion The anti freeze CHECKING ENGINE any OIL Check if oil is diluled with water gasoline Drain and refill oil if or does glycerine ethyl or contain not methyl alcohol to the psi of a lesler to Water temperaturethennoslat Notes the of cooling water Isolate the cause and take corrective b An oil with extremely low viscosity indicates dilution with gasoline capacity 7 U US qt fImp qt 6 8 0 liters 8 fUS qt 7 Imp qt cooling system The anti freeze must not be mixed with other products This coolant can be used measure leakage With heater flows freely transfers heat effi ciently and will not clog passages in milky oil indicates the presence detect any means 7 4 liters It A cooling system by Without heater It will not evaporate or boil away and can be used with either high or low necessary a With radiator cap removed apply 1 6 kg cm2 23 reference pressure out through the seasons of the year Whenever coolant is changed the cooling syslem should be flushed and 2 Check specified oil level level If below the raise it up 10 the H refilled with Check a new coolant the level See the instruc lions furnished by the manufacturer for the mixture ratio of anti freeze 10 level Engine oil capacity including oil filter water Maximum H leven 3 liters 4 4 MUS qt 3 Y Imp qt Minimum L level 3 liters US qt 2 U 3 f Imp ql CHECKING COOLING SYSTEM HOSES FITTINGS HOSES AND CONNECTIONS AND CONNECTIONS Check hoses and connections tighten REPLACING OIL CHECKING VACUUM or or replace fittings for loose deterioration Re if necessary FILTER be a cartridge removed using type and Oil Filter Check for oil leaks past gasketed flange If leakage is found retighten I ening mter is no as an vacuum or hoses replace can if neces be identified White line INSPECTION OF RADIATOR CAP Vacuwn tube to carburetor E G R Wrench STI9320000 just enough Retighten sary All by colors The oil mter is can Check the condition of filtings and hoses to stop leakage Ifretight longer assembly effective replace Apply kg cm2 means reference 13 of a psi1 cap 09 pressure to radiator cap tester satisfactory Replace to cap see by if it is assembly if Tube Vacuum tube to thermal Thennal vacuum control valve necessary 8 ET vacuum valve valve to E G R Tune up Engine Different Yellow line compression in two or cylinders usually indicates an improperly seated valve or broken piston ring I Spark delay valve to distributor Spark delay valve to vacuum tube more Distributor to vacuum tube 9 compression in cylinders can result from worn piston rings This condition may usually be accompanied by excessive fuel consumption Vacuum tube to carburetor Vacuum tube to canister Green line Anti backfire valve to intake mani ET010 fold TEST RESULT Fig ET Air control valve to emergency air Teding compression 10 pressure relief valve Intake manifold to vacuum If compression is low Depress accelerator pedal 5 Intake manifold to canister to open throttle and choke valves CHECKING ENGINE COMPRESSION Note Do not Start 6 engine as I quickly as 7 TEST 2 3 2 Compression pressure kg cm2 psi at rpm 12 0 9 0 Properly attach tester to spark plug being a compression cylinder hole in 8 oil increases the com the chances are that If pressure stays low is that valve is sticking probable or seating If cylinder compression in any adjacent cylinders is low and if adding oil does not help the compres sian there is leakage past the gasket 3 350 171 two 128 350 Cylinder compression in Should not be less than 80 surface cylinders of highest Oil and water in combustion cham bers can result from reading tested more or small quantity improperly Minimum valve connector one cause Standard engine sufficiently Disconnect all spark plugs Disconnect anti dieseling solenoid Warm up 4 If adding pression pressure rings are faulty pos sible PRESSURE COMPRESSION a pression pedal pump in cylinders pour of engine oil into cylinders through the spark plug holes and retest com hose connector I Low leakage IGNITION AND FUEL SYSTEM CONTENTS ET CHECKING BATTERY CHECKING AND ADJUSTING CHECKING DISTRIBUTOR CAP ET 10 ADJUSTING IGNITION TIMING CHECKING AND REPLACING SPARK PLUG CHECKING DISTRIBUTOR ADJUSTING ETlO AND MIXTURE ET 11 IGNITION WIRING ET 11 Unscrew inspect Check tery cell electrolyte level in each bat each filler cap and fluid level If the fluid is low approximately 10 to 20 H9 mm ET 12 ET13 linkage FUEL add distilled water to bring the level up ET 12 RETURN SPRING LINES pipings connections REPLACING I ET 11 CAP FUEL CHECKING Hoses RPM CHOKE MECHANISM Choke plate and ET11 DISTRIBUTOR LIMITER CHECKING ET 10 GAP lCalifornia models IDLE RATIO CHECKING CARBURETOR ETlO POINTS lNon California models ET 11 CARBURETOR ET10 OPERATING CHECKING BATTERY ET 11 CONDENSER IDLE PARTS AND IGNITION WIRING BREAKER ROTOR AND CONDENSER TIMING AI R 9 IGNITION 39 0 etc ET 13 ET 13 FILTER to 0 79 in above the plates Do not overfill 2 Measure the battery electrolyte specific gravity of p Engine r Rinse water pressed clean air to off and dry with com Top of battery must be prevent terminals tween Tune up terminal to current and leakage from down hold be positive on accumulation of acid and dirt ET002 Checking specific gravity ofbottery electrolyre Fig E1 11 Clean top of battery and terminals with a solution of bakin soda and of top If l l ry the may ca u iCbli t g I rj material covering connector straps and corrosion of straps After tightening terminals coat them with vaseline petrolatum from corrosion Full Pennissible to REPLACING SPARK PLUG I clamp In addition to current leakage pro longed CHECKING ANb protect them Remove and clean 2 Inspect insulator for cracks or 3 Check both center and ground electrodes If they are excessively place with new spark plugs Spark plug 4 worn re gap Breaker points type 0 8 to 0 9 mm charge at 200C in a sand chips value value plugs blast cleaner 0 031 to 680F 035 in 0 Transistor ignition type 10 to 1 mm Frigid Over 1 22 climates Tropical climates Other climates lOver lOver 1 28 0 039 to 0 043 in Tightening 1 18 123 120 26 1 torq kg m 5 to 2 0 1 11 to A4 ft lb CHECKING AND ADJUSTING IGN ITIONTIMiNG IGNITION ADIUSTING TIMING Fig ET 14 Checking spark plug point Check spark plugs and distributor breaker points for condition I Thoroughly 2 remove gap dirt and dust from timing mark on crank pulley and timing indicator on front cover engine sufficiently Imtalla timing light on No CHECK I DISTRIBUTOR OPERATING PARTS Warin up 3 4 cylinder spark plug wire and install I AND 1 WIRING a tachometer 5 Set idling spero toapproxintate BREAKER Check ignition timing light if it is timing with a specified value 1 oo Fig ET 13 Checking ignition timing be moved by hand Adjust ignition timing 0 3 to speci that timing is the distributor breaker ai1d correc 120 750 rpm Non California models 100 750 rpIll California models Automatic transmission 120 650 rpin in 0 position ET 10 Replace are if necessary Make properly aligned sure and that wear they point dwell and gap are correct Clean and Ignition timing Manual transmission Lock distributor setscrew sure ET169 distribu fied value make Check points for abnonnal pitting and it as follows Loosen setscrew until tor can 2 adjust POINTS Non California models I Ifnecessary lrI9N y 750 rpm 6 G apply distributor grease to the carn lobes Note 00 not apply grease excessively Point gap 0 45 to 55 0 mm Om8 to 0022 in Owell angle 49 to 55 degrees Tune up Engine cap and check cable resistance only If resistance is still more than 30 000 ped ohms replace cable assembly Be check should be per models fonned in the sure position D parking to engage to lock both front and brake and rear wheels with wheel chocks b brake your foot down on the Keep pedal while depressing the accelera tor pedal Otherwise vehicle surges forward dangerously EE322 Fig ET 15 Checking diltribu tor Notes point gap EF125 AIR GAP Gap refer to the in Section EE topic Air page EE 29 Check centrifugal advance unit for tion If it improper operating properly be due to a sticky opera or is not the problem may spring or excessively worn parts This operation needs a distributor tester For inspection procedures and ref data refer to relative topic erence under Distributor in Section EE If vacuum advance mechanism does properly not check operate Check 1 leakage retighten 2 at or Check inlet for signs of If necessary replace vacuum diaphragm for air leak If necessary replace diaphragm Note This be to per surfaces of all fully not are parts of Burned replacing minal When be before pushing sure they rubber and CONDENSER Clean wire 2 cap for lead if necessary Check condenser with a con ance to check resist cables from spark proper adapter spark plug plugs and install between Remove and secondary cables cable 20 0 a Check resistance of one cable at a time Connect ohmmeter between spark plug adapter and corresponding elec is more trade inside cap If resistance than 30 000 ohms remove cable from adjustment requires especially for mixture a CO meter When California models adjust idle mixture preparing to is essential to it have the meter thoroughly warmed up and calibrated I Check carburetor pipes for proper connection Warm up engine until water tem perature indicator points to the middle 2 engine The is procedure to warm up specifically recom not mended Either driving vehicle or oper ating engine at no load will be good 3 out 5Mn Mega ohms assembly Do not remove cables from cap IF Farad Condenser insulation resistance distributor cap as an to 0 24 Micro and Idle the use of Make that water tempera sure indicator points to the middle Further keep engine running at about 2 000 rpm for about 5 minutes with Condenser capacity Disconnect of secondary cables with adjustment idle CD meter ture denser tester Use an ohmmeter CO of gauge outlet of condenser and check for loose setscrew Retighten IGNITION WIRING down nipple distributor If plate does not move smoothly this condition could be due to sticky steel balls If necessary replace break I fully seated tower Check distributor rotor for damage cracks plate assembly causes wires in ter are or 40 em 15 7 in or arcing between end of wire and ter minai been N d When measuring CO percentage in sert probe into tail pipe more than be cleaned which seated has for automatic trans position P to secondary reduce possibility of voltage loss All system must tip cause mission cracks and flashover External to it made shift the lever to the for points Inspect distributor cap movement er is operation remove Idle Limiter Cap After idle adjustment formed while checking distributor over Inspect breaker plate for smooth 3 damage To install idle limiter cap refer to c be inspected and cleaned connection cause the idle completely If idle limiter cap obstructs proper adjustment corroded terminals indicate that wires vacuum could so screw down ew malfunctions b utor cap and coil so that terminals can prob following lem as required CHECKING DISTRIBUTOR CAP ROTOR AND CONDENSER wires should be removed from distrib for the items and correct the sc which in turn will tend to and DISTRIBUTOR loose connection Doing cable procedures inspection reference data adjusting Checking high tension California models For Do not attempt to a ADJUSTING CARBURETOR IDLE RPM AND MIXTURE RATIO applying load stabilize engine to engine in order to condition Engine hood should be open 4 Run engine for about 10 minutes at idling speed During this 10 proceeq as described i steps minutes 5 to 9 below 5 Remove air hose between 3 way 5 way connector for Cali connector Cautions a On automatic fornia models transmission T 11 equip shown in and air check valve Figure ET 17 Plug as the dis r Engine connected hose to prevent 12 dust from Connect Tune up air hose to air check valve entering To air check If valve 10 Repeat procedures increases engine speed the specified speed adjusting screw to readjust it with throttle speed for in step 9 can be carried out not following procedures Fig ET 17 Disconnect air hose from ojr check valve 6 Race engine 1 500 to 2 000 rpm two or three times under no load then engine for speed run minute at one idling step Adjust throttle adjusting until engine is at specified speed screw position it to for If Ignition timing rpm Non California California position idling speed engine adjust idle adjusting screw so that CO percentage is at specified level idling peed minutes proceed 5 to 9 below 5 D and make centage three times under is obtained specified 10 described in steps and modeis hose air air check to If engine speed increases the specified speed adjusting screw to readjust it with throttle IDLE LIMITER CAP Do not air check valve unless 1 as After If this unit is follows adjusting speed adjusting Sure that the tained in throttle check to be screws amount exhaust idle or of gases CO con meets the established standard 1 500 to 2 000 rpm 2 Install idle limiter cap in position sure that the adjusting screw further minute at one idling turn 1 8 rotation in the CORICH direction throttle Adjust that this idle limiter cap necessary proceed engine for speed 7 remove removed it is necessary to readjust it at the time of installation To adjust making adjusting engine speeds are as screw so indicated Carburetor stopper below 815 rpm Automatic transmission D in position 670 rpm at 650 rpm that Connect two or three times under no load then position sure 12 valve Manual transmission ldle limiter cap 3lSo T Repeat procedures as described in steps 6 7 and 9 above so that CO percentage is at specified level Check ing idle CO in step 9 can be carried out right after step 7 11 I 500 to 2 000 Race engine two or position 15 to 25 rpm Engine speed 10 rpm as this 5 way connector for Cali Race engine at tI 2 During Remove air hose between 3 way 750 rpm Automatic transmission in to Engine shown in Figure ET 17 Plug the dis connected hose to prevent dust from CO percentage Manual transmission tI 2 condition D in Run engine for about 10 minutes run At about 10 minutes after at without engine 6 120 650 rpm run minutes 2 000 entering Automatic transmission is at about load to engine in order fornia Manual transmission 9 good stabilize neces specifications 120 750 rpm 5 about connector D up that water temperature applying at This operation need not be carried at 1 600 Ian 1 000 miles service in at no load will be sure rpm 60 to 70 rpm Automatic transmission specifically recom Either driving vehicle or oper Make 4 out 750 100 warm screw hood should be open Check ignition timing adjust to specified not ating engine rpm 650 rpm sary The procedure is engine idle adjusting Manual transmission Wann up engine until water tern perature indicator points to the middle of gauge the Engine speed drops off 2 keep engine running 750 rpm Automatic transmission 8 below indicator points to the middle Further Manual transmission D may be used Turn clockwise until engine speed drops off connection 3 Engine speed in the Check carburetor pipes for proper mended 7 available right after 7 II If CO meter is engine best idle mixture is 815 rpm manual transmission models and at 670 rpm for automatic transmission models in D position Adjustment CO Idle adjustment without COmeter I described as in steps 6 7 and 9 above until no load CO per 8 Check ignition timing adjust it specifications if neces to the value required by This operation need not be carried out at 1 600 Ian 1 000 sary miles service 9 is At about 10 minutes after run adjusting at idling speed screw engine adjust idle until maximum rpm is obtained Fig ET 18 Setting idle limiter cap CHECKING CARBURETOR RETURN SPRING Check cracks throttle squarene necessary ET 12 ET031 replace s return or with spring for defonnation a new one if Engine CHECKING CHOKE MECHANISM that bimetal is out of order Refer or in Carburetor to Choke Tune up Section EF All engines cartridge type replaceable a use fuel filter as an as sembly plate and linkage 1 Check choke valve and mech anism for free operation and clean or if replace necessary A binding can result from on 2 petroleum choke shaft or from Check bimetal Index mark on bimetal gum formation damage cover cover CHECKING FUEL Hoses pipings connections setting is usually etc Check set at center of scale nections Note Always align the index mark bimetal mark cover on on with the center index fuel lines cracks and for loose con deterioration Retighten loose connections and re place any damaged or deformed parts choke housing Every day before starting engine depress the accelerator Pdal to see if choke valve is closed automatically 3 REPLACING FUEL FILTER If it fails to be closed the chances are @ LINES that link movement is unsmooth Check for water a ET011 contaminated filter and Fig ET 19 Fuel filler deposit EMISSION CONTROL SYSTEM CONTENTS ADJUSTMENT OF SET PRESSURE OF CHECKING CRANKCASE EMISSION CONTROL SYSTEM REPLACING BOOST ET 13 P C V CONTROLLED DECELERATION DEVICE VALVE AND B CD D ET 18 FILTER ET 13 CHECKING B C D D CHECKING VENTILATION HOSE ET 14 CHECKING AMPLIFIER CHECKING EXHAUST MANIFOLD HEAT CONTROL CHECKING SPARK TIMING TION Automatic transmission models only INSPECTION CONTROL CHECKING DELAY VALVE CHECKING ET 15 CONTROL OPERATING CHECKING B C DD CHECKING BOOST CIRCUIT ET 20 RECIRCULA ET 20 CONTROL SYSTEM EVAPORATIVE EMISSION ET 22 SYSTEM ET 23 ET 23 INSPECTION FLOOR TEMPERATURE ET 23 WARNING SYSTEM CONTROLLED DECELERATION DEVICE ET 17 B CD D I ADJUSTMENT CLEANER CHECKING CATALYTIC CONVERTER ET 15 CLEANER PRESSURE OF ET 20 PUMP AIR EXHAUST GAS E G R ET 14 AUTOMATIC TEMPERATURE AIR Manual ELEMENT ET 14 CHECKING AIR REPLACING CONTROL SYSTEM SPARK ET 20 VALVE transmission models ET 14 VALVE SOLENOID ET 23 INSPECTION WITH FUNCTION TEST CONNECTOR ET 17 CHECKING CRANKCASE EMISSION CONTROL SYSTEM with the following method REPLACING P C V VALVE AND FILTER Check P C V valve in accordance noise will be through the valve is finger is placed properly working ET 13 a hissing should heard the valve and With engine running idle remove ventilator ose from P C V valve If at be felt a as air strong immediately over passes vacuum when valve inlet a Engine Tune up 2 With engine check E F E stopped visually system for the following items 1 CoOl 2 Oil level gauge 8affle pia te 3 Flame arrester 4 Filter 5 P C V valve 6 Steel net 7 Baffle plate Thermostat spring for dismount I ing 2 Stopper pin for bend and count weight stop position for dislocation er 3 heat Check control valve for malfunction due to break of key that locates counterweight to valve shaft 4 Check axial clearance between heat control valve and exhaust mani fold mm o 1fiI Fresh air Fig ET 20 Crankcaae emi 3 VENTILATION full HOSE 1 hoses Check and hose connec tions for leaks them out with If any all compressed hose and blow hoses cannot or flaking Rotate heat control valve shaft with a fmger and check for binding between shaft and bushing in closing and opening operation of heat control control8 valve If any binding is felt in rotating operation move valve shaft in the position counterweight moves further clockwise exceeding the position described in 1 1 above and stops again coming into contact with Disconnect 2 6 rotation direction several times If this When heat control valve is in the open 5 1 Check welded portion of heat valve and valve shaft for any indication of crack tem ion to control EC716 Blow by gas CHECKING 5 Correct clearance is 0 7 0 028 to 0 059 in operation condition does not binding correct it is due to seizure between shaft and bushing and exhaust mani fold should be replaced as an assem bly stopper pin air free of be obstructions replace Ensure that flame arrester is surely inserted in the hose cleaner and rocker between air ct t cover C CHECKING SPARK CHECKING EXHAUST EC245 MANIFOLD HEAT CONTROL VALVE Fig Run engine and ET 21 1 Counterwe ht 2 3 Stopper pin Heat control valve Cold operation of weigh t visually check counterclockwise until into contact with stopper to Counterweight and clockwise ambient This moves engine warms up temperature goes higher discharge causes pressure of exhaust counterweight ward clockwise gases to move down VALVE only valve delays vacuum spark during rapid acceleration it also cuts off the vacuwn spark advance imme iately upon deceleration The valve is designed for one way opera advance as When engine speed is increased on non transmission models models EC246 around exhaust manifold 2 automatic Automatic transmission pin installed gradually system is installed California SPARK DELAY it comes exhaust manifold down This counte counterweight to see if it operates properly For some time after starting I engine in cold weather counterweight turns TIMING CONTROL SYSTEM 1 2 3 Counterweight Stopper pin Heat control valve Fig ET 22 Hot operation of counter weight ET 14 tion and consists of a la valve restrictor and one sintered way umbrel steel fluidic Tune up Engine CHECKING Distributor side Brown AUTOMATIC TEMPERATURE CONTROL AIR CLEANER 1 Air cleener element Viscous paper type air cleaner ele does not require any cleaning ment opera tion until it is replaced periodi cally Brushing will cause lOne way umbrella valve 2 Sintered metal disc should EC284 Fig ET 23 Spark delay valve installing this valve ensure properly oriented This valve be replaced periodically Refer When that it should to Maintenance Schedule Remove 2 Blow air valve spark delay through port on carbure then through the other port tor side on distributor side Spark delay valve is in good condition if when finger is side placed over port on distrib 3 If a considerable air flow resist is felt at port on distributor side in step 2 above and if the condition of distribut0 Yl EC278 From spark delay valve carburetor r l and mixture conducted be For reo placement interval of air cleaner ele ment refer to Maintenance Schedule Hot elr control system 2 I ance To carburetor never INSPECTION ajr flow resistance is greater than that on the other side See Figure ET 25 I and result in enrich clogging of ment blasting operation or is questionable dip In find warm ou t system it is difficult to wealher malfunction of hot air control In cold weather however malfunction of air control valve d um to hose between intake manifold and bility dura motor and insufficient vacuum of air con trol valve will cause control opera and result in engine automatic insufficient tion for intake air disorder including hesitation of engine opera port on carburetor side into a cup fIlled with water Blow air through the I other port Small air bubbles should 2 Increase in fuel consumption appear 3 Lack of power Stall or tion Fig ET 24 Operation ofspark delay These value e disconnection or deterioration of vacu phenomena reveal malfunc tionof hot air control system phenomena air control should system check hot occur as If these described in the following before carrying out inspec tion of carburetor 2 1 Vacuum hoses I Intake I tor sensor Carburetor side um connec to temperature 3 way connector to idle com pensator Distributor side manifold to 3 way 3 way connector temperature sensor to vacu motor EC279 Fig ET 26 Checking spark delay ualue 1 lr EC346 rJmlL Fig ET 25 Checking spark delay value Note or Check that curely 2 Be careful to avoid entry of oil dirt into valve ET 15 vacuum connected hoses in correct are Check each hose for cracks distortion hose clip se position for condition or Engine Note Vacuum hose Tune up sensor mark on side of the mark is for grad ually opens to under hood air inlet side as engine warms up When en the top of for intake manifold L R side of Nissan Check that air control valve 3 R R position vironmental temperature around perature sensor is low spend vacuum rootor time for engine warming tern more operation up facilitate smooth opera tion of air con trol valve to If the above test reveals any prob operation of air control lem in the EF217 Fig ET 28 lmpecting value position temperature sensing 2 2 Vacuum motor I engine stopped With Correct pC6ition of air control valve disconnect fresh air duct Place cleaner inlet is the reverse of paragraph I above control valve is in mirror at a pipe valve carry out the following test Remove air cleaner cover as the end of air shown and check to see if air control valve is in correct position Air position correct if Set 4 element of ther thermometer to a mistor or position where tempera ture around sensor can be measured In this case fix wiring of under hood air inlet is closed and hot thermistor air inlet is open tom surface of air cleaner with adhe With hot air inlet is open posi 3 tion descnbed as above in and cut of air from this condition valve paragraph 2 fingers hose with pinch vacuum vacuum hose In thermometer or on the bot tape in such a manner that the set position of temperature sensing ele ment will not be affected by airflow sive Then install air cleaner cover check that air control the maintains de condition 2 scribed in step for more than 30 seconds and that hot air inlet is open If actuates the air diaphragm spring control valve spring force by its to open under hood air inlet within 30 seconds replace vacuum assembly since this EF213 Fig ET 27 Impecting lJalv position from motor as an may be resulted air leak at vacuum motor dia phragm EF221 Fig ET 29 Checking 2 3 Temperature sensor Check temperature temperotur e ensor sensor for func tion to Air control valve is in correct posi tion if its under hood air inlet is open and hot air inlet is closed Check air control valve linkage for condition 2 Disconnect vacuum hose to vacuum hose vacuum and the inlet motor to apply Vacuum plied by breathing motor connect inlet another vacuum to can be ap in the hose end as shown Place a mirror at the end of air cleaner inlet pipe and check to see if air control valve is in correct position by proceeding as follows Be sure keep engine cold before starting 5 Carry steps 1 control valve With engine off check air control valve for condition In this hood air inlet is open Use inspection 2 2 1 as a mirror for above Start engine and 2 under case keep idling Immediately after engine starting check air control position as for correct described above case correct valve is the valve position of reverse inlet is open ET 16 this air control of 2 2 1 hood air inlet is closed In under and hot air I out test 2 hood air and test as described in When air 3 above begins inlet side to open to under severa minutes after engine starting read the indica tion of thermistor or thermometer If reading falls within the working tern perature range of temperature sensor the sensor ceeds the is normaL range with new one Note Before If replace reading the ex sensor replacing temperature check idle compensator as 8 EF described in Section EF page sensor Engine If voltmeter reading is OPERATI NG PRESSURE Tune up zero for disconnected connector OF solenoid valve BOOST CONTROLLED DECELERATION DEVICE B C D D 2 With 41 or inhibitor 2 D or ADJUSTMENT CHECKING a C D D CIRCUIT WITH FUNCTION TEST CONNECTOR erly If ohmmeter reading is 32 ohms or above check for poor connection inhibitor switch switch R Refer to of connector OFF @ and Figure ET 31 If ohmmeter reading is 25 ohms or below circuit is functioning prop faulty B C D D noid valve or inhibitor position check for resistance between @ check faulty 3 sole relay If by above checks faulty part unit is located and tested or should be removed it again If necessary replace models Manual transmission Check for continuity between @ and@ at a speed of zero km Refer I Figure to ET 30 BC D D circuit functioning is l properly if continuity exists and volt meter reading is 0 volt d c in step 2 E below for 1 switch amplifier detecting speed B C D D solenoid valve or Check for Ignition key 2 Fuse 3 Amplifier Speed detecting Above 10 mph Below 10 mph 4 If continuity does not exist check disconnected connector and or faulty 2 r switch OFF ON 5 Function test connector 6 B C D D solenoid valve of voltage presence @ and @ at a speed of more than 16 km h 10 MPH Refer to across Figure EF711 ET 31 Fig ET 30 B C D D circuit with function tedconnectoT Manual transmission modela Conduct following this test by one of the two methods iRaising up rear axle housing with stand 2 Chassis dynamometer test If voltmeter reading is 0 volt at speed MPH of more than circuit is 16 km h functioning @ a 10 prop erly If voltmeter reading is not 0 volt check for disconnected connector burned fuse BC D D solenoid valve faulty amplifier or speed detecting switch 3 If by above checks faulty part unit is located 1 Ignition key 2 Inhibitor switch or 3 it should be removed 4 and tested again If necessary replace Automatic transmission 5 N P I 2 positions ON D R positions OFF D C D D solenoid valve Function test connector Inhibitor relay EF712 models I or With inhibitor switch ON P position voltage across UN Fig ET 31 and @ Refer to Figure ET 30 If voltmeter c d reading BC D D is circuit 12 volts is func tfst connfctor Automatic transmiMion modtla check for presence of @ Checking B C D D circuit with function tioning properly ET 17 r Tune up Engine ADJUSTMENT Refer to the idling setting Idling Adjustment in page ET II OF SET PRESSURE OF BOOST CONTROLLED DECELERATION DEVICE it Manual transmission 750 rpm is unnecessary to ad Automatic transmission just the B C D D however if it should become necessary to adjust it the procedure is as follows in D position 650 rpm 1 4 Run the engine under no load Increase engine speed to 3 000 to Prepare the foUowlnB tools I Tachometer the to measure gine speed while idling and en a screw driver 2 Note A connecting pipe qui k response type such gauge Bourdon as recommended a boost type is type s mercury manometer should not be used To properly pressure I 3 500 rpm valve 5 A vacuum gauge proceed Remove set as models Idling engine speed B CD D Generally california Non item the B C D D then quickly close throttle At the time the manifold vacuum ET037 to 600 above and abruptly 23 62 inHg mmHg then gradually decreases or r the level to idling 6 Check that the BC D D sure is within the specified set pres pressure set follows the harness Specified of solenoid and valve screw e Cover California models pressure increases set at Adjusting 2 0 pressure 760 mmHg m sea 30 inHg level atmos 1 Adjusting nut Lock spring 2 EC692 pheric pressure TO D D solenrod Manual transmission VT FJ 510 to 550 mmHg 20 1 to BC D D 1 Fig ET 34 Adjusting Bet pressure solenni valve harness 8 7 inHg 21 Automatic transmission 490 to J turn the 20 9 inHg correct 10 Note When y pressure in EF262 For Connect rubber hose Figure IT 36 from the pressure and altitutde sion model vehicle is located at an altitude of 1 000 m 3 280 ft the between gauge and intake manifold as specified shown set for B C D D preSsure 445 mmHg 17 5 inHg Race If it is higher than the set level turn the adjusting screw counter clockwise nut or adjustment clockwise until is made screw nut vacuum gauge Note When type California higher than the nut 3 Warm up the engine until it is heated to operating temperature Then adjust the engine at normal in or out place Always erly BC D D turn with lock set lock to prevent changes sure In for set this case to The engine to idling speed pressure is pressure of the the engine road test must be 2 chassis or or adjusting the accelerator spring vehicle spring in prop in set pres to 64 to 80 krn h in in matic transmission top gear manual position auto D and then pedal decelerate and releasing letting the After doing this check whether the B C D D set pres sure is at the predetermined value or not ET 18 necessary B C D D 40 to 50 MPH type models does not fall negative idling erating the vehicle adjusting is drop not transmission Fig ET 33 Connecting speed it dynamometer or 3 by raising up rear suspension member on a stand accel California models Adjusting nut until and check for pressure of the B C D D labored by I Non California models Adjusting or reduce the negative idling pressure of the manifold to lower than the set speed will 7 engine idling speed to when the correct the screw is made When the engine if a manual transmis example adjusting adjustment adjustment If engine speed cannot be decreased to idling when checking B C D D set pressure proceed as follows of the given location solenoid valve vacuum set pressure find the specified set atmospheric g ET 32 Removing harneS5 of F 2 checking the of B CD D ri and check for If it is lower than the set level 9 530 mmHg 3 to 19 Race the engine adjustment Engine Tune up Vacuum gauge Vacuum gauge Vacuum gauge Intake m dJi 1 2 I Road te t Raise 3 Otassis dynamometer up rear housing by stand ET133 Fig ET 35 Testing mmHg axle set pressure inHg inHg of the B C D D mmHg 30 24 750 600 29 23 28 22 700 550 27 21 26 20 650 500 25 a 19 a Co 11 1 Co v 24 g 8 Co 18 600 450 0 E 0 23 17 22 16 550 400 2 15 0 20 14 500 350 19 13 300 1 o 1 000 2 000 3 000 4 000 5 000 6 000 ft Altitude o 0 5 10 5 1 2 0 km EF55B Fig ET 36 Changes in set pressure uersus changes in atmospheric pre6Sure and altitude ET 19 r Engine 3 CHECKING B C D D SOLENOID VALVE If Turn on Do not start engine key engine 2 Ensure when that solenoid valve clicks intermittently click is heard solenoid valve a is normal 4 I Tune up electrified If a click is for continuity not with heard at all a check circuit tester If discontinuity is detected replace sole naid valve as shown in Figure ET 37 CHECKING AMPLIFIER Manual transmission EC323 Fig ET 39 Repl4cing air cleaner models element The of the as 1 amplifier is installed at the rear speedometer To check proceed follows Set circuit tester in range IA min full scale probes of tester c d ampere connect test shown in Figure as ET 38 Do not confuse Fig ET 37 Checking solenoid l uolV line with positive negative line CHECKING EXHAUST GAS RECIRCULATION E G R CONTROL SYSTEM Checkln I E G R control system In Ita mounted condition l I M ake E G R M wipe 1 o L I of 2 J f T Ignition key Amplifier Speed detecting 2 EF264 3 4 B Make not inspect harnesses and con replace warning lamp Then ignition switch to ON position nectors or switch turn C D D solenoid valve and check the I has make Ensure that tester pointer deflects when ignition key is turned on 4 If tester panter does not deflect when solenoid valve and speed detect ing switch circuits are functioning properly amplifier is faulty ELEMENT check harnesses cleaner from hoodledge Air cleaner element and air cleaner lower body built into a unit construction air cleaner element and lower an assembly are If warning tector lamp drive or does lamp not lamp light and de connector counter detector replace warning drive counter if necessary Replace body as Note Operation lamp ET 20 warning that E G R warning lights then detach air that E G R has attained 50 000 counts sure REPLACING AIR PUMP AIR CLEANER Remove air hose 50 000 reached not sure If odometer of detector drive make 3 items does not light counter posi following If odometer of detector drive 2 ON that E G R warn sure light lamp to proper If E G R warning lamp does tor runs counts Turn ignition key check engine running warning system for counter tion fe ing lamp light when ignition switch is turned to START position starter mo Fig ET 38 Checking amplifiu 2 inspection broken With E G R function 1 or place A jt system cracked are check of If necessary oil to facilitate away If hoses II p thorough visual a control is as of E G R follows warning Tune up Engine Ignition Switch Position ON START Detector Drive Counter a After completing EG R control system inspection be sure to 620 models um engine inspect vacu valve for normal operation When engine coolant tempera ture EC254 is low Make Fig ET 41 Checking thermal that E G R control valve sure operate when engine speed is increased from idling to 3 000 to vacuum valw does not and Canada With running E G R control valve and thermal except those bound for California 3 With 4 I applies ON OFF to counter to zero b This item 50 000 counts of odometer of detector drive reset Above 50 000 counts ON Warning Lamp E G R Below stopped engine inspect E G R control valve for any indication of binding or sticking by movirig dia phragm of control valve upwards with 3 500 rpm Place fingers on the diaphragm of E G R control valve to check for valve operation If any difficulty is encountered in judging the condition of any compo check nent during above inspection the questionable component independ ently as follows fmgers E GR control valve Dismount EG R control valve from engine I Apply control to E G R vacuum valve referring to the following figure If the valve moves to full position it is normal EG R control valve will remain open for more than 30 seconds after vacuum has cut off EC253 Fig ET 40 Checking E G R control valve 0 r11 hC J 2 When ture is I engine coolant tempera control valve that E G R control valve Increase engine speed from idling to 3 000 to 3 500 rpm high Make sure operates when engine speed is in creased from idling to 3 000 to 3 500 rpm Place diaphragm of to check for valve 2 If E G R the control valve operation Disconnect one as follows end E G R control ofvacuum hose connect ing thermal vacuum valve to sure that valve is open vacuum is thermal at the end 2 Visually valve for check damage E G R wrinkle or control deforma tion If vacuum is weak or all vacuum thermal is present trol valve vacuum con ET 42 Checking E G R control VGlve and that carburetor present hose replace Fig vacuum E G R control valve side ofvacu urn control valve does not operate check valve side fingers E G R on Make ET152 EG R not present replace at valve If E G R 3 Clean E G R compressed matter port ET 21 the seating control valve with from air and around surface a remove the of brush and foreign valve and Engine Tune up little CHECKING EVAPORATIVE EMISSION CONTROL SYSTEM until mmH20 5 the Shut 6 After 2 5 Cleanil E G R control l Fig ET 43 Jlue lJ 8 Checking fuel tank vapor liquid separator and vapor vent line I all Check the measure When does filler cap height the zero in a short time 9 If the not close should drop to height does not drop to filler cap is zero in a short time when and fuel tank hoses minutes height of the liquid in the manometer 7 Variation of height should remain with 25 0 98 inH20 l20 mm completely EC350 and completely cock leave it unattended Vapor Rnes and fuel vepor control valve r 368 becomes pressure 14 5 inH20 roler cap removed it is the cause of a stuffy hose line vapor vent canister to vapor connecting carbon 2 Disconnect the liquid separator Thermal VBCuum 3 valve Connect a manometer and Dismount thermal vacuum valve from engine lent a cock charge cock way 3 or an a equiva the end of to the vent line Supply fresh vent line through air into the vapor connectoT 36 4 Note Before dismounting gine coolant from engine Apply connector way 3 vacuum drain e the cock little In case the vent line is Note the breathing in fuel stuffy tank is not in causing thoroughly made thl suffICient delivery of fuel to engine or vapor lock It must therefore be repaired by or replaced to thermal vacuum way 3 valve and check to be sure that ther mmH20 14 5 inH20 valve opens or closes in response to engine coolant tempera mal vacuum lt U iYCl i i1 lurt valve should open of 57 to 630C 134 temperature 1450F completing the vacuum Thermal at to a vacuum c Do not aUow water to inside the thermal vacuum s @ passage Note W I get Carbon canister valve r EC786 Fig ET 45 Checking evaporative emission control By Checking carbon canister purge control valve I Check for fuel vapor leakage in the distributor VC line at diaphragm of carhon canister purge control valve To check for leakage proceed I L as I follows 1 line Disconnect 242 EC Fig ET 44 rubber hose at valve the Tconnector Inhale rubber hose air into the running carbon canister and lChecki thermallXlCuuml in between T connector and carbon canister 2 tem opening to VC ensure of ET349 hole in that there Fig ET 46 Checking carbon cani ter purge control valve is no leak ET 22 Tune up Engine 3 If leak remove top contiol valve and purge check for dislocated or cmcked dia cover there is a from phragm phmgm retainer If kit ance is felt replace if or no as an cap resist assem 8 Adjust idle adjusting screw until specified CO percentage is obtained Refer to page ET 12 bled unit 9 necessary replace dia which is made up of a diaphragm If valve is clogged 3 Repeat the adjustment process as described in steps 5 to 8 above until specified CO percentage is obtained r and spring Adjustment Note in step 9 should be u made ten minutes after engine has warmed up I 10 @ ET369 49 ET Fig Fuel filler cap Cover 2 Diaphragm 3 Retainer 4 Diaphragm spring CHECKING CATALYTIC control valve Element contaminated element be can removed at the on cap and air connect Visually check condition of all component parts including hoses tubes body and wires Refer to replace if necessary Inspection of A I S on page EC 17 speed pleted After step 12 has been com wait for one minute before making CO percentage measurement 14 If CO percentage measured in 13 is less than 3 0 the catalylic step converter is normal If CO percentage measured in recheck IS A 3 step 13 is over 0 air valve Then and replace check Whether catalytic converter is or engine for about four 15 Catalytic converter mal screw Warm up minutes at 2 000 rpm under n load 13 Measure CO percentage at idling INSPECTION vehicle speed increases readjust it specified speed with throttle ad 12 Preliminary inspection bottom of canister installed load sure Remove justing CONVERTER Carbon unlster filter a 2 000 no If idling to ET 47 Carbon caniater purge Check for to three times under hose to air check valve ET350 Fig or that specified CO per centage is obtained I1 1 engine 1 500 Race rpm two and make not nOf be checked by ob in CO percentage can serving variation The checking procedure Apply parking is as follows brake Shift gears into Neutral for manual transmission and or Neutral steps 12 and 13 If CO percentage is still over perform inspection 16 03 in step 15 catalytic converter is malfunctioning Replace catalytic con verter for automatic Park transmission 1 Visually check catalytic for damage Fig ET 48 Replacing carbon canister filter 2 or relief valve operation Remove fuel filler cap and functions properly I see it connector and air check valve companied valve is in by good slight valve resistance ac indicates hose to Plug that mechanical condition the prevent dust TEMPERATURE WARNING SYSTEM from entering Refer to page ET 12 3 Check carburetor pipes for proper INSPECTION connection Floor warning temperature 4 system 5 Warm up engine sufficiently Race engine 1 500 to 2 000 rpm two or three times under no load Wipe clean valve housing and have it in your mouth 2 Inhale air A CHECKING FLOOR Remove air hose between 5 way disconnected Fuel tank vacuum converter cracks engine for speed run 6 Adjust one minute at throttle until engine attains to Refer to page ET 12 7 sary with valve clicks to page ET 10 adjust it to idling adjusting screw specified speed Check ignition timing Note also that by further inhaling air the resistance should be disappeared into Neutral brake Shift gears for manual transmission and Neutral or Apply parldng then 1 Ensure warning If specifications neces Refer that floor lamp lights If not check tern perature when switch is turned to the bul bs ET 23 for automatic Park transmission lamp S ignition position for burned Tune up Engine Replace bulb if bulb back wireis Repair or replace if necessary 2 Be sure that floor temperature is below 800C cool carrying out the 1760F before following procedure 1 Remove rear seat 2 Ignition switch is turned to the results do not floor 3 trace ignition switch to IGU position Ensure that is burned ou t If bulb is not burned tem perature the above reo warning lamp goes out 4 Heat surrounding areas of floor temperature sensing switch with a proper heater to ensure that floor glows when temperature warning lamp floor is heated to lh specifications as shown in the table below When floor temperature lamp 118hts warnln8 Check Temperature sensing switch satisfy place the floor temperature relay floor temperature warning lamp Temperature warning lamp Floor temperature I Open short circuit in wiring or harness Contact close 2 Off Below 1050C 22IOF the Check fuel system with regard to following items Refer to Inspec tion of Fuel Contact open On Above 1050C 2210F Floa t level 2 Choke 3 Normal fuel supply system ry and Note heating floor tempera sensing switch directly Avoid ture If lamp does not cinq sen the wiring back to relay following step wire s circuit tester Referring normal or Repair check the or replace Accelerator pump Power valve 6 BC DD 7 Fuel strainer 8 Air cleaner switch 3 by a proper heater rela To check floor temperature relay remove it and proceed as follows Check for continuity and@ Continuity disconnect floor temper position anf sensing connector The lamp ature If not check floor 2 @ continuity between Continuity should not exist Apply to a ensure 12 volt doC that 2 Distributor 3 Ignition coil High tension code Spark plug 4 4 Check idle CO to Inspection CO Refer Adjust D Note across@and continuity adjustment of Idle roeoC should exist Check for IG D Ignition System IgnItion AMI 5 should exist for continuity between of I between@ @ Continuity Check and@ Turn ignition switch to the Check ignition system with regard Refer to following items the Inspection 1 Prima secondary 5 to and on floor following Floor temperature The floor temperature sensing switch may be heated through the should remain the temperature relay if relay is trace wire s back to ignition Repair faulty wiring Note 3 to trace if necessary floor with reolace tem Vitch S perature sensing switch If continuity does not exist 3 a glow check floor temperature sensing switch connector for continuity with a circuit tester If continuity should exist after heated surrounding areas offloor tern wnTP rv 4 temperature relay for continuity System I Even if there is with exists come between D and@and that continuity does not between D and @ If test on a lower nothing wrong warning lamp may on if vehicle is being driven steep slope continuously in gears at high engine speeds engine 4 03 UJ GJO To floor temperature warning lamp 2 From S position GOt position 4 From ignition switch r I 141 3 From 5 To floor temperature sensing switch Fig ET 24 50 ET EC343 Checking floor temperature relay Engine Tune up SERVICE DATA AND SPECIFICATIONS Ignition timing and idling Manual transmission degree 120 B T D rpm 100 B T D jC 750 j750 C l20B T D j650 C Non Calif models California models Automatic transmission in D degree position rpm Valve clearance Cold Hot Intake mm in 0 20 0 008 Exhaust mm in 0 25 0 010 Intake mm in 0 25 0 010 Exhaust mm in mm in 0 012 30 0 Belt tension Fan Air pump mm Air coo compressor mm Pressure kg lb 8 to 12 315 0 to in 8to 12 315 0 to 0472 in 8 to 12 315 0 to 22 is 10 472 0 0 472 applied pressure at 350 rpm Compression Standard kg cm2 psi 12 0 171 Minimum kg em2 psi 9 0 128 kg em2 psi 09 kg cm2 Psi Radiator cap relief pressure 13 Cooling system Leakage testing pressure Battery specific gravity at 200C 1 6 23 1 26 680F Distribu tor Point gap mm in 0 45 to 0 55 Air gap mm in 0 2 to Dwell angle degree 490 Condenser capacity IF 0 20 to 0 24 Condenser insulation resistance Mil 5 0 018 to 0 022 4 0 008 to 0 016 0 to 550 Spark plug Gap mm 0 8 to 0 9 0 031 to 0 035 in Breaker points type 10 to 1 0 039 to 0 043 Transistor ignition Checking CO percent at idling speed type No air Manual transmission model rpm 21 1 750 Automatic transmission model rpm 2 1 1 650 Adjustment of operating pressure of B C D D BC D D set pressure Manual transmission Automatic transmission mmHg in Hg mmHg in Hg ET 25 510 to 550 20 1 to 21 7 490 to 530 3 to 19 20 9 r Engine Tune up A TC air cleaner Operating temperature OC OF 30 to 54 86 to 129 Tightening torque Cylinder head bolts 1st turn kg m ft b 4 0 29 2nd turn kg lll ft lb 6 0 43 3rd turn kg m ft lb Manifold nuts kg m ft lb 12 to 1 6 8 7 to 116 Carburetor nuts kg m ft lb 0 5 to 10 3 6 to 7 2 Spark plugs kg m ft lb 1 5 to 2 0 ET 26 5 to 8 5 6 47 to 61 II to 14 Engine Tune up TROUBLE DIAGNOSES AND CORRECTIONS Condition Probable CANNOT CRANK Improper grade ENGINE OR SLOW CRANKING oil Replace with proper grade oiL Discharged battery Charge battery Faulty battery Replace Loose fan belt Adjust Malfunction in charge system Inspect Wiring connection loose Trouble Switch When starting circuit in Correct Faulty ignition switch Repair or replace Faulty starler Repair or replace motor shooting procedure on starting on Corrective action cause the starting motor with light circuit ON light goes off or dims considerably a Check battery b Check connection and cable When light c Check starter motor a Check wiring connection between battery and starter stays bright motor b Check ignition switch c Check starter motor ENGINE WILL CRANK NORMALLY BUT WILL NOT START In this case the following trouble Ignition system causes may exist but in many cases ignition system or fuel system is in trouble in trouble Fuel system in troubk Valve mechanism does Low not work properly compussion Trouble shooting procedure Check spark plug firstly by following procedure high tension cable from one spark plug Disconnect about 10 mm 0 39 in and hold it from the engine metal part and crank the engine Good spark occurs Check spark plug ignition timing b Check c Check fuel system d Check No spark cylinder compression occurs Very high current Check the current f10 in Inspect primary circuit for short Check breaker poiIit sistor ignition system ET 27 primary circuit operation except tran Engine Condition Probable Low or no Tune up Corrective action cause current Check for loose terminal or disconnection in primary circuit Check for burned points Ign tion system out of Burned distributor point Repair Improper point Adjust replace or order gap Faulty condenser Replace Leak at Clean or Faulty spark plug aean adjust plug gap Improper ignition timing Adjust Faulty ignition coil Replace Disconnection of high tension cable Replace rotor Loose cap and rotor connection disconnection or in Repair replace or or replace replace primary circuit Fuel system out of order Lack offuel Supply Dirty fuel strainer Replace Dirty Fuel pump will not Clean properly Repair or replace Check and Improper adjustment Correct of float level adjust Improper idling Adjust Dirty clogged carburetor Disassemble and clean breather pip Repair and clean or Malfunctioning comp ion work Carburetor choke will not work properly Clogged Low fuel pipe clogged or an ti of fuel tank dieseling solenoid valve sparle plug tightening Incorrect or faulty Check for loose terminal or wire harness to normal Tighten gasket Improper grade engine oil or low viscosity Incorrect valve clearance Compression Sticky Weak Sticking or Pour valve springs leak at cylinder Replace head gasket damaged piston ring Worn piston ring Trouble Remove cyljnder Correct or damaged Compression with proper or grade or replace gasket oil Adjust leak from valve seat valve stem or Replace torque head and replace valve lap valves valve and valve guide springs Replace gasket Replace piston rings cylinder Overhaul engine ooting procedure the engine oil from plug hole and then measure cylinder compression Compression increases Compression does not Malfunctiong cylinder change Compression leaks or head gasket or piston ring from valve cylinder head Except transistor ignition ET 28 system Engine Probable Condition Tune up Corrective action cause IMPROPER ENGINE IDLING Clogged order Incorrect idle Clogged or Clean damaged carburetor jets Fuel system out of Adjust adjustment manifold element Replace air cleaner filter Damaged replace or gaskets or carburetor Replace gasket or insulator insulator Adjust Improper float level adjustment Loose air hoses or air fuel mixture hoses of Check for loose connections carburetor Malfunctioning carburetor choke Check and Malfunctioning anti backfire valve Check for loose connection of vacuum hose Malfunctioning automatic temperature con adjust Check A r C air cleaner trol air cleaner Check for connection Inoperative idle compensator hose or Carbon canister purge line hose damaged disconnected or tor replace Previously mentioned compression Others Connect or of idle compensator idle compen Repair Stick E F E valve shaft Low replace Incorrect valve clearance Adjust Extremely low revolution Adjust Faulty malfunction of the ignition system spark plug high tension cable breaker Replace point ignition coil etc Adjust Incorrect basic ignition timing Malfunction of choke valve Malfunction of vacuum or Adjust linkage motor sensor or Check for loose hoses hoses of air cleaner ponents if necessary Incorrect idle adjustment Adjust Clogged Malfunction of idle compensator of air com idle speed Replace air cleaner fdter Replace system air cleaner fdter Replace cleaner Malfunction of E G R control valve Loose manifold and High engine idle speed cylinder head bolts Clean or replace Retighten bolts Dragged accelerator linkage Check and correct accelerator Incorrect idle adjustment Adjust Malfunction of B CDD system Check for loose linkage idle speed vacuum hose and harness connections Adjust Malfunction of speed switch and harness Check or replace if necessary for loose replace if necessary ET 29 connections Repair or Engine Probable Condition Tune up Corrective action cause ENGINE POWER NOT UP TO NORMAL Previously mentioned Low compression Ignition system out of order iSnition Incorrect Adjust timing Damaged spark plugs Clean adjust Worn distributor points Dress or or replace plull points replace Also check condenser Fuel system out of order Malfunction of choke system floating Clogged fuel pipe Dirty clogged fuel strainer or or lst Adj valve Clean Replace Repair or replace Fuel pump will not work properly C10ssed Disassemble and clean carburetorjets Check and replace Malfunction of altitude compensator Air intake system of order out CIOJBed Ail Replace air cleaner from inhaling manifold gasket or element Replace gasket carburetor gasket Emission control Overheating Malfunction of E G R valve Check and replace Stick E F E valve shaft Repair Insufficient coolant Replenish Loose fan belt Adjust Worn Replace or oiled fan belt Inoperative Replace thermostat Replace Worn water pump Clogged or Flush leaky radiator Replace Ail in Retighten cooling system oil Replace grade Clossed Others carburetor lean mixture Connect Inoperative thermostat Replace each part of cooling system with proper grade oil Improper octane fuel Replace L tire pressure Inflate to brake Adjust Clutch slipping Adjust Dragging replace Overhaul carburetor Disconnected altitude compensator hOlle j or Adjust Incorrect ignition timing cooIing repair Worn radiator filler cap Improper engine O fan belt with specified specified octane fuel pressure Except transistor ignition ET 30 system Tune up Engine Probable Condition Corrective action cause NOISY ENGINE Car knocking Overloaded engine Use Carbon knocking Disassemble in driving right gear and head cylinder remove carbon Mechanical Timing knocking Adjust ignition timing Fuel knocking Use specified octane Preignition misusing of spark plug Use specified spark plug This strong dull noise increases when engine is accelerated To locate the place cause a misfire on each cylinder If the noise stops This is caused fuel knocking Crankshaft bearing Imocking by the misfire cylinder generates the this or by unevenly bearings and worn or adjust or damaged bearings crankshaft worn change Renew crankshaft Check lubrication system noise Connecting rod bearing knocking This is a little crankshaft noise than the higher pitched and Imocking is accelerated also Same as the case ofcrankshaft bearings increases Cause a misfire engine noise deminishes and if the cylinder almost completely this crankshaft bearing when on each generates the noise Piston and cylinder noise Piston pin noise This revolution of engine and which decreases as is warmed up this noise is caused by turn will cause a lower out engine piston and cylinder cause a misfire This noise is heared at each place cause This noise damaged a misfire piston on earings or by the consumption oil Overhaul engine highest and To locate the by worn uneven This may or cause a wear on piston pin or piston pin hole Renew each cylinder caused be may excessive put power and of place To locate the each cylinder on lowest dead end of Water pump noise of may cause an abnormal wearing which in cylinder and lower compression When you hear an overlapping metalic noise which increases its magnitude with the piston Replace and piston pin assembly water pump with a new one surface of sliding parts Air pump noise Damaged air pump Others An improper Repair or replace adjustment of valve clearance Adjust Noise of timing chain An excessive end Noisy Wear Note play on clutch This clutch is will renew main bearing Repair Renew bush and pilot bushing noise the tension of chain Disassemble engine and crankshaft E F E valve shaft on Adjust be heared disengaged ET31 when adjust drive shaft Tune up Engine probable Condition Corrective action cause ABNORMAL COMBUSTION backfue afterflre run on etc Improper ignition timing Fuel system Improper ignition timing Adjust ignition timing Improper heat range of spark plugs Use carburetor Damaged out of manifold or gasket specified spark plugs them with Replace new parts backfue afterfire order Disassemble carburetor and check it Cloled carburetor jet l Improper Uneven Run idling Others etc the level and check needle valve Adjust on B CD D Improperly adjusted Faulty cylinder head Adjust function of the float set pressure Adjust Malfunction of anti dieseling solenoid valve Check or replace Malfunction of Adjust choke auio Adjust valve clearance Improperly adjusted Excess carbon in combustion chamber Remove head and get rid ofcarbon Damaged valve spring backfire afterflre Replace a new one Malfunction of A T C air cleaner Check for loose vacuum it with hoses Replace if necessary Inoperative backfue ariti Loose oil drain plug Replape valve EXCESSIVE OIL CONSUMPTION Oilloak Tighten it Loose or damaged oil pan gasket Renew gasket or tighten it Loose or damaged chain cover gasket Renew gasket or tighten it Worn oil seal in front and Loose or damaged locker rear of cover crankshaft Renew oil seal Renew gasket gasket or tighten but it not too much Improper tightening Renew of oil filter gasket and tighten it with the proper torque Loose lo oil Excessi consumption or Cylinder damaged oil pressure switch Renew oil pressure switch and Overhaul pioton wear Improper location of piston ring reversely assembled piston ring piston ring groove Fatigue ofvalve oil seal and ring Inadequate quality Engine renew it piston Remoun t piston rings Repair or renew Renew piston of engine oil piston and cylinder and piston ring seal lip with Renew valve or guide Replace lip Worn valve stem Others or and tighten Renew rings Damage piston rings Worn gap cylinder or Use the designated a oil Previously mentioned overheat ET32 new one Engine Probable Condition the xplanation of the pow Oth Corrective action cause FUEL ECONOMY POOR Se Tune up r dec n Exceeding idling revolution Adjust it to the Inoperative acceleration Adjust it recovery designated tighten the Fuel leakage Repair pipes Malfunction of B C D D Adjust Malfunction of A rC air cleaner Check and replace Inadequate oil quality Use the designated oil Overheat Previously mentioned or rpm connection of fuel PROBLEM IN OTHER FUNCTIONS D cr d oil p ssure Worn oil pump Disassemble oil pump and regulator valve Functional deterioration of oil pump Repair or replace Blocked oil f1lter Renew it Increased clearance in various sliding parts Disassemble and repair it with a replace the or renew it new one worn parts with new ones Excessive wear on the sliding parts Blocked oil strainer Oeanit Inoperative oil Replace gauge pressure switch Previousiy mentioned Oil pressure decreases Improper quality or Overheat with mentioned Decrease of oil pressure Previously parts Insufficient clearances Readjust Overheat Previously Improper fuel mixture Check the fuel system high California only Problem in fuel system tion of Fuel Problem in one Check the fuel system mixture Scuffing of sliding Floor temperature too proper Previously mentioned overcoal Improper fuel oil element Change element air cleaner or the Exchange contamination of oil change Damaged it with a new one Refer to Inspec to the designated mentioned Check and repair System ignition system Refer to spection of Ignition System ET33 In Check and repair clearances and SECTION EM ENGINE MECHANICAL DATSUN PICK UP MODEL 620 SERIES lMlSSAN I oJ NISSAN MOTOR CO TOKYO LTD JAPAN GENERAL DESCRIPTION EM 2 ENGINE DISASSEMBLY EM 4 INSPECTION AND REPAIR EM 8 ENGINE ASSEMBLY EM 21 SERVICE DATA AND SPECIFICATIONS EM 2l TROUBLE DIAGNOSES AND CORRECTIONS EM 31 SPECIAL SERVICE TOOLS EM 33 Engine Mechanical GENERAL DESCRIPTION CONTENTS EM 3 EM 2 CAMSHAFT CYLINDER BLOCK EM 3 VALVE CRANKSHAFT EM 3 CAMSHAFT DRIVE EM 3 EM 3 MANIFOLDS EM 3 MODEL L20B ENGINE PISTON AND CONNECTING ROD EM 3 CYLINDER HEAD dependable power The cylinder block is cast as out smooth MODEL L20B ENGINE unit aluminum head and a balanced 5 bearing crankshaft to and engine The L20B engine features O H C valves combustion wedge shaped chamber EM 3 MECHANISM is corporates single deep skirting This equipped with a single 2 featllres carburetor that in barrel downdraft fully CYLINDER BLOCK a a special device to control The special casting emissions employs a and higher durability The cylinder bores turn a mono block structure support system for quiet bearing five ness block cylinder surrounded are by cooling jackets and machined di rectly in the block The oil ways in the block are arranged so that the full flow oil filter is directly attached to the right hand side of the block EM536 Fig EM 2 Cylinder block EM535 Fig EM Main Cross sectional view specifications L20B Oisplacemen t cc cu in The 1191 952 1 CRANKSHAFT forging Bore x stroke 3 35 x Fully smooth 85 X 86 in mm crankshaft 39 3 is dependable ratio 8 5 Main bearings MIT pumped through Non California model 750 10 California AlT Manual Transmission 12 650 in AIT power at uses model 0 position Automatic Transmission EM 2 are high eight balance lubricated by oil the main oil and the oil holes which with cylinder run bores There gallery parallel in are oilways drilled in the crankshaft for the lubri cating oil equipped MIT steel turns out weights 750 12 Ignition timing Degree B T O C rpm it speed The L20B engine Compression special a balanced The center main bearing is with thrust washers to take up end thrust of the crankshaft Engine Mechanical CAMSHAFT CAMSHAFT The camshaft is made of iron cast rocker and located is the aluminum alloy Four cover special a inside brackets support it Camshaft bearings are lubricated from oil holes which lead Fig EM 3 Crankshafl to the main Concentric the PISTON AND CONNECTING two rods front and through rear are drilled in parts of the The connecting rods are of a special forged steel Oil is sprayed to the ends an shaft a double by the crank The tension controlled by a of the chain is chain tcosioner which operated by spring and oil pressure The rubber shoe type tensioner damps is tension earn lobe is earn plied supplied oil hole drilled in the base Lubricant is sup circle of each lobe to the front oil gallery from the 2nd camshaft bearing and to the rear oil gallery from the 3rd camshaft bearing These holes on the base circle of the lobe supply lubricant to the earn pad surface ofthe rocker arm and to the valve a rod small roller chain driven vibration of the chain and controls its passages Oil to each compression rings and one combined oil ring The piston heads are slightly dished The piston pil1S are a special hollow steel shaft They are full floating fit to the piston and press fit to the connecting connecting gallery of the The camshaft is driven by row shaft ROD The pistons are of a special alumi num casting and have struts to control thermal expansion oil cylinder head DRIVE tip end The profile overlap long cams feature to reduce NOx EM537 emission Fig EM 8 Chain driving aystem through drilled passages in the large ends of rod Oil holes in the connecting rods located are so as to insure optimum lubrication under heavy load 0 5 01 Fig EM 6 Camshafl The intake manifold is of an alumi o E Moao Fig EM 4 num Piston and connecting rod VALVE MECHANISM The valve system has the rocker arms that are CYLINDER HEAD The MANIFOLDS is cylinder head made of a light strong aluminum alloy with good cooling efficiency it contains wedge A type combustion chambers special pivot type activated directly by the earn mechanism this has made its moving parts considerably lighter and provides ideal high speed perform ance Dual type valve springs are in cast alloy The exhaust manifold design and incorporates valve used A face to warm is of the intake air out pipe is of a dual heat control The heal control valve is in it plate a the intake manifold installed manifold through on the outer to draw hot it The exhaust is connected to the flanged sur face of the exhaust manifold stalled aluminum bronze valve seat is used on the intake valve while steel valve seat is a heat resistant installed exhaust valve These parts press fitted are on the all hot @l h if EM407 Fig EM S Cylinder head Exhaust Intake EM084 Fig EM 7 Valve mechanism EM 3 Fig EM 9 Intak and exhaust manifolds r Engine I Mechanical I ENGINE DISASSEMBLY CONTENTS PRELIMINARY CLEANING AND PISTONS INSPECTION 4 EM DISASSEMBL Y I gaskets disassembling engine oil crankshaft of and equipped water leakage 7 past disassembling and block check Prior cylinder to head Remove starter motor from Check carburetor and fuel pump for condition fuel hoses for deteriora 8 tion chain cracks their jointed or trans mission Visually inspect cylinder head Ner front cylinder block rocker C 2 or water may leak past head cylinder lInd Remove air pump drive belt cool compressor and idler pulley if so er oil pan and oil filter pump seals for signs their gasketed surfaces note following Fuel EM 7 EM 7 6 front chain cover INSt ECTION the HE RODS AD EM 4 PRELIMINARY CLEANING AND Before AND CONNECTING CYLINDER leakage of fuel past oil pan and all other outer cover for oil parts or connected surfaces breakage or water and fuel missing parts such leaks as bolts and nuts 9 cuits Check piping and electrical cir for deterioration breakage fit tings discontinuity 1 1ltermal 2 Check valve 3 Altitude in 4 Air Automatic refer I 11 E valve relief valve 2 3 Installation Remove transmission Remove clutch from en assembly from Thoroughly drain engine oil and Emergency air relief valve coolan t by removing drain plugs Store engine oil and coolant if they 14 Air pump air cleaner are IS Carbon canister 16 Air control 11 Air solenoid valve 13 to be used valve I Fig EM 0 Emiuion control devic s California mod 18 2 Remove carburetor air cleaner Disconnect air cleaner to A B valve Remove fresh air duct hot air duct from air 4 Disconnect 5 air cleaner to related Disconnect air cleaner to air pump hose at air cleaner Loosen air cleaner band bolt and Disconnect air cleanef to rocker sembly hose at rocker air 4 cover cIeaner to air remove con Plug hoses at air cleaner carburetor air cleaner prevent entry of foreign 5 alternator and alternator bracket Remove alternator 4 EM to matter fornia models drive right engine mounting Remove oil filter with Oil Filter Remove oil pressure swi tch Install engine attachment alternator bracket Set engine Engine on and stand Attachment ST05260001 belt Engine Stand ST050I SOOO to bolt holes in hole 6 trol valve hose at air cleaner Cali only as from carburetor up carburetor air horn cooling fan Remove cylinder block utilizing part vacuum Remove Wrench STI9320000 hose at air cleaner cleaner Disconnect engine bracket 3 cover on stand pump Disconnect again Place engine assembly 4 E T366 3 and flywheeL G R control valve B C D D control valve and 12 Removal gine Bee D D P cv Air vehicle instructions under the ER section Anti 8ackfire valve A B valve Boost Controlled Deceleration to the from engine remove to Engine temperature control air cleaner Device 9 To gallery pipe 6 7 8 DISASSEMBLY compensator air cleaner choke Auto insulation valve vacuum S or water drain Mechanical Engine 9 Remove valve hose block to P C V from block cylinder 10 cylinder blow by gas hose Remove manifold attaching bolts and remove intake and exhaust and manifold assembly cylinder head 1 Air control valve 2 Distributor EM410 Fig EM II Engine on engine Remove carburetor from intake block cylinder Disconnect to Disconnect A B valve to E G R passage hose at E G R passage 3 Disconnect vacuum tube to carburetor hoses vacuum white and yellow at fuel 3 carburetor Disconnect air cleaner hose vacuum from from hose 4 Remove check valve from air gallery pipe 5 Disconnect E G R 6 tube Disconnect 4 Remove E G R valve C V valve hose at P C V valve P 2 2 bracket manifold 1 EM531 Fig EM 13 Removing air control valve Californio model land Remove oil level gauge 6 EG R tube passage and exhaust manifold E G R and passage Remove E G R valve from intake manifold carburetor bolts and remove carburetor and and exhaust manifold attaching bolts and separate Remove dash pot bracket from Remov intake Remove 11 intake intake manifold 6 Fig EM 16 Removing intake and exhaust manifold assembly from carburetor 5 gasket from manifold from exhaust mani fold attaching assembly 12 Remove air gallery pipes from exhaust manifold gasket 12 Disconnect distributor sion cables from sparkplugs 7 8 Disconnect remove ten from distributor fuel Disconnect pump and hoses combined 10 from remove from fuel and fuel vacuum 14 I E G R passage 2 E G R Fig EM tube 14 EM532 Removing E G R tube and passage assembly pump left engi from cylinder Remove air mounting e blopk pump and cooler Remove cylinder 8 F lC D head if so Disconnect thermal vacuum thermostat crankshaft pulley in washer and then stalling bolt remove pulley with a two jaw puller bracket from equipped vacuum valve housing and hoses and from remove gasket from assembly 15 Remove water pump 16 Remove rocker cover 17 Remove spark plugs 18 Remove fuel pump drive 19 Remove camshaft sprocket head 7 Remove and from cylinder head fuel Remove cylinder hose Remove et compressor bracket as sembly 9 bra 13 hose vacuum distributor and high earn Refer to the following note during operation when removing camshaft sprocket from engine installed on car cylinder head EM412 Fig EM IJ Remove 12 Removing fuel intake and pump exhaust manifold assembly from cylinder head 1 Disconnect vacuum hose air control valve and remove air trol valve as an for California assembly and a r from EM089 EM091 con hoses Fig EM 15 Removing thermostat housing EM 5 Fig EM 17 Removing cammaf sprocket r Engine 28 Remove cylinder head Use Cylinder STl0120000 bolts Head assembly Bolt to remove Wrench cylinder Loosen bolts from CD to Mechanical 29 Invert 30 Remove oil pan and oil strainer 36 engine head @ Remove piston and connecting mbly Extract connecting rod rod a bearings keeping them in order as shown in Figure EM 18 EM094 Fig EM 20 Removing oil I traintir Fig EM 23 Removing pilton and connecting rod aatm b y and oil pump Fig EM IS Cylinder head bolt loosening equence 31 Notes When removing cylinder from engiJJe installed on car heao follow the instructions below a Turn crankshaft until No TD C is at on its I pilton compression Remove oil pump and its drive spindle See Figure 32 Remove front 33 Remove 37 Remove flywheel and Be careful EM 20 not to drop rear plate them cover chain tensioner and chain slack side guide stroke b Remove c pump To facilitate scribe 8 rocker Cover assembling on timing mark and o c fuel tion 8in and camshaft sprocket with paint be fore removal d Loosen camshaft bolt and fuel pump drive e EM415 remove Fig earn EM 24 Removing flywheel Support timing Chain ween chain by utilizing Stopper STl7420001 bet timiilg chains as shown in Figure This 0 EM095 38 EM 19 peration eliminates the prob lem of realigning timing chain timing sprocket and marks Fig EM 21 Removing chain ten ioner and tim ing chain on crankshaft Remove main bearing caps Use Crankshaft Main Puller KVIOI04ISO to and rear Bearing Cap remove main bearing caps center Keep them in order 34 Remove Figure EM timing chain See 2l 35 Remove oil thrower crankshaft wonn gear and chain drive sprocket KVIOI04IS0 EM539 Fig EM 25 Removing rear main bearing cap EM538 Fig EM 19 Supporting timing chain f Remove camshaft sprocket Loosen cylinder head bolts and g remove 39 Fig EM 22 Removing chain drive cylinder head Proc 6 EM et main 40 Remove two side seals from bearing ca Remove p rear oil seal rear Engine Mechanical Be careful Note not to shaft bearings and 3 Remove valves earn damage eam lobes using Valve Lifter STl2070000 EM103 EM411 STl2070000 Fig EM 29 Remouingpi tonpin Fig EM 26 Remouing rear oil eal 3 41 Remove crankshaft 42 Remove baffie plate Keep disassembled parts in order and cyl inder block net CYLINDER HEAD I Remove valve rocker Fig EM 32 Removing ualves springs Loosen valve rocker pivot lock nut and remove rocker arm by pressing valve spring down Notes a Take care not to lose valve seat oil seal valve collet spring and valve rocker guide b Be sure keep camshaft bearings bearing center is liable out of alignment to intact or the Fig EM 27 Removing baffle plate and to come nel PISTONS AND CONNECTING RODS Remove piston rings with a 61 8 ring Fig EM 3D Removing rockerarrm remover 2 Remove locate plate and remove camshaft O Exhaust Fig EM 28 Removing pilton rings Press piston pin EM105 out with Piston Pin Press Stand STl3030001 EM101 Fig EM 33 Value components EM102 2 Intake Fig EM 31 Remouing cammaft EM 7 r Engine Mechanical INSPECTION AND REPAIR CONTENTS PREPARATION CYLINDER FOR INSPECTION HEAD AND VALVE CHECKING CYLINDER VALVE SPRING ARM AND VALVE CAMSHAFT CAMSHAFT VALVE INSERTS AND CAMSHAFT BLOCK MEASURE CYLINDER CYLINDER Before BORE BORING cleaning check for Note Clean oil carbon sure that EM 8 BUSHING AND BEARING EM 9 EM 16 MEASUREMENT OF EM 17 MAIN BEARING EM 17 EM lO MEASUREMENT OF CONNECTING EM l0 BEARING EM 11 FITTING ROD CLEARANCE EM 1B BEARINGS EM 18 EM 19 MISCELLANEOUS COMPONENTS CRANKSHAFT AND CAMSHAFT EM 12 SPROCKETS EM 13 CHAIN TENSIONER AND CHAIN EM 13 FLYWHEEL EM 13 FRONT COVER deposits camshaft bear remove unless machine or ing in line have you boring a EM 19 EM 20 GUIDE EM 20 AND REAR OIL SEAL EM 20 Head surface flatnes Suitable Camshaft bear If you once camshaft Standard remove bearings bearing will come out o alignment reo conditioning is very difficult with out center borings and sealant from an parts Remove gasket 3 Clean all oil holes with solvent and dry EM 16 CRANKSHAFT Never ings signs of water and oil leaks in cylinder block and head 2 EM 15 ROD EM 14 PREPARATION FOR N INSPECTI I AND 8 EM 12 BEARING CLEARANCE TIMING HOW TO PINS EM EM 12 BEARING CAMSHAFT ALIGNMENT CYLINDER PISTON CLEARANCE VALVE GUIDE SEAT PISTON RINGS ROCKER PIVOT VALVE PISTONS B CONNECTING ASSEMBLY ROCKER 8 EM HEAD MATING FACE VALVE EM Maximum centers less than 0 05 mm O lmm 0 0020 in 0 0039 in with compressed air Make they are L not restricted Make a v isual check for cracks and flaws 2 Measure head on warpage the surface of cylinder block side for If it is found to be beyond regrind the the limit designated below affected surface with a surface grinder CYLINDER HEAD AND VALVE VALVE ASSEMBLY cylinder Check each intake and exhaust valve for worn damaged or deformed valve caps or stems Correct any valve that is faulty or 2 stem Valve face valve or surface should be refaced with CHECKING CYLINDER HEAD MATING replace a end valve grinder FACE 10 L I I I EM109 EM407 Fig EM 34 Cylinder head Fig EM 35 Checking cylinder head 8JJrface 8 EM Fig EM 36 Intak and exhaust valve dimensions Engine Mechanical VALVE SPRING H Valve head diameter mm I in Valve length L mm in In 42 0 to 42 2 1 654 to 1 661 Ex 35 0 to 35 2 378 1 In 114 9 to 115 2 Ex 1157 to 116 0 1 Check valve spring for squareness using a steel square and surface plate If spring is out of square more than to 1 386 524 4 555 4 to 4 535 1 6 mm 2 to 4 567 sion D mm a In Valve stem diameter 7 965 to 7 980 3136 0 to 0 063 in Measure lhe of each spring value exceeds 0 3142 replace length free and ten If the measured specified limit replace spring in Valve seat angle Intake and Exhaust Ex 7 945 to 7 960 In 45030 Ex 45030 3128 0 to 3134 0 I i T J EM112 Fig EM 39 Measuring spring quareneu EM110 Fig EM 37 Checking valve tern EMll1 diameter Fig EM 38 Regrinding valve face Note When valve head has been down to 0 5 nun 1 worn 0 0197 in in thickness replace the valve Grinding allowance for valve stem end surface is 0 5 or mm EM113 0 0197 in Fig EM 40 Measuring apring less ten Spring specifications Valve spring free length mm in Intake and exhaust Outer 49 98 Inner 44 Valve spring pressured 1 968 1 85 766 length valve open mmlkg in lb Intake and exhaust Outer 29 5 49 0 Inner 24 5 Valve spring assembled height valve close mmlkg 161 1 108 5 0 965156 2 25 in lb Intake and exhaust Outer 40 0 Inner 35 EM 9 12 0 3 21 3 1575 47 0 1378 27 I ion rr Mechanical Engine ROCKER ARM AND Replacement VALVE ROCKER PIVOT 8 3 to 8 5 dia Exhaust 0 Check pivot head and cam contact and pivot contact surfaces of rocker arm for damage found faulty pivot replace must be replaced together with its corresponding rocker arm A 3 0 1 If clearance 223 to 12 234 0 4812 to 0 4817 dia 6 to 7 8 0 299 to 0 307 1 Unit designated limit replace worn parts or both valve and valve guide In such from combustion rocker cover cylinder head side guide temperature room mm in Fig EM 41 Se11Jice value guide 10 6 0 In take valve 0 020 or dia valve guide in out side toward Ream hole at worn or mm drift EM572 it is essential to determine if Stem to guide clearance a use 2 ton pressure operation 2 clearance has been caused by a bent valve stem or by a worn a them 7 0 425 8 S9 0 2 323 a Heated cylinder head will facilitate the P 10 old guides under guide hammer chamber exceeds this case remove Drive JL I J between valve and valve stem guide 150 Intake VALVE GUIDE clearance a 12 I Measure I2 To and a press 1 4 If damage is or wear them I 327 to 0 335 of valve to E lj m3l 10 6 dl7 IV Exhaust valve 0 053 5t e l 0 040 to 0 073 0 0008 to 0 002 417 flH O II 0 00 6 to 0 0029 Maximum limit ofabove clearance mm 01 in 0 0039 Unit mm in EM116 Fig EM 43 Valve guide hole As an emergency can expedient be pushed into valve moved to the more it valve and and left If its right deflects about a guide 2 mm 0 00079 in tip For factory standard or indicates that the clearance between stem Guide hole inner and guide exceeds the of 1 mm 0 0039 0 diameter an 4718 0 For service valve in guide Valve should be moved in paral lel with rocker large arm Generally a amount of wear occurs in this direction 3 n mm 0 0079 in r l 18Iin 30mm new valve guide smoothly after to 150 to heating cylinder 2000C 0 2 press into valve so that it will fit 302 to head 12 185 to 12 4797 0 Reaming to 96 4802 0 bore 8 000 to 8 018 3150 0 rnm to 0 3157 in 3920 F Valve guide of 0 2 Max allowable deflection C1r Carefully to 0 4723 in mm maximum limit Note 11985 to 11996 valve guide oversize mm 0 0079 in diameter is available for ser vice as indicated above Interference fit of valve r guide to guide hole 0 027 to 0 049 mm 0 0011 to 0 0019 in EM115 Fig EM 42 Mea uring clearance between valve tern and valve gu ide 4 Ream bore with valve guide press using Valve Guide Reamer Set ed in KVIOI039S0 EM419 Fig EM 44 Reaming valve guide EM 10 Engine Mechanical valve seat surface with 5 Correct new valve guide as the axis 1 Old insert boring machine VALVE SEAT INSERTS of pitting at valve contact or replace if worn evidence ert be removed by can collapses The should be set so until it out depth stop that boring cannot continue beyond the bottom face of the insert recess in valve seat inserts for any Check it eat In valve Replacln cylinder head surface and reseat 2 excessively and check its outside diameter Valve seat insert of in 5 0 mm 0 0197 3 Fig EM 45 Correcting valve oversize is available for service as seat shown below the Select a suitable valve seat insert Machine cylinder head concentric center so recess to circles in valve that guide insert will have the correct fit 4 Heat cylinder head to ture of 150 to 2000C q lO 1 k k Intake 5 I the I i 37 0 mm 597 45 1 7 95 in EM573 0 32 6 Exhaust 12835 Unit mm I 14795 to 14802 dia in Fig EM 46 Seroice valve seat dimensions Cylinder head rece diameter For factory standard Unit 45 000 to 500 45 to mm in 45 016 1 7717 to 17723 insert Intake For service insert For factory standard insert 1 7913 to I 7920 516 45 37 000 to 37 016 1 4567 to I 4573 37 500 to 37 516 1 4764 to I 4770 Exhaust I For service insert Interference fit mm 0 0032 to 0 0044 Intake 0081 to 0 113 Exhaust 0 064 to 0 096 0 0025 to 0 0038 in recess and than 4 points clean valve and valve 0 295 U81 dia 37 580 to 37 596 it beds on against its seat until proper valve seat ing is obtained Remove valve and then dia 5 17 I 30 of its Newly fitted valve seats should be cut or ground at the specified dimen 47 EM sions as shown in Figure 7 small amount of fine grind Apply to valve contacting face ing compound and put valve into guide Lap valve dis 45 613 1 796 dia to to more ensuring that face tempera 6 co Unit bottom caulk 9 to 38 1 1492 to 1 500 eel q Fit insert a 302 to 3920 F EM 11 sea 1 Engine Mechanical I 600 Intake 38 W 45 Unit mm 1 496I dia 39 6 I559Ildia 18 16457 dia 71l1 1 in 30 Exhaust I 811 di 30 l1 32 6 2835 dia 34 6 1 3622 dia 137 1 4567 dia EM121 Unit mm m Fig EM 47 Standard value CAMSHAFT AND CAMSHAFT BEARING aeat dimensions VALVE TIMING This CAMSHAnBEARING CLEARANCE carn Measure inside diagram applies to all cyl inders If any valve is found out of that specifications one possibility diameter of lobe is worn or This damaged calls for replacement of camshaft earn haft beating with an inside dial gauge and outside diameter of camshaft jour nal with a micrometer found inside of bracket inder head If wear is EM119 replace cyl Fig EM 48 Checking cam haft bearing assembly Camshaft journal to bearing clearance Standard Oil clearance mm in 0 038 to 0 067 0 0015 to 0 0026 Wear limit 0 1 0 0039 B DC Inner diameter of shaft bearing mm earn in 48 000 to 48 016 EM421 18898 to 18904 Fig EM 49 Value timing diagram EM 12 Engine Mechanical j Bend limit Standard Using round of out Camshaft bend mm 0 02 bore 0 05 0 0020 0 0008 I in a bore measure gauge cyl inder bore for out of round or taper If or cylinder machine taper is excessive re walls with a boring should Measuremen t be taken along bores for taper and around See Figure bores for of round out CAMSHAFT ALIGNMENT EM 52 I Check camshaft camshaft journal and earn surface for bend wear or damage If damage is beyond limits replace affected parts Qu t of round X Y Taper A B A bend value is one half of the 2 reading obtained turned one applied gauge when camshaft full revolution with to 2nd and 3rd a is dial journals Fig EM 50 Checking camMa t bend M12 Fig EM 52 Measuring cylinder bore diameter Standard height of tam mm in I Intake 1 Exhaust to 30 40 35 40 1 5866 to 1 5886 4 When wear taper or out of round is minor and within limits remove step Wear limit of earn height mm in 0 25 0 0098 a able difference in diam Allo max worn and min ter betweim worn topmost portion of cylinder using ridge reamer or other similar tool at mm in 0 05 mm in 0 1 00020 parts of c mshaft journal Maximum tolerance in irri j01 0 0039 diameter CamShaft end mm play in Surface flatness in 0 08 to 38 0 0 0031 to 0 0150 A bore gauge is used Measure cylind r bore at top middle and bot tom positions toward A and B direc tions as shown in Figure EM 53 and Standard mm TO MEASURE CYLINDER BORE HOW Maximum tolerance less than 0 05 0 0 10 0020 record the measured values 0 0039 A I 120 0 79 IlL 60 2 36 B 100 el lll 3 1 94 Cy LlNDER BLOCK I Visually check cylinder block for cracks 2 or flaws Measure top of cylinder block head mating face for warp age If warpage exceeds limits correct cylinder it EM 22 r Unit mm m EM540 Fig EM 51 Cheching cylinder block au rface EM 13 Fig EM 53 Cylinder bort me08Uring positions Engine Mechanical Standard Wear limit 85 000 to 85 050 Inner diameter 3465 3 to 0 2 00079 3484 3 Cylinder bore Out of round in mm ot5 O 0 015 00006 Taper Difference in cylinder bore 0 05 in mm 00006 0 0020 0 2 0 0079 CYLINDER BORING I When any cylinder needs boring all other cylinders must also be bored at 2 Determine cording piston to amount oversize L ac of wear of cylinder aboull Oversize pistons spec Hicetlons Piston diameter mm 6 7 A the same time o 7323in m r in 127 84 985 to 85 035 Servioe standard 3459 3 Fig EM 55 MeCUJlJring piston skirt diameter to 3 3478 Rebored size calculation 0 50 0 0197 85 465 to 85 515 Oversize 3648 3 o to 3 3667 1 00 0 0394 3844 3 C 0005 to A 0 0002 to 00010 in mm where 85 965 to 86 015 oversize B A Q25 0 D Honed diameter to 3 3864 A Skirt diameter as measured 3 be The size to which cylinders must is determined by adding clearance cylinder to largest piston diameter at to Piston to wall clearance C Machining Standard clearance f im in 0 025 to 0 045 piston skirt Feeler gauge mm Extracting kg Ib in force Notes a To prevent strain due to heat bore the cutting cylinders in the order of 241 3 b 0 2 to 1 5 Before be honed to size 7 boring any cylinder install bearing caps in place and tighten to the specification so that the crankshaft bearing bores will 8 not become distorted from the bor ance Measure bore for Measure This the of out Do not cut cylinder bore at mm Measuring piston diamet r 00020 in a too much out of time Cut only 0 05 or so time EM 14 in diameter at a finished round piston clearance easily by using 4 O 44 to 3 31 5 Measurement of a just machined cylinder bore requires utmost care since it is expanded by cutting heat 6 As a final step cylinders should main ing operation EM 54 mm 004 0 0016 in thrust direction Fig 0 02 0 0010 to 0 0018 the EM126 allowance 0 0008 in honed piston B or to can cylinder tapered part cylinder clear be checked feeler gauge and a spring balance hooked on feeler gauge measuring the amount of force re quired piston to a pull gauge cylinder and out from between Engine Mechanical Notes a PISTONS PISTON PINS AND PISTON RINGS When measuring clearance slowly pull feeier gaUge siraight upward b It Is reConUnended that piston and cylinder hel ted be to 200C 680F I Remove carbon from piston and a ca bon scraper and grooves with ring a curved steel wire Clean out oil slots in bottom land of oil 2 Check for wear I Replace 3 ring damage 00 groove scratches and if necessary side clearance of rings in ring grooves as each ring is installed Side clearance should be as follows 1re Meas1 EM542 Fig EM 58 Measuring ring gap Notes t a J f rr piston ring only is to be replaced without cylinder bore being corrected measure gap at bottom of cylinder where wear is minor 1 11 When I b Oversize EM541 piston rings are available for serv ce Fig EM 56 Measuringpiaton fit in cylinder Oversize mm 0 0197 in 10 mm 0 0394 in 05 Fig EM 57 Measuring piston ring side clearance 5 and Measure piston pin hole in rela pin If wear tion to outer diameter of exceeds limit replace each piston pin together with the piston on which it is Side clearance Unit mm in installed 6 Standard Top ring Second ring Oil ring f 4 ton I I I 0 040 0 073 to 0 070 to 0 0012 to cylinder place it measure ring as to with of piston must be a 0 0039 tight pre This s piston pin fit into connect ing rod I I feeler gauge Ring should be placed in squarely gap 0 0028 fitting temperature room 01 0 030 Determine the into piston pin hole to such an extent that it can be finger pressed at pin 0 0016 to 0 0029 Push ring into cylinder with pis so Wear limit at upper a or to diameter lower limit of ring travel EM131 Ring gap Unit Standard Top ring Second ring 0 25 to rom in Fig EM 59 Piston pin fitting Wear limit 40 0 0 0098 to 0 0157 30 0 to 0 50 0 0 II8 to 0 0197 1 0 0 0394 EM132 Oil ring 0 30 to 0 90 Fig EM 60 Measuring pi ton pin 0 0118 to 0 0354 diamet EM 15 r Engine Mechanical Unit Piston pin outside diameter 20 993 to 20 998 mm in CRANKSHAFT 1 0 8265 to 0 8267 Whenever crankshaft from Piston pin hole diameter Piston pin 21001 to 21008 piston clearance to I 0 003 to 0 015 to thoroughly cleaning check crank 0 006 Rep If damage 0 015 to 0 035 0 0006 to 0 0014 connecting rod crankshaft pin Jor cracks Interference fit of piston pin to engine is removed be should cleaned in a suitable solvent 0 8268 to 0 8271 00001 it crocus is bias score air or replace minor After journal and wear or required as dress with fine cloth 2 Check journals and crank pins for taper and out of round with a micro meter Measurement should be taken along journals journals for CONNECTING ROD If I on connecting rod has a any flaw either side of the thrust face large end correct or replace or 2 the Check connecting rod for bend torsion it using If bend q rrect or or a connecting rod 63 EM or or torsion exceeds the limit of out with replace round of out See Figure for detailed information Ifjournals aligner for taper and around a or crank pins are tapered round beyond limits replace shaft new A B EM133 Fig EM 61 Ch cking rod alignment Standard Connecting Maximum Out of round XY Taper AB rod bend Unit per 100 mm in length torsion or 3 94 or 0 03 0 0012 0 05 19 5 0 0020 30 181 in mm 43 3 27 106 tt and old new ones and 1 E is within 7 oz All main Do not use a combination of new former 2 connecting rod big end connecting rod bolts which affect specified weight variations 4 Install connecting rods with bear ings on to corresponding crank pins measure thrust clearance ured value exceeds limit Ifmeas replace end play mm in 3599 l o 2 3604 All crank pm 49 961 to 49 974 1 9670 to 19675 EM424 Fig EM 63 Crankshaft and journal dimensions Fig EM 62 Checking big end play Standard Big journa 59 942 to 59 955 nuts and and 32 1 2 60 I replacing connecting rod select rod so that weight difference gr 0 25 in l 69 O When between mm 0 768 Maximum 0 2 to 0 3 0 0079 to 0 01 18 0 6 0 0236 EM 16 Engine Mechanical Maximum Standard STl6610001 Taper and out of round less than of journal and crank pin 0 0010 Q25 0 0 0004 in mm 3 0 01 Crankshaft bend by placing using a indicating finger dial gauge with its resting be checked can it on V blocks and EM425 Fig EM 66 Pulling center journal on outpilot bushing 2 Before thoroughly installing a new bushing clean bushing hole Press fit bushing so that its height above 5 to 5 0 mm 177 0 to flange end is 4 0 197 in Do not oil bushing EM137 bend Fig EM 64 Checking crankshaft Maximum Standard less than Crankshaft bend mm in 0 10 0 0039 0 05 0 0020 EM418 Note measuring bend When use a Fig EM 67 Press fitting dial gauge Bend value is half of the reading obtained when crankshaft is turned one full revolution with dial gauge attached to its a center BUSHING AND BEARING After regrinding crankshaft finish it to the necessary size indicated on MEASUREMENT by using an adequate bearing according to the EM 18 page undersize extent of 5 crankshaft block and measure I in OF MAIN BEARING CLEARANCE required repair Install pilot bush ng journal 4 new cylinder Thoroughly clean all bearings and check for scratches crankshaft free end Fig EM 65 Checking crankshaft end play play melting score or if any fault is wear Replace bearings detected 2 Wear limit Standard 3 Crankshaft free end play 6 mm At check wear or in the rear 0 05 to 0 0020 is detected to 03 for 4 00118 0 0071 To end of crankshaft pilot bushing damage Replace it if any fault crankshaft 0 18 replace crankshaft bushing proceed I Pull out as rear pilot follows bushing using Pilot Bushing Puller STl66 1000 I EM 17 Crankshaft journals and bearings should be clean and free from dust and dirt before oil clearance is measured Set main bearing Cut a on cap block plastigage to width of bear it in with crank ing and place parallel pin getting clear of the oil hole Install them cap on the assembly and tighten together to the specified Tightening torque 5 kg m 5 to 4 torque 33 to 40 ft lb Engine Mechanical Bearing 011 clearance Wear limit Standard 0 020 to 0 062 Main bearing clearance 0 0008 to 00024 in mm 0 025 to Connecting rod bearing clearance mm 055 0 0 0010 to 00022 in 0 12 0 0047 0 12 0 0047 Fig EM 68 P14stigage 2 Note tum crankshaft Do not plastigage is while being inserted Remove cap and compare width of the plastigage at its widest part with 3 Then value If clearance replace bearing with an under size bearing and grind crankshaft jour with a nal listed below exceeds specified measure bearing crush H feeler gauge See Figure EM 70 The standard bearing crush value is adequately 5 scale the printed in plastigage FiniNG BEARINGS enve lope Bearings crush to its bore manufactured are with make bearing snug down into To measure this proceed Weight as H follows I cap Set main bearing in main recess or cylinder block recess 2 bearing bearing correctly Lock one side of bearing and press other side until bearing back surface touches the recess Fig EM 70 Checking bearing crum Bearing crush All main Fig EM 69 Measuring bearing bearings mm in mm in o to 0 03 0 to 0 0012 clearance All connecting rod MEASUREMENT OF CONNECTING ROD BEARING 4 bearings 0015 to 0 045 Handle connecting rod bearing in the 0 0006 to 0 0018 same manner as above CLEARANCE I Measure connecting rod bearing same manner as above clearance in the Main bearing undersize Tightening torque 4 5 to 5 kg m Unit Bearing top 33 to 40 ft lb 1 827 to 1835 SID 0 25 00719 00098 Undersize 50 0 to 0 0722 1952 to 1960 0 0769 to 0 0772 0 0197 2 077 to 2 085 0 0818 to 0 0821 Undersize 0 75 thickness 00295 2 202 to 2 210 00867 to 0 0870 Undersize EM 18 mm Crank journal diameter 59 942 to 59 955 2 3599 to 2 3604 59 692 to 59 705 2 3501 to 59442 to 3506 2 59 455 2 3402 to 2 3407 59 192 to 59 205 3304 2 to 2 3309 in Mechanical Engine Connectlns rod be rlns undersize Unit Bearing top thickness 506 1493 to 1 SID 0 0098 Undersize 1 618 to 1 631 0 0637 to 0 0642 0 50 0 0197 Undersize 0 75 0 0295 Undersize 1 743 to 1 756 0 0686 to 0 0691 1 868 to 1 881 0 0735 to Crank pin diameter 49 961 to 49 974 0 0588 to 0 0593 0 25 0 0741 1 9670 to 1 9675 49711 to 49 724 1 9571 to 1 9576 49461 to 49 474 1 9473 to 1 9478 49 211 to 49 224 1 9374 to 1 9379 MISCELLANEOUS COMPONENTS CRANKSHA CAMSHA SPROCKETS Replace sprocket or tion wear or stretch at exces roller links sprocket is preset at hole at the factory If chain becomes loose adjust it by setting camshaft sprocket at NO 2 hole If chain is too loose adjust it by setting camshaft sprocket at No 3 hole Camshaft found 2 Check chain for damage sive location holes Nos I 2 and 3 fault is if 3 Replace if faulty 4 To properly adjust chain tension or valve timing camshaft sprocket has a earn locating plate and three AND Check tooth surface for flaws I wear in mm Install camshaft sprocket in posi and check for rounout If it 0 1 exceeds mm 0 0039 in indicator No I Fig EM total 72 Checking camshaft end play camshaft reading repl sprocket Also check for end play ce Camshaft end play 0 08 to 38 0 mm 0 0032 to 0 0150 in Location match 2 3 3 EMl48 Before adjustment Fig EM 71 Checking eam haft sprocket Tunaut After adju5tmen t EM311 Fig EM 73 Adjuating camshaft aprocket location EM 19 Engine Mechanical Turn I at T DC Determine engine until No I piston is its compression stroke whether camshaft sprocket on location notch of the comes oblong locating plate CHAIN TENSIONER AND CHAIN GUIDE Check for off the left end groove on camshaft place wear and breakage Re if necessary If the location notch is off the left end of the oblong groove chain stretch is beyond limits EM426 Fig EM 76 Checking flywheel deviation 40150 3 r Check tooth surfaces of ring gear for flaws I or wear Replace if necessary FRONT COVER AND L REAR OIL SEAL First check front EM147 EMl46 Fig EM 75 Cam haft dri mechanilm Fig EM 74 Camshafllocating plate rear oil seal for worn or folded over sealing lip or oil leakage If necessary seal When installing new It is good practice seal whenever 2 its camshaft setting compression on be used 3 a The amount of the modifica 40 rotation ofcrankshaft When modification becomes im possible even location hole by transferring camshaft replace chain assembly a seal to replace oil is overhauled r No 2 location of the oblong groove When No 2 hole is used NO 2 timing mark must also a new r stroke hole in camshaft sprocket This No 2 notch should then be on the right end tion is engine Turn engine until No I piston is on install pay attention to mounting direction Note at T D C cover an Frant FLYWHEEL I Check clutch disc contact surface with flywheel for damage Repair or replace if necessary 2 t Measure runout or of clutch wear Front disc contact surface with a dial gauge fit exceeds 0 15 mm 0 0059 in total indicator reading replace it EM 20 JI Real EM150 Fig EM 77 Oil eals of crank haft Mechanical Engine ENGINE ASSEMBLY CONTENTS PRECAUTIONS EM 21 PISTON CYLINDER EM 21 ENGINE HEAD PRECAUTIONS I Use cleaned thoroughly Especially Cylinder block as s uIe apply engine to Ill s e oil 00 000 to them 3 Use new 4 Do not reuse lock washers 5 Keep tools and oil seals packing o Points to be 6 Keep near at hand 7 Be sure to follow necessary parts and applied sealant EM151 Fig EM 79 Applying sealanl Main bearing cap and cylinder block work benches and clean Fig EM 81 Installing valves Notes tools Ensure a specified tight ening torque and order 8 Applying sealant Use sealant to eliminate water and oil leaks Parts I EM 22 20to2Smm When installing sliding parts such be EM 22 parts make sure that oil holes are bearings ROD ASSEMBLY Rear main bearing cap clear of foreign matter 2 AND CONNECTING requiring sealant are Front cover and corners of cyl Cylinder block 3 Step portions at four mating surfaces cylinder block to front chain cover and cylinder block to rear bearing main that valve face is free from foreign matter b The L20B engine uses double type valve springs See Figure cap 2 EM 80 Valve rocker pivot assembly valve rocker pivots joined Screw Note Do not apply too much sealant inder block See Figure EM 78 with lock nuts into pivot hushing 3 Camshaft assembly Set locating plate and carefully install camshaft in cylinder head J Do damage the bearing inside Oblong of locating plate must be groove not directed toward front side of engine Camshaft bracket tightening torque 1 8 to 2 0 4 Apply sealant at hese points EM152 Fig EM 80 Applying sealant Cylinder block EM153 Fig EM 78 Applying Front alant cover cylinder and kg in 13 to 15 ft lb Install camshaft shaft and tighten it pump drive cam to sprocket on earn together with fuel specified torque Tightening torque 12 tol6 kg this time m 87 to 116 ft lb check camshaft end block CYLINDER HEAD Valve assembly and valve spring Using Valve Lifter STl2070000 set valve pring seat in position and fit valve Main bearing cap and cylinder block Each side of rear main bearing 2 cap and each corner See Figure EM 79 of cylinder block guide with oil seaL Assemble valve in the order shown below springs valve inner spring and valve rocker and outer valve retainer guide EM 21 valve collet Fig EM 82 Installing camshaft sprocket Engine Mechanical Install 5 rocker arms by pressing b Arrange valve springs down with a screwdriver 6 Install valve rocker springs assembling cylinder head camshaft until No I piston is at After 7 turn T D C on its that oil so jet of connect ing rod big end is directed toward right side of eylinder block Be c sure to install piston in cylinders mark of piston head with notch compression stroke toward front of engine 2 Notes a EM1S5 c as lower c Assemble pistons piston pins and connecting cylinder on a as rear I is also the bearing No 5 The difference is that an oil hole is in the front bearing d All upper and lower bearings are interchangeable Apply engine oil 4 surfaces on to main both sides of bearing cylinder block and cap and then install crank one j c6J CONNECTINGROD the is shaft PISTON AND rods type same 5 1 3 No 2 and No 4 bearings inter the same type Front bearing No provided Top ring is chromium plated on liner contacting face Second ring has larger taper surface than top ring In the combined oil ring upper rail same No bearing are Install piston rings is the Aembling cylinder head Fig EM 83 center Only flanged type Notes b cyl inder block net b All InstalI top and second rings in right position with marked side up a Install baffle plate including 3 ignated de en 3 86 EM Fix bearings to 40 ft lb Notes a lalling pidon rings on specified torque Tightening torque 5 to 5 kg m 33 4 EM158 Fig Install main bearing cap and tight bolts to connecting rod and connecting rod cap Apply sealant to each side of rear main bearing cap and each comer of eylinder block as shown in Figure EM 79 b Arrange parts so arrow mark on bearing cap faces toward front of engine Note Clean back side of bearing care c fully STl3030001 tightening bearing Prior to bolts place bearing position by shifting cap cap in proper crankshaft in the axial direction d EM156 Fig ENGINE ASSEMBLY Installing piston pin 84 EM is The first step in engine assembly to bolt Attachment Engine ST0526000 I cylinder to hand ide of install block on right block Next Engine Stand ST0501S000 with engine bottom up cap bolts gradually in two to three stages outwardly Tighten bearing from center bearing in the sequence 88 EM as shown in Figure e After securing bearing cap bolts ascertain that aankshaft turns smoothly another 2 Set main bearings at portion of cylinder block EM157 85 EM Fig Assembling piston and connecting rod Notes a Piston is rod with tons aid pressed into connecting fitting force of 0 5 to 5 of Piston Pin the proper @ Rear Front III D III D m It IlL D D D i d Press Stand STl303000 I is necessary pressing piston pin necting rod apply engine oil to pin and small end of connecting rod When into con l 15 4 1 13 12 11 EM159 Fig EM 87 Main bearings EM 22 j 1 @EM543 Fig EM 8S Torque sequence cap 0 bolt Mechanical Engine 6 Make sure proper end that crankshaft has Note When Crankshaft end oil seal oil engine give mating to shaft to prevent scratches and fold ed lip Also give coating of oil to play 18 0 0 05 to installing of coating play mm periphery of oil seal 0 0020 to 0 0071 in 9 Install rear end plate Install 10 flywheel securely tighten bolts to specified torque and Fig EM 94 Installing connecting rod cap Tightening torque 14 to 16 101 II kg m Note to 116 ft lb Insert pistons in corresponding Install side oil seals into to rear as on the EM03470000 direction with respect to cylinders same side and in the SlIme 13 Make sure that connecting rod big end has proper end play EM03410000 bearing cap Prior con cylinder using Piston Ring Compressor Fig EM 89 Checking crankshaft end play 7 Install connecting rods and necting rod caps 80 that their signed numbers are positioned I main installing apply sealant to seals EM544 Fig EM 92 Installing pi8ton rod Sembly a Fig EM 95 Checking big end play Notes a Apply engine b Arrange 80 piston head oil to sliding parts notch that mark faces to front of Big end play on gine c Install other piston rings avoiding thrust and Fig EM 90 Driving side oil seal 8 Install rear oil seal using at their piston pin Crank 1800 r Piston pin in 3 mm 0 0 008 to 14 Ql2 0 in Install cylinder head assembly the directions 6 shaft Rear Oil Seal Drift STI5310000 to each fit 0 2 to en Top ring I iilring ireClioJ Fig EM 96 Tightening sequence cylinder head 01 bolts STl5310000 EM165 Fig EM 93 PUtan ring direction r Thoroughly clean cylinder block J and head surface 12 EM163 Fig EM 91 Installing rear oi seal Install connecting rod caps Tightening torque 4 5 to 5 kg m 33 EM 23 Do not apply sealant to any other part of cylinder block and to 40 ft lb face head sur Engine Mechanical Turn crankshaft until No I 2 ton TD C at is pis compression its on Make sure thai camshaft 3 Install chain slack side guide aligned are groove sprock and plate oblong notch location their at to b Install Cront in cylinder block 4 When Adjust protrusion oC chain spindle to 0 mm 0 in Note ten valves are Do not separately camshaft or 0 0059 in mm d Note that difCerent types oC bolts are used e Before head apart front installing cylinder engine oil crankshaft and rotate DifCerence must upper Cace 15 0 be less than from heads of pistons 5 diCCerence between height cover sioner correct cylinder installing that all sure gasket cylinder block upper Cace and Cront positions make with head cover place Check c Install chain tensioner 18 stroke et 17 block 10 apply on cover oC coating sealing lip of oil seal valves will hit heads of pistons Temporarily tighten 6 CD V two bolts Fig re EM 96 sJiown in Tightening torque 2 15 oil kg m 14 ft b Install crankshaft sprocket and and fit oil pump drive gear Fig EM 98 lmtalling chain tensioner thrower EMS11 Press new oil seal in front cover 19 lhat maling marks of crankshaft sprocket face 10 Cront Note Make Notes Install timing chain cover placed Size M8 Make sure that crankshaft and shaft keys point cam b BeCore upwards oil seal into Cront pressing give coating of engine oil cover periphery of oil seal This oil seal is a Do not teristics apply grease to Install kg 7 2 to 9 4 ft lb m 236 0 4 to 0 6 0 21 threaded seal type which has improved sealing charac c Size M6 to in 315 0 10 to 13 sembled Noles a Tightening torque oil seal should be reo when Cront cover is disas Front a 16 Fig sure EM lOD Front cover bolts in kg m 2 9 to 4 3 ft lb crankshaft and pulley water pump assembly then set No I piston at ToO C on its compression stloke sealing lip Crankshaft pulley Install front 20 Fuel pump drive earn 2 Chain guide 3 Chain tensioner 4 5 Crank sprocket earn sprocket 6 Chai cover with gasket in nuI tightening torque 12 to 16 kg m B7 place to 116 ft lb guide EM439 b Set timing chain by OOgning its marks with those oC crank mating shaft sprocket and camshaft sprock et at the right hand side There are forty four chain links between mating c NO is Cactory EM546 EM545 Fig EM 99 Installing fronl Fig EM Ol lnstallingcran haft pulley COlHlr water adjust camshaft sprocket 22 adjusted chain stretches excessively at No 3 hole set of timing location hole numbers marks and Finally the Notes a a mark mark two When d Use Timing Timing and pump marks of timing chain hole 2 1 2 according sealant to Cront Apply corners block as cover and oC upper section of cylinder shown in Figure EM EM 24 78 tighten head bolts specified torque to the in to three steps lightening sequence shown in Figure EM 96 Note thai Iwo types of bolts used are Engine Mechanical Speci Wren Tightening torque ol Cylinder Head Bolt h 8110120000 Oil strainer bolts 0 8 to I l Tightening torque 1st turn 4 0 kg 2nd turn 6 0 kg m 29 ft lb m 43 ft lb kg I m 47 to 61 ft lb O a Apply at four b 26 A Figure 80 EM Oil should be pan pattern O R O m valve tigh tened to a final in torque 4 3 to 6 5 ft lb clearance to the dimensions Special tool Pivot Adj iier STl064000l A EM Tightening torque 5 0 to 6 0 kg m 36 to 43 ft lb 176 Fig EM I02 Cylinder head boll EM I04 Fig 24 Install 11l6lalling oil pump fuel pump water inlet elbow and front engine slinger in their Notes tighten Be sure to two small bolts positions operated for retighten if neces b After engine has been several minutes Fuel pump tightening torque 12 to 1 8 sary kg m 8 7 to 13 0 ft lb Install oil pump and distr butor 23 5 ft lb 6 B A a Adjust specified B 3 to 4 sealant to the step portions mating surfaces as shown in of 0 6 to 0 9 kg A O B 5 8 to 8 0 ft lb Notes cross criss B m 0 6 to 0 9 kg m 3rd turn 6 5 to 8 5 kg Oil pan bolts driving spindle Note in front cover pump spacer and spacer and block Tightening torque 1 to 1 5 kg to forget Do not install fuel packing spacer and fuel pump m 8 0 to 10 8 ft lb Fig EM I05 Adjusting valve clearance between b After engine has been assembled run it for at least several minutes Install oil strainer oil pan gasket 25 and and oil pan to the finally adjust clearance specifications warm Notes a Assemble oil pump and drive spin die aligning driving spindle face with oil pump hole b Install oil pump together with drive spindle so that the projection on its top is located position shape bow at the II 25 will front c Do not forget a m point the smaller be facing toward the At this to install gas 27 Install rocker cover to cylinder Note et Make that sure rocker cover others It bolts is of the one longer than the IC D F secures assist Install intake Install face which manifold air pump cooler compressor to EM 25 bracket and cylinder block to ex The intake manifold comes into contact with with that of gasket should be even exhaust manifold Note that two dif ferent sizes of attaching bolts bracket 28 29 haust manifold head Tightening torque 2 5 kg m 18 0 ft lb are used Engine Mechanical Install heatshieid plate 30 mani on fold assembly gallery pipe air on ex pot bracket and dash intake manifold dash pot 46 Connect all air vacuum hoses and then secure with haust manifold manifold Install 32 Install to Install 31 45 manifold assembly gasket and cylinder head on I valve hose A B valve to E G R passage vac uum hose A B 3 8 7 to 116 ft lb clamps block to P C V Cylinder 2 Tightening torque 1 2to 1 6kgm and fuel valve to passage air E G R I hose Install blow by gas pipe on cyl inder block and tighten with rear 33 engine slinger 34 ket uum thermostat housing housing gas and thermo 6 35 Install thermal apply a vacuum Before thermostat valve on installing housing liquid packing slightly to the threads on cylin Install and EGR E G R valve on passage intake manifold tube and exhaust manifold Install check valve 39 air gallery on Install air control valve on air cleaner bracket California models Install combined 43 vacuum on and fuel cylinder tubes Check valve to air control valve 10 Install seat plate heatshield joint Carbure10r tightening torque 5 to 1 0 kg m 3 6 to 7 2 ft lb 0 When sure to vacuum valve to hose vacuum Thermal I 47 valve to Install carburetor air cleaner on vacuum vacuum hoses as 2 follows to instalUng joint to exhaust manifold seat be Air cleaner to rocker Air cleaner to air control cover hose valve Air cleaner toA B valve hose 6 Other put the duct into primary hole in intake manifold vacuum er 51 fasten it to cylinder block by hand Note Do not overtighten 55 flit or oil occur Install alternator bracket alternator cooling adjust fan and belt 5 50 bracket oil filter oil pressure switch level gauge and water drain plug ing bar air pump hose 4 hoist and overhead lifting cable hoist engine away from engine stand and then down onto engine carrier 54 Install right engine mounting leakage may Air c1eaner hoses 56 Adjust the deflection of drive belts when thumb pressure is applied midway between pulleys A pressed force is above 10 kg 22 0 lb Deflection ofdrive belts Install spark plugs in place Connect all distributor high ten sion cables to an When installing oil filter 3 49 Using oil tube hose Air cleaner I 48 and carburetor Note Thermal hose head Install distributor assembly 44 hose hot air duct intake manifold 42 53 9 vacuum carburetor and then connect air and on Install air cleaner bracket 41 hose Air control valve pipe 40 vacuum 8 vacuum Connect E G R tube to E G R 38 spark delay valve I embly Fig EM I07 In talling clutch Fuel tube to fuel pump fuelhose Distributor to vacuum switch or E G R valve der head 37 fuel carburetor to hose Install FJ C D bracket 36 KV30100200 EM440 ube hose 7 stat vac hoses Fuel 5 Install thermostat I Vacuum tube to carburetor 4 8 to 12 315 0 mm to 472 0 in spark plugs Install air pump drive belt cool compressor and idler Install left pulley engine mounting bracket S 52 Install flywheel with clutch Clutch assembly on Aligning Bar KV30100200 Tightening torque 2 to 2 2 kg 1 m 8 7 to 15 9 ft lb EM613 J 2 Heatshield plate Primary hole 3 Duct Fig EM lOB Fan belt tension 4 Joint seat 5 Secondary hole EM534 57 Fig EM I06 Installing carburetor joint seat level EM 26 Fill engine oil up to specified Engine Mechanical SERVICE DATA AND SPECIFICATIONS GENERAL SPECIFICATIONS L20B Engine model 4 in line Cylinder arrangement co Displacemen t cc Bore and stroke mm 85 in x 86 19 1 3 35 x 3 39 O HC Valve arrangement I Firing order Engine idle J 1 952 in 42 3 rpm 750 Manual transmission Automatic transmission in D 650 range 8 5 ratio Compression Oil pressure Warm at 2 000 rpm 3 5 to 4 0 kg cm2 psi 50 to 57 SPECIFICATIONS a Valve mechanism Valve clearance Warm mm in 0 25 0 010 Intake Valve clearance mmOn Cold Intake 0 20 0 008 Exhaust 0 25 0 010 Valve head diameter Valve 0 012 30 0 Exhaust mm in Intake 42 0 to 42 2 1 654 to 1 661 Exhaust 35 0 to 35 2 1 378 to 1 386 stem diameter mm in Intake 7 965 to 7 980 3136 0 to 3142 0 Exhaust 7 945 to 7 960 3128 0 to 3134 0 115 2 524 4 to 4 535 555 4 to 4 567 mmOn Valve length Intake 114 9 Exhaust 115 7 to 116 0 mmOn Valve lift 5 10 Intake and exhaust Valve spring to out of square Valve spring free length Intake and exhaust mm in mm in 413 0 less than 1 6 0 063 Outer 49 98 1968 Inner 44 85 J 766 EM 27 Engine Mechanical pressured length Valve spring kg in lb mm valve open Intake and exhaust IM 5 49 0 1 29 108 24 5 25 5 0 965 56 2 Outer Inner Valve spring assembled height valve close kg mm lb in Intake and exhaust 40 0 Inner 35 0 12 3 Valve guide length Intake and exhaust Valve guide Valve guide height from mm head surface inner diameter in mIll in mm in service outer 59 0 323 2 10 6 417 0 8 000 to 8 018 Intake and exhaust Valve guide 3 1575 47 0 21 27 I 378 1 Outer 0 3150 to 3157 0 diameter mm parts in 12 223 to 12 234 Intake and exhaust 4812 0 Valve guide to stem clearance mm to 4817 0 in Intake 0020 to 0 053 0 0008 to 0 0021 Exhaust 0 040 to 0 073 00016 to 0 0029 in mm Valve seat width Intake 14 to 16 0 0551 to 0 0630 Exhaust 1 8 to 2 2 0 0709 to 0 0866 Valve seat angle 450 Intake and exhaust Valve seat interference fit mm in 0 113 0 0032 to 0 0044 Intake 0 081 Exhaust 0 064 to 0 096 0 0025 to 0 0038 Valve guide interference fit b Camshaft and Camshaft end timing to mm in 0 027 to 0 049 0 0011 to 0 0019 rnm in 0 08 to 038 rnm in chain play Camshaft lobeift 00032 to 00150 7 0 0 276 Intake and exhaust Camshaft joumal diameter mm in 47 949 to 47 962 1st 2nd 3rd and 4th 1 8877 to 1 8883 Camshaft bend Camshaft journal to mm bearing clearance Camshaft bearing inner diameter 0 02 0 0008 in mm in rnm in Q38 to 0 067 0 00 I 5 to 00026 0 48 000 to 48 016 1st 2nd 3rd and 4th 1 8898 to 18904 EM 28 Engine c Connecting rod Center distance mm in 146 5 748 mm in 1493 to 1 506 00588 Big end play mm in 0 20 to Connecting rod bearing clearance mm in Bearing thickness Standard Connecting d rod bend or torsion 30 0 to 00593 0 008 to 0 012 D25 to 0 055 0 0010 to 0 0022 0 per 100 mm or 2 937 in mm in Journal diameter mm in Journal taper mm in less than 0 03 0 0012 Crankshaft and main bearing out ofround Crankshaft free end play Wear limit of dittoed play Crank pin taper 942 to 59 955 59 3 0 in mm out of round Main bearing thickness StJlndard Main bearing clearance 0118 0 49 961 to 49 974 in mm in mm 1 827 to 1 835 in Wear limit of dittoed clearance mm in 0 12 0 0047 Crankshaft bend mm in 0 05 0 0020 in less than 0 15 1 9670 to 19675 0 0004 less than 0 01 mm Flywheel 3604 2 0 05 to 0 18 0 0020 to 0 0071 in mm io 3599 2 less than 0 0 I 0 0004 in mm Crank pin diameter 0 020 to 0 062 0 0719 to 0 0722 0 0008 to 0 0024 runout at clutch disc contact face mm e Mechanical 0 0059 Piston Pistondiarneter Service standard in mm 84 985 85 035 to 3 3459 to 0 50 0 0197 Oversize in mm 85 465 to 3648 3 100 0 0394 Oversize mm in mm in 3478 3 515 85 to 3667 3 85 965 to 86 015 3 3844 to 3 3864 Ring groove width Top 2 030 to 2 050 00799 to 0 0807 Second 2 020 to 2 040 00795 Oil 4015 to 4 040 0 1581 to 0 1591 Piston to bore clearance mm in Piston pin hole mm in 0 95 to 1 05 mm in 21001 to 21008 mm in 20 993 to 20 998 Piston f Piston set off pin hole diameter Q25 to 0 045 0 0010 0 to to 0 0803 0 0018 0 0374 to 0 0413 0 8268 to 0 8271 pin Pin diameter 0 8265 to 0 8267 Pin length in mm 72 25 to 73 00 2 8445 to 2 8740 Piston pin to piston clearance mm in Interference fit of piston pin to connecting rod mm 0008 to om 0 0 0003 to 0 0004 bushing in om 5 to EM 29 035 0 0 0006 to 0 00I 4 Engine Mechanical g Piston ring Ring height Top and second mm Side clearance mrn Ring in 1977 to 1 990 0 0778 to 0 0783 in Top 0 040 to 0 073 0 0016 Second 0 030 to 0 070 0 0012 to 0 0028 0 0029 in mm gap to 040 0 0098 0 0157 Top 0 25 Second 0 30 to 0 50 0 0118 to 0 0197 30 0 Oil to to to 0 90 0 0118 to 0 0354 h Cylinder block Cylinder bore 85 000 to 85 050 in mm inner diameter 3 3465 to Wear limit of dittoed inner diameter Cylinder bore taper and Difference in cylind out of round bore Surface flatness i 3484 3 mm in 0 2 0 0079 mm in om 5 0 0006 mm in 0 05 0 0020 mm in less than 0 05 0 0020 Cylinder head Surface flatness less than 0 05 00020 in mm TIGHTENING TORQUE head bolts kg m fl lb 5 to 6 kg m ft Ib 5 to 5 5 4 kg m ft Ib bearing cap bolts kg m ft lb Camshaft bracket bolts kg m ft lb 1 8 to 2 0 Camshaft sprocket bolt kg m ft lb 12 to 16 Oil pan bolts kg m ft 1b 0 6 to 0 9 3 to 6 5 4 Oil pump bolts kg m ft lb J to 1 5 I 8 0 to 10 8 Oil strainer bolts kg m ft lb 0 8 to 1 5 8 to 8 0 Oil pan drain kg m ft lb 2 0 to 3 0 14 to 22 Rocker pivot lock nuts kg m ft Ib 5 0 to 6 0 Camshaft locating plate bolts kg m ft lb 0 6 to 0 9 Carburetor kg m ft lb 5 to 1 0 3 6 to 7 2 0 Cylinder Connecting rod big end nuts Flywheel fixing bolts Main plug nuts 5 8 14 to 16 5 4 to 47 to 61 33 101 to 40 to 116 5 33 to 40 13 to 15 87 to 116 36 to 3 4 to 43 5 6 Manifold bolts kg m ft lb 2 to 16 8 7 to 116 1 Fuel pump nuts kg m ft lb 1 2 to 18 8 7 to 13 0 Crank pulley bolt kg m ft lb Water pump bolts kg m ft Ib Front kg m ft lb cover bolts 12 to 16 87 to 116 4 0 8 mm 315 0 in dia 6 mm 0 236 in dia EM 30 to 05 2 9 to 3 6 1 0 to 1 3 7 2 to 9 4 4 to 0 6 2 9 to 0 3 4 Mechanical Engine TROUBLE DIAGNOSES AND CORRECTIONS Probable Condition I Corrective action cause Noisy engine Knocking of crankshaft and bearing Seized bearing Replace Bent crankshaft Repair or replace Uneven Knocking of piston and connecting rod Replace bearing Loose main wear Correct of journal Replace Loose bearing Replace Seized bearing Replace Loose piston pin Replace pin Loose in piston Improper connecting Loose rod Realign alignment Replace Replace bearing Excessive axial play Broken Timing chain noise gear teeth Repair gear Replace eam Worn and Worn or damaged Replace chain Replace sprocket and Worn thrust plate Adjust chain tension Improper bushing Replace bearing Rough or bearing Recondition cylinder cylinder Broken piston ring Camshaft knocking cen ter Excessive crankshaft end play tension broken or adjusting Replace mechanism Excessive camshaft and bearing clearance Camshaft and valve Improper valve clearance mechanism knocking Worn adjusting Adjust Replace screw Replace Worn rocker face Loose valve stem Water pump II knocking Replace Replace guide 1 guide i1 Weakened valve spring Replace Seized valve Repair or replace Improper shaft end play Replace Broken impeller Replace Improper valve clearance Adjust Insufficient clearance between valve stem Clean stem Other mechanical troubles Stuck valve and or ream guide Weakened Biting or or broken valve spring damage of valve stem Replace Replace Use Poor Quality of fuel EM 31 or clean ood fuel guide Engine Mechanical Condition Seized valve Excessively seat worn cylinder and piston Probable Improper Corrective action cause valve clearance Adjust Weakened valve spring Replace Thin valve head edge Replace Narrow valve seat Reface Overheating Repair Over Drive at proper speeds speeding valve or Stuck valve guide Repair Shortage of engine oil Add Dirty engine oil Clean or replace replace oil crankcase replace oil and element Poor quality ofoiL Use right oil Overheating Repair or replace Repair or replace Wrong assembly of piston with connecting rod Improper piston ring clearance Adjust Broken piston ring Dirty Faulty connecting rod Replace aii cleaner Clean Mixture too rich Adjust Engine Drive at proper speeds over run Stuck choke valve Clean and Overchoking Start correct way Shortage Add oiL of engine oil Low oil pressure Correct Poor quality of engine oil Use proper oil Rough surface of craokshaft Grind and replace Clogged Clean Bearing oil passage worn or eccentric Bearingimproperly Replace assembled Correct Loose bearing Connecting Faulty crankshaft bearing adjust Shortage of rod Replace alignment incorrect engine oil Repair Add Low oil pressure or or replace replace Correct Poor quality of engine oil Craokshaft journal worn or Use proper oil of out Clogged oil passage in crankshaft Bearing worn or eccentric Bearing improperly or Repair Clean Replace assembled Eccentric craokshaft round Correct bearing Replace 32 EM bearing oil niter IFfIDrnJrnJ 1r DfA 1r ijJJlk1 3u AT WHIPPL E 480 VETERANS u Sa e TEL EPHONE 3155 6390 VETERANS BL V PlfIDrnJ1r 1 e S REDWOOD CITY D CALIFORNIA I DATE NAME ORDER CU5T DDR E55 OUAN 94063 CHARGE I PART WHOLESAl E RETAIL rETe rDS I NO I NO J LIST DESCRIPTION NET I r 1 fr r k AI v 1 I w idP Ji i II I J I 1 ll HI tl 1 1 I 11 s vnAAwf 11 Q C r Y J h If Ii JJ plt is NO REFUND AFTER 30 DAYS NO REFUND ON 10 TAX ELECTRICAL OR RESTOCKING CHARGE ON NO CARBURETOR PARTS REFUNDED MER HANDISE REFUND WITHOUT THIS INVOICE REC O BY r Engine Mechanical SPECIAL SERVICE TOOL Tool number Description No tool ST050lS000 stand Engine Unit name mm in This engine stand assembly is used for disassembling or assembling engine block or differential carrier throughout For Reference use page on Figure No All Fig or EM II models 3600 in all directions assembly ST050 11000 Engine stand ST050 12000 Base SE184 2 ST0526oo0l This engine attachment is installed to engine stand ST0501S000 in disassembling or Ll6 Fig EM II Fig EM 18 Fig EM 105 Ll8 assembling engine Engine attachment L20B Q li SE185 3 STl 0120000 Special in series L hollow set bolts engines head bolts and its head 1 rench wrench 4 STl 064000 I Pivot can cylinder heads torque cylinder used in tightening This wrench is used to Cylinder head bolt 10 are All L series be inserted into the torque 0 39 SE186 This tool is used togetller with tightening pivot lock nut for valve clearance a torque wrench in adjustment series L adjuster SE187 33 EM Al Engine Mechanical For Tool number Description No tool S Unit name mm in t Referenl use page or on Figure No KV10 1039S0 Valve guide reamer set This o 0 STIlO81000 0 guide All is used for Pressing used guide out of place Driving a new guide into place Finishing the bore of new Fig 44 EM Fig 4S EM Lseries and A series guide Reamer 12 2 mm dia STlI 032000 Reamer 8 0 mm dia STl1320000 Drift V SE192 6 STll6S0001 Valve seat cutter set This valve seat cutter set is used to or refinish a valve seat All L series SE193 7 STl2070000 Valve lifter ol is used to compress valve spring by the combined action of its eam and lever thereby facilitating the removal This or t installation of valve collet for general use SE194 34 EM All Fig models Fig EM 32 8l EM Engine Mechanical Tool number Description No tool 8 name Unit This tool is used with ST13030001 a press to drive pin into or mm in out of For Reference use page on Figure No All L series connecting rod or Fig EM 29 Fig EM 84 Piston pin press stand 1 20 0 79 I 8 M e 120 4 0 722 SE1BS 9 engine into Crankshaft push a lip type rear oil seal for place by giving hammer blows This tool is used to ST153 10000 rear oil Lseries All Fig EM 9l Fig EM 25 series L seal drift SE189 10 KVI01041S0 This tool is used to remove Crankshaft main bearing cap in main All the cap from main bearing When using thds tool turn its adapter into the threaded hole Lseries bearing cap puller KVI0104110 Body 250 9 8 l ST165 12001 Adapter se1g0 II ST166 10001 This tool is used to pull pilot bushing out of All place L series Pilot bushing puller SE191 35 EM Fig 66 EM r Engine Mechanical Tool number Description No tool 12 name Unit mm in This tool is used to prevent chains from falling out of place in removing cylinder heads or earn gears and shafts STl742000l Chain stopper 40 For Reference use page on Figure No All or Fig EM 19 series L S1 1 r SE196 13 STl9320oo0 Oil filter wrench This tool is used to the filter do not use take oil filter out of place this tool to prevent n excess tightening tightening All Page EM4 models 120 4 7 SE197 14 KV30100200 This tool is used to install clutch assembly to All engine Fig EM 107 Lseries Clutch aligning bar SEGOl 15 EM03470000 This tool is used to compress piston rings while piston is being inserted into cylinder Piston ring compressor 2 SE199 36 EM All models Fig EM 92 SECTION EL DATSUN PICK UP MODEL 620 SERIES I NISSANJ NISSAN MOTOR CO TOKYO LTD JAPAN ENGINE LUBRICATION SYSTEM ENGINE LUBRICATION SYSTEM EL 2 SERVICE DATA AND SPECIFICATIONS EL 5 TROUBLE DIAGNOSES AND CORRECTIONS EL 5 SPECIAL SERVICE TOOLS EL 6 ENGINE LUBRICATION SYSTEM ENGINE LUBRICATION SYSTEM CONTENTS LUBRICATION CIRCUIT EL 2 Inspection EL 3 01 L PUMP EL 2 OIL PRESSURE Removal EL 2 OIL FILTER EL 4 Installation EL 2 RELIEF EL 4 Disassembly and assembly REGULATOR EL 4 VALVE VALVE EL 3 From directly through this cam to holes camshaft go bearings brackets Oil supplied No oil gallery all to through the No 2 bearings is then and 3 camshaft the lobe rocker arm valve and the oil through gallery fed eam in the camshaft and the small channel at the base circle portion of each earn OIL PUMP The oil pump is secured on the bottom of the front cover with four bolts and driven by the oil pump drive spindle assembly which is driven by the helical gear an E L049 Fig ElrI Lubricating outer and inn circuit on the crankshaft The oil pump assembly consists of oil pressure regulator valve and r rotors The spring loaded oil pressure regu lator valve limits the oil pressure to LUBRICATION CIRCUIT The pressure is engine maximum of 5 6 lubrication of the accomplished by tro a choid type oil pump This pump draws the oil through the oil strainer into pump housing cylinder head to and then forces it the full flow type oil filter into the main oil gallery Part of the is supplied all Removal I Remove distributor 2 Drain engine oil if necessary Remove oil pump body with 3 crankshaft drive spindle assembly chain bearings chain to kg provide lubrication of the valve mechanism and timing chain as shown in Figure EL2 through oil a 80 psi em tensioner and timing supplied to crankshaft Oil is fed to connecting rod bearings through the drilled passages bearings in the crankshaft jet holes on Oil injected cates the cylinder walls pins The other part brought to from Installation connecting rods Iubri the oil and piston of the oil gallery in I is ELOSO the Fig EL 2 Lubricating EL 2 vallie mechanism Before engine piston installing oil pump turn crankshaft so that No is at TD C on I ENGINE LUBRICATION SYSTEM 2 oil housing with engine then align punch mark of spindle Fill pump with hole Figure in oil pump as shown in wear Disassembly and assembly I EL 3 Remove bolts pump attaching cover and cover pump 3 cover and slide out pump rotors 2 Remove regulator cap gasket Install and related parts 4 Install outer Punch mark valve regulator pressure rotor inner inner shaft rotor for wear scoring or 5 regulator valve and spring 3 Check looseness in pump body 4 Inspect regulator valve for Check regulator spring to see that it is not worn on its side or collapsed 6 check tip Using feeler gauge a clearance 2 and outer rotor to clearance I shown in Figure EL 7 body rotor and shaft in pump body and do not gasket turn cover up CD EL009 EL3 Fig 3 Using a Aligning punch mark and oil hole new install oil gasket pump and drive spindle assembly that the projection on its top so located in II at this time 25 a m position the smaller bow shape will be placed toward the front in Figure EL 4 9@ @ J i It L I tr Regulator spring 7 Washer 8 4 Outer rotor Oil pump cover Regulator cap Cover gasket 5 Regulator 3 9 Fig EL 6 Oil pump I pindle 3 Tip clearance Gap between rotor and straight edge 4 Gap body and straight edg e rotor between Fig EL 7 7 Place body clearance Checking a rotor clearance straight edge Wash all parts in cleaning solvent and dry with compressed ir Inspect pump body and for cracks 2 EL011 Ascertain Imtalling oil pump whether gagement is in order top of spindle or not the by checking or Inspect cover excessive wear 0 0012 to rotor side clearance cover pump rotors for excessive clearance 0 0024 rotor to Olm in Rotor tip clearance @ mOl in mm inl then with gasket should satisfy the specifications 0 04 to 0 08 0 0016 to 0 0032 bottom cover in rotor to bottom Wear limit Less than 0 12 0 0047 020 0 0079 0 20 0 0079 through distributor fit ting hole 4 Tighten bolts securing oil to front cover Rotor side clearance en the Outer pump the 0 03 to 0 06 The gap should be mm Standard Fig EL 5 across between body and straight edge or gap 3 between rotor and straight edge Inspection I o Outer face of pump and depress it slightly as shown in Figure EL 7 Check gap 4 EL010 Setting drive to 1 2 valve d I EL 4 CD@ 6 2 J V r @ Oil pump body Inner rotor and shaft 1 c Fig @ shown as JI Front El012 is rotor to clearance body D EL 3 0 15 to 0 21 0 0059 to 0 0083 0 5 0 0197 ENGINE LUBRI CATION SYSTEM Note Pump rotors and body are separately If pump body are damaged or not serviced rotors or worn replacement of the entire oil pump assembly is necessary OIL PRESSURE REGULATOR VALVE oil pressure regulator valve is the released At adjustable The not position the valve permits the oil to by pass through the passage in the cover pump the inlet side of the to pump Check regulator valve spring to ensure that spring tension is correct Tightening EL014 Fig ELB Regulator value torque kg m ft Ib l to 15 bolts kg m ft lb 07 cap nut kg m ft lb 4 to 5 Oil pump mounting bolts Oil pump cover Regulator valve to 8 0 to 11 10 5 Ito 7 2 29 to 36 Specifications Oil pressure at Regulator kg cm2 psi idling mm in 525 2 067 Pressured length mm in 34 8 370 1 valve opening pressure oil filter is a cartridge type filter element should be placed periodically reo with the use of Oil Filter Wrench ST19320000 When installing it to kg em2 35 to 5 0 50 to 71 psi RELIEF VALVE OIL FILTER The an oil filter fasten The relief valve With located at the portion securing oil fIlter to the cylinder block by passes the oil into the main gallery when the oil fIlter element is excessively clogged Do not leakage may overtighten filter or oil fIlter removed check operation Inspect for a If replace or broken valve necessary remove valve by valve unit for cracked center cylinder block by hand Note to 40 valve spring Regulator oil II length Free The 0 8 to 2 8 ment is prying it Install a tapping it out with new valve a screwdriver in place by oil occur STl9320000 EL016 EL015 Fig EL 9 Removing oil filter 4 EL Fig EL JO Relief lJOlue ENGINE LUBRICATION SYSTEM SERVICE DATA AND SPECIFICATIONS Oil pump Wear limit Standard rotor to bottom cover Rotor tip clearance Outer rotor to body clearance Oil pressure regulator mm in mm in mm in 0 0079 0 0016 to 0 0032 less than 0 12 0 20 00079 0 0047 05 0 15 toO 21 0 0197 0 0059 to 0 0083 valve kg cm2 Oil pressure at idling 0 8 to 2 8 psi II to 40 valve spring Regulator Free 0 20 0 04 to 0 08 Rotor side clearance Pressured in 52 5 2 067 mmOn 34 8 1370 mm length length 5 to 5 0 50 to 71 3 kg em2 psi Regulator valve opening pressure Tightening torque Oil pump cover bolt Regulator valve cap nut 5 8 0 to 10 8 1 1 to m ft lb kg m ft lb 0 7 to 1 0 5 1 to 7 2 kg ft Ib 4 to 5 kg Oil pump bolt m 29 to 36 TROUBLE DIAGNOSES AND CORRECTIONS Probable Condition Oil leakage Damaged or Corrective actions causes cracked body Replace cover Oil leakage from gasket Replace Oil leakage from regulator valve Tighten Oil leakage from blind Leak of oil in engine oil pan Correct pressure Dirty oil strainer Clean or worn quality engine or replace Replace pump rotors Replace Faulty regulator Use of poor replace Replace plug Decreased oil Damaged or Replace oiL Warning light Decreased oil pressure Previously mentioned remains Oil pressure switch unserviceable Replace Electrical fault Check circuit Excessive backlash in pump rotors Replace on engine running Noise EL 5 ENGINE LUBRICATION SYSTEM SPECIAL SERVICE TOOL Tool number No Description tool name STl9320000 Unit This tool is used to take oil f1Iter out of place the f1Iter do not Oil filter wrench I use this tool to prevent nun in Reference use page on Figure No In tightening All tightening models excess 120 4 7 SE197 6 EL For Fig or EL 9 SECTION CO COOLING SYSTEM DATSUN PICK UP MODEL 620 SERIES COOLING SYSTEM SERVICE DATA AND SPECIFICATIONS TROUBLE DIAGNOSES AND CORRECTIONS LNISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN CO 2 CO 6 CO 7 Cooling System COOLING SYSTEM CONTENTS DESCRIPTION COOLANT LEVEL DRAINING INSPECTION 4 CO 4 CO TEM COUPLlNG CO 2 PUMP REMOVAL OISASSEMBL Y CO 2 AND FLUSHING THE COOLING SYSTEM WATER CO 2 INSPECTION CO 2 AND INSTALLATION CO 5 REMOVAL DISASSEMBLY CO 3 INSPECTION INSPECTION AND ADJUSTMENT CO 3 AND INSTALLATION CO 5 CO 5 RADIATOR CO 3 REMOVAL AND INSTALLATION CO 5 THERMOSTAT CO 3 TORQUE COUPLING 4 CO 4 CO CO 5 REMOVAL AND INSTALLATION CO 5 INSPECTION CO 6 DESCRIPTION The cooling system is of the con ventional pressure type A centrifugal pump installed on the timing chain cover serves to circulate the coolant The pressure type radiator filler cap installed on the radiator operates the cooling system at higher than atmos pheric pressure The higher pressure raises the boiling point of the coolant and in creases the cooling efficiency of the If it is necessary to remove radiator cap wben radiator is hot turn cap radiator When the thermostat is closed the counterclockwise to the r slowly coolant remains in the cylinder head and block for swift warming up of the step After all pressure in the cool ing system is released tom cap passing the stop and remove it engine After it reaches normal oper ating temperature the coolant circu lates through the radiator cooling fan drive coupling type The is of a DRAINING AND FLUSHING THE COOLING SYSTEM To drain the cooling system re radiator cap release drain cock at the bottom of radiator and drain move plug on the right side of cylinder block If the heater system is installed set heater temperature control valve to open position After the coolant is drained completely close drain cock and plug and refill the system with clean soft water C0055 Fig CO I Cooling ry lem PUMP The water pump COOLANT LEVEL Caution The coolant level should be check ed and maintained at SO WATER mm 197 in below the upper face of filler neck when the engine is cold To injury quickly avoid never serious remove when personal I3diator cap engine is hot Sudden release of cooling system pressure is very dangerous CO 2 and torque cooling fan pulley coupling are a unitized construction The water pump is of type which is mounted front cover a centrifugal on the engine Cooling System The pump shaft is supported by a row of ball bearings press fit in Adjustment Tightening torque double 4 to 0 5 0 aluminum die cast pump body The bearings are permanently lubricated 3 0 to 3 6 ft lb an and sealed to prevent loss oflubricant and entry of dirt The pump is provided with an impeller which turns on a steel shaft The steel shaft rotates together with the torque coupling wheeL The volute chamber is built in the engine front cover The inlet of the pump is connected to the radiator s lower tank by Fan justed leaks at pump 3 and Install fan blade tighten at taching bolts securely Install belt and adjust for specified tension 4 Operate the engine at fast idling and recheck for leaks belt should be at all times belt ad causes of alternator and water pump bearings A loose belt brings about improper cooling fan and alternator operation water pump Check the belt slack between alter nator and fan pulley by force of 10 kg 22 lb Slackness of fan belt 8 to 12 Ensure that clearance between shroud and Can is properly tight A wear Install fan shrouds Note hose a m Fill cooling system and check for 2 5 assembly kg even at any mm 47 in 0 0 31 to place If adjustment is necessary loosen retaining alternator adjusting bar bolt to alternator Move alternator toward DISASSEMBLY Water pump is made of aluminum and its bearing outer race is of a press fit type For this reason or away from engine until the correct tension is obtained water pump should not be disassembled TORQUE COUPLING i o INSPECTION AND Except air CQ047 Fig CO 2 Water pump and engine front ADJUSTMENT REMOVAL AND INSTALLATION Inspection models Inspect pump assembly for the fol lowing conditions and replace if nee The torque coupling keeps the fan speed at 2 500 rpm rated or below to essary a clean 1 Badly rusted or corroded body sembly and vane 2 Excessive end play con bearings in or as roughness of operation assembly Oil leakage in torque speed a It also helps coupling at high engine reduce fan noise to during high speed opera minimum tion This unit is 3 Reduced cooling efficiency due to deteriorated silicone oil 4 horsepower conserve Removal in to equipped conditioner cover silicone oil filled with used as a which controls the fan oil can not be fluid speed replenished special coupling a Silicone I CQ048 Fig CO 3 Removing water pump Torque coupling wheel Torque coupling cover 3 Torque coupling bearing 1 Installation 1 Be sure 2 to clean the gasket sur faces in contact with pump and front cover Always use new gaskets when installing pump assembly tighten bolts Be sure 4 Pulley 5 Water pump C0060 to Fig CO 4 Sectional view of torque coupling and water pump 00 3 Cooling System REMOVAL AND DISASSEMBLY INSTALLATION To replace follow the The the torque coupling INSPECTION torque coupling is so Inspect designed coupling for torque If necessary leakage that it can not be disassembled oil replace procedure as in the water pump The torque coupling can not be separated from the water same pump TEM COUPLl G For air conditioner equipped models w I 6 1 Bi metal 2 Slide valve 3 Reserve chamber for 4 Bearing Driving chamber for ON ouplingpart labyrinth 5 6 thermostat OFF coon Fig CO 5 CrQM sectional view of is coupling Tem coupling which is a type of fan provided with a ation is temperature control system The conventional slips the fan The coupling always installed the Tem cooling requirement The coupling with the ON coiled high speed under a regardless of the engine at a constant ratio placed under OFF slips at about 1 and the fan slipping however is of the Tern properly changed cooling requirement denotes that cooling of air re quired and the front center portion of relative to the engine coolant tempera ture and the inside slide valve is opened is bimetal the or closed ON OFF as required and thus control the fan operates up to about 2 150 rpm When high cooling is When required during cold season with the engine warmed up etc the oper opened silicon oil not 650 rpm thermostat coupling detects temperature passing through the radiator air temperature is directly The ratio on condition is bimetal is temperature rises the expanded and the valve is is forwarded to the groove that transmits 4 CO torque and the placed under ON con dition When the valve closes silicone oil is supplied to the driving chamber driving chamber is accumu lated on periphery due to the centrif ugal force and led into the reserve not oil in the chamber Now oil is eliminated from the driving chamber and the system is placed under OFF condition With this system when fan cooling performed the air is system coupling Tem is not required minimized reduced and the noise output loss can be is far Cooling System re After checking thermostat install with a new housing gasket in 4 place Conventional COUplin9 WATER PUMP SPEED 5 Reinstall water outlet 6 Replenish should be sure that it is in inspected to good condition 1 Measure coolant mostat make temperature when thermostat valve starts to open 2 coolant and check for Measure lift maximum the of thermostat valve leaks INSPECTION F Z Tern coupling WATER PUMP SPEED C0029 Fig CO 6 Characteristic of Tern coupling will sticking thermostat A the cooling properly If the open prevent system from functioning the thermostat sticks in position the engine warms slowly If the thermostat the closed position over up very sticks in Fig CO S Impecting therm06t heating will result Therefore the ther INSPECTION t Check Tem coupling for oil leakage or bend of bimetal If the above symptoms replace it with a new are found one as Valve pellet type cylinder head temperatures operating properly moved and tested as type iype 5 83 5 to 89 5 86 177 to 183 187 to 193 167 1 00 8 8 90 to 8 95 31 0 inF 203 if and should be does If thermostat the not operate at On it matic must be be repaired re 2 partially Remove bolts and gasket models with equipped transmission combined with auto the oil cooler is the radiator to cool transmission fluid INSTALLATION RADIATOR The radiator is Disconnect upper radiator hose at outlet 194 31 0 REMOVAL AND water outlet 3 to 172 described below INSTALLATION Drain coolant 212 31 0 specified temperature replaced because it cannot above REMOVAL AND I 75 to 78 thermostat is lating coolant temperature The ther mostat is designed to open and close at not oC mm to control the flow of coolant facili tating fast engine warm up and regu predetermined type 80 5 Maximum valve lift water outlet The function of the Tropical is thermostat mounted in the thermostat housing at the opening temperature oC OF THERMOSTAT wax Frigid an assembly A Temperate remove water and thermostat from thermostat housing flow type tanks to a and having top bottom distribute the coolant flow uniformly through the vertical tube of radiator The radiator filler cap is kg cm2 designed to 09 pressure pre set above psi atmospheric a 13 pressure relief The valve blow off valve and helps to consisting a the prevent vacuum when the to is pressure below atmospheric um valve allows pressure air to from it How reduced the vacu re enter the radiator preventing the formation of a Fig CO 7 Removing therm06t t 2 Disconnect lower vacuum in the cooling system CO 5 con hoses radiator upper and On models with auto disconnect cooler inlet and outlet lines from radiator 3 Remove bolts and fan remove Remove front 5 Remove and then 6 shroud grille radiator retaining bolts remove radiator upward Install radiator in the quence retaining fan shroud 4 a valve coolant boiling by giving pressure ever of clean a tainer matic transmissions core maintain Drain coolant into conventional down of removal Note reverse se the fol lowing I Insert hoses in their positions until they bottom 2 Ensure that hoses are clearly arrow marks on visible from upper r Cooling System direction when hoses 3 Ensure that are radiator hose and any 30 mm I 181 in after cleaning it Then assembled clearance between cap on adjacent parts is minimum On mod will a not sure install radiator tester If cap does not hold If a leakage replace radiator or is detected repair or release at the specified pres replace cap els equipped with air conditions a minimum clearance of 18 mm 0 709 in should between exist compressor and hose 4 Ensure that shroud and fan is Note clearance between even at Be careful not to fins and tor core any place damage radia tube when in stalling INSPECTION Fig CO 9 Telting radiator cap Radiator cap should be checked for working intervals cap for pressure First at cracks tears regular Also inspect radiator for leakage using cap tester and applying a pres sure of 1 6 kg cm 22 8 psi tune up check rubber seal on deterioration or Fig CO IO Testing cooling 6ystem pUSure SERVICE DATA AND SPECIFICATIONS Thermostat Temperate Frigid type Tropical type type Valve opening temperature oC F 5 to 83 5 80 177 Maximum valve lift mm oC inj 5 to 89 5 86 to 183 187 8 95 F 31 0 to 193 8 100 31 0 203 75 to 78 167 to 172 8 90 212 31 0 194 Radia tor Type Manual transmission Corrugated fin Automatic transmission Corrugated fin type equipped with oil cooler Cap relief pressure type kg em psi 0 9 3 1 kg em psi 1 6 22 8 Cooling system Leakage testing pressure Capacity with heater Manual transmission Automatic transmission 8 0 liters US qt Imp qt liters US qt Imp qt 8 Ii 7 8 8 Y without heater 7 74 i 6 J 7 2 Fan Number of blades x outer diameter Without air conditioner mm in 7 x 380 With air conditioner mm in 8 x 380 6 CO 15 15 i6 7J 1i 7 X 6 X Cooling System TROUBLE DIAGNOSES AND CORRECTIONS Condition Loss of water Probable Damaged radiator Repair seams Leaks at heater connections or Leak at water Loose Corrective action cause temperature plugs gauge Repair Tigh ten Tighten joints Damaged cylinder head gasket Replace Check engine oil for contamination and refill as necessary Replace Cracked cylinder block Check engine with water Poor circulation Corrosion Cracked cylinder head Replace Loose Tighten cylinder Restriction in head bolts oil in crankcase by pulling oil level for mixing gauge Check hoses for crimps and clear the system of rust and sludge by flushing radiator system Insufficient coolant Replenish Inoperative Replace water pump Loose fan belt Adjust Inoperative thermostat Replace Excessive impurity in water Use soft clean water Rain water is satis factory Infrequent flushing and draining of system Cooling flushed system should periodically Ethylene glycol base out the seasons periodically Overheating Inoperative thermostat Replace Radiator fin choked with mud chaff etc Clean Incorrect ignition and valve timing Dirty oil and sludge Inoperative Adjust Adjust Restricted radiator Flush radiator Inaccurate temperature gauge Replace Use soft clean water in water Inoperative thermostat Replace Inaccurate Replace temperature gauge CO 7 and be used through change and passage thoroughly by using air from pressure engine side of radiator out air Replace water pump can of the year Refill engine drained at intervals recommended Loose fan belt Impurity Overcooling in be Permanent anti freeze SECTION EF ENGINE FUEL DATSUN PICK UP MODEL 620 SERIES l NISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN AUTOMATIC TEMPERATURE l CONTROL A T C AIR CLEANER H IDLE COMPENSATOR H 7 FUEL FILTER H 8 MECHANICAL FUEL PUMP H ELECTRIC FUEL PUMP H ll CARBURETOR H 14 2 9 Engine Fuel AUTOMATIC TEMPERATURE CONTROL AIR CLEANER A T C CONTENTS DESCRIPTION EF 2 VACUUM MOTOR OPERATION EF 3 CONTROL A T C AIR CLEANER HOT AIR AIR EF 3 CLEANER HOT AIR AIR TEMPERATURE COLD AIR EF 4 CLEANER FRESH AIR COLD AND AIR OPERATION TEMPERATURE EF 5 SENSOR EF 5 VACUUM MOTOR OPERATION A T C EF 5 REMOVAL AND INSTALLATION OPERATION AT C AND AIR VALVE EF 4 SENSOR EF 5 DUCT EF 5 CLEANER EF 6 INSPECTION EF 5 EF 6 1 AIR 2 HOT AIR CONTROL CLEANER ELEMENT EF 6 EF 6 SYSTEM DESCRIPTION The air cleaner removes dust and dirt from the air before it enters the and carburetor and engine sists of the It also muffles noise into intake resulting from the the engine The air cleaner of air especially designed Tempera Control Air Cleaner reduce HC emission hood the In order to when the under is temperature 860F below automatic control system maintains at 30 to thereby 540C enabling 86 lean carburetor calibration this twl the automatic 1 to 1290F for setting n addition temperature to con system is effective to improve warm up characteristics of the engine between the exhaust manifold and hot air cleaner system con following devices is be cleaned Automatic temperature manifold to the air cleaner Blow by gas filter The blow by gas nIter removes dirt and oil from the blow by gas sucked in the air cleaner from the engine rocker control 5 air cleaner is actuated vacuum by the air intake Fresh air duct Except for to control the intake The fresh air duct leads the outside fresh air directly 6 air flow circuit The temperature sen See 7 vacuum models passage Hot air duct exhaust manifold Page on the The air warmed up EF 2 tor the air cleaner paragraph Idle Compensator EF 7 Altitude compensator See The hot air duct is mounted to Idle compensator detects the temperature inside the air cleaner and opens or closes the sor 3 led Canada In the A T C valve is the hose cover air cleaner control duct 4 employed viscous paper type It requires only periodical replacment and should not 2 air through Air cleaner element a 300C temperature the tempera ture of air to be sucked in the carbure tor carburetor icing The air cleaner element for improved exhaust emission control is referred to as Automatic ture to remove The A T C California paragraph Altitude Compensa Page EF 20 Engine Fuel @ 1 Except for Canada 2 Fresh air duct Air inlet pipe 3 Vacuum 4 Air control valve 5 Hot air 6 Idle 7 8 Temperature motor assembly pipe compensator Blow by gas fiI teT Altitude 9 sensor assembly compensator California models EF713 Fig EF 1 Automatic temperature control air cleaner OPERATION The automatic temperature control system of the air cleaner is controlled by sensor and the vacuum Under hood air Sensor vacuum at temperature vacuum the inlet air temperature and the Air control valve motor side 36 2 Below 300C Sensor operation operation Open cold inHg Above 210 mmHg 8 27 air Close hot air inHg 30 to 540C Half open cold air hot air 1290 F Above 55 oC Open cold 1310F A T C vacuum Close 860 F to intake by the engine motor is actu Below 60 mmHg 86 ated load condition of the engine The inlet air temperature is detected by the Open Open air AIR CLEANER HOT AIR OPERATION When the under hood air tempera ture is low the sensor air bleed valve the remains in the urn establishes closed position vacuum passage and between intake motor With manifold and this condition vacuum the vacu at the intake manifold side actu ates the air control valve attached to EF 3 the motor vacuum duce hot through air the into hot haust manifold diaphragm the to intro air cleaner air duct on the ex Fuel Engine A T C AIR CLEANER COLD AIR OPERATION f f l I Air inlet pipe Air l ID Cif trol valve con The Hot air pipe in the Diaphragm Vacuum hose s 6 Diaphragm spring Air bleed valve Ittl closed ID Temperature sensor assembly Holair EF114 Fig EF 2 Hota r delivery mode When under hood air temperature is low During cold engine operation sensor and vacuum passage is established between the in take manifold and the vacuum motor and the intake manifold applied the to is vacuum dia motor vacuum phragm When the vacuum when the engine is is small or operating under 1004 the air control valve opens widely irrespective of the temperature eavy around the sensor to introduce the under hood air cold air for increased 7 power of the engine 2 When under hood air temperature To manifold Small Dr 1 air Underhood I air bleed valve remains closed position @ is vacuum 2 Air inlet pipe Air control high The valw fully sensor air bleed valve opens to shut off the vacuum passage 3 Hot air pipe 4 Diaphnp S V leuum hoses vacuum 6 Diaphragm prinl vacuum 7 Air air control valve closes the hot air bleed between the intake manifold and the valve closed II motor Due to the force of the motor the diaphragm spring pipe of the air cleaner and introduces the Temperature senSOr assembly under hood air cold air EF20S Fig EF 3 Cold air delivery mode During cold engine operation A T C AIR CLEANER COLD AND HOT AIR OPERATION f liP J omanifold 1 Air inlet 2 Air pipe control valve fully open Temperature assembly 8 EF715 ID f R fjr lfl ow Air inlet Hot air pipe 5 underh pipe Air control valve 2 Diaphragm r Vacuum hose rv Itti Diaphragm spring Air bleed valve ID partially opened Temperature sensor assembly air Hot 8 EF716 Fig EF 5 Regulating 4 EF air delivery mode air of the intake manifold With the air control valve the cold air together and and hot air sensor Fig EF 4 Cold air delivery mode During hot engine operation @ opening of the control valve varies with the vacuum Air bleed valve @ air bleed valve is partially opened Diaphragm spring I sensor Diaphragm Vacuum hoses Underhood air When the Hot air pipe mixed for perature are open half sucked controlling of the air tem of the air to be introduced to the air cleaner Fuel Engine TEMPERATURE SENSOR neeting vacuum hose to sensor vacuum The to the temperature sensor 2 into vacuum tube of clip Insert After installing each hose secure hose with the clip tube sensor is attached vacuum inside of the air cleaner The bimetal built in the detects the sensor position is R H correctly 3 Fixed with mark at the top side to Nissan of for intake manifold face sensor adhesive The to install vacuum hose sure 2 Calch sensor 4 Hose construction of the tempera ture sensor is shown in the Be Note Pipe I under hood air temperature and opens or closes the vacuum passage in the 5 following Correct L H side for vacuum motor Tab 6 Clip 7 Gasket EC019 CD V 00 @ I I Fig EF B Removal of semor 2 Disconnect hose from 3 Take off clip from tube and dismount VACUUM MOTOR sensor sensor vacuum sensor body from air cleaner 2 I Protector j @ 1 I Note cover Screw Air gasket air cleaner is Adjusting frame 1 The cleaner side temperature bimetal Valve seat between and sensor bonded to the air and should not be removed Rivet screws Disconnect securing vacuum valve shaft attached to vacuum motor valve control motor 3 frame diapluagm from and assembly from To install remove air cacuum air cleaner the removal reverse procedure Inatallatlon Lower frame Remove motor to air cleaner Air bleed valve EF206 Mount Gasket Fig EF 6 Temperature senior sensor on the specified position For see the mounting position of sensor FRESH AIR DUCT following I VACUUM MOTOR AND cleaner AIR CONTROL VALVE 2 pressure which varies with opening of the carburetor throt The the diaphragm carefully pull support while shaft attached to is then moved up or be introduced into the provided with air inlet side end a hand and out from radiator core turning it in either direction 3 To install procedure Be reverse sure EF717 air Fig EF 9 cleaner lalling se or mounting hole port the removal to insert lions of fresh air duct valve to control the temperature of the to on its Hold fresh air duct with motor dia vacuum The valve projections down in response to the vacuum on the diaphragm This movement of the valve shaft actuates the air control air Fresh air duct is vacuum tle acts upon the phragm Disconnect fresh air duct at air projec securely into in radiator core sup to pr I 1 00 @ E F 207 Valve 2 spring Diaphragm 3 Retainer 4 Valve shaft Fig EF 7 Vacuum motor REMOVAL AND INSTALLATION Fresh air duct Air cleaner Duct mounting hole Radiator TEMPERATURE SENSOR Radiator core support Removal EF518 Using pliers flatten clip Fig EF I0 Removal offresh air duct con EF 5 r Fuel Engine AIR CLEANER 1 Loosen bolts These air cleaner securing air control system Loosen air cleaner lock bolt and 2 air remove Disconnect cleaner from carburetor following hoses when the malfunc reveal If these check hot occur as described in the following before carrying out inspec tion of carburetor air cleaner dismounting should phenomena air cleaner bracket to phenomena tion of hot air control system 2 1 Vacuum hose Under hood air inlet hose Intake manifold Hot air inlet hose Vacuum hose Sensor to intake Vacuum hose Sensor to pensator vacuum um motor Vacuum hose Idle compensator intake manifold Hose Carburetor Blow by hose to Air hoses vacuum are se or Vacuum vaive to sensor air hose Nissan position mark RH the top of is for intake manifold L U on side of the mark is for cleaner California models only To install reverse the removal vacuum Vacuum motor 1 AIR CLEANER fresh air duct Viscous paper type air cleaner ele does not require any cleaning ment operation until it is replaced periodi cally Brushing or blasting operation will cause clogging and result in enrich of should carburetor never be refer to mixture conducted placement interval of ment With engine stopped Place ELEMENT above at disconnect the end of air condition actuates the spring valve by its control In de replace phragm from since reo motor as an vacuum this may be resulted air leak at vacuum motor dia 2 3 Temperature ensor Check temperature air cleaner ele air spring force to under hood air inlet within 30 seconds position sensor for func tion Maintenance Sched by proceeding as follows Be sure keep engine cold before starting to test I 2 HOT AIR In warm weather it EF213 is difficult to Fig EF 11 Inspecting valve position find out malfunction of hot air control In system cold wea thee With engine off check air control valve for condition CONTROL SYSTEM 2 however Air control valve is in correct posi disconnection and hot air inlet is closed position um hose between intake manifold and vacuum bility motor and insufficient dura of air control valve will insufficient automatic tion for intake air disorder I cause control opera and result in engine including Stall or hesitation of engine oper ation control valve 2 vacuum hose for condition vacuum and motor connect inlet another hose to the inlet to apply vacuum to vacuum motor Vacuum can be ap plied by breathing in the hose end as shown Place Increase in fuel consumption uck of power linkage Disconnect Check air mirror at the end of air cleaner inlet pipe and check to air control valve is in correct 6 EF see if position air control as case correct valve is the valve for correct In described above position reverse this of air control of 2 2 I hood air inlet is closed under and hot air inlet is open 3 Check that air control valve grad ually opens to under hood air inlet side a mirror for Immediately after engine starting check deterioration of vacu a Start engine and keep idling tion if its under hood air inlet is open or In this case under hood air inlet is open Use inspection as 2 2 1 above malfunction of air control valve due to 3 the maintains assembly ule 2 hose vacuum check that air control this condition cleaner inlet pipe as shown and check to see if air con trol valve is in correct and For in described and cut off air from open mirror a posi paragraph 2 vacuum hose with fingers pinch as If diaphragm I ment tion scribed in step 2 for more than 30 seconds and that hot air inlet is open procedure INSPECTION position if under hood air inlet is closed and hot valve motor 2 2 above Air Jpar graph air inlet is open 3 With hot air inlet in open air cleaner Note is the reverse of control valve is in correct postion Check each hose for cracks distortion hose clip for condition Air cleaner to rocker control to vacu Correct position of air control valve connected in correct side of Hose sensor 2 cover 3 temperature Check that curely Hose Air pump to air cleaner Hose AB valve to air cleaner Fig EF 12 Inspecting valve position motor I to EF217 temperature 3 way connector to idle com sensor manifold 3 way connec to 3 way connector to tor as engine warms up When en vironmental temperature around tern perature sensor is low spend more time for engine warming up operation Fuel Engine facilitate smooth operation of air to element will not be affected by air flow Then install air cleaner control valve operation of Remove air cleaner cover Set temperature around be measured thermistor bottom test as described in When air air inlet side several minutes after engine starting read the indica tion of thermistor thermometer If or tern perature range of temperature sensor the sensor is normal If reading ex sensor can ceeds fIx wiring of thermometer on the In this case or out 2 and 3 above reading falls within the working temperature sensing element of ther mistor or thermometer to a position where I hood air control valve carry out the following test 4 Carry control valve begins to open to under If the above test reveals any prob lem in the 5 steps cover with the range replace the sensor new one surface of air cleaner with adhesive tape in such a manner that the set position of temperature sensing Note Fig EF 13 Checking temperature Before replacing temperature check idle compensator described in Idle compensator sensor sensor as IDLE COMPENSATOR CONTENTS DESCRIPTION EF 7 REMOVAL AND INSTALLATION EF B OPERATION EF 7 INSPECTION EF 8 DESCRIPTION The idle compensator operates in response to the under hood air temper The idle compensator is basically a thermostatic valve which functions to ature as shown below introduce the air directly from the air cleaner to the intake manifold q to compensate for abnormal enrichment of mixture in high idle temperature The bi metal attached to the idle compensator detects the temperature 1 Orifice of intake air and opens or closes the valve Two idle compensators having 2 Bi metal 3 Rubber valve different are temperature installed temperature l580F 158 to EF222 characteristics Fig EF 14 Structure of idle opens at an intake air of 60 to 700C 140 to one and the other at 70 to compensator 900C 1940F Bi metal Intake air temperature Below 600C OPERATION No 60 to 70 C 1 140 The construction of the idle pensator is shown in the com following 1400F OF 158 Below 700C 1580F 70 to 900C 158 to 1940F Above 900C EF 7 operation Fully closed Close to open to l580F Above 700C No 2 Idle compensator 1940F Fully open Fully closed Close to open Fully open Engine REMOVAL Fuel Note AND INSTALLATION tor When checking idle compensa on leading connect check 2 vehicle to idle hose disconnect and compensator then carry out above other hose bed descn as temperature is above the specified operating tempera ture visually check to see if the valve is in open position If valve is not When bi metal replace open idle compensator as an assembly EF718 Watcr Fig EF 15 Location of idle compenl otor Observe temperature valve Remove air cleaner cover 2 Remove hose compensator and 3 Loosen air If excessive air leakage is found at idle connecting 3 way connector screws securing idle pensator to air cleaner then idle compensator com pensators valve of Notes to one as to 11t air cleaner plug the of these idle compensa prevent air leak while remove gasket and plate screw securing compensator NO 2 70 to metal Bi 900C 158to 1940F EF226 @ idle CD install reverse the I removal INSPECTION 3 Others I Check hoses for correct installa tion distortion or cracks tl procedure 2 Check rubber valve seat of idle compensator for sticking faulty Check closed 1 Orifice position when bi metal temperature is lower than operating temperature To 2 Rubber valve check 70De to air cleaner be care ful not to miss the saew I to 140 to 1580F Fig EF 17 Checking idle compensator removing idle compensator b When removing To mounted 1 Bknctal 60 checking the other one When 4 are and that it is necessary to remove tors so a No the valve replace idle compensator as an assembly Note that two idle com tha t valve IS m breathe air into tube or suck or any other conditions EF225 Fig EF 16 Checking idle compelll lor FUEL FILTER REMOVAL DESCRIPTION Disconnect The fuel fJlter is a cartridge type It paper element which can be checked for condition from the out uses inlet and lines from fuel fJlter and a outlet fuel remove fuel fJlter side 1 2 Body Paper element 3 Cover Fig 1 EFOO5 EF 18 Sectional view ofcartridge type fuel filter EF 8 Note Before disconnecting fuel lines container to receive the fuel use a remaining in lines Engine Fuel MECHANICAL FUEL PUMP CONTENTS DESCRIPTION EF 9 REMOVAL AND FUEL PUMP TESTING EF 9 INSPECTION EF 10 EF 9 ASSEMBL Y EF 11 TEST STATIC PRESSURE CAPACITY TEST DISASSEMBLY EF 10 EF 10 DESCRIPTION 1 The fuel pump transfers fuel from the tank to the carburetor in sufficient quantity the engine require speed or load to meet ments at any The fuel pump is sists of a fuel a pulsating type easy maintenance designed for It con body a rocker arm assembly diaphragm a fuel diaphragm a spring seal inlet and outlet valves Figure EF 19 shows a cross sectional view of the pump The fuel specially affected by by consists diaphragm gasoline of which is not treated rubber and held in two metal discs and a pull place rod 1 Outlet valve 2 3 Diaphragm Diaphragm spring 4 Inlet valve S Rocker EF006 ann Fig EF 19 Schematic view offuel pump FUEL PUMP TESTING A fuel pump is when its operating properly pressure is within tions and its capacity requirements Pressure and capacity engine s mined by is specifica equal at all to the speeds must be deter while the pump is the engine Be sure two tests still mounted on there is fuel in the tank when carrying out the tests STATIC PRESSURE TEST The static pressure test should be made as follows I Disconnect fuel line between Note Locate this Tconnector close to carburetor as as possible car buretor and fuel pump 2 Connect a rubber hose to each Connect a suitable pressure gauge the opening of Tconnector and fasten hose between carburetor and 3 open end of a T connector and con nect this connector hose assembly be to tween carburetor and fuel pump T connector with EF 9 a clip securely Engine Fuel 4 Run the engine 5 The at varying speeds indicates gauge pressure 2 Take off cap and cap gasket by removing cap screws fuel pressure in the line The gauge reading should be within the 3 Unscrew elbow and connector 4 Take following screwing static range 5 3 0 to 3 8 psi To remove down its center If the fuel in carburetor float Note chamber has run out and engine has and pour fuel stopped clip into carburetor Fasten clip secure 1 static pressure test ly and repe retainer by J un retainer screws and re move two valves kg em2 0 21 to 0 27 off valve two With diaphragm press against spring force diaphragm pressed down tilt it until the end of pull rod touches the inne wall of body Then EFOO7 release diaphragm Be careful to unhook push rod during this operation not damage diaphragm or oil se L to Fig EF 20 Remouing pull rod 6 Drive rocker press or arm out with pin a hammer Pressure below the lower limit indi cates extreme wear on one part or a small amount of wear working part It also indicates ruptured dia phragm worn warped dirty or gum on seats ming valves and diaphragm above return i each or spring weak a Pressure the upper limit indicates an excessively strong tension of dia phragm return that is too spring a or 8 diaphragm Both of these condi tight require the removal of pump assembly for replacement or repair tions o TEST CAPACITY The when capacity test is made only 6 static pressure is within the specifications To make this test pro ceed as follows 1 Disconnect install a in its vacant suitable container as 8 Cap gasket Valve packing 4 fuel pump e val S Valve retainer 6 Diaphragm assembly Diaphragm spring 7 8 fuel sump Run engine at 1 000 rpm 2 3 The pump should deliver 1 000 3 assembly place a fuel pump cap 7 pressure gauge from T connector and I 2 9 PuRro Lower body seal washer 10 Lower body seal 11 Inkl connector 12 Outlet connector 13 Rocker arm 14 Rocker arm fuel flows from the IS Rocker artyl side pin open end of pipe it is an indication that fuel line is clogged or pump is 16 Fuel pump packing 17 Spacer fuel pump fo cylinder block 11 2 US pt of fuel in one minute cc or less If little or no malfunctioning spring EF510 @ REMOVAL AND Fig EF 21 offuel pump ure Slruc DISASSEMBLY Remove fuel unscrewing two disassemble in the 1 pump assembly by mounting nuts and following 2 INSPECTION order Separate upper body and lower body by unscrewing body set screws valve I Check upper body and lower Check valve assembly for and valve assembly with brea th function body for cracks EF 10 spring wear on Blow valve to examine its Engine Check 3 carcks 4 6 arm for wear at the Reverse the order of with camshaft Check rocker pin To test the function proceed as follows mating portion worn 3 ASSEMBLY or wear Check rocker 5 for small holes diaphragm Fuel pin for wear A leakage other components for any abnormalities and replace if I meter instruc tions arm may cause oil Check all Position fuel pump assembly about 3 ft above fuel level of fuel disassembly Closely observe the following L 2 strainer Use new Lubricate rocker link and rocker neces arm ann connect Operate rocker rocker arm a from pipe arm by hand Iffuel is drawn up soon after rocker arm is pin before installa released tion sary and strainer to fuel pump gaskets fuel is pump functioning properly ELECTRIC FUEL PUMP CONTENTS DESCRIPTION EF 11 DISASSEMBLY EF 12 INSPECTION EF 11 ASSEMBL Y EF 12 REMOVAL AND INSTALLATION EF 12 TROUBLE DIAGNOSES AND EF 13 CORRECTIONS DESCRIPTION The electric fuel pump is on air conditioner adopted equipped models The silicon transistor type fuel pump consists of a transistor diodes a sole noid a pump mechanism and filter parts J ev J I Tr lOsistor 6 Ou tIet valve 2 7 Return spring Filter 3 Plunger Diaphragm 4 Diode 5 Magnet coil 8 9 10 I T 2 Re nsistor 3 Dinde 4 Signal 5 Main coil I f ist coil 3 6 Resistor 7 Zener dlOdl 8 Resistor 2 Magnet EF719 Inlet valve Fig EF 22 Construction of electric fuel pump INSPECTION I Disconnect fuel hose at pump outlet 2 meter If diameter is too small 6 a mm suitable hose 0 24 in approxi inner dia the proper delivery capacity cannot be obtained even if pump functions properly following Connect mately Note to pump outlet 3 a than pump 15 seconds 4 EF 11 With hose outlet in higher posi operate pump and check delivery capacity for more than tion The capacity should be I 400 cc Engine Fuel 854 co in in one minute If no gasoline or b Do not let less only a little flows pipe with pump or open end of operated or if pump does not work from c perform the following diagnosis Notes 3 battery Do not connect which polarity would time a Fuel long it may 46 kg cm ASSEMBLY I Before assembly clean all parts with gasoline and compressed air com pletely Notes a maximum pressure 0 32 transitor damage as tronic components in reverse if left for fall pump damage electronic components max Do not apply overvoitage l8Y Overvoltage starting by tage running quick charge or would deteriorate or damage elec If t an d fdterare faulty gask r place psi b Clean magnet and cover for fault c Take care not to defonn thin tube circuit and disable pump d Assemble REMOVAL AND INSTALLATION plunger inlet valve To carburetor spring e spring return Oring washer and set retainer in that order Assemble filter gasket and cover with f Tighten cover with wrench to the stopper If component parts are dirty after disassembly clean as follows 2 Elecuic fuel pump Mounting bracket 3 Fuel mter 1 Flom fuel tank Wash fIlter and strainer with clean gasoline Wash Fig EF 23 Electric fuel pump located on R H side member adjacent to fuel tank Remove I pump to ning Also inlet remove engine hose fuel from outlet hose Receive fuel remaining in fuel hose in a suitable container 2 Disconnect harness 3 Remove bolts securing fuel pump at connector to bracket and detach fuel pump Installation is the reverse order of 4 cover cover with wrench and gasket magnet filter from pump body 2 When removing plunger and Then out take inlet valve return washer spring and O ring plunger Do not disassemble electronic If n replace new ones 9 6 @ Cover 8 Oring 2 9 Inlet valve 3 Magnet Cover gasket 10 Retutn PIing 4 Filter 11 5 Gasket 12 Plunger Plunger cylinder 6 Spring retainer 13 Body 7 Washer v EF721 Fig EF 24 Exploded view of electric fuel pump EF 12 m lI parts for wear they are found faulty replace them 3 Insert assembly into cylinder of body and apply plunger electric current to it Move the assembly up and down If the assembly does not move it shows that the electric uuit is and it must be from tube with c damage plunger take out spring retainer from plunger tube 3 Check If Remove components 1 or faulty Note removal 2 Do not disassemble unless pump is take out run inlet valve with clean gasoline and blow dust off with compressed air DISASSEMBLY I cleaning parts check replace plunger plunger cylinder and fllter for fault If faulty EF72D Electric fuel pump is installed on bracket with two bolts This bracket is and blow with compressed When air replaced faulty Engine Fuel TROUBLE DIAGNOSES AND CORRECTIONS Probable Condition Fuel pump fails to Terminals operate Rust on Frozen or Corrective action cause Retighten connections loose terminals liquid in or grounding plunger or Clean metal Clean pump plunger assembly plunger is stuck or Replace pump if seized Fuel pump fails to discharge sufficient Clogged filter Clean pump interior Clean and if necessary replace fIlter flow Insufficient fuel Replenish Insufficient fuel Air in fuel hose Apply through connections discharge during high speed travelling Low float level at idling a coating of end sealing compound connections and Hose necked down tank Fuel or breather Check and correct bent tube to retighten bent or necked Check and correct down Replace Weakened return spring sucked through connection Fuel pump is actuated Air more and fuel pump joint frequently than Fuel hose under normal condi Clogged tion Rattling noise on suction side fuel hose Apply a coating of end sealing compound connection and retighten Check and correct bent Clean fIlter or replace fIlter Retighten Mounting bolts loose EF 13 to Engine Fuel CARBURETOR CONTENTS DESCRIPTION EF 14 CHOKE EF 14 ELECTRIC PRIMARY SYSTEM EF 15 INTERLOCK OPENING OF SECONDARY EF 16 SECONDARY THROTTLE EF 17 DASH EF 18 ACCELERATING STRUCTURE AND OPERATION SYSTEM ANTI DIESELING FLOAT SYSTEM SYSTEM B CD ELECTRIC D AUTOMATIC CHOKE DASH POT SYSTEM ALTITUDE AND VALVE EF 24 POT EF 25 PUMP EF 25 SOLENOID BC D D EF 20 TEST CONNECTOR EF 20 ALTITUDE COMPENSATOR CIRCUIT WITH VALVE EF 25 FUNCTION EF 25 EF 29 California modelsl MAJOR SERVICE OPERATION EF 20 ADJUSTMENT AND INSPECTION MIXTURE EF 24 PRIMARY EF 1B COMPENSATOR California models CARBURETOR EF 23 AUTOMATIC CHOKE ANTI DIESELING BOOST CONTROLLED DECELERATION DEVICE UNLOADER EF 29 REMOVAL EF 21 EF 29 DISASSEMBLY AND ASSEMBLY IDLE RPM AND RATIO CLEANING EF 21 EF 30 AND INSPECTION FUEL LEVEL EF 22 SERVICE FAST IDLE EF 22 TROU8LE DATA VACUUM BREAK EF 23 CORRECTIONS EF 34 AND SPECIFICATIONS EF 35 DIAGNOSES AND DESCRIPTION EF 36 STRUCTURE AND OPERATION The carburetors two barrel optimum are of down draft types which produce the air fuel mixture under all operating conditions They present several features of importance to distinct the vehicle summary of the features is as follows 1 A slow economizer smooth connection or deceleration to make a with acceleration during light load run ning It also assures stable low speed performance 2 A BC D D hydrocarbon 4 An 5 6 An to a minimum These reducing emissions electric automatic choke to to reduce dieseling solenoid dieseling run on to A The float system accelerating comes equipped of common to both mechanism etc are a power dieseling valve mechanism under all pensator corrects air fuel mixture pensator is installed in the California models EF 14 an also also are installed com se solenoid valve and with dash pot which ensures smooth deceleration without engine stall operating conditions The hand operated altitude a attached An anti carburetor consist primary and secondary systems a condary switch over mechanism speed operation 7 carburetors primary system for normal running and a secondary system for full load running A anti power valve or vacuum actu ated booster to ensure smooth high 8 An idle limiter to reduce harmful exhaust emissions H C device for facilitate cold starting and exhaust emissions eliminate owners A 3 The an hand operated altitude optimum ratio com to Engine Fuel jli@ I tZrJ I III @ Fuel nipple I 2 Fuel filter 3 Needle 4 Float S Primary 6 Idle 7 I die hole 12 Air bleed 19 Choke valve 25 8 Primary bypass hole Secondary 13 Primary slow jet 20 26 Secondary small 9 Primary throttle valve Primary altitude compensator pipe California models Secondary altitude compensator pipe California models 14 Primary small venturi High speed enricher air 27 D C D D bleed 28 Secondary 10 11 main adjust Do not Note jet screw remove Plug 15 Primary 6 Primary 17 Primary 8 the parts marked with 21 slow air bleed main air bleed 22 Richer nozzle air vent pipe 23 Primary main nOlzle 24 Richer jet Secondary an air vent a main nozzle enturi sembly throttle valve pipe EF722 asterisk Fig EF 25 Sectional view of carburetor PRIMARY SYSTEM main Prlmar sstem The primary main system is a Stromburg type Fuel flows as shown in Figure EF 25 through the main jet mixting with air which comes in from the main air bleed and passes through the emulsion into tube venturi the and is through pulled the into the the idle hole and and engine through the idle hole bypass hole Adoption of the submerged type of slow jet eliminates such hesitation as sow occurs on nozzle sudden deceleration of the Slow economizer system smooth deceleration at high obtains Accele atlns mechanism speeds Small opening of the throttle valve at idling vacuum or partial load creates a large pressure in the intake mani sstem low engine speed as shown in Figure EF 25 fuel flows through During By this vacuum pressure fuel is measured through the slow jet located behind the main jet And air coming from the 1st slow air bleed is mixed the slow jet located on rear right side of main nozzle mixing with air com with fuel in the emulsion hole ing from the 1st slow atomized with air coming mixing with slow air air bleed again coming from the bleed and then is pulled air 2nd out This mixture is further mixed and 2nd slow mixture is air bleed supplied to EF15 The from the atomized the engine from equipped The carburetor is piston linked fld IdUns and slow hole via the vehicle out main bypass sysem passage accelerating type to the throttle valve throttle primary Figure EF 26 is valve closed with the mechanism When the shown the in piston and fuel flows from the float goes up chamber through the inlet valve into the space under the piston When the throttle valve is opened the piston goes and down opening the outlet valve fuel is forced out injector through the Fuel Engine 1 L if 1 Pump injector 2 Piston 3 Spring Weight Damper spring Piston return spring 4 5 6 7 8 Inlet valve Outlet valve EF023 Fig EF 26 Acceleration mechanism Power valve mechanism The called valve mechanism power vacuum vacuum SECONDARY SYSTEM so piston type utilizes the below the throttle valve When the throttle valve is opened during light vacuum fold is created in the intake mani This piston load slightly running high pulls the against the vacuum upward vacuum spring leaving the power valve closed When the vacuum below the throttle valve is lowered during full load or Secondary main lIYlltem pulled out through the main nozzle into the small venturi The secondary main system is Due to the double venturi of the a Stromburg type secondary system Fuel air mixture produced by the functions of the main jet bleed and emulsion tube manner as in the main air current air velocity passing through the main nozzle promotes the fuel atomization in the same primary system the higher The structure is almost the is same as the primary side accelerat ing running the spring pushes the vacuum piston downward opening the power valve to furnish fuel 1 11 I 1 1 2 Primary vacuum port Secondary vacuum port 3 Diaphragm chamber cover I 1 1 Vacuum piston 2 Power valve a ET02 Fig EF 27 Sectional view of po 11 ll W l v of S 6 Diaphragm spring Diaphragm Secondary throttle valve 7 Primary theo nle valve 512 EF r valve Fig EF 16 EF 28 Full throttle al high peed Fuel Engine HI Step system richer jet high speed bleed and richer nozzle The The construction of this system correspond to the idling and slow system of the primary system Tlris system aims at the proper may filling high speed h speed circuit circuit improves high engine output performance during high speed driving This circuit operates only when driving at high speed It consists of a velocity of the air When the suction air flowing through secondary bore in carburetor creases enricher additional fuel is drawn out of the richer nozzle up of the gap when fuel supply primary system to the secondary one The step port is located near the secondary throttle valve edge in its fully closed state is transferred from the @ 2 Secondary switchover mechanism The throttle secondary linked to actuated the the by diaphragm vacuum valve is which is created in the jet provided at and secondary primary venturies and the composite vacuum of these jets actuates the diaphragm As the linkage causes the secondary throttle valve to close until the prima ry throttle valve opening reaches ap proximately 500 fuel consumption during normal operation is not exces venturi A vacuum is each of the sive During shown in at the high Figure venturi speed EF 28 is running as EF234 as the vacuum increased Secondary Primary the dia is pulled against the diaphragm spring force and then secondary throt The Richer jet High speed enricher air bleed phragm tie valve is I 2 3 opened Richer nozzle Fig EF 29 High speed circuit other side during low speed running as the primary throttle valve the opening does not reach 500 secondary throttle valve is locked to close completely by the locking arm which is interlocked with throttle arm primary ANTI DIESELlNG SYSTEM The carburetor is equipped with is an dieseling solenoid valve As the ignition switch is turned off the valve anti brought into operation shutting off the supply of fuel to the slow circuit The following figure shows a see tiorial view of this control by linkage the primary throttle valve opening reaches wider position than 500 the secondary throttle valve is When arm CD open because the locking revolves and leaves from the se ready to condary throttle 1 g 1 arm @eI EF230 1 dieseling Anti solenoid va1 2 Ignition switch 3 Battery @ l Fig EF 30 Schematic drawing of anti dieseling sydtm EF 17 Fuel Engine FLOAT SYSTEM determined duces There while Jnd stl only IS two one float chamber arburetor systems primary l ondary provided are Fuel fed from the fuel pump flows through the filler and needle valve into flo the level t chamber is maintained A constant the float by fuel fuel will consumption fluenced by quantity into the manifold by opening a separate mixture be not in dirt accumulated in some the air deaner of H C amount its considerably long use Besides the of a spring wiU prevent the at flooding rough road running inserrion the carburetor During vacuum takes contained in exhaust the transition to a idling signal which period from the transmission turns on the opening the vacuum engine speed the to predetermined idling transmission serves to it and amplifier hydrocarbons He gine during coasting The en consists of B C D D valve solenoid during vacuum vacuum con and fold vacuum reduced @ This to be result that bons a large amount of is emitted into hydrocar tile atmosphere The B C D D has been correct designed to this problem It opern tes manifold as vacuum exceeds when the a pre the at of mixture amount the upon pre coasting depends bleed air while the mixture ratio is deter mined by coasting the @ coasting jet @ bleed air See and Figure EF 31 Vacuum control solenoid Manual transmission models The vacuum control solenoid valve con troDed by speed a as a when the fetermined pre As the vehicle speed falls below 10 this switch is activated pro causes the manifold into introduced chamber and the acts so open the actuates the vacuum control solenoid valve second actuates Automatic transmission models valve vacuurn dia phragm ll@ When diaphrngm II operates the valve @ opens the passage and introduces the additional mixture into the manifold EF 18 to vacuum value to open the vacuum control vacuum detecting switch that is actuated by the speed ometer needle amplifier I Qj monitors the mani and mixture control follows kept ducing a signal This signal exceeds of mixture per cyl inder per rotation of engine with the The mainly inhibitor BC D D operation coasting prevents the mixture from complete combustion because of the amount may that the manifold MPH Diaphragm high manifold so be determined value is reduce the emitted from @ models On automatic transmission models trol BC D D vacuum of the and vacuum valve operation manual On Boost Controlled Deceleration Device control valve CID con chamber to switch A mixture control valve action the atmosphere The mixture control valve is then closed returning the BOOST CONTROLLED DEVICE by servo the valve is lifted off its place tecting switch B C D D the control solenoid valve As this this system consists of B C D D vacuo urn control solenoid valve speed de DECELERATION The amount of the mixture is trolled II@ dramatically reduced coasting produces seat The needle valve includes special hard steel ball and will not wear for all in passage Complete combustion of fuel is assist ed by this additional mixture and the gases is Because of the inner air vent type of the float chamber ventilation the intro mixture ratio and mum and needle valve the B C D D value additional mixture of opti an When P the shift lever is in position mounted on the inhibitor N or switch the transmission turns on to open the vacuum control solenoid valve Fuel Engine I Secondary main jet Coasting jet 14 Coasting air bleed I 12 13 Air 2 jet Diaphragm 3 Mixture control valve 4 Coasting 5 Mixture air II air bleed II 15 7 16 8 Boost passage 17 9 Vacuum control 6 N Inhibitor switch ON passage Secondary baHel Intake manifold P for automatic transmission solenoid Amplifier Speed de tecting 10 M P H ON valve swi tch below for manual transmission 10 Vacuum control II Diaphragm valve 18 Ignition CID switch I 11 6 I @ fI3 r 101 1 j W @ i r @ JJ I t i J l J Note Broken line applies only to Automatic Transmission EF231 Fig EF 31 Schematic drawing of B C D D I 2 3 Ignition switch Amplifier Speed detecting switch 10 M P H ON Inhibitor switch Non California models below for manual transmission ru I 4 ON N r p lJ for automatic transmission 5 Solenoid valve 6 Vacuum control valve 7 Altitude corrector i7 I To intake manifold 1 J To air cleaner I LlJ I l f L8 J l E F235 Note Broken line applies only to Automatic Transmission Fig EF 32 Schematic drawing of RC D D EF 19 California models Fuel Engine The ELECTRIC AUTOMATIC each CHOKE construction and function of of this carburetor part are as bi metal which mixture ratio controls the air fuel required for starting follows An electric heater wanns a bi metal interconnected to the choke valve and controls the position of choke valve and throttle valve in accordance with the time the elapsed engine tion of the warm up condi and the outside ambient temperature When outside ambient temperature is above operating temperature the automatic choke control serves to fur ther reduce during exhaust warm selecting one tion modes by up of the gasemission automatically two choke fast acting or opera slow acting Slow acting choke operation When ambient temperature is low electric current automatic to through the choke relay to the P T C heater A bi metal flows and This gradually causes warms l Electric ttea r and heater in choke tl 1SI nd war The deflection of the engine bi metal is transmitted to the choke valve through the choke yalve lever 2 fast idle opening of cam determines the the throttle valve so that the proper amount of mixture cor responding to the opening of the choke valve opening of ent upon the engine 3 obtained will be the choke valve is the warm The depend up condition Fast idle adjusting This of 4 choke the liUle period that is before the valve so as obtain to an adequate air fuel mixture 5 Fast acting choke operation the When ambient temperature is high bi metal switch is in on This causes the PT C ing electric current to flow through automatic in choke relay to heater A and heater B the result quick opening of the choke valve diaphragm enginThas been started by cranking this diaphragm forces the choke valve open to the predetermined so as to provide the proper air fuel ratio 6 metal Bi The used link pot engine stall resulting from quick application of the brake or from the quick release of the accele ra tor pedal after treading it slightly In such a situation a throttle lever strikes against the dash pot stem and makes the primary throttle valve close thus gradually running keeping the engine ALTITUDE COMPENSATOR The higher the altitude the richer the air fuel mixture ratio and there fore the higher exhaust gas emissions though the engine is properly ad justed for low altitude driving even Vacuum After the extent a is intended engine during opens sufficiently this unloader forces the choke valve open a open slowly through The dash California models accelerating the warm up ked wi h the interl throttle valve primary mechanism equipped are screw U nloader When carburetors adjusts the opening of the throttle valve of the fast idle earn screw These with a dash pot to prevent Fast idle cam The DASH POT SYSTEM flows through the current le t as bi metal the the the choke valve Bi metal cover The altitude compensator is design to meet EiiriSSion S13ndards for ed driving in both low and high altitudes At high altitudes additional air is sup plied to the carburetor by the altitude compensator case metal bi index mark case index When the altitude pensator lever is set at mark is for setting the moment of the D H com air is conducted through an air passage to the carburetor The air passage is closed when the lever is set at L H L Lever When operating the H L lever fol r low these instructions Il H @@ r position Should be used for EF232 1 4 @ Automatic choke P T C heater cover Bi metal switch 6 P 7 Bi metal 8 Choke valve B Fig EF 33 Schematic drawing of electric automatic choke heater EF 20 Counties L position A 5 T C heater general driving designated by law as relay Automatic choke 3 areas High Altitude Alternator 2 in those For nated use as outside those areas High Altitude Counties desig Fuel Engine a 1 219 b Counties Notes The idle rpm and CO vary accord ing to the altitude Therefore they properly adjusted the position of the H L lever changed 4 000 m sea level designated by law when should be above more High as ft Altitude For further details Counties or have been shown in Figure EF 35 the dis Plug connected hose to prevent dust from entering refer 0 to 1977 OATSUN PICK UP Service is Bulletin Pub No 257 o n Air cleaner 0 I rID Low altitude Ll n If mOl EF259 n L Fig EF 35 Disconnecting air hose from air check valve 6 Race two or I 500 to 2 000 rpm engine three times under no load then engine for one minute at idling speed 7 Adjust throttle adjusting screw until engine is at specified speed run Engine speed Fig EF 34 EF729 Manual transmission 750 rpm probe into tail pipe 40 em 15 7 in sert ADJUSTMENT AND INSPECTION more Automatic transmission than 0 in position 650 rpm CARBURETOR IDLE R P M AND MIXTURE RATIO Idle adjustment with CO 8 CO meter If Check ignition timing neces adjust it to specifications This operation need not be carried sary Idle mixture the Cautions 3 On ped automatic transmission models equi check should be per formed in the 0 Be sure to engage position parking brake and to lock both front and rear wheels Keep your foot down on the brake pedal while depressing the accelera tor pedal Otherwise vehicle surges forward dangerously 00 not attempt adjusting Ooing so could to screw the idle completely damage to tip down screw cause which in turn will tend to cause When idle it adjust mixture have the meter preparing I 2 120 750 750 100 Check carburetor pipes for proper water specifically mended Either driving vehicle is 3 ture Make not at no sure recom that water tempera adjustment has been speed Ouring this 10 proceed as described in steps minutes 5 to 9 below mission connector 5 screw so that CO percentage specified level tl 2 at 750 rpm Automatic transmission in 0 position tI 2 10 at 650 rpm Repeat procedures as 7 and 9 above in steps 6 described so that CO level Check Remove air hose between 3 way 5 way connector for Cali fornia models engine adjust idle CO percentage Manual transmission applying load to engine in order to engine condition Engine made shift the lever to the N or P position for automatic trans d When measuring CO percentage in is at stabilize idling position idling speed at run adjusting Further keep engine running at about 2 000 rpm for about 5 minutes with at California At about 10 minutes after 9 indicator points to the middle Idle Limiter Cap Non California rpm 120 650 rpm is or oper load will be good 0 in perature indicator points to the middle of gauge The procedure to warm up engine rpm Automatic transmission tem To install idle limiter cap refer to idle Manual transmission thoroughly warmed up Warm up engine until 1 000 miles service Ignition timing is essential to hood should be open Run engine for about 10 minutes 4 After out at 1 600 Ian to and calibrated out malfunctio11ll b If idle limiter cap obstructs proper adjustment remove it c adjustment requires especially for CO meter California models ating engine Notes a a connection with wheel chocks b of use and air check valve EF 21 as percentage is at specified ing idle CO in step 9 can be carried right after II out step 7 Race engine 1 500 to 2 000 Fuel Engine two or three iimes under rpm and make that sure no is load CO per specified adjusting centage is obtained 12 10 hose to air check valve engine speed increases readjust it the specified speed with throttle Repeat procedures speed for COidle edJustment without CO meter not is following procedures available may be used Warm up engine until water tem perature indicator points to the middle The procedure mended Either 3 to specifically driving vehicle at no indicator points to keep engine running for stabilize to without in order to engine condition engine should hood 4 about 5 minutes load applying about 2 000 at Engine be open in D Remove air hose between 3 way 5 way connector for Cali and air valve 3 Float chamber If engine speed increases readjust it to the specified speed with throttle 4 Needle valve adjusting Do not remove necessary moved check valve Plug the dis I After engine 1 500 three times under to 2 000 rpm no load then engine for one minute at idling speed 7 Adjust throttle adjusting screw so that engine speeds are as indicated throttle adjusting speed adjusting screw standard Race To readjusted at lime adjust proceed as 2 amount gases or idle check to be sure of CO meets contained in float Adjust bottom that clearance this idle limiter cap If this unit is re it must be that the IIf I t ET032 Fig EF 37 Adjusting float level 2 unless seat screw Idle limiter cep exhaust or it Float entering two I Float connected hose 19 prevent dust from 6 off I follows models i 2 of installation shown in Figure EF 35 j position Connect air 5 fornia right after hose to air check 12 5 to 9 below connector fuel level wi th attached 15 to 25 rpm Run engine for about 10 minutes at idling speed During this 10 minutes proceed as described in steps is level gauge 60 to 70 rpm recom temperature approximalely 7 float position lOp p up the middle Further is in check ment Automatic transmission or oper load will be good Make sure that water rpm warm not ating engine models and Manual transmission 2 H 0 283 The top float position can be ad justed by bending float seat Upon completion of the adjust engine is 815 rpm 7 Engine speed drops connection is transmission EF 37 correct 11 Turn the idle adjusting screw clockwise until engine speed drops off below specified rpm the Check carburetor pipes for proper engine 7 and 9 above until best idle mixture at manual step Figu re When described as in step 9 can be carried out CO meter of gauge in idle 670 rpm for automatic transmission models in D position Adjustment adjustingsqew L adjust mill in steps 6 If If speed until maximum rpm is screw obtained Connect air to idling at run h position and needle valve stemis I 3 0 051 to rals 0 067 in n 3 so between float seat Jloa t to L7 when Iloat is goppe mm fully re q After adjustments in steps I and have been made make sure 2 above that when fuel is delivered to the float chamber the fuel level is maintained within the range of23 mm 0 91 in shown in FigureEF 38 as the established Install idle limiter cap in position sure that the adjusting screw making run can another rotate CO RICH Carbo to 1 8 turn in the direction per CO below rich rotation 450 lIS Engine speed Manual transmission CO 815 rpm t Automatic transmission D in position SQ Check ignition timing sary adjust at 1 600 if cap Fig EF 36 Setting idle limiter neces need not km 1 000 miles service 9 1dle lim Iter 0 91 in EF260 At about 10 minutes after engine FAST IDLE cap I required by specifications This operation out mm Fig EF 38 Checking ruellevel ET031 8 be carried 23 J 670 rpm it to the value H lean With moved FUEL LEVEL valve clearance 1 Turn down float chamber to al low float to come into contact with placing needle cam valve and carburetor from engine measure EF 22 Hu shown screw the on A assembly measure with upper side the first step a wire gauge of fast on reo throttle fast idling idling Fuel Engine Fast idling earn steps o 04th l Fast Choke connecting 1st rod Z EC528 Fig EF 39 Mea uring throttle valve clearance carn Fast idling screw Choke valve 2nd EC527 idling Nut Throttle valve Fig EF 40 Fast idling cam steps ET033 The clearance should be 2 specified value in the following table Ifnot ad the just idling clearance turning fast by Fig EF 41 Adjusting the clearance of throttle valve screw Clearance A mm in Fast idling 1 33 to I 47 0 0524 to 0 0579 MfT 1st 1 58 to 1 72 AfT 3 To check fast idling cam idling cam at 2nd step and read engine speed Fast idling cam is prop erly set if engine speed is within Set Fast Engine speed rpm idling specifications below Clearance A in 2nd step is reference value A Clearance earn 18 1 0 94 to I 900 to 2 800 MfT step 0 0622 to 0 0677 fast setting follows by engine speed proceed Warm up engine sufficiently as earn mm in 0 0370 to 0 0465 2nd step L16 to I 40 0 0457 to 0 0551 2 200 to 3 200 AfT CHOKE UNLOADER VACUUM BREAK I 2 Close choke valve completely Hold choke valve by stretching rubber band between choke piston 4 out Under this condition clearance carburetor 42 EF vacuum to between choke body specified B adjust the j valve in value by LL Close choke valve iXo CK a lever and stationary part of carburetor 3 Grip vacuum break rod with pliers and pull straight B S completely Hold choke valve by stretching rubber band between choke a piston lever and stationary part of carburetor 3 Pull throttle lever until full open r Under this condition I il and 2 ance L J adjust body to 2 45 mm 0 096 bending unloader tongue tor Figure clear between choke valve and carbure in by bending Note brake rod EF516 4 2 Choke piston rod Choke spring 5 Diaphragm cover Choke piston lever 3 Choke piston 6 Choke valve 1 Fig EF 42 Adjusting vacuum break Make that throttle valve is mounted opens when carburetor on the vehicle If throttle valve rails to open un loader becomes inoperative resulr ing in poor acceleration after is started EF 23 sure engine Fuel Engine celerator pedaJ to press al choke valve doses properly heater circuit with function Do not altach designated I test to those tester Refer to leads of a other than 43 Ef figure engine not running check for continuity between A and B as With shown in figure and tioning properly If continuity d for disconnected Check cover at center position except the choke housing index of not exist connector or open tE jL 2 across volts c d 3 exists to termi that ensure terminals between 4 Check voltage when no them If results is 2 applied satisfies not 4 and the across above choke relay is functioning automatic if not properly does continuity t lal exist between terminals relay choke replace 12 is reading volts zero for disconnected connector Bi metal check open faulty automatic choke Thermostat 3 Groove 4 EF723 cover Fig EF 46 Checking automatic choke housing relay ET034 Fig EF 44 Bi relay y 3 chamber 2 2 1 J 43 EF If vohmeter reading is tting metol Automatic choke heater Measure I 3 in check Thermostat or shown in of marl s properly circuit of any heater circuit is functioning c d as cenleT check shown as and ontinuity i bi rnetal that 44 EF mark With engine running at idle check for presence of voltage across A and B figure finger Do not set b metal cover index Note heater is func a I 2 and sure index mark is set at the Figure 2 If voltmeter be 0 choke housing index mark P T e heater circuit shown in with Apply nals operational an choke relay 46 EF Figure that ensure heck for binding 3 43 Ef If continuity exists as choke valve Push test connector de fully Before starting engine I Checklna automatic choke circuit Make automatic CHOKE Caution 2 Automatic choke ELECTRIC AUTOMATIC Replace faulty parts heater as shown in spe 4 automatic Check source choke heater ified of resistance re figure is san ce choke 47 EF 3 7 to 8 9 ohms wiring for proper connection then start engine 5 After warming up the engine that choke valve is 6 If automatic choke heater wiring not see fully open source is normal and choke valve does operate hi metal after warm up replace t er co F Automatic EF261 choke relay J Fig EF 47 Automatic choke heater j I Remove automatic choke relay check 2 Auto the choke heater relay If measured value is not within specification replace bi metal cover N INTERLOCK OPENING OF j 1 ignition key 2 Automatic choke relay OFF Engine stop 3 Automatic 4 Function test connector Altema tor Engine EF710 5 PRIMARY AND SECONDARY THROTnE VALVE ON choke heateI start Figure tie valve EF278 Fig EF 43 Checking oulomalic choke heater circuit with fu nc non led connector Fig EF 45 Location of automatic choke relay EF 24 48 EF opened shows SO primary throt When primary throtlle valve is opened 50 plate integrated the adjust with throttle valve in contact with return plate at A is Fuel Engine When throttle valve ther locking is opened fur detached is arm B C D D CIRCUIT WITH FUNCTION TEST CONNECTOR from secondary throttle arm permitting ondary system to start operation see Do not attach test leads of a circuit tester to those other than Caution Linkage between primary and see ondary throttles will function properly designated if distance between throttle valve and Menuel trensmlsslon models inner wall of throttle chamber is 74 mm 291 0 I in Adjustment is made by bending BC D D @ I 49 EF Fig Adjusting dash pot l L If continuity does Secondary Connecting 3 Return plate ary t 7 4 lever Visually I I I Jl Roller prm switch accelerating inspect 2 gasket and replace if necessary Figure amber 5 Throttle 6 Throttle valve c closed is in replace solencid valve DASH POT by of the one methods with housing solenoid valve than more circuit is MPH 16 km h functioning a 10 prop erly If voltmeter reading is not 0 volt unit a Chassis dynamometer test If voltmeter reading is 0 volt at check for disconnected connector Idling speed of engine well engine sufficiently and mix a tuned up and warm read engine speed when dash pot just touches stopper lever 3 Adjust position of dash pot by turning nut until engine speed is in the Tightening torque kg b Turn throttle valve by hand and specified of voltage a speed of more 10 MPH Refer to up rear axle speed of Notes 2 detecting stand engine good condition as or at this test two 2 striking and EF 50 If engine does not stop when igni tion switch is turned off this indicates a speed presence and B I Raising If harness be A ANTI DIESELING SOLENOID VALVE is shutting off supply offuel to must for than 16 km h that ture Check Conduct Adjust plate exist check B C D D solenoid valve pump cover for any sign of fuel leaks 2 If fuel leaks are found check across not connector amplifier or following Fig EF 48 Adjusting interlock opening 1 disconnected faulty ACCELERATING PUMP CAl is below 1 4 circuit functioning properly if continuity exists and volt meter reading is 0 volt d c in step 2 for 1 Check for continuity between A and B when vehicle is brought to a complete stop Refer to Figure EF 50 connecting link 2 Refer to Figure EF 50 m After 18 is to 3 5 13 to 25 ft Ib replacement check to be leaking sure and that star dieseling anti sol noid is in good condition fuse B C D D solenoid faulty valve amplifier or speed detecting switch engine and that fuel is not burned 3 If by above checks faulty part or it should be removed unit is located and tested again If necessary replace range Specified engine speed 1 Manual transmission 1 900 to 2 100 rpm 11 P4 Automatic transmission 1 650 to 1 850 rpm 0 8 4 Tighten lock 5 Make sure 1 2 Ignition Icey 3 Amplifier 4 Speed detecting switch Above 10 mph OFF Below 10 mph ON 5 Function test connector 6 B nuts that engine drops smoothly from 2 000 to speed 1 000 l rpm in about three seconds Fuse C D D solenoid valve EF711 Fig EF 25 EF 50 Checking B C D D circuit with function test connector for manual transmission Fuel Engine AUtomatic trailamlsalon modela I With inhibitor switch P or UN check for resistance between A and B 3 Refer to heated to check for presence of A and B Refer to position voltage across Figure EF 51 If ohmmeter reading is 25 ohms below is ading BC D O If voltmeter 12 circuit volts is above func of ading solenoid valve HI m IY 3 faulty switch idling Idling Adjustmenl prop or oR it in or D again If necessary replace 4 Run the engine under engine 5 vacuum 1 @ increases idling Check that the B C D D set pres Ignition key sure is within the Specified T switch Inhibit N P positions ON I 2 D R positions and OFF C D D solenoid valve 3 D 4 Function test connector 5 Inhibitor relay pheric Generally just the B CD it 510 to D 490 to to harness ad to adjust it a to mmHg 20 9 inHg while idling and en line b connecting Connect vacuum rubber hose between gauge and intake manifold as such of the hoost type is s type mercury type recommended a an proceed Remove set as the B C D D given example the of pressu specified set from the and altitude pressure location if an automatic trans altitude of 1 000 the manometer should not be used To properly 56 the set mission model vehicle is located at Bourdon as FiguEF find atmospheric shown For response See checking in Figure EF 56 pressu pipe quick B When B CD D screw 2 gauge and vacuum Fig EF 52 Removing harness of solenoid valve a operating is pressure pressure will be by tracing the arrow line A See Figure EF 56 When alti tude is known operating pressure will be found by tracing the arrow EF262 the atmospheric found tool measure When known the driver I 530 Notes olenoid valve is 3S follows Tachometer pressure 7inHg 21 Automatic transmission however if it should Prepare the foUowing gauge atmos 550 mmHg 20 1 to 19Tto 1 B C D O is unnecessary necessary A level sea 30 inHg pressu solenoid valve BC D D Note pressure m Controlled Deceleration Device A 0 Manual transmission Fig EF 51 Checking B C D D circuit with unction t st connector for automatic transmision D D specified pressure 760 mmHg EF712 2 then 600 abruptly to 23 62 inHg or above and mmHg then graduaUy decreases to the level 2 gine speed to At the time the manifold p ssure 6 I load throttle set at procedure no 3 000 to valve yu become speed quickly close 3 500 rpm @ of Boost position 650 rpm moved Increase To B EF 21 750 rpm position Set pressure in page Automatic transmission faulty part should be is Manual transmission inhibitor relay or it Idling engine speed B C D D sole If by above checks and tested OFF faulty until engine operating temperature adjust the engine at nunnal Refer to the item setting is 32 ohms or for poor connection connec or unit is located inhibitor switch inhibitor 2 functioning Warm up the Then or reading check noid valve is zero check for disconnected connector With circuit is If ohmmeter tioning properly 2 EF 51 Figure erly If voltmeter dc ON specified BC D D is m set 3 280 ft ssu p 445 mmHg for 17 5 inHg set follows the harness of solenoid valve 7 If it is higher than the set level turn the Fig EF 53 Connecting EF 26 vacuum gauge correct adjusting adjustment screw or is made nut until Engine Non California models Adjusting Note Counterclockwise models turn for In this adjusting labored with lock spring in place Always spring prop erly to prevent changes in set pres nut 40 sure models 1 8 Race the engine and check for If it is turn the 1 Adjusting Cover screw 50 MPH CD s e ET037 California models or the accelerator lower than the set level adjusting screw or vehicle nut until When the engine speed does not must 2 or in top gear in be chassis pedal decelerate manual 0 position auto and then releasing and After letting sure is at the the doing this check whether the B C O D adjustment is made Race the engine and check for 10 adjustment If engine speed cannot be decreased to idling when checking B C D D set pressure proceed as follows correct 2 10 matic transmission adjustment 9 engine road test I transmission 2 the case by dynamometer or 3 by raising up rear suspension member on a stand accel erating the vehicle to 64 to 80 km h set lock Clockwise California Non B C D D adjusting in or out nut California models Adjusting When California screw Fuel set pres predetermined value or not fall idling speed it is necessary to reduce the negative idling pressure of to t 1 2 the manifold to lower than the set pressure of the B C D O Adjusting nut Lock spring EC692 Fig EF 54 Adjusting et pressure speed will when the The engine drop to idling speed negative idling pressure is higher Ihan not the sel pressure of the B CO O vacuum gauge acuum gauge Vacuum gauge Intake gjl 11 Road test M Intakema V 9iI 21 Chas amomeler 3 iY n Raise up rear axle housing by stand ET133 Fig EF 55 Testing sel EF 27 ure of the B C D D pre 300 n o 1 000 2 000 3 000 4 000 5 6 000 000 ft Altitude 0 5 o 10 1 5 2 0 km EF558 Fig EF 56 Changes in set pres ure versus changes in atmospheric pressure and altitude B C D D valve 3 solenoid 4 I Turn on engine key Do not start a dick is heard I f a dick is not heard ar all discontinuity Ensure that solenoid valve clicks intermittently shown in solenoid valve Figure electrified check for continuity with a circuit tester engine when If is normal is detected If replace sole noid valve as Amplifier EF 57 Manual transmIssIon models The amplifier is installed EF262 Fig EF 57 Checking solenoid valve EF 28 at the rear ofthe speedometer To check proceed as follows Fuel Engine I Set circuit IA min range probes of in d tester fuU scale tester c ampere connect test shown in Figure as Ensure that when tester ignition key pointer deflects is turned If tester pointer does 4 Do not confuse negative positive line with properly amplifier line Turn circuits ing switch ignition key ON to is b not Counties 1 219 above more on when solenoid valve and EF 58 2 3 deflect designated by detect Counties speed functioning faulty m sea law 4 000 ft level as or have been High Altitude For further details refer to 1977 DATSUN PICK UP Service are BuUetin Pub No 257 posi tion I v t Q0 1 EF733 EF264 Fig EF 61 Checking altitude compensator 1 Ignition key Amplifier 3 Speed detecting 2 4 switch B C D D solenoid valve Fig EF 58 Checking amplifier If results satisfy Inhibitor switch bitor Automatic transmission models not relay replace is oJ at all for the particular engine designed By com pletely disassembling which will allow deaning of all parts and passages the carburetor can be maintained its origi l 4 carburetor perfectly adjusted speeds for which it was condition and will continue to deliver the proper ratios To L maintain of passages and EF287 Fig EF 60 Checking inhibitor relay ALTITUDE COMPENSATOR California models Make The delivers the proper fuel and air ratios nal 11 44 OPERATION if @ I jj models inhi functioning properly relay it Automatic transmission above inhibitor Refer to the AT section Inhibitor relay the MAJOR SERVICE accurate carburetion discharge holes treme care must be taken in Use ex cleaning only carburetor solvent and compressed air to clean all passages and discharge holes Never use wire or other pointed instrument to clean or carburetor calibration will be affected that altitude com pensator to carburetor hoses are con sure nected properly and that they Inhibitor relay EF724 Fig EF 59 Location of inhibitor relay 2 Make an inhibitor Apply 12 volts that c d ensure across termi that continuity continuity does not exist between terminals 2 and 3 when no voltage is is applied across them not REMOVAL Remove Check that altitude compensator properly set At low altitudes as exists between terminals 2 and 3 Check 2 At high altitudes 60 EF shown in Figure nals 1 and 4 to relay check are cracked and obstructed Close Open taking sufficient a properly adjusted when the position of the H L lever is changed disconnecting fuel lines spill fuel from fuel pipe do b When removing carburetor do not drop any nut or bolt into intake manifold should be EF 29 engine the following When not The idle Pm and CO vary accord ing to the altitude Therefore they care to Precautions Notes a carburetor from c Be careful not to bend any part or scratch Engine Fuel DISASSEMBLY AND ASSEMBLY A B C Choke chamber Center body Throttle chamber ff oI C f Q @ J ID tJ @ 1 Lock lever 11 2 Filter set 12 screw 3 Fuel filter 13 Accelerating 4 Fuel 14 Throttle return spring 5 Needle valve 6 Needle valve 7 Fuel chamber 8 Accelerating pump parts Altitude compensator pipe California models 9 nipple tng ail body parts bleed adJ @ 15 Accelerating Automatic 17 Automatic choke body and cover diaphragm chamber Richer jet 19 Coasting air bleed I 20 Primary main jet 21 Secondary main jet 22 Secondary slow air bleed 23 Secondary slow jet 24 Plug 18 Air bleed Coasting jet 27 Secondary main @ air bleed 28 Power valve 29 Primary main air bleed Plug Primary slow jet No 2 primary slow air bleed Primary and secondary small 30 31 32 33 venturi 34 35 Venturi stopper screw Choke connecting rod dieseling Anti 36 J pump rod choke 26 @1 I pump lever 16 25 @ High speed enricher air bleed Choke valve solenoid valve 37 Fast 38 Diaphragm chamber parts 39 Idle limiter cap 40 Idle adjust 41 Idle adjust screw spring 42 Throttle adjust 3 44 idle cam screw screw 5Crew Thr9ttle spring dj t Primary and secondary throttle valve 45 B C D D 46 California models Vacuum control solenoid valve 47 B C D D Califomia Non models Note Do not remove the parts marked with an asterisk Ill @ EF725 @ff Fig EF 62 Carburetor part EF30 Engine Disassembly Properly screwdrivers nozzles screws wrenches filling be must and jets as used well as and and nuts ex ercised not on the 2 on the beiore to Fuel and damage care must be any parts Clean the carburetor thorougWy disassembly 3 Do not attempt to remove any parts marked with an asterisk CO in Figures EF 62 EF 63 EF 64 and EF 66 Choke chamber parts 1 2 Coasting air bleed adjusting screw High speed enricher air bleed 3 Choke valve 6 ing pump lever spring Accelerating pump rod 7 Automatic choke 8 Richer jet Automatic choke body and 4 AcceJera 5 Throttle return 9 10 cover diaphragm chamber Coasting air bleed @ Note Do not remove the parts marked with an asterisk fi I 1i 8 J l EF 225 Fig EF 63 Removing choke chamber parts EF 31 Engine Fuel Vacuum control solenoid Center body parts valve Sets 2 B CD 3 Coasting jet 4 Secondary slow jet 5 ptug 6 Air bleed 1 Secondary slow air bleed Secondary main air bleed 8 9 10 11 12 13 14 15 16 1 D Power valve Primary main air bleed Weight and outlet valve ptug Primary slow jet slow air bleed Ptirnar Accelerator pump assembly AntkUeselingsolenoid vain 17 Fast idle earn 18 19 Choke connecting rod Fast idle earn shaft 20 Ventuci stopper 21 Primary and screw secondary small venturi @ l Note Do not remove the parts marked with an asterisk It EF726 Fig EF 64 Removing jets Float i i j L 1 V 4 2 Ji @ c @ 4 S JlJ I 4 6 11 e4 Qll1D Yr i lil c u 1 p if 1 @5 I 1 Secondary main jet CJi 2 Primary main jet 3 to1 4 r r U I 1 tt J 1 7 4 1 Float chamber parts Fuel inlet assembly Lock lever 4 2 Filter set 4 3 Fuel f1Iter 44 Fuel nipple 45 Needle valve body Needle valve Hi 5 lv 8rtj screw Diaphragm chamber aiSembly EF227 Fig EF 32 EF 65 Removing float Engine Fuel Throttle chamber parts I Idle 2 Idle 3 Idle limiter cap 5 adjust screw adjust screw sprinl Throttle adjust screw Throttle adjust screw sprini 6 Primary and secondary 4 throttle valves 7 Nut Notc Do not remove marked with an @ff the parlS asterisk EF827 Fig EF 66 Removing throttle chamlHr parta Assembly To assemble bly procedcre following I Thoroughly reverse the disassem taking care wash all to the the parts Inspect gaskets to see if they or if edges are If any of such undesirable condi tions is noted they must be replaced Install jet and air bleed having the same size number as that of original 3 before assembling 2 appear hard or brittle torn or distorted EF 33 one 4 After reassembling carburetor check each rotating portion or sliding portion for smooth operation Engine wuler gum or l arbon taminatiun in or on exterior parts of arburctor a sihk for reason dcpends upon inspection I Blow with con moving often respon arc unsatisfactory performance For this efficient carbutetioll careful while all and cleaning servicing and castings air and blow off all parts until dry Do not seriously affect carburetor calibrs lion 2 Check all parts for is noted placed wear damaged parts Note especially Check throule and choke shaft bores in throtlle chamber and choice of roundness out chamber for wear or Inspect idle adjusting needle for Such a condition re or ridges 3 burrs quires replacemen 1 Inspect gaskets 0 see if they or briUle or if edges are appear hard torn or distorted If any such condi must If wear be re the following 4 noted they must be replaced Check filter screen for dirt or lint Clean remain 5 and if screen is distorted linkage for rod of Jets Carburetor jet performance depends That is why and air bleed be fabricated these components must with utmost care To clean them use solvent and blow air on them cleaning Larger inner jet numbers tamped larger diameters indicate on the Ac cordingly main and slow jets with lalger nUmbers provide richer mixture operating the smaller the numbers the leaner the Conversely the main and through which air to make the fueLleaner if through passes they bear larger numbers the smaller condition mixture 6 Inspect operation of accelerating pump Pour f el into jloat chamber slow air bleeds and make throtlle lever operate Check condition of fuel injection from the the numbers the richer the fuel EF 34 dia phragm chamber and block passage of vacuum with finger When connecting rod becomes free check for leakage of air or damage to diaphragm or plugged replace Check accelerating nowe 7 Push connecting on tion i pass drills or wires calibrated through jet or passaaa as this may enlarge orirlce and Note assembly must replaced 2 3 passages compressed If wear is noted wear be Dirt Check float needle and seat for I CLEANING AND INSPECTION Fuel Engine Fuel SERVICE DATA AND SPECIFICATIONS California Nl n modell I Manual transmiSsion California modeb Automatic transmission I Manual transmission Automatic transmission Airclelllcr Ail control val fuUy opens Idle ompensatoI partially opens Hi mettiNo metal Bi Oc oF oCeF oCeF partially opem ntrol valve Air 86 above 55 129 to 30 to 54 86 to 129 above 55 131 131 l 60 to 70 140 to 158 60 to 70 140 to 158 No 2 70 to 90 to 194 70 to 90 158 to 194 158 Oc OF tor fully opens ompen Idle 30 to 54 No 1 above 70 158 above 70 158 Hi metd No 2 above 90 194 above 90 194 metal Bi Fuels Stem kpJcm2 Fuel prtuure Fuel pump C rbu US apacHy pt min at 0 21 poi 0 27 to t OOO rpm 2 99 3 84 to 0 21 0 27 to i I OOO 2 to 2 99 i 2 1 000 3 84 I OOO tor C rbu tor Stromt rg type Strombcra type type Carburetor model OCH340 rom Venturi diameter 48A DCH340 Secondary Primary Outlet diameter 7A in 30 I8t 340 339 in mm 24 0 945 310 220 Main jet 199 Main air bleed Slowjet Secondary Primary 1 181 30 24 199 170 160 148 1100 Float level U mm fuel preuure kg cm2 psi 23 in Secondary 30 181 1 34 1 339 31 1 220 24 0 945 31 1101 170 160 170 148 1100 148 1 30 24 0 945 60 1339 31 101 1220 1160 170 1100 60 1 148 180 140 0 906 23 0 17 2 40B Secondary 34 181 140 23 0 906 2 408 1220 Primary 1160 143 0 906 0 17 Primary 46A DCH340 1339 1160 143 Power val 34 0 945 1160 45B DCH34Q 23 0 17 2 408 0 906 0 17 2 408 Adjustment Engine idling Ignition timingIdle speed mloro Fuel level CO at 1201750 rpm 2 1 120 650 rpm position CO 0 750rpm 100 t 1 2 t 1 C02 120 650 rpm 0 position CO t 2 1 adjustment Gap between Ive at and noat stem mm in H 7 2 0 283 7 2 0 283 7 2 0 283 7 2 0 283 H 23 23 0 906 23 0 906 23 h Fast idle CO adjwtmcnt Fast idle Gap between throttle earn 0 906 1 3 to 13 to 17 0 051 to 0 067 0 051 13 to 17 to 0 067 133 to 147 0 0524 to 0 0579 17 to 0 to 172 to 0 0677 0 051 067 0 906 13 to 17 0 051 to 0 067 158 to 172 0 0622 to 0 0677 tint step IYe and carburetor 33 1 body 0 0524 in mm to 147 to 0 0579 158 0 0622 Vacuum break adjustment Gap between choke alve and carburetor body 142 0 056 1 42 0 056 142 0 056 1 5 0 059 2 45 0 096 2 45 0 096 24 2 45 in mm Choke unloadel adjusttncnt Gap between choke alw and carburetor body rom 0 096 0 096 in Bi metalsettinl metal Bi resistance at 2Ioe 700F 3 7 n to lnterloc k opcnina of primary and secondary throtUc valves Duh pot adjustment without diclClinasolenoid Anti cD D a 30 inlla RC D D 3 7 89 8 9 to 3 7 Center of the ndex mark metalsettina Bi C valV set p JSure 0 m loadin tiahtenina torque ka sea 7 38 Im 900 1 m lb in 180 to level and 760 atmospheric pressure J tiahteninl torque mmOn mmHg mmHa inHg kg m n b 20 to 7 38 0 291 to 650 1 2 100 350 156 to 304 180 to 510 to 550 490 20 1 to 21 7 19 3 40 17 4 to 34 1 EF 35 20 to 40 3 7 to 8 9 B 9 Center of the index mark 0 to 350 to 291 7 38 0 850 1 1 900 to to to 11 490 to 530 21 7 19 3 to 20 9 to 20 1 to 20 to to 40 17 4 to to 304 34 7 180 1 850 550 510 20 9 34 7 180 to 291 156 530 4 to 304 0 350 156 to 1 650 2 100 350 156 7 38 290 to 20 to 40 17 4 to to 304 34 1 Engine toms and causes of carburetor troubles TROUBLE and DIAGNOSES AND CORRECTIONS remedies for them Condition Overflow Excessive fuel consumption are listed appears to have some problems when actually the electric system is at fault to facilitate quick repairs There are the syml Probable that Therefore whenever the engine is mal various causes of malfunctions In the following table Fuel It sometimes carburetor which has a engine happens no functioning fault ing carburetor Corrective action cause Dirt accumulated on needle valve Clean needle valve Fuel pump pressure too high Repair Needle valve Re place improperly seated Fuel overflow on each main jet Clean Choke valve does not open valve seat overflow Replace Main air bleed clogged Outlet pump See condition Slow jet too large the fully Adjust of accelerator pump Lap improper Linked opening of opens too Power shortage secondary throttle valve Clean Every throttle valve does not open fully Adjust Idling adjustment incorrect tr Improper idling AdjusL clogged FIICI Vacuum jet Air c1eane Adjust early Main jets clogged ir pa clogged Clean clogged Clean Diaphragm damaged Replace Power valve operating improperly Adjust Altitude compensator setting incorrect Cali fornia models Correct H L lever position Slow jet clogged Clean Every throttle valve does not close Secondary properly throttle Throttle valve shafts valve adjustment Overhaul and clean Replace carburetor fauJiy tightening improper Fuel overflow BC D D im worn Packing between manifold Manifold carburetor Adjust operating Replace packing Correct See incorrect Vacuum control solenoid l Stuck anti stall dash pot Replace Replace EF 36 tightening ondition Adjust damaged electrical should be checked rust rl1ow ov system before adjust Engine Condition Engine hesitation Probable Main jet or Fuel Corrective action cause Clean slow jet clogged By pass hole idle passage dogged Clean tube Emulsion tube Clean dogged Idling adjustment Secondary Adjust incorrect throttle valve operating im Overhaul and clean properly Altitude compensator setting incorrect Cali Correct H L lever position fornia models Engine start does not Fuel overflows See condition No fuel Check pump fuel pipe and needle valve Idling adjustment incorrect Adjust Fast idle adjustment Damaged dieseling anti incorrect solenoid EF 37 Adjust Replace overflow SECTION EC DATSUN PICK UP MODEL 620 SERIES I NISSANI NISSAN MOTOR CO TOKYO LTD JAPAN EMISSION CONTROL SYSTEM 2 GENERAl DESCRIPTION EC CRANKCASE EMISSION CONTROL SYSTEM EC 2 EXHAUST EMISSION CONTROL SySTEM EC 3 EVAPORATIVE EMISSION CONTROL SYSTEM EC 30 SPECIAL SERVICE TOOLS EC 32 Emission Control System of GENERAL DESCRIPTION There are system These J Closed three types of control 2 Exhaust emission control system are 3 lhsion ell type CIllnkcase Evaporative control sys sions to tem emission Pericxiic control system seCV1Clng of these systems should be carried out to reduce harmful emis and inspection a minimum required CRANKCASE EMISSION CONTROL SYSTEM INSPECTION DESCRIPTION This system returns The blow by gas p blow by er cover gas through into the crankcase draw blow by flow the insufficient tluough the to the and its flow goes through the tube connection in the reverse diree valve the P C V tion On vehicles with valve Normally the capacity of is blow by the valve some through the is sufficient to handle any blow by and a small amount of ventilating air retor an excessively high of the P cV VALVE AND FILTER con air cleaner to rock vacuwn the intake manifold sucks by tube Under full tluottle condition During partial throttle operation of blow the manifold gas to the intake manifold the is then drawn tluough necting carburetor The positive crankcase ventilation C V valve is provided to conduct the engine cleaner air air cleaner crankcase air from the dust side of the cadlUretor to both the intake manifold and carbure tor ventilating flow will go tube connection to carbu air cleaner under all conditions Checking P C ance V valve following with the in accord method With engine running at idle remove the ventilator hose from P C V valve if the valve is working will be heard as a air passes hissing noise through the valve and a strong vacuwn should immediately when a fmger placed over valve inlet felt Replace be is P C V valve and filter in accordance with the maintenance schedule 4 VENTILATION HOSE 1 Check 2 Disconnect If any and rocker II tll TIL 1j GUuuu 2 Sealtypc oil level gauge Bame plate 3 Flame arrester 1 4 Filler 5 P C Y valve 6 Steel net 7 Bame plate EC716 EC l connec all hoses and clean cannot be free of replace Ensure that flame arrester is surely inserted in hose between air cleaner If Fig hose obstructions 1 Blow by gas hose with compressed air Lkf c Fresh air and hoses tions for leaks 01 c Crankcase miaion control ay tem EC 2 cover Emission Control System EXHAUST EMISSION CONTROL SYSTEM CONTENTS EC DESCRIPTION EARLY FUEL EVAPORATIVE CONTROL SYSTEM EC 19 DESCRIPTION DESCRIPTION EC 6 OPERATION OPERATION EC 6 EC 7 EC 7 EC 7 DESCRIPTION EC 26 EC 7 OPERATION EC 26 INSTALLATION INSPECTION SPARK TIMING CONTROL SYSTEM DESCRIPTION EC 19 REMOVAL AND INSTALLATION EC 23 INSPECTION EC 24 CATALYTIC EC 26 CONVERTER REMOVAL SPARK DELAY VALVE AND INSPECTION EC 27 EC 27 EC 7 EC 8 FLOOR TEMPERATURE WARNING EC 8 SYSTEM DESCRIPTION EC 8 OPERATION EC12 OPERATION REMOVAL AND INSTALLATION EC 14 REMOVAL DISASSEMBLY AND ASSEMBLY EC 14 INSTALLATION EC 29 INSPECTION EC 17 INSPECTION EC 29 Automatic transmissiom models only INSPECTION AIR INJECTION SYSTEM DESCRIPTION The exhaust emission control sys tem is made up of the 3 EC 19 6 REMOVAL AND 2 E G R EC E F E I GAS RECIRCULATION EXHAUST 3 SYSTEM following Early fuel evaporative system Spark timing control system Air injection system A IS 4 5 INSTALLATION EC 27 DESCRIPTION Exhaust gas recirculation control system Catalytic EC 27 converter E GR EC 28 EC 28 7 Altitude compensator California models California models 6 Boost controlled As regards the last two units refer deceleration de to vice B C D D 3 EC the Engine Fuel section Emission Control System IV 7 ID 9 I Thermal 2 Check valve 3 Air 4 Auto vacuum valve gallery pipe 6 choke canet Automatic temperature control air c Anti Backfire valve A B valve 7 Boost 5 Controlled Deceleration Device P 10 E 11 Air pump air cleaner Carbon canister 12 t3 14 8C D D C V valve Air relief valve 8 9 G R control valve Air pump ET365 Spark delay valve AfT models models Fig EC 2 Exhaust emission control system Non California 4 EC Emission Control System 5 7 @ @ 1 2 3 4 5 6 1 Thermal acuurn valve Check valve If Altitude compcnlator in air cleaner Air gallery pipe choke AutQ Automatic temperature control air cleaner 8 Anti 8ackfue valve A B valve Boost Controlled Deceleration 9 P C V valve DeVice B C D D 10 Air relief valve II 12 E G R control valve B C D D control valve and solenoid valve 13 Emergency air relief valve 14 16 Air pump air cleaner Carbon canister Air control yai e 17 Air pump 15 ET368 Fig EC 3 E hau EG S t emilsion controlay tem California mod ls Emission Control EARLY FUEL EVAPORATIVE SYSTEM E F E valve shaft is wtalled DESCRIPTION manifold through 4 EC trol Construction of the early fuel evap system is shown in Figure orative rI A control valve valve is The System valve welded on This bushing called Heat heat control spring and counterweight which are assembled on the valve shaft projecting the the to con rear manifold control valve is luated by the coil spring 1 to the exhaust cured to ac and snap thermostat of the exhaust outside The counterweight is se the valve shaft with key bolt ring @ rW 1 Intake 2 Stove 9 manifold gasket Sc w 10 Thennostat 11 spring 4 Heat shield plate 12 Coil spriiig Control valve shaft 5 Snap ring Counterweight Key Stoppel pin 13 Heat control valve 14 15 Bushing Cap 16 Exhaust manifold ManifoktstOve 6 7 g EC532 Fig The early fuel evaporative system is provided with a chamber above a is manifold stove moonted between the exhaust gas heats the manifold stove intake and exhaust manifolds During engine warming up air fuel mixture in control changed the solid in direction lines in close Open Figure operation valve is as shown by 4 The EC of the controlled heat the the carburetor is heated in the cham by counterweight and thermostat spring bet by exhaust gases which is sensitive This results in improved evaporation of atomized fuel droplets in the mixture and in smaller content of exhaust gas hydrocarbons He in the especially in cold weather operation The exhaust gas flow from the engine is obstructed by the heat con trol valve in the exhaust manifold and to the ambient tem perature around the exhaust manifold 4 Early Fuel EC With this condition The counterweight rotates counter tem E FE the heat control valve is in the fully closed position obstructing the flow of exhaust gas As engine tempera lure goes up and the ambient temperature becomes high enough to actuate the thermostat spring the counterweight begins to rotate clockwise and again comes into con tact with the stopper pin With this condition OPERATION Evaporutive the heat control valve is in the full open position and exhaust gas passes through the exhaust manifold as clockwise and stops at the stopper pin mounted on the exhaust manifold shown by the dotted lines in Figure 4 without heati ng the manifold EC while the engine stove temperature is low 6 EC Emission Control System stopped visually check E F E system for the following 2 REMOVAL AND INSTAUATION With engine items spring for dismount Thermostat 1 ing Stopper pin for bend and count er weight stop position for dislocation 2 3 control heat Check valve for malfunction due to break of key that locates counterweight to valve shaft Check axial clearance between 4 heat control valve and exhaust mani 1 Snap ring 2 Lock bolt 3 6 Key Counterweight Thermostat spring Coil spring 7 Heat control valve 8 Valve shaft 9 10 Stove gasket Manifold stove 11 Heat 4 5 EC533 fold shield plate mm is 0 7 Correct clearance to 1 5 0 028 to 0 059 in 5 Check welded portion of heat control valve and valve shaft for any indication ofcrack or flaking 6 by Rotate heat control valve shaft and check for binding a finger between shaft and bushing in closing and opening operation of heat control valve If any binding is felt in rotating Fig EC 5 Exploded view of E F E stem valve move operation shaft in the rotation direction several times If this ring D and lock bolt and the following parts can be Remove snap @ detached valve control heat from position described in 1 1 above and stops again coming into con tact with stopper pin shaft Key 00 Counterweight @ spring lostat TherI Coil Note CID shaft not correct shaft and bushing and exhaust mani fold should be replaced as an assem 1 is CHECKING SPARK TIMING CONTROL SYSTEM heat welded to valve at exhaust manifold @ it is due to seizure between j descnoed previously control valv does condition bly spring @ As binding operation and cannot be disassembled install To reverse 2 Counterweight S topper pin 3 Heat 1 INSPECTION control valve Run engine and visually check counterweight to see if it operates properly For 1 engine turns Fig EC 6 Operation of counterweight when engine is cold serves um in cold after counterclockwise until it and ambient NOx emissions installed non on transmission automatic SPARK DELAY VALVE Automatic transmission moves models only as 2 When engine speed is increased discharge pressure of exhaust gases causes counterweight to move down ward clockwise con is system models This around exhaust manifold trol valve is in the counterweight open position moves further clockwise exceeding the full advance under varying travelling so as to reduce HC and comes engine warms up temperature goes higher When heat system pin installed gradually Counterweight down clockwise control tirnin conditions California exhaust manifold 3 spark to control the distributor vacu This time starling weather counterweight some into contact with stopper to DESCRIPTION The cedure I EC246 the removal pro delays vacuum spark during rapid acceleration it valve advance EC246 1 2 Counterweight Stopper pin 3 Heat control valve Fig EC 7 Operation of counterw ight when ngine is hot EC 7 also cuts off the immediately valve is vacuwn spark advance upon deceleration designed for one The way opera tion and consists of a one way umbrel la valve restrictor and sinlered steel fluidic System Emission Control I C bur tor Distributor side 1 2 EC219 umbrella valve way One Fig EC 11 Checking spark Sintered metal disc d tay valve EC284 Fig EC 8 Spark delay valve Note or installing When that this valve oriented ensure Tlus valve properly replaced periodically it shuuld be Refer Maintenance Schedule to Note is in port If ance a finger is greater than that Figur ET lO considerable air flow resist is fell at port on distributor side in step 2 above and if the condition of spark delay valve port horn distributor when distributor side on the other side See 3 DisInDutor sideBrown over air flow resistance is on Carburetor sideBlack good condition if placed To carburetor on Be careful to avoid entry of oil dirt into valve is questionable carburetor side into a dip cup filled with water Blow air through the other port Small air bubbles should appear AIR INJECTION SYSTEM DESCRIPTION The Air Injection System A LS is aeSigiieino iiiject coinpressed air sec air corning from the air pump into the exhaust manifold to reduce ODllary ribUI0 TOdi hydrocarbons and carbon monoxide in combustion re exhaust lris through carburClor lCiJr EC There type is mounted and Fig EC 9 Operation 01 park delay Carburetor side Distributor side on sists of an non valve and through then through the other port distributor side Spark delay valve EC346 Fig EC IO Checking park delay valve 8 EC non A I One S California models on non California California type con air pump air cleaner an air California type has in components of the type an air control to the California Remove spark delay valve Blow air side other is The addition port on carbure on pump a relief valve a check valve an anti backfIre valve an air gallery and hoses INSPECTION tor the models The value 2 types of two are an emergency air relief valve These valves prevent ahnonnal tem perature rise of the catalytic converter Emission Control System 1 Check valve 2 3 Air gallery pipe Automatic temperature control air cleaner 4 Air carburetor hose B to A air cleaner val 5 Anti backfire valve 6 Air hose A A B valve B valve to intake manifoW 7 Air hose carburetor air cleaner to aU hose connector 8 check valve to air hose Air hose connector 9 10 3 way connector air hose connector to Air hose air pump 11 Air hose 12 air cleaner Air pump air cleaner air pump to air pump 13 Air pump EC776 Fig EC 12 Non California type A IS 1 Air control 2 Check 3 valve val Air hose check valve to air hose connector 4 Air 5 Automatic temperature control gallery pipe air cleaner 6 Air hose to 7 8 carburetor air cleaner A B val Anti backfire valve A B valve Air hose A B valve to intake manifold 9 Air relief valye 10 Air hose carhuIetor air cleaner to air control valve 11 Air hose air relief valve to air hose connector 12 Air hose air hose connector to emergency air relief valve 13 Emergency air relief valve 14 15 Air pump air cleaner Air hose air hose connector to 16 air pump Air hose air pump to air pump air cleaner 17 Air pump EC777 Fig EC 13 California typo A I S EC 9 Emission Control Air pump aIr cleaner The air cleaner element is paper lype placement and The die a viscous requires periodic re The air pump air cleaner is bolted to the left front of the hood ledge aluminwn cast assembly attached engine is driven belt A rotor System to by pump air the the front of the an air pump drive housing shaft drive hub inlet and springs unit of the pump type make up the rotating The rotor located in the completes Each housing Carbon shoes revolu tion of the EC778 Air pump air c leantr moved into pression a smaller cavity Air pump The air pump is a a Leaf springs which are the leading side of the shoes The rotor ring the rotor end is a steel bolted to It positions ihe rotor and holds the carbon shoes The vane uses needle bearings All bearings have been greased and There are two typCg of bearing which support the rotor Ball bearing is used for the front one and the the com vane the slots of the compensate for shoe abrasion vane area After compression has vanes cavities behind in every rotor Air is drawn Air is sealed between the in and to seal the rotor interior from the air into the inlet cavity through a tube connected to the air pump air cleaner Fig EC 14 pumping support the vanes They are designed to penni t sliding of the vanes pumping cycle a again reaches the repeat the rotor form two vanes and to cycle ofT center pivot pin and follow the circular shaped pump bore In the two vane that separates the outlet and inlet cavity the center of the pump is driven belt The vanes rotate freely around the chambers in the cavity Subsequently it stripper and a section of the inlet cavities outlet tubes are visible on the pump exterior A rotor vanes carbon shoes and shoe outlet passes the needle bearing is used for the passes rear two vane type It positive displacement vanes requires no lubricating seJVice two which i lJ1 I Jr l j 1 2 3 Air pump drive hub HOII ing Rotor ring spring 7 Shoe 8 Stripper 9 10 Rotor shan bearing II Front 5 Vane 12 6 Carbon shoe 13 4 End cover with needle Ball j bearing bearing Pulley PuDey for air cover con itioner EC560 Fig EC 15 EC IO Stctionol view ofoir pump twtrvone type Emission Control and injected air which backfire I Tointake manifold secondary according to engine speed and load condition and prevents ex cessive temperature rise of the cataly air Construction is spring fails shown in Figure EC 18 air fed from the of quantity causes the con troIs valve air control When relief valve 2 burns with the aid of high temperature CalifornIa models The and combustion chambers the from Air control valve System pump tic converter EC 16 Figure shown as m applied coupled actuate the valve which is I manifold intake The pump in and air pump discharge pres to the diaphragm chamber vacuum F rom vacuum construction is The sure c to L AirdisChaJ1le From air engine condition ts ven which the backflow occurs The valve pre of exhaust in one of the gas following When the air pump drive belt Into axhaust port The secondary air fed from the air to pump goes through the check valve the air gallery where it is distributed to each exhaust port The secondary air injected from the air injection nozzle into the exhaust port near the exhaust valve fails c Check valve is then cases 1 Fig EC 1B AIr InJaction pump discharge lines To Secondary air Exhaust gas valve Fig EC 11 Anti back ir A check valve is located in the air From Seat EC292 Check valve air pump Rubber valve 3 ECQ69 the to Spring 2 cleaner the diaphragm and control the quanti into the ty of secondary air to be fed exhaust manifold in response 1 I to mtake manifold carburetor air cleaner lr J n EC291 Air control valve Fig EC 16 Anti backfire valve This valve is con trolled manifold in the period to vacuum y by intake prevent backfire exhaust system L the ini tial at of deceleration the mixture in the period At this intake manifold becomes too ignite and combustion burn in the rich chamber and burns easily in the to ex air in the haust system with injected exhaust manifold The anti backfire valve to intake manifold the mixture air fuel leaner provides make to and air r the prevents backfire A schematic backfire valve drawing is shown of the in anti Figure V EC 17 backfire The anti nected to 3 I Air 2 Exhaust port 3 Air 4 Exhaust manifold gallery jnjection nozzle EC293 valve inlet is con the air cleaner and the outlet Fig EC 19 Air injection into exhaust port to the intake manifold Th reduces hydrocarbon emission during If the valve does not work unburned mixture Air pump relief valve air pump relief valve controls injection of the secondary air into The aeceleration will be properly emitted high speed under a heavily loaded condition It accomplishes the following functions without affecting running correct function of ItjS valve the the exhaust system when the EG 11 engine is at the effectiveness of the exhaust emis sion control system Emission Control Minimizes gas tempera rise 2 Minimizes from horsepower air injection losses re into the exhaust system 3 Protects pump excessive from back pressure The air pump relief valve is installed as shown in The Figure secondary EC 20 air is discharged from the air pump relief valve to the dust side of the carburetor air cleaner California type The California stand ard type includes a system which Emargency air retial valve E AR lure suiting exhaust System Valve controls injection of secondary air so as to assure proper function of the California models The emergency air relief valve con trols the quantity of secondary air fed catalytic from the air pump according to load condition and it discharges the see ary air to air into the The A L con valve prevent abnormal tempera catalytic converter consists of the following I S system which allows injection A of secondary air into the exhaust port diaphragm a spring and a which is coupled to diaphragm sists of system a of second systems converter The emergency air relief valve supply tUfe rise in the atmosphere to prevent overheating of the catalytic ondary and converter which controls the a 2 A ondary valve bypasses system which sec from the air pump relief the carburetor air cleaner air to during high speed engine operation 3 To carburetor air cleaner A system which supplies air from Secondary the carburetor air cleaner to the intake air manifold by valve so as means of the anti backfire to prevent after fire during deceleration A system which controls injection of the secondary air by means of the air control valve so as to maintain the 4 1 Diaphragm 2 To carburetor air cleaner J r Val catalytic 3 Spring 4 Diaphragm chamber erCOndary optimum temperature level under lightly loaded EC 21 Califomia type only mergency air relief valve 5 A system which controls the sup ply of secondary air r gency OPERATION Fig EC 20 Air pump relief valve two air through the there emer ab pfevent io relief vilve normal temperature rise of the As mentioned previously EC294 an at condi tions EC536 Fig converter cataly tic converter are California type types of Air Injection Systems a California non type and a A I S IS A only operation is as follows I I t 1 r 9 I I 0 2 L 3 r EC179 Air pump Air pump air deaner Air relief valve 6 Check valve 7 Air gallery pipe Injection non e 8 4 Air cleaner 9 5 Carburetor 10 Exhaust manifold Anti backflIe valve Fig EC 22 Non California type A IS EC 12 Emission Control System The non follows California type operates air secondary through the air pump the air pulley pump It as sucked is air cleaner into by the crank discharged through the air gallety where driven is then the check valve to To intake To manifold manifold intake it is distributed to each exhaust porL The from secondary air the injection exhaust port near is then nozzle injected into Air the diSlcharge to intake manifold the exhaust valve Secondary air The air relief valve opens only when the discharge pressure of the air pump spring force of relief valve during high speed surpasses the tion EC297 the air Fig EC 23 Operation of A B opera When the air relief valve opens The the secondary air is discharged in to the carburetor air c1eaner predetermined tion and non manifold from California The type includes air components of the type an air control emergency air relief valve an air control valve opens when applied to predetermined the the air into the air cleaner um cleaner secondary When valve diaphmgm reaches a level and discharges the pressure becomes low the doses with the spring force of the air control charging the valve and secondary stops dis air Figure EC 25 When the intake manifold vacuum applied to the diaphragm reaches a E A R valve predetermined level operates to discharge the secondary air into the atmosphere When the pres sure becomes spring stops high tension the valve closes of EA R discharging the valve secondary by and air fl f I Qj rn in the sum of the air pump discharge pressure and the intake manifold vacu air to now into the the to valve and value during decelera permits fresh intake California addition The anti backfire valve opens when the intake manifold vacuum reaches a the lve t riu Jl l 3 I Air 2 Air pump air 3 Emergency 4 Air pump cleaner air relief valve relief valve j I @ 5 Air cleaner 9 6 Check valve 10 7 Air II 8 gallery pipe Carburetor 12 Air control valve Injection l Exha t nozzle manifold Anti backfire valve EC780 Fig EC 13 EC 24 California type IS A Emission Control System o To intake jJ To manifold Intake mamfold lm vaCUl vacuum rF r r To air cleaner To air cleaner From air pump Y 9 Gf 9 4 T From air pump l h 1 I I Actuated Not actuated EC299 Fig EC 25 Operation of air control value Notes REMOVAL AND Apply engine a INSTALLATION times during Air p mp sir cleaner Remove cleaner air from Air cleaner hoodledge r EC781 Fig EC 27 Locotion of E A R wive Disconnect vacuum Unfasten air 4 Check air gallery fractures or and nozzle for air leakage Clean nozzle with At time of installation 5 injection wire brush a hold air to a torque of 5 0 to 5 9 kg m 36 to 43 ft lb Check cylinder head air injection nozzle and air gallery for leaks with 6 J o damage other to 3 screw and hose c t 323 EC air hose from anti backfire valve tt not injection nozzle hexagon head with a wrench and tighten air gallery flange Antl backflravalve JJ several injection nozzle from cylinder head applying engine oil to screwed portion several times deancr lower body are built into a unit construction Replace air cleaner clclnen and lower body as an assembly element and Ii rews parts then detach air hose atreful b Be 011 to above work Fig EC 26 Replacing oir cleaner engine running Check valve element Disconnect hose and Air pum Remove air hoses from air pump Loosen air pump adjusting bar 2 mounting bolts and air pump ing bolts remove check valve from air gallery pipe mount then remove air pump drive Air pump relief vslve Loosen mounting Air ganery pIpe andinJactlon air carburetor sc ews and cleaner remove air order of reo pump relief valve nozzles bell 3 Remove air pump 4 It is very difficult to pulley Remove air pump from bracket gallery from the valve removal of the air gallery pipe and injection nozzles should be under Disconnect air hoses and um hose 2 a vacu from air control valve Remove air con trol valve from bracket taken only when they I valve Remove California modela vacuum pipe and and dismount E A R valve air hose are damaged Lubricate around the connecting portion of air injection nozzle with oil engine gallery 2 E AR There leakage or InstallatIon Install in the reverse moval fore California models l the air manifold without bending the pipe which could result in fractures Air control remove exhaust Hold air injection nozzle head with screw a and air hexagon wrench and unfasten flare connecting ait gallery to injec gallery tion nozzle Remove air EC 14 DISASSEMBLY AND ASSEMBLY Disassembly of air 1 and Remove four remove pulley pump pulley drive bolts from hub Secure air pump drive hub in a EC 28 and vise as shewn in Figure 2 remove four end cover bolts Emission Control Note Never clamp on the aluminum b Discard Always installing housing which screws moved System were re when use new ones 8 four Remove front bearing tach bearing securing screws cover place in and de cover Support the rear end face of air pump housing with Rotor Adapter STl9890000 Drive rotor out by push ing rotor shaft with Bearing Pressing 9 5 Remove vane from rotor Tool STl9940000 STl9940000 Fig EC 28 Removing 4 Remove Put end cover match marks 0 on Fig EC 30 Remooing cover by carefully tapping around dowel pin with a plas tic mallet and lift up straight 3 6 Remove two shoe needle nose four carbon springs pliers or from Note Carbon I I shoes and rotor STl9890000 vanes EC303 Fig EC 32 Removing rotor shaft using tweezers rotor ring and side of rotor to ensure correct reassembly and remove four screws that retain rotor ring to rotor using a Hexagonal Wrench STl9810000 1Ul EC661 EC302 A shoe 0 039 in wider than is B I mm Do not confuse them 10 Support the front end face of with housing Bearing Adapter STl9930000 Attach Bearing Driver STl9910000 to front bearing on the inside of air pump housing iuid press out Notes a Generally cated on match marks both rotor are ll indi ring and rotor I I by the manufacturer STl9910000 i L 9930000 J 1 EC304 Fig EC 33 Remouing ball bearing If replacement necessary ECll1 Fig EC 29 Removing rotor ring proceed of front bearing is as follows Remove air pump drive hub with standard puller 7 EC 15 11 rder Keep disassembled parts in Emission Control System EC562 EC 34 Componenbr of two vane type Fig Assembl I Front of air pump bearing the Support Press drive hub into place with 1 C preand until the end face of drive hub touches end face of air rear with a press arid Tool STl9940000 froE ST 19910000 pump housing with RotOL Adapter STl9890000 Press front bearing into place a Bearing Driver STI 991 0000 c ing in n c Bearing Ptessing j I I ST19920000 STl9940000 STt9910000 EC3Q7 I Fig EC 36 Pressing rotor shaft e L Notes X8 03 a Be STl9920000 sure race Fig EC 35 Pressing ball bearing to drive front bearing Bearing is installed in rotor Torque four bearing bolts to 0 1 to 0 2 kg ft lb 3 cover m securing 0 7 to is pump housing 4 1 pump Support the inward bottom place with a 150 0 mm 2 press 4 touches front rotor with Rotor Stand STl9920000 bearing inner race Air pump drive hub the inward EC 16 Place air pump drive hub in a bottom Clean carbon dust etc from shoe grooves 3 Align rotor with housing proper ly Refer to Figure EC 38 Then insert and Bearing Drive STl9910000 until the stepped portion of rotor shaft Support 1 Carbon shoe vise 00020 to 0 0059 in rotor with Rotor Stand STl9920000 Press rotor into housing 0 050 to of Fig EC 37 Pressing air pump drive hub 5 Position of rotor end below air Rotor shaft EC308 place that the rotor end pos tioned below the end face of air cover r in b After ensure 2 inner of carbon shoes into directions place noting their Emission Control System Notes a b tue u Do not apply an when shaft vane inserting If two vanes stress to dislocated when are shaft correctly inserting align by inserting dummy shaft Then draw out dummy shaft and vane vanes insert c Note a Carbon shoe A in wider than is 1 B make 0 039 mm ing Do not confuse b If carbon shoes are Be carbon remove shoes and clean shoe grooves Reassemble carbon shoes sure of spring Rotor ing the Pack vane bearing 1 melting point grease MIL Esso ANDOK260 insert dummy or with G 3545 A and the Vane shaft into face in the wall of push spring four cover in place Snugly the bolt close to the dowel tighten Then tighten four bolts to the speci fied torque 0 7 to 0 9 kg in so that m 5 1 t06 5 ft4b ring ring by correctly align end face of rotor with the rear mark in rotor 0 high equivalent spring Tightening torque to sure is as cover spring end face is flush with rotor 8 Vane shoe that the outward bend Install rotor 6 a shoe groove exposed beyond the rotor end face instaUing side faces in shoe and that both ends them End Position end When bearing cover Installing shoe spring Jl Notes rear sembly EC123 40 EC replace necessary 11 EC540 Fig shaft when replacement of rear i 111 Fig EC 38 Install carbon shoe vane When wear occurs on vane shaft or screws ring and tighten the specified to torque with Hexagonal Wrench ST19810000 Tightening bearing torque 5 to 0 7 0 kg m 3 6 to 5 1 ft lb STl9900000 EC302 Fig 12 to 5T19810000 2 Install in place on 0 7 to 0 9 kg m 5 lt06 5 ft lb as a EC124 guide INSPECTION Fig EC 41 In8talling rotor ring Note may require 6 to 16 km 4 to 10 miles wear in running time In the event a slight squeaking The 80 km h most cases 40 to 50 MPH 6 to 16 km miles will be sufficient for Shoe spring Place shoe springs in of shoe Air InJection vanes still remains drive the car about 64 7 bolts rotor using Dummy Shaft STl9900000 to end cover Tightening torque EC 39 Vane assembly vane ling Insla Pulley Tighten four pulley securing the specified torque EC563 Fig EC 42 4 In to 10 wear in 9 Carefuny from withdraw groove dummy shaft with high air connections Retighten vane 10 or system hoses for loose cracks replace or deterioration if necessary Vane shaft Pack rear bearing melting point grease G 3545 A MIL so equivalent ANDOK 260 or thin coating of grease to shaft and rotor ring and insert Apply deeper Check Removal of dummy shaft system hosas shaft into its bearing EC 17 vane vane Air ystem manifold Check air gaUery nozzles cracks sary for pipe loose Retighten or and injection and connections replace if neces Emission Control a reaches until it Operate engine I and air if necessary correct air before connec Check air injection pump belt tension and adjust to specifications if supply hose air control vacuum hose from the California valve type only Insert open pipe end ofAir Pump Test Gauge to supply adapter STl9870000 in Adapter Check hose opening for any indi detected replace check valve Race the engine lightly at about 2 000 cpm and idling VisuaDy then return it to check the hose for any indication of exhaust gas leaks before the engine returns to idling speed If leaks are detected replace check valve and etc repair or correct if necessary 3 With engine idling disconnect the outlet side hose of the air control valve and place your hand on the air hose outlet to check for air If no air is felt replace the air control valve 4 Pull con vacuum hose off from air If discharge of air from trol valve stops the air con trol valve is normaL Ifdischarge is still felt replace air hose the valve up the removed vacuum hose Plug Clamp hose securely prevent it from blowing to stabilize engine running adapter and test out Position air blast emitted that check hose to Warm up engine thoroughly Before checking air control valve leaks 4 Disconnect air thoroughly hose leading to Disconnect 3 valve check all hoses for loose connection valve from air hose COJUlector at check valve 6 functioning properly cation of exhaust gas leaks Ifleaks are necessary 4 Disconnect Air control C U ornla models Warm up engine 2 3 air as Check valva checking injection pump 5 engine 2 for leaks and gallery unit is I normal operating temperature 2 Inspect all hose hose tions that the must be determined Air pump System lliuge so through drilled pipe plug will be harmlessly dissipated 7 Install a With engine tachometer speed pressure produced serve at Air pressure should be 3 94 inHg on engine 2 600 rpm ob at test gauge 100 mmHg or more 8 If air pressure above specifications does not proceed meet as EC310 fol Fig EC 43 Checking check valve lows I Repeat 2 and 2 Disconnect backfire anti and ing 3 above air supply hose at valve Plug air hose open screw with a clamp Repeat pressure test 3 With engine speed at 1 500 rpm close hole of test gauge with finger If a leaking sound is heard or leaking air is felt by ftnger at relief valve relief valve is malfunctioning Relief valve should be replaced or repaired If air injection pump does not meet minimum requirement of pres 4 sure test it should be replaced Air pump raIle After valve completing inspection of air check air pump relief valve in pump the following steps J Disconnect hoses valve and leading air control hose connector to check valve from air and install blind cap to the connector 2 With EC312 engine running 3 000 rpm under no at about load place your the air outlet of air pump relief valve to check for discharged air hand on If no air is felt replace the air pump Emarsancy air rella E AR 2 Control valve valve Valve lCalHornla models L relief valve Checking air control valve 45 EC Fig Warm up engine thoroughly Before checking air control valve check all hoses for loose connection The following procedures are reo commended for checking and or as certaining that the various components leaks of the exhaust emission 2 000 rpm under no load Place your hand on air outlet of E A R valve to con Irol system operating properly The engine and all components must be at normal operating tempera when the tests are performed diag Prior to performing any extensive and repair necessary 3 Race are tures etc engine or correct if approximately check for presence of discharged air If no air is felt E A R valve is normal EC311 Fig 44 EC Checking air pump relief nosis of the exhaust control system it valve EC 18 4 Disconnect B A R valve 46 as vacuum hose from shown in Figure EC Emission Control System Race under 2 000 approximately no load E G R RECIRCULATION CONTROL SYSTEM for presence of discharged air If air is felt E A R valve is normaL 5 ing system which indicates tXHAUST GAS Place your hand air outlet of E A R valve to check rpm on engine spected E G R properly replace valve In system exhaust a returned to gas recirculation of the exhaust gas is part the lower the pump I a EG R 2 Open finger engine place 3 a Run under no load at about 3 000 If you feel R c1ose operation of the E G R valve is controlled by the vacuum temperature 1 I D t Y1 I ID JO 4 0 the outlet near then con by the E G quantity warn Disconnect hose from air cleaner and through the to the E G R valve which opera tes carburetor vacuum and engine cool on VI thoroughly is manifold thermal vacuum I @ valve trol valve The exhaust gas is then control tube and hose A in 620 and is introduced into the intake ant trol valve con exhaust manifold in E G R con be in all of the exhaust gas is led chamber thermal Fig EC 46 Cheeking E A R volve Warm up engine valve con ET267 A the The exhaust gas recirculation sys tem consists of an E G R passage volve Anti backfire valve from trolled in the exhaust gas tent To air in some passage spark flame temperature during combustion This results reduction of the nitrogen oxide installed the E G R open EG R the combustion chamber to also is When DESCRIPTION E AR system models except those bound for Coli fornia and Canada If E A R valve does not function at above steps control when the must quickly rpin cetum it pull or suction finger the anti backfire valve is functioning normally If no suction is felt replace the anti backflre to idling force on a your valve 2 3 E C R control valve E C R passage 4 Intake manifold 5 Thermal 6 E C R 7 Exhaust vacuum valve tube manifold EC349 Fig EC 4 Exhaust Gas Recirculation system E G R OPERATION Operation Fig EC 47 Checking anti backfire valve EG R E G R system operating water temperature oC OF Below 570C of E G R system is as shown below 135OF Thermal vacuum Intake manifold E G R vacuum control valve valve Remarks Close Close california Non Above Not actuated Above 57 to 630C 135 to 145OF Open Below Actua ted Above 57 to 6 oC 135 to 145OF Above Open EC 19 MfT models Idling only 70 mmHg 76 inHg California models and N on f alifomia AfT models 50 mmHg 197 inHg Close Fullthrollle Open Emission Control E G R OFF When is low operation this engine coolant temperature recirculated exhaust gas causes irregular engine operation To prevent be System recirculation of exhaust gas must off for a few minutes after It remains closed while engine um has started valve is thermal The provided for engine coolant temperature is low and keeps the E G R control valve closed thereby cut vacu culling off the E G this purpose R circuit rn I lW 11 1 L e7 r Thermal vacuum Note j E G R 2 is When engine coolant temperature the working temperature of vacuum The valve port valve come Throttle valve close valve m Vacuum condition EC227 clo above the thermal I controlval le jS to the top Fig of the throttle valve du ring engine idling for improved idling operation At this point vacuum does not actuate the E GR control though high intake i manifold actuated vacuum is closed valve l JllrI L r E G and E G R control valve remain D T J 49 EC R not t q Throttle valve II Thermal E G R control valve vacuum valve ope close EC228 Fig EC 50 E G R 2 In the full throttle tion the suction vacuum driving posi on the vacu um um passage does not surpass the required to actuate EC 20 vacu the E G R control valve nol actualed Emission Control System 6 Thermal vacuum valve Open I Note Vacuum condition I E GR control valve Close EC793 Fig EC 51 E G R ON circuit only when engine Y i3 m m not actuated operation E G R The E G R is is above completed coolant temperature l fj ti EN the thermal 3 0 1t d iiA the t1f retor working temperature of valve and carbu vacuum l P@ 0f Y f vacuum Wg i0 1 il nk suction is large enough open the E G R control valve to i 1 Throttle valve n L Thermal vacuum Note valve r Open iiiI Vacuum condition EC794 EG E G R The the R control valve control valva EG R control valve controls quantity of exhaust gas to be led through vertical to the intake manifold movement of the taper valve connect ed to the diaphragm Fig EC 52 E G R actuated Open to which vacuum is applied in response to the opening of the carburetor throttle valve E G R control valve is installed The on the E G R passage through a gasket E G R con trol valve construction and type vary with transmission EC 21 type and car destination For identification the part number is stamped purposes on the recessed portion at the top of the valve The control construction valve is of the EG R shown below Emission Control System the E G R control must system be checked j The E G R warning system consists an odometer switch detector drive of 0 o o counter E G R harnesses When the o m o warning earn switch connected eter o lamp and in the odom the to speed ometer turns once for each OAkm 4 mile the contact point of the elec trica circuit closes coil allowing electric through the magnet to flow current of detector the drive counter Thus energized the magnet coil ac Wates the latchet to turn the c unter l 2 Diaphragm spring Diaphragm wheel by one pitch When the number of counts reaches 50 000 the latchet 3 Valve shaft 4 Valve drops in periphery 1 l @ 5 6 Valve Seat Valve cham ber activate a provided groove of the the detector on the wheel to counter drive counter switch EC231 Fig E G R control value EC 53 the Then EG R warning lamp indicating that the E G R comes on control system Should be checked The detector drive counteT is ped Thermal The vacuum thermal mounted in valva vacuum valve is the engine thermostat housing It detects engine coolan t tem perature by means of a built in bi metal and opensor closes the vacuum passage in the thermal vacuum valve with When the vacuum passage is open the when to carburetor suction system to the diaphragm trol valve to vacuum valve is taper odometer which service E G R the equip can tell contr0 I After completing periodic check to zero by hand proceeding as follows con the odometer reset valve diaphragm theconsiiiictlo vacuum applied of the EG R actuate the connected to the is an nlie thermal shown below 1 Remove the side grommet installed on surface of detector drive counter unit 2 insert a bar or screwdriver a tip into the hole from which grommet has mt To E G R control valve been removed li provided and press down knob in the detector drive counter for resetting The E G R warning lamp comes on under the following circumstances From carburetor 1 When the number of counts has reached 50 000 In this indicates that E G R case the lamp control system must be checked When operating starter motor 2 1 Spring 2 Bi 3 Oring Notes metal t 00 a It is an indication of problem in the E G R t EC232 Fig EC 54 Thennal vacuum valve warning lamp or problems point or in the harnesses if lamp does not light at 50 000 in the the counts b The E G R warning system ed independently of the E G R trol system The E G R warning system install car con monitors the distance the has travelled and indicates when EC 22 E G R mounted those Canada warning system is all 620 models except bound for California and on Emission Control System 1 1 I I I 1 v Ignition v I I I I switch E G R warning lamp f I I I Ignition I switch start 1 position I I Odometer switch I Fuse I 1 A r I I I I 0 I v I I I I U I I I I I I I EC541 I i lQ Magnet coil 1 Fig EC 57 Removing E G R passage mi L J L Detector drive counter EC233 Fig EC 55 E G R warning circuit 3 Thermal vacuum valve After removing the following parts vacuum valve can be dis the thermal mounted REMOVAL AND Vacuum hose INSTALLATION mal Remove air cleaner before control E G R system Vacuum removing For Page section carburetor to ther valve hose thermal vacuum valve to E G R control valve removal and installation of air cleaner refer to Air Cleaner vacuum Note EF S Drain engine coolant before dis mounting thermal vacu m valve EC234 Removal Fig EC 56 Removing KG R control valve I E G R control valve After removing the following parts the E G R controi valve be dis can mounted Vacuum valve to EG R Note ten To hose thermal control valve mounting remove vacuum hose vacuum nut flat hose to control valve and pull the hose off with hand E GR pass ge After removing the following parts the E G R passage can be dismounted Exhaust gas E G R control valve clip connecting EG R vacuum 2 tube return exhaust manifold to E G R passage B1ow by hose cylinder block P to Fig EC 58 Removing thermal v valve C Vacuum hose AB valve to E G R passage E G R passage mounting bolt EC 23 vacu um valve Emission Control EGR 4 System warning system CID r V drive counter 1 Detector 2 E 3 Speedometer G R warning lamp EC251 EC 59 E G R Fig 3 Detector drive counter Detecfor disconnect counter and loosen two bolts securing detector drive counter to hoodledge 2 E G R warning COJUlector w as E G R warning lamp proceed To switch proceed Cam in the rotated is switch speedometer 2 the by dismount odometer as follows as Remove masking panel equipped with radio On models Loosen 4 screws printed Remove odomete type switch Remove lamp and socket as assembly Push and twist lamp off and dismount securing speed circuit housing then speedometer warning lamp from under in strument panel 2 E G R warning lamp is a twist remove cover screws to plate ometer to remove E G R control system in I Make thorough visual check a control E G R system away oil to facilitate If any hoses are of If necessary cracked inspection or broken replace Remove meter front shadow Checking its mounted conditionS wipe Dismount combination meter take off clips and 3 follows 1 odometer speedometer sembly lamp E G R warning lamp is mounted at the top cen ter of instrument pad To remove back side of I panel INSPECTION Odometer switch Odometer switch is mounted on the drive counter is secured the top of R H hoodledge panel in engine room To remove detector drive on y tem warning securing switch to the back side of speedometer and running engine warning system for detach odometer an check With E G R sure ing lamp lights when turned to START proper that E G R warn function Make ignition switch position is starter mo If E G R wanung lamp does tor runs screws two 2 inspect harnesses and con nectors or replace warning lamp Then turn ignition switch to ON position and check the following items not light If odometer of detector drive reached 50 000 has not counter I counts make sure that E G R lamp does not light If odomete 2 warning of detector drive counter has attained 50 000 counts can make sure that E G R warning lamp lights If warning lamp check harnesses EC239 Fig EC 61 Removing odometer switch tector lamp does not connectors light and de drive counter replace warning detector drive counter if or necessary InstaUatlon Notes EC554 Fig EC 60 Removing E G R warning lamp To install reverse the removal pro Operation is as cedure EC24 oC E G R Collows warning lamp Emission Control ON START Ignition Switch Position Detector Drive Counter E G R Warning Lamp b After E G R control system be sure to to zero counter c of odometer of detector drive reset This item applies to all 620 models except those bound for California and Canada 3 With engine stopped inspect E G R control valve for any indication of binding or sticking by moving dia phragm a finger of control valve Below Above 50 000 counts 50 000 counts ON inspection completing upwards with System ON OFF With 4 E G R um running engine inspect control valve and thermal vacuo valve for normal operation engine coolant tempera When 1 ture EC254 Fig EC 63 Checking lhermal is low valve vacuum Make sure that E G R control valve does not operate when engine speed is increased from idling to 3 000 to 3 500 rpm Place EGR a fmger the on diaphragm of control valve to check for valve operation If any difficulty is encountered in judging the condition of any compo nent during above inspection check the questionable component independ ently as follows E GR control Dismount valve E G R control valve from engine I Apply valve vacuum referring If the valve to to the moves E G R control following figure to full position it is normal EG R open for vacuum control more valve will remain than 30 seconds after has cut off la EC253 Fig EC 62 Checking E G R control valve ET152 When 2 ture I is engine coolant tempera Increase engine speed from idling high Make sure that E G R control valve 3 000 to 3 500 rpm operates when engine Make creased from idling 500 3 rpm Place diaphragm of E G to check for valve 2 control valve If E G R one as is in 3 000 fmger on control to the valve operation control valve operate check Disconnect a R speed to does not follows end E G R control valve side of vacuum hose connect ing thermal vacuum valve to E G R su re that thermal Fig EC 64 Checking E G R control to ualue vacu um valve is open and that carburetor vacuum E G R is at present the control valve side end of vacu um hose If Visually check E G R control damage wrinkle or defonna valve for tion vacuum is weak all replace thermal vacuum 2 or not present at vacuum is present control valve replace valve If E G R 3 Clean compressed matter port EC 25 the seating E G R control valve with from air and around surface a remove the of brush and foreign valve and Emission Control System CATALYTIC CONVERTER and catalytic converter accelerates the exhaust gas and to changes them carbon dioxide the item to This air is caUed catalytic harmful Refer air pump the chemical reaction of hydrocarbons HC and carbon monoxide CO in non reac process requires the proper a mount of air which is supplied by the DESCRIPTION The This chemical H20 water tion secondary converter AJ S air The is mounted on vehicles destined for California into the Refer 67 EC Figure C02 3 EC350 4 Fig EC 65 Cleaning E G R control valve Thermal vacuum Dismount valve thermal valve vacuum from engine Note Before gine Apply vacuum vacuum response to to thermal vacuum Thermal to a sure thaI ther valve opens or closes in engine coolant tempera 1 Front tube 4 Main muffler 2 Catalyti 5 Rear tube 3 Center tube vacuum EC782 Fig EC 67 Location ofcatalytic converter valve should open temperature of 57 1450F completing to 630C the 135 car OPERATION not allow water vacuum to get inside the thermal vacuum valve and carbon monoxide in the exhaust gas are oxidized with oxygen 02 Exhaust gas emitted from the Do He ons CO passage Note converter specified ture as at en engine valve and check to be mal drain dismounting coolant from gine due secondary en harmful contains some harmful substances to incomplete combustion water in the combustion chamber The air injection system is designed to reduce the con contained dioxide exhaust manifold With this secondary air carbon dioxide C02 and H20 catalytic converter further engine exhaust gas Through catalytic action it changes residual hydrocarbons and carbon monoxide In this system the secondary air is led from the check valve and injected the the The gas injection of in air and converted into non cleans tent of such substances in the exhaust into the gradually is hydro in exhaust gas into carbon and water before exhaust gas discharged to the atmosphere c Secondary air Carbon monoxide hydrocarbon Carbon dioxide gas water EC242 Fig EC 66 Checking hennal EC444 vacuum F valve EC 26 EC 68 Operution ofcatalytic corwerter Emission Control INSPECTION Removal and Remove air hose between 5 way 2 REMOVAL AND inspection can be done as follows System If CO percentage is still over step 15 catalytic conyerter is 16 in connector and air check valve 03 disconnected malfunctioning Replace catalytic hose Plug the prevent dust to from entering Refer to page ET 12 3 Check carburetor pipes for proper con verter connection 4 Warm up engine sufficiently Race engine 1 500 to 2 000 rpm two or three times under no load then Removal 5 Catalytic converter 1 Apply parking brake 2 Place wheel lock under each tire 3 Jack up the vehicle Remove lower shelter of catalytic 4 Dismount catalytic INSTALLATION If 7 converter adjust sary it to To install specifkations neces Tightening torque Catalytic converter 2 6 to 3 4 kg m Adjust idle adjusting screw until specified CO percentage is obtained B 19 Refer to page ET 12 9 Repeat the adju stment process as described in steps 5 to 8 above until Note EC453 the removal pro specifications Refer to page ET 10 specified reverse cedure Bolt lightening torque Refer to page ET 10 Check ignition timing converter 5 engine for oe minute at idling speed 6 Adjust throttle adjusting screw until engine attains to specified speed run to 25 ft Ib CO percentage is obtained in step 9 should be engine has Adjustment made ten minutes after Fig EC 69 Removing catalytic wanned up conuerter 10 Inspection rpm and make Preliminary inspection check condition component parts including tubes Refer of A IS Inspection to of all hos if necessary replace on hose catalytic converter is nor be checked by ob not can in CO serving variation The checking procedure Apply parking percentage is as follows brake Shift gears into Neutral for manual transmission and or Neutral Park for automatic transmission 1 Visually check catalytic for damage or cracks to that specified to cap and 2 000 CO per connect converter air air check valve to speed increases readjust it specified speed with throttle ad 13 speed pleted FLOOR TEMPERATURE WARNING SYSTEM DESCRIPTION WaRn up floor The screw engine for about four minutes at 2 000 rpm under Catalytic converter or 500 If idling 12 mal sure Remove 11 justing page EC 17 Whether 1 centage is obtained Visually and wires engine Race two or three times under no load noload Measure CO percentage at idling After step 12 has been coin sensing switch installed on the vehi cle s floor floor temperature relay and a warning lamp on the instrument before panel making CO percentage measurement If CO percentage measured in 14 3 0 13 is less than the catalytic step parts wait for one minute an will If CO percentage measured in 3 0 13 is over recheck A IS step and replace air check valve Then driver perform inspection steps 12 and 13 EC 27 and wires that connect these When the floor tempera ture rises to abnormal level the warning lamp converter is normal 15 temperature warning temperature system consists of a floor light to call the attention of the The system and location of of this the floor sensing switch are ilIus Figures EC 70 and EC 71 temperature trated in wiring diagram Emission Control System The lamp starting lamp Ignition switch motor The tween IG on I I Battery J Relay J floor tis operation The the ignition position chart furnishes the the relationship I I sa while the when foUowing information T on is in out goes switch is in Ignition key Off functioning is if it is remains factorily I temperatures lamp and sensing be warning switch L Floor temperature 77 77 warning lamp Floor temperature sensing swi tch Contact close ECJ40 77 77 I EC332 Fig EC 70 Win ng diagram offloor temperature warning system rl Contaclopen ECJ41 Fig EC 72 Operation of floor t mperature sen6ing @ J 6witch REMOVAL 1 Floor temperature Floor temperature sensing switch 1 Remove seat section of Seat as outlined in the Body and Frame service manual 2 Ij floor From EC556 temperature sWitch Floor temperature cr Fig EC 71 Remove sensing under this part Refer to relay relay cover Figure remove EC 73 Location of iJoor temperature sensing switch Floortemperature OPERATION Floor temperature will exceed nor mal level when temperature rise in the exhaust lytic system succeeding converter is caused engine malfunction conditions or the cata byeilher severe an driving Under this condition the floor temperature sensing switch turns off causing the starting switch line of the floor temperature relay to turn off and the ignition switch line to turn on result the floor temperature as a warning lamp When lower t comes on the an the floor temperature is specific temperature the floor temperature sensing switch turns on The ignition line of the floor temperature relay turns off while the starting switch side is in on The floor temperature warning lamp goes out EC 2B EC783 Fig EC 73 Location of floor ttmperature relay Emission Control System Floor temparature warning lamp Refer to Figure EC 74 for the loca tion of this part L 1t 1 RAt Temperature warning lamp Contact close Off Below 1050C 221 OF Contact open On Above 1050C 221 OF Note Avoid ture If sensing To install perature sensing switch order the of Referring s step 3 connector ignition switch tester Repair faulty wiring replace tem When relay trace as relay or check the Repair or replace 3 ignition 1 Check for continuity between ID Continuity should exist @ Check for continuity between and@ Continuity should exist CD Check for continuity between CD and ID IG Floor warning temperature position and disconnect floor temper ature sensing connector The lamp system should remain on parking brake Apply Shift gears into Neutral foI manual transmission and Neutral or for Park If not Ensure warning floor that when lamp lights If check not S ignition position J back to replace wire CD that and doc @ replace dn not the floor across continuity and that does not between test results CD and carrying out the Repair O temperature 4 5 To floor temperature 3 or sensing is I Remove rearseat IG Ignition switch position 3 Ensure that is turned to the temperature relay switch When floor temperature 1 Float level warning lamp lights 2 Choke 3 Normal fuel Check out temperature proper sensing heater to areas switch ensure of floor with that a floor glows when temperature warning lamp floor is heated to the specifications shown in the table below If Fig EC 75 Checking floor temperature relay floor temperature warning lamp goes 4 Heat surrounding @ ti EC344 1760Fj before following procedure 2 exists con satisfy the above below 800C cool @ and temperatwe warning lamp From S position From IG position From ignition switch 2 s if necessary Be sure that floor 2 trace switch ignition nuity check floor To floor is burned out If bulb is not burned ensure r I 141 bulbs Replace bulb if bulb to should notexist 2 00 for burned lamp Continuity Apply a 12 volt automatic temperature switch is iumed to the @ between temperature relay for continuity with transmission 1 checking floor temperature remove it and proceed for unit follows and temperature sensing switch to the back s Floor temperature relay 2 INSPECTION is normal relay to switch may be heated through the floor by a proper heater Turn following floor trace wire if necessary The floor Note removaL back to the temperature relay If con tinuity does not exist wiring to if perature sensing switch the circuit tester directly If continuity should exist after heated surrounding areas of floor tem wire reverse a does not glow check floor lamp following INSTALLATION switch Floor temperature floor tempera heating temperature sensing switch for continuity with a circuit Fig EC 74 Location of floor temperature warning lamp Temperature sensing switch as floor temperature warning lamp 1 Open or shorj circuit in wiring harness 2 Check fuel system with regard to the following items Refer to Inspec lion of Fuel System EC 29 supply ry and secondary 4 Accelerator pump 5 Power valve 6 BC D D 7 Fuel strainer 8 Air cleaner system Prima Emission Control 3 Check ignition system with regard the to Refer following Inspection of Ignition System items 1 Ignition 2 Distributor to AMP 3 Ignition coil 4 High tension Spark plug 5 4 to System Note code come Check idle CO adjustment Inspection of Even if there is nothing wrong warning lamp may on if vebicle is being driven steep slope continuously in gears at high engine speeds with engine the on Refer a lower Idle CO Adjustment EVAPORATIVE EMISSION CONTROL SYSTEM CONTENTS DESCRIPTION EC 30 CARBON CANISTER PURGE CONTROL OPERATION EC 30 VALVE INSPECTION EC 31 CARBON CANISTER FILTER FUEL TANK VAPOR AND VAPOR VENT LIQUID SEPARATOR The evaporative This reduction of hydro IEC 32 VACUUM RELIEF VALVE EC 32 EC 31 carbons is accomplished by activated charcoals in the carbon canister This emission control system is used to reduce hydrocarbons emitted to the atmosphere from the fuel system FUEL TANK LINE DESCRIPTION IEC 32 system is made up 2 Vapor liquid separator Vapor vent line 3 to the 4 Carbon canister following 5 I 6 Canister purge line Fuel tank with positive sealing filler Vacuum signal line cap @ 5 1 Fuel tank 4 Vapor vent line 2 Fuel nIler cap with vacuum relief valve 5 6 3 liquid vapor separator 7 Canister purge line Vacuum signal line Carbon canister EF274 Fig EC 76 Schematic drawing of lIaporotive emiaion control6ydem OPERATION Fuel vapors from the sealed fuel are led into the carbon canister tank The canister is fined with activated when the charcoals to absorb See 30 EC the fuel vapors engirie is Figure EC 77 at rest or at idlin ll Emission Control J System Close at Open at rest idling i i j J 17 f Fuel vapor 1 Fuel tank 6 Canister purge line 12 Filter 2 Fuel f1l1er cap with vacuum relief valve 7 Throttlevalv 13 8 Engine Liquid vapor separator Vapor vent line Vacuum signalUne 9 3 4 5 Carbon canister 15 Purge control valve Spring Diaphragm 10 Activated carbon 16 Fixed 11 Screen 14 orifice EC784 Fig EC 77 Evaporative emu ion control sy tem Fuel vapor flow when engine i6 at red or idling As the vehicle throttle valve speed increases opens and vacuum pres in the vacuum signal line forces sure rHL the purge control valve to open and admits an orifice to intake manifold intake manifold through the canister purge line See Figure EC 7B and fuel vapor is then drawn into the JL I I J o I Fuel vapor Fresh air EC785 Fig EC 78 Evaporative emiuion control system Fuel vapor flow when engine i running manometer and a cock INSPECTION lent 3 way charge cock the vent line FUEL TANK VAPOR LIQUID SEPARATOR AND I VAPOR Check all VENT LINE hoses and fuel tank Disconnect the liquid separator Connect a 3 way connector a Supply fresh line through until mrnH20 14 5 vapor vent line connecting carbon canister to vapor 3 vent little mler cap 2 4 Shut equiva the end of into the vapor the cock little by cock with 25 mmH20 0 98 inH20 8 When completely air becomes pressure 5 inH20 the or an to 368 zero in a short time 9 I f the zero and hose the Note height does not drop to in a short time when filler cap is of a stuffy In case the vent line is stuffy removed completely filler cap does not close the height should drop to it is the cause leave it unattended 6 After 2 5 minutes measure height of the liquid in the manometer 7 Variation of height should remain EC 31 the breathing in fuel tank is thoroughly made thus causing not in Emission Control System sufficient delivery of fuel to engine or vapor lock It must therefore be 1 3 connectur repaired or replaced 368 mmH20 14 5 inH20 LL COCk Air Manometer liqUid IPO 36 @ epoo ET37Q r Carbon canister s2 EC Fig Replacing carbon canuter filter EC786 Fig EC 79 Checking evaporative emmion control syatem CARBON CANISTER PURGE CONTROL VALVE 3 If cover there from is leak a check for dislocated Check for fuel vapor leakage in the distributor vacuum line at diaphragm of carbon canister purge control valve To check for leakage proceed as If phragm phragm kit retainer a remove control purge or necessary top valve and cracked dia dia replace which is made up of diaphragm and a spring in the 2 air into the it Wipe clean valve housing and have Inhale air A slight resistance ac by valve indicates that valve is in good mechanical condition Note also that by further inhaling air companied canister at Tconnector Inhale see it in your mouth @ line between T connector and carbon fuel filler cap and Remove functions properly I Disconnect rubber hose 2 RELIEF VALVE a follows I FUEL TANK VACUUM @ opening of rubber hose running to vacuum hole in carbon canister and ensure that there the resistance should be disappeared with valve clicks is no leak 3 1 2 Cover 3 Retainer 4 Spring ance Diaphragm If valve is is felt clogged or if no resist replace cap as an assem bled uni t ET350 Fig EC 81 Carbon catU ter purge control valve l u CARBON CANISTER FILTER Check for ET349 Fig so EC Checking carbon canuter purge control valve a contaminated element Element can be removed at the bottom of canister installed on vehicle body ET369 Fig EC 83 Fuel filler cap 32 EC Emission Control System SPECIAL SERVICE TOOLS Tool number No Description tool name STI98 10000 For removing and installing the rotor ring assembly For Reference use page or on Figure No L20B Fig EC 29 A14 Fig L20B Fig EC 39 41 EC Hexagon wrench SE279 2 ST 19900000 For assembling the vanes A14 Dummy shaft SE284 3 STl9890000 Used as a mount when rotor is removed and when bearing is installed A14 L20B Fig EC 32 fig IlC 35 L20B Fig A14 Fig EC 35 f Rotor adapter SE347 4 Used when rotor is removed and when front bearing installed STl9940000 Bearing Pressing tool d 9E348 This service tool is designed for use in disassembly 33 EC and assembly of the air pump EC 32 Emission Control System Tool number Description No tool name 5 STl9930000 Used mount when front as a bearing is removed For Reference use page on Figure No L20B Fig or EC 33 Al4 E9 Bearing adapter SE349 6 STl9910000 Used as a drift when front bearing is installed Also used as a support when rotor is installed L20B Al4 Fig EC 33 Fig EC 36 Fig EC 37 L20B Fig EC 36 AI4 Fig Bearing driver SE350 7 STl9920000 Used as a drift when rotor is installed C 37 o Rotor stand SE351 8 ST19870000 Used as a adapter when air injection pump pressure is tested L20B Al4 Air pump test gauge adapter SE389 EC 34 Page EC 18 SECTION EE ENGINE DATSUN PICK UP ELECTRICAL MODEL 620 SERIES SYSTEM BATTERY STARTING MOTOR CHARGING CIRCUIT ALTERNATOR TOKYO LTD JAPAN EE 4 EE 12 EE 15 EE 20 IGNITION CIRCUIT EE 26 Non California models NISSAN MOTOR CO 2 REGULATOR DISTRIBUTOR I NISSAN I EE EE 30 DISTRIBUTOR California models EE 33 TRANSISTOR IGNITION UNIT California models EE 36 IGNITION COIL EE 46 SPARK PLUG EE 47 Electrical Engine System BATTERY CONTENTS LEVEL ELECTROLYTE CHECKING CHECKING SPECIFIC GRAVITY EE 3 BATTERY FREEZING EE 2 REMOVAL EE 2 CHARGING EE 3 EE 2 INSTALLA TION EE 3 REMOVAL I Disconnect negative and positive cables 2 Remove clamps 3 from nuts battery take off clamps Read top level with scale Remove battery 1 2 CHECKING ELECTROLYTE LEVEL Fig Remove six vent plugs and check for electrolyte level in each cell If nccessaJ pour distilled water S EE l Checking pccme gravity Converted specific gavity Where St 520 20 of electrolyte Specific gravity at feOOl 20 0 0007 t St 20 Thermal gauge Hydrometer 1Je tOe of electrolyte Specific gravity 1 28 corrected at 200e 680F @ Electrolyte temperature S 126 t For example of 1 260 reading would be 6goF 1 267 at 300e corrected indicating to fully of reading Specific gravity of battery electro lyte is tested by a hydrometer If the charged battery srate of charge of battery is 60 or specific gravity reading is below 1 20 be determined by the following table if the specific gravity of electrolyte is corrected tery must electrolyte Add be 200e 680F recharged concentration or according at subtract or battery gravity points or made A correction by using the charge of battery BefOIe checking be cells filled to correct level u sure U21101 can 1 I dOldlOiJ that EEOO3 Fig o N b below 200e E t JI u ol can following 1 m I I I I lilt I i J Sf J 0wJIztI to 1 1 7 II It EE002 Fig EE 2 EE 2 ffing ChaJ I 100 COJJditioD then be formula OSQ Electrolyte temperature oC U G electrolyte The gravity of electrolyte chlll ges 0 0007 for 1 80F tem every Ioe petature e 0 known are o l adjusted to whether the temperature is above 680F standard bat u o lOoe 1220 at 140 F would be 1 199 corrected to 200e 680F indicating a partially as l a CHECKING SPECIFIC GRAVITY The state of E l 860F 200e charged hydro battery On the other hand meter Sow hydrometer A condition Specific lNWity at eiectroly te temperature EE 3 Engine Electrical System nals should be cleaned with a brush and common baking soda solution In BATTERY FREEZING indication that battery is Battery electrolyte freezing point varies discharged specific insufficient charge will freeze at lower a temperatures If specific gravity of battery 11 below falls this is and will completely freeze readily when temperatures fall below freezing with acid concentration or its gravity A battery with an Note Use extreme caution to avoid freezing battery an since freezing will generally ruin the battery addition be following the I Be that electrolyte level is sure plate Keep removed plugs in a safe place Do not allow electrolyte tempera 3 I130F After charging check to be cer tain that specific gravity does not Cor exceed 1260 at 200C 680P 4 20 rection 30 u 40 0 e 0 SO I I 70 80 1 104 108 l2 t 1 16 t 20 of 24 1 28 1 1 32 After all vent EEOQ4 electrolyte Fig EE 4 Froezing point of electrolyte INSTALLATION 1 CHARGING Install and tighten clamps secure Iy electrolyte level is satisfactory battery must be charged when electro lyte gravity reading falls below 1 20 If If car necessary plugs have been tightened clean all sprayed electrolyte off upper face of battery 6 Specific gravity battery as Keep battery away from open flame while it is being charged 5 100 is be made by adding dis can tilled water into cells 60 E on being above top of each ture to go over 450C 10 il is charged 2 0 g items should while battery observed quick charged to After clamps have been it up to full charge the opera tion should be carried out with nega 2 clean battery tive cable removed apply grease bring Prior to charging corroded EE 3 termi corrosion cable to tightened terminals and retard formation of Engine Electrical System STARTING MOTOR CONTENTS EE 4 OVERRUNNING EE 6 BRUSH CONSTR UCTI ON EE 7 REMOVAL EE 7 DISASSEMBL Y EE 7 CLEANING AND INSPECTION EE 8 TERMINAL EE 8 FIELD EE B EE B SERVICE DATA AND SPECIFICATIONS BRUSH SPRING TENSION EE B TROUBLE ARMATURE EE B COIL BRUSHES AND BRUSH LEAD WIRE ASSEMBLY CLUTCH ASSEMBLY DESCRIPTION OPERATION EE 9 EE 9 BEARING METAL EE 9 MAGNETIC SWITCH ASSEMBLY EE 9 ASSEMBLY EE 9 TEST EE 9 PERFORMANCE TEST EE 9 MAGNETIC EE O HOLDER TEST FOR GROUND SWITCH ASSEMBLY TEST EE DIAGNOSES AND CORRECTIONS EE 11 DESCRIPTION 5 @ The function of the starting system which consists of the switch to crank the battery ignition motor and solenoid starting engine is The electrical supplied from the battery solenoid completes the circuit to energy is the I Brush operate the starling motor and then the motor carries out the actual crank 2 Field coil 3 ing of the engine 4 Magnetic switch Pludgcr Torsion spring 5 9 6 7 Shifll 8 Pinion 9 Armature r Overrunning clutch EE315 Fig 4 EE EE 5 Sectioool view of slarting motor Sl14 180B Engine Electrical System INHIBITOR RELAY INHIBITOR SWITCH FUSIBLE LINK A Y O 1Y b J I @ I A rJ BATTERY f l STARTING MOTOR fB EARTH POINT f WBBYBY rBW B @@@@ I j I FUSIBLE lIN 000 ggg I I California Bd CJ BW f 00 00 00 H r For I T BATTERY BWI 000 00 Q I BW I @@@ Y B @ @ Y BY l BY BW BY BWWB BY WB BY BY @@@ @ @ @ @ I AfT I Black OW BW @ Equipped with cooler COLOR CODE B I BY Black with white stripe Black with yellow stripe W White WB White with black stripe 9 IGNITION SWITCH I M T Equipped with cooler I Notes a b @ @ T only M A T only Inhibitor switch is on in neutral L STARTER MOTOR INHIBITOR SWITCH eE491 Fig EE 6 Circuit diagram EE 5 0 starting systom Electrical Engine System OPERATION When the ignition switch turned clockwise to the START posi cp fully tion battery current series and shunt solenoid magnetizing flows through coils the of the solenoid The plunger is pulled into the solenoid so that it move operates the shift lever to the drive flywheel ring gear pinion into the I Then the solenoid switch contacts close o after the drive 1 W r pinion is partially engaged with the ring gear Closing of the solenoid switch Fl contacts c uses the motor to crank the engine and also cut out the coil of the solenoid of the hold shunt series the magnetic I I m pull coil being sufficient to the pinion in mesh after the been performed After the engine starts running the driver releases the ignition key and it automatically returns to the ON posi EE274 shifting has I Ring 2 Shift lever guide 3 Armature 4 Battery tion 5 Field coil The torsion spring then actuates the shift lever to pull the pinion which 6 Stationary contact 7 Monble contactor 8 Shunt coil 9 10 Plunger Ignition 11 Series coil 12 Torsion 13 Shift lever 14 Pinion gear switch spring allows the solenoid swi tch contacts to open Consequently the starting Fig EE 7 Starting motor circuit mo tor stops More positive and meshing of the pinion and the ring gear teeth are secured by means of the demeshing overrunning clutch clutch The overruIUling employs a shift lever to slide along the armature shaft the pinion 6 EE into or out of mesh with the ring gear overrunning clutch is de transmit driving torque from teeth The signed to the motor armature to the ring gear but prevent the armature from over running after the engine has started Engine Electrical System CONSTRUCTION V S 4 O o 8 f w il I jj 1 Magnetic switch assembly 13 Brush 2 Dust t4 Brush 15 Yoke 3 Torsion t6 Field coil assembly 4 Shift lever 17 Armature assembly 5 Dust 18 6 Thrust washer 19 Center plate SI14 1808 only Pinion assembly 7 E 20 8 Rear 9 Through cover Adjusting washer pring cover ring metal cover bolt 10 Rear tl Brush holder 12 Brush cover assembly spring 21 Dust cover Pinion stopper 22 Stopper clip 23 Gear 24 Gear jl I JI P case case metal EE316 Fig EE B REMOVAL 4 transmission case motor to assembly forward and starter starting er @ @ draw cover 3 connecting plate from Remove brush holder two screws yoke assembly and with armature assembly and shift s 7 Remove pinion stopper located at the end of armature shaft To remove stopper pinion Disconnect away hook lever E ring and thrust washer M a Remov 6 O EE317 Fig EE 9 Remouing dUlt I bolts and Remove brush holder Pull DISASSEMBLY through by moving each brush spring from brush with remove motor two Remove b rushes from their hold 5 yellow stripe from magnetic switch terminal and black battery cable from battery terminal of magnetic switch 2 Remove two bolts securing start ing Remove rear cover Disconnect battery ground cable Disconnect black wire with Exploded view ofstarting motor securing assembly first move and after stopper toward removing stopper clip with remove overrunning stopper clutch assembly from armature shaft terminal of magnetic switch Re move switch two screws and securing magnetic magnetic switch remove assembly 2 Remove thrust washer dust cover E ring and s Pinion stopper Pinion stopper clip EE318 EE277 Fig EE IO Removing brush holder d crt w EE 7 Fig EE l1 Removing pinion stopper Engine Electrical System CLEANING AND Check brush holders and spring cUp to INSPECTION Clean all disassembled parts but do not use grease since such deformed not are properly or hold brushes commutator If brushes or brush holders are dirty they should be cleaned solvent a would dissolve grease packed in c1u tch mechanism and would damage coils or EE017 other insulators or they and will against the dissolving solvents for cleaning overrunning clutch annature assembly magnetic switch assembly and field coils if see bent Check them for excessive damage wear and replace if necessary Fig EE I3 Testing rU ld coil for ground BRUSH SPRING TENSION Check brush spring tension by a as shown in Figure EE 13 spring scale The reading should be 1 6 kg 3 5 Ib Replace spring if tension is lower than I 4 kg 3 1 Ib TERMINAL terminal Check and wear for damage and replace magnetic switch assembly if necessary ARMATURE ASSEMBLY Check FIELD COIL Check field coil for insulation the insulation of coil is damaged worn it should be replaced If 1 or for continuity tester or an the probe of a circuit ohmmeter to field coil be No a mica is less than 0 2 mm from commutator surface Check the surface condition brush contact and replaced or with sanded lightly LEAD WIRE holder circuit If the commutator BRUSHES AND BRUSH positive terminal and positive brush no Inspect sur face of commutator is rough it must loose contact is If tester shows of appearance 500 emery cloth If the depth of insulating Testing field coil Connect external armature and commutator continuity field Check found it brush If a should be mica should also be its depth worn so mm that its 0 472 in length is wear meter is 2 diameter of replace the connection of lead is clip insulating undercut 5 to 0 8 mm 0 so that 0 01 97 to 0 0315 in The Ifbrush is less than 12 coil is open wear of of 0 0079 in 31 mm limit of commutator dia mm 0 0787 cammu 1 220 in in If the tator is less than replace annature assembly and lead wire o EE016 Fig EE I2 Testing field coil for continuity @ TestIng field coD for ground Place onto one probe of circuit tester yoke and the other coil lead positive EE018 onto field tenninal If very little resistance is read Fig EE 14 Inspecting brush spring tension field coil is grounded 8 EE Engine Electrical System L l File 0 L0 5 to 0 8 Commutator mm Segmen t 71j IWMica Ee026 Fig EE 19 Testing brush for round Incorrect Correct EE021 Fig EE 15 BEARING METAL Undercutting i118ulating mica Inspect bearing metal for side 2 armature loose using 3 connection soldered Inspect lead commutator and connection is found of If solder it resin flux Check armature for continuity by placing probes of tester on two seg ments side by side If tester shows no continuity the circuit is open Armature test for ground tester place one test Using a circuit probe onto armature shaft and other onto each commutator bar If tester shows continuity is 5 grounded and must be armature replaced play bearing metal and more sleeve Screw sleeve must along armature damage shaft is found or armature shaft is 0 0079 in replace MAGNETIC SWITCH ASSEMBLY Using a circuit tester check con l tinuity between S terminal of mag netic switch and switch body metal If ASSEMBLY Inspect pinion assembly and than 0 2 mm metal 1 OVERRUNNING CLUTCH wear or If the clearance between screw slide freely If splines resistance is felt sliding it must be repaired Inspect pinion teeth If excessive rub bing is found on teeth replace Flywheel ring gear also must be in spected when continuity does not exist shunt coit is opened Replace switch assembly 2 In the same check continuity S and manner as between above terminals If continuity does not M exist series coil is opened Replace switch assembly ASSEMBLY EE022 Fig EE 16 starting motor in re verse sequence of disassembly When assembling be sure to apply Reassemble Testing annature for ground to grease 4 Check placing with core it on for armature armature tester short by growler l piece of iron over armature rotating armature If the plate a bearing pinion gear and case metal and apply rear cover oil lightly to EE278 vibrates armature is shorted Fig EE 18 Overrunning clutch auem bly to FOR GROUND l EE023 Fig EE 17 Testing annature for ahort PERFORMANCE TEST Starter motor should be BRUSH HOLDER TEST j TEST a been no load overhauled Using a circuit tester place one test probe onto negative side of brush performance holder and another onto positive side If tester shows continuity brush should also be holder is shorted to ground brush holder EE 9 Replace installed when the on subjected test whenever it to will be ensure that satisfactory engine Starter subjected to has its when motor the test ofabnormal operation is to be determined A brief outline of cause the test is given below Engine load No MAGNETIC SWITCH starting battery and of indicating capable Specified in series motor 12 volts specified ammeter an System test Connect with Electrical tion in draw and revolu current these test shown are ASSEMBLY TEST in Switch Specifications o 1 000 amperes Switch Battery 6 Starter motor I IB Et Fv I D Starter motor Battery EE351 FiN EE 21 Circuit ofmagndic awitch assembly If Ammeter Voltmeter the OK Ee026 Fig EE 20 No load l ting starting motor check magnetic switch check sembly ted Connect cables is as between negative battery tenninal and start ing motor M terminal positive battery terminal and starting motor S terminal connecting a switch in as shown in Figure EE 21 series Diagnoses of test Low 1 speed with draw current may following 1 Tight dirty 2 no load result and high from the or worn bearings or loosened two 3 negative side brushes from commutator c Using probe place one input tenninal and the onto other onto yoke d If Weak brush of mica contact continuity 3 field noload separately armature determine whether field or to armature is grounded 2 Fallure current draw Low arc may occur on motor is push pinion l measure between pinion front edge and pinion stopper The clearance should be held within 3 0 to 15 mm 0 012 to 0 059 in If neces adjust it by changing or adding adjusting washer s Adjusting washers commu tator thrust out biush or a and available in to two different sizes mm 0 020 in and O S mm 0 031 in spring tension broken rubber bush are 5 0 commutator bar between clearance on all slack and sary operate may be with high caused by the speed and draw current would cause internal resistance due to loose nections to in the the switch to remove loose 0 3 to IS rom 0 012 to 0 059 in l com to burn raise the other two brushes and check and out back mutator would cause commutator bar indicates tester Burned brush spring circuit tester a for excessive damaged commutator when operated with no load A grounded armature or field Remove input tenninal Raise commutator burning In this case Check armature further b Armature coil does not operate 2 Inspect Shorted armature a trace circuit with a circuit tester field probe 4 open field coil or Inspect the connection and Bent armature shaft 3 With following A grounded I mutator damaged and leads causes dirty listed on low high con corn EE029 item Fig EE 22 MeO uring clearance 23 EE10 t Engine Electrical System SERVICE DATA AND SPECIFICATIONS Automatic transmission Optional Type Manual for manual transmission transmission S114 170B SII4 ISOB v 12 Terminal voltage V 12 Current A Revolution rpm System voltage No load Less than 60 More than 7 000 More than 6 000 Outer diameter of commutator mm in More than 39 1 54 Brush length mm in More than 12 Brush spring tension kg 3 1 to 4 0 4 to IS 1 Ib 47 0 Clearance between bearing metal and armature shaft L Clearance edge and mm Less than 0 2 in O OOS between pinion front pinion stopper mm 0 012 to 0 059 3 to 1 5 0 in TROUBLE DIAGNOSES AND CORRECTIONS Probable Condition Starting motor will not operate Noisy starting motor Discharged battery Charge or replace battery Damaged solenoid switch Repair or replace Loose connections of terminal Clean and tighten terminal Damaged brushes Replace brushes Starti Remove starting Loose Worn Starting cranks motor slowly Corrective action cause g motor inoperative solenoid switch motor and make test Tighten securing bolt Replace pinion gear Poor lubrication Add oil Worn commutator Replace Worn brushes Replace Discharged battery Charge Loose connection of terminal Clean and tighten Worn brushes Replace Locked brushes Inspect brush spring holder EE ll tension or repair brush Engine Electrical System Condition Starting cranks Probable Dirty motor slowly Starting motor operates but does not crank engine Starting motor will not disengage even if ignition switch is Corrective action cause Clean and repair or worn commutator Armature rubs field coil Replace assembly Damaged solenoid switch Repair Worn pinion Replace Locked pinion guide Repair Worn ring gear Replace Damaged Repair solenoid switch Damaged gear teeth or or replace replace Replace damaged gear turned off CHARGING CIRCUIT charging The circuit consists of the alternator battery wiring necessary and regulator to these connect parts The purpose of this system is to convert mechanical energy from the into electrical energy which is engine used to operate all electrically operat ed units and to keep the battery fully marks Then the warning lamp lights When the alternator begins to op current flows from the battery current is coil armature This alternating current is rectified by the and positive diodes The silicon negative rectified direct output reaches the alternator When the ignition switch is set to ON phase alternating induced in the stator E charged three erate the reaches the N neutral and E voltage regulator N terminal to E terminal or ground through the coil VCI as shown in Figure EE 24 by contact IF point PI P2 movable voltage regulator terminal alternator IF rotor field terminal the dotted line arrow shown in Figure EE 23 by full line arrow marks Then the rotor coil is in the alternator into contact with terminal switch L tor P5 nal On the flows from the ground through the ignition warning lamp voltage regula terminal and as is excited current to P4 point E as other hand battery coil and alternator lamp movable side contact contact voltage regulator E shown by dotted line point termi arrow VCI movable contact to turn complete as marks Then the excited contact point P6 point and IPS comes This action causes off the warning lamp and the voltage winding circuit the full line arrow marks by When the alternator or excessively the Therefore is contact P2 point Pin contact and comes into again and the alternator Thus the rapid vibration of the movable contact point voltage speed is in starts to rise the movable contact point EE 12 increases voltage IPl maintains voltage alternator output an constant When the alternator increased or speed is further voltage starts to rise the excessively the movable P2 the voltage winding side shown creased VC2 applied into the rotor circuit and output voltage is decreased AJ the output voltage is decreased the primary side side point coil RI movable and terminals nearly a half of the output and current flows from voltage contact of registor contact once other hand point voltage force A ground through the ignition switch voltage regulator IG terminal primary to separated from the primary PI by the magnetic contact current terminals On is P2 side into comes side secondllJ contact contact contact point point with P3 Then the rotor current is shut off and alternator output immediately movable voltage This contact is decreased action n to causes separate from Thus secondary contact P3 rapid vibration of the movable contact point P2 or breaking and the completing an the rotor circuit alternator output voltage maintains constant Engine Electrical System l r I I i I Stator ma ture r coiJ Ff Ye p FF I I Rot L R Coil field r t 11 c I vw RI c 5 9 c c e 0 I I I J i J Battery u I t I J Fusible link 8 t J 1 Voltage regulator Alternator EE029 Fig EE 23 Charging circuit II ns 1 p Slator ar ature coil teJ I Roto field I A3 coil e t I Lh PS L A l a o l R r R2 I M H J i I U 2iI g I I j U V It g t Fusible link 0 t Battery f EE030 Fig EE 24 Charging circuit II EE 13 Engine Electrical System B v W WR WL L2 VOLTAGE REGULATOR co WLI I LW LW IB P cJ r m I B WR FUSIBLE LINK t EARTH POINT CHARGE WARNING lAMP 00 00000 g m I Equipped WR with cooler m I I I CLB TjT WB B YWR I I I W I I W W 1 B M COLOR CODE OW Black with white stripe W White WB WR White with black stripe White with red stripe WL White with blue stripe LO LW Blue with black stripe Blue with white stripe Y Yellow BW IG IGNITION SWITCH J lOA C Black LW j rn ALTERNATOR B BwtIl I l M 0 0 o 0 0 0 0 0 o 0 FUSE BLOCK lOA Ii California models E E492 Fig EE 14 EE 25 Circuit diagram of charging lfY t m Engine Electrical System ALTERNATOR CONTENTS DESCRIPTION EE 15 INSPECTION OF DIODE EE 17 EE 16 INSPECTION OF BRUSH EE 1B EE 16 SPRING PRESSURE TEST REMOVAL DISASSEMBLY EE1B EE 16 ASSEMBL Y EE 1B ROTOR INSPECTION EE 17 ALTERNATOR TEST EE19 INSPECTION OF STATOR EE 17 SERVICE DATA AND SPECIFICATIONS EE 19 INSPECTION AND REPAIR DESCRIPTION field is like the rotor which consists that In the alternator produced by of alternator pieces magnetic a field coil shaft and slip rings pressed pole a small field current Output current is in the armature coils located generated in the stator and windings alternating The stator generates has three three electricity current passes easily so but current is shut out In this alternator pack type silicon Six diodes three negative and three installed in positive and positive are negative plates tive and They negative conjunction mounted are plates which combine heat dissipating plate negative terminals di odes are used phase current Silicon diodes act way valve for charging reverse The slip rings in the shaft conduct only a one as an These diodes are assembly direct soldered at their tips and constructed with posi weight on the two the function of and and are positive light in and easy to service The pulley mounted on the air conditioner models is different from that on the standard models without air conditioner @God A tfff 3 2 4 I e o e 9 1 Pulley usem 2 3 Front cover bly 4 Front bearing Rotor 5 Rear bearing 6 Stator 7 Brush assembly 8 9 Rear cover Diode set plate assembly 10 Diode 11 Through botrs cover EE345 Fig EE 26 Exploded view EE 15 Engine Electrical System REMOVAL 3 Remove front Disconnect 1 negative battery ter Separate rear cover adjusting bolt loosen 4 Remove alternator drive belt 5 Remove 6 Remove alternator from vehicle associated pulley cover screw Disconnect Remove A tenninaJ nut and diode and nut diode remove J CD 4 C EE035 O assembly Fig EE 29 Separating front with rotor from cover rear cover 11 4 Remove bearing three set retainer from front screws 1 Diode assembly 2 Diode cover Fig EE 32 Note Use AJ e f ecA oo EE039 Removing diode 088embly from and separate rotor cover care assembly C on @@@ fIXing assembly J and pulley nut diode with DISASSEMBLY Remove cover remove installation 3 1 Remove diode 7 connector from alternator parts alternator from engine 6 and three stator coil lead wires from diode terminal with a soldering iron wires and lead two Disconnect bolts through with rotor from with stator by lightly tapping front bracket with a wooden mallet minaL 2 cover in handling to an diode undue st it EE033 INSPECTION AND Fig EE 27 Removing pulley ond fan REPAIR Remove 2 Remove and screws cover brush holder remove fIxing brush remove brushes Q DO holder Pull brush holder fOIWard holder EE036 Fig EE 3D Removing rotor and together with brush connect 5 Pull rear assembly bearing with a out from rotor press or bearing puller Note When and F resistance the is approxi mately 5il the condition of brush and fIeld coil is satisfactory When no exists in brush continuity or when significantly from stator coil lead wire car tester between tenninal and E terminal coil Do not disconnect N tenninaJ from alternator circuit a resistance or fIeld differs between those parts dis assemble and inspect L I EE037 E A O o 1 EE346 1 N terminal 2 Brush 3 Brush holder Fig EE 28 ld holder co Q r Remouing brush Fig EE 3I Pulling out of roar EE 16 bearing EE040 Fig EE 33 Inspecting alternator Electrical Engine 1 rotor as there is slip rings of Figure EE 34 If between shown in no If each test of rotor coil Continuity Apply tester continuity field coil is INSPECTION OF DIODE Ground test 2 ROTOR INSPECTION System lead tive with of stator coil wire including neutral wire stator stator coil is condition core If there satisfactory is not conduc is is continuity grounded rotor assembly A total are of six diodes mounted plate The performed on Stator core used three are positive EEl plate are on the negative e on the continuity terminal and EE041 continuity test on diodes using an ohmmeter a and other three open Replace Perform in both directions test should be each diode between the plate Ee044 Fig EE 37 Teding stator for Fig EE 34 Continuity test of rotor Ound P coil Ground test of rotor coil 2 Check continuity between slip ring and rotor core If continuity exists replace coil or rotor assembly may be slip ring Conductive direction because rotor grounded I I plate ptate 2 Diode 3 EE045 Fig EE 35 Testing rotor coil for diode Fig EE 38 Conductive direction of round INSPECTION OF STATOR 1 Continuity Stator is continuity test normal when there is between individual coil tenninals stator When there is no conti nuity between individual terminals cable is broken Replace with stator assembly Diode positive flowing installed on EEl plate is a diode which allows current from terminal to EEl plate only In other words current does not flow from EEl plate to terminal Diode installed on e plate is a negative diode which allows current from e plate to terminal flowing only In other words flow from terminal to current does not e plate v 1 2 EE043 Fig EE 36 Testing stator for continuity Fig ptate Terminal EE046 EE 39 Inspecting positive diode EE 17 I plate 2 Terminal EE047 diode Fig EE 40 Insp cting negative Engine Electrical System flows in both positive If current If there is and negative directions diode is short If current flows in one direc circuited tion diodes only diode is in Test See good condition probe a ix faulty diode diode as table below an replace all assembly These diodes are unserviceable Reassemble alternator in the sequence of carry out the 2 terminal EEl plate EJ plate terminal terminal e plate e plate terminal o e plate @ plate o Xl plate e plate o movement is not smooth check brush holder and clean if necessary measure If it is worn Check brush pig tail and if dam aged replace Brush wear use of a 255 to 345 gr 0 7 line 02 per 1 A terminal bolt 3 Diode 4 Rear 5 Diode cover cover a sembly Fig EE 43 Sectional view of diode and A term inal brush spring is 9 0 to 12 202 Morevover when pressure decrease limiting new pas EE347 brush spring pressure by the pring balance Normally the rated pressure of a as Imulating bush 2 With brush projected approximate ly 2 mm 0 079 in from brush holder wear fast When installing diode A terminal 1 Check brush for as install insulating bush correctly SPRING PRESSURE TEST down to less than the specified limit replace brush assembly operation sible Gl Check movement of brush and if the I When soldering each stator coil lead wire to diode assembly terminal Conduction INSPECTION OF BRUSH reverse disassembly noting following of a circuit t ter e ASSEMBLY brush is worn approximately mm 0 0039 in 20 g 3 Tighten pulley 29 0 ft Ib wear make sure is less than t m nut with tighten 3 to 25 kg m When pulley is tightened ing torque of 3 5 to 4 0 that deflection of V groove 3 mm 0 01 IS in 0 0 079 in q or f Fig EE 41 Bnlsh wear limil t ffl EEO 9 EE127 Fig EE 42 M uring pring preaure CJ EE lB Fig EE 44 EE051 Tightening pulley nut Engine Electrical System ALTERNATOR TEST Before test conducting make an th tthe sure A alternator battery is fully test charged 30 V olt voltmeter and suitable probes Set up 3re a Figure EE45 and necessary for the test test circuit as shown in manner indica ted test auernator in the in the flow chart below Disconnect connectors at alternator 1 2 Connect 3 Connect one test Make sure A terminal to F terminal probe from voltmeter positive terminal to that voltmeter registers battery voltage terminal Connect the other test probe 4 Turn 5 Start engine Increase engine speed gradually until it is approximately 1 100 rpm and take the voltmeter reading 6 on headlights Measured value and switch to A ground High Beam Below 12 5 Volts Alternator is in trouble to remove Measured value and check it Over 5 Volts 12 Alternator is in good condition for condition Notes a Do Dot run engine at the speed of more than 1 100 rpm while test is being conducted on alternator b Do not Battery i 9 race engine l IV I Voltmeter EE052 Fig EE 45 Testing alternator SERVICE DATA AND SPECIFICATIONS IB LT138 Type For air conditioner LTl35 36B Nominal rating V A 1235 12 38 Negative Negative Minimum revolution when generating 14V with no load rpm 1 000 1 000 Hot output current 28 2 500 30 2 500 35 5 000 38 5 000 2 25 2 25 Ground Pulley polarity Nrpm ratio Brush Length Spring pressure mm in gr oz More than 5 0 295 7 255 to 345 diameter mm in More than 30 EE 19 5 0 295 7 255 to 345 9 0 to 12 2 Slip ring outer More than 9 0 to 12 2 181 1 More than 30 181 1 Engine Electrical System REGULATOR CONTENTS EE 23 SERVICE DATA AND SPECIFICATIONS REGULATOR VOLTAGE ADJUSTMENT REGULATOR VOLTAGE RELAY CHARGING EE 20 DESCRIPTION MEASUREMENT OF EE 24 DIAGNOSES AND EE 20 TROUBLE EE 23 CORRECTIONS Including alternatorl EE 25 EE 23 DESCRIPTION The regulator consists basically of a field circuit direct to ground and the upper contacts when closed the field circuit to ground voltage regulator and a charge relay The voltage regulator has two sets of points contact a lower set and resistance an field coil upper set to control alternator volt age An armature plate placed between alternator output The charge relay the two sets of contacts construction to the downward or or vibrates when closed contacts moves upward The and similar i charge warning lamp goes the v produce in voltage regulator When the upper contacts lower complete complete through a are closed 1 Charge relay Voltage regulator 2 on 46 EE Fig As EE285 View of removing cover regards the construction voltage regulator is very similar charge relay as shown in Figure @ IjDC@V @ I GJ J CD @ @ j @ @ @ @ 10 3111111 0 118 ill 41l1I11W 157in Armaturc II Cuil Core go 12 lock J3 Y kt 9 3 4 5 Low h Point 7 High speed 8 Contact gp Sllccd lnlacl ap conlat t Tlll tion Cnl1 t T di c1ia few CD r L @ 1 gf @ @ I Point gilp 2 Charge relay EEJ97 9 contllct Adjusting 10 Lock screw nut 3 Core gap 11 Coil 4 ArlllatlJre 12 4mm 5 Connecting 13 3mm 14 Adjllslin screw Adjll sting sprin 6 14 Contact iet 15 Yoke 7 Yoke gap Yoh 15 Voltage cgulatm contact B Adjusting pring nut c a Jb EE47 ID@ r @ 2 ID@ @ L r I1Jlccting spring J Q f lltagl l jllIOltllT b sprin 0 157 in dia 0 118 in dla screw crew Construction of charge relay Fig EE 20 the to the EE 47 Structural vi w Engine Electrical System MEASUREMENT OF REGULATOR Rqulator VOLTAGE Genera tor Regulator voltage is measured with regulator assembled with alternator When measuring voltage with regulator mounted rotate on engine Connect at cables I is necessary A to rated at 25W radio etc are circuit Short a with here starting the operation IG lamps B i air conditioner turned off V 2 Before starting engine be sure to make short circuit with a cable be tween between Fuse box Check to be sure that all electrical as Wire harness fuse side tenninal and terminal of ammeter before shown loads such Connector iJ r high speed l5 30A battery and resistor as it DC voltmeter l5 30Y DC ammeter O 25fl car Voltmeter Ammeter lOA 30V fuse side terminal of resistor EE055 O 25fl and negative side terminal of ammeter Failure to follow this pre Fig EE 48 Measuring regulator voltage with regulator caution will cause needle of ammeter swing violently resulting aged ammeter to in a dam 3 Refer to the determine following if regulator EE 21 and chart to relative parts are in good condition on vehicle Engine Electrical System I Start engine 2 Rotate engine at 2 500 rpm for several minutes Mter racing for several minutes ammeter reading After racing for several minutes below SA Fully charged battery available I Replace with fully charged battery 2 Check to see ammeter 5A reading over Fully charged battery not available I Connect 0 25 ohm resistor in series a if current falls below SA Current falls below SA Current does not fall below SA Recharge battery and see if current falls below SA Reduce engine speed to idling and then raise it to 2 500 rpm while observing needle of voltmeter Needle of voltmeter held within limits shown in the below table Needle of voltme ter Regulator functioning properly Adjust Regulator type ou t of limits shown in the following chart or replace regulator TLI Z 85C speed c Temperature Oc OF Voltage V may be approximately higher than rated for two to Voltage 3V 0 three minutes after 10 14 14 75 to 15 75 0 32 14 60 to 15 60 10 50 45 14 to 1545 ed 14 30 to 30 86 14 15 to 15 15 40 104 14 00 to 15 00 30 15 lator becomes self heated Measure minute after 3 Do not measure ly after regulator voltage immediate driving Do this while b To is cold voltage raise engine speed gradually from idling to rated measure EE 22 starting engine or when regulator is cold regulator is of a temperature compensating type Before meas uring voltage be sure to measure surrounding temperature and cor rect measurements according to the d The table at left Notes engine is start specifically when regu ments should then be made within one 20 68 or more Engine Electrical System ADJUSTMENT 4 VOLTAGE REGULATOR regulating voltage When as meas adjust regulator tact Adjust necessary gap core in that order required 3 and upper con as necessary upward See Figure EE400 035 to 45 0 mm D1S O 0 014 to in if adjust gap and point Fig EE 51 is adjustment No secure upper contact move in Point gap Inspect contact surface and if rough lightly polish with fine emery paper 1 500 or 600 I Measure each gap lIS O mm EE 50 in accordance with the following instructions 2 used to and downward or 3 screw diameter deviates from rated value ured above CD Adjusting point gap Loosen I Wrench 2 Crosshead screwdriver 3 Adjusting 4 l ock nut AdjUJJting screw Ulating rel voltage for yoke gap Adjusting core gap Loosen mm which is used contact set upward 4 screw diameter on Figure in to secure yoke and move contact downward or 0 157 CHARGE RELAY Nonna relay operating voltage is S See properly to IOV as measured at alternator EE399 49 EE Core gap I Thicknes 2 3 0 6 to 10 mm mm gauge 0 118 in dia screw 3 0 024 to 0 039 in 4 Use screwdriver Sshelld Cro Upper a DC voltmeter and set up Figure EE 52 contact Adjust Adjusting voltage Adjust regulating point voltage manner gap as charge relay in the same that for voltage regulator as follows Loosen lock nut securing EE398 I Contact set 2 ThicknesJ gauge 3 4 4 Crosshead Jcrewdriver mm 0 157 in dia Turn this increase core screw adjusting clockwise to counterclockwise or decrease screw Fig EE 49 AdjUJJting L screw regulating Figure EE 5 J to See voltage gap Connect positive tenninal of voltmeter to regulator lead connector N tenninal with negative terminal grounded 2 Start engine and keep it idle 3 Take voltmeter reading I Check tween for continuity be terminals of re gulator and alternator 2 Alternator circuit inopera tive if continuity Over 5 2 Volts Below 5 2 Volts o Volt Charge warning lamp I Check fan belt tension 2 If correct and adjust as Charge warning lamp on Charge relay coil or contact on remove necessary regulator points out oforder Replace regulator exists Over 5 2 Volts Charge warning lamp off Charge relay assembly is in good condition EE 23 a circuit as shown in Fig EE 50 Adjusting 5 A tenninal Relay itself however oper ates at 4 to 5V Engine Electrical System RegulatoI Yellow terminal r L WR A W IG WL Voltmeter N Y E B F WB EE348 Fig EE 52 Tuting charging Qy re SERVICE DATA AND SPECIFICATIONS Voltage legulator Type TLl Z S5C Regulating voltage Voltage fully charged battery inserting 5 at 200C 680F 10 resistance fl coil series resistance Smoothing 10 31 resistance 40 COle gap nun in Point gap nun in uge Ch 3 to 15 3 at 200C 14 v coil resistance RotOI coil Voltage with 0 6 to 1 0 0024 to 0 039 35 0 to 45 0 0 014 to O OIS lay Release voltage V 4 2 to 5 2 at Voltage coil resistance fl 37 S at N terminal 200C 680F Core gap nun in 0 8 to 10 0031 to 0039 Point gap mID in 4 to 0 6 0016 to 0 024 0 Standard tempelatUIe gIlIdient EE 24 O OISV oC 680F Engine Electrical System TROUBLE DIAGNOSES AND CORRECTIONS Including alternator Probable Condition No output Sticking brushes Correct Dirty brushes and slip rings Clean Loose connections or broken leads Retighten or soldef connections Replace leads if necessary Open sta tor winding Repair Open rotor winding Replace Open diodes Shorted stator Repair terminal or Broken neutral wire COIOf of wire is yellow Replace Voltage fegulator breakdown Check Poor grounding of alternator regulator En terminal output Loose or worn wire voltage and color of wire is black regulator operation required Sticking brushes and repair or as Retighten terminal connection Replace Retighten fan belt replace insulator Replace replace Low stator rotor Replace ground replace rotor Broken fan belt Broken replace brushes and brush springs Replace Replace A or Of Shorted rotor Grounded Excessive output Corrective action cause Correct or or replace replace brushes and springs if necessary Low brush Replace spring tension Voltage regulator breakdown short springs Check regulator OpefatiOn replace as required Clean Dirty slip rings Partial brush ground or open in stator Replace stator Replace rotor Replace diode winding Partially shorted Open Noisy alternator or or grounded rotor winding damaged diode Loose mounting Retighten bolts Loose drive Retighten pulley Replace Broken ball bearing Improperly Seat correctly seated brushes EE 25 and repair or Engine Electrical System IGNITION CIRCUIT CONTENTS NON CALIFORNIA MODELS EE 26 CALIFORNIA MODELS EE 2B NON CALIFORNIA MODELS The ignition circuit consists of the ignition switch wiring spark plugs The resistor coil and distributor battery circuit is equipped During cranking with secondary winding of the ignition coil high tension wiring distributor rotor cap and cap high voltage When a electrical on bypasses the resistor thereby connecting the ignition coil directly to battery This provides full battery voltage available at coil and keeps ignition voltage as high as possible are current The low voltage current is supplied battery or alternator and flows through the primary circuit It consists the of resistor ignition switch primary winding of the ignition coil distributor contact points condenser and all connecting low tension wiring The high voltage current is pro duced by the ignition coil and flows through the secondary circuit result ing in high voltage spark between the electrodes of the spark plugs in engine cylinders This circuit contains the by the the ignition switch is turned and the distributor contact points closed through the primary current flows the primary winding of the coil and through the contact points to ground When the contact points are opened by the revolving distributor earn the magnetic field built up in the primary winding of the coil moves through the secondary winding of the coil inducing high voltage The high voltage is produced every time the contact points open The high voltage current flows through the high tension wire Then the spark obtains while the current jumps the gap between the insulated electrode and the ground side electrode of the spark plug This process is repeated for each power stroke of the engine The distributor contact point and spark plugs should be inspected clean and regapped at tune up They should also be replaced periodically as ed ule current spark plug terminals to one of the in the distributor Maintenance Sched In addition consistency equivalent No MoS2 or I apply grease NLGl containing MoS2 or distributor to MIL grease shaft and G l0924B equivalent containing to cam as reo quired to the distributor cap Then the rotor distributes the in the specified The remainder of the ignition component parts should be inspected for only their operation tightness of electrical terminals and wiring con dition The ignition circuit is shown below 0 cl IR IB Battery is g J Re5istor I 21 To starter Ignition coil Secondary winding Cap Breaker point f Rotor head Distributor EE060 Fig EE 53 Ignition ydem circuit diagram EE 26 Engine E Electrical System CJI2t W R o Bf 00 00 fOl FUSIBLE LtNK m Wj BW BR I R BL IGNITION SWtTCH DISTRtBUTOR L oj RESISTOR ti J C L IGNITION COIL jjj COLOR CODE B Black OW Black with white stripe Black with red stripe DR aL Black with blue stripe W White SPARK PLUGS EE493 Fig EE 54 Circuit diagram ofignition ByJt EE 27 m Non California models Engine Electrical System CALIFORNIA MODELS The ignition circuit consists of igni switch transistor ignition unit tion distributor wiring spark plugs and battery The distributor is of the contactless type and is equipped with pick a up coil which electrically detects the igni tion timing signal circuit breaker in of the place of the conventional distributor The transistor ignition unit is a new addition which generates the signal required for the make and break of the primary electric ignition coil The circuit current for the primary winding of the igni transistor ignition unit and all connecting low tension wiring The high voltage current is pro duced by the ignition coil and flows through the secondary circuit result ing in high voltage spark between the electrodes of the spark plugs in engine cylinders voltage tion coil primary circuit opens The high voltage This circuit contains the secondary winding of the ignition coil distribu tor high tension wires to coil and high spark plugs distributor rotor and cap When the is equipped with a resistor During cranking electrical current bypasses the secondary resis tor thereby connecting the ignition coil through the primary resistor This makes battery voltage available at ef ficiently and keeps ignition voltage as high as possible The primary resistor selVeS to pro tect transistor ignition circuit The low voltage current is supplied by the battery or alternator and flows through the primary circuit It consists of the ignition switch on ignition switch is turned and the distributor reluctor rotates the primary current flows through the primary winding of the coil and through transistor ignition unit to ground When the prim ary circuit is opened by circuit of transistor ignition unit the magnetic field built up in the primary winding of the coil moves through the secondary winding of the coil inducing high voltage This high produced the high every Primary winding current terminals in the distributor cap Then the spark occurs while the voltage between the current jumps the gap insulated electrode and the ground side electrode of the spark plug This process is repeated for each power stroke of the engine plug should be inspected cleaned and regapped at tune up Spark plugs should also be replaced periodically as specified in the Main The spark tenance Schedule The remainder of the ignition butor tightness ofelectrical terminals and wiring condition Apply grease NLGI consistency I containing MoS or equivalent Secondary To starter I Secondary winding r ignition I unit I Pick up rcoil oi r Rotor head nl R5 1 U1f Retuctor r J l f S park plugs EE287 Fig EE 55 Ignition 8Y3tem circuit diagram EE 28 com ponent parts should be inspected for only their operation air gap of distri Resistor Transis tor flows distributor cap then the rotor distri butor cap then the rotor distributes the current to one of the spark plug I 1 time the tension wire to the to distributor rotor shaft as Primary Ignition through No Battery coo is resistor required Electrical Engine TRANSISTOR IGNITION System UNIT IHIIl II II BW BBV EARTH POINT RG I I r BW 111 a lof1 B @ 00 00 W SR 00 00 00 b Et liiI FUSIBLE LINK BATTERY TERMINAL BLOCK c r B BR ml lliJ LldJ0 IGNITION SWITCH d L j ilR @ BW c l i in 10 i9 RESISTOR D1STRliUTOR 0 IGNITION COIL COLOR CODE 8 DR Black Black with white stripe Black with red stripe W White L Blue R Red G Green OW J SPARK PLUGS EE494 Fig EE 56 Circuit diagram of ignition system EE 29 California models Engine Electrical System DISTRIBUTOR Non California models CONTENTS CONSTRUCTION EE 30 ADVANCE CHECKING AND ADJUSTMENT EE 31 DISASSEMBL Y EE 32 EE 31 ASSEMBLY EE 32 CONTACT POINT EE 31 SERVICE DATA AND SPECIFICATIONS EE 33 CONOENSER EE 31 CAP AND ROTOR HEAD MECHANISMS EE 31 CONSTRUCTION The distributor consists of breaker plate with contact points centrifugal advance mechanism vacuum control ler distributor shaft and rotor D @ v i @ t Cap assembly 2 Rotor head assembly Condenser assembly 3 4 5 Ground wire assembly Lead wire assembly 6 7 Contact set 8 Packing Breaker plate assembly 9 10 earn assembly Governor spring 11 12 GoVernor weight Shaft assembly 13 Vacuum controller 14 Terminal assembly IS 16 Housing Fixing plate 17 Oring IS Collar D @ EE32Q Fig EE 30 EE 57 Engine Electrical System CHECKING AND First turn wire connection Cap and rotor head should be in as spected periodically specified in the Remove cap Maintenance Schedule and clean all dust and carbon deposits from cap and rotor or If cap is cracked leaking replace with is a Deone with accordance the in Maintenance Standard point gap is O OIS to 0 022 in mm fingers holding pull contact out by arm toward set contact by of insulation sure it on capacity con degree attention to be requiring that terminals of and clean and are set tight screws are Checking of condenser is made by a condenser tester Contact raising slightly point and afm can then be removed together you new contact point and arm in reverse sequence of assembly removal Coat cam with a light coating 45 0 to 0 55 In case size ADVANCE MECHANISMS Specifications adjustment is made by loosening point screws Gap gauge is required for adjustment When point surface is rough take off any irregularities with fine sand is off the standard paper of No wear Application points is points together To replace proceed on with contact arm D4A4 07 D4A6 07 D4A6 0S Manual transmission transmission contact Vacuum advance replace noticeable D4A4 06 Automatic 500 or 600 or with oil stone as denser depends of grease Schedule When Satisfactory performance to lead wire While Install replaced just for enough out remove CONTACT POINT Contact point should be CONDENSER primary lead primary lead terminal Referring to Figure EE 59 unSCrew two contact set fixing screws and pull CAP AND ROTOR HEAD 1 5 set screws 1 to contact arm and turns at ADJUSTMENT out 00 30 Distributor degrees distributor 91 150 5 250 9 S4 6 00 170 6 69 50 300 1I S1 mmHg inHg follows Centrifugal advance Distributor degrees 00 600 110 1 950 00 550 11 0 distribu tor rpm 2 300 For Canada EE322 Fig EE 58 Adju ting point gap Vacuum advance mechanism Centrifugal mechanical parts mechanical parts If vacuum advance mechanism fails operate properly following items and check for to function 1 as required Check vacuum leakage 2 correct the mal or Check inlet for signs of Ifnecessacy replace with a new one vacuum diaphragm for air replace vacuum Primary lead termina 2 Ground lead wire 3 Set 4 Adjuster 5 Screw Inspect breaker plate moving If pia te does steel Fig EE 59 Breaker for smooth smoothly this condition could be due to sticky steel balls screw chanical part use balls breaker or or advance me distributor tester to See the specifications above When nothing is wrong conceivable not move pivot Apply grease if necessary plate as an assembly EE 31 part or others disassemble it to replace case with its causes are break down abnormal In controller assembly I of engine malfunction centrifugal driving If leak is found EE321 cause traced to characteristic leak 3 When is check its characteristic at its connection retighten the advance wearing out So do of not of improper characteristic take off contact breaker assembly and check closely cam assembly governor weight shaft and governor spring In case centrifugal advance etc me chanical part is reassembled be sure to check advance characteristic by dis tributor tester Engine Electrical System DISASSEMBLY When breaker plate is removed to lose steel balls not 4 be disassemble To proccd follow the below ure head 2 breaker spring and breaker between plate Take off cap and disconnect rotor I careful 5 Remove vacuum controller roll pin Pul collar to out remove and siconnect the entire rotating parts EE075 Fig EE 65 Removing When governor weight and spring disconnected be careful not to 7 are EE291 Fig EE 60 Removing stretch Remove contact set Refer to Page EE 31 deform governor After disassembling EE325 3 or vacuum controller cam governor spring apply grease to weights Fig EE 63 Removing rollpin when contact set i removed ASSEMBLY To assemble reverse disassembly Carefully the order of observe the fol lowing instructions are Align match marls so assembled to their original posi that parts tions EE323 Apply grease to assembly as required 2 Fig EE 61 Removing contact tel EE326 Fig EE 64 Removil1l rotation paTta 3 EE324 Fig EE 62 Removing breaker plate from the top of Remove packing cam assembly and bly setscrew Put match mark earn and shaft so unscrew earn astern across that original combi nation can be restored at EE 32 assembly cam Check the operation of governor before installing distributor on engine afteT dis timing Adjust ignition tributor is installed on engine 4 6 the top of Engine Electrical System SERVICE DATA AND SPECIFICATIONS Type D4A4 06 D4A4 07 D4A6 07 D4A6 08 42 3 4 2 13 Firing order 1 Rotating direction Counterclockwise Counterclockwise 490 to 550 490 to 550 Owen degree angle Point gap mm 0 45 to 0 55 in 0018 45 0 0 40 to 0 55 0 88 to 121 0 88 to 121 Condenser capacity JlF 0 20 to 0 24 Condenser isolate resistance Mrl 5 Cap isolate resistance Rotor head isolate resistance mm Cap carbon point length 55 0 to 0 018 to 0 022 0 022 0 40 to 0 55 lb kg Point pressure to 0 20 to 0 24 5 Mrl 50 50 Mrl 50 50 in 10 10 39 0 0 39 For Canada California models DISTRIBUTOR CONTENTS EE 33 ADVANCE MECHANISMS CONSTRUCTION EE 33 CHECKING AND ADJUSTMENT EE 33 DISASSEMBLY EE 35 EE 33 ASSEMBLY EE 35 EE 33 SERVICE DATA AND SPECIFICATIONS EE 36 CAP AIR AND ROTOR HEAD GAP CONSTRUCTION In the conventional distributor the ignition liming and breaker is detected arm by the cam while in this transis by the reluctor on the shaft and the pick up coil provided in place of the breaker The pick up coil consists of a magnet coil etc The amount of magnetic flux passing through the pole piece in the coil is changed at the moment the pole tor ignition unit it is detected piece faces the protrusion of the re luctor and then the electrical signal is generated in the pick up coil This electric signal is conducted into the transistor unit which ignition in turn breaks tI e primary coil current running through the ignition coil and generates high voltage in the secondary winding Also this transistor EE 33 ignition unit utilizes this electric signal to restore the primary coil to the original state after cutting off the primary current The vance for a fIXed time centrifugal mechanisms and vacuum employ ventional mechanical type tactor is used to eliminate and centrifugal advance I ad the con The con vacuum hysteresis Engine Electrical System tl t3 l @ 1 2 9 3 4 J @ r 9 V @ fW Pick up coil 6 Contactoi 7 Breaker 8 Packing 9 Rotor shaft plate assembly 11 Governor spring Governor weigh t 12 13 Cap 14 Vacuum controller 15 17 Housing Fixing plate O ring 18 Collar 16 @ ReJuctor S 10 l Cap assembly Rotor head a55embly Roll pin Shaft Jscmbly a setter EE327 Fig EE 66 Exploded view of di3tributor CHECKING AND assembly and distributor harness their positions ADJUSTMENT to CAP AND ROTOR HEAD Cap and rotor head must be spected periodically as specified in Maintenance Schedule in the Remove cap and clean all dust and carbon deposits from cap and rotor from time to time If cap is cracked or is leaking replace with a new EE328 Fig EE 67 Checking oir gap one To remove pick distributor harness and remove screw up cail EE329 disconnect at terminal block Fig EE 68 Remouing pick up coil securing pick up coil AIR GAP Standard air gap is 0 2 0 008 to 0 016 in If the gap Gap ment off the mould adjustment ening pick is to ADVANCE MECHANISMS 4 mm 0 Specifications standard be made up coil screws gauge is D4F4 04 Q3 D4F4 Item Manual Automatic required for adjust Air gaps must be checked from Vacuum advance Distributor time to time Air gap Type by loos 0 2 to 0 008 4 0 to mm 0 016 in 00 150 5 91 degrees 30 250 9 84 Distributor mmHg inHg Centrifugal advance Distributor degrees Distributor cpm EE34 00 550 110 2 300 00 600 1 950 110 Electrical Engine System Vacuum advance mechanism mechanical parts If vacuum advance mechanism fails to items and correct the following lem prob required as 1 check for the properly operate Check inlet for signs of vacuum leakage at its connection If necessary retighten or replace with a new one 2 Check vacuum diaphragm for air EE075 EE291 leak Fig EE 69 Removing If leak is found replace Fig vacuum EE 72 Removing rotor shaft controller vacuum controller assembly Inspect breaker plate for smooth moving If plate does not move smoothly this condition could be due to sticky steel balls or pivot Apply grease to steel balls or if necessary replace distributor assembly 3 Remove pick up coil assembly Using two pry bars pry reluctor 3 4 from shaft Be careful damage to distort or and Mark of the governor springs one of the one and its bracket Also mark pivot pins Carefully unhook and remove 10 pin Remove breaker remove 9 governor weights and its the teeth of reluctor Remove roll S not plate setscrews breaker plate assembly governor 11 springs Remove governor Apply grease to weights weights governor after disassembling Centrifugal advance mechanical parts engine malfunction centrifugal advance mecha When cause of is traced to nical parts check its use teristics or See characteristics specifications If nothing To to the to above is wrong with its charac wear causes are E330 faulty of driving part assem ble Fig EE 70 Removing breaker plate or etscrews Align match marks so that parts assembled to their original posi 1 are tions 2 improper character closely rotor shaft assem bly governor weight and shaft removed In the event of If any of above parts tioning replace are distributor malfunc assembly 6 Pull roll pin out and 7 Remove rotor shaft cam and drive contactor is If for any reason from breaker remove collar fol instructions others So do not disassemble it istics check the order of reverse disassembly Carefully observe the lowing conceivable abnormal tester distributor ASSEMBLY plate adjust clearance to contactor to 0 012 in as 3 mm 0 shown in Figure EE 73 after installation shaft assembly T DISASSEMBLY To disassemble follow the pro EE298 cedure below 1 Take off cap and Fig EE 73 Cam remove rotor head 2 Fig EE 71 Remove two screws Figure EE 69 and detach troller contactor to EE331 shown in shaft and drive shaft assembly Removing clearance rotor vacuum con 3 Ensure that reluctor is orien ted when 8 Mark rotor shaft and drive shaft Remove rotor shaft packing from and unscrew setscrew EE 35 the top of rotor shaft installing Always drive toward in roll the outer end Figure EE 74 pin on properly shaft pin with its slit of shaft See Be sure to use a new roll Engine Electrical System 4 Apply grease to the top of rotor shaft as required 5 Check the operation of governor before installing distributor on engine 6 Adjust ignition timing after distri butor is installed on engine EE299 Fig EE 74 Driving in rollpin SERVICE DATA AND SPECIFICATIONS Type Firing D4F4 03 order 1 04 D4F4 4 2 3 Rotating direction Counterclockwise Duty 70 20 to 40 at Air gap mm 0 2 to 0 4 O OOS to 0 016 MU More than 50 Rotor head insulation resistance MU More than 50 Cap insulation Cap resistance in carbon point length mm idling in 10 TRANSISTOR IGNITION UNIT 39 0 California models CONTENTS DESCRIPTION EE 36 TRANSISTOR REMOVAL AND IGNITION POWER CONTINUITY CHECK OF PRIMARY EE 37 3 PICK UP COIL CONTINUITY CHECK EE 37 4 PICK UP COIL POWER EE 36 INSTALLATION INSPECTION 1 2 UNIT CIRCUIT SUPPLY WI RING AND BATTERY PULSE CHECK EE 37 5 EE 36 EE 38 SIGNAL EE 38 CHECK TRANSISTOR IGNITION UNIT CHECK EE 39 DESCRIPTION TRANSISTOR IGNITION UNIT the L The transistor ignition unit provides following functions It makes and breaks current in the ignition coil primacy the electric circuit of the is provided This cuts off the The duty control circuit sets the rate of make and break within one ing cycle ie this maintains good ignition characteristics of engine from low coil when the ignition switch is turned high speed and is equal to dweU angle in the conventional Each component part of this unit is 2 speed the to breaker type distributor 3 A preventive circuit EE 36 against lock prilnaCY on electric current in the ignition with the engine not running highly reliable however should any part be found faulty the entire bly must be replaced assem Engine Electrical System The items are classified by numerals in Transistor ignition unit accordance with the objective of checks to diagrams 45 EE be performed Several wiring found on pages 41 to EE are The Power r1 Duty control circuit switching circuit 1 Spark timing Signal mom toring circuit Lock 1 circuit each When checking oscilloscope careful not or to To distributor Also circuit Distributor result Ignition coil EE437 do not attempt to Fig EE 75 Transistor ignition unit circuit diagram damage to oscilloscope INSPECTION ignition unit is located panel in 2 Disconnect wiring harness from Remove 3 move 4 two setscrews and te unit for To install reverse the order of to their Failure to do so wiring har proper positio will damage the unit Refer to Figure if and tension wires for make or a performance an circuit tester checks and adjust gaps spark plugs use necessary ignition oscilloscope Replace a tachometer with parallel or an circuit tester is al provided that such a connec wiring connections checks use as neces not If the above the problem ignition system with cannot correct check the entire oscilloscope or a POWER SUPPLY WIRING 1 AND BAnERY CHECK See wIrIng diagram In FIgure EE 88 Check spark plug which is suitable for further an EE 76 a a distributor sary Be sure to connect nesses cracked a cap and corroded tenninals or Visually inspect high to removal Note rotor condition unit or in tion system as follows Check Disconnect battery negative transistor tion is made with due consideration to If the engine does not run due to faulty ignition system check the igni passenger compartment cable the circuit tester or lowable designated unit as well as to the oscillo timing light a con in the points those The connection of the right hand dash side be of the lead wires will handling in ignition scope Transistor an potential difference other than Careless on tester confuse the polarity of nect the lead wires to any nm REMOVAL AND INSTALLATION circuit with circuit between tacted ttery the item the check points at which the lead wires are to be con exists Ba a a the lead wires if To starter individual check j preven ling thick lines indicate of objective Procedure I Turn on 2 Connect oscilloscope ignition switch a as circuit tester or an shown in the figure DC range below circuit tester CHECKING WITH AN OSCILLOSCOPE L An oscilloscope can checking almost all transistor be used for the items in a ignition system CHECKING WITH A CIRCUIT EE302 TESTER A circuit tester the duty Fig EE 76 External view of ignition unit t18nsistor methods circuit 50 volt can not be used for Fig EE 77 Checking power supply wiring and batt ry control circuit and power performance use tester of an are tests oscilloscope Both and a described in this section Criterion When power source voltage is indicated battery Lower or no indication EE 37 OK N G Engine Electrical System If the result is following I N C Check BW Check and an B proper con 3 low for voltage Check resistor and ignition coil for Resistance 10 range discontinuity 4 Check WB color wire harness of ignition coil assembly for proper of bat condition Check resistor and ignition coil terminals for loose contact con terminals excessively 2 color wire for proper battery proper connection Check charge 3 tery if respectively for ductance harness respectively ductance 2 harness Take the measures fp continuity is EE305 indicated 2 2 Chacklng IgnitIon coil auembly See wiring Fig EE BO Checking pick up coil Criterion diagram In Fig EE 90 When approximately 720 ohm Procedure is indicated I Far less than Disconnect ignition coil and dis tributor 2 2 PRIMARY CIRCUIT Connect in the CheckIng circuit from a N C If the result is circuit tester as shown pick figure below up coil N C Replace assembly prImary 89 EE Resistance 1 range Disconnect PICK UP COIL POWER L Q color wire from Procedure fD o unit 2 Turn 3 C ooneet on oscilloscope 4 SIGNAL PULSE CHECK Proced ure ignition 720 ohm ignition coil See wiring diagram In Fig I than external resistor CONTINUITY CHECK OF 2 1 harness OK or more ignition switch as a cireui t tester or I Disconnect anti dieseling solenoid ro an shown in Figure EE 78 valve connector 2 EE336 Fig EE 79 Checking ignition coil Connect in the figure a circuit tester as shown below 3 Rotate starter motor 4 Read the tester indication assembly DC 50volt range Criterion S tf When approximately 1 6 to 2 0 ohm is indicated Fig ignition EE 78 Checking primary circuit 3 N C EE306 When Donnal power battery voltage or no Source is indicated indication Fig EE 81 Checking pick PICK UP COIL wirIng dIagram Figure EE up coil power aignal pulse See In Criterion 91 When pointer deflects OK N G range Replace assembly CONTINUITY CHECK Criterion Lower coil volt S N C EE303 If the result is AC 2 OK More than 2 0 ohm slightly Procedure OK When pointer does not deflect If the result is N C Disconnect Take the following measures wires from 2 1 Check BW and L color wire ignition Connect in the R figure a and G color at all N C unit circuit tester below EE 3B as shown If the result is pick up coil assembly N C Replace Electrical Engine Procedure with an oscilloscope valve connector 2 Connect positive lead of a oscilloscope negative lead oscilloscope an Set 3 o to to the oscilloscope an select switch of SLOPE a positive side Rotate starter motor 5 Check the wave form as 0 C EB 80 shown in figure below the 8 r 0 EB If equipped 4 8W a color wire G so of Oscilloscope an olor wire and R to terminal Ignition coil dieseling solenoid Disconnect anti 1 System To body metal EE307 Fig EE 83 Checking operation of transistor ignition unit EE268 Fig EE 82 Wave form ofpick up coil @ Criterion When the the wave shape of When the shape of there is a form takes full line wave dashed line a OK form takes the or when @ N G form no wave EE452 If the result is N G Replace Fig EE 84 W uve form ofpulse pick up coil 5 TRANSISTOR IGNITION assembly UNIT CHECK See wiring Check items 5 1 and Connect ignition with an oscilloscope Where an oscilloscope ble check to make ous tests satisfactory and that no issuing from the secondary the part wire Replace After replacement sparks from the secondary cord Checking operatIon coil and dis tributor harness to ignition coil exter nal resistor shown in rotate the starter motor wave form the on 1 Connect ignition tributor harness to coil and ignition coil dis exter nal resistor 2 oscilloscope Connect wiring harness to igni tion unit 3 Disconnect anti dieseling solenoid valve connector 4 Criterion away See Figure EE 84 When a a the Keep secondary high wire end 4 to 5 mm starter form similar wave to a wave or 0 16 engine block motor across and to tension 0 20 in rotate the check whether the clearance OK form similar to b when no wave is form is N G N G the fault lies either in the transistor unit or in the secondary high from sparks fly is observed If the result is ignition as observed Procedure Connect Procedure and observe the obseIVed of transIstor Ignition unit I EE 83 When 5 1 avail not solenoid satisfactory ignition unit is discontinuity in the faulty check the is transistor faulty or there is secondary high tension the previ are spark is high tension wire If everything else then is not availa that all sure dieseling Connect oscilloscope Figure oscilloscope is an able unit valve connector 4 If the to harness wiring Disconnect anti 3 diagram In Figure EE 92 5 2 2 tension wire Replace these parts EE 39 Criterion OK Where sparks issue Where no spark N G issues N G the fault If the result is lies either in the transistor unit or in secondary high tension Replace these paris the wire Engine Electrical System 5 2 Checking operation of duty DC Procedure Connect anti While the fJ O BW tor Transi L valve connector 2 B rC solenoid dieseling 50 volt range ignition o engine the wave ronn the same way as on is idling t 1 observe 8 the oscilloscope in V stated in item 5 the ratio Figure EE 83 Determine as shown in Figure EE 85 unit tiT I x T 100 20 to at 1 401 EE357 idling Fig EE 86 Checking lock p h 1 Lt T Criterion tion in the When power is indicated When EE257 source Figure voltage OK approximately zero is indicated Fig EE 85 Wove form ofduty pulse following Criterion When a measures Replace is obtaiiied less than 20 If OK When the ratio obtained is transistor form on an N G If the result is to whether the wave oscilloscope rises source voltage within up to about see after ignition switch is on ignition unit When I Criterion using ignition N G an oscilloscope in arrange the connec The use of same a as described before for tester Replace unit 5 3 Checking lock preventive circuit a Turn oscilloScope is uSetl stead of a tester If Figure shown in 86 EE the the power 10 seconds turned Procedure or than 40 transistor Take the way as standard ratio of about 20 to 40 more N G or ignition switch Check voltage N G If the result is on same EE 83 uentive circuit Power source voltage circuit tester is used Oy Procedure 1 Connect a t circuit tester as shown in 83 EE or EE Figure 86 positive terminal of tester is connected to L color Ignition switch ON EE430 wire and negative terminal of tester is grounded 2 Turn on ignition switch Check to see Fig EE 87 Wave form of lock preventive circuit whether the tester indicates the volage of as soon as power source ignition switch ba t1ery is turned on 40 EE l1 5 l1 rn 1 Al13 n c E438 E bat e c and r I y 1 control switching Duty circuit Power dtCuit er PO 19niton prev nti g o timing uPP unit lonltoriOi l 1 sign t sparlt circui oClt l item for cl cuit ram l8 di Wiring 88 P EE am c s Fill Harne L llW II R G oC r b Terminal auemblY coil BR tC l nitonS IgnitOn o It 11 Utstnot i rn llO 3D l WC 0c f 3 439 0 eE con o switcnlOS unit DUtY circuit powet cucuil lng o on nit 19 monitrng cltCuit Itev nti s circuit tiR K Loc w 1 Spade oIgn alnP c o Il IlW Harnes L R G r k OC b Terminal asemblY coil igniton IlR o Wb DistrbuO rn l0 r Wo l IlS3 O blY EeA40 ncoi1 0 1 ing tdl cont o Iln1 i unit putY ciIcuit sVI rowel citCuit nll R Igniton CMC 2 2 ptel nu t oth1 o t tunin tnoo for cirCuit K lflc a sign atK ite citcuit S1 dioS Wirinl clarnp @ 90 EE rnesS Fig a H L ll R G B OC r o ina let1 uW auefC coll P iUO 19t llR Dutot tri sWitch o O gn1t10 b I Iu 5 l l ll l 01Il f EE44 o o lTcofO l unl swilchln DUtY tCU o1 l C powet CltCU1l tn o preyen onitoifl t titrllt tl l St signacircuit f LOCK circuit cump @ e Ratt I BW B l G blocK r oa Ter n rntM I a CO Of l ll t f1 bUlot o Witch s on gni Wt OliU El19ine l svstel O ElectriCal it j g j 15 0 i l 0 5 l J i CI g C e 0 t 0 t l l 2 0 l a a e t ll I t l S 1 ll 1 u oJ ll foil i i 0 t a e 0 u 0 S r e CD a 0 0 4S EE Engine Electrical System IGNITION COIL The ignition coil is type with oil which has good heat radiating oil f1l1ed an The ignition coil case California models califomia Non filled is insulating models and characteristics The ignition coil has a greater ratio between the primary and secondary windings step up battery voltage t voltage This causes stronger sparks to jump the spark plug gap to The which cap is made of offers high alkyd resistance to ID f high @ resin J lectric C arc and increased insulation ID The ignition coil and resistor should as a matched set be handled When high ignition coil to there should be 1W I tension wire is installed no clearance between their caps EE314 1 2 3 4 5 6 7 R bber cap for ignition coil Secondary terminal 8 9 Cap Primary terminal Spring Secondary winding Primary winding Fig Side core Insulator coil 10 Center 11 Segment 12 Case 13 Rubber cap Cor terminal core EE 93 Sectional view of ignition coil Notes a Do disconnect high tension spark plugs during en California models gine mnning only RoD up high tension wire mbber cap and instaD high tension wire to ignition coil securely Refer to Figure EE9S not wires from I Fig EE354 1 High tension wire 2 Rubber cap b EE 94 Correcl installation of high t Mjon win Fig EE 95 Installing high tension wire SPECIFICATIONS Non California California models models Type 618 C6R Primary voltage V Spark mm gap Primary resistance Secondary at 200C 680F resistance at 200C 680 F External resistor at20 C 680F HS 15 18 12 in more CIT 16 STC 9 12 than 7 0 28 more than 7 0 28 n 108 to 1 32 45 0 KSl 8 24 to 5 to 12 7 8 n 5 1 46 EE 4 12 3 1 to 4 0 55 0 09 Electrical Engine System SPARK PLUG CONTENTS TROUBLE EE 47 INSPECTION CLEANING AND REGAP White Overheating light gray or in sulator with black gray brown bluish burnt electrodes spots and or The spark plugs tional type spark plug and 0 8 models 0 031 to 0 035 in indicate engine overheating More over the appearance results from 1 0 to are Cali on timing ignition incorrect 09 to on non conven 0 551 in gaps 0 039 to 0 043 in 1 mm fomia of the 14 mm having The threads are 4B EE CORRECTIONS 47 EE DESCRIPTION EE 4B SERVICE DATA AND SPECIFICATIONS DIAGNOSES AND 47 EE DESCRIPTION mm spark plugs low fuel pump pres of fuel a wrong selection sure hotter plug etc It is advisable to having replace with plugs colder heat range loose California The inspection and cleaning should be made every suitable mainte models If necessary period nance All spark Note installed plugs Ir replace on i an must be of the same brand engine and the number of heat range same Carbon fould Normal INSPECTION L Remove pulling on plug spark by wire not on wire itself boot 2 Remove 3 Check electrodes and inner and spark plugs porcelains of plugs noting the deposits and the degree of type electrode erosion Refer to Figure outer of Worn Overheating Fig EE 96 Spark plug EE079 EE96 Normal posits and indicate spark de tan electrode slight correct wear heat plug carbon Dry fluffy the insulator on and usually caused by slow speed driving in city weak electrode are ignition too rich fuel dirty air cleaner etc replace It is advisable to mixture excessive oil entrance into combustion chamber through worn rings and pistons ance between stems If the mains after plug a or excessive clear valve same repair guides and condition use a electrodes smaU fine file to flatten the of both center and side parallel Set spark plug to specification gap 5 InstaU spark plugs and torque each plug to L5 to 2 0 kg m 11 to 14 electwdes in ft Ib Connect spark plug discard plugs cleaning spark plugs After renew firing surface of electrodes with me mentioned aboVe Then gap spark plugs to specified wire feeler gauge values with All a round spark plugs new or used should have the gap checked and reset by bending ground electrode wires plugs having hotter heat range Oil fouled Wet black deposits indi cate with 6 with dress After cleaning 4 surfaces range Carbon fouled deposits grayish to Brown re hotter CLEANING AND REGAP Clean spark plugs in a sand blast type cleaner Avoid excessive blasting Clean and remove carbon or oxide deposits porcelain but do If deposits 47 EE not are wear away too stubborn EEOBO Fig EE 97 Setting park plug gap Engine Electrical System SERVICE DATA AND SPECIFICATIONS Non California models California models Standard Hot type Type Cold type BP6ES ll BP6ES L45PW ll L45PW BP4E ll BP5ES ll BP4E BP5ES BPR4ES L46PW ll L47PW ll L46PW L47PW BPR5ES BP7ES ll BP7ES LMPW ll LMPW 10 to l Plug gap mm Tightening torque kg in m ft Ib For Canada except for Canada BPR6ES BPR7ES 0 8 to 0 9 0 039 to 0 043 0 031 to I 5 to 2 1 11 0 0 8 to 0 9 0 031 to 0 035 D35 0 to 14 TROUBLE DIAGNOSES AND CORRECTIONS Note When engine does not start If there system is no ignition checked detaching This a can high problem should system be spark at all fuel be easily done by tension wire from Condition No in spark plug starting engine and ob serving condition of spark that occurs between high tension wire and spark plug terminal After checking this repair as necessary Location Distributor Probable On California models nect anti dieseling discon solenoid valve connector to cut off supply of fuel to and engine then condition of motor is in operation spaIks observe Corrective action cause Faulty insulation of condenser Non Cali Replace fomia models Breakage of lead wire on low tension side Repair Poor insulation of cap and rotor head Replace Seized points Non California models Repair Open pick Air gap up coil California models wider than specification Replace Cali Adjust fornia models Ignition coil Wire High Wire coming off tension wire breakage Faulty Transistor ignition unit California or short circuit of coil Repair insulation Faulty transistor ignition models 4B EE Replace Replace unit Replace the while starter with new one Engine Electrical System Probable Location Condition Point gap too wide Distributor Spark length Corrective action cause California Non mo Correct dels I to 2 rnm 0 039 models Clean to 0 079 in Of Oil irregular Burned points Non California models Replace Spark plug gap too wide Correct Too much carbon Clean Broken neck of insulator Replace Expiration of plug life Replace Spark plugs More than 6 rnm 0 236 in point on California Non California models Distributor Air gap too wide Transistor ignition unit California Faulty transistor ignition or or replace replace Correct Replace unit models 2 Engine smoothly rotates but does not This may be caused misses system or complete inspection of ignition system other engine condi Hons not Therefore first a should be carried out related to ignition by the ignition Probable Location Condition Engine run Distributor Corrective ac ion cause Clean Dirty point Non California models Foreign pick mattef on up coil California Clean models Non California Improper point gap mo Correct dels Impropef California models air gap Correct Leak of electricity at cap and rotor head Damaged insulation of condenser Non Repair or replace Replace California models Malfunctioning arm Non Cali Oil shaft spring Non Cali Replace contact fornia models Faulty contact arm fornia models Breakage of lead wire Non California Replace models Breakage of pick up coil lead wire Cali Replace fornia models Ignition coil Worn or shaky breaker plate Replace assembly Worn or shaky distributor driving shaft Replace assembly Layer short circuit or inferior quality Replace coil High tension wire Deterioration of insulation sequent leak of electricity 49 EE with con Replace with good one Engine Electrical System Condition Location Spark plugs Probable cause Corrective action Fouled Clean Leak of electricity at upper porcelain Repair or replace insulator Transistor ignition Faulty transistor ignition unit Replace unit California models Engine causes knocking very Distributor Improper ignition timing Coming often off or too advanced of governor breakage Correct Correct or replace spring Worn pin Engine does not or hole of governor Spark plugs Burnt too much Distributor Improper ignition timing deliver enough Replace Improper functioning power Point gap models too Replace too retarded Replace assembly governor narrow Foreign particles stuck Non California in air gap Correct Cali Correct Oean fornia models Spark plugs Fouled EE 50 Oean SECTION ER ENGINE DATSUN PICK UP MODEL 620 SERIES REMOVAL INSTALLATION ENGINE REMOVAL AND INSTALLATION I NISSANJ NISSAN MOTOR CO TOKYO LTD JAPAN ER 2 Removal Engine Installation ENGINE REMOVAL AND INSTAllATION CONTENTS REMOVAL ER 2 FRONT INSTALLATION ER 3 REAR INSULATOR INSULATORS ENGINE MOUNTING ER 3 REMOVAL INSULATOR TIGHTENING Disconnect air deaner to A 4 ER 4 ER TORQUE 4 ER B valve hose It is much easier to engine single unit than to remove them separately After re moval engine can be separated from transntission assembly and transmission remove air Disconnect a as cleaner ta vacuum hoses Note Protect and foreign over carburetor from dust matter by placing cover air inlet opening Notes a Be sure to hoist transmission in b engine and jack Fig ER up l a safe manner Use fender cove to Automatic transmission models protect vehicle I body Disconnect selector range lever from manual shaft 1 Remove 2 Scribe 9 battery hinge hood location for reinstallation proper hood and remove to prevent damage to help you so as 14 Disconnect carbon canister hose engine side Disconnect C1eaner 12 body to al air pump air Drain radiator coolant 4 Disconnect and upper radiator hoses from engine lower 5 Remove hoses from lower matic two oil cooler Disconnect following cables end of radiator transmission models only to ignition Remove radiator shroud 7 Remove four bolts securing radia body ter Wires to B C p D Non California Note Always tighten securing bolt at upper right hand side together with body harness terminal Remove carburetor air cleaner solenoid cut models autochoke heater and anti only dieseling solenoid as follows cover hose air at cleaner to rocker rocker Disconnect air cleaner to air control valve hose California models only securing and flexi 16 Disconnect transmission control from transmission Manual transmission models Detach rubber boot Remove E ring and control lever from transmission striking rod and remove control lever ER 2 Manual front exhaust tube from exhaust manifold 17 2 3 lamp switch Cable to speedometer pin guide bolts operating cylinder as an assembly transmission models only Remove propeller shaft propeller bearing bracket from Disconnect Disconnect carrier 2 cover two tube companion Remove of Then dis Vacuum hose of Master Vac at in I hoses vacuum Remove equipped linkage se com clutch operating cylinder crossmember 13 the move Remove F LC D actuator Wires to starter motor Wires for back up Disconnect 3 center Remove hot air duct hose ressor comi battery support Wires to alternator taJce manifold Loosen air cleaner band bolt and air Then Remove I Remove fresh air duct cleaner supporting bolts Disconnect air cleaner ta air pump hose curing bolts ble Heater inlet and outlet hoses if so 8 flexible connect Wire to oil pressure switch Wires to thermal transmitter tor and detach radiator removing four After 15 distributor at minal 6 1 F LC D solenoid valve coil and distributor Wire equipped following procedures 2 Accelerator wire at carburetor Auto conditioner models need pressor to tension cable between inhibitor at remove support Engine ground cable High Air p hose p wires and hoses 3 wires 10 II assistant an Disconnect switch and down shift solenoid on Have Note 2 Disconnect fuel pump to fuel fdter hose and return hose propeller flange of Remove propeller shaft third shaft from differential shaft from transmission and plug up rear end of extension housing of transmission to prevent oil leakage 18 Attach to lift engine 19 Remove a suitable wire or chain front engine mounting bolts at engine mounting front sup port Installation Engine Removal ER207 Fig ER 2 Removing front engine mounting bolts Place 20 a jack under transmission and jack it up Loosen two rear 21 engine mount E ing bolts CD Fig ER 5 Lifting engine Loosen two exhaust tube hanger bolts V California models only 23 Remove four bolts CID securing engine mounting rear support to side 22 member and detach rear INSTALLATION support Install engine with transmission in reverse order of removal observing the O jr R367 following When I installing first secure engine mounting support to body 2 Refer to applicable section when installing and adjusting any parts rear 2 1 ER271 Removing Fig ER 3 rear engine mounting support 24 Remove steering idler arm secur ing bolts and push down cross rod Front 1 Bracket RH 2 Insulator R H 3 Bracket LH 4 Heat shield plate Insulator L H 5 iC @ 6 7 Rear 8 Exhaust tube hanger California models only support Rear insulator E A279 Fig ER 6 Structual view of engine mounting EA278 Fig ER 4 Removing idler Pull engine towards front as far and carefully raise if and 25 as arm possible transmission with a hoist and cable ENGINE MOUNTING INSULATORS Three insulators Note In this an r always be taken unit parts to hit not against care should to allow the any adjacent the engine are used and transmission to Replace mount two are located at the left and right of the at the transmis cylinder block and one sion rear extension housing ER 3 any insulator that shows signs of separation Be oil or sure to grease or deterioration keep insulator free from Engine Removal FRONT INSULATOR 7 To install Installation reverse order of re moval Removal and installation and jack it up slightly 2 Loosen two rear engine mounting bolts 3 1 Disconnect battery ground cable 2 Remove hood 3 Suspend with engine wire REAR INSULATOR or Loosen front engine mounting insulator upper nuts both 5 Carefully engine a hoist and cable 6 Remove raise Loosen two exhaust tube hanger California models only 4 Remove at chain 4 bolts a mounting rear removing insulator securing bolts 1 moval little with Place a jack under transmission To install reverse front mounting insula supports after removing front mounting bolts tors at front TIGHTENING Fixing TORQUE bolts and nuts Front mounting bracket to cylinder block kg ft lb 2 6 to 3 6 19 to 26 Front mounting in kg m ft Ib 2 6 to 3 6 Front mounting insulator to front support kg m ft lb 14 to 18 10 to 13 Rear mounting kg m ft lb 3 2 to 3 7 23 to 27 Rear mounting insulator kg m ft Ib 16 to 2 2 Rear support to frame kg m ft lb 3 2 to Clutch operating cylinder to transmission kg m ft Io 2 5 to 3 5 Exhaust front tube to exhaust manifold kg m ft lb 19 to 2 5 14 to 18 Center bracket to crossrnember kg m ft lb 16 to 2 2 12 to 16 to kg m ft lb 2 4 to bearing Propeller shaft lator to brac t insulator to transmission to rear support companion flange insulator extension after Ramoval and Installation 5 sides rear transmission m 4 ER 19 12 to 76 to 16 3 23 to 31 4 18 to 25 3 17 to 24 order of Ie SECTION CL CLUTCH DATSUN PICK UP MODEL 620 SERIES LNISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN CLUTCH CL 2 CLUTCH CONTROL CL 5 SERVICE DATA AND SPECIFICATIONS CL 9 TROUBLE DIAGNOSES AND CORRECTIONS CLIO SPECIAL SERVICE TOOL CL12 CLUTCH CLUTCH CONTENTS CL 3 DISASSEMBLY AND ASSEMBLY DESCRIPTION CL 2 REMOVAL AND INSTAllATION Cl2 D isassemb I y Cl3 CL 2 Assembly CL 3 CL 3 INSPECTION CL 4 Removal Installation DESCRIPTION The clutch is using the single dry disc type a a diaphragm spring clutch disc It consists of dia plate pressure phragm spring cover I thrust clutch rings and clutch release bearing A u o e M 0 8 s 62 2 44 o 8 dia 6 l150 225 91 dia 8 86 dia I 5 260 10 2 o dia CL231 C Unit Fig CL portant REMOVAL AND disc NSTALLATIO CL 2 I 3 Removal Remove 1 from ve hicle For details oftransmission removal refer to 2 Construction of clutch disc and six Loosen screws assembly attaching time each flywheel one turn at a is re un til spring pressure leased sure cover Be COller in support weight of clutch further steps See Figure to during clutch transmission l mm to to turn them out in a crisscross fashion Transmission Section Insert KV30100200 until it will Clutch into no Aligning clutch longer go Bar Note special care to on getting on Exercise disc hub grease It is im linings or avoid clutch Fig CL2 CL 2 Supporting clutch assembly CLUTCH Installation diaphragm spring is securely reveted to clutch cover and clutch cover assembly is balanced If necessary replace clutch cover disassembled since Apply a light coat of lithium base containing molybdenum disul I grease phide transmission main drive gear on assembly splines wipe off excess lubricant pushed by disc hub Install 2 cover clutch assembly disc off flywheel Support on as two assemblies with Clutch Aligning Bar KV30100200 See Figure CL 3 follows See Figure CL4 Remove 1 houisng 2 clutch and Be to sure from clutch cover CLOSS withdrawal lever from CL 6 Removing pilot bu hing Fig clutch housing 3 Remove retainer from spring withdrawal lever Remove release bearing bearing Asse 1 housing on as an assembly 1 7 1 bly Release mechaniam sleeve and holder spring from clu tch 00 R dust Remove 4 keep disc facings and flywheel pressure plate clean and dry Note complete unit as a Remove clutch release mechanism 2 Slide clutch disc on main drive gear several times Remove clutch disc and When assembling release sleeve squarely use a on J I I Release bearing Release 1 bearing sleeve rr Fig CL 3 CL109 l talling clutch cover assem 3 Holder spring 4 Dust 5 Withdrawal 6 Retainer bly J cover lever spring assembly Each bolt turn at a should be cover Remove KV30100200 tightened one specified torque II to 16 ft Ib m Three dowels clutch 4 flywheel squarely time to the 15 to 2 2 kg Note to on are Fig CL 7 1 CL119 Fig CL4 Exploded view ofclutch Install six bolts to tighten clutch cover 2 Take out clutch release from bearing sleeve puller See using a Before bricate light 3 CL215 1 releaae mechaniam 3 bearing bearing sleeve See Figure CL 7 l lo 2 press and seat e bearing rele during assembling lu following points with a or the coat tailing of multi purpose grease bearing universal Figure CL 5 I Inner groove of release bearing 8 CL sleeve See Figure used to locate flywheel properly Aligning Bar tightening the Clutch after Lf bolts securely 5 Install transmission Note Make certain that withdrawal lever engages lever ball pin I 6 n Connect push rod of clutch op erating cylinder to withdrawal lever D embling e rele b DISASSEMBLY AND ASSEMBLY I Clutch cover assembly 4 Remove by ST16610001 can not be aring CL216 Fig CL B Lu bricating bearing shaft Disassembly JQt C L014 Fig CL 5 pilot bushing Pilot in crank Bushing if necessary See 6 CL Puller Figure 2 of Contact surfaces of withdrawal lever lever ball pin and bearing sleeve 3 Contact surfaces of transmission front CL3 ee slee cover See Figure CL 9 CLUTCH If facings I be lt oily the disc should cover rear oil I Lubricating poinu of trans pilot seal oil seals and other points for oil leakage 2 The disc should also be CUll CL 9 front bushing engine o Fig replaced mission tJ P are In this case inspect If excessive clutch Measure the 2 spring front Place a of Contact surfaces then on main drive gear splines lithium base including molybdenum disul grease phide clutch assembly plate by using Set Bolls tighten the base Very IIIIJllII amount should be points applied If too much friction plates in d ated it will gi to run 1 t vernier iubricant at several caliper depth f drawal lever is to with Fit holder f Fig CL I0 ever then 4 assemble withdrawal Iever and install dust the old plate for 7 disc or C L23 new one STl005Q051 CL 12 Fig runout when a 05001O uring the height of Me diaphragm pring is installed If runoutexceeds the Install this value at Then place or case lining JIuringclutch Me Check disc 3 spring to release bearing and sleeve assembly bearing sleeve as a unit assembly on transmission Tl CL089 resulting facings Install retainer spring I rJrf when hot dutch disc gauge STl0050100 the on spring toe points with a diaphragm A height of grease the above out and cover Above 0 3 rom 10 012 in Note 3 i h 1 j1 Figure Plate ST20050010 b Measure II gauge See ST20050051 I l DePth transmission height of diaphragm Distance Piece ST20050100 Base on See Figure CL IO cover assembly outlined below as replace replaced withdrawal lever and 4 is found CL 12 when facings are worn locally or worn 0 mm 0 0118 in at down less than 3 revels wear cover as an cover the outer circumference Ie repair disc See Figure CLII 5 0 Pilot bushing installing a new bushing thoroughly clean bushing hole Install bushing in crankshaft using a soft hammer Bushing need not be oiled mm reading ST20050240 See Figure If necessary replace clutch cover as assembly Also unevenness of dia phragm spring toe height should be an 4 23 in mm in adjust the spring Diaphragm Adjusting with CL 13 R from the hub center 5 107 123 to 1 38 Wrench 0020 in mm total indicator Before beyond the height Runou t of spring end is A value of 33 to 35 specified If the height specified less than 05 mm 0 020 in ST20050240 INSPECTION Wash all the disassembled parts except release bearing and disc assem bly in suitable cleaning solvent to remove dirt and grease before inspection and making adjustment CL112 Flywheel and pressure plate Check friction surface of and Fig flywheel plate for scoring Slight roughness may pressure roughness ed the deeply scored or part should be replaced MeOlUring disc runout Check the or transmission be smoothly sliding smoothed by using fme emery cloth If surface is 5 CL ll groov clutch disc be 04 replaced mm fit of disc hub drive main or If splines gear on are worn main drive gear should that is backlash exceeds 0 016 in at the outer edge of clutch disc Clutch disc loose torsional springs for worn or oily and broken or Clutch cover I Check Fig 3 CL 13 the end surface of dia phragm spring for wear 4 CL the spring height wear or invisible As these parts from outside shake cover assembly up are damage down noise assembly AdjlUting Inspect thrust rings for and llembly at Inspect clutch disc facings loose rivets CL152 for or slightly noises to lightly listen for chattering hammer on rivets for mean a Any of these requirement for replace cracked noise ment as a complete assembly CLUTCH Pilot Release bearing and sleeve Check for abnormal Check wear on con tact surface of withdrawal lever bushing ball for wear replace pin and bearing sleeve pilot bushing roughness or in crankshaft If necessary When bushing is faulty be sure to check transmission main drive gear at the same time it CLUTCH CONTROL CONTENTS CL B Inspection CL 5 DESCRIPTION PEDAL CL 6 OPERATING CYLINDER Removal and installation CL 6 Removal and installation CL B I nspection and CL 6 Disassembly and assembly CL B Inspection CL B CLUTCH adjustment CLUTCH MASTER CYLINDER CL 7 Removal and installation CL 7 Disassembly and assembly CL 7 forwards clutch fluid to the DESCRIPTION The hydraulic clutch control con sists of a pendent pedal a master cylinder an operating cylinder and a the piston of the via of the operating cylinder piston through the a to is the withdrawal lever push rod thus disengaging is The operating cylinder is a CL B type that uses no return unit the withdrawal to In this spring rod push play adjustment is not neces adjustable sary since the CL 15 serves sate the clutch depressed master cylinder pedal operating pipe line The movement cylinder transmitted withdrawal lever When the clutch BLEEDING CLUTCH SYSTEM CL B for wear as shown in Figure automatically compen 8 to on the clutch disc non 2 I l 1 Clu tch pedal 2 Return spring Clutch master cylinder 4 Clutch piping 3 5 Operating cylinder 6 Push rod 7 Withdrawal lever 8 Release 9 Clutch 10 5 bearing Cl305 cover Clutch disc Fig CL14 Clutch operating system CL 5 CLtJTCH Stroke 30 I i Jt Sj 1 J i Fig CL 15 Non adj mm in 18 1 o table operating cylinder 1 Lock nut A CLUTCH PEDAL 2 Lock nut Removal and installation Pedal beiBht a 53 mm 6 02 in 117 10 23 4 6 Pedal full stroke b Removal See 1 Pry off clevis pin @ CL 16 Figure pin and take cotter 8 104 84 in Multipurpose grease out disconnect push rod from CL102 pedal assembly Fig CL 17 Adju ting pedal height Unhook return spring Loosen off fulcrum pin and remove pedal as 2 Note sembly Refer to Figure Clot8 for the correct direction of return CfJ ch 1 2 3 Return spring Pedal boss S Pedal 6 Bush 7 8 Nut Push rod 9 Fulcrum W5 fD 2 Turn in until screw Then A i pin clutch removing or out play push lock pin nut 1 Pedal assembly 2 Push rod 3 Return spring Fig pedal pedal CL 1B Hooking return pring Note Exercise play Installation the order of multi purpose grease to the friction surfaces of the disas sembled parts as shown in 3 Apply Figure CL 17 Tightening torque Pedal installation bolt Fulcrum pin 19 to 14 Lock nuts 4 2 kg m to 17 ft Ib A and 0 8 to 12 B kg m 5 8 to 8 7 ft lb m 5 8 adjusting 0 039 mm is obtained B to the m 5 8 eL116 not care in adjusting port or A blocked port cylinder After adjusting play at Clean all the following parts in cleaning solvent and check for wear damage or any other abnormal condi tion Replace the parts which are faulty Return spring 1 2 Bush 3 Pedal boss etc CL 6 clevis check the pedal full stroke is in 117 to 123 Inspection and adjustment the block the to may result if too small pin exists reverse rod of I to 3 at clevis tighten master install kg specified torque 0 8 to 12 kg to 8 7ft Ib pad removal a to 0 118 in note toe board clearance at 12 to to 8 7 ft lb pedal To pedal height to 153 by adjusting pedal stop tighten lock nut A to the 6 02 in specified torque 0 8 ll assembly Before the Adjust per and Fig CL 16 Exploded view of clutch Note spring 3 ij aevis pin Cotter pin 4 6 1 mm mm 4 61 to 4 84 in Note Depress pedal over sure erates noise that and release clutch its entire stroke to the clutch en linkage op smoothly without squeak interference and binding CLUTCH cylinder to the vehicle and dismount master cylinder CLUTCH CYLINDER MASTER Note Removal and installation Remove dust cylinder body er s cover on 2 Bleed air out of hydraulic system Tightening torque from master Master cylinder to dash panel the side of driv 0 8 to 1 2 seat Clutch tube connector Flare nut Installation Removal I 2 To Remove clcvis pin at push rod clutch tube from removal Disconnect master 3 bolts Disassembly securing and 5 to 1 8 1 reverse Closely the order observe the of II following instructions 3 1 Adjust pedal height by changing GG94310000 pedal stopper length to cylinder and drain clutch fluid Remove install master kg m 5 8 to 8 7 ft lb Flare Nut Using kg m to 13 ft lb Torque tighten each the specified torque Wrench connector assembly 1 2 3 4 5 6 7 8 9 10 11 Reservoir cap Reservoir Reservoir band Cylinder body Supply valve stopper Return spring Spring seat Valve spring Supply valve rod Supply valve Primary cup 12 13 Piston 14 16 Secondary cup Stopper Stopper ring 17 DU5t 18 Lock nut 15 Push rod cover CL265 Fig CL 19 Exploded view of maater cylinder Disassembly Remove dust 1 Assembly cover and remove stopper ring from body 2 Remove push rod and piston as sembly 3 Take off piston cups 4 Remove spiing seat from piston and take off supply valve if necessary See Figure CL 19 Note Discard piston cup supply valve and spring seat after removal To assemble Note reverse disassembly Closely lowing instructions the order of observe the fol I Dip piston cup in brake fluid before installing Make sure that it is correctly faced in position 2 Apply a coating of brake fluid to cylinder and piston when assembling 3 Press piston into spring seat when assembling CL 7 The clutch master cylinder is available in both NABCO make and TOKICO make There is no com changeability ponent parts between NABCO and repair kits inter of or TOKlCO makes When replacing component the parts repair ascertain brand of the clutch IIIBSter body Be same make sure as kit to use or the cylinder parts of the the former ones CLUTCH Inspection or wash all parts of cylinder operating cylinder and piping clean brake fluid must To clean Note and Disassembly assembly badly too damaged beyond speci fications master be used Never minera10ils llUch ton cylinder and piston for wear or damage and if neces Check If the clearance between piston is Renew assembled when more than dust 3 Remove piston assembly and pis It must wear spring The hydraulic clutch system must be bled whenever clutch line has been Remove bleeder screw also be 1 replaced 1 Push rod n 6 Cl11B Dust 3 Piston spring Piston 4 from Bleeder inder so that outlet hole is free from Assemble in the 1 order of reverse Prior to assembly dip piston When installing cup pay particular attention to its direction Detach clutch hose from operat ing cylinder 2 Remove two Install in the reverse order of b The re moval Bleed air thoroughly from clutch hydraulic system clutch install return will not be spring or disengaged piston assembly piston spring place clutch operating cylinder changeability of When replacing component inder Tightening torque repair no the kits or com the bndy same repair screw 0 7 to 09 m 5 1 to kg 5 ft Ib 6 Clutch hose connector 17 to 2 0 kg m 12 to 14 ft b 4 Close clutch as bleeder pedal clutch with bleeder slowly quickly screw as is on down stroke Allow 5 pedal screw Repeat steps 4 and use or to return closed 5 until no air several times check connections for external Notes a b Brake fluid containing out of bleeder no screw air runs a solid in stream without air bubble c Pay close attention to clutch fluid level in reservoir during bleeding operation d Do not ones e Inspection Brake fluid containing air is white and has visible air bubbles the parts of the former clutch Operate then operating cyl Be sure to make kit ascertain parts loosen bleeder to bleed air out of clutch sys screw inter Operating cylinder securing bolt 5 to 3 2 5 kg m 18 to 25 ft lb Bleeder pedal two pedal depressed fully ponent parts between NABCO and TOKICO makes brand of the clutch properly is available in both NABCO make and There is worker depress clutch three times With clutch hydraulic leaks in TOKICO make Observe the following instructions clean a co or 7 Be sure to install with Installation a bubble shows in the vinyl hose Notes housing Have 6 bolts securing op to clutch a 2 Do not in clean Dip cylinder and piston brake fluid before assembly erating cylinder Place the other end of it in tern cup in clean brake fluid Removal foreign rnaterial Install bleeder hose vinyl hose on bleeder screw any 3 disassembly Closely observe the fol lowing instructions Removal and installation screw container Assembly OPERATING CYLINDER of operating cyl Operating cylinder screw bleeder clean mud and dust 7 de is found Thoroughly 6 Fig CL 20 Exploded view of operating cyUnder clutch hose and tube if or cover with recommended brake fluid 2 Piston cup es Remove reservoir cap and top up I 5 2 weak sign of damage spongy is an indication that air has it Bleeding clutch system is an sential part of regular clutch service reservoir should be replaced Return spring and valve spring must also be replaced when they are broken any abnormal action has a entered the system dis cap Replace air has entered it or pedal When feeling mm deformation due to or fatigue or damage is found 4 Damaged dust cover oil fro ti BLEEDING CLUTCH SYSTEM cylinder 15 0 replace cylinder piston cup when 0 0059 in 2 with disconnected and 1 rod push replace 2 5 Remove lic system sary or 1 cover 2 uneven or Disassembly ruin the rubber parts of the hydrau I 3 It will and kerosene gasoline as use reuse brake fluid drained during bleeding operation Exercise care not to splash brake fluid it will on exterior fInish as damage the paint disassembled Visually inspect all parts replacing those found rl Q worn or f Pour brake fluid into reservoir up to specifIed level CLUTCH SERVICE DATA AND SPECIFICATIONS Clutch cover Clu tch C225S Diaphragm type cover mm in 33 to 35 Unevenness of diaphragm spring toe height mm in less than 0 5 Full load kg Qb Diaphragm spring to flywheel distance 1 23 to 1 38 400 882 mm in 0 1 mm in 1 0 0 040 mm in 225 Free mm in 8 3 to 8 9 Compressed mm in 7 6 to 8 0 Out of flatness of pressure Allowable refacing plate limit of pressure plate 0 020 0 004 Clutch disc Facing size Outer dia x inside dia x thickness 150 x x 3 5 8 86 327 0 to x 5 91 Thickness of disc assembly Number of torsion springs Allowable minimum depth facing run 0 299 to 0 315 6 of rivet head from surface Allowable 0 350 out in 3 0 0 012 mm in 5 0 0 020 mm in 4 0 016 0 mm in 153 mm in I to 3 mm in 117 to 123 mm in 15 87 mm in 0 15 mm in 19 05 Allowable free at the outer play of spline edge of disc mm Clutch pedal Pedal height Play at clevis pin Full stroke 6 02 0 039 to 0 118 4 61 to 4 84 Clutch master cylinder Dia of master cylinder 5 8 Allowable maximum clearance between cylinder and piston Clutch operating 0 0059 cylinder Dia of operating cylinder Yo Tightening torque Clutch assembly to flywheel securing bolt kg m ft lb 1 5 to 2 2 kg m ft Ib 19 to 2 4 Pedal stopper lock nut kg m ft b 0 8 to 1 2 Push rod lock nut kg m ft lb 0 8 to 12 5 8 to 8 7 kg m ftIb 0 8 to 12 5 8 to 8 7 Clutch tube connector Flare nut kg m ft lb 1 5 to 18 11 to 13 Clutch hose connector kg m ftlb 17 to 2 0 12 to 14 kg m ft lb kg m ft Ib Pedal installation bolt Master cylinder to dash Operating cylinder bolt Bleeder screw Fulcrum pin panel securing bolt to clutch housing securing CL 9 5 to 2 lito 16 14 to 17 5 8 to 8 7 5 18 to 25 3 0 7 to 0 9 5 1 to 6 5 x 0 138 CLUTCH TROUBLE DIAGNOSES AND CORRECTIONS Condition Clutch slips Probable Slipping and cause Corrective action testing of the clutch may be noticeable when any of the following symptoms is encountered during operation I Vehicle will not 2 Insufficient vehicle 3 Lack of power during uphill driving respond to engine speed during acceleration speed Some of the above conditions also are experienced when engine problem detennine whether engine or clutch is causing the problem If slipping clutch is left unheeded wear and or overheating will occur no on is clutch urring First oc until it is facing longer serviceable TO TEST FOR SLIPPING CLlJfCH proceed as follows to 31 MPH with During upgrade travelling engine gear shift lever in 3rd speed position shift into highest gear and at the same time rev up engine If clutch is slipping vehicle will not readily respond to depression of accelerator pedal at run Clutch Oil or W r Clutch drags facing grease worn on excessively clutch d clut h about 40 to 50 km h 25 r cov Replace facing Replace pressure Dragging clutch is particularly plat o tpa e noticeable when shifting gears as follows lace especially into low gear TO TEST FOR DRAGGING CLlJfCH proceed I Disengage clutch Shift into reverse gear and then into Neutral Gradually engine speed and again shift into reverse gear If clutch is dragging gear grating heard when shifting from Neutral into Reverse Start engine increase is 2 Stop engine and shift gear 3 Gears are Conduct this test at each gear position smoothly shifted in step 2 but drag when shifting to 1st speed position at idling If dragging is encountered at the end of a shifting check condition of synchro mechanism in transmission If dragging is encountered at the beginning of shifting b 4 5 Push change lever toward Reverse side If pedal b Ifpedal cannot be Check clutch control If no to step 4 below to check for free travel be depressed further check clutch condition depressed further proceed to step 5 below a can depress pedal proceed pedal height pedal abnonnal condition exists and if free travel withdrawal lever pedal cannot be depressed play etc further check clutch condition Clutch disc runout Wear or or rust on hub warped splines Diaphragm spring toe justment worn Worn or or toe tip improperly Repair or replace in clutch disc height out of ad installed parts CL10 Clean and lubricate with grease or Adjust or replace Repair or replace replace CLUTCH Probable Condition Clutch chatters cause usually noticeable when vchicle is Clutch chattering Corrective action and testing is just rolled off with clutch partially engaged Weak broken or clutch disc Replace torsion spring Oil or grease on clutch Replace facing Clutch facing out of proper contact Replace or clutch disc runout Replace Loose rivets Warped pressure plate clutch or cover Repair or replace toe Adjust or replace surface Unevenness of diaphragm spring height engine mounting Loose deteriorated or Retighten or replace rubber Noisy clutch A noise is heard after clutch is disengaged I Damaged release bearing A noise is heard when clutch is Insufficient grease of bearing sleeve Clutch on the and bearing cover Replace disengaged sliding surface Apply grease not installed are Adjust correctly A noise is heard when vehicle is suddei11y staited offwith clutch I Damaged pilot bushing Clutch grabs Replace grabbing of clutch occurs vehicle will not start clutch is engaged before clutch pedal is fully depressed When Oil grease or on Clutch facing Wear or rust on smoothly Replace loose rivets splines off Replace clutch facing worn or partially engaged in drive shaft and Clean or replace clutch disc Repair Warped flywheel or pressure plate Loose mountings for engine or train units CLll power or Retighten replace from a standing start or Cl Ul CFf SPECIAL SERVICE TOOLS Tool number For No Description tool name Unit mm Base plate or page on Figure in 620 ST20050010 Reference use No Fig CL 12 Fig CL 13 Fig Fig CL 2 Fig 6 CL B210 00 710 610 S30 y 2 ST20050051 Set bolt SE002 q 3 ST20050 100 Distance piece 7 8 @ mm 0 31 in @1 @J SEOQ3 4 620 ST20050240 B210 Diaphragm adjusting 710 610 wrench S30 SE032 5 KV30100200 Clutch aligning bar This tool is used to conduct disc centerilg by inserting the tool into pilot bush in flywheel when installing clutch assembly to 620 flywheel 610 710 CL 3 S30 SEaOl 6 STl6610001 620 710 Pilot bushing 610 puller S30 SE191 CL 12 CLUTCH Tool number Description No tool 7 Unit name GG94310000 Flare nut torque wrench mm nut A accuracy y CL 13 SE227 Reference use page on Figure No or in tighten and loosen brake and clutch tube flare assure torque in built torque limiting wrench is provided to This tool is used to For All models Page CL 7 SECTION MT MANUAL TRANSMISSION DATSUN PICK UP MODEL 620 SERIES TRANSMISSION TYPE F4W71 B MT 2 5 SPEED TRANSMISSION TYPE FS5W71 B MT 14 SERVICE DATA AND SPECIFICATIONS MT 21 TROUBLE DIAGNOSES AND toRRECTloNS MT 23 SPECIAL SERVICE TOOLS MT 24 SPEEo 4 I NIS J NISSAN MOTOR CO TOKYO LTD JAPAN Manual Transmission 4 SPEED TRANSMISSION TYPE F4W71B CONTENTS DESCRIPTION MT 2 GEARS REMOVAL MT 4 BAULK Oil SEAL DISASSEMBL Y MT 4 MT 4 OF GEAR ASSEMBLY MT 5 FRONT COVER ASSEMBLY MT B REAR MT 8 ADAPTER MT 8 GEAR REAR EXTENSION ADAPTER RING DISASSEMBLY TRANSMISSION CASE D ISASSEMBL Y AND SHAFTS DISASSEMBLY PLATE DISASSEMBLY INSPECTION ASSEMBL Y TRANSMISSION CASE AND REAR EXTENSION EXTENSION ASSEMBLY PLATE ASSEMBLY HOUSING BEARING MT B MT 8 8 MT 9 MT 9 MT 9 MT 9 MT 9 MT 9 MT 9 ASSEMBLY TRANSMISSION ASSEMBLY MT MT13 INSTALLATION MT14 DESCRIPTION The transmission is of forward a fully synchronized 4 speed constant mesh type that uses helical gears The reverse gear is ofa sliding mesh type using spur gears In construction the main drive gear pUshed the inner teeth of the coupling sleeve slide over the synchronizer hub and mesh with the outer teeth which provided on the mainshaft gear The synchronizer hub is fitted to are The transmission assembly consists of three main which to parts a with clutch housing case an installed and gears transmission adapter plate and shafts are rear extension The cast iron adapter plate supports is meshed with the counter drive gear the mainshaft by splines so the main shaft gear turns together with the the which is mainshaft idler The forward speed gears on the coun tershaft are in constant mesh with the The baulk ring serves to synchro nile the coupling sleeve and mainshaft bolted at the front to the transmission mainshaft gears which ride on the mainshaft freely through the needle gear extension bearing keyed When to the countershaft shifting is accom Placing the control lever in position brings the reverse case countershaft reverse shaft and three fork rods and at the rear to the and rear by means of through bolts all By removing these bolthroughts reverse idler gear mainshaft gears and shafts are stripped into mesh with mainshaft reverse gear e TM 858 1 Front 2 Transmission 3 Adapter plate Bearing retainer Rear extension hOUsing 4 5 cover case Fig MT 1 F4W71B lrammiasion MT 2 case compon nt Manual Transmission o cCl 1 Main 2 Baulk ring 3 Synchronizer hub 3 r 4 Shifting insert spnng Shifting insert Coupling sleeve 5 6 7 TM857 Fig MT 2 F4W71B drive gear d 4th 3rd main gear 8 Mainshaft 9 2nd main gear main gear 10 1st 11 ht gear spacer 12 Reverse main gear 13 Counter drive gear 14 Countershaft 15 Reverse 16 Reverse idler 17 Reverse idler gear counter transmlsBIO n gear shaft gear component @ 4 @ 4 Striking lever Lock pin Oring Striking guide 5 Oil sea1 6 Striking rod E ring Stopper guide pm Return spring plunger Return spring 1 fl 2 3 t 7 8 @ 9 10 13 Reverse check spnng Return spring plug Check ball plug 14 Check spring 15 Check baD Interlock ball 11 12 16 o n f1f@ 17 18 Retaining pin 1st 2nd 19 ht 20 3rd 2nd fork rod 4th fork rod 21 Reverse 22 3rd 23 Reverse shift fork 24 Con trollever 25 Control lever b shmg 26 Control lever p 27 Control lever bushmg @ shift ork fork rod 4th shift fork n TM045A Fig MT 3 F4W71 B 3 MT transmuswn shift controI components Manual Transmission 9 REMOVAL dismounting transmission from In proceed the vehicle as follows Disconnect battery I cable ground Remove bracket holding center bearing on 3rd crossmember by loosening off attaching bolts See 6 MT Figure from terminal Place transmission control lever in 2 neutIal position 3 Remove E pin from and guide ring and control lever striking rod transmission remove control lever See E A277 4 MT Figure 8 MT Fig Removing engine mounting rear PD219 Fig MT 6 Removing center balring holding brucket propeller shaft from companion flange of gear carrier by removing four bolts See Figure MT 7 10 Uetach 15 Remove starter motor 16 Remove bolt support securing transmis sion to engine After removing these bolts support the engine and transmission with jacks ion rearward and then slide tra from engine and away from remove the vehicle TM335 Fig MT 4 Remouing controllelJ r a Not Remove as Jack up the vehicle and support weight on safety stands Use a 4 its hydraulic hoist or open pit if avail and safety carefully propeller damage spline sleeve yoke rear oil oil from Disconnect exhaust front tube 6 Disconnect wires from rear Figure MT 5 8 I transmission cable See O case See cylinder Figure cover from trans Remove release bearing and with Fig MT 7 Remouing four bolt 6ecuring prop ller shtJft to companion ltJnge m Support engine by locating 11 a jacft pan with a wooden used between oil pan and jack block under oil 12 Support transmission with lamp switch 4 Remove 5 Move gear to Neutral reverse Remove speedometer pinion and pinion sleeve by taking off lock plate 6 7 Remove E ring and stopper guide rear end of ll extension re pin from See Figure MT 9 a transmissionjack @ pipe btacket by unscrewing attaching bolts 2 California models only See Figure 13 Remove exhaust 8 MT Speedometer cable Reverse lamp switch Outch operating cylinder 14 Remove insulator TM774 Fig thoroughly wipe transmis off dirt and drawallever J 3 disassembling Remove dust 3 P0220 1 to grease from it 2 Drain oil thoroughly MT5 2 Prior mission case Remove clutch operating from DISASSEMBLY sion extension housing dismounting trona adjacent TRANSMISSION CASE DISASSEMBLY reverse speedometer Disconnect from in out flowing lamp switch See Figure MT 5 7 care seal is insured 5 Take mission not to strike any parts and main drive shaft so b Plug up the opening in the rear of rear exteDSion housing to prevent able Confirm that not to Note shaft MT 5 Bottom view of car rear securing engine bolts I mounting and rear mounting member securing bolts 3 8 MT See Figure 4 MT TM337 Fig MT 9 Removing triking rod E ring and topper pin Manual Transmission 8 Remove return spring spring reverse from er rear plug return check spring and extension plung See Figure Fork rod MT 10 ht 2nd qJiiiiiI TM341 Fig MT 13 Removing trammission Interlock case ball 13 TM338 Fig MT 10 Removing return spring plull Set Setting Plate Adapter ST238 1000 I on adapter plate With countershaft side up place the above assembly in a vise See Figure up MT 14 TM344 Remove 9 rear bolts and turn the extension Fig MT 16 Layout securing o ch ck boll and interlock ball striking rod toward left Drive out rear extension backward by lightly tapping around it with hammer See Figure MT 11 a Gear assembly soft I With gears doubly engaged out TM342 Fig MT 14 Attaching l to mbly special tool or suitable each Fig MT 11 Removing rear extension fork rod Punch Draw out counter drive gear with main drive gear means of a gear puller plete Fork rod TM339 Remove counter drive gear snap 3 ASSEMBLY from retaining pins with ST23540000 Fork Rod Pin See a Figure ring DISASSEMBLY OF GEAR out See puller gear MT 17 2 Drive draw countershaft front bearing using Figure When out be careful assembly needle bearing front MT 15 drawing end com assembly by main drive gear not to onto floor of mainshaft drop pilot from See the Figure MT 18 Remove 10 bolts and front remove front cover securing cover S Detach countershaft front bearing shim Remove main drive bearing snap II ring with Expander See Figure MT 12 ST23540000 TM343 Fig MT 15 Drive 2 Remove three 3 out retaining pim check ball piugs and drive out fork rods from adapter pia te by lightly tapping on the front TM398 Fig MT 17 Removing countershaft front b aring end j Separate transmission case from adapter plate with a soft hammer See 12 Figure MT 13 Be careful not to lose three 3 check balls and four 4 interlock balls See Figure MT 16 Each gear and shaft can be detached from adapter plate with Note out removing each MT 5 fork rod TM345 Fig MT 18 Removing count r drive gear and main drive gear Manual Transmission Remove snap ring and then thrust washer from mainshaft front end 4 Draw out assembly 4th 3rd and synchronizer 3rd remove gear as sembly 5 Release nut caulking and loosen it on mainshaft sembly together with countershaft by lightly tapping the rear end with a soft hammer while holding the front of mainshaft gear assembly by hand Be careful not to drop off gear shaft See Figure MT 20 See Figure MT 19 2 Press out I st gear mainshaft bush ing together with 2nd gear and 1 st 2nd speed synchronizer using Bearing Puller STJ0031000 See Figure MT 2l Note When r h ft hold drop out bushing by hand so as not to it IJ H t I TM346 Fig MT 19 Removing maimhaft nut TM347 Fig MT 20 Driving out gear embly Cl 30031000 S1 6 Remove mainshaft washer and mainshaft 7 shaft nut reverse thrust Mainshaft assembly gear Remove snap ring from counter rear end and remove reverse idler gear 8 Draw 1 not out mainshaft gear as Remove thrust washer steel ball I st gear and needle bearing to lose steel ball washer Be careful retaining thrust TM049A Fig MT 21 R moving lItgear mtUlIIhaft bu hing 12 1 Pilot bearing 2 3rd 3 assembly Baulk ring 4th synchronizer 5 3rd main gear Needle bearing 6 Mainshaft 7 Needle bearing 2nd main gear 4 8 9 1st 2nd synchroni r assembly to II 12 13 14 15 Coupling sleeve Shifting insert Shifting insert spring Synchronizer hub 1st main gear Needle bearing 16 1st gear 17 Thrust weher Maimhaft bearing 18 19 bushing 20 21 ReftllSe main gear Thrust washer Nut 22 Steel ball 23 Thrust washer 24 Snap ring TM348 Fig MT 22 Explod d view of 6 MT haft main mbly Manual Transmission M in drlv 1 Count r g r h ft mbl Install Bearing Puller STJOO31000 Remove main drive gear snap ring countershaft on and spacer 2 Remove main drive bearing with Bearing Puller ST30031000 and a suit countershaft rear rear bearing press out bearing through a rod See Figure MT 25 able piess See Figure MT 23 Main drive bearing Main drive gear 1 2 TM349 Note Fig MT 23 Removing main drive bearing When pressing shaft by hand so out as bearing not to hold drop shaft onto floor III cl 1 2 iiiiiE Snap ring Spacer l drive bearing with snap ring 3 Main 4 Main drive gear TM351 TM350 Fig MT 24 Exploded view of main drive gear q e 1 Fig MT 25 Removing countershaft bearing f @ @ 1 Countershaft front bearing 2 shim Countenhaft front bearing 3 Snap ring 4 Countenhaft drive gear 5 Woodruff key 6 Countenhaft 1 8 Countershaft rear bearing Reverse counter gear 9 Snap ring j i TM352 Fig MT 26 Exploded view of MT 7 haft auembly counte Manual Transmission REAR EXTENSION Note DISASSEMBLY lock Remove and lever remove 00 not diSlssemble sion bush from pin from striking rod rear exten rear extension striking e 1 Control lever 2 Striking rod guide Striking rod Striking lever Return spring plug Stopper pin 3 4 5 6 TM353 Fig MT 27 Exploded view ofshifting mechani6m ADAPTER PLATE Remove DISASSEMBLY I Remove attaching wrench and from six 6 bearing with screws remove retainer an impact bearing retainer nicks projection a 3 extension bush is If rear or frne stone cracked replace bush and rear extension it 2 Check shaft for bending and wear as an worn or assembly of housing 3 Remove mainshaft bearing from reverse idler shaft BEARING side I 2 a worn or INSPECTION of round Wash all parts in a suitable cleaning solvent and check for wear damage or with clean bearing and dry compressed When race air and ball surfaces are rough or when balls are out or rough replacebearihg a new one See Figure If the above limits are exceeded drive and driven gears Measure gear end play replace 4 as a set 1st gear 0 32 to MT 28 39 0 mm 0 0126 to 00154 in 2nd gear other faulty conditions 0 12 to 19 0 mm 0 0047 to 00075 in Notes a 10mm to0 0 0020 to 0 0039 in Thoroughly with crack if necessary spline Standard 005 Remove rear extension worn replace 3 Measure backiasii in gears adapter plate 2 the all sealant with Be careful not to damage any 3rd gear 0 13 to parts with scraper b 00 not clean wash or 37 0 mm 0 0051 to 0 0146 in soak oil seals in solvent I TM372 TRANSMISSION CASE AND REAR EXTENSION HOUSING I Clean with and check for cause oil leak solvent thoroughly might faulty con cracks which or other ditions 2 Check mating surface of the case to engine or adapter plate for small nicks projection or sealant Fig MT 28 3 Replace damaged l pecting ball bearing needle bearing if worn or GEARS AND SHAFTS I Check all gears for excessive wear chips or cracks replace as required 8 MT TM374 Fig MT 29 Measuring end play Manual Transmission 5 Check for stripped damaged or speedometer pinion gear If necessary replace 2 ft lb I cracked or otherwise dam aged excessively 2 baulk ring in position Place on gear holding baulk ring against far as it will go as to 15 measure gap between baulk ring and outer gear If gap is small discard baulk ring Insert reverse idler shaft in 2 er Make sure that the cut out of reverse ASSEMBLY sion clean seal seat in rear exten housing adapter plate Install bearing retainer in adapter plate Align bearing retainer with reverse idler shaft at the cut out portion of REAR EXTENSION Wipe portion idler shaft is lined up with inner face of torque adapt plate 3 1 gear cone While 12 m if found to be Replace baulk ring deformed 16 to 2 1 kg to screw BAULK RI NG to withdrawal lever Apply sealant ball pin screw Install withdrawal lever ball pin to front cover and tighten press fit oil seal in place Coat oil seal and bushing with gear oil for initial lubrication this shaft torque kg m screws 14 to 18 ft lb screw at two to 1 9 to 5 2 and stake each poin Is with a punch See Figure MT 34 See Figure MT 30 25 to 1 60 rom 0 0492 to 0 0630 in 1 lr 5 Front Baulk ring h TM355 Fig MT 32 Rear extemion oil seal TM400 TM375 Fig MT 30 Baulk ring to cone gap Fig MT 34 Staking 2 er OIL SEAL Discard O ring once removed sealing lip is or oil seal which is oil Replace deformed seal if cracked or Also discard oil seal if spring is out of Apply grease to O grooves in striking rod Insert striking rod with guide through 3 torque screw 4 striking rod rear extension Install striking lever of striking rod SCN W ring and plung on in Install countershaft bearing adapter plate by lightly tapping around it with a rear soft hammer front end Install lock pin and to 0 9 to 12 kg m 7 to 9 ft Ib position GEAR ASSEMBLY ADAPTER ASSEMBLY To assemble disassembly Clean all parts in solvent and dry the order of reverse Observe ihe following instructions Place dowel pin mainshaft bear ing and oil gutter on adapter plate and tap with a soft hammer until they are 1 properly positioned Use FRON1 COVER ASSEMBLY expand cover then press fit oil seal in place Coat oil seal with gear oil to MT33 Wipe clean seal seat in provide initial lubrication a new on in place rear front side and on side with compressed air Synchronizer 888embly Assemble synchronizer assembly dowel pin Bend oil gutter front I PLATE ASSEMBLY See Figure J Position shifting insert springs and shifting inserts in three 3 slots in synchronizer hub put coupling sleeve on synchronizer hub Front Upper r Front J f r Front J C MT 31 Front cov oil eol MT 9 33 MT 15t 2nd TM351 Fig Fig 4th M356 TM354 Fig 3rd 7 Oil gutter MT 35 Installing synchronizer hub Manual Transmission Malnshaft assembly I 2nd gear Assemble 2nd gear ing needle bear baulk ring I st ing washer a I st gear bush ring steel gear on 2nd 1st speed synchronizer assembly baulk st gear apply I and thrust grease to it See Figure MT 36 Place woodruff new keys in press main drive bearing shaft of main drive gear ST23800000 lightly until they onto Use a seated securely are soft hammer to avoid dam the Make sure that snap aging keys shaft clears bearing 2 2 Place adapter plate assembly and mainshaft assembly so that counter shaft sion rear bearing rests on Transmis Press Stand KV31100400 prop erly 3 on main Place main drive that it See adapter Figure MT 39 Press Stand KV311 00400 and place adapter plate assembly it See on Figure MT 37 TM440 39 MT Fig 4 For counterman and reverse idler shaft For main5haft and l talling Thickness 1 80 0 0709 2 1 87 0 0736 3 1 94 0 0764 4 2 01 0 0791 5 2 08 0 0819 6 2 15 0 0846 UJ V Holes for reverse Idler Fig 3 bearing gear baulk ring and 3rd 4th synchronizer assembly on the front of mainshaft CD Insiall thrust washer on mainshaft I e ure it with snap ring of proper thickness that will fit the groove in mainshaft See Figure MT 40 TM438 mainshaft TM364 assembly to adapter plate assembly Be sure to place bearing squarely against shaft and press it into place on shaft gradu ally See Figure Available snap ring shaft MT 37 Tromminion PreS3 S tond Install in countersha t and J mm Position 3rd gear needle S V31100400 main ifnOai Sfdh reverse tdler haft bearing spacer bearing and secure Available snap ring l talling thrust washer Transmission on 4l MT Figure TM358 Set groove bearing with thicker snap ring will eliminate end play See drive No 2 drive ring Install countershaft into plate by pressing Fig MT 36 Adapter Transmission Using 1 grooves in countershaft and tap them needle bear ball mainshaft Before installing steel ball Main drive gear assembly Countershaft assembly No Thickness mm in Fig Installing snap ring 41 MT I 14 0 055 2 5 1 0 059 3 0 063 face of main drive gear 16 3 to MT 38 on Position baulk ring mainshaft pilot on cone sur Apply gear oil bearing and install it mainshaft Assemble main drive gear assembly on the front end ofmainshafl 4 Press counter drive gear onto countershaft with Counter Gear Drift ST23860000 by secure snap KV31100400 38 MT Installing Note haft mai em bly gears and ring See Figures MT 42 and 43 MT TM439 Fig meshing counter drive gear with thicker TM441 Fig 40 MT l talling snap ring MT l0 Be drive sure gear to and simultaneously drive in main drive gear counter Manual Transmission in a vise Support adapter plate with Plate Setting 6 ST238 10001 Adapter mainshaft facing with mainshaft washer plain on the reverse rear gear of mainshaft and install mainshaft nut Tighten TM442 42 MT Fig l talling haft counte drive gear mainshaft nut 8 Install counter rear of countershaft and map ring Use snap gear end 14 ring play See temporarily reverse gear on secure 17 to kg with torque Install 7 of converted torque Mainshaft nut should be tightened to down ST23860000 Explanation the ST22520000 of wrench needle to 123 ft lb of aid Wrench doing When amount should the so be to torque read be on modified following formula to the according 101 m the with L give a minimum Figure MT 45 to C kg 14 m to x L O lO L Available counter drive gear map ring 17 x L No No Thickness I 14 mm 15 0 059 3 16 0 063 10 0 in mm in or 0 055 2 Thickness I 14 0 055 2 15 0 059 L ft lb C 101 to x 33 0 L 16 3 0 063 L 123 x L 33 0 II Where C Value read kg the torque wrench on ft lb m L Effective wrench of length m torque ft ST22520000 c Torque wrench Imtalling counter gear TM366 43 MT Fig Installing nap ring 9 verse 10 Press countershaft front bearing 5 onto countershaft ST22360002 with Drift C See Figure MT 44 Install reverse reverse With I nap ring idler gear on re Lm ft O IOm TM587 0 33 ft idler shaft 1st and 2nd gears tighten mainshaft engaged h TM361 o 45 MT Fig doubly Fig 47 MT Setting wrench nut to the converted Cn See Figure torque using Wrench ST22520000 See Figure MT 47 MT 48 Example When que ST22360002 Figure kg ST22520000 KV3 II00400 TM443 Fig 44 MT Installing a TM768 haft counte front bearing Fig 46 MT Tightening mainshaft nut MTll m 0 40 m 31 1 wrench is used ft the long tor Cn in MT 48 will be 112 to 13 6 81 to 98 ft lb Manual Transmission Secure S 2 15 I 110 c 14 100 c 9 S c o check ball check Align notch shift check ball sealant to check ball I 6 1r f fdl 15 to retaining pin and check ball plug tightening line 2nd fork rod a new Install spring Upper limit u c 1st fork with s ball Prior to plug apply plug in 1st 2nd fork rod with check ball See Figure MT 50 Converted torque 13 90 I C Lower 80 limit line 11 TM367 U Fig MT 50 fork rod V 10 70 9 0 2 2nd l talling 1st Slide 3rd 3 0 3 0 4 0 6 5 1 10 L 05 0 7 0 8 2 5 2 0 adapter plate m and with secure Prior to Note fork rod balls into CO 1Vert d torque 48 MT a new retaining pin It Effective length of torque wrench Fig 4th fork rod through 4th shift fork and 3rd Figure 4 4th mbling 3rd 2 interlock two own in dap er plat a install MT 16 Install check ball and check ball spring 11 Tighten mainshaft nut to 101 123 17 0 kg m to to torque stake mainshaft and groove of main shaft with Figure MT49 a 14 0 Note ft lb nut The main drive gear and coun ter driVe gear should be handled as a to matched set When you punch See replace a main counter drive gear or replace as a be sure to set of main drive gear sealant to check ball Align notch drive gear in 3rd with check ball by fork rod as plug place 4th fork rod sliding necessary 3rd See 4th Figure MT51 and counter drive gear ShUt fork Apply and install it in nd fork rod mbly I Place 1st groove and slide 1st TM362 2nd shift fork in in 1st 2nd sleeve coupling 2nd fork rod through and 1st 2nd shift fork adapter plate Prior to installing 2nd fork rod 1st TM368 install 3rd Fig 49 MT Staking haft nut mai 3rd 4th shift fork in groove in 4th coupling sleeve Note Shift forks for 1st 3rd Measure gear end 12 play and back lash Make the specified that they are held within values For details refer to the instructions under topic Inspection are one 2nd and and the same parts Make sure 4th 4th Fig MT 51 Installing 3rd fork rod sure that the long end of shift fork for lot 2nd is placed long on counter gear side and the for 3rd 4th is on side the the end e 5 Place verse shift fork in shift fork and secure MT12 reverse idler gear Slide reverse fork rod with a new reverse through re adapter plate and retaining pin Manual Transmission Note Prior to assembling rod instaU two 2 into adapter Figure 6 reverse fork Front interlock balls piate shown as I in to 2 check ball plug reverse xt nslon ass ar I TM369 Fig MT 52 Installing fork reverse rod With Torque each check ball plug 5 kg m 14 to 18 ft Ib 2 to 1 9 to for ht 2nd fork rod longer than those for sion onto ID 2J1 Transmission case that speed change cross lever engages with fork rod brackets correctly 2 Countershaft 3 front bearing Countershaft 4 Shim Install washers and through bolts and torque to 1 6 15 ft lb 1 2 to kg m 12 TM371 to MT 54 Selecting countershafl front bearing shim Fig Available shim 4th fork rod see sliding Countershaft front A sur in rnm bearing shim mm in that shift rods and operate correctly engaged smoothly gears are TRANSMISSION ASSEMBLY lon Tranmis I JJ graduaUy slide rear exten adapter plate making sure No Apply @ shift rev gear oil to all faces and check to A D A fork rods in their neutral positions 3 8 shim of thickness mbly Clean mating surfaces of adapter 2 fork rod and 3rd a snap ring plate and fear extension Apply sealant to mating surfaces of adapter plate and rear extension plug Select Fig MT 53 Fitting main drive R BaD counter fork rod with bearing is to measured check ball See Figure MT 52 Note bearing follows See Figure MT 54 from front Measure depth A end of transmission case and install it in place 7 mbly shaft front bearing spring Apply sealant notch in s as 1 Install check ball and check ball Align r Select countershaft front shim MT I6 eov I 2 92 to 3 01 0 1150 to 0 1185 2 3 02 0 1189 3 0 1224 5 0 020 0 3 12 to 3 21 0 1228 to 0 1264 0 4 0 016 4 3 22 to 0 1268 0 1303 0 3 0 012 5 3 32 3 41 0 1307 to 0 1343 0 2 0 008 6 42 3 to 3 5 I 0 1346 to 0 1382 0 1 7 3 52 to 3 61 0 1386 to 0 1421 8 3 62 to 3 71 0 1425 mbly ea 3 11 0 6 0 024 to to 3I to to to 0 004 0 1461 1 Clean mating surfaces of adapter plate and transmission case Apply sealant to mating surfaces of adapter plate and transmission case 2 Slide transmission case adapter plate by lightly tapping soft hammer until case onto with a bears against adapter plate Carefully Clean cover install main drive bearing bearing Make certain that mainshaft rotates freely Fit main drive bearing snap ring to groove in main drive bearing by using Expander See Figure MT 53 mating surfaces of front and transmission case Apply retain and countershaft front 3 2 grease to shim selected to install front transmission case with gasket in place Install through bolts with washers under them and tighten to 1 6 to 2 1 kg m 12 to 15 ft lb torque Apply sealant to threads through bolts before installation MT13 Install speedometer pinion bly it on front cover cover to 3 of on rear that Sure groove in extension lock plate is lined up with speedometer pinion sleeve install through bolts to 0 5 kg 4 assem After making m and torque to 04 3 to 4 ft lb Install back up lamp switch and torque to 2 0 to 3 0 kg m 14 to 22 ft lb Be sure installation to apply sealant before Manual Transmission 5 Apply purpose light a grease coat of multi withdrawal to Install the transmission in the release bearing and bearing sleeve in stall them on 6 Install and cover on clutch 1 Before control lever gears to make lever sure mission temporarily through all that gears opera 2 Ie smoothly to rear plate installing spline reo Install drain plug mating lightly apply parts of clutch disc mission to ith sealant in place 0 9 to 2 1 kg bolts Tighten engine Figure MT 55 and filler plug 1 and trans and main drive gear 3 Note 32 to 43 ft Ib case Before grease dean installing surfaces of engine shift control m following points tion to the After connecting them with holder dust 5 9 kg uf removal paying atten order verse clutch housing spring instaU housing 4 to INSTALLATION lever to securing specifications m 7 to 9 rt lb TM773 Fig MT 55 Tightening torque trans See 4 Remove filler plug and fIll trans mission with recommended gear oil to the level of the plug hole mately 5 SPEED TRANSMISSION TYPE I 7 liters 3 Approxi pt 3 pt FS5W71B CONTENTS DESCRIPTION MT14 BEARING MT19 REMOVAL MT17 GEARS AND SHAFTS MT19 DISASSEMBL Y MT17 BAULK RING MT19 TRANSMISSION CASE DISASSEMBLY MT17 OIL SEAL MT19 DISASSEMBL Y OF GEAR MT17 REAR ASSEMBLY EXTENSION DISASSEMBLY ADAPTER PLATE DISASSEMBLY INSPECTION ASSEMBL Y FRONT COVER ASSEMBLY MT19 MT19 REAR EXTENSION MT19 MT19 GEAR TRANSMISSION CASE AND REAR EXTENSION HOUSING MT19 MT18 ASSEMBLY ASSEMBLY MT19 TRANSMISSION ASSEMBLY MT19 MT INSTALLATION 20 MT20 DESCRIPTION The transmission is speed fully synchronized The 5 uses a 5 speed 4 with mesh type that overdrive of forward OD constant helical gears speed transmission covered in this section is similar in all respects to the 4 speed transmission type F4W71B stated previously except the overdrive position of it The overdrive gear Placing the control lever rides on the mainshaft freely through the needle roller bearing and counter overdrive gear is fitted to the countershaft by splines The overdrive synchronizer system is on the mainshaft rear side drive position brings the coupling sleeve reverse OD main gear shaft into mesh with overdrive clutch gear hub The is splines shaft shaft MT14 in over reverse reverse fItted so to on OD synchronizer the mainshaft the overdrive gear turns on together with the by main main Manual Transmission j I @ b 00 7 @ f f 1 Front cover 2 Front cover oil seal 3 Front cover gasket 4 Transmission 5 7 Adapte plate Maimhaft bearing Bearing retainer 8 Rear 9 Breather 6 case extension 10 Rear extension oil seal 11 Sleeve yoke dust cover @3 TM046A Fig MT 56 FS5W71B transmission MT15 case components Manual Transmission j W h I l 1 Main drive gear 2 Baulk ring Shifting insert Shifting insert spring 3 4 5 6 Synchronirr c hub Coupling slee 7 3rd main gear g 9 Needle bearing Mainshaft 10 2nd main gear 11 Bushing 12 1st main gear O revcrse synchronizer hub 13 14 Rever 15 Circlip 16 Thrwt t7 Brake band 18 Synchronizer ring 19 Overdrive main gear 20 Overdrive gear bushing 21 Washer 22 24 Mainshaft nut Overdrive mainshaft bearing Speedometer drive gear 25 COlplteBhaft 13 26 27 gear block mt bearing shim fr Countershaft front bearing 28 Countershaft drive gear Coontcrshaft 29 Countershaft bearing 30 Reverse counter gear spacer 31 32 C counter Rever gear 33 rdrive counter gear Countershaft zear bearing 34 C untershaft nut 3S Reverse idler lIhaCt 36 Reverse idlcrthrust washer 37 Reverse idler gear nc idler gear bearing Reye Reverse idler thrust w8her 38 39 TM041A Fig MT 51 FS5W11B MT 16 trumiasion gear componenta Manual Transmission I 2 3 4 5 Oil seal 6 8 Striking rod Expansion plug Stopper guide pin 9 Return 7 j t e spring 11 Return spring plug Return spring plunger 12 Check ball plUS 13 Check spring Check ball 10 @ Striking lever Lock pin Q ring Striking guide 14 Retaining pin CD Interlock ball ist 18 1st 19 3rd 20 Reverse 21 3rd o O 2nd shift fork 2nd fork rod 17 4th fork rod OD fork rod 4th shift fork OD shift fork Revene Con trol1ever 24 Con trol1cver pin 25 Con trollever bushing TM048A control component Fig MT 58 FS5W71B trammi ion shift 3 Same for the F4W71B REMOVAL as DISASSEMBLY TRANSMISSION CASE DISASSEMBLY Same as Draw out counter drive gear com plete with main drive gear assembly by means of a gear puller When drawing out main drive gear assembly be careful not to drop pilot needle bearing onto floor from the front end of mainshaft See Figure 60 MT TM756 for the F4W71 B Fig MT 60 Removing counter drive gear and main drive gear DISASSEMBLY OF GEAR ASSEMBLY 4 Rem6vesnap ring and then thrust washer from mainshaft front end Fork rod Same as Draw out 3rd assembly and for the F4W71 B 4th remove synchronizer 3rd gear assem bly Geer I out Remove snap ring and then draw out speedometer gear and bearing 5 sembi from mainshaft With gears doubly engaged draw haft front bearing using a counte suitable gear puller See Figure MT 59 2 Remove counter drive gear snap 6 TM398 Fig MT 59 Removing countershaft front bearing ring MT 17 rear side gea doubly engaged re caulking on countershaft and With lease mainshaft nuts then loosen them Remove countershaft nut Manual Transmission II Remove reverse idler gear 12 Remove snap ring of mainshaft Draw out bearing using end bearing Mainshaft Rear Puller Bearing KV32101330 Remove other snap ring of mainshafl end bearing See Figure MT64 IT TM757 Fig Removing counterahaft 61 MT nut TM761 Fig tw Note When sembly removing mainshaft as TM160 Draw out counter overdrive gear end by using from a countershaft outgear sembly KV32101330 loosen mainshaft nut and bearing Driving Malnahaft Fig MT 64 Removing 7 65 MT haft mai nd bearing rear Same Figure MT 62 for the F4W7IB Main drive Same suitable gear puller See as as ear for the F4W71 B Counterahaft aaaembly 13 Remove washer mainshaft mainshaft nut reverse thrust gear Same as OD for the F4W7l B synchronizer and overdrive gear REAR EXTENSION 14 DISASSEMBLY Draw out mainshaft gear assem together with countershaft by bly lightly tapping the rear end with a soft hainmer Me holding the front of mainshaft gear assembly by hand Be careful not to drop off gear shaft See Figure 65 MT Remove lock lever and remove Note sion pin from striking rod siriking Do not disassemble bushing from rear rear exten extension TM758 Fig MT 62 Removing overdriv count r gear and bearing 8 Remove counter reverse idler gear and spacer 9 Remove countershaft by lightly tapping the rear end with a soft k J l hammer Be careful not to drop J off gear shaft 10 Remove reverse idler gear snap ring @ r 1 Striking 2 3 4 Control lever 5 Striking 6 Reverse select plunger Reverse select plug 7 TM759 Fig 63 MT Removing reverse gear idler lever Striking rod Stopper pin rod guide TM767 nap ring Fig MT1B MT 66 Exploded view of shifting mechanilm Manual Transmission If the above limits ADAPTER PLATE DISASSEMBLY Same exceeded replace drive and driven gears 4 Measure gear end play for the F4W71 B as are as set a 4 39 0 er 0 0047 to 0 0075 in Make mm plate Align bearing INSPECTION faulty Same wear as for the F4W7IB screws 14 to 18 ft lb m at two screw Figure to 1 9 to 2 5 and stake each points with a punch See MT 69 OIL SEAL conditions Same Notes a adapter retainer with reverse this shaft torque kg Wash all parts in a suitable other plate idler shaft at the cut out portion of BAULK RING solvent and check for that the cut out portion idler shaft is lined up with Install bearing retainer in 6 0 0126 to 0 0154 in adapt sure reverse inner face of adapter 0 0146 in screws cleaning damage or soft a plate of OD gear on mainshaft 32 to 0 39 mm 0 Fig MT 67 Removing by bearing Insert reverse idler shaft in 5 3rd gear 37 0 7 to m hammer 0 12 to 0 19 mm to kg it with lightly tapping around 0 0126 to 0 0154 in 0 0051 filainshaft Install mm 2nd gear 0 13 to to 0 9 to 1 2 screw torque 9 ft lb 1st gear 32 to 0 Install striking lever on front end of striking rod Install lock pin and 3 as for the F4W71 B ASSEMBLY Be careful not to damage with scraper b Do not clean wash any parts To or soak oil seals TRANSMISSION CASE AND REAR EXTENSION HOUSING as reverse the order of in structions in solvent Same assemble disassembly Observe the following FRONT COVER ASSEMBLY Same as for the F4W7l B TM764 for the F4W71 B Fig MT 69 Stahing REAR EXTENSION screw ASSEMBLY BEARING Wipe clean seal seat in rear exten housing press fit oil seal in place Coat oil seal and bushing with gear oil for initial lubrication See Figure Same as for the F4W7l B I 7 sion in 68 MT GEARS AND SHA around it with Check all gears for excessive chips or cracks replace 2 rear bearing soft hammer a GEAR ASSEMBLY S r I Install countershaft adapter plate by lightly tapping as Clean all wear with I required parts in solvent and dry compressed air Front Check shaft for bending crack and worn spline if necessary Synchronlz embly r wear Same replace 3 as for the F4W71 B Measure backlash in gears Ov rdrlve Main drive and Fig MT 68 R ar extemion oil I 1st 2nd 3rd reverse 2 Apply O ring and multi purpose plunger grease grooves in to striking mm 0 0020 to 0 0040 in Assemble 2 Position Insert striking rod with striking guide through rear extension MT19 rod reverse OD synchro overdrive gear assem bly rod gears r assembly mm 5th and 0 05 to 0 20 Assemble nizer 0 0020 to 00039 in ynchronlz sea counter drive gear 0 05 to 0 10 r mbly TM355 brake on synchronizer ring band thrust block and anchor block overdrive clutch gear install circlip Manual Transmission 2 Synchro ring Assemble OD nizer reverse OD assembly needle bearing gear synchro bushing OD gear assembly sreel ball and thrust washer on main 8andbrake shaft Circlip side Before installing steel rear ball apply 3 Install grease to it new mainshaft nut and tighten it temporarily 4 Install counter counter 5 th gear countershaft Anchor block TM449 Fig MT 70 Imtalling overdrive gear assembly Same as Install for the F4W7IB snap bearing ring reverse spacer as and snap ring Main drive gear assembly Procedures F4W7IB are trans the same as for the i n except Tighten mainshafl and as those for the F4W7IB Shift forks and fork rods assembly as for the F4W71 B I L u TRANSMISSION ASSEMBLY Same as for the F4W71 B follows I Insert countershaft and mainshaft TM4S1 into adapter plate and place adapter plate in a vise with setting plate counter dures for mainshaft nut are the same Same h for the F4W71 B new tem needle idler gear spacer Countershaft assembly Same nut gear shaft nuts and stake nuts at groove in shafts with a punch Tightening proce as roller Tighten and porarily 5 Malnshaft assembly nut reverse bearing Fig MT 71 R MT 20 lJerse idler gear INSTALLATION Same as for the F4W71 B Manual Transmission SERVICE DATA AND SPECIFICATIONS GENERAL SPECIFICATIONS Transmission type F4W71B FS5W71B Synchromesh type Warner 1st to 4th Warner 5th Servo 1 3 1 3 5 II T Shift type i 2 i 4 1 2 R 4 R Gear ratio 592 3 1st 2nd 2 246 3rd 1 415 4th 1000 321 3 2 077 308 1 1000 0 864 5th Reverse Oil capacity 382 3 375 4 Final gear ratio Speedometer 3 657 gear ratio US pt Imp pt 375 4 20 6 I 7 3 MT 21 20 6 3 2 0 4X f 3 Manual iTransmission TIGHTENING TORQUE Installa tion Unit Engine to transmission installation bolt Transmission to engine plate rear bolt transmission 7 to 9 2 5 to 3 0 Crossmember mounting bolt Propeller 32 to 43 0 9 to 1 2 installation bolt 18 to 22 0 8 to 1 6 to 8 3 2 to 43 shaft to diff installation bolt ft lb m 4 to 5 9 Clutch operating cylinder installation bolt Rear mounting insulator to kg 23 to 31 4 to 33 2 17 to 24 12 to IS Gear assembly Rear extension installation bolt 16 to 2 1 Front 1 6 to 2 1 12to IS 19 to 2 S 14 to 18 cover Bearing installation bolt retainer to adapter plate screw Main haft nut 14 0 to 17 0 Check ball 1 9 to 2 S plug lever lock Stri pin Reverse select return Speedometer Reverse sleeve locking plate nut lamp switch year oil Ge oil drain r plug Ier 101 to 123 14 to 18 0 9 to 1 2 7 to 9 09 1 2 7 to 9 0 4 to O S 3 to 4 2 0 to 3 0 14 to 22 plg 2 S to 3 5 18 t02S plug 2 S toTS l8 to 2S or SPECIFICATIONS Gear backlash Unit mm in Maindrive gear to counter drive gear 0 05 to 0 10 1st gear 0 05 to 0 20 00020 to 0 0079 2nd gear O OS to 0 20 0 0020 to 0 0079 3rd gear 0 05 to 0 20 0 0020 to 0 0079 OD gear 0 05 to 0 20 0 0020 to 0 0079 Gear end 0 0020 to 0 0039 play 1st gear 32 0 2nd gear to 39 0 0 12 to 0 19 3rd gear 13 0 to 37 0 OD gear 32 0 to 39 0 Counter gear 01 to 0 21 0 Reverse idler gear 0 0126 to 0 0154 0 0047 to 0 0075 0 0051 to 0 0146 0 0126 to 0 0154 0 0004 to 0 0083 0 05 to 0 20 0 0020 to 0 0079 Clearance between baulk ring and gear All gears Counter bearing adjusting 125 to 1 60 0 0492 to 0 0630 shim 0 6 0024 0 5 0 020 0 4 0 016 3 0 012 0 0 2 0 008 01 MT 22 0 004 Manual Transmission I TROUBLE DIAGNOSES AND CORREGTIONS Probable Condition Difficult to intel11lesh gears Causes Jor difficu t gear shifting are classi fied to troubles concerning control system Worn gear When gear shift lever is and it is difficult to shift gears clutch heavy also be unsmooth First disengagement may loose sliding part and transniissioo make that sure Corrective action cause shaft and Replace bearing or Insufficient operating stroke due to Faulty or pair worn or or replace Replace damaged synchronizer clutch operates correctly and inspect o transmissi Gear slips out of mesh In most interlock b all worn is or this trouble cases check ball weakened In this faulty or occurs and or when spring is when control system the trouble cannot be case corrected by replacing gears and therefore trouble shooting must be carried out care fully out It should also be noted that gear of mesh due to vibration weakened fron t and rear engine slips generated by Replace Worn interlock ball Worn check ball and or weakened or broken Replace spring Wom fork rod ball groove Replace Wom or damaged bearing Replace Worn or damaged Replace gear mounts Noise When noise ceases when noise occurs indicati90 occurs with engine idling and clutch is disengaged or while shifting gears it is an th e noise is from transmis that fa ule during engine idling air fuel Check mixture and idling above procedure Add lubricant Oil leaking due to faulty oil seal ignition or Clean sealant Of breather a Replace bearing Cyclic knocking sound at a 19W speed Replace bearing High humming occurs at high speed Damaged also occurs readjust engine oil etc clogged timing After improper or replace with designated oil Worn Transmission may or when sion t Insufficient Worn spline Replace Worn bushing Replace j MT 23 replace Manual Transmission SPECIAL SERVICE TOOLS Description No Unit tool Reference For Tool number mm in Figure on name ST23540000 Fig All For removal of fork rod retaining pin or page use No MT 15 models Fork rod pin punch 150 L 5 91 i 10 0 39 2 ST22360002 dia M llBT For assembly of counter drive bearing Fig 44 MT FS5W Drift C 63A oOler dia inner dia 3 ST23800000 32 126 23 0 91 SE034 All For assembly ofmain bearing Page MT 1O models Transmission adapter 480 18 90 outer dia inner dia 4 ST238 10001 For setting adapter plate in a 44 1 73 31 122 SE037 71BT M vise Setting plate adapter 74 2 91 MT 24 SE132 Fig Fig Fig MT 14 MT 15 45 MT Manual Transmission Reference For Tool number Description No Unit tool 5 in mm page use Figure on name ST22520000 71BT M For removal and assembly of mainshaft nut 63A Wrench TIM or No Fig MT46 Fig MT47 38mm 50 1 in SE313 6 ST23860000 7IBT M For assembly of counter drive gear Fig MT42 Counter gear drift 7 KV31100400 Transmission dia 38 inner dia 30 331 For assembly of rnainshaft countershaft counte counter drive 50 outer SE039 M 7IBT drive gear and bearing 48 press stand 0 189 75 Q 2 95 0 Fig MT 37 Fig MT 39 Fig MT44 J I 0 8 STJ0031000 For TM438 All replacing bearing models Bearing puller 80 3 15 50 1 97 SE041 MT 25 Fig MT 21 Fig MT 23 Fig MT 25 Manual Transmission For Tool number Description No tool 9 Unit name KV32101330 Bearing puller For removal of mainshaft end b lg ari Reference use mm counter overdrive gear and in page Figure on 63A fM l FS5W bearing 7IBT M 11 300 81 SE308 MT 26 Fig or No 64 MT SECTION AT j L AUTOMATIC TRANSMlsSIO N DATSUN PICK UP I MODEL 620 SERIES I DESCRIPTION At HYDRAULIC CONTROL SYSTEM AT 4 REMOVAL AND INSTALLATION AT 33 MAJOR REPAIR OPERATION AT 36 TROUBLLDIAGNOSES AND ADJUSTMENT SERVICE DATA AND SPECIFICATIONS SPECIAL SERVICE TOOLS I NISSAN I I NISSAN MOTOR CO TOKYO LTD JAPAN 2 AHD AT 59 AT 62 Automatic Transmission DESCRIPTION The model 3N7l B automatic trans mission is a fully automatic unit con element hydrau sisting primarily of 3 lic torque converter and two planetary Two gear sets brake dimulstipcle clutches dimulstipcle one way sprag clutch provide the friction elements required to obtain a the desir d function of lhe two plane planetary of the gear automatic in relation sets gear three forward ratios and on range also be manifold constantly fed are one ratios is to give reverse vehicle fully speed to vacuum signals the transmission provide the proper gear ralio for maximum efficiency and performance to at all throttle openings R N D 2 1 9sition LP I used 2 for engine 2 range can vehicle speed mission from be selected at any and prevents the trans shifting out of second gear I I be selected can range at any vehicle speed and the transmission will shift to second gear and remain in second until 10 vehicle 40 50 kmfh to 25 I gear prevents the position range transmission from out of low shifting This is particularly beneficial for maintaining maximum engin braking when continuous low gear operation is Identification of number Arrangements See below The torque converter is of assembly can nOlbe from rolling Model code disassembled for service JAPAN AUTOMATIC 0J in either direction This position should be selected whenever the driver leaves Ihe vehicle Thc engine may be slarted in Park FLUID RECOMMENDATION Use position automatic having R Reverse vehicle to be range operated enables in the transmission DEXRON fluid identifications only in the 3N71 B automatic I MODEL X2402 I I NO 4912345 I Unit number sion a reverse Neutral position enables the be started and engine driving the vehicle normal LTD Number designation to 0 J TRANSMISSION CO transmis direction N Identification number to 30 MPH welded construction and Park position positively locks the I hicle speed is reduced v approximately the output shaft to the transmission case by means of a locking pawl to prevent Fig AT desirable The model 3N71 B has six selector 1 can performance surfaces slippery braking and engine torque input V chide speed and engine range provides AT344 tary gear sets The two Changing 2 for driving a band brake and a 2 Drive range is run used without for all driving conditions Drive range has three gear ratios from the starting ratio to direct drive IDENTIFICATioN 4 9 NUMBER I 234 5 L Stamped position The hand plate is attached to the side of transmission shown io Figure AT I AT 2 right case as Serial production number for the month Month of production X Oct Y Nov Z last figure denoting the year A D Dec Automatic Transmission J o II IIlI r I r AT288 I Transmission 2 Oil ca e II Governor shaft 12 Output 13 Rear extension Oil 3 pump Front clutch 4 Band brake 14 5 Rear clutch IS 6 Front 16 7 Rear 17 Input Jlihafl Torque converter 8 One way clutch t8 Converter 9 Low 19 10 planetary gear planetary gear Rever5e brake pan Control valve housing Drive plate Tightening torque bolts and nuts kg ft lb T @ @ T @ T 5 5 33 1040 0 6100 8 4 106 0 5 to 0 7 4 10 5 T 2 @ CD 4105 T T T T AT3 of @ @ Oil distributor Fig AT 2 T m T 29 10 36 10110116 141016 4 5 to 5 14 10 18 0102 3 10 18 9 10 13 1 0 55100 75 4 105 0 25 10 0 35 2 to 3 Cross sectional view of 3N71B automatic transmission Automatic Transmission HYDRAULIC CONTROL SYSTEM CONTENTS FUNCTIONS OF HYDRAULIC CONTROL P RANGE PAR K AT14 AT 4 R RANGE REVERSE AT16 AT 4 N RANGE NEUTRAL D1 D2 D3 UNIT AND VALVES OIL PUMP MANUAL LINKAGE AT 4 VACUUM DIAPHRAGM AT 5 DOWNSHIFT SOLENOID AT 5 GOVERNOR VALVE AT 5 D CONTROL VALVE ASSEMBLY AT 6 2 HYDRAULIC SYSTEM AND AT13 MECHANICAL OPERATION FUNCTIONS OF HYDRAULIC CONTROL UNIT AND VALVES Oil pump Manual strainer I I I diaphragm RANGE 12 RANGE 2ND GEAR source oil for is of an and serves I of the port Transmission Lower port Control port Pump The hand lever motion gear space remote transmitted control to the hand s compart transmitted from linkage is further the inner manual lever in the transmission case from the range selector lever in the right center par tion of the transmission case the manual shaft lever is A I Housin 4 Inner gear 2 Cover 5 Crescent 3 Ouler gear suction Pump mechanically ment AT071 case r lever is localed in the driver route Oil pan Oil strainer bottom of the control valve Control valve lower brake MANUAL LINKAGE valve line pressure circuit with the engine operation The oil flows through the following Pump housing appropriate body ly coupled suction port reverse Lubrication internal Transmission oil Band brake to drive the pump suction port regulate to 1 converter Low and inner gear with the drive sleeve direct body valves transmission components lhe pump The pressure and direct it I involute gear type The drive sleeve is a part of the torque converter pump impeller transmission Rear clutch control system The oil AT 30 AT 32 solenoid These parts work in conjunc tion with valves in the valve body assembly located in the base of the I delivery delivery port e Torque I case control downshift I Control valve housing delivery the LOW GEAR vacuum I OIL PUMP pump is i medium and AT 28 t pump for packing p oil oil pan through the oil A shift control is provided by diaphragm AT 26 Front clutch Governor valve oil KICK DOWN centrifugally operated hydraulic control I Downshift solenoid The RANGE linkage Vacuum AT 22 AT 24 the two con 2ND GEAR RANGE TOP GEAR tains an oil from AT 20 RANGE 2ND GEAR governors on the output shaft The hydraulic control system RANGE AT18 LOW GEAR RANGE Fig AT 3 Oil pump 4 AT thereby through The inner manual turned pin installed on the bottom of the inner manual lever slides rhe manu al valve spool of the conlrol valve thus positioning the spool opposite rhe appropriate select posilion The parking rod pin is held in rhe groove on the top of Ihe inner manual Automatic The plate rod parking pin operates the range and operates the mechanical lock system rod p at The above described manual shaft is further equipped with switch A range p the inside rotor switch rotates in inhibitor an inhibitor each to response When tne range is selected N or starter engine the circuit magnet be can started is selected at back up R lamp lamp lights at closes the rotor that so flow When the range circuit and the back up velocity of intake m mifold increases since slow is the inside the mixture Contrarily when the engine speed increases and the flow velocity of the mixture in or creases the when carburetor I c C r 11 Kickdown h Dowri switch shift solenoid is closed the manifold negative pressure increases Le tends towards vacuum and the the the rolor closes the reaction vacuum Transmission vacuum Thus at loading control valve is trans trye from and the Fig most the vacuum diaphragm suitable timing for speed change and lin e pressure is obtaine so that the most proper torque capacity is AT 6 Downshifl80lenoid signal to generaIe hydraulic rfe tly suited to the engine a pressure P mitted AT089 reaction is reduced obtained against the transmitting GOVERNER the back of the oil distributoron the ft sha tn y op as thar iJf tile speed output shaft thai is they operate at a speed in proportion 10 the vehicle speed The line press retis applied to To manifold lkc inl outp transmission erate torque VALVE The primary and secondary gover nor valves are installed separately on the al those t same valves the input from the s through the transmission flange and oil distributor control valve case CD The governor the to ATOB7 1 2 Manual pia te Inhibitor switch AT088 Manual shaft Fig AT 4 Manual pressure in linkage vehicle is led to the shift valve ofthe control valve opposite the through route of the output In Fig AT 5 Vacuum diaphragm proportion shaft speed ouiput speed rod Parking rear this manner and line pressure speed change are controlled VACUUM DIAPHRAGM The on vacuum the left transmission diaphragm portio n of the center The case DOWNSHIFT SOLENOID is installed internal struction of the vacuum con diaphragm is follows as and A rubber diaphragm The tion in the center manifold through negative a vacuum forms engine a parti intake pressure l led tube and spring applied to the front surfaceof the rubber diaphragm while atmos pheric pressure is applied to the back force is surface The difference between pres sure to the front and ba K I applied surfaces a causes reactIOn vacuum which activates the throttle valve of inside valve the control the transrhis sion case Wheri accelerator the th pedal engirie suificientl plre sure is fully de buretor is fU IIy increased towards downshift e solenoid is dePresses down switch the the to sp eed is not the manifold lowers Le atmospheric pressure tends and the of a 19ca accelerator pedal stopper ted in the a kickdown middle of the accelerator link is depressed by a push rod he kickdown switch doses cur rent flows to the solenoid noid push rod is depressed the sole the down shift valve of the control valvc insidc the transmi ssion case is the speed 3rd cle to speed Note depressed nd changed forcedly fmm 2nd within a cerlaill vehi is limit Since theki kdown closes when the accelerator pressed and opened but negative T magnetic type installed on the left re r portion of the transmission case When a driver requires accelerating power arf rd The wries a pedal is ped adjusted omplete stro arrangement ccording AT S m eI so as I valve swit h secondary T e secon ary valve is a contro valve Y hich receives line pressure an cqQ rols the governor pressu e When D at is the manual valve is selected 2 applied or t l range line pressure the ri this valve from g sh aped circuit I of area l and this I v is depressed Jy tI lOW jr Movemcnt of this valvl III positillll 15 rronl sr simultaneously IS press port and lowered to re in Iii cenlrifugal v fer cr a in Olto making a center dniin it l5j is stopped 1 d the tllc When thc vehicle is the c doses the dr uit from while cirJ force of this valve is zero lve is balanced At this poini a govcr lOr pressurc yhich bali1 nced with th spr ng force occurs on IS Wh e of the of governor switch depr ssed from 7 i t I S I 6 of tiie whole stroke the a ccel rator 1 should be correctly Operation n thc vehicle is st rted nd the centrifugal fqr incre ses this valve movcs slightly 10 Ihc oUlSide and as Automatic Transmission the space from I to IS increases to the drain port space from 15 As decreases simultaneously of governor pressure 15 a To onlml valve resull j 1I5 S1I pre force 1 to J J Q Ai09 1 Fig AT S Output shaft with oil CID The governor thus changes in response I f increases and the governor pressure is balanced with the sum of centrifugal force and spring D@ l Governor pressure the vehicle distributor and l overnor force speed change centrifugal r m @ Line Operation of prlmar The nor OFF ON l Primary 2 Secondary governor Governor valve body governor 4 Oil di lributor 5 Output governor minimum the speed exceeds speed aBUlllI8 certain level I Oil distributor 2 Governor nlve 3 AT092 Primary governor valve 4 body Secondary governol valve Fig and when the vehicle a V iUQlli JlAU governor pressure regulated by the secondary gover valve when the vehicle reaches the closes 0 lft sh Fig AT 7 Cr05s sectionallliew of an @ AT090 valve which IS is valve t I 3 governor valve pressure AT 9 Exploded view of governor the governor opens and forwards the gov ernor pressure 15 to the control ASSEMBLY CONTROL VALVE valve Flow cbar of control valve system When the vehicle is stopped the pressure is zero However when the vehicle is running slowly this valve is depressed to Ihe center governor and the groove to 15 the governor pressure is closed since to the applied ring shaped area is higher than the centrifugal force of this valve When the governor speed exceeds a certain revolution the governor pressure in the circuit 15 Oil from pump also increases j i as the centrifugal I I I I I Throttle valve I I II Manual valve How Auxiliary valve t t I I I I I Line pressure I I L L n j the governor pressure is transmitted to the circuil I I force increases and exceeds the governor pressure this valve moves toward the outside and 1 l I ever Regulator valve Speed change valve I I L I I Governor valve I I 1 L 5 Two different valves in the governor so are j employed Clutch and brake that it will inde speed at high pendently and low speeds That is within the low speed range the governor pressure is not generated because of the primary control the The control valve assembly receives oil from the from pump the and vacuum individual diaphragm valve whereas at the high speed range signals above and transmits the individual line pres sures to the transmission friction ele the pressure is valve The breaking point regulated by governor the secondary breaking point is the point one at of the governor is transferred to the other the speed changes from the as low speed to the high speed range changeover valves including ON valve and regulator valves are newly reformed to a throllle system and oil pressure and operate other valves Finally the line pressure is transmilled to the required dutch or brake servo lubricating system circuit as outputs More specifically the oil from the oil pump is regulated by the regulator pisJon unit in response to the individu af running conditions after re ejving signals from the va uum diaphragm line pressure build up the line pressure is fed out from the control downshift ment which the function of tion OFF valve valve torque converter circuit as assembly through 6 AT various direc and or solenoid manual linkage governor dlvc V Automatic Transmission the line pressure The control valve assembly consists of the following valves See Figure 16 pressure 6 and the throttle 18 to equal is AT 20 I Pressure regulator valve 2 Manual valve 3 I st 2nd shift valve 4 2nd 3rd shift valve 5 Pressure modifier valve 6 Vacuum throttle valve 7 8 Throttle back up valve Solenoid downshift valve SDV 9 Second lock valve SL V 10 Manual valve PRV MNV FSV converted motion of reciprocating through a pin and positioned so that the line to the manual valve PMV VTV TBV the MNV is the indi pressure 7 is distributed to vidual line pressure circuits at each P N R D 2 I or range shown below as TMV P range 7 regulator valve Pressure motion is turning The manual lever SSV 2nd 3rd timing valve MNV 4 SDV and TBV 5 FSV Low 12 TBV and reverse brake PRV R The pressure regulator valve re ceives valve spring force force from the created by the throttle pres plug force With and line 16 sure pressure 7 throttle pressure of the and 18 11 the interaction of those forces orifice 20 depressed 7 port As shaped a area up to R When the range is selected at 6 is Reverse the line from moves applied has also been opened result the is oil the oil in circuit As filled 14 above 6 PRY and SSV F C 7 a manner line 7 pressure When vehicle speed None I Governor valve FSV and rear clutch 2 SLY 3 SL V and SSV range 7 identi I Same 2 SL V 4 SDV and TBV as above 9 Band applied further in I range 7 increases and the governor pressure rises the theot tle pressure 18 is applied to the port the top of the PRV and pressure is applied contrarily against the spring I Same as above 4 Same as above 5 FSV on a with the line pressure 7 decreases Moreover at individual con force As and this further used for lubrication of a result ditions the line pressure unit Moreover part of the oil rear the plug in 10 the ly Ihe space circuit 2 creases from port 7 to the converter oil pressure 14 subsequent is range caito the throttle pressure 16 and is added 10 the spring force Consequent balanced with the spring force there by balancing the PRV In this opera pressurized D pressure such extent that the converter range through space to the next drain port marked X in Figure AT 10 with opens slightly Thus the line pressure 7 is tion N Fig AT 10 Pressure regulator ualue the PRV is result downward and above same as AT095 pump is ap from the oil the ring to same as 5 7 driving conditions The oil 4 and band release the PRY regulates the line pressure 7 to that most suitable for individual plied range 7 7 is equal to 1 Moreover 6 are where 3 2 always drained the line tributed from 4 at pressure a is 5 and position not dis 7 is branched and used for lubrication of the front unit for the front and rear clutches When presscd creases Ihe accelerator pedal is de u the throttle pressure 16 in as described in the preceding paragraph oil pressure the plug through orifice is 21 applied and this pressure is added to the spring force As a result the PRV is contrarily forced upward is reduced and space to the drain Ihe jd to P l tJj 1dIil lt R N JJX dlMIi W fitMi td ld IiIb j L@ g4Vhl 17 l It i x x port line pressure B J jj AT096 7 increases Fig AT AT7 11 Manual ualvp Automatic Transmission 1st 2nd shift valve high The FSV is transfer valve which a shifts gears from low second When to Ihe vehicle is depressed the right side by force of to stopped located spring putting the position a the the on FSV is in FSV left the Ihe 15 pressure is side of the FSV right toward the returned to the left the line pressure I Low alled is This j 1 c5 to 13 Contrarily togelher with the I 15 level the exceeds the pressure and Ihe governor sum When the FSV closed the is depressed 10 and only the spring FSV toward depressed to the right I a Fig the end for a moment As AT 12 lsl 2nd engaged through the SLY and the speed is shifted to 2nd With the When the vehicle is accelerator pedal is remains iIi the depressed Low the FSV position unless the governor pressure IS increases to high leVel corresponding to the line pressure I since the line pressure I a increase when the accelerator pedal is depresse9 Contrarily decrease shifted Howeve f to pressure governor the creases when vehicle speed de Low the gear 15 is not nless the governor pressure 15 becomes zero since the force depressing the FSV toward the right is being delivered only by the spring in range low and reverse I clutch through 5 sure 2nd is end line simultaneousiy is led to thougp creases the from line pres prbssure led to 12 the spring unit Consequently ieft al the goverflor in pressure the valve is still forced toward right Low shifts gears forced is so and the SFV is fixedjn the position When kicked down to speed the SDV operates 2nd and the line pressure 13 forces the FSV toward the right Although the right by the 2nd d however design the SSV stopped the is in the position It that the FSV decide to shift either Low to or 2nd When the vehicle pressure the right end surface the is running 15 governor is and forced toward the left applied th to Contrarily When vehicle speed exceeds a tain level the governor pressure cee sur spring force line the forces the force SSV the toward thus the SSV is end for depressed pressure pressure leased a Con being rapjdly depressing the right decreases and depressed to the l ft moment With Ihe SSV toward the left end lhe line 3 10 is connected with the line the band servo the front clutch is engaged 8 AT is re and line SDV and is led from the toward the right high the is forced valve loward the right completely 2nd to tht and posi fhis operation is called K cli down shift iever When the shift 2 I or the line pressure MNV and shifted is range at the 3rd to speed 3 if diained at the Consequently the front clutch band servo drained As a oils releasing are result the transmission is shifted to though the SSV is in the 2nd low or speed ai posi 3rd tion When the specd IS 1 3r way a topof one shifted io the orifice 24 the on the SSV relieves oil transmitting velocity from the line pressure 3 the line pressure shock generated Contrarily to 2 I or 10 fioni drained shifting the is shifted range and the speed is 3rd to the 2nd the orifice checking valve effective to and reduces the when the lever depressed is then closed shifting 3rd at siderably line unbalanced 3rd to is con shifted from sequently 2nd is forced pressure and throttle pressure and the valve is forced toward the left The 3 to speed slightly lower a ure the toward the right 3rd the governor pres SSV is line pressure 3 l force Spri and throttle press re 19 force the SSV pressure Shifting slightly a Although 3rd to is returned at from SSV is thus returned SSV 2nd toward spring and can from passes the sum of the Low shift valve transfer valve which a position 13 SSV the tion SSV is the SSV occurs at pressure 2nd 3rd shift valve The 2nd speed shifting 3rd When kicked down AT091 is while applied to than that for q depresses the resull line p ressure lJ is for to 8 the band servo is a warded 1 is and it 2nd the I r the I position the lire pressure from 2nd t of the throttle is right which lower FSV is forced toward the left certain In the 3rd position force de pressing ihe SSV toward the right is retained only by the throttle pressure 16 and the throttle pressure 16 is slightly Idwer than that toward the Consequently a pressure spring force and the throttle pressure 19 are high allll the SSV is thus retained in nd to 0 certain 3rd When the accelerator pedJI is de prcssed both the line pressure 3 and unless the governor pressure 15 ex the line pressure 3 and the throttle pressure 19 the When the vehide speed exceeds is shifted to speed ceeds 15 the FSV Kickdown shift spring force force the FSV toward the right opposing the governor pressure the the position 15 and the FSV is forced toward is operation and right the low applied considerably the valve is forced completely side When vehicle speed increases governor is is 15 governor pressure FSV the throttle the spring line pressure quickly and 24 is becomes in delay in 10 is shifting speeds is thus eliminated The throttle of line pressure 6 transmits Hie oil transmitting velocity from line pressure 6 to line pressurc 10 wtien the lever is shifted to the R ty range from and transmits drain veloci line pressure 10 to line Automatic Transmission 6 when pressure 2nd to at end readjust generated the piessure loss is added to the spring force and the plug is lhus forced back from the right to the left When this pressure 19 increases ex cessively the plug is further depressed which varies toward the left from shif ing range D 3rd Thus the throttle of line pressure 6 reduces the shock generated froshifting A in plug the throttle depending the SSV left piessu e I 6 on engine the throttle con 19 throttle pressure suiled to the sp ed change control Moreover the plug is a valve which applies line P esspre 13 in lieu of the dition to throttle a to the SSV and the pressure FSV when kickdowri is space from the lhrot tle pressure 19 to the drain circuit 13 increases and the throttle press balanced 19 Wheri SDV the space is formed from 6 10 19 A throt throttle pressure 19 is lower by the tIepressu 1iFh w drained right slight a pressure loss equivalent throttle to Ii the to performing a moves speed decreases governor ipressure 15 de the force toward the fight when the vehicle rily arid the creases governor exceeds ithe valve is forced back and the throttle is valve the pressure is led pressure are line pressure the toward the right 18 is sWitched when the pressure drained to the spring unit throttle the is reduced Contra 7 pressure source and high both Tow or the governor when tIiey are i which had been 13 circuit pressure and the force of the line the PRV This 6 from 19 circuit pressure value kickdowri line high plug is pressure certain against the throttle pressure performed throttle the reduced the Thus imd the is pressure 16 is applied to the left side of this plug and the plug is epressed toward the When decreases 19 ure 18 This throttle 16to circuit pressure 18 is applied to the top of i the plug is forced toward the left and circuit 19 becomes equal to 11 I 16 18 the line pressure 13 to this space is n r I 3 f Jit 1 I 15 ng valve Fig AT 14 Pre 24 15 3 Vacuum thro I I The regula W L valve Js I i ilr the vacuum dia ATOgS throt le 2nd 3rd Fig iT 13 shift vallJe the pressure in When plied to Odifier valve PMV When the governor I to the operating pressure Compared required in starting th vehicle ppwer trimsinitting capacity of is required at high to a high of the value and the spring foice and t he circuit from circuit 18 vehicle nor pump loss also jncrdases In order to lrott pressure must le prevent his the t hanged over is forced ence the speed shock gerieraled from shirring increases arid the oil l the valve the PMV is low vehicle be IS right side of toward the right by the throttle ines sure 16 applied to the area differ operating pres level up pressuie the When the line pressure is a to the applied the may be lower when the vehicle is started which is with the operation of pressure level the left is closed speed circuit 16 15 to However when increases andl the exceeds gaver a certain toward the governor pressure applied to the right which is side exceeds the spring force and the throt 16 the governor pressure 15 to reduce Ihe line pressure The PMV is used for tle pressure this purposc the throttle pressure is led from valve is toward thc right the depressed depending condition vacuum on the negative inta e line line pressure 7 is ap the bottom through the valve va ve is forced upward space from the line pressure 7 to the throttle pressure 16 is dosed and I Pressure retained a line the the hole and the 1 The diaphragm phragm yories engine t rH once uses I I sure VTV valve is 7 for the pressure source pressure and regulates the throttle pressure 16 which is proportioned t the force of l r clutch that rottle whiCh AT099 modifier valve le valve t vacuum tor ure loward the lefi and AT 9 circuit the space from the Ihrottle pressure 16 to the drain circuit 17 is about the throttle to open In this operation lower than the 16 becomes pressure ureY btthe linep of the loss of s alenl p e space sur 9 iv and Ihe if thevaeuum rod depressing tlie diaphragm is balanced wit Ii thethrot tie pressure 16 a pplied upward tOlthe force bottom When the erigine torque in the negative pressure rises tending ioward pressure is high Ihe intake iirie atmospheric and the force of the rod to depress the valve increases As a result the valve is depressed downward the Automatic Transmission space from the throttle pressure 16 to the drain 17 decreases and the space from the line pressure 7 throttle pressure 16 increases Ihe to torque lowers and the negative in the intake line lowers toward vacuum depressing pr tending the force of the rod the valve decreases and the throttle pressure 16 also decreases When pressure regulated by the throt tle p valve back described in the subsequent paragraph is led to circuit 17 a high pressure is applied through the space from the circuit 17 to the throttle pressure 16 Consequently the VTV is unbalanced 16 pressure becomes back up pressure locked upward 17 r the pressure Consequently the throttle pressure 16 increases and the valve is bal anced Contrarily when the engine sure to Ihe upper drain about to open back up pressure 17 which is lower than the line pressure 4 by the 17 circuit 4 with the loss due to the space from to circuit 17 is balanced spring force Further 2nd when gear is shifted from Low to at the range pressure is led from circuit I line 12 and the line pressure is applied the bottom of the valve valve hole forced Consequently and upward pward to the through the valve is locked As a result the space from the line pressure 4 the back up to closed is 17 pressure and the back up is drained upward completely 17 pressure AT102 the throttle equal to Fig AT 17 Solenoid the hift valve dow Second lock valve and the valve is This valve is assists the transfer valve which a shift valve in fixed the SLY 2nd determining the at speed 2 range In the D force spring APplied upward 2 sure area AT101 difference line of the pressure applied as a sum ds the xce which is As a result the range and linepres to the valve downward force the valve is locked upward and the circuit from line pressure Fig AT 16 Throttle back up Jlve lJ to line pressure 9 is Consequently 2nd speed the I 16 pressure is engaging circuit pressure Solenoid downshift valve Fig AT 15 AT100 Vacuum throttle valIN when Usually is TBY depressed downward by the spring force circuit 17 is drained upward As soon as and the lever is shifted either 2 or I range line pressure is led from circuit 4 the line pressure is to applied valve to the area difference of the the valve is forced upward the from circuit 4 to circuit 17 is space closed and with the space from circuit a kickdown signal is re from the downshift solenoid ceived this valve transfer valve which leads the line pressure 7 to 13 and transmits the same to the FSV and SSV Throttle back up valve a Usually the solenoid valve locked are rod and upward by the spring in the lower end line pressure 4 push and the circuit from to FSV becomes condition the and line to the band 9 only when line servo is released to line pressure 1 In the This valve is 2 is retained the range only on upward downward line pressure the upward As 2 exceeds force result a force the spring and the Ihe valve is locked downward line pressure 2 is released to 9 regardless of the operating condition servo is of the FSV and the band engaged J line pressure 13 is opened When kickdown is push rod operates pressed downward from line pressure performed Ihe and 7 the 2 valve is de the circuit line pressure 13 opens Line pressure 13 opposes the governor pressure 15 at Ihe SSV and FSV thus to accomplishing downshift operation AT 10 8 opened 8 SDY III led 3 the 8 ATl03 3 Fig AT 18 Second lock Jlve lJ Automatic Transmission valve 2nd 3rd timln TMV the force exceeds the down upward ward force the valve is locked This valve is switches orifice sure the 22 a by transfer valve which pass circuit in the front circuit II of the clutch pres in response to vehicle speed and throttle condition A force created IS TMV is when applied the governor pressure to the bottom of the constitutes the upward force and passage from circuit l0 from the closed Top Consequently to the top of the TMV consti pressure II through the orifice 22 However under normal throttle pressure downward force applied is and the oil pressure is thus transmitted slowly force the the line 2nd II is led to the front clutch circuit exceeding and circuit 10 and a force created when the spring throttle pressure are to upward force a certain As a result tutes the downward force downward When the throttle pressure 16 is lower than the governor pressure IS 10 16 shifting has a level exceeds the the pressure and the upward the valve is locked AT104 the passage from circuit to circuit II is opened and the orifice 22 is bypassed ATll Fig JlT 19 2nd 3rd timing valve Automatic Transmission ern I n d lLU J I A1094 1 2 Pressure regulating valve Manual val MNV 31st 2nd shift val fSV 4 2nd 3rd shift val 5 Pressure modifier valve SSV PMV 8 Vacuum throttle valve VfV Throttle back up valve TBV Solenoid down shift valve SDV 9 Second lock valve 6 PRV 7 10 2 3 timing val SL V TMV Fig AT 20 Controloolve AT 12 Automatic Transmission HYDRAULIC SYSTEM AND MECHANICAL OPERATION The operating system of oil pres in each range is described below sure The oil in pressure each circuit shown in the illustration is classified as follows according to the function fhe numeraJs show the circuit num Oil pump suction hole bers Pressure source of the line 7 Operating Iinc prcssure for friction elements ATl06 123456 8910 1112 Auxiliary line pressurc Fig AT 22 Identification of oil channels in 13 case front face Throttle system pressure 16 17 18 19 Others 14 15 I Oil pump discharge hole 7 o dischar hole Oil pump Torque Rear converter pressure iutch FTOOI c1 J1 Governor pressure 15 I9JM Cd Torque 7 tL h prc 011 pump 14 ur 14 clutch pressure l Rear 1 surc prc converter pressure It Sllctlon pressure M Os ervo Ie I ease pressure 0 10 Servo t ightening 0 IT U 11 Front clutch hole f 0 c1L 1 c pressure 9 ho lJ I I 0 rrOil J r F T pump suction hol JC CJf Governor feed pressure l L L reverse LIO brake pressure 12 II O An07 IIJ1iIII AT105 Fig AT 21 Identification of oil channels in oil pump Fig AT 23 Identification of oil channels in AT 13 case face Automatic Transmission P PARK RANGE The operation of clutches and band Neu are functionally the same as in tral parking however when the parking pawl meshes in a gear which is splined to the output shaft the output In shaft locked mechanically is from Lock Free rotating AT086 Fig AT 24 Parlling mechanum oil The pump is fed discharged from to each part the oil a CID through circuit valve 5 s As the the line pressure 1st 2nd shift to th force right actuates the low and Also teeth of the oil distributor by of the manual lever locking the output shaft Fron Rear brakt Operation 2 132 on the r clutch Neutral PI Drive Ihe Lw 2 on 3 P2 Second 14S3 on 03 Top 1 000 on on on on on outer Second 2 458 1 means mechanically Release On on on reverse through the groove parking pawl engages with brake ervo on er hand ide by the spring the line pressure 5 and 12 atia Park Re Band IlYer5e N has been introduced into the manual I st 2nd shift valve Il reaches the valve Range Low Clutch Gw similar range The oil having the line pressure 7 which manner to that of the in 12 Second 1458 II Low 453 2 AT 14 on Parkin pawl Automatic Transmission P Park range A L k r k 8r ll FrOl ter Con Torqu I Au Clutch tth 0 I ump rr 4 f 1 1 r I I r I 011 Coo I AM Lubr i t n TIlro V v v t 1 j 1111 il III l n rt 1ft lv Front o to Sol BI Cow VK II D V I 1111 tlo CID I r Llrll I Orlflc K v Throttl Dr ln v 2 ID Mocl 1 5 II 11 @ I J w 5 2nd 3 V l d Timing JQ I r R 3J I IKOnd Lock I II D tOl V V L Not q I nu V u l P 21 I Or LlMl pr J1 r A I J I 1 BIeOM OOll I IV nor Oo rr J ll n ln 10010r r J2 3 l II t rk l II I l I t rJ R V Y M rlmarv OoverrwJf VIIfve or It Torqu conv ner Throttl Fig AT 15 A T 25 Oil circuit pressu diagram P range Parh Automatic Transmission RANGE R R In REVERSE range the low and R the front clutch and reverse brake applied are The power flow is through the input shaft front clutch and connecting shell to the sun tion of the sun Clockwise gear gear clockwise rotation of the the With ry gears planeta rear connecting drum held stationary by the low and brake the the rear rear rota counter causes reverse gears rotate planetary internal gear and drive the flange counterclockwise The drive flange splined to the output rear shaft rotates the output shaft counterclock wise at reduced a increase in torque for speed reverse with Fig AT 26 Power tranamis ion during an R range gear m i 1 ATOBS Fig A T 21 Optrationof each mechanism during When the manual valve tioned at R line pressure pressure V is posi Gear range the oil having the 7 is directed to line circuits 5 and 6 Ranae ralio Low Clutch Band One servo re ne Front Rear brake way Openlion Relulie clutch into line pressure circuit through the I st 2nd shift valve Park 2 182 Ruene on on on servo led DI Low 2 458 on D2 Second 1458 on D3 Top 1000 Second 1458 on on 12 Second S8 on on II Low 2 458 on and the front c1u tch after to through line the circuit pressure 2nd 3rd being shift valve CD and press against its valve Driowe 0 @ degree of accelerator pedal depression both act on the pressure regulator 2 CD increasing line pressure 7 In Rn range the governor pressure is absent making all such valves as the shift valve @ on the release side of the band The throttle pressure I 6 and the line 6 which vary with the pressure valve Neutral The pressure in the circuit op erates ID and pressurc lnd 3rd Partina plwl on on introduced ID range The pressure in the circuit 5 actuates the low and reverse brake after being 12 R 1st 2nd shift valvc modifier valve inoperative AT16 on on on on on Automatic Transmission R range Reverse Low Br Con Torq Front ltc Cll a Aev k k B I R Il Clutch f r III rr I CID VEL 1 Thrc V Oil Cool I 1 11 I A Lubtlcetlon r 0 o or ln Vel iL l n I IU 111 11 T Ilrfl Ir l I II II Front jL r I r r r Orlflc LJ Check Velve Throttl D ln 2f v ID @ l 2nd 3n J lf v If I @lnd n 22 e Mc p 3rdShlft v D h I 1i t lil Timl x II 5 r Q A uletor U Val nu r 1 NIJte L kld Ll ni l3 II O nOl ft p r a Goy nor v Q V 1ve l norpreat Torque Throttl 15 eln O p 15 rmrp p Fig AT 17 A T 28 Oil preBBure circuit diagram R range Reverie Automatic Transmission N RANGE In N and band range are transmitted NEUTRAL none power is the output shaft applied to of the clutches thus Geu no R atio Low 4 Clutch Front Rear Park the The pressure of oil discharged from oil pump is regulated by the pressure regulator valve Dto maintain the line pressure 7 and the oil is led to the manual valve @ vacuum throt tie valve valve @ @ and solenoid down shift converter at its torque erating pressure 14 and a op portion of this oil is distributed to each part as the front lubricant The oil which has been from the torque con verter is also distributed to eacn part as the discharged 2 182 WI clutch on Drive on on Low 2 458 on D2 Second 1458 on on m Top 1000 on on Second 1458 on on 12 Second 1458 on on II Low 2 458 2 discharge increases with engine speed oil is returned to the oil pan by the pressure regula tor valve D AT la on on on on Pultin pawl on Dt rear lubricant surplus Release Neutral As the oil pump rotates at the same speed as the engine the oil pump But the Operation on Reverse The oil is further introduced into the brake One Band crvo on Automatic Transmission P range Park 1 Brllk ar Con Torqu Front Cluteh u Bond o ID VK Th V all o I IftY II Coo A k tlon Lb II e 1 I Front LubrkIt n Orltlc Check O ln V I ThrOttle D ln V 21 j r tUI lor V h @ V hI 5 I N01 M rked X Line r D I ln pr Go nor td pr I no Ocw J L J c Q RO V Gover V p Torq Th ottl X y Iecond co p f p Fig AT IS A T 25 Oil pressure circuit diagram P range Park Automatic Transmission R RANGE R In REVERSE the low and R the front dutch and range reverse brake applied are The power flow is shaft through the input clutch and connecting front shell to the sun tion of the sun gear Clockwise rota causes counter gear clockwise rotation of the rear planeta the connecting drum held Slationary by the low and reverse With ry gears brake the the rear planetary rotate gears internal gear and drive the counterclockwise The rear rear flange splined to drive flange the C output shaft rotates the output shaft counterclock wise at reduced a with speed increase in torque for reverse Fig an AT 26 Power transmi ion during R range gear f ATOS5 Fig AT 27 Operation attach mechanism during When Ihe manual valve tioned R at Ihe oil range line pressure 7 pressure circuits CV is directed and 5 is posi having 6 introduced into line pressure circuit 12 through the I st 2nd shift valve The servo led and the front clutch after to through line the The throtlle pressure 6 pressure being circuit 10 shift valve @ pressure 2nd 3rd 16 and the line which vary with 1 181 Rdr ue clutch plwl on on Driw on D2 Second 1458 on on DJ Top 1000 on on Second 1 458 on on 12 Second 1458 on on II Low 2 458 on 2 on on I shift valvc pressure modifier valve on on 1 418 the governor pressure is absent making all slldl valves as the J SI 2nd @ Operllioo Low range 2nd 3rd brake DI CD and press against its valve CD In R increasing line pressure 7 @ Rear Neutnl valve and Front Parkin wa on Revctte the degree of acceJerator pedal depression both act on the prcssure regulator shift valve One servo no k pressure in Ihe circuit op release side of the band the erates ratio Band range The pressure in the circuit 5 actuates the low and reverse brake after being @ G Ran line to Low A Clutch Ihe R j inoperative AT 16 on on Automatic Transmission R Reverse range LowaoA B e B Front Clutdt TOlQuaConverter k k Clutch 0 o ou IIi 14 Q ID VK V FI Lu IUt @ n ftV 1 lv I O j Front Lub O lnV lc Otlflce Check V ly III Throttle in O V @lnd 3rdShih V zz If @ 2nd V rd TIm Iy Second Lock V I 3 Zl R MO V l Not M LI dX k er 0 1 O p nOf f P co s O G J Torqu I Throttl 0 V O V preau 00 p pr 1 Fig A T 28 Oil pressure circuit diagram AT 17 II n range Reverse Automatic Transmission N RANGE In N range and band are transmitted NEUTRAL none applied to of the clutches Low Clutch thus no power is ntlo the output shaft The pressure of oil discharged from oil pump is regulated by the pressure regulator valve the line pressure 7 to the manual valve tle valve valve @ @ CD to Rur its at erating pressure 14 portion of op this oil is distributed to each part as the front lubricant The oil which has been verter as the Drive The oil is further introduced into the torque converter a from the torque con is also distributed to eacn part discharged rear Release clutch 2 182 on on on 01 Low 2 458 on 02 Second t458 on on 03 Top 1 000 on on Setond 1458 on on 12 Second 1 4 58 on on II Low 2 458 2 on on 1 lubricant As the oil pump rotates at the same speed as the engine the oil pump discharge increases with engine speed But the surplus oil is returned to the oil pan by the pressure regulator valve CD AT 18 on on Pukiq pawl on throt and solenoid down shift and Optruion 1 Neut and the oil is led V br ke on Reverse maintain vacuum One servo w Front PIlIi the Band G R on Automatic Transmission N Neutral ranee I a a 8 nd VK Th o Vtlv 011 Coolei Lubrlc J @ Vtlv I I tlon 11 D ln I v Ol OIIt Lubrlut D lnV O lfIC Check Vtlv I T uott O in v 8Jl 12 ht 2nd Shift y tve 5 CD Rl9UlttO Vtlv Nott M rkedX 1 or no oov z c liia in IOonOf fNd IH cs ond a y Ol V o V tve p er Torqu Throttl D r con pr p Fig AT 29 Oil pressure circuit diagram AT 19 N range Neutral Automatic Transmission D RANGE The low LOW GEAR in gear D is range somewhat different from that in I range The I c1utdl is applied as III the one way clutch rear but range holds the connecting drum The power now is the same as in 1 J range That is the power now takes place through Ihe shaft input and into the rear clutch The input shaft is splined to the rear clutch drum and drives it Rotation of Ihe rear clutch clutch drives the rear The front internal gear front planetary the cause sun clockwise of the ATOSO hub and front internal gear gears rotales the clockwise to Fig AT 30 Power transmission during DJ range to rotate counter gear Counterclockwise rotation gear turns the rear planetary gears clockwise With the rear plane carrier tary one sun held stationary by the way clutch the clockwise rotation of the rear rear planetary gears rotates the internal gear and drives the flange clockwise The internal drive is flange to the outpul shaft and the output shaft clockwise splined liIIl I IW L rotates AT08l Fig AT 31 Operation of each mechanism during When tioned the manual valve is at 3 posi The pressure in the circuit 1st 2nd shift valve The circuit second lock valve actuates the for the at same 2 leads @ change to The circuit shift valve pressure I SI 2nd circuit is 3 @ pressure 16 CD Orivt ch lch Parking pawl 2 t82 on on on on 01 low 2 S8 02 Second 1 458 OJ Top 1000 Second t2 tt on on on on on on 1458 on 00 Second 1 458 on on low 2 458 on I actuates CID the 2nd 3rd @ and pressure modifier When the governor pressure the pressure modifier valve ID direction as on on t and increases the introduced from the line a Rekase which ID high way Operation Neutral locks the second shift valve acls in such brake the shift valve valve Rur on RellerK the line pressure 7 When Ihe speed of the vehicle has increased the governor 15 Front Park changes with the degree of accelerator pedal depression presses Ihe pressure pressure On servo I 2 regulator valve Band speed change and lime throttle low Rllelle ratio @ lock valve The to 2nd 3rd 2nd 3rd the CID Clutch Cur Ran acluates the rear clutch and the gover nor and al the same time operates the speed range D the line pressure 7 introduced into the manual valve is led to the line pressure circuits l 2 and VJ to compress the spring and the throttle pressure is led to the throttle pressure 18 This against the force of the pressure regulator valve CD and also against the throttle pres sure 16thus lowering the line pres pressure acts spring of the sure 7 The governor pressure also increases with the speed of Ihe vehicle exerting a on one side of the pressure lst 2nd shift valve and counter acts the Ihrottle pressure 19 AT 20 line pressure on l and the spring which are exerting against t 1e governor pressure There fore when the governor pressure ex ceeds Ihis pressure the speed is shifted from the I st gear to the 2nd gear The further the accelerator pedal is depressed the higher becomes the 19 increasing the throttle pressure governor pressure speed change point and to shifting the higher side the Automatic Transmission 0 range Low gear L A e B Front I Conven Torque Clul Clutch 6 I Q TIC 011 p V ID v Th O V 011 Cool RUf LubtJuflon n Ii IO lln V l F ont Lub D nV lclt Orifice n V l ThroW L 01 V I 13 t 12 tt llttY 2NtSt 5 Q P P tOO V Note U X Ir no GoY Torque Th or n nor feed IO Llnep Iecotodary nOl V QoY i Y roo Oew v p co p on Fig A T 32 Oil pressure circuit diagram AT 21 uD 1 range Low gear Automatic Transmission D RANGE In this 2ND GEAR the case h rear c1ut IS the band brake the and holds applied fronl h drum dUh the connecting gear from rotating The power flow lakes place through the input shaft into the rear clutch and shell and the the front sun internal gear With the sun gear held stationary the front planeta ry gears rotate around the sun gear planet carrying the front them The fronl splined the to carrier with carrier planet being shaft output causes clockwise rotation of the output shaft at a reduced speed compared with the t of the speed increase with the As torque brake is not reverse wise in input shaft Fig AT 33 Power transmission during Dz range an low and applied the clock rotation of the output shaft clockwise rotation of rear inter causes nal gear and the rotates rear around clockwise planet the sun direction clutch will act rotation of carrier also in gear The one a way to allow the clockwise connecting drum AT079 Fig AT 34 Operation of each mechanism during Low Clutch G Range ratio Fronl Rur running D at st 2nd speed increases while range shift valve ID ing the line pressure I duced into the line I st gear moves to be intro pressure clutch 2 182 on on Drive 8 on on 01 Low 2 4S8 on 02 Second 1 4S8 on on OJ Top 1000 on on Second 14S8 on on 12 Second 14S8 on on II Low 2 on 1 AT 22 4S8 2 on on Patking pawl on Neutral the through the second lock valve @ and by locking the band servo obtains the gear condition Optrltion allow Ihrough itself The line pressure 8 is further led to the line pressure 9 2nd w Release on Revtne car brake range On servo reverse PlIk When the Band D on Automatic Transmission 0 ran e 2nd ear I I 7 I l Throttle k up ftV V II I ont Lubtlclt Orifice n CKk C alnV I Val Th ottle O 2 n S V Mod l IS Valve 13 @2rlCl 3 dShlft V 13 F 311ft 2nd Shift V l S CD Regulator V Manual V PR Nota M X r Dr nor IGov LI p norp Gov J c Iiiiiiiiiiiiiii 00 TORI fINd P ieconoery Gov nor V I n 1 i O nof Vaw r pr Thronle pr Fig AT 23 A T 35 Oil pressure circuit diagram D z range 2nd gear Automatic Transmission D RANGE In TOP GEAR OJ a 3rd gear position the front and rear dUlches are engaged The power now takes place through the input shaft into clutch rear drum of the plates clutch drum The rear The rear rear drive steel clutch and the lined drive plates of the lined drive the rotates rear clutch and the plates of the front clutch clutch directs the power flow the rear clutch hub and front through internal gear the to front net pl carrier The front clutch directs Ihe power through the connecting shell to Fig AT 36 Power transmission during now the rear sun gear Wilh the hub clutch the front speed rotate the the speed in the same the at same planet assembly forced to range gear and the sun driven DJ output shaft direction is at to provide the top gear A T083 Fig AT 3 the When creases while running 2nd gear 15 at D2 exceeds em range shift valve and the throttle pressure 2nd 3rd shift valve @ 19 moves the 8t Ral ratio Low Clulch Band One KrVO w reverK Front Rear brake Operation Rdene Reverse 2 182 on on on Neutral Drive on 01 Low 24S8 on 02 Second 14S8 on on 03 Top 1000 on on Second t 4S8 on on Second 1 458 on 2 458 on 10 1 12 on on t I Lo AT 24 on Parking pawl on on Park range clutch and the line pressure 8 acts to release the front clutch and band servo through the line pressure hani5m UDJ force of the combined 2nd 3rd mf in and the governor pressure the spring of the @ speed further car Operation of aeh on Automatic Transmission 0 range Top gear A Low lI eke B e I I D VK J mf Thro V V 011 COO va J Lubfkatlon R y o Ot al oi v L Front Lubric 1 Oriliu n Check O nV 1 1 Th onla P M lflM V 2 O eln I 5 Vah 22 x i2J 3 j R 1n 2nd Shift v 1Ye 5 Pr I Of 1 1 Manue Val 5 PRND2 r Marked Dr Nota 11 ln IOono feold P Oo no p c Torq Th onl on rs l ond y G nor y Val Goy rnor Val np pr Fig AT 25 A T 38 Oil pressure circuit diagram uD J range Top gear Automatic Transmission RANGE KICKOOWN 0 operating While 80 appruximately 55 MPII a pressing 3rd lst can also or be approximately fully t f 2nd lst to from 2 82 Opcullon Release clutch performed the Drive the 02 low cond 2458 on 1458 on on Second 1 458 on on low 2 t ooo Second 12 tl 2 3rd 2nd downshift the hne the force of the pressure lst 2nd op 13 shift valve spring oppose the governor pres I st 2nd shift valve at the sure 15 and thus st perform 3rd 2nd operation on t eration Moreover on on on Top D on on 1 458 15 thc governor pressure 2nd 3rd shift valve @ and thus performs on on on or downshift AT 26 4 8 on on pawl on Neutral Dt the 2nd brake lnl Parll w 50 kmfh at ID On servo on Reverse hne pressure 7 to the hne pressure 13 opens The h e 3 plus the force of the press e 13 2nd 3rd shift valve spring oppose plus Rear Park push rod operates by the solenoid the valve is depressed downward and the circuit Band de accomplished 40 When kickdown is r Fronl downshift by La ltr5e rf e nUo 25 to 30 MPII f Clutch Cur Ran the accelerator downshift below speeds below kmfh 50 to 3rd 2nd kick kick A 90 accomplished be an at to on Automatic Transmission 0 Shift valves In 2nd gear position kickdown range Low a A 8 8 Front To queeO t e e a Clutch o 14 0 7 VK Th V Oil Throttle ID So BKk up o V lv e COw 1 iftV 8 hl COO R Lubrication n Drain 0 j 4 1 v I Front Lub icet P Ifk Check p o n V I I Thron 24 p ain V 5 Mod Yo I I @2nCl lilr 3rdSl V 12 3 j gu R ato V ht 2nd Shih V 5 I I 1 M I 0 r J f4fL nual PR L Not Ma Li ked X r pr p I n IGo no fd p l COnd S G rw Va X Primary Gov norValve Governor p c Torque CO I1 p ThrOWepr Fig AT 39 Oil pressure circuit diagram AT 27 D ronge kickdown shift values in 2nd gear position 1 Automatic Transmission 2 RANGE 2ND GEAR In 2 range the gear rario is IOI keJ the 2nd forward speed In this case III the rear dutch is engaged and the band brake holds the front clutch drum the connecting shell and sun from gear rotating The power flow takes place the input shaft and the front sun gear with them being clutch stationary Ihe the front gears rotate around the sun the front carrying gear through rear internal gear With held planetary inlo the The splined front planet carrier planet carrier AT078 the to output shaft clockwise rotation of the OUI causes put shaft at a Fig AT 40 Powu tTansminion during 2 H range reduced speed compared the speed of the input shaft with increase in torque As the low and to an brake is reverse wise not rotation causes engaged the clock of the output shaft clockwise rotation of fear inter nal gear and the rear around rotates clockwise clutch planet the sun direction will act carrier also one allow to in gear The a way clockwise rotation of connecting drum A1079 Fig AT 41 Operation of each mechanism during When the manual valve tioned 2 at V is the line pressure posi 7 is is led I and the governor to I st 2nd of shift valve rear CID clutch as 2 is led band thc tightening 2nd gear of regardless high pressure in the circuit 17 increasing thc throttle pressure li 6 7 pressure increased and is quickly brake Release Parking Operalion dutch pa on 2 182 on on on Neutral Drive 01 Low 2 458 on 02 Second 1 458 Oft Oft OJ Top 1000 on on Second 1458 on Oft 12 tocond 1458 tt Low 2 458 1 a line Rear on When speed DJ range 3rd gear is shifted to 2 range the line pressure 4 enters Ihe throttle back up valve V and produces The On o side of Ihe is therefore fixed vehicle ser on e Revtrs servo The Front Pui D to Band w utio range in the range The line pressure locks the second lock valve @and case Ran8t Low Clutch Gw introduced into the line pressure cir cuits I 2 and 4 The line pressure 2 on on on J therefore tightens on on on the band 2 sure N DJ e range 3rd gear to 2 range If DJ to 2 manual position causing the circuit range valve 3rd gear is shifled during operation V is the also shifted to be to line pres drained the line pressure circuit Therefore 10 which range 3 is situated at the release side of the front clutch and also drained shift val e through the @ forcing AT 28 servo is 2nd 3rd the speed to decrease from gear 3rd gear to 2nd In this case the speed change quickly pressure takes 7 heightened pressure 4 place because the line and other pressure are by the action of the line in the described under 2 same manner as range Automatic Transmission 2 2nd gear range l A ow B ke Br Fron Torqu Con I Clutch 12 i 12 ID IL 011 7 v Th ot Valve T ID onl Beck up Id So 1ft v 0 V Cool Front Lubric Or Orltic t Check Va e lnVal Va Modif P Throttle Dr 15 in V l BJl If @ 2nct 3rd Tim Ve 12 3 1 2nd Stolt 21 Se l onc Lock Va I 3 J I A r ul Gr v 2 w Valve PR Note Merltedl Line a D 02 Jl I s 1 n nOf f d pr IOo p ond a G no p oTorque c Thron con p nor v I G v r pr re Fig A T 42 Oil pressure circuit diagram AT 29 2 range 2nd gear Automatic Transmission RANGE 1 LOW GEAR Wilen I the slJrting in range gear is IOlked to the low gear drlvlIlg fJIIIJ H In the range hulds reverse brake he onnecting drum and from rotating tlow lakes place through planet feac carrier power input shaft and into lhe is clutch rear and the low and engJged The the clutch rear ROlalion of the rear clutch drives lhe dutch hub and front internal gear The front internal gear rotates the rear front C planetary gears the sun gear to rotate counter clockwise cause AT076 to clockwise Counterclockwise gear turns the clockwise sun The Fig AT 43 Power transmission during rotation planetary rear 1 range J of the gear Fai1 planet carrier splined to connecting drum is held from rotating by the low and reverse brake rear the The clockwise rotation of the f rear planetary gears therefore rotates the rear internal gear and internal drive The internal drive tlange splined to tlange the output shaft and is rotates ATOn the uutput shaft clockwise However the output shaft rotates at a lower speed compared to that of the Fig AT 44 Operation of each mechanism during shaft This is caused by the fact Ihat the front planet carrier rotates at the same speed same direction splined to since but carrier the planetary rotating in the the planet carrier are front Low Front Rur Park Band On servo Parking w Release Operatlon brake pawl clulCh on Reverse gear assem same and rear range is on 2 182 on on on direction Neutral is rotating at a speed slower than the ring gear So the gear ralio of this speed range is a combination of the ratios provided by the Clutch reverse ratIO the output shaft The front internal gear and bly Gm Range Ihe OUlput shaft in the as JJ input planetary gear 01 low 2 458 on 02 Second 1 458 on on 03 Top 1000 on on Second 1 458 on on 2 Second IAS8 on on 1 low Drive as on on on semblies 2 I When the manual valve tioned at applied I 4 actuates I Vis the line pressure posi the 7 pressure is into the line pressure circuits and 5 The oil pressure in 5 the luw and reverse brake after being introduced into the circuit 12 ID through and Ihe 1st 2nd the line pressure rear in 2 4 The line acts in the same manner as range line to pressure reases inr D range with the degree of accelerator pedal depression and I the increase of car the on 15 pressure I st 2nd which acts shift valve does on not the increase until it overcomes the combined force that of the shift valve acts on on clutch and governor Similar the 458 2 line pressure decreases with speed The AT 30 governor of the spring cha nge line pressure causing no 12 st 2nd and the speed Automatic Transmission 1 range Low gear ift Down Oid llll 14 @50 VK Th 10 I D o IttV v il Dr in 14 I Front Lubrlc O mV I Oritlc ChKk t V i P Modif Th on 0 t IS 1 11 V 1M 2nd hlf 23 J 6 g M V nu l PR i NOI M 11 keel X Ir 0 nOt IOov P I 1 11 tMod P s ond O O no Torqul Tn ont V I V Oov Of 1 v p con pr pr Fig AT 31 A 45 T Oil pressure circuit diagram II II range Low gear Automatic Transmission 1 2nd ran ar L l ak v 0 ou r Coo L O fi u Co nro O So h OId v Th o V IhV we UIIoft ein iv Lubolcat 0 OtHIc CO v v Tlwont Q MOdIf in v 1 0 V h1 joy ll v iJl N 8I1l L1 a 0 1 10011 p 0 fd P lli Onct a v nor Y 0 V no Torq Th on conv pt Fig A AT J2 46 T Oil pr ure circuit diagram 1 z range 2nd gear Automatic Transmission REMOVAL AND INSTALLATION CONTENTS ASSEMBLY TRANSMISSION REMOVAL AT 33 INSTALLATION AT 33 ADJUSTMENT 8 ASSEMBLY When transmission from the a automatic vehicle at pay following points dismounting the trans mission rigidly inspecl it by aid of the and dis Troubleshooting Chart mount it only when considered to be Before necessary 2 Dismount utmost the observe cated on the transmission with and care tube vacuum and wire diaphragm from connee when mounting tightening torque indi another table not to exert Disconnect 9 from speedometer 10 Disconnect oil charging pipe II Disconnect oil 12 Support engine under oil Note by locating with pan a Plug up the opening such as oil charging pipe oil cooler tubes a wooden INSTALLATION Installation of automatic transmis block used between oil pan and jack Support transmission by means of a sion transmission removal However observe the follow jack Detach converter 13 cover Remove bolts to housing dust ing installation securing torque See Figure drive cating against plate Replace 0 5 In dismounting automatic transmis sion from vehicle proceed as follows ground order of reverse notes Turn crankshaft measure REMOVAL is Drive plate runout plate drive vehicle on plate finger of Disconnect battery be removed and etc case 4 AT I can take out transmission under the car cooler inlet and outlet tubes at transmission jack AT 35 rear extension converter excessive force cable AT 35 bolts support engine and transmission with jack and lower the jack gradually until transmission lions at downshift solenoid dismounting tention to the Disconnect vacuum AT 35 CONTROL LINKAGE REMOVAL AND INSTALLATION TRANSMISSION 1 TRANSMISSION AT 33 mm See drive a one full turn and mnou t with indi dial gauge Figure plate rested 48 AT if in excess of 0 020 in Maximum allowable mnout 0 3 mm 0 012 in cable from terminal Disengage torsion shaft from celerator linkage 3 Jack up vehicle and support 2 ac AT261 its safety stands Recommend a hydraulic hoist or open pit be utilized weight on Fig AT 47 Removing torque conv rter attaching bolts if available Make 4 sure Remove that safety propeller is insured Note shaft Before verter two Note Plug up the opening removing torque parts replaced in the rear con scribe match marks so that in their on they may be original posi A T262 Fig AT 48 MeCJ uring drive plate tions at assembly runout extension to prevent oil from flowing out 14 5 6 securing Disconnect front exhaust tube Disconnect selector range lever Disconnect inhibitor switch wire connections at bolts rear and engine mount crossmember mounting bolts 15 from manual shaft 7 Remove 16 Remove starter motor securing transmis After removing these Remove bolts sion to engine AT 33 2 Installation of torque converter Line up notch in torque converter with that in oil pump Be extremely careful not to parts See in cause installing Figure 49 AT undue stresses in torq e converter Automatic Transmission Bolt 4 converter to drive plate Starter should be brought into op eration only when selector lever is in P Note S AT116 Fig AT 49 Torque aligning 3 When verter to tan A connecting transmission torque d S mbi correctly t can measure to be certain that cu dis they are painted a cross both parts during disas sembling processes crankshaft several turns and check to sure that transmission rotates freely without binding 6 Pour fluid up to correct level through oil charge pipe 7 Connect More than 215 mm 0 846 in 8 I manual lever to shift and selector levers in positions it should not R D 2 positions Back up lamp should also light when selector lever is placed in R position 10 in transmis Check level of oil sion For detailed procedure see page AT48 II Move selector lever through aU to be sure that transmission positions engine the correctly hand above through felt brake applied Without idling at and to Connect inhibitor switch wires N and With N A and be started when lever is in operates rod Opeiationsliould oecaTrie fbue with manual Distance automatic recommended transmission F AT 50 marks After converter is installed rotate be converter Align chalk rotate disturbing lever sclUng ffiovTSelector N R D to A slight 2 to to I shock should be by hand gripping selector each time transmission is shifted A Notes a Refer under covering topic Checking and adjusting inhibitor to switch Note See page AT 49 for checking engine idling n on page AT 49 b Inspect and adjust above whenever it switch as has to be removed for service ATl17 9 Fig AT 50 Installing torque converter Check inhibitor eration switch for op 12 Check to be that line pres refer to relative topic under Testing line pres sure on page AT 52 sure 13 is correct Perform stall instructions AT 34 on sure To do this test as page AT 50 per the Automatic Transmission TRANSMISSION CONTROL LINKAGE 4 j B 120N L p r G 4 AT273 Tightening torque 1 nuts and screw kg m 1 Control lever knob 2 Pusher 3 Control lever assembly 4 5 Selector range lever Control lever bracket 6 Selector rod of ft lb @ T 07 to 0 @ T 16 to 2 T 3 to 4 22 to 29 0 35 to 0 45 5 to 3 3 2 0 8 to 1 6 to 8 @ C8i T T 0 5 to 0 9 13 0 2 12 to 16 Fig AT 51 Control i kage f tem sy REMOVAL AND important INSTALLATION as Inspection of oil level Disconnect control control knob lever by removing from two 2 screws 2 Remove console box 3 Remove selector rod selector range lever and control lever assembly with bracket To install reverse the order of removal Therefore exercised adjustment trunnion 1 Prior to installing control knob A to II to 12 mm set the dimension Install control knob same time is as @ Figure on lever At check the dimension and adjust it to See C 1 to 0 1 mm by turning pusher AT 51 AT 35 Set and selector lever moreover to I mm in or out J @ the set 0 039 in by adjusting with connects nuts at selector rod @ After adjusting make sure that be set in any position and that selector lever oper control lever 0 43 to 0 47 in 2 @ @ nuts adjust position clearance turning 0 004 to 0 043 in of linkage faulty adjustment N at transmission B The should be will result in the breakdown of the the ADJUSTMENT great because care Loosen control lever for the automatic transmission 1 3 can correctly ates properly without any binding If levers do not operate satisfactori ly readjust sary or replace parts as neces Automatic Transmission MAJOR REPAIR OPERATION CONTENTS SERVICE NOTICE FOR DISASSEMBLY COMPONENT PARTS AND ASSEMBLY TORQUE CONVERTER INSPECTION SERVICE NOTICE FOR DISASSEMBLY AND ASSEMBLY I It is advisable that repair opera tions be carried out in a dust proof to the differences of the engine capacities the specifications of component parts for each model s transmission may be different They however have adjust common and repair ment procedures as well as inspection procedures and cleaning LOW SERVO PISTON 42 AT AT 36 GOVERNOR 43 AT AT 38 OIL PUMP AT 38 PLANETARY CARRIER AT 44 CONTROL VALVE AT44 3 During repair operations refer to Service Data and Specifications see for the correct parts for each model tion Before semblies removing any thoroughly clean the outside prevent dirt from entering the mechanical parts 5 Do not use a waste rag Use housing 2 sleeve bolt Withdraw pinion Remove bosses and affected Refer to the of extent As a how they are Service Data for damage rule pilots and converter due to 2 diaphragm rod follows 5 liter 0 I pinion Remove downshift solenoid and phragm as Remove speedometer burnt clutch into torque converter mately Remove vacuum Drain oil in torque converter Pour non lead gasoline or kero sene to transmission case converter oil is fouled or flush the torque converter I 3 4 completely contaminated torque sembly Do not leave dia this stage of disas Rod is assembled in top of at diaphragm vacuum See Figure AT 53 approxi U S pt U Imp 3 Blow air into torque converter and flush and drain out Fill 4 converter torque gasoline with converter torque oil approximately I 5 liter 0 V S pt U Imp pt blow air into torque con Again 5 verter Fig AT 53 Down hilt olenoid and and drain torque converter oil vacuum dilJphragm Remove bolts which hold valve body to transmission case See Figure AT 54 wash all dis that justifies replacement 7 from rust Remove bolts securing converter 5 assembled parts and examine them to see if there are any worn damaged or parts 43 AT Check torque convertf for any sign of damage bending oil leak or deformation If necessary replace a or defective 42 AT 1 TRANSMISSION paper cloth After disassembling 6 BRAKE 2 of subas of the transmission to nylon REVERSE pt outlined hereinafter 4 41 AT If torque Due do REAR CLUTCH INSPECTION room 2 40 AT AT 36 AT 36 DISASSEMBL Y ASSEMBL Y FRONT CLUTCH AT 36 TRANSMISSION INSPECTION AT 40 AT 36 packings seals and DISASSEMBLY I Drain oil extension from the end Mount of rear transmission on Transmission Case Stand ST07870000 ST07860000 Remove oil pan See Figure AT 52 or similar parts once disassembled should be replaced with new ones Fig 6 TORQUE CONVERTER The torque converter is construction sembled and can not a be stem welded disas AT118 Fig AT 52 Removing AT 36 oil pan AT 54 Removing Loosen lock nut D as @ valve body on piston shown in Figure AT 55 Then tighten piston stem in order to prevent front clutch drum from falling when oil pump is withdrawn Automatic Transmission Ii AT127 AT124 AT121 Fig AT 61 Remouin Fig A T 55 Loosenin band seruo Withdraw oil pump using Sliding Hammer ST25850000 Do not allow 8 front clutch to and come onto drop out of floor rear extension shell With the aid of Snap Ring Re HT69860000 pry snap ring off 12 Pull out input shaft 7 Fig AT 58 R mouin connectin 16 Pull out output shaft remove oil CV together with governor mover distributor output shaft See Figure AT 59 valve CD See Figure AT 62 position Figure See AT 56 Fig AT 62 Remouinggouernorand Fig AT 59 Remouing sruzp ring oil distributor connecting drum and Pry off snap ring using a pair of pliers Remove retaining plate drive plate driven plate and dish plate in 63 AT that order See Figure AT122 Fig AT 56 Removing oil pump 13 Remove inner gear of rear an Remove band strut This 9 done See by loosening piston Figure AT 57 can planetary carrier as assembly See Figure AT 60 be 17 stem further AT126 Fig AT 63 Remouing driue and Fig AT 60 Remouing connecting driuen drum Fig AT 57 R moving band strut 14 10 Remove rear brake clutch band as an front assembled unit connecting shell rear clutch hub and front planetary carrier as a unit See Figure AT 58 11 Remove snap rings and then planetary carrier internal Remove remove rear clutch and plates connecting drum one way clutch 18 Reaching through back side of transmission case slotted bolts outer race and one way clutch in that AT 64 To oroer Extension gear 15 Remove rear extension loosening securing bolts 61 AT See by Figure ST25570000 do hex head remove shown this use in Figure Hex head ST25570001 One way clutch inner washer piston race thrust spring and thrUst spring ring be removed AT 37 as return can now Transmission Automatic i I Up 0 V t iL lli 0 I1 ST25570001 J l @ j Lj Y h 1 AT130 j l i rr J 0 1 l P Ii 61 p i l dng Seal ll t 1 w J1i @ Clearance j 1 j ry J AT133 I Fig AT 67 Removing manual plate I Fig AT 64 Removing hex head slotted bolt 22 19 Blowout low and brake reverse piston by directing a jet of air into holeJn cylinder See Figure AT65 inhibitor Remove manual shaft by switch loosening and two secur ing bolts AT134 Me qsuringseal ring to r 68 A ig ring groove clearance ASSEMBLY Assembly is in reverse order of disassembly However observe the fol lowing assembly notes After INSPECTION Torque rear I Fig AT 65 Removing piston extension Check for damage necessary 20 Remove band attaching bolts Note difficulty If loosening servo or surfaces mating score Repair marks as way clutch inner Torque race hex head slotted bolt to L3to 18 kg m 9 to 13 ft ib using Hex head Ex tension Torque Socket ST2SS7000 Wrench ST2SS70000 GG93010000 and ST2S490000 Extension nee See Figure AT 69 ST2SS 12001 essary is encountered in removing retainer direct a jet of air toward on cracking if or replace Check for dents 2 one and case of low and assemble thrust spring reverse orake ring return spring thrust washer and housing converter transmission installing piston release side shown in as 3 or If rear extension bushing is worn cracked replace it as an assembly of bushing and housing rear extension ST2557000t Figure AT 66 ST25490000 I II GG930JOOOO Gaskets and O ring 1 Always use new gaskets when the units are to be disassembled Check O rings for burrs or crack ing If necessary replace with new rings 2 AP I Fig AT fiB Removing bond servo Check for signs of rings CD from both ends of parking brake lever @ and lever remove the Back off manual shaft lock plale @ Figure nut and 67 AT ID and remove parking rod manual CID See wear on seal ring and ring groove replacing with new ones snap ont if found worn beyond use Check that clearance between seal ring and ring groove is correct If out is of specification replace whichever worn beyond limits Correct clearance is from 0 04 to 0 0063 in 16 0 See Figure AT J8 mm 68 AT 0 0016 to woy clutch inner 2 011 distributor Pry Fig AT 69 Installing fWl1 AT132 21 A T135 After low and been assembled reverse measure race brake has the clearance between snap ring CD and retaining plate @ Select proper thickness of retaining plate plate to give clearance See correct Figure ring AT 70 Low and reverse brake clearance 0 80 to 1 05 rom 0 0315 to 0 0413 in to Automatic Transmission 7 Install planetary rear clutch hub and front carrier shown as in Figure AT 72 Rear i c clutch N edle bearing Bearing Fig AT 70 Measuring ring to plate AT139 A AT142 retaining plate I Fig AT 75 Measuring the distance clearance Available race Fig AT 72 Installing planetary carrier 2 the distance Measure of oil D and cover pump as B C and shown in Figure AT 76 Thickness mm 1l8 0 465 12 0 0472 12 2 0480 124 0488 12 6 0496 12 8 0 504 8 in Assemble connecting front other parts reverse order of disassembly to up shell and Clutch in IL Oiipi mp I AT140 Measuring the distance Fig AT 76 B For and inspection procedure reverse brake see page for low 42 AT for Assembly 3 Install vehicle only one mark arrow It way clutch so that the is toward front of should be free in clockwise direction to rotate AT143 Fig AT 73 Installing connecting shell 9 total end play and front Adjust end playas follows B W r L thickness of oil pump Required cover L bearing race mm Measured distance A mm in B Measured distance B mm in W Thickness of bearing temporarily race inserted mm r CD Available oil pump L J I @ play 1 cover bearing race Thickness One way clutch mm 2 1 047 0 I 4 0 055 in AT138 installing rear extension torque attaching bolts to 2 0 to 2 5 Place manual kg m 14 to 18 ft lb 4 After lever in P that rear 2 range and check to be sure output shaft is securely Front clutch 5 Trammission 1 6 0 063 thrust washer 6 Oil pump gasket Oil pump cover 1 8 0 071 bearing 2 0 0 079 2 0 087 3 Oil pump cover Front clutch 4 Rear clutch blocked 5 Tighten at this case race Fig AT 74 End play servo retainer temporari stage of assembly 6 Place rear clutch assembly with needle bearing on front assembly ly 7 1 C Measure the by Figure vernier distance calipers as A and shown in Specified total end 25100 0 play 50 mm 0 0098 to 0 0197 in AT 75 AT 39 in A I AT137 Fig AT 71 A TT Front end play Total end play Select oil pump cover bearing race by calculating the following formula TT AT 71 o oml of total end Adjustment D where See Figure mITIJ and in Automatic Transmission 02 D C TF H check be to properly in detailed procedure mm it that op refer ni i For range page AT and Adjusting Inhibi ing Checl 49 for sure each erates II to A c iif tor Switch where TF i n stalled t front dutch thrust washer by Sele calculating the following formula i in is switch inhibitor After 12 Adjustment of front end play clutch thrust washer mm in C Measured distance C mm in D Measured distance D mm in L between L length Check the 13 thickness of front Required 1 throllle case end to rod end ofvacuum Then select in valve fully AT145 pushed of corre adequate diaphragm rod sponding measured length See Figure Fig AT 77 Measuring the distance L AT 77 Available diaphragm rod Available front clutch thrust washer Thickness Distanl e measured L Under25 55 OO59 in mm l 25 65 to 26 05 5 1 0 059 I 7 0 067 1 9 0 075 2 1 0 083 23 0 091 5 2 0 098 15 26 55 26 to 26 65 to 27 05 Over 27 parts that construction front end 0 5 to 1 0098 to 1 0256 29 10295 to 1 0453 30 0 1 10492 to 1 0650 30 5 1201 310 I The transmission cons 106 0 play sts of many quite alike are machined yet close tolerances to in very When disassembling them in order in parts be sure to place in part rack so they can be restored 0 8 mm 0 020 to 0 031 in the unit in their proper positions It is also very important to perform func tianal test whenever it is designated Notes Correct thickness of a bearing race and thrust washer is always the one which is nearest the calculated one length in mm 29 00 142 1 0689 15 27 rod Diaphragm in COMPONENT PARTS small Specified ITIm FRONT CLUTCH I 1161 5 off snap Pry suitable screwdriver Remove a plate CID u 81 O D ring or a @ retaining plate @ driven plate with a pair of pliers drive and dished plate @ in the order listed in Figure AT 78 as shown I Compress clutch Clutch Spring springs using Compressor 2 ST25420001 or Re 25420000 51 re snap ring @ from spring tainer using Snap Ring Remover ST2532000 I See Figure AT 79 move Disassembly b Installed thickness of oil pump gas ket is 0 4 mm 0 016 in Front clutch 10 Check servo piston refer ptocedure Servo be to moves Piston that brake sure I Pinon freely For detailed lcz page AT42 for to Use drum to care AT147 prevent piston from coming out of place dUI ing testing since servo retainer is not tightened at this point of assembly Make II sure that brake band Fig correctly installcd stem to Back off f1 lb secure 12 to with lock ening torque is 9 f1 lb Torque piston 5 kg 1 two nut 5 1 to 9 to 11 m full lurns Lock 4 0 nut kg m Removing snap ring strut t is AT 79 and tight II to 1 S Snap ring 2 Retaining plate 3 Drive plate 4 6 Snap ring 7 Spring retainer Driven plate Fit AT146 Dished plate AT 78 8 Coil spring Sectional view of front clu tch 40 AT Note sor the When Clutch Spring Compres ST25420000 is to be used toe grinding cut tips of three legs by wheel See Figure 80 AT a Automatic Transmission r L 1 E 5 Eo 1 20 3 AT148 0 l mm 079 in Cut off hatched portion Fig AT SO Modifying coil spring compres or AT150 Lub ication hole spring retainer f and See Figure AT 78 spring @ 4 Blowout piston by directing a jet 3 Take out of air inlO hole in clutch drum Figure Fig AT B4 Testing front clutch Fig AT 82 Inserting clutch plate See REAR CLUTCH AT 8l 3 After clutch is assembled make that clearance between snap sure ring retaining plate @ is held within specified limits If necessary CD and Disassembly try with other plates having different thickness until correct clearance is obtained See Figure AT 83 Specified clearance I 6 to 1 8 0 063 AT149 Fig AT 81 Blowing Available retaining to mm 0 071 in plate out piston Thickness mm 10 6 0417 Inspection 10 8 0425 I 11 0 0 433 112 0441 Check for signs of wear or dam to clutch drive plate facing If age found worn discard See 2 damaged excessively or Service Data Check for for weakened AT153 1 Rear clutch drum 2 Front clutch piston 3 Snap ring 4 for limits on snap ring and broken coil spring wear or in II 4 0 449 116 0457 Retaining plate 5 Drive plate rear I Take @ plate @ warpage can sembling Assembly of snap @ retaining @ driven plate f Same tech ring plate be applied front clu tch clutch as in See disas Figure AT 85 Assembly 2 is in reverse the order disassembly Dip automatic out drive plate and dished nique I 8 Spring retainer 9 Coil spring Fig A T 85 Sectional view of If necessary replace with new ones Spring retainer should also be in spected for 6 Driven plate Dished plate 7 all transmission Remove spring parts in clean fluid before snap retainer See ring from Figure AT 86 coil AT151 installing 2 Line up driven plates so that stripped arcs are properly aligned paying particular attention to the loca tion of oil holes in clutch drum 4 The number of drive and driven plates varies with the type of vehi cle For detailed information see Service Data Specifications to plate clearance See Figure AT 82 Note Fig AT 83 Measuring ring Testing front clutch With front clutch assembled on ST2532001 oil Xf pump cover direct a jet of air into hole in clutch drum See Figure AT 84 Fig 41 AT AT 86 Remolling snap ring Automatic Transmission 3 3 Blowout piston by directing a jet of air into hole in clutch drum Figure AT 87 w 1 See Ai I Without setting is within j 3 i above between snap ring and retaining plate 1 i the disturbiilg check to be sure that clearance use specified limits If necessary other plates of different thickness until correct P2 is clearance obtained 0 i V Specified clearance 0 80 to 1 05 rom J 0 0315 to 0 0413 in i AT157 j 4 Fig A T 89 Testing rear C U tch Blow in low compressed reverse air into oil hole brake to test for AT155 definite brake operation Figure AT 90 Fig AT 87 Blowing ioW S REVERSE BRAKE Refer to page AT41 for Inspection ofFront Clutch Disassembly Fllow steps 1 as described in page AT 36 for Transmission Assemble in disassembly After parts clean in fluid before with type details refer to Serv rear sure ring held clutch is assembled D that clearance be and retaining within plate toler prescribed Specified AT 90 Testing low reverse brake Inspection plate facing for wear or damage if necessary replace Refer to Service Data Specifications for Check drive I spring for weakness Discard if weakened beyond Test piston return use clearance Replace faulty parts 3 1 0 to 15 rom with new Disassembly I Blowout piston by directing of air into hole a jet in release side of piston 2 Remove servo piston return spring ones 0 039 to 0059 in SERVO PISTON tolerances 2 See Figure AT 88 ances Fig plates varies Specifications tween snap is the order of mow out piston by directing a jet of air into oil hole in clutch piston Note that the number of check to be l all Dip of vehicle F or I reverse transmission drive and driven ice Data Disassembly 2 Assembly assembling shown in out piston Inspectl automatic as Inspection Assembly I piston is installed assemble thrust spring ring retum spring thrust washer and one way clutch inner race Using After low Extension Hex head ST25570000 ted bolt AT156 Fig AT SS Measuring ring to plate clearance reverse Testing Install rear clutch rear clutch oil ST25570001 3 to I 18 Insert dished 2 drive Blow compressed air into oil hole shown in Figure p Note to test for defInite clutch 89 AT operation as v r plate plate 111 driven and retaining ring to secure 0 9 to 13 kg m plate plate Ll into Install the installation I pump cover operation ft lb sn on proper brake torque hex head slot transmission case in that order 2 Check piston for wear damage or other faults which might interfere with 7 J The number of drive and driven plates wries with type of vehicle For detailed information Service Data AT42 AT159 refer to Specifications Fig AT 91 Removing pi3ton Automatic Transmission 3 If primary governor is assembled for any purpose spring seat primary spring and spring seat be dis to remove valve governor j i r 11 @ I @ 1 Anchor end 2 Band strut 3 Apply 4 Release 5 Return 6 Band pin Inspection 7 spring piston Band servo piston 8 Servo retainer 9 10 servo stem Brake band assembly Transmission case AT290 Fig AT 92 Sectional view ofseruo piston faulty condition found weakened if spring Replace beyond use Faulty piston should also be replaced with a new one 2 Examine to see if primary gover nor slides freely without binding 3 To determine if secondary gaver I Check valve for nor is model Assembly in blow air good condition under light pressure into hole at A and listen for noise like that of a plane Prior to assembly dip all parts in I clean automatic transmission fluid Reverse to i assemble brake aging rubber ring care to when avoid dam installing seal compressed Blow side test to of piston piston operation definite for 9c Do not confuse Note with primary gover secondary governor After installation fa check that spring is not from pump deflected AT161 Fig AT 94 Testing piston shown in Figure as Y to assemble governor nor t apply air from 1 disassembly procedure Reverse 1S z 1 i lace 3 J I Use extreme 2 Assembly o 7 procedure disassembly Release side AT 93 GOVERNOR OIL Disassembly i8 ror1 1r c 7 f J 0 2 nor f A 1 II 1 r c O L @ j IV I iJ fl n 0 Disassembly tributor I 1 Separate governor from oil dis by unscrewing attaching bolts To disassemble secondary gover I remove spring seat spring and secondary governor valve from valve body in that order as shown in Figure PUMP I Free pump cover bolts housing by removing attaching 2 Take out inner and outer gears from pump housing AT 95 1 To control val 5MI AT160 Fig AT 93 Testing piston Apply side n r ID 3 Inspection i Inspect for wear or damage to Replace rubber ring if gear teeth found damaged beyond use 2 Using a straight edge and feelers I Ii measure I pump and gear clearances as follows Clearance between inner gear and pump 4 cover or See outer Figure AT 96 4 apply With side of piston with thumb blow cylinder from Figure AT94 little it is bolts are an compressed release side as plugged Line pre sure air into shown in If retainer is raised a indication that attaching loose calling for From control valve I Standard clearance ATOgO I I Primary governor 4 Oil 2 Secondary 5 Output shaft 3 Governor valve body governor 0 02 to 0 04 mm distributor 0 0008100 0016 in Replace if Fig AT 95 Testing secondary retightening govemor 43 AT in over 0 08 mm 0 11 00 Automatic Transmission Replace if over 0 80 0 0315 mm in 6 CONTROL VALVE u The control valve assembly consists ST255801JOO of many preci ion parts and requir s extreme care when it has to be reo AT264 moved and serviced It is good practice AT 96 Fig Fig AT 99 Measuring Measuring runout they 5 Clearance between Tighten pump securing bolts specified torque 0 6 to 0 8 kg m seal ring and ring groove See Figure Note 16 0 6 sembling Gauge Seal ring I 1n l AT Fig AT 97 5 Measuring clearance Pump As is to be used make Set up pump housing with inner and outer pump gears on it 2 Using Oil Pump Assembling carrier cannot be faulty carrier as a unit ST25580000 instail pump coverta pump housing as shown in Gauge Figure clearance between washer and feeler See if oil should be di ssembled and Remove oil retain moved bolts trainer with a and nuts recommended that and HT62350000 be Hexagon Spinner Wrench See used re but it is screwdriver HT610oo800 which Bolts may be Handle Figure AT 101 Inspection Check or Disassembly divided into its individual components If any part of component is replace the burnt the control valve as flushed Assembly I sembly I planetary is band or becomes fouled PLANETARY CARRIER The t check to be certain that they are free of lint and other minute particles If of oil hole in side of it a screw q Oil care to dip all parts in clean automatic transmission fluid and clutch former that Before assembly cover When so positions Added be exercised scattered and lo being learance Note part rack prevent springs and other small parts from converter runout a be reassembled in valve body should also 4 bolt holes check the Again pump a1ign to sure housing securing mm 0 0016 to 0 0063 in I Be parts in can in their proper to to 6 ft Ib AT 97 Standarddearance 0 04 io place to clearanc planetary carrier Figure AT 100 pinion with a Standard clearance AT 98 0 20 to 0 70 mm 0 0079 to 0 0276 in ST 5 000 I J Clearance HT61000800 I I JL AT166 Fig 3 AT 98 Centering Temporarily lighten oil pump pump secur ing bolts Jr Figure 11 2 r bolts Disassembling plate for valve body bolts attaching removed free are I valve lower and upper valve removal See With body body Figure AT 102 Note AT167 Fig Remove separate 4 Set the runout of oil pump cover within D7 mm 0 0 0028 in total indicator reading See AT 99 1 Fig AT 101 AT 100 Measuring pinion washer to 44 AT ca ier clearance Do not allow orifice vah e and valve body spring check in lower valve to be scattered and lost when removing separate plate Automatic Transmission Note I Do not w it off with screw drivers To avoid darnagingmachine F 1 D screws do not work it ff with screwdriver l t a f J n Ull IU P 19l1 C J o CJ CC t lhl fB IODrR SJQIl2J LL6 rt Fig AT 103 Removing manual val AT169 5 Fig AT 102 Removing separate pllJte Remove side plate pull out pres regulator valve second lock valve pressure regi1lator plug and two valve sure springs 3 Pull out manual valve Figure 4 shown in as 6 Ar103 Remove 1st 2nd Remove plate side shift Take plate valve With plate solenoid side downshift valve throttle back up valve vacuum 2 d 3rd t ing valve and three valve springs are free for out 2nd 3rd side removed shift AT1 valve pressure modifier valve and three valve springs See Figure AT 104 1 throttle valve HT61000800 Fig AT 104 Removing side plate removal g p or e eguJa Of le6Ve I @iO f reguJl essure r oL g y 2I JI h l r Io t SecOni J lOCltvalYi l J j 1 i 2nd S taltimivneg 3rd r 0 r x en i C 1iJrilth rottle t i 3 1 lY e lI a M 1 st 2nd 2i1d S ft alVSY aIvel I j1 f If 2i 3 CP g dSt1itLvalv 3 fI iit a so hrottle f iicnjp P ie mo stiift i V81v yi VB i Fig AT 105 Components ports of control uolue Inspection r I Check valves for sign of burning and if necessary replace 2 Check to be certain that strainer is in good condition If found damaged 3 oil in any manner disCard Test valve springs for weakened tension 5 4 if necessary replace Examine for any sign Check oil oLdamage for sign of marks on separate plate If left unheedcd oiL will bypass correct tions which oil 6 or score passages causing many types of abnormalities in thesystem AT45 er passages in valve b dy damage and other condi might interfere valve operation Check bolts for Replace as required with prop stripped threads Automatic Transmission Valve spring chart Valve spring Installed Mean coil Wiredia No of dia in mm mm free length active coil mm in Length in mm Manual detent 6 0 3 1 0 051 Pressure regulator Pressure modifier 2 1 5 10 2nd shift 4 0 3rd shifl 06 2nd 3rd timing Throule back lIP Solenoid downshift 07 6 Second lock 0 55 5 0 Orifice check 0 9 Secondary Free A f i n n 0 740 22 0 12 5 12 0 lenglhm DO ri Wire dia AT172 sembly However observe the follow ing assembly noles Refer to Valve Spring Chart and illustralion in as sembling valve springs Dip all parts in clean Fig AT 106 Value spring automatic before assembly transmission Tighten AT46 parts to 32 1 2 01 0 5 7 I 9 483 0 02 0 215 295 0 474 0 10 5 I 10 413 0 43 2 ifications when Assemble in reverse order of disas 0 60 453 0 0 988 Assembly installed 32 1 11 5 25 1 335 0 0 60 0 748 21 8 5 5 4 23 19 0 0 858 8 5 1 92 0 827 0 610 5 0 21 1 210 J5 5 327 0 0 55 0 492 1055 3 8 0 028 18 8 26 8 1878 0 0 0177 0 7 governor 14 0 4 77 45 0 governor 36 0 1417 33 5 0 220 3 09 1 063 319 1 5 6 0 0091 Primary 16 0 0 197 1 40 27 0 0 866 5 0 0035 0 23 12 0 0 197 378 1 0 669 5 32 14 0 0 625 17 0 1280 0 256 02 0 630 1 614 6 5 0 1 16 0 410 15 0 6 2 354 0 1 260 80 2 8 9 0 32 0 0 217 0 0217 Throule relief 6 0 5 5 0 0217 5 23 5 18 0 244 0 031 55 0 0 1 12 0 925 0 728 6 2 0 028 08 5 0 0 236 0 028 0 7 43 0 0 315 5 5 1043 1 693 80 0 024 2nd 13 0 kg lb 26 5 4 32 1276 413 0 0 047 0 016 1st 15 0 0 236 Load in designated Slide valve into valve particularly careful that body arid they forced in any way 2 Install side plates Driver fluid Wrench spec AT l 07 are be not using Torque Hexagon HT6 I 000800 See Figure ST25160000 and Automatic Transmission Note Install spring so positioned check valve and relief that they are properly L in valve body ST25160000 Install upper and See Figure AT 108 4 J AT173 Fig AT 107 Installing side plate 3 Install orifice check valve spring valve throttle relief valve spring and steel ball in valve body lower valves HT6 1 000800 AT174 Fig AT 108 Installing valve body Tightening torque 0 25 to 35 0 kg m 5 2 to 3 ft lb Reamer bolt tightening torque 5 0 to 0 7 kg 4 to 5 ft lb AT47 m Install oil strainer Tightening torque 25 0 to 35 kg 0 2 to 3 ft Ib m Automatic Transmission TROUBLE DIAGNOSIS AND ADJUSTMENT CONTENTS INSPECTION AND ADJUSTMENT BEFORE ROAD TEST DIAGNOSIS TRQUBLE TESTING INSTRUMENT FOR INSPECTION CHECKING OIL LEVEL CHECKING SPEED CHANGING 4B AT CONDITION AT49 ENGINE IDLING REVOLUTION CHECKING DqWNSHIFT SOLENOID Qt CII 8li p JYSTMs T OF L N JJ AT 52 SHIFT SCHEDULE AT 52 PRESSURE TEST LINE KICKDOWN SWITCH AND AT 52 PRESSURE governor feed pressure JUDGEMENT 49 AT IN 3 AT TR6 uBLE SHOOTINC CHART 49 At CHECKING AND ADJUSTING INHIBITOR INSPECTING SWITCH AT49 TROUBLE STALL TEST AT 53 ITEMS AT 53 SHOOTING CHART FOR 3N71B AT 50 AUTOMATIC TRANSMISSION STALL TEST PROCEDURES AT 50 TROUBLE JUDGEMENT AT 50 AUTOMATIC TRANSMISSION Since most automatic transmission troubles be can adjustment do not Firstly inspect adjust the auto matic transmission in place utilizing the Trouble Shooting Chart If the trouble can not be solved by procedure and remove and disas semble the automatic transmission is check advisable to repair each part overhaul It Trouble Shooting I In the Trouble Chart items The transmission should not be on meas s should be and the data should be recorded INSPECTION AND ADJUSTMENT DIAGNOSIS I Engine Vacuum gauge tachometer Approxi of operation will raise the temperature to this range idling conditions are stabi Then the CHECKING OIL LEVEL tion the car must be checking the automatic transmis trouble shooting oil in linked with an easy and effective since some procedure condition are shift and lever on a level The amount of the oil varies with the temperature As a rule the oil level must be measured after its temper ture becomes often 1 developed troubles placed surface sion the oillevel and the condition of changes the brakes apply transmission through all drive positions and place it in park P position In this inspec sufficiently high Fill the oil the line to H The difference of capacities between both For instance by causes faulty operation making the clutches slip resulting in severe and brakes This is because the oil pump sucks air causing oil foaming thus rapidly deteriorating ducing sludge H and L is liter Ji VS p therefore line wear the oil quality and pro and varnish approximately 0 4 Y Imp pl and do not fill beyond the to H 2 When oil care topping up and should be taken mixing the oil with dust and changing to prevent water Excessive oil is also bad because of oil foaming up the oil caused by the gears stirring During high speed driving excessive oil in the transmission often out from the breather InspectIng 011 condition The condition of oil sticking to the level gauge indicates whether to over haul and repair the transmission or look for the faulty part TESTING INSTRUMENT FOR 2 l760F 122 to SO temperature o ten minute mately lized blows INSPECTION 800C to move In AT 57 and engine Lack of oil the basis of standard values BEFORE TROUBLE these seat removed unless necessary adjustments install way that allows examined This is Shooting diagnosis items are arranged ac cording to difficulty from easy to difficult therefore please follow these Tests and a to oil around the oil level gauge should be Chart the made convenient FOR 3N71B ing temperatures urements to be made from the driver and in the order listed in the 2 is instruments in mediately this It disassemble im AT 54 SHOOTING GUIDE 3 Oil pressure gauge repaired by simple AT 53 MEASURING LINE PRESSURE LINKAGE MANUAL AT 52 CHANGE LINE 49 AT AND ADJUSTING AT 51 CHECKING ITEMS DURING SPEED EAKAGE CHECKING SHIFT 48 AT INSPECTION AND REPAIR OF OIL AT 51 VEHICLE SPEED AT GEAR AT 4B If the Measuring 011 level To check the fluid level engine and run start the it until normal operat AO T oil varnish ike has quality trol valve to stick cates a burned deteriorated to a it causes the con Blackened oil indi clutch brake band etc Automatic rransmission In these cases and deiecl the spol of oil eakage l se nonflammable organic solve t s ch as be repaired Notes a In checking oil cloth to paper level use handle special the level gauge and be careful not to let the scraps of paper and cloth stick to the gauge b Wipe off the leaking oil and dust the transmission must Insert the gauge fully and take it quickly before splashing oil out tcmperalure by op the erating engine and shift the lever Raise automatic transmission Use DEXRON having increase to the oil pressure The spot of oil lcakage will then be found more easily er at LINKAGE The adjustmcnt of manual linkage equaUy important as Inspection of is for the automatic transmis Oil Level Thereforc great care should be exercised because incorrect adjustment sion will in the brcakdown of the rcsult transmission sible to place except when high speed it is impos locate this leakage with Inspection vehicle stationary the selector lever toward you Pull trans and turn it mission as far P as to I range wherc clicks will be felt by the hand d Pay attention because the oil to be used differs from that used in the Nissan OF MANUAL does not take running fluid leakage from the breaih As oil Note identifications only in the 3N71B automatic D to the oil AND ADJUSTMENT carbon tetrachloride for wiping adheres to the gauge Then observe the level c INSPECTION Full Automatic TranSJTIis sion 3N71A Never mix the oils CHECKING ENGINE IDLING This is the detcnt of manual valve in REVOLUTION the revolution should engine idling properly adjusted If the engine revolution is too low the engine does not operate smoothly and if too high a strong shock or creep develops when changing over The OF OIL LEAKAGE from leakage takes place the portion near the leakage is covered with oil presenting difficulty in N to D indicates th and body position of the lever Inspect whether the pointer be INSPECTION AND REPAIR valve correct of selector dial corresponds to this point and also whether the lever in comes alignment with the stepping of posi tion plate when it is released R or When oil detecting the spot Therefore places where oil seals and gaskets equipped are enumerated below 11 the CHECKING AND ADJUSTING are KICK DOWN SWITCH AND This ed refcrring can to be accomplish page AT 35 for Removal and Installa tion Converter housing Oil seal of engine crankshaft Bolts of converter housing to Trarismission and Junction of transm extension rear ss case extension ion and rear Figure AT il2 Mounting portion of vacuum phragm and downshift solenoid Breather and oil charging pipe Speedometer pinion sleeve to se the kickdown operation is made properly or the speed chang ing point s too high check the kick down switch downshift solenoid wiring between them When li n key is pqsitioned a t the deeply Oil pan Oil pressure inspection holes Refer Oil When not nd the accelerator J Oil cooler tube connectors dia pedal is the igni I st stage depressed closed and the solenoid should click If indicates it a INHIBITOR SWITCH and the switch contact should be it does not click CHECKING AND ADJUSTING The inhibitor switch lights the verse the starter and Then check each part with the testing instruments See Figure ATl09 d leaka le as @ I 7 @ sampling t a pit and by AT10S the leaked oil determine if it the torque converter oil The torque converter oil has a color like r d wine So it is oil or easily distinguished gear oil from engine Fig AT 109 Downshift solenoid Watch oil for transmission case 4Q AT leakage from motor in the ranges ol peratio and also rotates N b ell L @ If t dl @ 4l 1l j7 @ AT109 t Inhibitor switch 6 Washer 2 Manual shaft 7 Nut 3 Washer 8 Inhibitor switch 4 Nut 9 Range select lever 5 Note range CD follows Place the vehicle in re of the P defect l of rear extension proceed lamp R in the transmission To exactly locate the place of oil is by procedure DOWNSHIFT SOLENOID Rubber ring of oil pump housing Oil seal of oil pump housing 2 Adjustment Manual plate Fig AT 110 Construction of inhibitor switch Automatic Transmission Chcck and the whether the starter in these ly lrouble vehicle is held in lamp reverse operate normal motor The carburctor is in full throttle opera tion with the selector lever in ranges If Ihere is any ranges first check the If linkage 2 f no and the I fault is found in the linkage check the pare inhibitor switch slandard values Separate selector rod and turn the range selcct lever In the N position the tester Using BY yellow I the slot of the check in the range 2 Torque tioning 3 Engine two for continuity Turn lever in both directions the select electricity is on while the lever is an angle of about 30 on both within sides from each lever set if its line How range is obvious continl ity ly unequal on both sides adjustment required ever If any the screw malfunction is fastening of the switch body screw found is fastening and then bolts remove under the switch becomes vertical the works to position the shaft with detent correctly clicking sound MSlVe the switch slightly a that the screw asjJe so hole will be aligned with the pin hole of the internal rotor combined with the manual shaft and check their alignment by inserting a 5 mm 0059 in diameter pin into 1 the holes If the alignment is correct as pin tighten up the screw and fasten the selector before Check the continuity again with the tester If the malfunc tion still remains replace the inhibitor switch The purpose of this test is to check the For properly normal rpm the selector lever in the range P for several minutes Warm up the torque clutch slipping converter oil clutch High fro the dri specified on 2 seat er s at visibility and put a mark revolutions on Secure the front and To wheels apply the hand brake depress the brake pedal a foot before de Throw the selector lever into the range 1 4 Slowly If whilc engine revolution begins to rotate when at approxi rpm minute to cool down the torque verter oil and coolant 6 2 one con Make similar stall tests in ranges I and RIO The stall test operation as speci item 4 should be I l3de fd in wiihin five seconds If it takes too long the oil deteriorates brake and band an the ad the transmission and engine for trou clutches ble by measuring the maximum num bers of revolutions of the engine while versely affected Sufficient cooling are time should be given between each AT 5O brake slipping 1 the lever However if it 2 in revolution increases to as in properly the is slipping clutch is slipping of the band brake is diffi cult to ascertain level starting engine brake the front Slipping range work not Jp I strange occurs engine range to thesarne It is impossible check it in the stall test Standard stall revolution 2 If the engine N for more than 200 1 is after coasting reverse Otherwise pedal the engine reverse engine and then the selector lever to operate mately the steadily release the accelerator Shift and with depress the accelerator until the pedal throttle valvc is fully opened Quickly read and record the Front only which with the lever in pressing the accelerator pedal 3 and 2 One way road test is nceded low with the left R determine braking does fumly and I low and or Be to 0 in in rpm with chocks and sure and Rear clutch front clutch or low and reverse brake the meter rear I and slipping a good 2 R in rpm High suitable temperature 140 to 2l20F allows D rpm in slipping to that test low Iine in all ranges High Mount the engine tachometer are further presumed causes are engine cooling water to suitable tem perature by running at 1 200 rpm with I no following abnormalities normal rpm in Note STALL TEST therefore required is for overall and Before Icsting c heck the engine oil and torque converter oil warm up the and lever slipping pressure pull the hole for proper fune STALL TEST PROCEDURES fasten the switch body with the bolts in slipping converter or more transmission the High rpm location in stall indicates that one in clutches the respective 5 out the than more engine revolution it values un body Adjust the manual shaft correct ly to the position N by means of the selector lever When the slot of the shaft brake and band in trans 6010 1000C nut of the range selector lever and two the machine If the R from each lever set position and check each continuity range It is normal if revolution stall condition is higher than the standard mission for wires from the in be tested and items Clutches hibitor switch in the ranges N and I and the twre d black RBj wir s range JUDGEMENT High Components to test N to 2 standard revolution the manual shaft is vertical black results with the the manual lever from Ihe remote control Note respectively Com measured 0 test for the four ranges R I and stalled condition a condition values is I and Also tIle clutch the the control elements mally operating 2 revolution within of the normal in in the in stall standard are ranges nor 0 R engine torque and one way converter are and operation The one way clutch of the torque converter however sometimes sticks performance This is determined in the road test 3 Lower stall revolution than stand ard revolution If the engine revolution in stall condition is lower than the standard Automatic Transmission torque converter s one way clutch sticks vehicle speed can not exceed approximately 80 km h 2 values it indicates that the engine is in abnormal condition or the torque con verter s one way clutch is slipping Others is poor until vehicle mately 50 km h 30 MPH and then normal can be judged that beyond speed verter s one way clutch is care guide speeds is If the it con down diagnosis for each stage of the up and shiftings be prepared Measured vehicle speeds are to be filled in the adjoining column after each testing slipping Also it is advisable to mount Kickdown 0 Half throttle Fuol throttle 200 51 to 65 D2 92 to 106 D3 D2 D3 D2 Dl Dl D2 9t023 D2 D3 D3 D2 D3 48 to 61 Note D2 Dl Dl 12 I 12 I can 2x 1f x rx RF x where 3 340 to 3 840 82 60 to 51 3 460 to 2 960 6toI4 19 I x 51 to 38 32 to 24 1 860 to 1 360 51 to 38 1 860 to 1 360 range from D following 32 to 24 range output shaft 2 000 rpm formula 60 h km Propeller R r Final gear ratio Tire effective radius TT The ratio of circumference of a circle to its diameter revolution rpm m 375 4 6 00 14 AT 51 850 700 Max Np 0321 1 350 to 1 000 shaft 830 1 720 to 2 220 12 Vehicle speed RF 330to 30 to 38 V r 1 790 to 1 290 30 to 22 37 to 24 23 to 15 1 Np 1 840 to 2 340 or be calculated by the V to Propeller shaft rpm MPH 57 to 66 49 to 36 1 speed by shifting to Vehicle speed 96 km h 32 to 40 D2 450 Reduce the speed Dl 0 Minimum throttle Vehicle Gear shift mmHg 14 3 a the throttle SPEED AT GEAR SHIFT Throttle opening an chart with the standard vehicle stopper for positioning opening VEHICLE the auto diagnosis It is recommended that a so required 3 transmission does not op erate properly at all vehicle speeds it indicates poor engine performance special is attained that the torque exact knowledge of transmission is required for ltic l JT tem and abnormally rises perature performance speed of approxi If the accelerating 1 oil torque converter the case An accurate in the road test In such a 50 MPH 4 ROAD TEST If the Automatic Transmission SHI CHECKING SPEED SCHEDULE CHANGING CONDITION The driver s feeling during hk gear changes should also be checkedatten tively 12 100 2 I 1 I 2 I sharp shock or unSffioothness is felt during a gear change A gear change is made with a long 2 I A These indicate oo I E I I 300 I Z 5 that the I I 3 c dragging feeling and J I 2 3 L1 mmHg tIuottle t 400 I pressure is too low or some valve connected to the throttle is faulty I 3SA 1 500 000 Output shaft speed rpm CHECKING ITEMS DURING I In D D2 MPH range gear D3 are I I In I the speed io io 60 50 70 R 4 315 Should be quickly fixed at 2 P vehicle can 321 0 r he parked If any malfunction occurs in second is if gear during the road test that while vehicle shakes drags or slings D in to shifting If these troubles remain after adjusted check piston seal for oil leakage the brake band is servo directly to up from D the brake band should be ad or D2 justed D the ATll0 Shift IChedule or When any slipping brake or the feeling change is not correct occurs in clutch during a speed the line pressure t I Measuring line pressure is done by a pressure gauge attached to two pres sure measuring holes after removing 1 I l 1 D c properly from 6 00 14 LINE PRESSURE TEST case plugs See Figure located at transmission 7 jf AT 112 line pressure measurement is at begun idling and taken step by step by enlarging the throttle opening sharp shock in up shifting or too high changing speeds are caused mostly by too high throttle pressure 2 Slipping or incapability of opera I c o The shifting up 60 0 Fig AT 111 blind range In 6 00 90100 80 40 30 Vehicle speed does not in crease 5 30 40 must be checked erly 4 Ii 20 R By moving the lever from D to 1 gear changes D 12 2 and effected In the ranges 12 the engine braking works prop are 1O changes DI effected In increase range the speed does not 2 The kickdown operates properly 3 hO km SPEED CHANGE CV ATl13 A tion is leakage mostly due to oil within the gear trains valve AT S2 pressure or spool 1 2 Lige pressure Governor feed 3 SerVo release pressure Fig AT 112 uring line preuure MeCJ Automatic Transmission GOVERNOR FEED PRESSURE LINE PRESSURE At cut back Range 15 Unit After cut back point under approximately Throttle opening Unit mmHg Full throtlle 0 9 4 to 110 Minill1um throttle 450 3 0 to Fulllhrotlle 0 Minimum throttle 450 Full throtlle 0 Minimum throttle 450 over approximately 22 MPH 35 kmfh kmfh 10 MPH kgfcm2 psi Unit kgfcm2 psi 134 to 156 5 to 5 6 78 to 92 to 4 0 43 to 57 5 5 to 7 0 78 to 100 5 5 to 70 78 to 100 D 4 0 10 0 to 12 0 2 142 6 0 to 12 0 to 3 0 57 43to 171 85to171 14 0 to 16 0 199 to 228 43 to 78 14 0 to 16 0 199 to 228 R 3 0 to 2 I R and pH the pressure supply system output of power caused by too low or of the puncture phragm be can the absorbed checked by torque the into ascertained oil is converter engine and the Low idling line pressure in tain ranges only This is presumably caused leak in the devices by cer an oil nected to the relevant ranges When there is I rear clutch the line and governor D 2 and I are low pressure in but the pressure is norrrial in When low and an reverse pressure in R oil leak in the brake circuit the line P and are D 2 and High idling line pressure This is presumably caused by increased owing vacuum or by an 450 mmHg and 0 with the stall test I mmHg in accordance procedure line pressure do not n despite the vacuum decrease If lo 78 check whether the vacuum rod is incorporated 2 pressure increased line If the line pressure do not it is caused mostly and piping solenoid kickdown switch and wiring F Engine idling rpm pressure throttle G Oil H Engine stall rpm I Rear lubrication Control valve manual K Governor valve L Band servo M Transmission air check N Oil quantity o Ignition switch and starter motor P Engine adjustment and brake spection 2 Inspection after inspecting in auto meet by m Rear clutch n Front clutch a TROUBLE SHOOTING CHART INSPECTING ITEMS Inspection with on diaphragm E Downshift q Band brake Low and reverse brake r u Oil pump Leakage of oil passage One way clutch of troque coilVerter v One way clutch of transmission w Front clutch check ball x Parking linkage Planetary gear s mission select linkage matic transmission on vehicle sticking pressure regulating valve pres sure regulating valve plug or amplifier 1 lge Ra Inhibitor switch and wiring D Vacuum the an to a leak in the vacuum tube or dia phragm line pressure is increasing In this check the line pressure should be measured with vacuums of low but I throttle be checked when the the standard R occurs the pressure is normal in Items to crease oil leak in the an 4 circuits con or C J An 2 4 A Oil level dia vacuum easily exhaust pipe emits white smoke oil pressure leak in the oil valve body or case pump A sticking regulator valve 3 3 A because A worn oil pump 2 2 leakage is directly measuring the negative pres sure after removing the vacuum pipe be atlributed to trouble in can sticking regulator a B Vacuum Low idling line pressure in the D due to pressure valve LINE PRESSURE I 5 5 a JUDGEMENT IN MEASURING This 3 0 to The line pressure during idling corresponds to the oil pressure before cut down at minimum throttle b The oil pressure After cut back means that after the pressure modifier valve has operated Notes ranges 5 5 automatic vehicle AT 53 trans t y Automatic Transmission TROUBLE SHOOTING CHART FOR 3N718 AUTOMATIC TRANSMISSION be taken up The number shown beluw indicates the sequence in which the checks should Trouble ngine does EFGHIIJKL ABeD P N not start in 2 3 1 2 MNOP stuv tnnqr wxy 1 ranges Engine starts in other range than N and P in Sharp shock 0 shifting to 2 1 @ 3 4 I 2 3 1 2 4 5 6 3 1 2 3 5 6 4 1 2 3 5 6 4 1@ 1 2 3 5 7 @@ range Vehicle will 2u TUns in not run ranges Clutch bul runs R Iukh 2 range I r nges run brakes runs Maximum @ @ @@ 1 @ in in any range slip N speed @ poor acceleration somewhat 6 starting Vehicle 7 range bul R in and 2 Vehicle will not or 1 0 R nol run slips Very Clutches ranges Very poor acceleration slips Vehicle will 0 runs in in range bul D in and l Vehicle will not run in in N from allained 1 4 2 5 4 2 3 I range not I @ 7 6 3 3 2 1 8 OO I@ Acceleration poor Vehicle braked by Ihrowing Icver inlo R No creep Failure @ 1 I all dumge gear from 2nd tllchJllgC gear from 11 2 4 5 3 I 2 3 5 6 8 7 4 1 2 3 5 6 8 7 4 1 2 @@ @ 1 @ @ 3rd Failure to al 10 I I Excessive creep to @ range 2ud Too high I sC to gear change poinl from from 2nd to 2nd @ @ a 3 5 6 1 4 3rd Gear rd change directly from lsl to 2 occurs AT 54 4 3 1 @ @ @ Automatic Transmission Trouble Too sharp l1st to EFGH 1 2 shock in change from a I J KL MNOP 5 4 mnqr s t u v w x @ 3 2nd Too sharp 2nd ABCD shock in a change from 1 2 3 3 5 4 @ 3rd to Almost no slipping in shock change no shock or clutches 1st from to 1 2 3 4 6 8 7 1 2 3 4 6 8 7 5 @ @ 5 2nd Almost change from Engine races slipping by gear change from Vehicle braked by gear 2nd to 3rd 3rd to Gear from change gear from change from or change 3rd to 2nd 3 2 1 1 3 4 6 5 2 1@ I 3 4 6 5 2 1 @ high a from 1 2 3 4 5 6 f I 2 3 4 5 6 f 2 1 from change point 2nd to @ shock felt during releasing accelerator pedal 3rd @ V lIst deceleration by Too @ 2nd 10 1st to 1 2 gear from change to Failure @ @ 2nd to Failure in 3rd to extremely Vehicle braked 1st or 2nd 2nd to 1st Kickdown does not operate when depressing pedal in 3rd within kickdown vehicle or when depressing 3rd engine pedal beyond kickdown speed limit Races extremely from Jrd to 5 3 5 6 7 4 @ f speed Kickdown operates runs 4 slips or 2nd over in 1 vehicle in 2 3 @ @ I changing 1 2 4 I 2 4 I 2 3 when 6 5 3 f@ @ 3 @ j depressing pedal Failure to to when change from 3rd changing lever into 2 range Gear change from or from 2nd to 2nd 3rd 10 in nd 1st 2 range 55 AT 51 @ y Automatic Transmission ABeD Trouble No shock at or range change engine from races I 3rd when shifting lever into Engine 1 not I J K L 1M NO I 2nd to 2 3 4 I 6 1m n change from frum 2nd to I sr 3rd lu in q I 2 1 I 2 4 57 7 5 @ 6 3 @@ range upcrate P r t s u v Iw x y I @ @ in @ 5 3 range Gear or brake does I F G H 2 to extremely Failure to change from E f 2nd I 1 2 2 4567 3 @ range Does not to 1st shock Large to change in 1st Vehicle changing P range 1 from @ when 1 2 @ 3 4 changing range or parking gear does not disengage when shifted out of Transmissic m overheats Oil shoots out 2 2nd range moves P 2nd range in into from 2 I I 3 4 2 6 5 6 2 7 8 @@@ Q@@ @ 8 4 @@@ Q@@ @ 2 OG@@ f@@ @ 7 5 during operation White smoke emitted from exhaust I 3 pipe during operation Offensive smell at oil Transmission noise in charging pipe p and 1 N 1 2 I 2 10 ranges Transmission noise in and R D 2 I ranges AT 56 0 G I @ @ Automatic Transmission TROUBLE SHOOTING GUIDE FOR 3N71B AUTOMATIC TRANSMISSION Procedure Test item Order Check gauge for oil level and leakage before and after each Oil level gauge Checking test 2 Downshift solenoid Check for sound of operating solenoid when depressing accelerator pedal fully with ignition key ON 3 Manuallinkage Check by L shifting into P lR D IN and 2 I ranges with selector lever 4 Inhibitor switch Check whether and whether Check whelher 5 Engine idling 6 Vacuum pressure of rpm vacuum 7 Operation idling Creep I tesling ranges only only vacuum pressure is more than 450 mmHg it decreases with increasing rpm and whether idling Check whether of vehicle Oil pressure before p range Check whether transmission engages positively by shifting N l R range N I and N N 0 2 in each range R Stall test R rpm meet standard while idling with brake 8 and N in Check whether in pipe operates in lamp operates starter reverse applied there is any creep in D I and 2 and ranges 1 Measure line pressures in 2 D R range while idling 2 Stall test Measure engine rpm and line pressure in R ranges during full throttle operati n D I 2 and Notes of torque converter oil used in test should be from 600 to 1000C 1400 to 2120F i e sufficiently Temperature a warmed up but not overheated b To cool oil between each stall test for and idle R engine D 2 I ie rpm at about 1 200 P range Measurement ranges rpm for more than 1 minute in time must not be more than 5 seconds 3 Road test Same Slow acceleration Check vehide I 2nd range and st 2nd 2nd3rd 2 item I Oil pressure after testing Quick acceleration lst 2nd D as and speeds range and engine engine cpm in range while Jo3rd 2nd vacuum shifting up running with Ist lever in 200 I11I1lHg pressure of about except with engine vacuum pressure in position just before kickdown Same as item 1 above of 0 mmHg ie 2nd3rd 3 Kick down operation 2nd1st 3rd 2nd or Check whether the kickdown operates and measure the time delays while running at 30 40 50 60 70 km h 18 25 30 37 43 MPH in AT 57 D3 range Automatic Transmission Procedure Test item Order 4 Check vehicle Shift down Dr 0 O2 speeds 2nd 3rd accelerater and engine rpm in shifting down from sequentially while coasting with I st pedal released in range and D3 engine vacuum pressure of about 450 mmHg 5 Shift down Check for DJ 12 further for 1 shifting down OJ shifting down 12 and engine braking and 12 I and engine braking after I range with the accelerator pedal shifting released and the engine vacuum pressure of 0 mmHg while driving at about 50 km h 30 MPH in OJ range the lever into 6 Shift down DJ 2 Check for 2 and engine after while driving 50 quick shifting down 0 shifting the lever into 2 range km h 30 MPH in OJ range check for locking of the regardless of vehicle speed Further ratio 7 Shift up I 12 8 Shift up iog in 2 9 or down when start range Parking Abnormal shock oil leakage about at transmission in 2nd gear Check for failure of the transmission to shift up acceleration when starting in I range during Check the transmission for not during acceleration or P shifting move on as rang when shifting during these tests gear noise abnormal clutch noise and acceleration performance 58 AT grade 2 range Enter into record conditions observed such up or down deceleration when starting in Confirm that vehicle will not to Others biaking Automatic Transmission SERVICE DATA AND SPECIFICATIONS General specifications AfT Torque converter Type Symmetrica13 element I 2 phase torque converter Stall torque ratio 20 stage I Transmission Type 3 speed forward and one speed reverse Control elements Multiple disc clutch Selector positions gear train I disc brake I One way clutch Gear ratio planetary 2 Band brake Multiple with I 1st 2 458 2nd 1458 3rd 1 000 Reverse 2 182 P Park Transmission is placed in neutral shaft is fIXed Output Engine can be started R Reverse Backward N Neutral Transmission is in neutral o Drive Engine can be started Up or downshifts automatically running to and from I st 2nd and top 2 2nd lock Fixed at 2nd I Fixed at low Lock up or downshifts from 2nd Oil pump Internally intermeshing involute Type gear pump Number of pump Automatic transmission fluid Oil DEXRON type 5 5 liters Capacity 4Ulmp qt Approximately 2 7 liters s qt SUU s qt 2XIrnp qt 2UU in torque converter Hydraulic control system Controlled by measuring the nega tive pressure of intake manifold and the revolution of output shaft Lubrication system Forced lubrication by Cooling system Water cooled by a an circulation type auxiliary cooler located radiator AT59 oil pump at the Automatic Transmission Specifications and adjustment AfT Automatic transmission assembly Model code number Torque converter X2402 assembly Stamped mark on th e TiC 16 B Front clutch Number of drive plate Number of driven 3 plates 3 Clearance mOl in 16 to 18 0 063 to 0 071 Thickness of retainin g plate mm in 10 6 0 417 10 8 42S 0 11 0 0 433 112 441 0 114 0 449 116 0 4S7 Rear clutch Number of drive plates 4 Number of driven plates 4 Clearance Thickness of retaining plate Low reverse mOl inJ mOl in 1 0 to 5 0 039 to 0 OS9 1 4 8 0 189 brake Number ofdrive Number plates fdriven pla 4 Clearance Thickness of retaining 4 es plaie mOl in mOl in 0 80 to 10S 0 0315 to 0 0413 118 0 46S 12 0 0 472 12 2 0480 12 4 0 488 12 6 0496 12 8 O S04 Brake band Piston size Big S mOl in dia 64 2 S2 all dia 40 1 57 Control valve assembly Stamped mark on slraine E Governor assembly Stamped mark on governor body 35 60 AT Automatic Transmission Engine Idling and stall revolution Idling revolution rpm 6S0 ai Stall revolution rpm 2 000 to 2 200 TIghtening torque kg Drive plate to crankshaft Drive to torque plate Converter housing to 14 0 to 16 0 29 engine 4 0 to S O 29 10 36 4 S to 5 5 33 Transmission case to rear to converter Oil pan to transmission housing extension case Servo piston retaine T to transmission adjuting Control valve case band brake body to transmission case to transmission case to 14 O S to 0 7 4 to S OS to 07 4 to S 4 0 to 18 9 to 11 I I to 9 to 13 4 to S 0 25 to 3S O 2 to 3 Side plat 0 25 to 35 0 2 to 3 Nut for control valve bolt O S to 0 7 4 to S Oil strainer to lower valve body 0 25 to 2 to 3 Governor valve D S 100 7 4 to 5 0 6 to 0 8 4 to 6 5 0 to 0 7 4 toS Oil pump body housing to reamer to oil distribu tor oil pump cover Inhibitor switch to transmission Manual shaft lock Oil cooler pipe case nut to transmission case Test plug oil pressure inspection hole Support Oil actuator I charging pipe Dust parking rod inserting position cover to rear extension to case to converter housing Selector range lever to manual shaft Turn back two turns after 35 0 3 0 to 4 0 22 to 29 3 0 22 to 36 to S O I 4to 2 1 10 0 8 to I 1 6 61 AT to IS to 8 5S O to 0 7S 4 to S 5S O to 0 75 4 to S 3 0 to 4 0 tightening 29 3 to 1 8 1 0 5S to 0 75 control valve body 40 S Lower valve body to upper valve body to 36 to 5 to 1 race to 2 0 2 to 15 1 nut One way clutch inner 101 to 116 4 0 to 5 0 case Piston stem lock ft lb converter Transmission Pislon slem when m 0 position 22 to 29 Automatic Transmission SPECIAL SERVICE TOOLS Tool number Description No tool name ST2S0SS001 Use for checking hydraulic For Reference use page on Figure No 3N71B pressure Fig or AT 11 2 and Oil pressure gauge 3N71A set AfT SE119 2 ST07870000 3N71 B Use for setting transmission Page AT 36 AfT Transmission case stand SE120 3 ST2S850000 Use for removing 3N7IB oil pump Fig AT S6 and Sliding hammers 3N71A AfT J JIB SE121 4 ST2S42000I Use for assemblilJg or disassembling front and 3N71B rear clutch and Clutch Fig AT 79 Fig AT 86 3N7lA spring AIT compressor SE 122 S GG93010000 Use for tightening Max torque Torque wrench Drive angle 46 3N71B correct torque kg m and 0 33 ft lb 3N71A 3 8 square AlT SE123 62 AT Fig 69 AT Automatic Transmission Tool number No Description tool 6 name ST2S490000 Socket extension to connect torque wrench GG93010000 W square socket wrench with For Reference use page on Figure 3N71B or No 69 AT Fig AIT Socket extension V SE124 7 ST2S160000 Use for tightening Max torque correct 1 04 kg m 3N71B torque A T 90 ft lb Torque driver Fig Fig AT 107 Fig AT S9 AT 108 and 3N71A 3 SE125 8 HT69860000 Use for removing and 3N71B replacing snap ring and Snap ring remover 3N71A AIT SE126 9 ST2S320001 Use for removing and 3N71B replacing snap ring and Snap ring remover Fig AT 79 Fig AT 86 3N71A AIT SE305 10 ST2SS70001 Hex head extension Use for removing and torque wrench Drive angle installing W square and 6 3N71B way clutch inner race with one AIT mOl across flat width SE128 AT I Fig Fig Page 64 AT AT 69 42 AT AutomaJic Transmission Tool number No Description tool II name HT623S0Q00 Use for disassemlbing and assembling control valve For Reference use page on Figure No 3N71B and Spinner handle Fig Fig or AT IOI AT I04 3N71A AIT SE129 12 HT61000800 Hexagon Use for disassembling and assembling control valve 3N71B wrench AT IOI and Fig Fig 3N71A Fig AT I07 AT 104 AIT Fili AT 108 3N71B Fig Fig AT 98 0 SE130 13 ST2SS80000 Use for centering oil pump and Oil pump Ssemlbing l 3N71A gauge AIT SE131 AT 1l A AT 99 0 SECTION PD DATSUN PICK UP MODEL 620 SERIES PROPELLER SHAFT DIFFERENTIAL CARRIER PROPELLER SHAFT AND CENTER BEARING DIFFERENTIAL CARRIER TYPE H19D TROUBLE DIAGNOSES AND CORRECTIONS PD 2 f PD 5 PD 14 I SERVICE DATA AND PD 16 SPECiFiCATIONS SPECIAL SERVICE TOOLS I NISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN PD 19 PROPElLER SHAFT DIFFERENTIAL CARRIER PROPELLER SHAFT AND CENTER BEARING CONTENTS CHECKING AND CORRECTING DESCRIPTION PD 2 REMOVAL AND INSTALLATION PD 2 UNBALANCED PROPELLER DISASSEMBLY AND ASSEMBLY PD 3 SERVICE INSPECTION PD 3 TROUBLE SHAFT 3 PD DATA 4 PD DIAGNOSES AND CORRECTIONS i 4 PD 2 tl J I O t I 148 5 5 85 483 750 987 19 02 53 29 35 38 86 38 1 Long wheelbase 1 Sleeve yoke assembly Center bearing 5 Companion flange 6 Plain washer 10 Center bearing insulator 4 Center bearing bracket 7 8 Self locking nut 11 2 3 9 The shaft propeller joint type The propeller shaft and universal joint assembly is carefully balanced during original assembly that is the on the 620 series is 3 dynamic unbalance is under 49 0 in oz If the propeller assembled so that at S 800 cm gr Raise vehicle both on on hoist Put match propeller in ctional Crou v w of propelkr hafl 3 Remove bolts connecting shaft to companion flange of differential car rier See Figure PD 3 shaft and companion flange so that shaft can be reinstalled in the original position 2 Remove bolts retaining center bearing bracket See Figure rpm PD 2 shaft has to be it must be made the above 35 I mm PD218 PD l REMOVAL AND INSTALLATION marks Unit Bearing race assembly Snap ring Journal assembly Flange yoke Fig DESCRIP TION and Deluxe cab models Rea Front carefully limit is not ex ceeded Therefore when the vehicle is to be undercoated cover the propeller PD220 shaft and universal joints to prevent application of the undercoating ma Fig PD 3 Removingpropclkr t cha terial 4 PD219 Fig PD2 Removing center bearing bruckel PD 2 Withdraw yoke from shaft rearward axle propeller transmission shaft sleeve by moving passing it under rear DIFFERENTIAL CARRIER PROPELLER SHAFT leakage from Watch for oil trans Note not to as and yoke shaft carefully careful damage not to damage spline sleeve When disassembling and repairing center bearing are required the follow oil seal ing procedures propeller Remove rear b Plug up the opening in the rear extension oil from removal to housing flowing install To from removing journal journal and yoke bole Notes so be yoke mission end a When rear of prevent out the reverse foregoing procedure applied Put match marks 1 Align propeller shaft with com panion flange using reference marks in removal kg I Drive Pinion Flange ing nut and Figure PD 5 remove center bearing See assembling pro follows Install center bearing in center bearing insulator bearing assembly center 2 Install and companion flange Flange Wrench specified torque on front shaft ST3IS30000 to Pinion m Insert bolts through the holes of Tightening torque beariug bracket and torque nuts retain center bearing on cross center to are as usiug reference marks established in disassembly procedure 3 Install washer and locking nut on front shaft and tighten nut using Drive 17 to 24 ft Ib 2 adjust unbalance less than 3S 800 S rpm flange Applying in lb 49 in oz at 0 gr cm Center bearing cedures Tightening torque 3 13 propeller shaft Remove bolts connecting flange yoke to companion assemble with bolts 4 to 2 em so When the above steps are complete place the shaft in a balancing machine flange and and procedure kg front 2 assemble components that joint moves under friction resistance of less than is o and on Wrench ST3lS30000 loosen off lock 1 prescribed are Install and correctly 20 0 to 24 0 kg m I4S to 174 ft lb member Tightening torque 1 6 to 2 2 12 kg m do not disassemble pro shaft because it is balanced as an Primarily Tightening torque To assemble reverse the foregoing procedure using reference marks scribed in disassembly procedure New bearing need recommended Fill joint check propeller shaft journal for movement When journal does not move smoothly dis with grease whenever overhauled assemble Use related snap rings of the same thickness and be sure that play is so propeller the original Mark that shaft and journal combination Remove snap ring with screwdriver a standard in Install center center Thickness mm in i bracket on for dent or bearing bearing is INSPECTION Check I journal pin brinell marks and yoke hole for sign ring Snap ring should also be bearing and seal ring inspected to Color damaged worn place if necessary identification 2 or see if these deformed White 2 02 0079S Yellow insulator cannot be tolerated here Red 3 2 06 0 08 II Green face 2 08 0 0819 Blue necessary 10 2 0 0827 Right Brown 12 2 0 83S No paint Pink bearing PD 3 Check for is by rotating rough noisy or 2 00 00787 2 14 00843 Re heck center bearing bearing race If it damaged discard Q4 0 0803 2 PDOO5 kg m to 24 ft Ib of wear or damage Available snap 4 PD Fig PD 4 Remo S are 3 Lightly tap base of yoke with a hammer and withdraw bearing race See Figure shaft can be restored at assembly 2 below 0 02 mm propeller 0 0008 17 multi purpose with However 2 4 to 3 3 pre not be lubricated since it is lubricated for life assembly 1 and torque DISASSEMBLY AND ASSEMBLY peller flange of front f1ange yoke of rear shaft tighten connect bolts to specified shaft with nut Fig PD 5 Remouing locking to 16 ft Ib Join companion 4 ST31530000 P0172 Cracked propeller dent or bearing shaft tube crack sur Change if PROPELLER SHAFT 8l DIFFERENTIALCAAR ER CHECKING AND anced propeller shaft proceed as CQRRECTING UNBALANCED follows PROPELLER SHAFT foreign materials which could upset Remove I undercoating and and check shaft vibra shaft balance To check and correct unbal an other tion by road 2 If shaft vibration is noted test road test disconnect propeller shaft at differential carrier companion rotate companion flange 180 and reinstall propeller 3 check Again vibration during peller still shaft flange degrees shaft shaft vibration persists replace assembly SERVICE DATA Pe issible dynamic unbalance Axi gr cm in play of spider journal mm Journal swinging torque Propeller kg shaft front and out of round rear in 0 49 at S 800 rpm Less than 0 02 0 0008 in Ib em mm 3S oz Less than IS O 13 in Less than 0 6 0 024 Tightening torque Shaft to conipanion flange Gear carrier bolt Self locking nut front shaft Flange yo e rear shaft to companion flange front shaft bolt Center bearing bracket to cross member m ft lb 2 4 to kg m ft Ib 20 0 to 24 0 l4S to 174 kg m ft lb 2 4 to 3 17 to 24 kg m ft lb kg bolt 3 17 to 24 1 6 to 2 2 12 to 16 TROUBLE DIAGNOSES AND CQRRECTIONS Condition Vibration medium during at high speed or Probable Worn or damaged Corrective action cause universal joint needle Replace propeller l I eplace bearing Unbalance due to bent or dented shaft Loose propeller shaft installation Worn transmission Damaged Tight center rear extension bushing bearing or insulator universal joints Undercoating or mud Retighten Replace Replace Impact yokes with hammer to Replace joint if unable to free up feels rough when rotated by hand on the shaft causing free or up ifjoint Clean up shaft unbalance Tire unbalance Balance wheel and tire from known Balance weights missing Replace PD 4 good assembly vehicle or If pro replace DIFFERENTIAL CARRIER PROPELLER SHAFT Condition Probable Knocking Worn sound during starting or noise during coasting on propeller damaged Worn sleeve shaft Corrective action cause universal joint yoke Replace and main shaft spline Replace Loose propeller shaft installation Retighten Loose joint installation Adjust Damaged Loose missing bolts at center ring Replace center bearing or insulator or snap bearing Replace or tighten bolts bracket to body Scraping noise Dust cover transmission sleeve on rear yoke rubbing extension Dust companion flange rubbing on c Straighten on dust out cover to remove inter ference ver on differ mtial carrier Whine or whistle Damaged center bearing Replace DIFFERENTIAL CARRIER H190 TYPE CONTENTS DESCRIPTION PD 5 ASSEMBlY OF REMOVAL PD 7 CASE PRE DISASSEMBLY INSPECTION PD 7 ADJUSTMENT DISASSEMBLY PD 7 HEIGHT INSPECTION PD 8 ADJUSTME NT OF DRIVE PINION ASSEMBLY AND ADJUSTMENT PRECAUTIONS IN PD REASSEMBLY ASSEMBLY OF DIFFERENTIAL CASE 8 PD 8 ADJUST PD 8 PD 9 OF DRIVE PINION PRELOAD t PD DIFFERENT Al PD lO ENT OF SIDE 8EARING PD 11 SHIMS PD 13 INSTAllATION REPLACEME NTOF PD 13 FRONT Oil SEAL DESCRIPTION The differential carrier series has a gear ratio of on the 620 37S 4 The drive pinion is rnounted in two tapered roUer bearings which are pre loaded by pinion bearing adjusting spacer and washer during assembly The drive pinion is positioned by a washer located between a shoulder of the drive pinion and the rear bearing The differential case is supported in the carrier bearings by two These are tapered roller side preloaded by in serting shims between the bearings and the differential case The differential is for proper ring gear and drive pinion backlash by case assembly positioned varying bolted case these shims to the The differential houses two ring gear is case with two pinion mates mounted pinion shaft The chored in the pinion The side gears in mesh case on a pinion shaft an by lock pin The mates and side gears are backed by thrust washers The carrier is of malleable cast iron PO 5 PROPEllEff SAAFT 8 CARRIER DifFERENTIAL TYPE H19O Q@ 4 @ nut 1 2 Drive pinion 3 Oil 4 Front bearing Companion flange al adjusting washer DIive pinion bearing bearing preload by 5 Adjust pinion ecting @ and @ @ Drive 1 Drive pinion 8 Rem 9 Drive pinion 10 loci pin @ bearing and cIrive @@ @ spacer adjusting wamer mint Side bearing adjusting and preload bearing side Adjust geu betwam ring backlash 11 @ pinion beating 6 12 Side bearing 13 Side gear nUust washer 14 ting @ pinion by to side mate Adjust pinion backlash Of the clearance face of side between the teat to 0 02 to washer ttuust gear and in 0031 10 0 0 08 nun 0 0008 @ @ gear 15 by@ Differential 16 Thrust washer 17 Pinion 18 Pinion sbaft 19 Ring gear Backlam between ring gear 20 cast mate and drive pinion 0 t5 to 0 20 nun in 0 0059 10 0 0079 boll cap Bearing 21 22 Thrust block Ring gear bolt 23 Lock strap of torque f m ft lb bollS and nut kg Tightening @ L 101 to 123 14 0 to t7 0 36 4 0 to 5 0 29 10 @T @T @T 7 58 0108 0 5110 4010 198 L 1 198 55 nun 8110107 8169 in P0229 Fig PD 6 6 PD croectional uiew of differenwl carner DIFFERENTIAL CARRIER PROPELLER SHAFT I Jack up port it rear by placing a shaft and axle shafts These works by referring Suspension under safety stand propeller Remove 2 of vehicle and sup Drain gear oil rear axle case can rear I Put match and tpark caps bearing caps and case assembly on and carrier Hold rear bearing inner race with Bearing Inner Race Drive Pinion Rear side bearing remove side Puller ST30031000 and extract from drive pinion with a press take out differential be done Rear Rear Axle and to 5 DISASSEMBLY REMOVAL Loosen off bolts securing differ and rear axle cas 3 ential carrier to STJ0031000 take out differential carrier assembly PD205 PRE DISASSEMBLY P0203 INSPECTION carrier should Differential spected before any parts are be in case assem bly removed from it These fmd the inspections cause of a are helpful to Note and to problem Mount differential carrier on Care confuse determine the corrections needed I Fig PD 10 Removing pinion bearing inner Fig PD B Removing differenlwl should be the left taken not to and right hand 6 To remove front and drift to rear race draw them with a outer races bearing apply rear race of both a brass side surface and with by tapping the top of drift hammer bearing caps and bearing outer race so that reassembly will be easily Dif ferential Attachment ST063 I 0000 carried out with the same parts in the original position 2 Remove Drive drive pinion nut using Wrench Flange Pinion ST31530000 flange using a and pull off companion standard puller Fig PD l1 Removing pinion front and rear bearing outer races ST063 10000 Fig PD 7 Holding differential Visually inspect parts for damage 2 canier wear or Dissssembly of dHferentIeI case Rotate gears to see if there is any roughness which would indicate dam 3 aged bearings or chipped the gear teeth for gears scoring or 1 ST3306S00 I signs of Fig PD 9 Removing drive pinion pinion See Figure Set up a dial indicator and check the backlash at several points around nul wear Measure preload PD 19 drive replacing Differential Check of abnormal When Side side bearing use Bearing Puller Set set of ST330S100 I and ST33061000 4 ring gear Backlash should be 15 0 to 0 20 mOl 0 00S9 to 0 0079 in S Check the gear tooth contact with a mixture of ferric oxide and ring gear teeth For the tooth contact pattern see paragraph dealing with tooth contact g ar oil to all pattern adjustment 3 Extract drive pinion assembly to by tapping the front end the rearwards with a soft hammer Drive be taken out ing nner together with pinion rear can bear bearing spacer and race washer 4 Remove seal and oil front bearing inner Note take out race Oil seal must not be PD 7 used Fig PD 12 Removing ide bearing PROPElli ER SHAfT Notes a Note PUller should be handled with in the catchins of edge care DIFFERENTIAL GARRIERf Drive and pinion ring supplied for replacement bearing therefore inner race should gear are as a either part damaged replace as a set 2 I set Check pinion shaft mate for scores and 2 out Remove ring gear by spreading lock strap and loosening ring gear replace 3 Punch ICV31100300 same and their gear and pinic m wear and signs of required Follow the bolts in diagonally Punch off pinion mate shaft lock pin from ring gear side using Solid as procedure seats on for side differential case all Inspect and bearing scoring chipping or evi dence of excessive wear They should be in tiptop condition such as not worn and Replace races with mirror like if there is surfaces their efficiency as an bearing operation may result 2 Fit case so be can 3 Adjust pinion PD 13 Removing lock pin Note Lock i cauIked at pin hole mouth on differential case Do not punch it Draw move off forCibly how it is checkins 4 pin without uIked to corrected with 0 0031 in replace thrust S Inspect case for cracks condition is carrier or and evident If either replace faulty parts As a 6 general rule oil seal should be replaced at each disassembly Assembly verse ing a Thickness 8re worn faulty Repair and or whichever is I damaged how they are affected replace ail faulty parts necessaiy Check cracking if they and or gear teeth chipping otherwise for scoring and make sure that tooth contact pattern indicates correct evident meshing depth If any fault replace parts as required is nun in Over 0 7S to 0 80 0 029S to 0 03IS Over 80 0 to 8S O Om IS to 0 033S Over 0 8S to 090 0 033S to 003S4 Over 090 to 0 9S 0 03S4 to 0 0374 Lock pinion shaft lock pin using punch after it is secured into place S Apply a oil to gear tooth surfaces and thrust surfaces and check if they turn 6 properly Place ring gear and install bolts Torque bolts on differential and lock case washers specification to 7 0 to 8 0 kg S1to be done in the can and directions for adjustment Sifft m Ib reo order of disassembly The foDow and perfect differential operation Notes ao Use and b gear bolts only genuine ring new lock strap bolts in cross criss Tighten lighdy tapping fOund with see side gear Side gear thrust WlISber INSPECTION disassembled by selecting Tightening torque usage of special tools enable to obtain clean all in thrust 0 0008 bend up lock strap ADjUSTMENT Thoroughly and 4 differential distortion Note parts and examine them to of side gear to 0 02 to 0 08 mOl 0 0031 gear thrust washer sand washers ASSEMBLY AND ed in their original positions from which they were removed toide mate the clearance between the side gear and thrust washer exceeds limits 0 02 to 0 08 nun 00008 to gears and thrust washers gear and thrust Wasliersotliat they can be reinstaD differential to in noises pinion shaft and re thrust block pinion mates side on or incorrect out Put marks pinion shaft face washer paper If pinion mate toide gear backlash or the clearance between Fig side that it meets lock pin holes backlash and gear seizure 4 Inspect thrust washer faces Small faults mates pinion gears thrust block and thrust washers in differential case shadow of doubt a oil PD022 Assemble rear 3 rollers for KV31100300 DIFFERENTIAL CASE be b Be careful not to confuse left and right hand parts ASSEMBLY OF fashion bolt Js heac a hammer PRECAUTIONS IN REASSEMBLY I Arrange shims like to install them 2 Thoroughly which shims w shers and the 7 correctly clean the surfaces washers bearings on and bearing caps are installed 3 Apply gear oil when installing bearings 4 Pack grease cavity between lips when fitting oil seal 8 PD When replacing side bearing bearing width using a stand 20 00 nun 0 7874 in gauge measure ard thickness S S Ib Figure and prior a weight to block installation PD I4 Standard bearing width 20 00 nun 0 7874 in 5 2 kg See DifFERENTIAL CARRIER PROPELLER SHAFT Where Rear ST306 II 000 and T Required thickness of rear bearing adjusting washers mOl N Measured ST3062I 000 I 1 2 Fit rear on carrier and bearing install Dummy Shaft Sf3 I 942000 and Standard Collar ST3197oo00 gauge and on place on Height Gauge ST31941000 with thickness Figure marked on the drive pinion head See Figure PD 18 Figure marked on the dummy H bearing rear value mOl gauge 0 carrier shaft marked Figure S the on height gauge ST31941000 uring bearing width Me Fig PD 14 and S 0 Figures for H sional variations in a are unit of 1 dimen 100 mOl against each standard measurement 8 Press fit side bearing cone into case using Differential Side differential Bearing Drift ST33230000 and Adapt er ST33061000 Set numblr PD2 b J t Head Fig PD 16 Adjusting pinion height ST33230000 number HI I P0186 3 io o1 Measure the clearance N be Fig PD 18 the tip end of height gauge and the end surface of dummy shaft using tween thicknes a Variation number on drive pinion gauge Examples of calculation P0244 I Ex Fig PD 15 ln talling side bearing cone N 0 5Imm S O T N H D H 0 2 1 xO 01 S 2 18 ol O Adjust washer the ld a Press fit races Drive Pinion 51 0 with height Fig PD 17 bearing the back of pinion gear provided inner race outer pinion between 2 rear 0 t 1 x 0 01 18 2 P0235 PINION HEIGHT 0 18 2 O SI ADJUSTMENT OF DRIVE I 2 51 0 x 51 0 Measuring clearance 3 x 0 03 2 18 0 01 18 2 2 66 mOl front and rear bearing into gear carrier using Ou ter Race Drift Tlie 4 thickness of drive height adjusting wa shers tained from the following can pInIOn be ob formula Front ST306 I 1000 and Sf30613oo0 T N H 0 2 18 PD 9 S x 0 01 The thick correct See washer is table following pinion adjusting washer 2 67 mm for drive PROPELLER SHAFT Ex 2 DIFFERENTIAL CARRIER Drive pinion N O 68mm 3 H D washer Note I N H 0 S 3 Om x 2 1 2 61 0 1028 2 64 18 2 0 68 0 1016 0 01 x 218 068 58 2 3 1 2 0 01 x heing tightened select 0 1063 2 73 0 107S pinion by hand while it Measure pinion bearing prelo d using Preload Gauge ST3I 27S000 and 1051 70 2 and 2 1039 0 2 67 0 washer bearing with thicker ones if cannot be turned in mm is T Replace spacer Thickness 2 S adjusting washer and spacer that will provide required preload 18 2 0 68 2 0 68 i88 2 18 02 0 2 79 0 1098 82 2 0 1110 mm is washer correct 1087 0 2 76 N8 02 0 0 68 The 18 2 0 01 x Preload 2 85 OJ 122 2 88 mm thick 2 91 0 70mm N S H O 0 0 O T N H 0 S 0 70 0 0 0 x 0 01 2 18 0 70 0 x 0 01 0 70 0 0 70 2 18 2 18 2 97 1169 0 3 00 1181 0 kg 4 to8 2Ib 6 Note 1205 0 Preload same 3 09 0 1217 3 12 0 1228 3 IS 0 1240 3 18 0 I2S2 of old bearing is the value as that of a new bearing 2 18 2 88 mm The 1IS8 0 3 06 2 18 companion flange bolt hole 2 9 to 3 7 3 03 0 1 193 0 01 x At 0 1146 2 94 cm kg 8 7 to II in lb 2 88 OJ 134 Ex 3 without oil seal 10 0 to 13 0 S washer correct 2 88 is mm thick Fit determined drive pinion ad justing washer fit preSs rear in drive pinion bearing and inner race in it using Base ST30901000 ADJUSTMENT OF DRIVE Note are lues signifying H D and S If not and given regard C n check to correct tooth r see e them After as zero assembly that tooth contact is If not contact readjust pattern PJ 12 for Contact Pattern For the see page IPIENLOADIONPI AdjUst the preload of drive pinion with spacer and washer between front and rear Fig PD 19 Measuring pinion preload bearing inner races This procedure has nothing to do with thickness of drive pinion adjust ing washer This adjustment be carried must Pinion bearing adjusting spacer out without oil seal inserted I Lubricate pinion front and bearings carrier front flange rear Install drive pinion in gear Be sure that spacer washer t bearing inner race and flat washer pinion Tighten and confum nut to are fitted 14S7 2 S4 80 2 IS7S SS IO 2 1693 SS 70 2 1929 m to 123 ft lb PD l0 in 5S 40 2 1811 Tightening torque 14 0 to 17 0 kg 50 S4 mOl on specified torque preload 101 Companion Length S6 00 2 2047 DIFFERENTIAL CARRIER PROPELLER SHAFT Drive pinion bearing adjusting T washer A C D B T2 Thickness mm over 3 80 to 3 82 0 1496 to over 3 82 to 3 84 84 3 over 86 3 to lS04 O Ex A F to 0 ISI2 T1 to 0 IS20 bearing adjusting shim mm T2 Required thickness of right side bearing adjusting shim mm A Figure marked on the left side bearing housing of gear carrier B Figure marked on the right side bearing of gear carrier 0 C Figure marked on the differ lS20 O to 3 88 to 3 90 lS28 O to 0 IS3S O IS28 over 3 90 to 3 92 over 3 92 to 3 94 0 IS43 to over 3 94 to 3 96 lSSI O to over 3 96 to 3 98 lSS9 O to 0 IS67 over 3 98 to 4 00 lS67 O to 0 IS3S to O IS43 4 00 to 4 02 0 S7S to lSS O I lS59 O lS83 O E the or standard width 20 00 4 06 to 4 08 lS98 O to 0 1606 If bearing width is 19 89 the differ over 4 08 to 1606 0 to ence 1614 0 will be 20 00 oil n press seal into gear carrier Tool Fitting KV38I02SS0 Apply grease cavity be tween seal lips Oil using H Unless companion flange and Seal Again install companion flange and washer and tighteh nut to speci to fied torque 14 0 to 17 0 kg IO m as Measure S Preload preload again with oil seal I 1 0 to 14 0 cm kg 1 flange 4 Figures for A dimensional 1 100 mm B C varia tions in a unit against each standard can 0 175 1 7S 0 11 0 0 11 mOl The correct shims Thickness are as follows Quantity 07 0 x 2 0 14 0 20 x I 0 20 34 0 Total thickness rj f 71 Right side T2 B 0 H mOl 3 2 Markj 2 O ISO Mark B 2 3 O ISO 3 x 0 27 The of shim on l ft and righ t sides gear set carrier dif side bearing has been Fig PD 21 Variation number ing formulas on ring gear PD ll 20 0 correct mm thick 0 01 x 0 01 0 15 2 0 01 x 0 O OI 0 03 Mark C 0 x F lSO O bolt hole be calculated by the follow OO a @ replaced with new one adjust the side bearing preload with adjusting shim The required thickness of adjusting shim x 0 11 0 01 32S 0 meas ADJUSTMENT OF SIDE BEARING SHIMS case or 2 urement Fig PD 20 Thickn hypoid x of P0214 If 0 01 1 0 11 3 0 04 0 and H are 6 8 to 8 81b I 3 2 x 0 01 x 0 11 19 89 1 to 4 0 kg 3 ferential 2 1 H E 0 17S 9 S to 12 in lb At companion 0 follows Figure marked on the ring gear See Figures PD 20 and PD 2 I 4 123 ft lb C liS O is found remove drive nut and pinion completed mm mOl 3 is A T mOl to 0 IS98 bearing preload anything wrong O IS Left side right side bearing against lS9I O Check and adjust tooth contact pattern when former adjustment of 2 3 0 2 C F l7S O 4 04 to 4 06 10 4 H 2 mm case over over B 0 11 These are differences in width F of left to 0 IS91 lS83 O I E thickness of left side Required entia lS7S O I xO OI lSI2 O 3 86 to 3 88 4 02 to 4 04 H lS04 O over over Examples of calculation xO OI Where over over D O ISO in H E l7S O 15 O IS O ISO lSO O lS O mm shims are 0 07 plus PROPELLER SHAFf Ex 2 2 A 0 3 B C 0 20 mOl E H I F 0 0 17 Fit determined adjusting 0 mOl 2 DIFFERENTIAL CARR IER shim on side differential press fit left and right side inner races and bearing it using Side Bearing ST33230000 and Adapter Drift on ST33061000 3 Left side TI A C D 0 17S 0 0 0 I7S 0 I 0 03 17S 0 Align that on a rubber Thoroughly mark on bearing cap with gear carrier and install And tight n bearing bolts to Paint ring gear teeth lightly and a mixture of ferric oxide and gear 3 to Rotate produce contact a pinion through several directions until 0 20 Tightening torque 4 0 to S O kg m a reverse defmite contact pat tern is 4 29 to 36 fHb rect thick developed on ring gear When contact pattern is incor readjust thickness of adjusting washer Right side Incorrect can be contact adjusted pattern in the of following manner B H xO 0l D O ISO 3 0 3 0 150 x drive to pinion If backlash is too small om right side To reduce backlash shims from 0 ISO remove shims from left side and add them to 0 I7 right remove side and add them to left side 0 17 a Heel contact To correct increase thickness of pinion height adjusting washer in order to bring drive pinio close to ring gear mrn shims correct 1 0 plus 0 20 0 x 1S0 0 37 0 om 17 0 001 O OS x 0 17 2 Measure ring gear backlash 2 0 S F O ISO The oil pattern S S clean ring and drive evenly with teeth T2 con drive pinion gear teeth revolutions in the forward and shinjs are O OS plus 0 20 mrn pattern of ring gear and I assembly 0 20 0 17S with side bear Check and adjust the tooth tact specified torque mrn correct plus 0 01 x case tapping with cap on carrier 0 20 O 34S The 2 0 Om 3 0 01 x 0 20 17S 0 0 10 2 7 2 4 it ing shims mallet E I specification adjust pinion Install differential into gear carrie H x om If preload does not accord with this bearing case mm are Backlash 0 07 plus 1S O thick to 0 20 mrn 000S9 to 0 0079 in Note If w1ues and H are signifying A given regard not and compute Aftassembly check to B C 0 them P0193 Fig PD23 Hul contact as zero preload and backlash not readjust are see that correct If b Toe contact To Side bearing adjusting Thickness shim mm O OS 00020 0 07 00028 correct reduce thickness of pinion height adjusting washer in order to make drive pinion go away from ring gear in Fig PD 22 Mccuuring back1aah At 6 bearing the same preload time check Bearing 10 0 0 0039 0 20 00079 should read 12 0 to 20 0 17 in lb of 50 0 00197 S 8 cm kg rotating torque kg side preload 10 to 3 S to 7 7 to 12 8 Ib at ring gear bolt hole 1 P0194 Fig PD 24 To PD 12 contact DIFFERENTIAL CARRIER P ROPELLER SHAFT Flank oontact c Adjust in the INSTALLATION same manner as in b Installing can be done in the reverse order of removal Tightening torque Gear carrier to cV t rear 5 kg 2 17 to axle case m 12 to 18 ft lb Drain and filler PD195 6 0 to 10 0 kg Fig PD 25 Flank contact P0238 plug Fig PD 29 Removing companion m flange 43 to 72 ft lb 10 liter Gear oil capacity 2 US pt I Y Imp pt d Face contact Adjust 6 Remove oil seal 7 Set oil seal in position using Fitting Tool KV38102SS0 new Oil Seal in the same manner as in a REPLACEMENT OF FRONT OIL SEAL Replacement of front oil seal with carrier assembly installed on the vehicle w difer ntial When replacing front oil seal do as P0196 Fig PD 26 Face contact 1 Drain gear oil 2 Raise the rear end of vehicle and support it with safety stands 3 Detach propeller shaft from panion flange of sher secure them in position by tightening nut to the given preload drive pinion flat and on torque confirming specified using Drive Pinion Flange WrencliST31530000 follows t grease in between seal lips Fit companion flange and Apply 8 Tightening torque 14 0 to 17 0 com kg 101 to 123 ft Ib carrier Pinion bearing preload 4 Rove drive pinion n t holding 1 companion flange with Drive Pinion Flange Wrench ST31S30000 with oil seal 110 to 14 0 cm kg 5 to 12 in lb 9 At companion flange bolt hole 1 to 4 o g 3 6 8 e 8 8Ib Correct tooth contact Notes a Preioad value as of old bearing is the that of a new bearing b If the desired nut can P0237 same tightening torque ot be obtained renew nut and readjust Fig PD 28 R moving drive pinion Fig PD 27 Correct contact nut Note ing Change in thickness of washer is adjWll accompanied by change in backlash Oled it when instaIIi gear S Extract companion flange using standard a 8 Reinstall propeller shaft and fill up differential carrier with gear oil puller PD 13 PROPELLER SHAFT DIFFERENTIAl CARRIER TROUBLE DIAGNOSES AND CORRECTIONS When differential carrier is a pected of being noisy it make a thorough lest whether the noise tires sus is advisable to to determine originates in the surface exhaust carrier Noise which Condition Noise on drive road universal places joint propeller shaft wheel bearings engine transmission or differential Probable Shortage originates cannot be corrected replacement ment or by adjust of parts in dif ferential carrier in other cause Corrective action of oil Supply coast and float oil gear Rebuild gear carrier if necessary Incorrect tooth contact between ring gear Adjust tooth contact and drive pinion gear set Incorrect backlash between ring gear and drive pinion Adjust backlash Seized up damaged ring gear and drive or or or replace the hypoid the replace hypoid gear set if necessary Replace the hypoid gear set Replace the pinion Replace the side bearing and pinion Seized up damaged or damaged or broken drive pinion bearing and faulty parts bearing Seized up Loose bolts or nuts broken side fIXing ring gear bearing bearing cap etc Noise on turn Seized up pinion mate damaged Seized up damaged pinion thrust washer or Pinion mates too tight Knocking starting or sound gear during shifting or broken side and broken side gear and on their shaft them to Clamp faulty parts faulty parts specified torque and Replace faulty parts Replace faulty parts Replace faulty parts Excessive backlash Incorrect pinion or backlash Worn gears Worn ring ar to drive rear or case axle shaft and side gear spline Drjve pinion bearing under preload cap or nuts ftxing ring gear etc PD 14 Replace worn Replace worn parts parts Adjust preload Loose drive pinion nut Loose bolts Adjust backlash side gear to pinionmate bearing Repair or Clamp them replace or replace if necessary replace PROPELLER SHAFT IFFERENTIAl CARRIER 1 Condition Seizure of breakage Probable Shortage of oil or use j Corrective action cause of unsuitable oil Replace faulty parts and use reconunended gear oil Excessively small backlash Incorrect adjustment Severe service improper Adjust backlash and replace of bearings leakage damaged front oil seal mally worn loading Replace faulty parts or or as ring gear bolts Replace faulty parts improperly bruised dented or driven abnor slide face of companion flange Replace faulty oil seal Repair the affected flange with sandpaper or replace if nee essary Tighten Faulty gasket Replace faulty gasket with Clogged or required Replace faulty parts Loose gear carrier bolts Loose fIller as of clutch use out Worn gears due to an excessive Loose bolts and nuts such Oil or or drain the bolts to Tighten plug damaged breather Repair PD 15 the or plug replace specified torque new one PROPELLER SHAFT DIFFERENTIAL CARRIER SERVICE DATA AND SPECIFICATIONS Type HI90 Ge ar carrier material Malleable cast iron Gear ratio number of teeth 4 375 3S 8 Spacer and washer Drive pinion Drive preload adjusted by pinion cm in Ib kg Preload without oil seal 10 0 to 13 0 8 7 to II with oil seal 110 to 14 0 At companion flange olt hole kg Ib 2 9 to 3 7 without oil seal 6 4 to 8 2 1 to 4 0 6 8 to 8 8 3 with oil seal Thickness of drive pinion adjusting washer nun in 2 S8 2 61 1016 0 0 1028 2 64 0 1039 2 67 0 IOSI 2 70 0 1063 2 73 O I07S 2 76 0 1087 2 79 0 1098 2 82 0 1110 2 8S 0 1122 2 88 2 91 0 1134 1146 0 2 94 0 1158 2 97 0 1169 3 00 0 1181 3 03 0 1193 3 06 0 120S 3 09 0 1217 3 12 0 1228 3 IS 0 1240 3 18 0 12S2 Length ofdrive pinion bearing adjusting spacer 5 to 12 9 nun in 50 S4 2 14S7 54 80 2 IS7S SS IO 2 1693 SS 40 2 1811 SS 70 1929 2 S6 00 2 2047 PD 16 DIFfERENTIALCARRI ER PROPELlER SHAFT Thickness of drive pinion bearing adjusting washer in mm over 3 80 to 3 82 0 1496 to O IS04 over 3 82 to 3 8 over 3 84 to 3 86 0 ISI2 to 0 IS20 over 3 86 to 3 88 0 1520 to 0 IS28 over 3 88 to 3 90 0 IS28 to 0 IS3S over 3 90 to 3 92 over 3 92 to 3 94 0 1543 to O ISSI over 3 94 to 3 96 0 over 3 96 to 3 98 IS04 to HO 0 IS3S to I5si OcISI2 1S43 0 to 0 ISS9 0 I5S9 to 0 IS67 over 3 98 to 4 00 0 1567 to 0 IS7S over 4 00 to 4 02 over 4 02 to 4 04 0 IS83 to 0 IS91 over 4 04 to 4 06 0 IS91 to 0 IS98 over 4 06 to 4 08 0 1598 to 0 1606 over 4 08 to 4 10 0 1606 to over 0 7S to 0 80 0 029S to 0 03IS over 0 80 to 0 8S over 0 8S to 0 90 0 0335 to 0 03S4 over 0 90 to 0 9S 0 157S to 0 IS83 1614 0 Side gear and pinion mate Thickness of side gear thrust washer Pinion mate to side gear backlash in mOl 0 03IS to 0 033S 0 03S4 to 0 0374 or clearance between side gear and thrust washer mOl in mm in 0 02 to 0 08 0 0008 to 0 0031 Ring gear Ring gear to drive Thickness of side pinion backlash 1S O to 0 20 0 00S9 to 0 0079 bearing adjusting shim mOl in O OS 0 0020 07 0 0028 0 10 0 0 0039 0 20 0 0079 0 50 0 0197 Side bearing standard width mm kg m TIghtening torque Drive Ring pinion 20 00 0 7874 in ft Ib 14 0 to 17 0 nut 7 0 to 8 0 SI toS8 gear bolt 4 0 to S O Side bearing cap bolt Differential carrier to axle case Companion flange of front shaft and flange yoke connecting nut Center bearing bracket ut Companion flange 101 to 123 to propeller shaft 29 to 36 17 to 2 S 12 to 18 4 to 3 3 2 17 to 24 1 6 to 2 2 12 to 16 4 to 3 3 2 17 to 24 6 0 to 10 0 43 to 72 Oil drain and filler plug PD l1 PROPELLER SHAFT Oil capacity about liter US DIFFERENTIAL CARRIER pt Imp pt 1 0 2Ji I Y Adjusting methods Variable numbers expressed by 100 1 Dummy shaft Drive pinion Side mOl Use adjusting fonnula bearing adjusting fonnula T TI N H A C 0 17S T2 PD 18 B 0 0 S D H x 0 01 18 2 xO OI E H x 001 0 150 F PROPELLER SHAFT 8i DIFFERENTIALCARRIER SPECIAL SERVICE TOOlS Tool number Description No tool I Unit name ST063 10000 This tool is used for attaching gear carrier to ease mOl disassembly Reference use page on Figure No in 620 or or Fig PD 7 610 assembly Diff For attachment SE023 2 ST3I 94S000 These tools are used to adjust the pinion 620 height 610 Fig PD 16 Fig PD 17 Drive pinion setting gauge assembly @ H190 ST31942000 Dummy SE209 shaft ST31941000 Height gauge SE210 3 ST31970000 This tool is used for Type H 190 to the adjust pinion height PD 16 di 35 1 38 30 Fig 610 This tool is used with ST3I 94S000 Collar 620 18 1 dia 1 1 06 27 l 4 KV311 00300 620 For driving out oflock pin of pinion shaft 610 Solid punch 710 S30 4 5 0 177 di 95 Y 65 PD 19 2 56 3 74 Fig PI 13 PROPELEER SHAFT GIFFERENTIAl CARRIER Tool number No Description Fur Reference use page on Figure tool name Unit 5 Drive pinion outer drift These tools are used when assembling drive pinion outer nUll in 620 race race Page or No PD 9 610 ST30611000 Bar 0 l t i ST306130qo 0 350 13 78 i ti Wt UWrflIfl UU Adapter 0 350 13 78 ST30611oo0 L Bar I 1 I j e II G ST3062 1000 2 83 dia J2 L 0 gI 2l 79 3 11 dia j Adapter 6 ST309OS000 Drive pinion rear bearing inner race This assembly hydranlic clamps rear bearing inner race and pulls it out by a press Before insertion place another drift facing inner race and then 620 Fig 610 Page PD IO PO IO S30 press fit puller lb 45 1 17 dia 35 2 1 386 dia ST3003Ioo0 Puller ST30901000 l Base 7 KV38102SSO Oil seal For installing 24 0 94 80g the front oil seal filling tool ST30720000 Drift KV38102SIO Drift 55 5 2 185 dia PD 20 5 dia 620 Page PO U 610 Page PO l3 PROPELLER SHAFT DIFFERENTIAL CARRIER Toollltlltlbcr Description No tuol 8 Unit nallle ST3 1530000 This tool is used to hold the Drive pinion flange wrench to case Ilange mOl in the operation of tightening and lousening drive piniun nut For Reference use page on Figure or No 620 Fig 8210 PD 5 Fig PD Y 610 Fig PD 28 Fig PD 19 Fig Fig PD 12 710 SJO l 54 9 ST3127S000 This toul is used to Ilwasure 2 b 13 the preload of piniun All bearing models Preload gauge GG91030000 Turque 2 wr CD nch L IIT62940000 Socket adapter J O lJ ct IIT62900000 1 4 II J x 3 8 3 8 UJ L 2 1 r Socket adapter 10 ST3J06S001 This tool is lIsed to oul side Jut bearing 620 Diff side 610 bearing puller SJO PD I 5 set ST3JOSIOOI Diff side bearing puller STJ306 I 000 38 1 50 di Adapter II ST33230000 Diff side bearing Use of this tool makes it damaging possible to drive in it bearing without 620 610 drift 5t 2 0t di 0ll 1B 1 PD 21 Fig PD IS r SECTION FA DATSUN PICK UP FRONT AXLE FRONT MODEL 620 SERIES SUSPENSION FRONT AXLE AND FRONT SUSPENSION FA 2 SERVICE DATA AND SPECIFICATIONS FA 13 TROUBLE DIAGNOSES AND CORRECTIONS SPECIAL SERVICE TOOLS lNISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN FA 14 FA 17 Front Front Suspension Axle FRONT AXLE AND FRONT SUSPENSION CONTENTS GENERAL DESCRIPTION FRONT FA 2 REMOVAL FA 3 AXLE AND INSTALLATION INSPECTION 8 FA 9 REMOVAL AND INSTALLATION FA 3 FA 9 ADJUSTMENT FA 4 REMOVAL AND INSTALLATION FA 9 DISASSEMBLY AND ASSEMBLY FA 4 INSPECTION FA 9 INSPECTION FA WHEEL BEARING TORSION BAR SPRING FA 5 UPPER AND FA 8 FjEMOVAL REMOVAL AND INSTALLATION FA 8 INSPECTION FA 8 DISASSEMBLY AND ASSEMBLY INSPECTION SHOCK ABSORBER FA 8 STABILIZER LOWER LINKS FA 10 AND INSTALLATION FA l0 FA ll FA ll FA Il ADJUSTMENT FA 8 VEHICLE POSTURE FA ll INSPECTION FA 8 WHEEL ALIGNMENT FA 12 ROD FA 8 STEERING ANGLE FA 12 REMOVAL TENSION AND INSTALLATION GENERAL DESCRIPTION uUl FA224 Fig FA 2 FA j SectionallJiew of xle fronta and fron t suspension Front Axle The design of the front suspension double the independent Front Suspension FRONT AXLE adopts wishbone type suspension used the torsion bar spring Both the upper and lower links are installed on the bracket which is welded on INSTALLATION the the frame 1d A swing to allow the knuckle to move freely in a vertical above links spindle REMOVAL AND Removal support vehicle Jack up and I dimension the stands the at in frame on safe a manner The top and bottom of the knuckle 2 spindle support are connected to the upper link through rubber bushing and to the lower lick through screw bushing The tension rod held by the brack 3 ets on the chassis frame and lower lick nut from knuckle wiih 6 rubber bushings bears the force is installed to the torque which attaches to the lower link is installed to the anchor that The shock is absorber S Remove hub cap and then remove pin adjusting cap and spindle cotter Remove spindle wheel outer and hub wheel bearings of the bracket installing front to sliding parts 8 Remove knuckle from arm knuckle spindle 9 Remove double of the Furthermore matters axle ring se lightly when coat grease the lower end of on support In The this select operation spindle shims to obtain the specified clearance between knuckle spindle and knuckle spindle support ance bracket Of the frame limits the verti cal motion reverse spindle support Install thrust bearing and spindle shim together with knuckle spindle to knuckle spindle rubber secured to the bumper in by noting the fol knuckle the lower lick The axle to removal Insert O I king pin lock bolt bracket is bolted to insulated front The spring frame Install the flange of knuckle spindle is attached to the chassis Installation bearing washer telescopic hydraulic type The upper stem lower Remove brake drum arm firmly The both ends of the torsion bar spring are serrated action cylinder 4 quence lowing to chassis frame secures FA226 Fig FA 3 R moving knuckle piridle and grease seal from knuckle spindle 7 Remove brake disc assembly from The front end of the torsion bar opposite end connector from wheel inner of fore and aft direction spring Remove front wheel Re ove brake hose together with with a bottom of spindle suspension lick Clear To measure the filler gauge up the jack slightly Standard clearance The knuckle spindle is connecied 0 1 mOl to the k ufkle spindle arm by the king pin The king pin bushings are fitted to the upper and lower the knuckle provided keep arm spindle at the seals water and dirt from enteri arm transmit ttLe steering wheel movement to the knuckle The wheel hub is on Line knuckle to of the 10 move with spindle two the knuckle Tlie brake drum and wheel spindle secured to ihe bearing Be sure to iristsll thrust to face coverea side 2 to spindle supported by taper roller bearings less upward are g is connected the lower end of the knuckle to Note or portIOns of and portions mentioned The knuckle FA225 R mol1ing king pin loch nut Fig FA 0 004 in are hub by the hub bolts After removing air breather re plug from the top of king pin the the plug M 12 1 2S hole and II in 413 0 screw pull Apply with a a on tap bolt into threaded out the out and detach it Take Be sure plug king pin along with knuckie spindle from a spindle smoothly and shim if necessary for Press knuckle plug soft haJnmer fit plug spindle as to Then sure to check required the upper of install lower to the lower knuckle Make reailjust In addition bushings and king pin Note with to check killJckle smooth movement Be certain to move 3 drift to the top ofking Tap spindle support a Drill diameter hole thread hole pin and drive lower plug 12 method following 5 mm 10 notch in locking bolt hole of spindle support with the king pin and secure lock bolt up spindle place lower plug conectly knuckle spindle io drop thrust care not 4 bearing FA 3 Secure knuckle arm to knuckle Front Axle Front 3 to 10 spindle and torque bolt to 12 1 kg m 75 to 88 ft lb Bend lock plate to engaged flats on boll head bearings proceed Note I When used lock disassembled To attain proper Suspension preload on wheel following opera the tions discard kg plate Torque spindle 22 to m 25 nut to ft lb 3 0 to 3 S using torque wrench 5 Pack lower until grease the to grea bushings on c omes r and upP knuckle spindle from out grease seal 6 fA22S Fill wheel up to grease and hub with cap Fig FA 6 Meauring bearing rotation the described level See atarting torque 4 Figure F A S FA227 Fig FA 5 Tightening apindle nut Install a new cotter pin Bend the ends of coller pin around the castel lated flange of adjusting cap Then install hub cap 2 FA141 Gre ing wheel hub Fig FA 4 Rotate clockwise wheel and bearings seat hub few turns a counterclockwise to Then retighten spindle nut to the same tightening torque Be certain to rotate hub 7 Pack roller and assembly cone and the cavity of grease seal lip with grease 8 Coat knuckle spindle bearing thread washer of and Secure wheel hub bearings bear ing washer and spindle nut on knuckle spindle and adju t bearing preload Wheel referring to the paragraph bearing adjustment Note the castellation cotter 4 spindle If Spring balance indication bearings for the of rpose pu ving their long life care to taking keep wheel be8rlngs seal grease bearing washer and spin dle nut clean when installing them New If hub bearing measure starting torque torque is deviated from the value r place beari gs r re The starting torque can sured by a spring balance as Figure F A 6 wheel on in the properly DISASSEMBLY AND ASSEMBLY Knuckle spindle the cap with the tion Be sure to obtain correct pre load pin hole on Check the hub rotation rotates lock nul bearing 9 the to grease smoothly 3 Back off spindle nut in range from 40 to 70 degrees Locate adjust ing cap on spindle nut so as to align rota measured specified dju st be mea shown in I Drive spindle bushing and grease seal out of knuckle spindle with KiTlg Pin Bush Drift ST3S380000 Discard bushing and grease seal when disas sembled 2 After cleaning king pin bores thoroughly install bushing carefully by using the above special tpol Posi tion bushing in accordance With the instructions fIlled in Figure FA 7 and at hub bolt 8 FA bearing 2 1 kg 4 Ib o ess Used bearing 10 kg 2 2 lb or 34 34 1 less Upper side mm in lower boss in I I Notes a WHEEL BEARING D TM ing on causes connected between hub boll and the abnonnal bearings II gential direction against normal line NT Wrong adjustment 1 When measuring the starting force pull the spring balance toward tan of wheel bear wear and and knuckle score spindle b spindle center Axial play is permissible 1 0 mm 0 004 in 4 FA or less to exist in I Pla ce this position grease nipple Upper side in upper boss in line with hole FA229 Fig FA 7 King pin bu hing Front Front Axle Suspension Wheel hub Level line 1 INSPECTION removing grease seal with After lightly tap screwdriver outer race King pin and bushing and replace king pin andlor tne following faulty condi if bushing cir Check with a hammer by ap brass bar and remove outer cumference plying bearing a outer race 2 Remove from Level line FA230 Fig FA 8 Bushing location Remove nipple and drill grease hole on bushing through thread ed grease nipple hole When grease hole is drilled remove metal chip and burr thoroughly grease tion is detected When all between of old grease traces and hub bearings partial meter knuckle Note When grease king pin and bushing in dia exceeding limit listed below 3 Install and inner in hub with outer bearing properly seat the races to 4 Pack the inside of hub and hub cap with grease to 0 15 in hub sure specified Clearance limit suitable tool Be a Standard dimensions the de King pin outer same When 118 0 mOl nipple hole it into pressing nipple lubricant Bushing inner diameter 20 010 to 20 035 in it has a hole ThorougWy clean grease and dirt from wheel bearing with cleaning sol vent with of moisture that in see Pin Bush Reamer HT56802000 Place inner ler assembly mOl ly reaming from both lower bushings When out upper and check outer Fig FA 10 Greasing bearing cone and roller assembly freely and pit ing or crack for condition race moval of outer is free from wear race Also Re from drum is not necessary 0 7878 to 0 7888 in Carry FA009 5 20 010 to 20 03S that it rolls noise diameter when fitted Note and dry with compressed air free Check wheel bearing to position align value with King Bushing inner Wheel bearing 2 ad an Ream the inside of bushing to the specified mOl in spindle bushing 4 mm 0 7866 to 0 7874 in ditional hole need not be drilled grease diameter 19 979 to 20 000 scribed level See Figure FAA Also pack the bearing cone and roller as semblies with the 0 00S9 in mOl 0 7878 to 0 7888 in spindle bushing a scores direction Drilling diameter approximate 3 deformation and excessive clearance wear spindle races 3 from hub tapping circumference tap evenly race to the seat it bearing cone in hub Coat grease lips of new Shown and rol slight grease seal below is the cha rt which furnishes the necessary information on Visual Serviceability Standard for and Wheel Bearing properly reaming upper side use lower side as reaming guide and when reaming lower side ing guide correctly 5 use upper side as ream King ST35390000 take care serviceability standard for wheel bearing @ Press fit grease seal with Visual align the center line to Pin on Grease upper Seal Drift @ installing grease seal damage seal lip In not to J arm @ 1 Outer race 2 Roller @ @ 35390000 51 3 Small collar 4 Inner race fitted surface 5 Collar surface 6 Inner race surface A @ 7 Outer race 8 Outer race 9 2 CD Q jJ @ Roller 10 Inner tilted surface rolling lcc surf surface race 11 Large collar 12 Supporter FADD6 FA231 Fig FA 11 Fig FA 9 Installing grease seal FA 5 Wheel bearing assembly Front Axle Judgement X Unserviceable 6 May be Suspension Front used when minor Rust should be removed with 0 emery paper Race and roller C 2 e 0 0 Flaking Cause E Components u 0 0 0 CIl X Service life due to rolling fatigue However this symptom the service life The following causes are occu before considered Abnormal load overload Fig a b Crack Improper handling X X X installing or Excessive tightening Excessive gap and a considerable shock received from the outside Rapid heat generation on the race due to creep Bitten supporter with seizing rollers Abnormal thrust load Fig c d Seizure Tapped X X X n with the most a hammer while removing cases seizure occurs as the result of grown discoloring or flaking Scratch 6 6 6 Shock is given carelessly during installation Bit foreign matter Recess or wear 6 6 6 made by pressing removal or other rough handling scar due to striking striking Fig e f g or Wear Careless installation Recess made by foreign matter 6 6 6 Poor lubricant quality or deteriorated lubricant Intrusion of dust Fitted surface is worn remarkably Wear due to preliminary excessive preliminary pressure Biting 6 6 6 Excessive Fretting 6 6 6 The fitted part is discolored to brown Fretting corrosion rust metal contact surface FA 6 pressure or on faulty lubrication or fitted part black means fine relative slip on Front Axle Front Suspension Race and roller u u Cause e Components 2 2 0 3 0 t c Rust 6 6 6 Temperature increased during operation lowers when the moisture inside the stops bearing is condensed bearing becoming fine drips and the grease is moistened The bearing has been placed in a highly moistened place for a long period of time Intrusion of moisture h Fig bare hand and The wheel bearing is Discoloring chemicals etc or the bearing is touched with rustproof action has been taken Slight discoloring may become serv iceable if discoloring no can In the most cases be removed with solvent like oxidized oil stain due to grease this occurs when preliminary pressure is too high by polishing or I I n I v 1 dJ i f Inner a race b flaking RoUer flaking c Cracked inner race t c fJ v d Cracked roller iT t 1 1 t 11 I 1 tt e Recess Jt l inner race Rust outer race on f Recess on outer race t F 1ll j JJ J I t l 1 ollf c oe g Recess on foDer h F A007 Fig FA 12 Defective conditions of bearing FA 7 Front Axle Specifications for SHOCK ABSORBER Raise vehicle 2 Remove wheel on a All models hoist or Piston stroke stands 3 m sec 0 rubber bushing Remove bolt from the lower end 110 4 3 in mm kg lb Damping force the upper stem of shock absorber and remove outs washer and 4 shock absorber Item Hold 3 Suspension Model REMOVAL AND INSTAUATION 1 Front 0 98 ft sec j Rebound 76 168 Compression 38 84 of shock absorber and rubber bushings for crack wear and deterioration Replace if ne STABILIZER cessary REMOVAL AND INSTAUATION FA232 FA 13 Shock absorber Fig I Raise vehicle 2 Remove wheel 3 Loosen secUring nut at the lower a on hoist or stands link side of stabilizer Remove bolt securing stabilizer mounting bracket to chassis frame 4 Retain S lower rubber bushing in position install the lower end of shock absorber to the bracket of lower link and torque the bolt to 3 1 to 4 1 kg 23 to 30 ft lb Note m Insert the bolt from the front side of vehicle Install the upper end of shock absorber to body bracket and tighten Jt n to the specifjcations Tightening torque 1 6 to 2 2 kg m 121016 reverse se REMOVAL AND INSTALLATION quence to removal noting the follow ing instructions I Raise vehicle S 2 Remove wheel 3 Remove Attach stabilizer mounting brack tightening bolt to et to chassis frame 16 6 lock Install stabilizer in the TENSION POD to 2 2 kg 12 m to 16 ft lb 6 Install stabilizer lower link side to connecting rod and tighten specifications as shown nut to the in a CD hoist stands from both ends Remove bracket bolt @ from the front end of tension rod and remove tension rod with bracket Figure FA 14 Then torque lock nut toJ 6 to 2 2 kg m 12 to 16 ft lb ft lb or of tension rod 4 torque nuts on CD @ INSPECTION I Check shock absorber for visible defects oil and leaks Place shock absorber vertically in a vise and hand stroke shock absorber as outlined be f A234 low Fig FA 15 Ten ion rod Extend sorber long as as and compress shock faI as possible travelling ab not present in hydraulic resistance is bqth Iirection replace absorber or Replace A233 Fig FA 14 Stabilizer detail possible If smooth 2 F as Install tension rod in INSPECTION qunce to removal rubber bushing if crack deterioration is detected Check stabilizer FA S for deformation instructions reverse noting the 00 following Front Axle s Install tighten nut tension to rod at rear end 4 make the distance of kg 12 to 16 ft lb m 6 Install bracket Anchor arm rear and detach spring S Withdraw torsion bar after pulling spring to A 0 98 in distance Temporary tightening rear anchor ou t setting post ion ISt02Smm 59 0 ring to the at cover snap ward rod tension dust Remove end of torsion bar rubber bushing to be 4 mm 1 315 33 in and torque lock nut to 1 6 to 2 2 Suspension Front B 60 to 70 mOl arm 36 2 realWard to 2 76 in chassis frame bracket and torque nut to 1 6 to 2 2 kg m to 16 ft lb 12 Installalation When two rubber ferent bushings are dif arrange adjusting nut in size Standard dimension is 11 0 in as shown in lock Figure to 1 6 to 2 2 nut kg 433 0 mOl FA 16 the Torque to 12 m Install reverse I 16 Il 0 11 0 spring in the of removal noting bar the serrations of on spring and torque arm Note Be sure to install install it to torsion bar can L Left marked R Right on the end Adjusting 4W Fig FA 18 Setting procedure Notes 011 0 0 433 Install anchor adjusting nut sion See Figure arm is nut arm obtain to FA 17 and tighten A dimen upper link should be in contact with rebound bumper rubber b See Figure FA 18 Install snap ring and dust cover Temporarily tighten adjust B ing nut until specification is w reached mm adjustment height are found under Adjustment on Discard Install ring to 4 I kg page FA II old snap ring moving it Replace with during reinstallation wheel full fuel tank Fig FA 16 Tension rod detail after re new one and lower vehicle no at curb passengers refer Adjustment Torque lock nut to 3 1 to 1 4 22 to 30 ft lb m INSPECTION Check tension rod for bend and faulty condition Repair or replace as required 2 Check bushing rubber for wear and deterioration Replace if neces I Check torsion bar spring for wear twist etc When adjusting vehicle the thread for replace posture FA236 Fig FA 17 Installing anchor arm with a new one can not torsion if the bar TORSION BAR SPRING Specifications for torsion bar be obtained spring REMOVAL AND All models INSTALLATION Removal 1 Raise vehicle 2 Remove wheel 3 Loosen on a at hoist Diameter or spring stands anchor x length mOl in Torsional rigidity kg m 219 x 830 0 862 3 74 27 I deg FA 9 ft lb deg spring specified height sary bolt weight I INSPECTION nuts are the final performing Adjust vehicle posture in FA235 I specifications preliminary rough settings that determines the ride 3 36 6 l 441 the directions for A to 8 and only When anchor properly adjusted specification i Y Unit A 3 2 I 1 bumper j right and left springs correctly They be identified with and 4 1 33 315 433 0 Rebound rubber 433 0 surface 11 0 UjP je instructions Coat grease lP t bar sequence following torsion ft lb torsion x 32 68 FrClnt Axle Front Suspension 4 UPPER AND LOWER LINKS link Install upper link spindle to upper mounting bracket with used camber adjusting Torque bolt REMOVAL AND to 6S ft lb INSTALLATION S Removal I Raise vehicle 2 an 6 hoist on a or stands FA238 Remove wheel and brake drum as Fig assembly 3 Remove wheel hub Refer to FA 20 Removing upper link spindle see 4 Loosen bolts retaining brake disc to knuckle spindle and remove brake 12 Remove knuckle 5 spimgJ stabilizer arm torsion bar shock absorber tension rod in t ili order and referring the related sections Remove upper 6 curing knuckle fulcrum bolt spindle support se to upper link assembly and disassemble them retaining lower link Remove nut spindle and disc SI to the lower end seat spindle support Coat grease on the thread of fulcrum pin and line up the notch of fulcrum pin with knuckle spindle sup port for inserting cotter pin Fit fulcrum pin to spindle support with a soft hammer Secure cotter pin and torque lock nut to 0 8 to 1 kg m Front Axle tion to 7 0 to 9 0 kg m Install dust of j nuckle shims and bolts remove lower link spindle Remove lower link with torque from mounting bracket Using Transverse Replacer ST36070000 Unk 13 bushing drive it tap out with lower link to a arm of Coat grease to the tIuead portion screw bushing inside liberally Posi tion knuckle Bushing lower link hammer and from bushing S 8 to 8 0 ft lb 7 bracket at the spindle support center of lower link and secure screw bushings temporarily by the ascertaining correct hand shown in Figure as Mter dimensions become torque screw bushings kg m I4S to 217 ft lb FA 22 20 to 30 to Remove upper link bushings from 7 knuckle 8 spindle support Remove screw bushings from both ends of lower link fulcrum pin 9 Loosen nut at lower portion of knuckle spindle support and out cotter pull crum from inside pin retaining ful pin 3 Pull out fulcrum pin with drift and remove knuckle spindle support 10 with knuckle spindle Then detach dust from lower link F cover Fig FA 21 A239 Removing lower link bushing 9 05 to 11 05 0 3563 to 0 4350 36 5 1 431 9 05 to 1105 0 3563 to 0 4350 FA240 Fig FA 22 In tailing IICrew bu hing InstallatIon Install upper and lower links in the sequence to removal the following instructions reverse I link noting When the collar inside of lower mounting bracket and bushing outside are rusted remove rust with emery paper FA237 Fig FA 19 Removing fulcrum pin 2 Fit lower link link mounting verse Link bushing into lower 8 comes filler 9 plug with grease out from dust cover plug Upon installation make grease Reinstall sure that with smoothly Operating torque Less than Replacer 5 kg 0 m 3 6 ft lb ST36070000 with II link Remove spindle bolts and retaining remove upper upper link a 10 Install drift squarely knuckle 3 II Secure lower link to lower link bushing spindle with camber adjusting shims torque from S8 ft Ib body bracket When tapping the frift hammer be careful to hit the filler fulcrum pin operates the following torque bracket using Trans Bushing Replace nipple and pack grease until with lower link spindle and nut to 74 to 8 0 kg m 54 to to upper link torque 38 ft lb 14 1n upper link bushing to spindle support Install knuckle spindle support insert fulcrum bolt and nut to 3 9 to 3 S kg m 28 to Front Axle Note When fulcrum pin installing 4 insert it from rearward of vehicle 12 Install sorber and tension stabilizer I knuckle rod shock torsion bar arm ab to Install brake disc to out from dust cover Reinstall f1ller plug 14 When screw of upper link spindle fulcrum pin and screw bush ing and repair or replace if necessary Note Discard dust cover and dust seal when disassembled installing torque tighten it to the lower link arm on following specifications as and torque knuckle spin dle nut to 8 0 to 9 0 kg m 58 to 65 assembly the Lower link to 4 2 Install wheel and brake drum an Check the knuckle spindle and torque securing bolt to 5 0 kg m 30 to 36 ft Ib to operate upper link sure comes spring referring Suspension spindle smoothly after installation 5 Replace filler plug with grease nipple and pack grease until grease related paragraphs 13 Make Front Serration boss VEHICLE POSTURE 1 8 to 2 6 ft Ib ADJUSTMENT kg m Vehicle posture may be incorrect 13 to 19 ft Ib due to weakened Arm head 2 7 to 3 7 20 to kg condition m 27 ft tb are spring or other faulty following procedures when adjustment is Ie The necessary quired That is the vehicle posture can be adjusted by obtaining only the speci INSPECTION DISASSEMBLY AND Upper link spindle fulcrum pin screw bushing I 2 ing I mm in spindle from Apply screw bushing to upper link spindle or fulcrum pin and measure clamp dust axial end and dust seal Secure upper link When Detach upper link cover a and remove vise and loosen screw bushing link spindle sequence to disassembling following instructions 2 Torque mm ft Ib to Install cover and reverse noting the bushing on upper kg m 253 to 398 new dust seal and dust secure them with screw between them the end play exceeds or 35 0 in replace upper link fulcrum pin together with bushings H on stands dimension with turn Adjust adjusting nut anchor bolt H dimension changes approximately 0 J38 in nut is turned one complete turn To make the best vehicle 3 H 5 3 vertically when adjust posture dimension must be in the follow ing range the 55 screw link to 3S in play 0 0138 spindle Assemble changing Raise front of vehicle and links dimension length of anchor bolt Upper link upper H fied ASSEMBLY H dimension in All models Condition clamp mOl 3 Coat grease to screw bushing in side and the thread portion of upper link spindle liberally Screw front and rear same fied links to length figures Vehicle empty no payload upper link spindle in the to obtain the speci 79 to 84 3 11 to Vehicle loaded 5 2 15 54 so as as 31 3 shown in Figure FA 23 Notes a i o Vehicle empty no payload consists of the following conditions I Full tank of gasoline radiator f1lled and engine oil level full 2 Spare tire wheel jack and jack handle in design position b Vehicle loaded consists of the fol Unit mm in I 44 6 1 FA2 1 56 Fig FA 23 Upper link and upper link spindle lowing conditions FA242 For all models leg I 103lb 2 persons and SIlO payload FA Fig FA 24 Dimension for standard vehicle postl4re Front Axle Front Suspension When WHEEL ALIGNMENT Correct side wheel front attains proper vehicle alignment handling charac Before After correct sure toe in is to 8 0 to nut rJ to carry out a pre of the front end 1 Tire pressure and balance r HI CD r cCJ ter Steering gear play 4 Steering gear housing at frame S Steering linkage and connections 6 Shock absorber action Do not front f b equip inspection c inst c tions furnished with the should be made with the vehicle level make difference between and FA244 shims in thickness rear beyond 2 mm 0 079 link spindle When using the equipment for front wheel alignment inspection follow the the in on a Fig FA 26 Adju6ting toe in upper STEERING ANGLE Umit shim thickness for anyone stack within 6 Do not more use nun 0 236 in Check steering angle and shims for anyone stack the 2 sheets Loosen lock nut at stopper bolt and Measure toe in and adjust if neces Camber and caster and caster and adjust them in accordance with the following procedures if necessary camber and caster ad are justed by increasing and decreasing thickness of adjust shim inserted be link spindle and upper link mounting bracket upper To adjust caster make a difference between thickness of front and shims By in adding front at creased by a side 33 shim I mm At the To adjust camber add rear mOl amount sides in a in 2 mOl by steering wheel straight to ing gear straight ahead position Loosen lock nuts thread and and turn Turn cross shown by ID cross @ left hand right hand thread rod CD adjust to toe in rod to forward direction arrow as FA245 and toe in is reduced Fig FA 27 Adjusting steering angle 6 S or remove an Item Model I mOl by 13 0 079 in and 4 mOl 0 039 in 1 All models 2 to 3 0 079 to 118 0 Toe in degree thick at both sides mm in thickness Turn ahead position with front wheels in the same position Then check steer time same available in I are follOWIng procedures 0 039 pack of shims camber will be decreased Shims the carry out of shims to front and By adding 0 039 rear For adjustment sary caster will be de camber will also be decreased equal the adjust steering angle with stopper bolt Mter obtaining correct steering angle secure lock nut firmly Toe in tween use follow ng procedures if necessary and at curb weight camber 0 Notes a Furthennore I e Fig FA 25 Adjustingcamberand 3 Both m FA243 2 Wheel bearings and nuts Measure kg S8 to 72 ft Ib liminary inspection parts for the following conditions ment obtained 10 0 front wheel align adjusting make rod is turned to opposite in is increased tighten lock teristics and the least steering effort with a minimum amount of tire wear ment cross toe 2 10 to 16 Camber lOIS Io Caster 10SO 4S 157 0 Kingpin incIinal10n Steering angle 60IS I Innerwheel 10 360 I Outer wheel 10 310 1 The extreme front and rear of the tire center 2 The total FA 12 angle of the both tires Unladen Front Axle Front Suspension SERVICE DATA AND SPECIFICATIONS King pin Clearance limit between the king pin and bushing inner diameter when fitted Bushing 0 15 in mm 0 0059 20 010 to 20 035 in mm 0 7878 to 0 7888 Clearance between the knuckle spindle support and spindle mm less than 0 1 in 0 004 Wheel bearing kg Tightening torque m ft Ib 22 to 2S 40 to 700 Spindle nut returning angle Wheel bearing rotation starting torque When both bearing and seal are new When 3 0 to 3 S readjusted kg kg em in Ib em in lb less than IS 13 0 less than 7 6 1 At the hub bolt bearing and seal are readjusted When both When Suspension new less than 2 1 kg lb kg lb 4 6 less than 10 2 2 link Upper link sliding resistance kg m ft Ib less than O S 3 6 Lower link kg m ft lb less than O S 3 6 sliding resistance lightening torque kg ft Ib m Brake hose connecting nut 19 to 2 S 14 to 18 Wheel bearing lock nu t 3 0 to 3 5 22 to 2S Brake disc fIXing bolt 4 2 to S O 30 to 36 3 to 12 1 10 Knuckle arm fixing bolt 2 1 to 2 S King pin lock bolt Torque IS 74 to 88 to 18 arm Arm end 2 7 to 3 7 20 to 27 Serration boss 18 to 2 6 13 to 19 74 to 8 0 S4 to 58 Lower link spindle Upper link screw nut 24 to 35 bushing Upper link spindle bolt fIXing 174 to 2S3 7 to 9 51 to 6S to bracket Cotter pin lock nut 0 8 to l 5 8 to 8 0 Lower link 25 to 32 screw bushing 3 9 to Fulcrum bolt 181 to 231 3 28 to 38 S Tension rod Lock nut 16 to 2 2 12 to 16 Bracket bolt 1 6 to 2 2 12 to 16 1 6 to 2 2 12 to 16 3 1 to 4 1 22 to 30 Shock absorber Lock nut of the upper end Lower end Stabilizer 16 to 2 2 12 to 16 Bracket bolt 3 1 to 4 1 Lock nut of the anchor bolt 22 to 30 0 8 to l 5 8 to 8 0 Bumper rubber bolt FA 13 Front Axle Suspension Front TROUBLE DIAGNOSES AND CORRECTIONS Probable Condition Vibration shock and shimmy Too much backlash of steering gear Vibration of each part of ing of steering wheeL wheels traveJling over When is Very much noticeable when bad roads and at higher the front wheels the roads bumpy transmitted to the in many cases are speeds travelling are noticeable when travelling sion over of the steering linkage is play transmitted to the steering wheel This is Shimmy wear and vibration of front linkage steering wheel This Shock Corrective action cause especially road rough Abnormal vibrations of the front suspen group and the whole steering linkage which when a occur Improper is attained specific speed Adjust air pressure of tire Correct the unbalance Unbalance and deformation ofroadwheel place Unevenly worn tire or Improperly adjusted Replace insufficient tightening or worn front wheel bearing or loose suspension link Damaged idler screw Replace bushing Replace arm Insufficiently tightened steering Worn steering replace Adjust Faulty wheel alignment Worn Adjust tighten or or TIghten housing gear ball joint Replace linkage insufficient back Improper steering gear adjustment Adjust lash Faulty shock absorber or loose Replace installation pulls to right or left tighten Adjust Unbalanced vehicle posture Vehicle or When driving with hands off the steering wheel on a fiat road the vehicle gently swerves to right or left Note A faulty rear of this condition chapter dealing and with the therefore rear see cause also the suspension air pressure of tire or insufficient Improper of wheel also be the suspension may tightening Adjust or Difference in height of right and left tire treads Incorrect adjustment or abrasion of front wheel Replace Adjust tires or bearing Weakened standard tighten nuts front torsion spring or deviation from Replace specification Readjust Improper wheel alignment Worn or loose suspension link screw FA 14 bushing Replace replace or re Front Axle Condition Vehicle puBes to Front Probable right or left Deformed of steering Suspension Corrective action cause and suspension link linkage Unbalanced vehicle level Instability of vehicle Worn or Correct the unbalance air pressure of tire Improper Adjust loose suspension link screw bushing Replace Incorrect wheel alignment Worn Adjust deformed steering or Replace linkage and suspension Replace link Incorrect adjustment of steering gear Adjust Deformed unbalanced wheel Stiff steeirng wheel Correct or replace Check and correct in the following Jack up front wheels manner detach the steering gear and operate the steering wheel and a If it is light check steering linkage and suspension groups b If it is heavy check and steering gear steering column groups Improper air pressure of tire Adjust Insufficient lubricants or mixing impurities in steering Replenish linkage or excessively the part worn steering linkage Insufficient lubricant in gear box contaminated or Add or grease replace or replace gear oil lubricant Unsmooth king pin damaged part Or insufficient Replace lubrication Worn or incorrectly adjusted wheel bearing Replace Worn damaged steering gear and bearing Replace Incorrectly adjusted steering gear Adjust Deformed steering linkage Replace Incorrect wheel Adjust Interference alignment of steering column with turn signal or adjust Adjust switch Excessive steering wheel Incorrectly adjusted steering gear Adjust play Worn steering linkage idler Replace Improperly fitted of gear box Incorrectly adjusted Worn Noise or Retighten wheel bearing loose suspension link Improper screw Adjust bushing air pressure of tire Insufficient link arm screw lubricating oil and grease for suspension bushing and steering linkage or their breakage FA 15 Replace Adjust Replenish lubricating or replace grease oil and Front Axle Front Probable Condition Loose Noise Suspension Corrective action cause steering gear bolts linkage and suspension Retighten groups Faulty shock absorber Replace wheel bearing Replace Damaged Grating tire tire or partially Replace Worn ofloose suspension link Replace Improper noise Jumping of disc wheeL Excessively Worn steering linkage and steering gear bushing Adjust air pressure of lire Incorrect wheel alignment Adjust Deformed knuckle spindle and suspension linkage Replace Rough driving Avoid rough driving Improper worn screw Adjust air pressure of tire Unbalanced wheels Adjust Faulty shock absorber Replace Worn tire Replace Deformed wheel rim Replace Improper air pressure of tire Adjust Adjust Incorrect wheel alignment Damaged wheel bearing Incorrect brake Improper tire Replace Adjust adjustment shifting rotation Rough and improper wiving FA 16 manner Adjust Drive more gently Front Axle Front Suspension SPECIAL SERVICE TOOL Tool number Description No tool name Unit mOl For Reference use page or on Figure No in ST35380000 22 2 dia 0 874 King pin bush This tool is used to drive out drift king pin bushing FA 4 620 Page 620 Page FA S SE234 2 HTS6802000 King pin bush This tool is used to correct reamer king pin bushing FA 17 SECTION RA REAR AXLE REAR DATSUN PICK UP MODEL 620 SERIES I NISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN SUSPENSION REAR AXlE AND REAR SUSPENSION RA 2 SERVICE DATA AND SPECIFICATIONS RA 7 TROUBLE DIAGNOSES AND CORRECTIONS RA 8 SPECIAL SERVICE TOOLS RA 9 Rear Axle Suspension Rear REAR AXLE AND REAR SUSPENSION CONTENTS RA 3 DESCRIPTION REMOVAL AND INSTALLATION Rear axle RA 3 RA 3 assembly Rear axle shaft and wheel spring RA 6 fJ RA Rear axle shaft and wheel 4 RA bearing Rear axle case Rear Shock absorber tNSPECTION Rear axle RA 6 bearing RA6 case RA 5 Rear RA 5 Shock absorber fJ RA spring fJ RA 4 J I i I LJ o 1 1 Air 2 3 Thrust block Nut T @ RA132 breather 14 Wheel 15 Rear bearing axle bearing grease seat Supply 3 1 to 4 1 kg m 22 to 30 ft lb oil wheel bearing 16 Rear axle Shock absorber mounting rubber bush 17 Rear axle shaft 18 Grease catcher 5 Rear spring clip V bolt Rear axle oil seal spacer Rear axle shaft oil seal 19 Bearing 20 Rear axle 21 Nut 7 Supply 8 wheel bearing grease oil seal lip when assembly Rear axle bearing lock nut T 15 to 20 kg m 10810 9 10 11 T to 145 ft b 12 13 Road wheel nut T 58 to grease to Oil capacity 1 30 cage bolt case end case m 43 to 72 ft4b bearing spacer US qt about 10 7 8 Imp qt Drain plug T 6to 10kg shim m 31 5 4 to 6 4 kg m 391046 ft lb Nut 5 to 13 0 kg 11 T m Rear spring pad Rear spring 32 23 33 Rear 24 Nut 34 Rear spring shackle Nut 22 T 25 7 3 to 9 9 kg m 53 to 72 ft4b 35 1610 2 2kg m 12 to 16 fHb 36 T Nut T liter 43 to 72 fHb m 26 Shock absorber rubber bush 65 fl Ib 27 Shock absorber 8t09kg Filler ptug T 6toIOkg 83 to 94 fHb Rear spring rear bush Rear axle bearing lock washer Plain washer Rear axle bearing cage Road wheel bolt Rear axle 29 seal lip when assembly 4 6 28 spring 1 15 to 13 0 kg 83 to 94 fHb m 37 Rear spring Rear spring front bush 38 Rear spring front pin T Fig RA 2 Tightening torque RA I Crou uctional view of rear a xl and uapension Rear Axle DESCRIPTION The axle rear 2 is of the assembly semi floating type in which the vehicle weight is carried on the axle shafts through bearings enclosed in the bear ing cages axle is case axle case outer rear on pressed steeJ a The Banjo type housing The rear axle assembly is attached to the frame through semi elliptic leaf and springs absorbers end telescopic hydraulic shock Rubber of the absorbers bushings leaf springs across propeller three clamps ID and connector nect combination is restored removing three clamps ID assembly 3 Remove bolts retaining center bearing bracket and connecting shaft to companion flange Withdraw pro peller shaft sleeve yoke from transmis sion by moving passing 4 shaft rearward it under rear axle Disconnect Q the at rear hand brake cable by removing adjusting @ nut and shock @ Slide front cable rearward and discon 5 cable rear @ ID by at connector Disconnect frame rear brake hose at Cover brake hose and pipe @ openings to prevent entrance of dirt Disconnect shock absorbers at lower end f and push shock ab 6 sorbers up out of the way 7 Lower jack under axle case U bolts spring clips separate axle case from spring move @ Re to to absorb vibra designed are relationship Suspension shaft flange and companion flange of differential carrier so that the original either at Mark Rear tion and noise The rear axle shaft splines engage the differential side gears with a float ing fit The outer ends are supported in the bearing bearings The cages bearings by tapered roller lubricated are by wheel bearing grease The axle shaft oil seals are located outboard and inboard of the bearing The bearings are se cured against shoulders on the shafts by press fit and held in place by a large nuts The bearing cages hold the against shoulders Whee side on the axle thrust bearings case is taken at the wheel bearings block so moved simply by removing the bolts holding the through axle shaft may be an the brake disc to the cage and the thrust rear axle re bearing case RA312 Fig RA 2 Under view 8 jack under center of axle case through space above spring and take it out to the REMOVAL AND INSTALLATION Place case Pass a axle Tightening torque U bolt side 53 to 72 ft lb REAR AXLE ASSEMBLY It reaT Shock absorber lower end nut is not necessary to remove the axle assembly for any normal 1 6 to 2 2 the aged removed if the axle case Raise to IS starts to raise rear axle Place members wheels stands on just Fig RA 3 Removing rear rear kg m the Install the axle reverse case assembly order of removal RA 3 in 2 7 kg m Center bearing bracket fixin 9 to 14 to 20 ft Ib axle assembly solidly under frame Remove 20 RA134 assembly both sides 18 Propeller shaft to companion flange connecting bolt rear center of axle case so it to II to 13 ft Ib of vehicle high enough working underneath Place a permi t jack under m Brake pipe flare nut is dam axle assembly may be and installed using the fol rear lowing procedures I kg 12to 16ft Ib repairs However Spring clip kg m 3 to 9 9 7 holt 1 6 to 22 12 kg m to 16 ft Ib Rear Axle 8 REAR AXLE SHAFT AND Raise of vehicle and support case on stands Remove Unbend lock washer with wheel 2 Disconnect rear Disconnect nut and brake tube cylinder openings to prevent race oil seal in new a outer by brass hammer evenly bearing Lubricate cage Place cavity between seal wheel bearing grease after bearing apply cone cage with brake disc brass drift to a race side surface and tapping the top of drift with a hammer Remove brake drum Not Install bearing a and bearing spacer on axle shaft and fit bearing cone To install bearing entrance of dirt 4 tapping with while fitting 3 rear wheel cylinder Cover brake tube and wheel Fit wheel lips with fitting seal clamps at I 2 Do not use used lock washer again hand brake cable by removing adjusting a screw driver Note rear 3 Position axle shaft in vise with 9 rear under axle Suspension Rear Axle Stand ST07630000 WHEEL BEARING I Rear If brake drum cannot be removed return install two holes brake easily adjuster M8 I2S bolts the on drum and x in RAl38 Fig RA 6 face of brake flange tighten bolts evenly until brake drum is driven out 10 Unbending lock washer Remove Axle lock Bearing nut using Nut Lock Rear Wrench ST38020000 5 Remove bearing nuts retaining wheel I cage to brake disc AA141 Fig RA 9 Installing whetl bearing 4 Place bearing shaft and Rear AJde AA139 I Jq AA135 Fig RA 4 Removing nuts II Fig RA 7 R mouing lock nut wheel to Withdraw gether disc with bearing bearing cage and brake Axle Shaft using Rear Bearing lock washer tighten Bearing ST38020000 @ lock nut Q and on @ axle using Lock Nut Wrench and bend up lock wash er Notes a Be careful to the faced side of place nut to washer side not Puller HT72480000 bearing nut lock washer so that washer is damaged b Coincide washer lip with nut groove tightening nul and bend washer carefuljy so that lip will nol be damaged correc HT72480000 ly by r t Tightening torque Rvr IS to 20 kg G o l AA343 Fig RA 8 Removing bearing 12 Remove oil seal in bearing cage if necessary 13 To race after AA418 Fig RA 5 Removing rear axle shaft assem bly brass Remove oil seal necessary and install against damaging in axle case if new the seal seal lip Insure to it a Installing reverse wheel bearing removed oil seal drift withdraw drift with 7 remove race i t i S side surface a and 11 iI i j hammer be fifii Litf 4 outer apply by tapping the lop of can m J08 to 14S ft Ib proceeded order of removal follows i in the procedure I as AA142 Fig 4 RA t J Mf pu y RA IO Layout ofock nut Rear Rear Axle Apply wheel bearing grease in wheel bearing and recess of axle case S Suspension Install shaft in opposite side 8 adjust end axial end Axial end play by applying shim 0 02 to O IS play Installing and reverse Differential carrier fixing Tightening torque of bearing cage fixing nut 5 4 to 6 4 kg m to the proceeded in procedure Tightening torque mOl 0 0008 to 0 0059 in 39 be can order of removal to I 7 to 2 5 nut 12 6 to 10 kg kg m to 18 ft Ib plug Oil drain and fIller 46 ft Ib axle case m 43 to 72 ft lb Lubricating portion AA143 REAR SPRING Fig RA l1 Lubricating portion in and around wheel bearing Raise rear of vehicle and 1 under both frame support with members stands 2 6 Apply gear oil to the spline at the Apply a coal inner end of axle shaft of wheel bearing grease on end Spring clips the seal Fig RA shock Disconnect lower CD 2 and absorber remove at U bolts Measuring axial end play 13 surface of the shaft 7 Install left shaft right or and adjust axial end play by applying rear axle case end shim indicated by arrow 9 Install other parts in reverse se quence to removal mark Axial end play 3 to 0 9 0 0 012 to mOl 035 0 in REAR AXLE CASE Standard shim thickness 5 mm 0 059 in 1 bearing cage fIXing 54 to 6 4 cedures nut kg Rear axle case may be removed and using the following pro installed Tightening torque of m Raise I 39 to 46 ft lb securely rear under of vehicle and support both frame members with stands Remove rear axle 2 removal of rear assembly See assembly axle Remove rear axle shaft at 3 See removal of sides and wheel 4 rear both axle shaft Position differentiai carrier jack under rear axle case Raise jack and float axle case from spring 4 Disconnect removing bearing Remove 3 rear spring shackle by nuts as sembly w Installing AA144 Fig RA 12 Installing rear reverse axle shaft be can proceeded in the procedure order of removal Another procedure is available as listed below Rear axle case end shim I Thickness mOl in Raise under rear both of vehicle and support frame members with stands O OS 0 0020 0 07 0 0028 0 10 00039 0 20 0 0079 O SO 0 0197 2 Remove ear axle shaft at both AA147 Fig RA 15 Removing spring shackle sides 3 Remove differential gear carrier assembly 4 Disconnect spring from body by removing spring front pin 5 Remove rear axle case RA 5 Suspension Rear Rear Axle Check axle shaft for I SHOCK ABSORBER cracks Raise rear under axle case mended that pit of vehicle and support on stands It is recom hydraulic hoist a 2 open Disconnect lower end of shock absorber spring 3 by removing Q nuts wear straightness and distortion Check the lip of oil seal for damage deformation and wear 3 Check bearing for wear and 2 damage at seat REAR AXLE CASE Disconnect upper absorber by removing RA148 or be utilized if available damage end of shock nut 2 at Check axle frame tion Fig RA 16 Remvoing spring pin cracks case or for yield deforma oil leakage and replace if necessary 6 Remove rubber bush in spring if REAR SPRING necessary and install new bush Coat rubber hush with a soapy solution prior to Clean all rust and dirt from spring leaves using assembly 1 spring in the reverse of removal noting the following InstaH order rear 2 RA146 Vehicle weight must be on rear wheels when tightening front pin Fig RA J 7 Removing shock absorber shackle and shock absorber lower end clamp rubber bush neutral or unloaded position nut in order to nut reverse order of removal Vehicle weight must be tigtrtening on Tear or unloaded position kg m U bolts replace with new bracket and and ones 3 Inspect all rubber parts for wear damage separation and deformation Replace them if necessary SHOCK ABSORBER Data INSPECTION Test shock absorber and compare Shock absorber lower end m 12 to 16 ft lb 2 REAR AXLE SHAFT AND nut WHEEL Inspect faults and replace following as required RA 6 Check for oil leakage and cracks Also check shaft for straightness BEARING the specifications given in Service Replace if and Specifications necessary m S3 to 72 ft lb kg front pin spring seat for wear cracks straightness and damaged If faulty parts are found threads with the 83 t094 ft b 1 6 to 2 2 Check shackle I nut 3 to 9 9 7 spring leaves for frae cracks shock ab upper and lower ends in order to clamp rubber bushings in a m neutral 11 5 to 13 0 kg U bolt the of shock absorber in or wire brush if necessary sorber kg 83 to 94 ft Ib shackle Installation wheels when 11 5 to 13 0 Spring a Note Tightening torque Spring fTont pin in Examine tures poinc a 3 parts for age Inspect rubber bushings for dam cracl s and deformation Replace parts if necessary Rear Axle Rear Suspension SERVICE DATA AND SPECIFICATIONS Applied model All models Item Rear shock absorber Stroke x Maximum length 190 x 7 48 47S x 18 70 in mOl Damping force 3 m 0 at 10 ft sec Expansion kg lb 75 to 101 Compression kg lb 3S to S3 165 to 223 77 to 1l7 Option Standard Rear leaf spring 1 200 Dimensions x Length x mOl 47 24 36 2 x 5 1 6 1 13 1 13 2 IS3 mOl in Laden camber mmlkg Spring kg mOl lb in lb in 47 24 0 243 x in Free camber x 36 2 play mOl 0 24 1 0 512 140 24 440 6 440 0 24 970 2 6 to 10 0 2 1 to S O 118 to 280 5 S 0 94 970 146 to S60 thickness mm Recommended for in use on 0 0008 to 0 0059 0 02 to O IS Rear axle case end shim heavy load under high center of O OS 0 0020 0 07 0 0028 0 10 0 0039 0 20 0 0079 50 0 0 0197 gravity such as camper loading Tightening torque Shock absorber upper end nut kg m ft lb 3 1 to 4 1 22 to 30 Shock absorber lower end nut kg m ft Ib 1 6 to 2 2 12 to 16 Rear kg m ft lb 3 to 9 9 7 53 to 72 spring U bolt Clip RA 7 0 28 2 0 51 1 60 in x 0 20 1 Rear axle End 72 1 200x60x 6 3 60 x Width Thickness Number of leaves constant x Rear Axle Spring front pin Spring shackle Rear Suspension kg m ft lb kg m ft Ib 115 to 13 0 83 to 94 5 to 13 0 11 83 to 94 fIXing bolt kg en ft lb S 4 to Wheel bearing lock nut kg m ft Ib IS to 20 kg m ft Ib 0 7 to 0 9 S I to 6 S kg m ft Ib 17 to 2 7 12 to 20 kg en ft Ib 2 0 to 2 7 14 to 20 kg m ft Ib 6 to 10 43 to 72 kg m ft Ib 1 6 to 2 2 kg m ft lb 8 to 9 S8 to 6S Bearing cage Air breather Differential gear carrier to axle Propeller shaft flange case nut bolt Drain and filler plug Bumper Wheel rubber fixing bolt nut 4 6 39 to 46 108 to l4S 12 to 16 TROUBLE DIAGNOSES AND CORRECTIONS When rear axle and suspension is suspected of being noisy to make whether tires a thorough the noise shaft it is advisable road surface exhaust in the propeller Condition Noise transmission bearings Probable one Lack of or more lubricating and rear there is any Tighten the bolts to the oil Lubricate grease Replace rear restriction in Corrective action securing bolts of first check if or breather nuts adjustment leak damage Tighten the wheel or suspension of oil case cause Faulty shock absorber Incorrect In or Loose wheel nuts Loose rear axle universal suspension Noise which originates in other places can not be corrected by adjust ment or replacement of parts in the test to determine originates engine joint wheel axle shaft end as the shock absorber the Adjust specified torque required rear axle shaft end play play Damaged Worn or worn wheel spline portion bearing Replace wheel bearing of rear axle shaft Replace if necessary Broken leaf spring Replace leaf spring Loose Tighten to journal connections or so no Wheel and tire unbalance Damaged Instability Oil leakage in driving Balance wheel and tire rubber parts such bush shock absorber the given torque moun as leaf spring Replace the required parts ting bush Faulty universal joints Adjust Loose wheel nuts Tighten Worn shock absorber Replace faulty Worn or broken leaf spring Replace leaf spring Clean replace Damaged Damaged or restricted air breather oil seal in or differ Replace between the differential Tighten rear axle or case or replace to the given torque shock absorber air breather the damaged oil seal ential carrier Oil leakage from carrier and axle case gasket 8 RA to the specified torque or replace Rear Rear Axle Suspension SPECIAL SERVICE TOOLS For Tool number Description No use Unit tool mOl KV40101000 Rear axle page in on name This tool is used to Use with sliding remove rear axle shaft All hammer ST36230000 Reference Figure Fig or No RA S models stand SE402 2 ST36230000 Sliding hammer This tool is used to remove rear axle shaft All Fig RA S Fig RA 7 models Use with rear axle stand KV40101000 SEll1 3 ST38020000 This tool is used to loosen and tighten rear axle bearing lock nut 620 Bearing lock nu t wrench SE238 4 HT72480000 This tool is used to drive out rear All axle shaft bearing rigid axle Rear axle shaft bearing puller car models parts Iools are used for other rear axle Iype SE382 RA 9 Fig RA 8 SECTION BR BRAKE SYSTEM DATSUN PICK UP MODEL 620 SERIES GENERAL DESCRIPTIDN BR ADJUSTMENT BR 2 SERVICE BRAKE BR HAND BRAKE BR 18 SERVICE DATA AND SPECIFICATlDNS 4ISSAN l I NISSAN MOTOR CO TOKYO LTD JAPAN 2 4 BR 2D TROUBLE DIAGNDSES AND CORRECTIONS BR 22 SPECIAL SERVICE TOOLS BR 25 System Brake GENERAL DESCRIPTION The ped with wheels on the 620 series vehicles the are equip brakes on the four hydraulic and mechanical hand brakes rear and the type with duo servo controlled by a hand brake lever locat ed in the driver s compartment wheels The front brake is servo uni the rear built in the hand The mechanical hand brake is brake For added safety tandem Master Vac cylinder 1lI3ter I the are standard equipment on all models The Master Vac is installed to increase braking force The N LS V greater safety and reliability ensures and N LS V Nissan Load Sensing Valve ADJUSTMENT CONTENTS BR 3 BRAKE PEDAL BR 2 HAND BRAKE FRONT BRAKE BR 2 BLEEDING HYDRAULIC SYSTEM REAR BRAKE BR 3 Parking brake 3 After completing adjustment operate brake pedal several times to BRAKE PEDAL stroke of 137 Qi without ing or l A 148 Full stroke at pedal pad B 134 10 140 5 28 to 5 51 Depressed height C 43 to 49 Free II t height its entire smoothly showing squeak noise twist interference Raise 1 2 Push rod adjusting nut Switch adjusting nuts 3 BraKe lamp switch vehicle BA765 wheel clear rubber boot from brake Remove disc 3 tap adjuster housing and forward Turn down adjuster Ughtly it move brake in until floor wheel with mm over 5 39 in FRONT BRAKE 2 Unit mm 5 83 1 69 to 193 1 travels that it ensure f BR 3 a shoes wheel when screwdriver and spread turning adjuster considerable drag is Jelt Stop a and lock up brake drum Fig BR Adjusting brake pedal l For both Note I Under the condition that the push rod of brake lamp swi tch is pushed in position the height of brake pedal from toeboard to 148 mm 5 83 in operating the switch adjusting nuts Then tighten nuts securely with its adjusting nut 0 6 to 12 play Then so as to become 0 024 to 0 047 in in mOl 5 kg 1 Tightening 4 torque 1 6 to 2 2 kg to m drum drum turns m the length of push Return adjuster wheel 12 ratches obtain correct clearance between brake 12 to 16 ft lb Note Take care not to allow the rod to get into master Adjust wheel is turned downward and brake brake drum and make 9 to I I ft Ib 2 right and left brakes spread when adjuster tigh1en nut securely Tightening torque 1 2 to brake shoes rod free condition BR 2 push cylinder in without shoes sure Turn that brake dragging when brake shoes interfere with brake drum clearance then readjust 5 Install rubber boot Brake System Clean all dirt around master cyl inder reservoir remove cap and top up I t 1 I reservoir fluid 0 0 free Install from a Place BA655 Fig BR 4 Adjusting lock BR 2 Adjusting front brake Fip is c nJ and dust from bleeder valve so that outlet hole I o Thoroughly clean mud 2 t 6 brake recommended with nut any foreign material bleeder hose the on bleeder valve other end of hose in a container filled with brake fluid Depress brake pedal two or three then keep pedal fully depressed 3 times 4 With brake pedal fully depressed expel air open bleeder valve to REAR BRAKE With adjust hand rear the service brake For brake shoe clearance procedures Fully release 3 fully released hand No rotate rear wheels brake and drag should be Notes a present refer to Front b Do not Notes Brake a Before adjusting hand brake reuse brake fluid drained during bleeding operation com plete the adjustment of rear brakes b After adjusting hand brake operate c Bleed air as follows cylinder front cylinder rear 1 Master 2 Master stable 3 N LS V Hand 4 Front wheels S Rear wheels left 6 N LS V rear 7 N LS V center the c Pay attention to brake fluid level in master cylinder reservoir during bleeding operation brake released make to operated pulled and while being Make noise sure cable be must brake smoothly mal lever that dragging other faulty condition no abnor twisting or d Exercise occurs fluid on front care one not to first splash brake exterior finish as it will damage the paint Fig BR 3 Adjusting rear brake 5 Close brake ly BLEEDING HYDRAUL Ie SYSTEM Parking brake I Raise vehicle until rear wheels are clear of the floor 2 Apply hand brake lever operate lock nuts to be 80 to 100 3 94 in mrn lS 3 to in hand brake lever stroke and tighten lock nuts securely Applying force to hand brake lever 20 to 30 kg 44 to 661b Hydraulic brake system must be with bleeder 7 no valve quickly pedal screw to return slow closed Repeat bleeding operations until air bubbles show in hose Notes Brake fluid containing air is white bled whenever any line has been dis connected or air has entered into a system b Brake fluid containing no of bleeder valve in When feel it pedal is an action has a and has visible air bubbles out spongy BR 3 air nms a solid stream free of air bubbles indication that air has entered the system Bleeding the hydraulic system is an essential part of regular brake service as is on down stroke Allow brake 6 HAND BRAKE pedal bleeder 8 Repeat above steps maining brake lines to on expel the all air re Brake System SERVICE BRAKE CONTENTS BR 4 REMOVAL BR lO REMOVAL BR 4 DISASSEMBl Y AND ASSEMBLY BR 1O INSPECTION BR 4 INSPECTION BR lO INSTAllATION BR 4 INSTAllATION BR ll BR 5 REAR BRAKE BR 12 REMOVAL BR 5 REMOVAL BR 12 DISASSEMBl Y AND ASSEMBLY BR 6 DISASSEMBLY AND ASSEMBLY BR 13 INSPECTION BR 6 INSPECTION BR 13 INSTAllATION BR 5 INSTAllATION BR 7 BRAKE PEDAL MASTER BRAKE CYLINDER LINE BR 13 BR 14 MASTER VAC REMOVAL BR B DESCRIPTION BR 14 INSPECTION BR B INSPECTION OF OPERATION BR 14 INSTAllATION BR B REMOVAL BR 16 BR 9 DISASSEMBLY BR 16 DESCRIPTION BR 9 INSPECTION BR 17 N LS V BR 9 ASSEMBl Y AND ADJUSTMENT BR 17 INSTAllATION BR IB N LS V FRONT TEST BRAKE BR lO BRAKE PEDAL REMOVAL Remove pedal return spring i b t 5 I pin spring 2 I Fulcrum 3 2 Return 3 4 Pedal bushings Clevis pin 5 Brake 4 BR766 Fig BR Broke 5 BR657 pedal mounting pedal Fig BR 6 Broke pedal 2 Remove cotter pin and separate Vac push rod 3 Remove pin from clevis pedal from INSPECTION Check brake fulcrum pin and Loosen fulcnun pin pedal for the following items pedal I servicing as necessary Check pedal bushing for deformation Note INSTALLATION Master clockwise 2 or Check or wear damage pedal Install brake pedal in the reverse attention sequence of removal paying to the following instructions 1 shaft sleeve for wear roughness Insert fulcrum pin into hole in pedal and bracket from right brake side 3 Check for bent brake 4 Check for fatigued 4 BA pedal return 2 spring side Install clevis pin from left hand Brake Hook return spring to brake pedal assembly from accelerator pedal side To install it 3 Apply 4 coating a of recommended multipurpose grease to the inner and clevis outer faces of pedal bushing and hooks of pin Charge the clearances spring bushings with I System proceed Turn retention retention cap fully as ring used in the 3 1 j 1tr L I I 00 Nabco 1 Reservoir cap 2 Reservoir tank 3 Secondary piston return 4 5pring Stopper CD Greasing place 7 6 5 lnstali brake lamp switch 6 Adjust the brake to screw Secondary piston Primary piston return spring after in pedal 7 BR926 Primary piston the instructions Fig BR B Sectional view of tandem under Adjustment Tightening torque Fulcrum pin 1 9 to 2 4 kg in the Tokico 5 Refer ring fully Turn retention I BR298 stallation in retention return in U BH projection TIGHTEN direction @ Fig the and push retention cap in the tank in the REMOVE Grease n Align cap with the slit in the reservoir tank direction grease m g 2 follows master cylinder m 14to 17ft ib REMOVAL 1 Disconnect front and rear brake tubes from master cylinder Notes MASTER CYLINDER a The diameter of cylinder is 19 05 GG94310000 y in for all models The tandem master cylinder contains two fluid mm Never Braking force the front brake brake is failure system system Failure main BR658 in either the or the in When sure constantly occurs b o lines independently tained when rear 2 still operative or failure in the rear brake system will leave the front brake nut a retention cap remove this cap proceed as follows I Tum retention ring fully in the REMOVE direction 2 disconnecting to use a adjustable brake tubes be container to receive Remove master Then master taken out system still operative To or parts and area clean front with open end draining brake flnid Use of rags is also suggested to keep adjacent Fig BR 9 Master cylinder brake system will leave the rear brake The reservoir is equi pped use wrench reservoirs which connect the front and rear brake When removing brake tubes use Nut Flare Torque Wrench Pull out retention cap BR 5 cylinder securing cylinder can be Brake System DISASSEMBLY AND ascertain the brand of the brake ASSEMBLY master use parts of the former ones 1 same Thoroughly clean all 00 oC 1 damaged parts Replace 11I is r b r way of deteriolllting parts Use brake fluid or alcohoL When alco hol is used for leaning BA927 Secondary piston stopper 11 Primary piston 7 Bleeder 12 3 Oil 8 Secondary Piston stopper Piston stopper ring 4 Packing 9 Secondary piston Primary return spring 10 screw return 13 spring if found Check piston If it ance Master BR 10 Master cylinder 3 off stopper ring using Valve cap Tokico a screwdriver 3 screw and take replace cylinder valves shows 5 to 3 S kg 2 in the order shown or m S 18 to 2S ft Ib Discard moved use a from new 0 7 to 0 9 piston cup if it is re piston sembly and damage cylinder clear than O IS mm either piston or inner diameter Yoin mm fatigued or be master sure Replace cylioder to discard is disassem and cups any other part which evidence of deformation damage Replace damaged oil wear reservoirs and caps Bleeder Note When bled Nabco stopper primary piston assembly spring and secondary piston assembly to more Check for weakened 4 m S8 to 6S ft Ib out wear or faulty sary 8 t09 kg Remove stopper compressed damaged springs and replace if neces Tightening torque and drain out brake fluid is 0 OOS9 in 19 0S and filter are air cylinder Fig reservoir cap longer After parts Check cylinder and position for evidence of abnonnaI 2 Reservoir cap Oil mter 6 2 with dry Replace Valve cap these parts do not immerse them in it I reservoir parts with since this will be the sure cIeaned Pry part that any Do not clean robber minerai oil than 30 seconds 2 a or faulty L Remove in WOol O 01 1 the as parts suitable solvent and check for Note 5 make INSPECTION 00 1 Be sure to cylinder body kg m S to 7 ft lb INSTALLATION one Notes 4 Unscrew plugs to gain check valve for disassembling Note access reason a sequence of disassembly ing particular ing notes packings with or rubber grease contact surfaces of facilitate parts of master assembly cylinder pay attention to the follow Install master cylinder in the re sequence of removal Bleed air out of master cylinder by verse sliding to dis one Assemble master cylinder in the reverse and Apply brake fluid to U c S Replace gaskets new ones b Never detach reservoir tank it is removed for any canI it and install a new to loosening bleeder screw after it is installed in its original position Tightening torque The blllke master cylinder is avail Brake master cylinder attaching able nut in both NABCO make and TOKlCO make changeability of There is repair no kits inter or com ponent parts between NABCO and TOKlCO JIIlkes the kit repair or When replacing component parts BR 6 0 8 to 1 kg m 6 to 8 ft Ib Brake tube connector I S to 18 kg m II to 13 ft Ib Brake System BRAKE LINE Detail A Detail D Detail G Detail B Detail E Detail R Detail C Detail of Detail 1 Detail K Detail L BA767 Fig BR ll Brake line BR 7 Brake stead REMOVAL new Removing flare nuts on both ends and clips effects the removal of brake replace one after 1 damage an tube and brake hose 2 Rear brake hose can the by disconnecting turning round the hose Note be removed tube Nut use OpeD end an INSTALLATION Front brake hose Torque Fig BR 13 Rear brake ho In Wrench GG943IOOOO Never seating surface Never reuse old copper washer Brake hose Flare use copper washer with a checking for sign of and then When removing brake tubes and hoses on System adjust or an able wrench brake hose first jack up vehicle to take off the weight of vehicle from wheels so that suspension is in rebound all hoses for swell cracking ozone rubbing marks or re those with found placing any ofabove badly beyond use Also inspect end fittings and be sure that no fluid leak through staked end has taken place replace if necessary Hose with badly rusted fitting should also be replaced with 2 Clean and dirt with tubes to remove dust cylinder with the kg The m Hose to bracket twist or brake secure with lock Note hose plate so to as the clamped connecting as rotating or mOving parts tire and rim as 57 in and 1 40 mm more more brake hose at pay keen attention not to twist the hose when additional is be must Hose to stationary part 2S mm 0 98 in and both eiuIs tightening such not to abnormally bend the hose After clearance wow follows 12 to 14 ft Ib Then through its rotating steering wheel extreme lock positions up and down between two Tightening torque 7 to 2 0 1 moving wheel full stroke and specified torque ing for collapse wear cracking swell or rusting Replace if foun d with any of wove Use care not to damage brake tubes while operation are enough The check should be carried out while isopropyl alcohol check Check if tubes that there is To connect brake line first connect a new one all sure also be kept in straight ahead position brake hose to wheel Examine wheel should Steering After brake hose has been installed check to be clearance between hose and adjacent parts to avoid contact with other ones INSPECTION 1 e installing In the above clearance be obtained it may be caused cannot by the required that case hose twisted Accordingly the correction with hose out carry following connection again the above instructions secure ly Mter brake lines all have Brake tube been installed retighten aU connections if necessary to assist in obtaining correct torque In retightening at front wheel cylinder first remove hose clamp and loosen flare nut on opposite side to avoid twisting hose Hold pedal as far downward as possible 80 kg 176 lb or more examining evidence as to whether fluid is leaking through brake lines or con nections Leakage in any manner can not be permitted here In case fluid leaks tightening to specified torque tighten additionally up to 2 5 kg m Under no circumstances J 8 ft lb not should be tightened over 2 5 kg m 18 ft Ib torque since this elongates end reuse fitting making it impossible to no circumstances should rear brake hose and 3 way connector be retightened over specified torques In installing its a end brake tube use care mating noting the fact that nut can be turned freely by a light finger twist squarely on seat Then tighten Brake to correct torque with a Pipe Torque Wrench GG943 10000 Fig BR 12 Front brake hose torque Flare nut 5 to 1 8 kg m 1 Tightening Rear brake hose First secure 11 to 13 ft Ib rear brake hose to 3 way connector on rear axle case to the specifications hose Mter tighten it additionally since do not connector connecting at Tightening torque I 7 to 2 0 kg m 12 to 14 ft Ib BR 8 3 way this oper ation causes hose to be twisted brake tube Under In to locate In addition care should also be damaging or col lapsing during operation Be sure to make enough clearance between all tubes and other adjacent exercised to avoid brake tube parts to avoid contact In installing tube through hood ledge grommet be sure to position it at the center of grommet Brake be connecting brake tube After check the clearance to prevent sure to clearance The from damage following portions distance or Tube to be must at The System N LS V frame being is installed inclined at 10 the on degrees Over 5 specified Tube to edge ofeach Over 10 TI II Master and frame cylinder 0 20 in mm r in I y 1 panel 39 0 mm v operation is summary of the N L S BR 14 in and BR 15 Figures given the more body panel A Tube to tube Loop pitch OVer 5 0 20 in mm J Between front tube and rear tube Over 9 35 0 mOl in Tube to moving parts Over 10 mm 39 in 0 Loop tube to hood ledge Over 10 39 0 mm I panel Attaching angle l in Notes D Brake tubes a are shaped at factory specified clearance and may not require reshaping Discard if they call for excessive reshaping In reshaping a brake tube take care to avoid damaging galvanization or collapsing section to b Wheel cylinder secure Mter brake lines have been asssem BR928 bled to check fittings and flare correct make nuIs sure ale that lightened all to Fig BR 14 Construction of N L S V torques Performance Tightenint torque Brake tube to connector I Ston kg pressure is as curve m S c Brake tube to brake hose 2 0 kg to 0 m C 12 to 14 ft lb to 5 to 2 4S O kg U1U oadea o Connector and clip fixing bolt 3S O A 0 II to 13 ft Ib 17 of brake fluid follows l 0 m 3 ft lb fixing 3 way connector Front wheel cylinder bolt fluid on rear axle case 0 8 to 1 kg BR769 pressure Fig BR 15 Perfonnance curve offluid pressure m 6 to 8 ft lb N L S V TEST N L S V When Operating test DESCRIPTION The Nissan N LS V the following occurs The test should be conducted under Load serves to Sensing Valve change braking in response power of the rear wheels to changes in the load and fluid pressure improving braking stability and shortening stopping distances a then with concrete or vehicle with pay load and a dry only driver asphalt road applying on brake suddenly N LS V is wheels lock ft whether loaded or Stopping distance should these conditions Drive rear place applied to is first the actually functioning normally if stops simultaneously wheels the be measured pedal place the vehicle Front with 43 0 unloaded where the brake from the flat at 40 km h 25 MPH BR 9 stopping distance is shorter than 13 1 m or wheels ahead of lock rear Brake Ibove mentioned st is available N L S V is when the except system correctly adjusted Wheel cylinder brake entire op System simply by be disassembled can following procedures the described below Remove retainer and and dust cover piston from wheel cyl take out damage sliding piston cup piston Thoroughly wash u disassembled inder Be careful not to part of FRONT BRAKE and parts in brake fluid or alcohol parts with Do not wash rubber Note mineral oil since they deterio are rated 8 9 10 After shoe return spring When alcohol is used however do Adjuster assembly Adjuster head Adjuster head shim Lock spring Adjuster housing not immerse rubber 1 Brake disc 11 2 Brake shoe assembly 12 3 Wheel cylinder assembly Brake shoe upper return 14 spring 15 Brake shoe lower return 16 Adjuster wheel Adjuster screw Retaining spring Lock plate Adjuster shim spring 17 Rubber boot 4 5 13 parts in alcohol After parts longer than 30 seconds are cleaned dry them with com air pressed Assemble wheel in reverse cylinder sequence of diassembly When securing connector bolt sert in location tip to the hole of its wheel cylinder firmly and tighten Fig BR I6 Front brake REMOVAL I Jack up front of vehicle just high enough to remove tire and support it with safety stands 2 securely Carry out operations carefully so that component parts are not damaged or no dust and other foreign materials enter cylinder Note Remove wheel and brake drum If M8 in holes on the 1 25 x install two bolts adjuster face flange 3 In order spindle 4 from Unhook upper lower Disconnect and after Loosen wheel 7 shim and rubber remove inter or com changeability ponent parts between NABCO and 3 Rubber boot TOKICO makes BA312 When Fig BR 17 Removing wheel cylinder replacing ent the parts repair body same Be sure to use make as kit ascertain brand of the brake wheel DISASSEMBLY AND ASSEMBLY or the cylinder parts of the the former ones remove hose from @ nut and remove boot adjuster rr l t @ lock plate and retaining spring then repair no kits Wheel cylinder attaching bolt cylinder Remove There is Wheel cylinder brake securing of Brake hose wheel cy linder 6 is 2 knucRle and then cylinder 1 re Refer to Front Axle shoe return springs brake shoe assemblies S operation ease assembly hub move to driven out wheel brake TOKICO make of brake drum and tighten bolts even ly until brake drum is The available in both NABCO make and brake drum cannot be easily removed return brake it adjuster assembly from brake disc Wheel cy linder housing 2 Piston 3 Piston cup 4 Dust 5 Retainer cover a INSPECTION BR649 6 Connector 7 Packings 8 Connector bolt I 9 Bleeder meter is 10 screw Bleeder cap Fig BR 18 Front wheel cylinder SR tO Brake drum Replace brake drum beyond the limit whose dia of 1 5 mm 0 OS9 in with respect to the standard 10 00 inner diameter of 2S4 0 rom in Brake out of The allowable maximum 2 of brake round drum is System Standard dimensions of shoe springs 0 02 mm Installed 0 0008 in Re condition or replace in mOl if specified limit is exceeded 3 Measure for tapered If specified limit of 0 02 in is exceeded re condition 4 Contact linings in lengthlload coils 0 079 37 3 2 091 0 35 14 O OSS S 37 a 134 S Lower inlet 2 0 kg mm in lb IS9 S 14 to 16 6 28 31 to 3S 5 21 to 23 IS9 28 6 30 5 Sl 46 to which with 83 2 After shoe 3 28 99 4 to S 27 S 3 90 9 to II extent that it is an 120 to 150 sand No a No of brake drum surface finished to such mOl 5 136 Upper into contact should be come ground by at from away replace or 0 0008 mm distance of 4S mm position where the 177 in is kept of spring brake drum measured as Dia Free length Item brake drum paper Using a drum racer finish brake by machining if it shows any S drum sign of score marks partial wear stepped wear on its contact surface Wheel cylinder Adjuster sliding or S to 12 I Replace cylinder any which is scratched scored After brake drum is completely Note conditioned or re check renewed drum and shoes for proper contact pattern its sliding 2 or worn on Replace parts if piston to worn beyond O IS is mm 0 OOS9 in 2 When installing wheel cylinder be sure to secure the cylinder with right hand disc and the mark to cylinder 19 0S mOl inner diameter Y in with mark L with other When I cracked brake shoe incompletely linings seated are uneven andlor deteriorated due to heating or soiled with oil and brake fluid replace grease 2 Replace linings if the thickness is Iy worn excessive worn down to less than 1 0 mm Replace piston cup which is worn or otherwise damaged 4 Replace if contacting face of cyl inder and shoe is worn locally or in step S Replace damaged dust cover fatigued piston spring or faulty connecting no its threaded adjacent parts or contact is existed Tightening torque Wheel cylinder SA to 6 6 kg on brake m 39 to 48 ft lb Connector bolt portion 19 to 0 039 14 5 kg 2 m to 18 ft Ib Brake hose 1 7 to 2 0 Note When brake shoe lining is in stalled grind brake shoe lining face to diameter equal Width 4S 4S x 177 3 Thickness x x x 244 0 177 x Length x mm 9 61 in Check adjuster for smooth oper ation I Replace broken or fatigued brake in the When assembling adjuster bly reverse 0 7 to 0 9 4 2 to S O brake grease to adjuster bore adjuster wheel and ad disc kg m 30 to 36 ft lb brake shoe Before installing 3 When installing m Brake disc assem housing juster screw kg 5 to 7 ft Ib apply to brake shoe return springs which m Air bleeder Install front sequence of removal paying particular attention to the following instructions lining dimension kg 12 to 14 ft lb INSTALLATION to that of brake drum are As to the instructions of brake hose line in 4 disc hose referring the related topic Brake threaded parts 6 Replace tube connector which is worn on twist left hand to R one brake hoses may interfere Otherwise 3 Brake assembly to 261b piston or contact surface cylinder clearance Wheel resistance kg II as brake grease to wheel adjuster assembly semblies apply brake grease to cylinder and adjuster brake shoe in apply disc adjuster and retaining spring slid ing surfaces to slide adjuster smoothly resistance stalling grooves brake shoe two places and brake disc and assembly Exercise adjuster sliding Adjust by adjuster shim when sliding allow grease resistance is in linings and adjuster Measure rrect BR ll to come contact care faces not to into contact with Brake 4 brake shoe clearance and Adjust brake bleed System system instructions under Refer to the topic Adjustment in this section Upon completion of the above ad justments make sure that brake oper ates correctly and no brake fluid leaks BA313 Fig BR 19 Greasing points REAR BRAKE 1 2 Brake disc Brake shoe assembly 3 Wheel cylinder assembly 4 5 Return upper spring 6 After shoe return spring 7 Retainer 8 Antirattle spring 9 Spring seat Adjuster assembly Adjuster head Adjuster head shim Lock spring Adjuster housing Return lower spring 10 11 12 13 14 17 Adjuster wheel Adjuster screW Toggle lever 18 Extension link 19 Return spring 20 22 Adjuster spring Lock plate Adjuster shim 23 Rubber boot 24 Antirattlc pin 15 16 21 BA315 Fig BR 20 Reor brake REMOVAL 7 I Jack up enough lever withdraw clevis pin Disconnect toggle lever 8 toggle rear of vehicle just to remove lire and high support hand brake from rear cable with safety 2 Remove wheel loosen hand brake Turn disc pin by 900 10 shim and remove and cylinder by loosening from installation extension link S Remove return springs 6 Remove shoe assemblies secondary brake shoe assembly must be separated from toggle lever When separating after secondary brake shoe assembly from BR316 Fig BR 21 Remouing toggle leuer BR 12 rubber boot adjuster plate and adjuster springs remove adjuster assembly from Remove lock brake disc Open brake shoe assemblies out ward against return spring and remove 4 brake wheel flare nut nuts antirattle springs Note that after Remove brake stands and detach brake drum 3 cylinder by loosening 9 it Disconnect brake tube at wheel Brake 3 DISASSEMBLY AND ASSEMBLY Check System adjuster for 4 smooth oper ation Replace shoe are broken or return springs which fatigued Wheel cylinder Standard dimensions of shoe springs Remove dust and head piston Refer and cover piston out assembly Wheel Cylinder to pull Free of Front Item in mOl Brake mOl Installed No of Dia of spring length in lengthlload mmlkg in lb coils 175 Upper l 345 7 2 3 6 22 ID 83 2 After shoe 0 11 184 5 32 158 Lower CD 2 0 0 079 6 89 176 18 to 20 30 0 091 14 0 055 6 93 40 to 44 99 4 to S 5 27 3 276 5 20 AntiratUe Dust 2 Piston head cover 3 Piston Piston 5 6 Wheel cylinder housing Bleeder cap 7 Bleeder 8 Connector 9 II 12 3 S to 5 4 8 to 9 9 47 0 p 2 Wheel cylinder screw When assembling toggle lever and after brake shoe assembly I Washer 10 3 5 3 90 9 to BR318 4 Cll 1 6 0 063 0 807 1 to 13 24 24 to 29 Replace cylinder any which is scratched scored Connector bolt piston or or worn on its Fig BR 22 Rear wheel cylinder sliding contact surface 2 Replace worn parts if piston to cylinder clearance is beyond O IS rom brake shoe assembly to 0 to to 0 012 in with a clear lever and after between toggle ance adjust 3 0 properly mOl 0 selected toggle pin washer 0 00S9 in cylinder Wheel INSPECTION 19 0S rom inner diameter Xin Toggle pin Brake drum 3 Check brake drum in the same or outlined in the Front Brake manner as Drum When cracked ly worn excessive 4 Replace if contacting face of cyl worn locally or in linings are incompletely seated uneven andlor deteriorated due to heating soiled with oil or 0 091 3 0 102 faulty 4 2 9 0 114 threaded parts 6 Replace tube connector which is S 3 2 0 126 Replace damaged fatigued piston spring worn on its threaded dust cover or portion replace lining is in shoe lining face semblies apply following places brake equal 10 lha I of brake drom Width x Thickness x Length 4S x 4 5 x 244 rom 177 x 0 177 x 9 61 in the reverse paying particular attention to the Rear same dimemion in brake sequence of removal I Lining rear as following instructions adjuster assembly is the front Refer to the paragraph covering Front Brake Installation Adjuster sliding resistance S to 12 kg II to 261b BR 13 brake grease to as the Brake shoe installing grooves of 1 Install brake shoe Before installing 3 When brake shoe to diameter in 0 079 3 2 INSTALLATION grind rom 2 6 down to less than 1 0 rom 0 039 stalled 2 0 I if the thickness is in Note Thickness 2 5 shoe brake Replace linings WOol No damaged step grease and brake fluid 2 cup which is worn inder and shoe is Brake assembly I Replace piston washer adjuster and wheel cylinder 2 Extension link 3 Lower surface of spring seat 4 installing grooves Contact surfaces between brake disc and brake shoe assembly six places At this time be sure not to coat brake grease to brake linings Brake System f Note The Master Vac diaphragm dif fonner ones for improved fers from braking are label color follows force Do not install fonner Master Vac on 1976 models identified by the Master Vacs as 1976 model The Caution Label Former models YeJlow BR317 Fig BR 23 4 ing point Gre Tightening torque Wheel cylinder S to 1 8 kg J m BR321 II to 13ft Ib 13 operating rod spring Poppet return spring 1 Plate and seal 6 Seal 14 Exhaust valve 2 Push rod 7 Vacuum valve 15 Valve 3 Diaphragm 8 16 Reaction 4 Rear shell 9 Poppet assembly Valve body guard Diaphragm 5 Diaphragm plate 17 18 Connector bolt 1 9 to 5 2 kg m 14 to 18 ft Ib Brake tube 5 to 1 8 1 kg m II to 13 ft Ib Air bleeder 0 7 to 0 9 kg 10 Air silencer filter 11 Valve 12 Valve return plunger disc return spring Front shell Fig BR 24 Sectionall1iew of Master Vac m S to 7 ft Ib Brake disc 5 4 to 4 kg 6 INSPECTION OF OPERATION m 39 to 46 ft Ib Checking yscuum pressure S Adjust brake shoe clearance and bleed brake system Upon completion of the above make adjustments sure that brake operates correctly and brake fluid leaks Connect I a vacuum gauge in the Vac as shown in Figure BR 25 line between check valve and Master no MASTER VAC 1 Check valve 2 Vacuum gauge DESCRIPTION A vacuum Master Vac is suspended the master installed behind cylinder BA169 As the brake pedal is depressed fluid is forced under high pressure through the brake pipes to the wheel cylinders to retard or The loaded stop the vehicle Master Vac diaphragm in diameter pressure Fig BR 25 Air tight contains a of IS2 4 It operates produced n the mm spring 6 in negative engine intake on 2 Start engine and increase engine speed gauge Stop engine indicates SOO inHg capable even mmHg vacuum 19 69 I if the Master Vac is Fifteen seconds stopped after engine is observe the rate of drop in air registered by vacuum gauge pressure drop of 25 mmHg 0 98 inHg is exceeded refer to the follow cylinder is high pressure master of producing t up Air tight test If tandem t pressure manifold The when t a ing chart faulty failure BR 14 to determine the cause of System Brake Probable Corrective action cause leakago at check valve 2 Air leakage a 3 Air leakage between valve body and Repair seal partes at valve Air 5 Damaged piping leakage or plunger I Replace seal t push rod seal 4 1 Replace check valve I Air Manifold side seat joints replace or 1 Repair or replace Repair or replace seat seconds after engine is stopped and brake fully applied ob serve the rate of drop in air pressure registered by vacuum gauge Probable If 0 98 a following of 25 is exceeded inHg Connect an oil mmHg refer to line 2 leakage the Install 2 chart to determine the cause Air leakage at check valve Replace vacuum Relationship and in Replace faulty part seat a each pedal operating force between oil pressure to respect Reinstall and check push rod off With pressure gauge of 500 mmHg 19 69 inHg oil pressure with measure an held Replace poppet assembly brake pressure for proper turn 4 on Start engine and increase engine speed until a vacuum pressure of 500 mmHg 19 69 inHg is registered on Corrective action cause dropped spring scale a 3 at check valve Reaction disc master on pedal of failure Damaged diaphragm 3 pressure gauge in connection at cylinder vacuum 1 Air BA289 valve drop pressure Spring Valve Operating test brake Fifteen 2 Fig BR 27 Sectional view of check 1 2 Master Yac side faulty as s pedal operating force is illustrated Figure BR 28 If test results are not specified in Figure BR 28 check Master Vac for condition in and valve body a manner described under Inspection as before removal of this unit Also check brake line for evidence Note is When replacement of any part required be sure to renew Master Vac as an assembly 15 seconds new one 3 When Master Vac Inspecting check valve valve Remove clip and a of fluid a pressure is applied to the side of check valve and does valve with at connections replace check valve with not open new one Note leakage occurs check valve replace check whether Determine tion in Always inspect can 120 I 7IG 1 I 100 I 420 i u yr I 90 1 280 17 I 80 1 140 I 70 1 000 60 850 0 Z 40 BA3 Fig BR 26 Location of check valve a I I I I 570 30 430 I 20 280 vacuum inHg a Master Vac tester pressure apply a of 200 mmHg 7 87 to the port of check valve on the Master Vac side 10 mmHg 39 0 10 140 I 7I 50 710 5 I I f I 0 Using in disconnect hoses The check valve 110 1 560 2 or check valve fiTlit be removed now malfunc Master Vac I y1 I I I I L I 5 to 22 If a pressure drop of inHg is exceeded in 15 20 44 25 I I I II I I y1 I I I I 30 66 35 I L I 40 88 45 50 110 55 60 132 BR772 Pedal operating force kg lb Fig BR 28 Performance BR 15 curves of Master Vac Brake Identify front shell and rear shell clearly so that they may be reassem bled in their original positions from which they were withdrawn Bolts 3 REMOVAL Referring System Figure to parts in numerical BR 29 remove order enumerated attached dashboard on not are the same in pitch Using 4 Master Vac ST08080000 1 cD remove Wrench rear shell seal assembly and disassemble diaphragm plate assembly front shell assembly diaphragm spring and push rod assem bly 2 BA079 FlIf BR 33 Separating diaphragm 2 Using evenly pry BR17S Fig BR 29 Removal method of screwdriver a is detached from Mcuter Vae as shown air silencer retainer until it diaphragm plate as sembly DISASSEMBLY When serve a the disassembling Master Vac following instructions Thoroughly clean mud Note ob dust from or Never use a hammer to remove this retainer since this win be the sure y of damaging it Master Vac b Extreme to should be taken care allow dirt other foreign dust water or not f Q any matter into any com select place BA076 Fig BR 31 Removing reor shell ponent parts Be to sure before disassembly c Rear shell seal assembly mating joints so that they installed exactly in their original positions Mark be may d Keep all disassembled arranged properly readily e clean a or so f place care come 1 to BA322 parts clean work bench bly unless absolutely Whenever this is to be removed not to damage on Place rear use it Master Vac Use soft jaws 2 Remove clevis and lock 3 Pull out and are valve withdraw plunger stop key silencer and plunger assembly Use Note valve plunger stop proceed as follows With key hole facing down lightly push valve operating rod simulta neously while applying vibration to parts in nut To remove key properly shell spacer vise retainer necessary allow dirt and dust to Install spacer tach valve body Do not disassemble seal assem Note care into contact with these temporarily of screw suitable clean solvent a on a not use detach bearing Fig BR 34 Removing air silencer disassembled cleaned in and that they may be assembled at any time all shown and seal parts in alcohol Mter as parts Clean rubber parts and synthetic resin off retainer with Pry driver a it De guard rW BRD7S Fig BR 32 Removing retainer ID Diaphragm plate 1 Clevis 2 Lock 3 Place Valve body guard nut Fig BR 30 Removing BRD7S rear hell on a diaphragm plate assembly clean work bench phragm Detach dia from groove in plate BR 16 as shown BA180 Fig BR 35 Pulling out top key Brake System ASSEMBLY AND ADJUSTMENT 1 Assemble in the reverse sequence of disassembly SR1S6 Fig BR 41 Rear shell seal BA1Bl Fig BR 36 Remouing ualue operating rod assembly Apply 1 a grease to the coating of Master Vac sealing surface and lip of seal and install that seal in with the use rear shell Install plunger assembly and diaphragm plate and lightly push plunger stop key in place silencer in of Master Vac Oil Seal Note Retainer Drift ST08060000 4 2 Requiring grease place Diaphragm plate bakelite Withdraw reaction disc Exercise care plunger assembly diaphragm plate not is made of in instaJJing to damage BA286 Fig BR 37 Remouing reaction disc Fig BR 39 Installing oil seal BROB3 Note I Detach flange Referring stall from front to Figure BR 40 in place by properly aligning the pawl of special tool with seal hole Adjustment is cor rect when specified length at A is Front shell seal shell assembly seal in obtained Length Fig BR 42 Inserting stop key A Before installing diaphragm into position apply a thin coating of mica power to it except outer diameter and seating portion with which shell comes 3 into contact 6 7 to 7 Omm 4 0 264 to 0 276 in Before place on installing reaction disc in diaphragm plate apply a thin coating of Master Vac grease Front shell seal Before installing front as seal shell sembly apply a coating of Master Vac g BR287 Fig BR 38 Removing lange grease to the inner wall of seal and front sheU with which seal comes into contact 2 Withdraw front seal assembly Final sssembly INSPECTION BA1S5 Check poppet assembly for condi tion If it shows evidence of wear or I damage replace rod it and valve Check other component parts for condition If any part shows evidence wear or new one damage replace at A operating assembly 2 of Apply thin coating ofMaster Vac Fig BR 40 Length it with a grease to the outer edges of diaphragm with which rear and front shells come before instaIling dia position 2 Before installing push rod assem bly in place apply a coating of Master Vac grease to the sliding con tact surface of diaphragm plate into Diaphragm plate I Apply a thin coating of grease to sliding contact portion on the periphery of plunger assembly the BR 17 contact phragm in Brake 3 in the Align marks scribed shell and front shell Master Vac Carefully Wrench clockwise until it rear turn the ST08080000 Length INSTALLATION B 10 0 to 394 0 System 5 10 mID 413 0 to Install in the in reaches notch in Tightening torque Master cylinder shell retainer rl 0 8 to I 1 6 BA290 Fig BR 44 Lelllth After assembly push adjust Master Vac m B m 8 ft Ib Master Vac on vehicle is be properly sure to air tight test and oper ation test described previously in an this section shell length the rod to less than the value indicated below ment of at to After conduct of to body 0 8 to 1 kg installed reor sequence of 6 to 8 ft lb Note Fig BR 43 Tightenilll kg Master Vac to J 4 reverse removal push specified Length adjust rod is made at the tip of Fig BR 45 Adjusting push rod length push rod HAND BRAKE CONTENTS HAND BRAKE Stick lever typ e REMOVAL BR 18 INSPECTION BR 19 BR 19 INSTALLATION BR 19 HAND BRAKE Stick lever type The hand brake system is of reaction type a cable which actuates rear wheel brake shoes justment can be All the cable ad made BR 18 by operating only adjusting nut at balance lever Brake System k 1 BR663 Fig BR 48 Balance lever Rear cable Fully release 2 control stem Remove both and disconnect rear brake drums rear cable from toggle lever 3 Detach spring and spring retainer Remove rear cable from brake 4 disc 1 Control bracket 5 2 Control lever balance lever bracket 3 Control stem 4 Front cable 5 Balance lever 6 Rear 7 Rear cable LH Disconnect 6 Detach cable rear cable clips from and remove rear cable cable R H BAS6l Fig BR 46 Hand brake linkage INSPECTION 1 Check control stem for evidence of wear or and ratchet other damages REMOVAL Replace parts which are faulty 2 Replace worn or fatigued springs Control stem 3 I Disconnect 3 terminal from hand Pull out lock pin and colter pin and then remove control stem assem brake warning switch 2 Remove nuts bracket in place on bly control securing Check wires for evidence of dis continuity or other deterioration Re place if necessary 4 Replace faulty warning light and dash panel or switch S Check parts at each connection and if found deformed or damaged y replace J i1 b INSTALLATION Install hand brake I I 1 II i I assembly in the sequence of removal by closely observing the following instructions reverse l When installing apply a coating of grease to sliding contact surfaces BR773 Fig BR 47 Control stem Make 2 Front cable Sure that each sliding part func lions smoothly Upon completion of installation of hand brake Fully release control stem Loosen adjusting nut at 2 5 balance lever 3 Disconnect front cable from Remove retainer guide bushing LH con 6 rear cables R H and from balance lever brackets See Figure trollever 4 Disconnect 48 BR Remove at cable 7 lions ment balance lever brackets from crossmember spring assembly adjust the referring to the instruc described under topic Adjust entire system Detach front cable front cable rearward BR 19 3 Make sure that each cable is not interfered with by any clip and pull Do not cables apply an adjacent undue parts stress to Brake System SERVICE DATA AND SPECIFICATIONS Brake Brake pedal mOl in 148 S 83 mOl in I to 3 Full stroke at pedal pad mOl in 134 to 140 5 28 to Depressed height mm in Free height Free play at pedal pad 0 04 to 0 12 43 to 49 169 51 S to 193 adjustment notches Front 12 Rear 12 Master cylinder Inner diameter mm in 19 0S Piston to cylinder deaJance mm in O IS 0 OOS9 mOl in 4 6 152 Yo Master Vac Diaphragm diameter Maximum vacuum leakage after 15 sec mmHg inHg 2S 0 98 Shell seal depth A mOl in 6 7 to 7 0 0 264 to 0 276 Push rod length B mOl in 10 0 to 5 0 394 to 0 413 10 Front drum brake Uni Type Wheel cylinder inner diameter in I9 0S 45 Lining Width Lining mm x Thickness mOl x in mm in Yo 4 x 244 5 x 77 1 Length wear limit servo x 0 177 x 9 61 1 0 0 039 Rear drum brake Duo servo Type Wheel cylinder inner diameter mOl in 19 0S mm in 254 0 10 mOl in 2SS mOl in 0 02 0 0008 maximum Yo Brake drum Inner diameter Repair limit of thickness Inside runout S 10 06 PaJking brake Stick type Type in Stroke mm Adjuster sliding resistance kg lb 80 to 100 S to 12 BR 20 lS 3 to 3 94 11 to 26 Brake System Tightening torque Master cylinder to Master Vac kg m ft Ib 0 8 to l 6 to 8 Brake tube flare nut kg m ft Ib IS to 18 Brake hose connector kg m ft lb 1 8 to 2 1 Air bleeder valve kg m ft lb Fulcrum pin of brake pedal kg m ft Ib 2 to 1 1 5 9 to II Connector and clip kg m ft lb 0 35 to kg m ft Ib 0 8 to l 6 kg m ft Ib 12 to 1 5 9 to II kg m ft Ib 0 8 to l 6 to 8 kg m ft Ib S 4 to 6 6 kg m ft Ib 5 to 1 8 II to 13 1 kg m ft lb 1 9 to Front kg m ft Ib 4 2 to S O 30 to 36 Rear kg m ft Ib S 4 to 6 4 39 to 46 kg m ft lb 0 8 to l 6 to 8 kg m ft lb 0 8 to 1 6 kg m ft Ib 16 to 2 2 kg m ft Ib 1 9 to 3 way connector fIXing fIXing bolt bolt on rear axle case Brake pedal stopper lock N LS V to nut body II to 13 13 to IS 0 7 to 0 9 S to 7 4S O 5 to 2 to 8 Wheel cylinder mounting nut Front Rear connector bolt Wheel cylinder Brake disc Back plate 5 2 39 to 48 14 to 18 nut Master Vac Master Vac to Flange to shell body cover Operating rod lock Push rod nut adjusting nut nut nut BR 21 to 8 12 to 16 4 14 2 to 17 3 Brake System TROUBLE DIAGNOSES AND CORRECTIONS Condition Excessive pedal travel Probable Low brake 1uid cylinder reservoir Leakage in master Corrective action cause level master empty or Fill and bleed necessary Air in system Bleed system adjustment Low 1uid level in master cylinder Correct brake adjustment as hole clogged Swollen hose due to deterioration Inspect for leakage necessary shoe Adjust aut vent clearance operation Top with 1uid and inspect Air in system Reservoir filler cap connec and bleed system shoe to drum Adjust autoadjuster Faulty lines Overhaul master cylinder cylinder Replace check valve brake Test for source by examining all tions and wheel cylinder Deteriorated check valve Faulty Spongy pedal as of leakage to drum clearance Inspect adjuster operation Clean and bleed system use or of Replace hose and bleed system poor quality hose Distorted or Soft or swollen Use of Poor braking effect brake shoes excessively or worn Replace faulty parts cracked brake drum caliper brake a seals Drain hydraulic system and replace all seals 1uid with too low boiling Replace with specified point system Fluid leakage in brake lines Check master Low brake 1uid level cylinder pIpIng cylinder for leaks and repair empty or master Air in brake lines Excessive shoe Fill and bleed as oil ta mud drum clearance water or Deterioration of linings Local fit of linings or or wheel necessary Adjust linings or pads on Master cylinder condition or pads Clean brake mechanism and check for Shave wheel cylinders in poor at or replace Replace worn Binding mechanical linkage Replace linings Replace pads Linings or pads excessively brake pedal Repair or Free up replace as required and shoes Clogged and Bleed system of problem Brakes drag brake 1uid and bleed reservoir cylinder Grease flush with alcohol brake lines Incorrect adjustment Improper shoe t Check and clean of wheel bearings drum clearance Adjust or repair Adjust Weak shoe return springs Replace No free travel in brake shoe return Adjust pedal height BR 22 or pads cause Brake Probable Condition chatters Brake required Grind Loose or bent brake disc Tighten support plate bolts torque or replace plate Grease squeals Corrective action cause Groove or out of round brake drum Distorted brake shoes Brake System Dirty or as to specified necessary Replace linings brake fluid on linings compressed with assembly Blowout scored brake drums or replace as Replace pads or or air or refinish drum Distorted brake shoes Weak or or Replace faulty unit if faulty Replace spring ground lining to doesn t replace linings contaminated brake lining Pedal pulsates Out of round Brakes fade Brake fluid has Use of bent support plate broken brake shoe retaining spring or return Glazed or Cam Turn drum off center drum or too low or brake replace as linings are If it glaze necessary approved Drain and fill system with boiling point improper linings or eliminate fluid Replace linings contaminated Brake drums are out of round master cylinder and Hydraulic connections wheel cylinders are corroded Bleed Brakes drag screw or replace Repair as necessary Close or necessary as damaged is open Pedal linkage is binding ment is too or Repair push rod adjust screw Lubricate and bleed system linkage check pedal return for condition and adjust push rod long spring as neces sary Master cylinder compensator part is ob Blowout foreign structed air Seized master cylinder piston Disassemble matter master with cylinder compressed and replace piston Bleed system Clean and repair Poor shoe condition Poor wheel or replace Deformation of piston cups Replace Hand brake will not Check and repair Clogged Unbalanced brakes Repair cylinder condition master Improper return cylinder return port Clean Inflate tire inflation Improper adjustment of shoe to drum clear to correct pressure Readjust anee Grease oil mud or water on linings or pads Clean brake mechanism and check for of problem Clean Mud in brake drum Deterioration of linings Excessive wear or of linings Replace pads or pads BR 23 Replace Replace linings or pads cause Brake Condition Probable Wheel Poor Corrective action cause in poor condition Repair condition of brake shoe Adjust cylinder sliding System Looseness of cylinder body or back plate Fasten or replace or replace securing bolts Scored or out of round drums Recondition or replace brake drum as reo Check for improper lining contact quired with drum and grind lining if necessary Sticking wheel cylinder Deformation of back Recondition or cups plate replace cylinder Replace Incorrect adjustment of wheel bearings Adjust Incorrect adjustment of wheel alignment Adjust Looseness of leaf spring securing U bolts Tighten Faulty Replace N LS V or replace or replace Pedal yields under Deteriorated check valve Replace slight pressure Ex ternalleaks Check master cylinder Leakage on master check valve and bleed system piping cylinder for leaks and repair cylinder Overhaul master cylinder BR 24 and wheel Brake System SPECIAL SERVICE TOOLS Tool number Description No tool 1 Unit name GG943 10000 Flare nut torque wrench This tool is used to A built in tighten torque limiting and untighten brake provided to wrench is mOl in tube flared nut assure For Reference use page or on All Figure Page No BR 8 models torque accuracy SE227 2 ST08080000 Master V ac This tool is used to remove bolt with the opening rear shell after aligning rear shell stud All Fig BR 3l Fig BR 39 models in this tool wrench SE073 3 ST08060000 This tool is used when rear shell seal is driven into position All models Master Vac oil seal retainer drift Note Make sure tool touches that this tool is pushed in until rear guide of this rear shell SEll5 BR 25 SECTION WT WHEEL AND TIRE DATSUN PICK UP MODEL 620 SERIES WHEEL AND TIRE TROUBLE DIAGNOSES AND CORRECTIONS I NISSANJ NISSAN MOTOR CO TOKYO LTD JAPAN WI 2 WI 5 Wheel and Tire WHEEL AND TIRE CONTENTS DESCRIPTION WT2 TIRE MAINTENANCE AND SERVICE WT 2 CHANGING TIRE ROTATION WT3 WT3 TIRE INFLATION WT2 INSPECTION WTA TIRE WT2 WHEEL WTA WHEEL REPAIR WT 2 WHEEL AND TIRE WEAR WT 2 REPAIR BALANCE DESCRIPTION The 620 series models WT 4 TIRE REPAIR equipped are with 4lV 14 wheels with 25 mOl In 0 98 order to inspect soapy solution to tire in offset All tires are tubeless leak a or tire and wheei in the water after to specified pressure spection for leaks should tire Tire size out Model Tire size All models apply submerge 6 00 I 4 6PR along Wheel size Tubeless around the valve the tread inflating Special in be carried wheel rim and Exercise care to bead and rim where leakage occurs Wipe out water from area which leaks air 4UJ 14 bubbles and then mark the place with chalk Tire pressure Unit 2 kgl em psi After removing the materials which caused puncture Vehicle speed km h MPH Under h km 100 Model seal the point When repairing the puncture use the tire repair kits which are furnished from Over 100 km h 60 MPH 60 MPH tire dealers provided Front 15 Rear 175 21 18 26 following other damage 2 25 In case that a puncture becomes large Unloaded 25 the instructions with the kits 32 on or there is any the tire fabric repair must be carried out All models by authorized tire dealers Front 15 21 Rear 3 0 42 18 26 Loaded 15 3 4S WHEEL REPAIR Note Tire inflation pressures should be measured when tires are cold underinflation promotes wear ter tread or shouider of tire If aU tires are at cen inspected frequently and maintained correct tire pressure is possible it detect sharp material in to the tread Also the above check avoids abnormal MAINTENANCE AND SERVICE serious If tires indicate abnormal problem uneven which invites wear the wear cause Inspect bend or The the wheel rim flange for dents flange should be cleaned by a wire brush when rust is found on the flange Furthermore pitting with a occurs on if the rim excessive eliminate it file or of problem should be detected and eliminated TIRE INFLATION After inflating tires leakage in valve should be checked Without valve caps Correct tire portant comfort sound longer pressure to ease of to This a is steering also very reduces minimum im and riding driving resulting tire life that is overinflation in or leakage water will resulting cordingly checked firmly occur due dirt and in underinflation whenever tire be to sure to pressure tighten valve by hand Ac is caps WEAR Missilgnment When excessive front toe in tires scrape wear WT 2 the or wheels align in toe out condition the tread rubber off The of tread appears feathered edge Wheel and Tire and on the other hand Center wear This wear is caused by overinflation value specified at the kept Tire tread Tread on driving former or camber on pension two Underinflation common are occurs wear I 0E round brake drum Toe in wear correct the above CHANGING TIRE To i 1 I 1 1 Overinllation wear wear 1 unevenly and become The spare lire has from 4 tires in tire noise which is attributed to rear Right front axle gears bearing etc Meanwhile the I tend of because to wear it is Right necessary to equalize rotate tires rear is necessary to @ Spare It cap and temporarily to loosen wheel To jack side frame rear front Left rear up front remove jacked about S20 mOl brake up place jack of front axle center ing parking Left wheel 2 3 wear peri tire different brand r J tire a spare the vehicle x front wheel to on nuts before vehicle is unevenly wear improperly aligned Accordingly installing lighten a lifting up and lock Fig WT 5 Removing unbalanced according to running dis tance Uneven tire wear often results jack WT007 wear TIRE ROTATION tires insert I t Uneven When little strong after I wear a and then turn it counter guide clockwise using observe the To remove spare tire rod to Fig WT 1 A bnormal tire wear tire with wheel change in the safe manner jack following procedures Ii Underinnation indicator faulty parts J nf I wear other mechani I toe out or Fig WT 4 Tread out of wheel or WH024 cal conditions To repair this abnormal both sides of treads d by incorrect malfunctioning sus unbalanced I front indicator is caused caster or I Tires wear c Uneven by under wheel camber high speed general the In causes wear may be caused incorrect continuous curves one Uneven wear inflation causes side of treads For curves Shoulder The camber cornering tread wear the driver must down on operate vehicle slowing of the tire The inflation pressure must be only on under 5 in at 20 after apply and blocking rear wheels odically All the tires including the spare tire are of the same Right front Right Left 1 I @ The tires wear Spare J in wear tread 1 g 1 provided with tread at six places around indicating depth When 1 6 mm the and then the marks appear place them rear WT 2 Tire rotation are indicator tire circumference t Left Fig emergency only Fig WT 3 Tire rotation 2 rear 1 front pare in an type 1 14 t tire should be used The with new ones See tires re Figure WT012 Fig WT 6 Jacking up front side WT 4 WT3 Wheel and Tire 4 To rear axle jack case close under place jack rear up the side of rear to spring after applying parking brake and blocking front wheels Proper tire balance is necessary when driving the vehicle at high speeds Consequently the wheel and tire assembly should be properly re balanced whenever is puncture re Thoroughly remove oxidized rubber rust rim with wire brush emery cloth or Use dial gauge to wheel rim for lateral out run paper dust sand from wheel or examine paired The comes uneven wheel and tire of according Less to run Qut tltan limit 5mOl 1 0 059 il total indicator Severe acceleration wear reading fast cornering is the or wear Lateral assembly be of ba1ance out and braking cause tire tire on resulting in unbalance of tire and wheel assembly The as symptom ofunbalance appears tramp vehicle shake and steering malfunction WH077 To correct Fig WT 7 Jacking up S Remove wheel rear side and wheel nuts To 177 gr cm wheel install reverse the nuts fashion to 8 0 to 9 0 kg ft Ib Note Nerer while it is get in 10 gr 3S O 5 in 2 oz at rim circumferences oz WTOO5 m use at S8 to 6S only by the fety stands S8 Fig WT B Whetl rim 10 to 60 gr cross criss under the vehicle supported jack Always proper Balance weight above steps Tighten wheel use Maximum allowable unbalance from drum 6 unbalance wheel balancer to support the side member of body construction when you must get Note Be of rim 10 gr as weights 12 2 to 0 3S oz place the to sure balance 3S O on shown in 00 not put more than two on each side out check points intervat correct the inner Figure run oz edge S WT Note weights In not to replacing tire t e extra care damage tire bead rim flange and bead seat beneath the vehicle Do not use tire irons to force beads away from wheel rim flange that is always use tire replacement device whenever tire is removed WHEEL AND TIRE INSPECTION 2 In WHEEL BALANCE The wheel arid tire asSembly order to ensure steering condition should be kept balanced statically and dynam ically tire life proceed as as well satisfactory as maximum follows Check wheel rim for rust distor tion cracks or other faults 4 WT Discard when any of the follow ing problems occur 1 Broken 2 Ply 3 Cracked etc o or damaged bead wire treairsepanitiori or damaged side wall Wheel and Tire TROUBLE DIAGNOSES AND CORRECTIONS Condition Wheel wobbles Probable Corrective action cause Improper tire pressure Measure and adjust Damaged tire or distorted wheel rim Repair or replace Unbalanced wheel Balance Loose wheel nuts Tighten Worn damaged or wheel bearing or excessive Correct play or replace wheel bearing play of wheel bearing Improper front wheel alignment Align Worn or damaged ball joint Excessive Replace linkage play steering or worn Adjust Or replace steering linkage Loose steering linkage connection Tighten worn nuts to rated torque Broken suspension spring Replace Damaged shock absorber Replace Unevenly or Improper tire rotation Conduct tire rotation excessively Improper tire pressure Measure and adjust worn tire Unbalanced wheel Balance Improperly adjusted brake or periodically Adjust Align Excessively Repair replace distorted replace replace Improper wheel alignment or or parts if any improperly installed or if necessary reinstall suspension link High speed on Sudden start due to and rapid acceleration plication Tire squeals Reduce curves improper speed or improper brake ap speed Follow correct and proper Improper tire pressure Measure and Improper front wheel alignment Align Distorted knuckle or suspension link WT 5 Repair or adjust replace driving manner SERVICE MANUA L 4 SECTION ST STEERING SYSTEM DATSUN PICK UP MODEL 620 SERIES I NISSAN I NI55AN MOTOR CO TOKYO LTD JAPAN STEERING ST 2 SERVICE DATA AND SPECIFICATIONS ST 8 TROUBLE DIAGNOSES AND CORRECTION ST 9 SPECIAL TOOLS ST 10 STEERING SYSTEM STEERING CONTENTS DESCRIPTION ST 2 STEERING GEAR ST 3 al and installation Remo Disassembly and The other end of the linked to steering gear used model series vehicles is circulating type e on this same re This steering gear is designed especially for easy operation and high durability The steering linkage is of design of which gear to one end of the arm is adjustable a relay connected cross rod the idler cross arm rod is on safely arm and idler arms right arm left andlor the idler right wheel moves rotation is converted gear arm motion operates the side rod on the same side At the same time to the sides even arm is moved through the rod and the opposite side rod is also moved if the cross vertical Steering column shaft Steering column jacket 3 Steering wheel 4 Column clamp 10 Side rod S Post 11 Steering 6 Steering 1 7 Cross rod 2 8 Cross rod socket 9 Idler llmet gro gear be to gear arm motion in proportion to the gear ratio by the steering gear The and left hand With this construction can maintained Steering wheel the opposite side of the steering gear The two side rods serve to connect the both knuckle 6 ST ST 7 ly and independently steering connecting with the side member located steering gear ST 6 Inspection and repair 4 ST assembly ST 5 LINKAGE Removal and installation ST 3 DESCRIPTION The Inspection and repair STEERING arm assembly gear assembly arm ST528 Fig ST I Structural sr 2 u w of l teeriTl tem STEERING SYSTEM STEERING GEAR A i p u I 1 jj @ @ @l ST199 Sector shaft adjusting J 9 2 3 Filler plug Sector shaft Worm bearing adjusting shim Column jacket Sector shaft adjusting screw shim 11 5 Gear housing Sector shaft 13 8 12 14 Oil l 7 assembly 10 cover 4 6 Worm ball nut assembly screw 15 Steering column shaft Column jacket bushing ring Worm bearing Gear housing bushing Fig ST 2 Sectional view of steering gear Removal and installation 3 Remove Removal nut Steering after wheel steering Wheel Puller backing with ST27I80001 6 Remove column clamp fixing bolts off steering wheel fIXing @ c Disconnect battery ground cable I from the terminal Remove horn 2 pad by unscrewing I two bolts from the rear side of steering c wheel bar Note 0 Be sure on to punch f I mark with 1 the top of steering column shaft i I 1 T201 Fig ST 5 Removing column clamp Fig ST 4 Removing teering wheel Note Be special sure not to hammer the 7 tool while removing Remove four bolts securing steer ing post grommet Remove upper and lower steering column shell covers 4 S Fig ST 3 R moving horn pad Remove turn signal switch as arm with the ST2902000I sembly ST3 to dash panel Remove nut securing gear arm to sector shaft and then withdraw gear 8 use of Pitman Arm Puller STEERING SYSTEM and Disassembly assembly 9 Disassembly I Drain oil in gear ST202 Fig ST 6 Withdrawing gear Note Before arm and be screw few turns a Remove so from the rear Do not remove sector shaft bushing housing If necessary replace as a gea2 nousing assembly from b Do not disassemble ball nut and un geir worm screwing four fixing bolts them with If necessary replace new ones as a worm gear assembly can three bolts securing steering gear housing to frame 10 Withdraw steering gear assembly toward engine compartment 9 a coun by cover O ring Notes easily in their original posi assembly housing replaced tions at that they gear on arm Remove of column jacket and discard it Remove column jacket bushing a terclockwise Remove sector shaft removing steering scribe match marks ann adjusting and discard it cover Loosen lock nut and turn sector shaft housing housing in sector shaft oil seal from out 10 11 steering by unscrewing fIller plug 2 Place steering gear assembly vise securely 3 Pry gear rn ST203 Fig Installation Install steering gear assembly in the reverse order of removal observing the following instructions I When installing steering gear housing securing bolts insert two bolts through gear housing to frame 2 When align four tions with installing steering grooves of gear ST 7 4 a Remouing sector haft Turn sector shaft adjusting pull few turns clockwise and shaft cover from gear together with couer screw sector shaft housing Assembly Apply and adjustment recommended gear oil to all disassembled parts gear arm arm Fig ST 9 Removing steering worm assem bly sector 1 serra Fit column column jacket in four projections of sector jacket bushing to place shaft serrations 3 Tightening torque ST204 Steering gear housing 4 6 to 3 kg m 33 to 38 ft lb S Gear kg m adhesive to fitting apply exterior and grease to in terior 2 S 51 to 54 ft Ib 6 With front wheels set in a straight that punch mark on the upper end surface of steering column shaft is at the center upper side Separate screw ahead position make sure in its installing portion S bushing Fig ST B PuUing out ector haft 94 to 108 ft lb Steering wheel 7 0 to 7 S kg m of the When arm 13 to IS 4 Note 7 Remove steering worm Fill the space between to gear unscrew 3 worm worm bearing adjusting housing shims worm shims 4 from assembly and column jacket steering wheel may be run down to the worm end worm suddenly end to If the the ends of ball guides damaged ST 4 worm housing assembly in together with Install column jacket with O ring and on worm gear bearing Be sure to install thicker shims to Be careful not to allow ball nut ball nut rotates in gear bearings bearings and gear sector housing Place steering position assembly new shaft oil seal lips with grease and fit it from gear housing 8 Detach worm to smoothly adjusting and shim from cover installing steering wheel apply grease to sliding parts 6 After installing make sure that turns shaft Remove jacket tube by ing three fixing bolts Note When sector the gear housing side Standard shim thickness 5 mOl 0 OS9 in 1 Tightening torque 5 to 2 S 1 kg m 11 to 18 ft Ib STEERING SYSTEM Available worm 8 bearing adjusting shim Install sector shaft Be housing cover each face of sector shaft No Thickness I 0 762 2 0 2S4 0 0100 mOl in when installing 9 0 0300 3 0 127 0 0050 4 O OSO 0 0020 Pull sector shaft toward bearing preload with Preload Gauge ST3127S000 by selecting suitable bearing shims so that the initial turning torque of steering column is the Initial worm specified value of turning torque steering column shaft shaft kg cover 11 m worm 4 0 to 6 0 Used bearing kg em S6 to 83 in oz 4 to 2 61 in oz into the screw adjusting shaped groove at the sector shaft head and adjust the end play between T sector shaft and adjusting it is within 0 01 to 0 03 to in 0 0012 screw mm 5 2 to 18 ft Ib Push sector shaft against ball nut gear by gradually Sector shaft 1 Check gear tooth surface for pit ting burrs cracks or any other dam age and replace if faulty 2 Check sector shaft for distortion of its serration this and if necessary re be sure to check place housing for deformation case gear turning adjusting clockwise until sector shaft gear lightly meshes with ball nut gear and temporarily screw with lock 12 Install gear and move sure or nut Adjust to sector shaft arm smoothly mOl column shaft assembly Inspect the ball nut gear tooth surface and replace if pitting burrs wear or any other damage is found 2 Ball nut must rotate smootWy on worm arm screw neu by turning that so movement of the gear arm less than 0 1 times and make the backlash at the adjusting Steering 1 arm sector shaft several that it turns out adjusting secure in If found too gear should be bly replaced top end Move is until 0 0004 ball nut to its entire Note In mOl 57S 1 0 0620 I 2 550 1 0 0610 wear 3 525 1 0 0600 4 IS00 0 OS91 S 1 475 0 0581 excessive 6 I 4S0 0 0571 3 ST207 Fig ST 10 Mea uring backlash adjusting screw approxi 1 8 to 1 6 turn clockwise and Rotate ball nut by hand until it is in the center of its trovel sector screw shaft together in gear housing then install with adjusting ensuring that the center gear of sector shaft engages with that ofball nut mately then retighten lock kg m 22 to 29 ft Ib or freely may be with a new one as be inspection ball nut e careful guide tube bushings worm any other bearings if pitting damage is found on them 2 Repiace column bushing which is worn deformed or If sector shaft are found bushings worn or replace as an assembly and bushing in gear damaged of gear housing nut to 3 0 to 4 0 Fill recommended gear oil ap X U S pI 33 0 liter proximately IS gear assembly pt through the filler hole and install filler X Imper and Replace housing 7 this Bearings in Thickness above move no assembly stroke not to dama shim Turn either end of weight In the own if ball nut does test over 14 fol gear and gradually stand steer ing column shaft assembly until ball nut moves downward on worm gear under by choosing suitable 0 as worm 0 004 in Available sector shaft adjusting I assem lows damaged Replace an assembly No tight Check the adjusting shims screw disassembled screw tral position of gear Insert screw sector II 13 6 repair the in solvent and check for condi parts In from the side of gear bearing 4 kg em 33 to worm cover bolts to lS to fixing Wash cover 0 08 to mOl counterclockwise then New 3 to by turning adjusting and tighten in all clean screw coun gear housing and then temporarily secure it with its fixing bolts 2 and Inspection tions to 12 0 the packing terclockwise attach sector shaft approximately Adjust cover cover By turning adjusting 10 5 to gear to apply sealant to sure into Oil seal O gasket ring Do not removed ST 5 reuse above parts which are once Be sure to reassembly plug and use new parts at each STEERING SYSTEM STEERING LINKAGE Cross rod both side rods and the 6 adjacent parts can Removal and the vehicle as an installation 7 I Jack up the 2 on the front of vehicle and pins To from knuckle side arms rod insert Ball Joint the following Ball stud must be done without this baIl stud Must head arm the on in the reo kg 4 kg Ic ann Remove riut securing gear S See Figure Remove idler arm rod length 8 to 10 a side toe in and 31 20 in steering angle ing angle adjustments Ie described in Section FA mm 0 04 to 0 20 in Steering angle m Inner wheel Outer wheel Cross rod adjust bar lock nut ball 3S030 30030 to to 36030 31030 kg m 72 f fL Cro 2 3 Side rod Cross rod socket 4 Idler 5 mm 20 31 in rod 1 s assembly Gear housing arm Mter adjustment of toe in be sure that dimension A at both ends of cross rod is not less than 20 nun 0 79 in ST210 assembly Fig ST 13 Adjusting cross rod assembly armOD sector shaft and remove gear arm with the of Pitman Arm Puller use ST29020001 cross m assembly in this operation Ball joints Adjust 1 to 5 S S to 10 0 5t6 ST 11 Standard observing 23 to 27 ft lb 2 Fig be the notes 3 2 to 3 7 not socket of side rod and side rod with hammer and so joints at 40 to 72 ft lb Idler hammer backing up the opposite side a large hammer and bail stud the done Toe in of it with strike be rod both end of cross rod assembly Tightening torque tool strike the knuckle arm boss with is freed from knuckle arm linkage sequence of removal verse and separate them by striking the top of this tool with a hammer If this a should Adjustment cross The procedures of toe in and steer Install steering ball studs Remover HT72520000 between them operation adjust tween the centers of ball 3 to knuckle Assembly detach separated length correctly 516 rom arms 3 are Then separate the ball joints of and nuts fas rod ball stud tening side When cross rod sockets and cross rod stands safety Remove cotter assembly steering linkage assembly following the procedure for removal ofthe side rods ball joints at knuckle arm sides Removal support it then be freed from 2 Idler ann assembly ST 6 assembly from frame by backing off fixing bolt and @ nut A 1 Idler 2 Collar 3 idler body Plain bushing 4 Screw bushing body welded to T529 Ffa ST 12 Removing idler Fig ann ST 6 ST 14 Sectional W of idler arm sembly as SYSTEM 1 Apply recommended grease to bushing interior plain bushing interior dust seal inside and bushing sliding surface of idler ann nipple screw Screw and reinstall filler In make A is installing sure plug arm S 42S to Before installing idler arm assem iller plug with grease bly replace f nipple and apply recommended grease to idler ann through this grease nipple See Figure ST 14 Furthermore be washers correctly A I I I J I FIODt Idler sure to 1 When ball stud is play is too excessive socket 2 replace side rod with or When defonned dust be cover sure worn or to axial cross rod a new one is broken replace with or a new one Axial end play 0 1 to 5 mm 0 0004 to 0 020 in Initial swing torque S to 15 cm kg 70 to 209 oz in until grease is forced Figure arm 3B8embly Remove old grease and dirt and check idler ann assembly for wear install ST IS STERING CrOBS rod side rod and Check them for bending damage and crack and replace as necessary Inspecting steering system the vehicle which comes on into collision is very important vehicle When the vehicle Steering system for driving L6 comes a into collision especially the front of the vehicle is damaged special inspection should be done for the following Spring washer matters 3 Plain washer If any component parts of steering system is found to be damaged re 4 Weld nut place 5 Self locking nut 1 Frame them with new ones Steering angles correctness Inspect side rods and cross rod for bend and sector shaft for distortion ST212 2 Level of steering wheel bar the front wheels in Ifits deflection is 70 to 209 cm kg oz in a with straight ahead position 90 degrees the bend more or than about distortion of sector shaft and column shaft can be seen 3 Noise during operation of steering wheel Inspect column shaft and jacket tube for bend Smooth 4 operation of steering wheel Inspect ball nut gear for breakage for dint and column sector screw shaft for bend S Gear 6 Gear housing ST213 ST 7 arm gear Initial swing torque 5 to 15 Ball joint nipple in Fig ST 15 Locations of washers Inspection and repair grease deformation and damage I 8 nipple mm until grease is forced out at the lower end of the dust seal lip Remove grease I grease out at the grease vent hole 504 S See renew remove grease cap and apply recom mended grease to ball joint through adjusted correctly 137 8 to 139 8 To sary assembly that the standard dimension 87 ft lb kg m idler Standard dimension bushing tightening torque 12 2 3 In breakage breakage addition inspect gear housing arm f IXing bolts for looseness 7 Distortion of sector shaft tion 8 Sector gear breakage serra STEERING SYSTEM 9 Column shaft breakage on the 10 welded section In Deformation of body construc tion and frame addition inspect column shaft Inspect steering system on the body construe tion and frame for deformation or any the installation portion of other faulty conditions for scratch SERVICE DATA AND SPECIFICATIONS SPECIFICAnONS Gear type Recirculating Gear ratio ball type I 19 8 SERVICE DATA Standard thickness of worm adjusting bearing shims in mOl 5 0 OS9 1 Initial turning torque of steering column New worm bearing Used worm bearing kg kg em in lb 4 0 to 6 0 em in lb 2 4 to 4 5 to S 2 3 2 1 to 3 8 End clearance of sector shaft adjusting screw Backlash at the gear arm top end Oil capacity Bail in om to 0 03 0 0004 to 0 0012 rom in o to 0 1 t U S pt Impel pt joint axial Standard rom cross end play rom in rod length rom in Toe in 0 33 0 to 0 004 J X 0 1 to 0 5 0 004 to 0020 516 in 31 20 I to S 004 to 0 20 Inner wheel 35030 to 36030 Outer wheel 30030 to 31030 rom Steering arigle Tightening torque Unit Steering column jacket Sector shaft to gear housing kg m 1 5 to 2 S cover IS to 2 S ft lb II to 18 II to 18 Sector shaft lock nut 3 0 to 4 0 22 to 29 Gear housing 4 6 to 33 to 38 Gear arm Steering wheel Bail studs of cross rod 3 5 13 to IS 94 to 108 7 to 7 S SI to S4 S S to 10 0 40 to 72 Ball studs ofside roo Knuckle Gear or arm idler side arm side ST 8 S S to 10 0 40 to 72 5 to 10 0 S 40 to 72 STEERING SYSTEM TROUBLE DIAGNOSES AND CORRECTIONS Probable Condition Steering wheel heavily Steering wheel but sluggishly moves Corrective action cause Wheel alignment out of specifications or air Align or inflate tires to correct pressure pressure in tires too low turns Steering linkage out of adjustment Steering column out of alignment Wheels out of alignment or air pressure in see relative topic under Front Repair Repair or inflate tires to correct air pressure tires too low Replace and Suspension Damaged steering linkage Vehicle pulls to Adjust and Suspension one Wheels out of proper see relative topic under Front Align alignment side Wheel bearing out of adjustment Adjust Damaged steering linkage Replace and see relative Suspension ST 9 topic under Front STEERING SYSTEM SPECIAL SERVICE TOOLS Tool number For No Description use tool name ST27I80001 Steering Unit This tool is used to mOl in drive out steering wheel All page or Figure No Fig ST4 models wheel puller on Reference Caution Do not hammer on steering column shaft v o J 2 ST29020001 Pitman SE 116 This tool is used to remove sector arm steering pitman arm from steering shaft 620 Fig 6 ST B210 710 puller 610 SE401 3 ST3I 27S000 This tool is used to measure the worm bearing preload All Page ST 5 Page ST 6 models Preload gauge GG91030000 Torque D wrench 2 I HT62940000 IJ Socket adaptor 3 t 114 3 8 YID Go 318 HT62900000 1 2 Socket adaptor 4 HT72520000 This tool is used to remove ball joint All Ball joint models remover SE399 ST 10 SECTION FE ENGINE CONTROL DATSUN PICK UP MODEL 620 SERIES l NISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN FUEL EXHAUST SYSTEMS ENGINE CONTROL SYSTEM FE 2 FUEL SYSTEM FE 4 EXHAUST SYSTEM FE 6 Control Engine Fuel Exhaust Systems ENGINE CONTROL SYSTEM CONTENTS DESCRIPTION FE 2 INSPECTION FE 3 REMOVAL FE 3 ADJUSTMENT FE 3 AND INSTAllATION DESCRIPTION The accelerator control system is of flexible cable type so that the linkage ul L f operates smoothly and the system is not affected by engine vibration The choke system is automatically controlled @ i 4 @ @ p I @ CV j Arrow E 78 T 2 to 4 mm B 3 07 in mm 0 08 to 0 16 in MUlti purpose grease I 2 3 Accelerator pedal Accelerator pedal bracket II Screw 12 and return 13 Pedal stopper bolt Kickdown switch striker spring 4 Accelerator pedal arm Pedal stopper lock nut 5 S pring 6 Lock nut 7 Adjust 8 9 10 FE260 Automatic transmission models only clamp 14 Kickdown switch Wire holder 15 Accelerator wire 16 models only Switch stopper Carburetor Automatic transmission nut Accelerator wire outer nu t case Fig FE l Accelerator control sy FE 2 t m Engine Control REMOVAL AND INSTALLATION E 78 Fuel Tightening Accelerator wire Systems 3 07 in mOl 38 0 Exhaust 2 7 to 01 torque to 0 4S then automatic choke effect will be released nut 3 kg Set throttle valve to m closed 2 ft b 3 position and ficiently I Remove air cleaner assembly Disconnect accelerator wire from 2 3 Loosen lock nut and disconnect accelerator wire outer from wire case holder See Figure FE I 4 Remove spring clamp and discon S Release auto choke effect throttle I with 2 lever is until earn nect accelerator wire from accelerator pedal lighten adjust engine Keep fingers by fast idle opened warms choke since up valve Accelerator pedal play is lime See 4 Unscrew open adjust a nut Tighten lock Figure FE 2 approxi half turns accelerator pedal play is 3 in Pull throttle lever up by hand at this zero FE 2 two and mately fully Figure nut move nut so that 0 012 mOl securely See arm Remove two screws celerator wire outer securing ac body and to case 1 detach accelerator wire 6 wire suf until throttle lever is about to 2 carburetor slackened completely with To install the order reverse I of removal Apply recommended multi purpose grease slightly to portion MG shown in Figure FE I Accelerator pedal assembly Remove I pedal ann Remove celerator two screws bracket to pedal 3 Remove dash panel 4 1 accelerator wire from tip of connect 2 then dis spring clamp accelerator securing body pedal ac from See Figure FE I To install reverse nut 1 Adjust 2 Lock nut 3 Accelerator wire 4 Dust @ co CD r order of the FE184 removal Fig FE72 AdjU6ting accelerator wire play INSPECTION I Check spring Replace 2 accelerator for rust pedal fatigue return damage or if necessary Check accelerator wire fastening locations for rust cases and damage or 5 After completing the adjustment previously as I Repair or replace if necessary Make recommended multi explained purpose grease slightly portion as shown in Figure FE I Also refer to that accelerator the following looseness Apply 4 check the sure on the periodic maintenance schedule system functions smoothly and quietly without disturbing any adjacent parts ADJUSTMENT Depress accelerator pedal down 2 until Accelerstor pedal and wire Adjust pedal Section A ed height FE I so E Secure stopper lock FE I as as stopper to obtain shown in pedal stopper nut Refer bolt specifi Figure bolt with to Figure sure throttle valve fully opens Make that the clearance T between accelerator pedal floor is 2 to 4 reverse without floor mat Adjust pedal stop per bolt and lock nut if beyond limits 3 Check throttle lever if it returns to the original position as pedal is released accelerator FE 3 soon as Automatic transmission models only side and dash 0 08 to 0 16 in mm Kickdown switch Kickdown switch adjustment is rect if it is actuated switch striker when accelerator is cor by kickdown pedal fully depressed Always tighten switch stopper nut securely after proper adjustment is obtained Engine Control Fuel Exhaust Systems FUEL SYSTEM CONTENTS DESCRIPTION FE 4 INSPECTION FE 6 REMOVAL FE 5 INSTALLATION FE 6 DESCRIPTION The fuel tank is4Sliters gal 9 Ji Imper gal in tank unit is mounted to of the rear II Ji s U capacity The the right side floor 1 Fuel 2 3 Drain plug Filler tube 4 RescfYOir tank 5 Filler hose 6 Breather hose 7 Ventilation hose 8 Evaporation hose 9 Fuel outlet hose and tube The filler shutter is installed to the filler tube on on California models For the electric fuel pump refer to Section EF The electric fuel pump is adopted air conditioner equipped models tank 10 Fuel 11 Protector 12 Bracket 13 Retainer 14 Return tank gauge unit tube FE194 Fig FE 3 Fuel tank 4 FE Engine Control Fuel Exhaust Systems 4 A Detail Detail e Bn Detail Detail G @ Detail Detail E D Detail U B Detail Detail T F FE261 Fig Note REMOVAL Fuel tank Plug hose and tube prevent entry of dust removing See Figure FE a prevent entry of dust removing opening to l or dirt while 3 I Disconnect 2 Remove the remaining battery ground cable drain fuel into a 2 battery ground Disconnect wires from fuel tank Fuel filter hose 4 refer to fuel tank removal filter 4 FE 5 5 Disconnect filler tube Remove fuel tank frofiller securing bolts Disconnect two ventilation hoses fuel tank Unit gauge is a For details bayonet type and I Disconnect fuel hoses from fuel by removing clamps See Figure be removed by turning it counter fuel return hose and fuel outlet hose can from fuel tank clockwise with screwdriver 6 Unfasten clips that hold tube on body and remove tube from the cable gauge unit 3 Remove 3 dirt while vehicle Disconnect suitable container or under Fuel tank gauge unit and receive plug 4 Fuel piping FE Disconnect fuel tank gauge unit wires at connector Fuel piping Remove fuel tank 7 Note Plug hose and tube prevent entry of dust or opening to l dirt while removing tube not ReservoIr tank 1 2 Disconnect 3 battery ground cable Disconnect two ventilation hoses evaporation hose and breather hose Remove reservoir bolts and Fuel sembly remove can tubes so See Figure are that serviced as replacement 4 FE an as of fuel be easily done However do disconnect any fuel line unless absolu tely necessary I Drain fuel from fuel tank 2 Loosen fuel hose clamps and dis connect fuel tubes on each end FE18S tank securing tank with protector Note Plug hose and tube FE 5 openings to Fig FE S Removing fuel filter clamps Control Engine 2 Fuel Exhaust Fuel filter is of Remove fuel filter a cartridge type and cannot be cleaned Always with INSPECTION fuel Check tank for cracks or deformation If necessary replace 2 replace Check gauge unit for rust deforma tion or deterioration If necessary fIller hose after fuel tank has been mounted in place Failure to unit align the projection of tank tighten securely it Inspect all hoses for cracks fatigue sweating or deterioration Replace any gauge unit with O hose that is connections damaged Replace ed rusted 6 INSTALLATION Fuel tube 3 any fuel tube that is crack collapsed or deformed To Note Inspect cording nance 4 to hoses the and tubes periodic install ac mainte schedule Install hose not tighten damaging of to excessively the surface of fuel tube the periodic maintenance schedule or 3 restricted are place at plug kg m Fuel tank securing bolt 8 to 1 0 Ikg m 6 to 8 ft Ib to Reservoir tank securing bolt Do not kink or twist tube when they in 36 to 43 ft Ib hoses to ring 5 0 to 6 0 avoid damage Be sure to install engine and check for leaks Drain Do Fasten according or gauge Tightening torque clips holding fuel tube on under body securely Failure to follow 2 filter clogged order clamps securely this caution could result in Fuel filter Replace fuel when it is the reverse Run removal Observe the following I result in leakage from around hose connections When installing fuel tank gauge 5 unit with the notch in fuel tank and replace Fuel hose Install 4 follow this caution could new one a Fuel tank gauge unit 5 Fuel tanle Systems hose and 032 to 0 44 kg routed m 2 to 3 ft Ib EXHAUST SYSTEM CONTENTS DESCRIPTION FE 6 INSPECTION FE 8 REMOVAL FE 8 INSTAllATION FE 8 DESCRIPTION The the exhaust non systems installed on differ in from those installed on California specifications California Non models the California models The models California models exhaust system consists of front exhaust tube a main a muffler assembly with rear tube mounting hangers brackets and a heat insulator The exhaust system cOllsists of front exhaust tube ter assembly muffler a catalytic center tube a assembly with a conver main a rear tube mounting hangers brackets and heat insulators The nected catalytic to the is converter front tube and center tube with bolts and nuts FE 6 COD the Engine Control Califomia Non Exhaust S ys tems Fuel model Qf l tr Qf Si @ Si tIJ Qf i l l t I j l tr Qf r l i Si l 1 l tr I 9r 8 1Bi 1 Front tube 2 Exhaust 3 Rear 4 Muffler 5 Rear tube mounting Front tube mounting 6 tube clamp tube assembly assembly California model 6 @@ Qf @ 8 fit 0 J I 1 Front tube 2 Catalytic Center converter tube Muffler assembly Diffuser I Rear 7 tube mounting tube mounting Front FE390 Fig FE 6 FE 7 r E t ha system Fuel Engine Control Exhaust Systems REMOVAL Install the exhaust system assembly models California Non I INSTALLATION ijl exhaust Remove tube in reverse order U bolt the clamp 2 of removal Observe following Break sealant off at front tube to Notes main muffler 3 and connectio n Remove rear tube mounting bolt remove muffler assembly with rear When there is b Remove nuts securing front tube shaft turn tube 4 tube to exhaust manifold and remove front tube mounting bolts Then detach FE189 c the exhaust Q d off at t lse ant 1e connection by lightly tapping around the tube witlJ a hammer and twisting 8 FE tap on the front end of muffler while pushing it toward rear The mumer assembly can After old muffler See Figures FE 7 and 2 Using a rubber hammer then be taken out See Figure I Remove all heat insulators 2 Remove tube exhaust U bolt vibrations may be transmitted to the vehicle body or Break sealant off at center tube rear Remove Exhaust manifold to tube mounting bolt and remove muffler assembly with tube 5 Tightening torque e to main muffler connection Remove front tube nut rear 19 to bolts securing U bolt 14 to 15 ft lb Remove bolts and nuts Mounting securing 710 9 ft lb Front tube mounting bracket bolt california models Remove nuts securing front tube and remove front to exhaust manifold Fig FE 7 Breaking Bealant bolts mounting bracket bolt 1 0 to 1 2kg m catalytic converter to front tube and detach catalytic converter tube securing nut kg m 19 to 2 1 Then detach center tube FE187 m lb ft catalytic center tube mounting bolts 7 5 kg 2 14 to 18 converter to center tube and remove 6 that If any of the above parts is not installed properly excessive noises clamp 3 check installation mounting brackets and mounting rubbers are free from undue stress California models 4 FE 9 connecting running following point Break the manifold in propeUer or center line of haust gas leaks and entire system for unusual noises with engine rubber hammer tube connections pay attention to the I along and obtain proper clearance Check all tube connections for ex Fig FE 9 Tapping muffler with disconnecting clearance between unit front tube When 110 front tube and floor Remove front tube heat insulator 5 tube until it touches emboss tube 4 front Insert a 19 to 2 1 Then detach kg m 14 to 15 ft lb front tube Catalytic converter to front and center tube bolt California models 3 2 to 3 4 kg m 23 to 31 ft Ib INSPECTION I Check cracks Qr muffler and tubes connection damage Replace any part that is damaged beyond limits 2 FEl88 Fig 8 FE Twisting muffler Replace insulator that If exhaust tubes for etc use are separated t renew muffler at assembly the Genuine Nissan Sealant Exhaust Sealant Kit 20720 N2225 bracket and are cracked sweated FE 8 mounting fatigued or or equivalent See Figure FE IO eliminate gas leakage at the sure to observe the following joint to Be Fuel Engine Control Exhaust Systems Start 7 for ten and let it idle engine minutes to minimum slowly hilfden sealant with the heat of exhaust gas Sealant tube 8 polyethylene condition of sealant Check the before driving the vehicle It is also essential that the vehicle should not be Injector accelerated minutes sharply for 20 to 30 subsequent to this operation Noles a The sealant should be used within Exposure of sealant cause Wipe clean all tions of tube joints thoroughly 2 on 3 as Be sure to place cap back to sealant tube since sealant will dry an place a Do not ture assembled unit tube until it touches to the skin may keep the sealant tube in a where the ambient tempera is above I040F Insert front the kit rash Wash sealant off the sealant the vehicle on skin with water c place in mount Temporarily muffler assembly the contact por allow them to dry indicated case b I term guaranty Fig FE IO Exhaust sealant kit 400C A I040F 4QoC above hardened cannot be used The most suitable storage temperature is from 15 to 350C 59 to 950F If sealant emboss becomes hardened because of low temperatures 5 b nlfrnnjj Ij lJ Fig FE 4 ll Torque female securing the male and the connection Tightening torque is 1 6 to 12 to 14 ft lb 5 Squeeze approximately cu in 2 0 Position nozzle of injector to the guide and press it there firmly Inject kg m sealant slowly until sealant begins to flow out of the slit of tube This indicates that the bead requires further sealant Excessive sealant cause a clogged tube See no can Figure FE 13 5 CC 31 0 of sealant into injection from sealant tube See Figure FE 12 sealant is softened tube at a 1040F After injecting thoroughly the sealant wash in clean water to injector remove all traces of sealant FE191 Fig FE 13 Injecting sealant FE 9 Do not warm temperature a long time over 400C for d Thoroughly FE263 at in 6 Exhawt tube connection nut Cll Fig FE 12 Squeezing sealant to injec tor J @L tubes 0 31 FE1l1 mm m cc wann tube with lukewarm water until the Approximately read the instruction sheet furnished with the kit before using the sealant i SECTION BF BO DY FRAME DATSUN PICK UP MODEL 620 SERIES CAB BODY AND FRAME BF 2 REAR BODY BF 5 BODY FRONT END BF 7 HOOD BF 8 DOOR BF 11 WINDSHIELD GLASS BF 16 INSTRUMENT PANEL BF 17 INTERIOR TRIM AND CENTER CONSOLE SEAT I NISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN BF 18 BF 19 Body Frame CAB BODY AND FRAME On the 620 series models chassis classified into three types the standard wheelbase model long frames The frame consists of right and left side are members which are heavy linked to is gether with crossmembers to form a rigid structure that can withstand wheelbase model and Deluxe Cab loads The second crossmember located somewhat to the rear permit individual replacement of transmissiol to the FRAME ALIGNMENT STANDARD WHEELBASE MODEL 9 rd 9 8 0 ij 1sol r 00 1 l 085 42 721 1 4 069 r1 f 7 42 1 587 5 X 62 50 9ClSCl b b I 1 I J q e e 6 1 I 1 JA t 1 11 i11 1 r 1 H 10 1 I I OO 175 6 89 5 37 11 942 I r T 1007 284 18 11 L 39 65 295 11 61 r r c 8 d 8 o M o BF025B Fig BF I Underbody dime1l8ion SF 2 Standard whee b e Frame Body LONG WHEELBASE MODEL l1 4 In IS S M t r y J t v D c I b f G c M 0 raj V N 085 42 72 78 1 350 I I 1 d3 1 20 63 U n So p Ii I T II L r J t I I o 10 9 1 M y r M 0 I bi 1 I 0 1 873 8 mrn IN 0 v p v 1 Ir M e C o M BF0268 o Fig BF 2 Underbody dimensions Long wheelbase DELUXE CAB 17 C l 0 y r dJ M r 2 iO 1 b I 00 o V JSO 0 0 I li4 t I 37 11 l 1 284 18 11 bu I 007 39 65 b n It o U j 1 1161 c I Jr 0 N 00 8Qa 3 OS t A 942 5 r M 0 1 1 b I t c tl f 0 1 085 42 72 1 P N S 1 069 4 42 10 b u r I T M 8 o It R M o BF027B Fig BR 3 Underbody dimensiom BF 3 Cab Delu Frame Body CAB BODY 2nd mounting Ist mounting 1 Bolt 2 3 Plain washer Rubber washer 4 Upper 5 Bottom rubber Plain w er 6 7 Upper 8 Lower washer BF472A 1st mounting 2nd mounting rubber washer Unit mm in 3rd mounting Fig BF 4 Cab body mountings REMOVAL AND II INSTALLATION from frame and pull it out into engine at compartment nect cable from dash Remove 12 Remove from battery engine 2 Disconnect oil cooler hoses from automatic radiator model transmission only housing gear Loosen hand brake control cable brake control lever Note Disconnect carbon vacuum rolling between gallery and canister to intake manifold canister to wheels to prevent vehicle from rear hoses 24 off accidentally Free Disconnect air conditioner tubes from condenser if so equipped pump air cleaner hose at air cleaner 25 4 15 engine side Drain water from and completely cooling remove system radiator and condenser if so equipped 5 Remove engine hood from hood hinges after scribing hood for rein stallation 6 and remove bumper stay from frame front bumper 7 Remove radiator grille 8 With the aid of Steering Wheel Puller ST27 180001 remove wheel from steering shaft 9 Remove steering gear sector shaft steering arm from using suitable puller 10 air to pump air Disconnect air conditioner hoses from compressor if so equipped 16 Disconnect air cleaner duct from body 17 Disconnect Master Vac vacuum Remove 18 Remove snap ring and control transmission striking lever pin from guide and remove control lever 19 Disconnect fuel securing steering and insulator in posi screws Disconnect 26 and 22 tubes Remove all brake tubes and clutch tube at 4 BF on right engine mounting frame 29 With the an use of suitable ropes overhead hoist lift cab up slowly and body place it on a up cab body use care clutch cylinder clips securing fuel cab body rear level surface at connectors brake near Remove six bolts securing body 28 straight Disconnect at member 20 21 hoses harnesses at their connection strainer evaporation hose heater Disconnect wire harnesses from and Disconnect fuel return hose and car related engine electrical parts 27 Disconnect engine and chassis to hoses at fuel accelerator wire from buretor sidemember tubes from each master shaft dust seat tion Disconnect hose at intake manifold Remove steering 14 Then discon panel Place blocks against front and canister at canister 3 23 Disconnect speedometer cable at transmission 1 3 compartment steering Note In lifting not to dash it body mately against engine or rear Cab body weighs approxi 220 kg 485 Ib Body 30 For steps However installation reverse Frame above observe the following instructions i Ifthe cab body is to be replaced note position and location of insula tors and washers used See Figure 2 Adjust hand brake stroke pro perly 3 Air system bleed brake and i o 4 BF clutch thorougWy kg q j 1Q Cab body to frame mounting bolt torque 1 6 to 2 2 k b rr1 m 12 to 16 ft Ib crru V J 4 n 8F630 Fig BF 5 Lifting up cab body REAR BODY 1 Bolster 2 Shim B 3 Bolster 4 Shim A 5 6 Frame Rubber washer 7 Plain washer BF664 Fig BF 6 Rear body mountings REAR BODY REMOVAL AND tank INSTALLATION body The rear Remove fuel tank from rear 5 Remove eight rear body attaching bolts body is securely fastened eight places It should to the frame at be hoisted after the fuel tank is moved from the rear body Use the following procedures guide when removal or as a installation of rear body is I Apply parking brake 2 Disconnect cables from 3 Disconnect necessary rear lamp wiring harness at 4 re battery combination connectors BF665 Disconnect fuel hoses from fuel Fig BF 7 Rear body mountings BF 5 Frame Body 6 Attach rear body and lift ropes to hooks in 8 BF shown in Figure lifting as body slowly and rear up REAR GATE 00 REMOVAL AND INSTAllATION W 1 carefully Notes When a lifting body make rear that it is in a good sure balanced cond ition b While lifting rear any The c body use care to hit cab against body or adjacent parts rear Rear gate chain 1 not to allow body weighs approxillllte @ Iy 130 kg 286 Ib 2 Rear gate chain bolt 3 Rear 4 Shim S Hook handle 6 Reargate body BF661 Fig BF 9 Rear gate I Open 2 Remove rear 2 gate body rear at any I adjust To order rear of removal body reverse Carefully the or remove observe thickness rom adjust rear gate hook loosen attaching bolts and move rear gate hook or left right in elon down up holes as gated required reverse the 1 6 height shims at mm FRAME Optional REMOVAL AND INSTAUATION The points the To GUARD Two sizes of shim To install required gate should be portion add 7 in the left and two adjusted so that there exists an equal clearance between body and the periphery of rear gate There should be no stepped The rear gate 3 ALIGNMENT up rear Remove rear gate hinge attaching 3 bolts and take out rear gate and rear ear order of removal Fig BF 8 Lifting adjust gate gate chain from gate hinge shims 4 To install rear gate BF0288 To right directions loosen rear gate hinge attaching bolts and move rear gate as rear of rear gate rear are gate hinge available in 0 0630 in and 0 8 0 0315 in guard frame optional equipment I guard frame at guard frame optional guard frame bolts and detach To install reverse as an nine Remove taching 2 is furnished the order of removal the following instructions Make sure that spacers and shims used with bolts are properly placed rr r original positions Refer to Figure BF 6 for the location of these parts The rear body to frame attaching in their bolts should be kg m torqued 24 to 30 ft Ib to 3 to 4 2 f r @ L C s i SF673 Fig BF lO Guard frame 6 BF Frame Body BODY FRONT END 4 ZID @ 1 2 Hood 3 Hood @ Hood support rod 4 bumper Fender 5 Bumper bracket shim 6 Bumper side bracket 7 Bumper 8 9 Bumper stay 10 7 @ Front apron Radiator BF029B grille Fig BF 3 FRONT BUMPER REMOVAL AND INSTALLATION L Remove bumper to For installation reverse above steps observing the following Check to be certain that I fender at taching bolts Remove four bumper stay to side frame front attaching bolts Pull bum six guide studs enter holes in radiator support lower frame before tightening top screws 2 forward per assembly straight reverse 3 For installation steps Align bumper with front fender and apron then tighten them up radiator and two on Radiator grille 2 3 Guide stud 4 Radiator Guide 632 stud hole support lower grille by re Fig BF 12 Radiator grille guide six on top studs both ends Remove ornament grille by removing radiator 1 frame screws grille on Remove radiator 3 Disconnect front turn radiator nuts from behind 2 at bumper grille signal wire connector Remove front apron by removing For steps REMOVAL AND INSTAUATION Remove Remove front S RADIATOR GRILLE I I 2 attaching bolts @ B moving attaching REMOVAL AND INSTALLATION 4 above Body front end FRONT APRON harness CD 11 Align grille with head lamps and fenders BF 7 installation reverse above Frame Body However COWL TOP GRILLE observe the following items When installing air box drain apply adhesive to its lower end I @ @ 2 Align cowl top grille with fend ers FRONT FENDER 1 Cowl top grille 2 Cap 3 Air box dtain seal 4 5 Cowl top Air box drain 6 Screw 6F633 Fig BF 13 Cowl top grille REMOVAL AND 2 Open engine windshield blad Remove cowl top 3 screws hood two Remove I Remove front 2 Remove radiator 3 Remove front apron 4 Remove cowl top S Remove hood bumpers bumper grille grille two on each side INSTALLATION I REMOVAL AND INSTALLATION wiper grille straight forward to To Remove nine attaching screws BF ll Remove air box drain 5 6 front fender to hood ledge See Figure remove 4 grille attaching Pull install reverse above steps 7 To install reverse above steps HOOD HOOD 5 REMOVAL AND INSTALLATION 1 Place protective fender and cowl top 2 covers over front grille Mark hinge 1 Female lever hood and loosen offfour 2 Safety bolts securing hood to hood hinge Use 3 Return 4 Dovetail S Lock nut 6 Hood lock pring 7 Spring Open engine locations extra on caution hood to avoid damaging painted surfaces of fender and cowl top grille 3 4 Remove engine hood To install reverse above J Four slotted holes in hood hinge provide for fore aft and side adjust to correct space between hood and hood and cowl top and fender grille just enough to engine hood and move hood to desired position if necessary to correct move space To make vertical hinge bolts just permit movement of Loosen hood to far enough to hood Shift hood in elongated hole until hood parallel space is reached between cowl top grille Tighten and fender or 2 j I bolts securely adjustment adjust height of dove tail bolt bolt Fig BF 14 Hood lock male and female ADJUSTMENT Loosen four bolts spring BF641A pro cedures ment catch lever 8F635 at hood lock Fig BF 15 Engine hood alignment male until hood is flush with fender BF 8 Frame Body Vertical Note adjustment 5 should be and female adjustment has D been completed 3 bolts and move attaching r hood lock male and female in the lateral and fore and aft directions as required lock nut dove tail bolt driver to secure 1r To correct hood lock alignment loosen two hood lock male Tighten holding carried out after hood lock male firmly while with a screw adjustment Tightening torque Lock nut of dove tail 1 9 to 2 6 kg m 14 to 19 ft lb BF642A Fig BF 16 Adjusting hood lock male provides for vertical adjustment in aligning hood to make it flush with Male and female attaching bolts 0 45 to 0 60 3 to Dove tail bolt at hood lock male 4 Tightening torque kg m fender To correct loosen lock nut 3 ft Ib 4 on dove tail bolt and turn dove tail bolt in or out as necessary to obtain a correct height BF643A 1 Lock nut 2 Hood lock male 3 Safety catch Fig BF 17 Doue tail bolt height adjustment HOOD LOCK CONTROL JI I I i r J lPP J jJ I f r j f ifryI ff U J aj Sr I 1 Dove tail bolt seat I 2 J 3 Lock nut Cushion rubber ii1iiilliiijiWI Y 4 7 j 1 5 Spring Spring 6 Dove tail 7 8 Clamp Clamp 9 Hood lock female 10 retainer bolt Control cable assembly JJ BF644A Fig BF 18 Hood lock and control cable 8F 9 Body Frame REMOVAL AND I INSTALLATION spring for rusting Remove hood lock male by I re 2 moving two attaching bolts 2 To remove remove grille Back off two lock to dash side paneL Disconnect female and cable remove at hood BF645A 1 Hood tock handle 3 Clamp 2 Hood lock handle 4 Hole bracket 5 Attaching bolt lock cable clamps Pull Fig BF 19 1MtalIing hood lock handle cable out into cab 4 brocket removal reverse or lever and return disengagement be sure engine that hood hood latch has been safety catch properly when disengaged 0l they are 5 To procedure check to insure that Mter installation properly aligned install hood lock handle sembly following notes Check to I clamps are tight reverse steps I ADJUSTMENT AND as observing the I If hood lock handle is heavy turn nun 0 3t5 in coun Fig BF 20 Safety catch lever to radiator upper support terclockwise to reduce tension of hood acVu5tment dove tail bolt of hood lock male lock secure spring Lock nut of dove tail bolt should Install hood lock handle bracket two of four holes BF409A 11 mm 433 0 in INSPECTION be certain that cable and place by using See Figure BF 19 in and To install hood lock male and female 2 Make hooks attaching hood assembly cause may 3 @ handle fatigue tween female lever and dove tail bolt be taken out Remove two bolts Check female lever securing hood lock female in position Hood lock female can now bolts 3 catch lever safety deformation spring for deformation fatigue or rust ing Improper operation of female hood lock female first radiator Check fust be loosened When If looseness is noticed hood is not tight and will vibrate To correct this turn bolt clockwise and recheck 2 Lubrication Check hood lock mechanism follows thoroughly as or adjusting the Also lubricate the lever of the hood lock female for smooth and correct BF 10 checking hood lock lubricate the pivot catcher and return spring of secondary latch operation Body Frame DOOR CONTENTS DESCRIPTION BF12 DOOR BF 12 REMOVAL REMOVAL AND INSTALLATION BF 12 ADJUSTMENT ALIGNMENT BF12 DOOR RUN VENTILATOR WINDOW Optional REMOVAL AND INSTALLATION GLASS AND REGULATOR BF14 AND INSTALLATION BF14 BF14 LOCK REMOVAL BF12 REMOVAL AND INSTALLATION DOOR DOOR BF12 TRIM AND SEAL REMOVAL AND INSTALLATION GLASS DOOR BF 14 AND INSTALLATION BF15 ADJUSTMENT LOCK BF 15 BF13 DOOR STRIKER BF 13 WEATHERSTRIP BF 15 BF 15 BF13 DESCRIPTION 8F 15 BF13 REMOVAL BF 15 AND INSTALLATION CD CV CID @ @ @ 1 Door 2 Window outside 3 Wmdow inside weatherstrip 4 Door 5 Rear 6 Door weatherstrip weatherstrip glass run rubber 7 finish holder Rear lower sash 8 Seal 9 Door screen 12 weatherstrip clip glass run rubber Lower door hinge Upper door hinge 13 Front 14 15 Door glass Glazing rubber 16 Door 10 11 j sash Front lower sash glass bottom channel BF030B Fig BF 21 Door without ventilator window BF 11 Body Frame @ I CD 1 @ r L 1 3 Door sash Window outside weatherstrip Window inside weatherstrip 4 Door 5 Rear 6 Door finish holder 7 8 Rear lower sash Seal screen 9 Door 2 @ ID @ c @ AJ @ weatherstrip clip 11 Front glass run rubber Lower door hinge 12 Upper door hinge 13 Front lower sash 14 15 Door glass Glazing rubber 16 Door 11 18 Lower support Upper support 19 Door ventilator assembly 10 @ atherstrip glass run rubber glass bottom channel BF031B @ ntilator window Fig BF 22 Door with 4 DESCRIPTION The outer rigid door consists The curved ALIGNMENT a Elongated holes hinge and door window is also a ventila available as to an BF023 option The weatherstrip is inserted on the door side 2 3 Separate lower door While supporting door back off REMOVAL AND INSTALLATION inside cab With door in full open position a garage jack or stand beneath hinge hole from dash side trim body hinge attaching I To as above upper and lower bolts accessible from to three each Door place door to support its weight when bolts removed Place rag between door and jack or stand to avoid damaging I lf p1JJ W 1 painted surface door move lion to obtain a door to door alignment loosen door to desired posi parallel space between sides and door opening Also check to be certain that contacts vent weatherstrip body opening evenly to pre entry ofmud and water DOOR TRIM AND SEAL INSTALLATION 1 door Remove screw securing handle escutcheon inside remove es cutcheon i 2 Remove handle and Sl fit REMOVAL AND t I door can now be taken out from cab body are proper adjust bolts and cover DOOR assure opening Fig BF 23 Supporting door into the groove on the door sash side and is attached by clips in lock striker pro vide for up and down forward and backward and or sideways adjustment glass provides greater incorporates three each door room A door that tor and to form structure shoulder removal pro reverse cedure of inner panels welded together To install Optional handle and j screws arm arm which hold pull rest in position Pull rest can then be taken out 3 Fig BF 24 Removing door hinge bolt 8F 12 Pull retaining spring off regulator handle Take out regulator handle and seat washer Frame Body 5 Remove door 6 Remove glass front and glass run rubbers from lower sashes and from rear those of fixed door caution Use avoid to damaging rubbers during removal operation Remove front 7 and rear lower door sashes is not provided 8 1 BF640 On vehicles lator Seat window washer BF 25 Removing regulator handle To install ing 4 door finish are not With taining clips exercising pry off re care not to Adhesive f Section A I A i jl II Ii iif A ir coil J IIIII Fig BF 27 Adhesive for seal With door glass up set regulator handle at an angle shown in Figure To cedure install J l replaced into be position Sure to screen securely water sealed door This Broken be leaking new one to can evenly applying adhesive inside door Fig BF 28 Installation angle of regulator handle back ensure be done a by to grooves in panel must suspected be replaced with to a 1 Door sash 2 Glass 3 Adhesive run rubber Fig BF 29 Applying adhesive to glass run ru bber Optional REMOVAL AND INSTALLATION I Remove GLASS RUN of door REMOVAL AND to and INSTALLATION I With door in full out position five ventilator window 2 Remove regulator 3 seal 4 pull handle 2 For detailed relative topic Lift frame out procedure under refer Door Glass Regulator Remove nuts and spring securing end of ventilator window to lower lower glass all the way screen Or one CID BF641 frame attaching bolts is to be cement it good fit WINDOW BF462 notes When water seal i a DOOR VENTILATOR reverse However ing instalJation run CD Spring 1 removal pro observe the follow glass to and fit it correctly Particularly care should be taken at corners and contact BF 28 inside door 6 adhesive door sash contacting face screen 2 from on I 900 screen clean J Fig BF 26 Removing door finish Separate water seal panel adhesive lUJJ d 5 applying nil BF641 ldI I Apply rubber face to assure JJ A I a L Before 2 f damage clips I removal pro observe the follow reverse However the inside ofdoor sash damaged screwdriver a ventilator lower door rear notes I When removing door finish it is important that inside door panel and with venti remove sash 9 cedure Fig equipped window frame and Regulator handle Retaining spring 3 when ventilator window arm rest and frame Work off rivets which hold upper end of ventilator window to frame 3 handle Remove door fmish and water take out window screen Remove outer and inner weather 4 To cedure strips from door BF 13 install reverse removal pro Frame Body DOOR GLASS AND REGULATOR CD j fffi I BF035 Fig BF 32 Removing door 12 To install reverse glass removal pro cedure ADJUSTMENT Fig BF 30 Door gl and regulator In and out I justment REMOVAL AND 10 INSTALLATION lator remove three bolts L Open lower glass door way 2 Remove iflllide all the door handle es cutcheon 3 Remove pull handle Remove arm rest 5 Remove regulator handle 6 Remove door finish 7 Peel off water seal suitable plain place a driver and door lifting it up Back off the five guide channel base remove or large access front or rear fore and aft ad be required The ease with which window bly raises and lowers depends attaching screws regulator Take out regulator assembly through screwdriver piece of rag between go Remove ventilator frame attaching bolts and lift frame straight up out of to screen similar flat bladed tool io glass the bottom of door 11 erstrips from door being sure not to scratch door paint during operation a to with venti securing door bottom channel then let straight Work off outer and inner weath Use glass equipped door Remove door glass by 4 8 On door and made by moving sash and guide channel as can hole in inside door panel justment of lower sash rear should front lower sash 2 Fore and aft lower be assem on ad sash Rear parallel with adjustment is deter mined by position of guide channel and front lower sash Moving front lower sash backward reduces window play in assembly DOOR LOCK and screw panel j CID @ 1 Outet weatherstrip 2 Screwdriver 3 Piece of rag BF643 Fig BF 31 9 outer 1 Escutcheon 8 Nylon nut weather trip 2 Inside handle 9 3 Spring Removing Remove three door glass bottom channel attaching bolts glass by lifting it straight Remove door up 4 Door lock knob 11 Locking plate ring LOcking plate Door lock cylinder 5 12 Door lock 6 Knob grommet Outside handle 13 Stopper 7 Outside handle rod 10 BF 14 BF410A Fig BF 33 Door lock mechonillm Frame Body REMOVAL AND INSTALLATION ADJUSTMENT OutsIde door I Open door 2 Remove inside door handle es cutcheon Adjustment handle is of play pull handle ment of 4 Remove arm rest outside door handle rod regulator Remove 6 Remove door finish 7 Peel off water seal Raise door 8 glass screen below nut and to full up play as is 10 mm up and down 0 039 in between door locking plate lock latch WEATHERSTRIP Inside door handle Remove rear lower sash attach iog bolts Disconnect remote control rod 11 from key cylinder and outside door handle 12 Remove three door lock DESCRIPTION Elongated hole in inside door handle provides for play adjustment of The inside door handle clamp Correct play is 10 or below as provide for fore and aft adjust or to establish proper engagement lock striker and door ment measured between nylon Remove inside door lock knob 10 three Elongated holes posi tion 9 nylon Correct or lock striker should be made after door hinge has been adjusted correctly controlled by play adjust nut on threaded end of Remove handle Adjustment of door in outside door 3 5 DOOR LOCK STRIKER handle mm 0 039 ill weatherstrip is by clips retained 19 to the door sash and by panel No adhesive is used the weatherstrip to door to the door to retain measured at control rod assem A bly attaching 13 screws L A Remove two inside door handle attaching 14 screws take inside with Together handle door out assembly through large door lock access as an hole in door panel 15 Remove handle handle 16 two attaching can nuts 17 door Outside door Section A A Section B B j then be taken out Remove lock cylinder outside and detach plate from key key cylinder I To install door lock assembly 1 outside and inside door handles and key cylinder reverse removal pro cedure rB 18 Lubricate door lock with grease which meets the requirements of MIL G I0924B or equivalent as I B BF645 listed Fig BF 34 Door weatheratrip below ALVANIA GREASE RA BEACON 325 SHELL ESSO MOBILE GREASE 22 MOBIL REMOVAL AND INSTAUATION I Open 2 Free 3 door Pry off clips remove weatherstrip from door sash 4 BF 15 door panel weatherstrip To instaH cedure clamp from reverse removal pro Frame Body WINDSHIELD GLASS WINDSHIELD GLASS DESCRIPTION The windshield glass is retained in body glass opening through the There weatherstrip drain holes one on are twelve the water each side of the bottom of the glass opening and ten along the length of the weatherstrip Working from inside vehicle push windshield glass out of body opening by hand starting at right and left toward upper COIners and working out ends 6 After removing weatherstrip from 5 top and sides of body opening lift glass up sufficiently to permit removal of weatherstrip from bottom flange pry weatherstrip out of position This operation requires two men With aid of 3 being sure weatherstrip lip aligns ith body opening flange 4 Slowly pull cord ends from inside to overlap weatherstrip channel on body opening flange starting at center top and working out toward ends This operation should be done while one man pushes glass against body opening from outside technique should be installing glass opening and windshield glass on left and bottom ap wea th body weatherstrips channels Clean weatherstrip I plied right erstrips to the following checks press wind from outside INSPECTION Prior to helper assembly against body opening shield The same make a re those found with cracks or placing of deterioration signs Clean body openings noting if 2 1 Weatherstrip BF473A 2 Windshield glass 3 Water drain hole these are distorted or corroded INSTALLATION Fig BF 35 Windshield glass and weatherstrip L Fit sure tioned REMOVAL Place 1 protective strument sun 3 so inside rearview mouldings if Using a putty knife or similar pry lips of weather flat bladed tool out flanges Adhesive need not be applied mirror visor equipped strip top covers over en Remove windshield 4 Fig BF 39 Fitting weatherstrip panel Remove and weatherstrip on glass making properly seated and posi is front fender seat and in gine hood 2 it of place from opening top and side 0 Fig BF 40 Fitting weatherstrip bottom Fig BF 37 Fitting weatherstrip on glass of body weatherstrip is to be reused it is important that it not be damaged during this operation BF650 BF641 If 2 Insert around a draw cord weatherstrip completely outer channel Install 5 moldings on weatherstrip if so equipped 6 Install inside rearview mirror and sun i windshield visor I dYii Q 1 BACK WINDOW GLASS AND SIDE WINDOW GLASS Windshield glass 2 cord Draw 3 Weatherstrip 8F648 BF041 Fig BF 38 In8erting draw cord around Fig BF 36 Removing weatherstrip weatherstrip BF 16 outer channel Refer to relative topics under Re and Installa Inspection moval tion of windshield glass Body Frame INSTRUMENT PANEL wiring harnesses 1 5 Disconnect at connectors relative wiring har from instrument panel at nesses con nectors 6 Remove column steering shell Removal of steering wheel at this stage facilitates further removal of instru ment 7 panel Remove knobs two side ventilator Remove package tray attaching bolt and detach package tray 2 Bracket welded to dash panel BF646A 2 Nut 3 Instrument panel assembly Fig BF 41 Instrument panel assembly I Package tray 2 Side ventilator knob Fig BF 42 Package tray 8 INSTRUMENT PANEL REMOVAL AND INSTALLATION bly 2 Disconnect heater control cables from heater assembly 3 Disconnect the back Disconnect battery cables 4 speedometer cable of speedometer on Disconnect antenna and speaker 8F 17 Support instrument panel assem remove five attaching bolts and from it 9 Withdraw instrument sembly while lifting 10 To removal install it panel slightly reverse as the order of Frame Body INTERIOR TRIM AND CENTER CONSOLE HEADLINING DESCRIPTION The headlining assembly is of a suspension type which is held in place by listing wires The design is quite similar to that used in a passenger car 2 Install listing wires in place on roof rail 3 attach front First headlining to flanged portion of roof rail Secondly attach the rear edges of headlining in place while pulling the headlining material to avoid wrinkles the 4 Attach the right and left edges of headlining tions ct 5 material to the using Cut care excess cept for that front center flanged por to avoid wrinkles headlining at material ex the upper areas of not and rear pillars by body side welt The edges headlining material at these areas covered of should be properly cut that it can be folded so place Install garnish on in I 6 2 of headlining at 3 7 Drill a hole in 4 room 5 A 6 lamp the extreme end pillar headlining rear is located Install where room lamp 7 8 BF648A 9 Fig BF 43 Headlining 8 Install body side welts 9 Install windshield glass glass 10 Install back window 11 Install assist rail sun visor and inside rearview mirror BACK TRIM AND BACK INSIDE FINISHER DELUXE CAB REMOVAL 1 ror Remove two inside rearview mir attaching screws and detach 2 CD Remove three screws 3 and detach sun sun J I visor attaching visor and detach assist rail Remove 5 Open doors and remove body side room lamp welts on each side Remove windshield glass 1 Headlining cloth 4 2 Clip 5 3 Garnish Remove back window and weath erstrip 8 of Remove garnish securing headlining to rear pillar Door glass Back window glass Fig BF 44 Removing gami8h 9 Detach headlining the end Back trim BF661 I Move floor carpet aside Remove four bolts attaching back 2 trim to floor and weatherstrip 7 INSTALLATION I CID II 4 REMOVAL AND I Remove two assist rail attaching screws 6 rhir rear view mirror all cemented from edges of flanged portion of Disengage listing wires from headlining roof rail and detach INSTALLATION I Apply adhesive outer surface of attaching Remove five trim clips and detach back trim roof rail 10 3 cement flange surface evenly 8F 18 and to the headlining 4 Installation is the reverse order of removal Back Inside finisher I Remove seat belt retractor 2 Remove five trim clips and detach back inside fmisher 3 Installation is the removal reverse order of Body Frame Air conditioner equipped models Remove two bolts from front of I center console 2 Remove two bolts from the rear 2 and 1 Back trim 2 Back inside imisher 3 Clip remove center console CONSOLE WITH ARMREST 1 DELUXE CAB REMOVAL AND INSTALLATION BF0328 Fig BF 45 Back trim and back inside finisher I Remove two bolts from front of console armrest unit 2 Remove box and 3 one remove bolt in the console center console Installation is the reverse order of removal CENTER CONSOLE REMOVAL AND INSTALLATION Except for air conditioner equipped models Remove two bolts from I rear of center console 2 Remove center console by pulling it back To 3 sole bracket tighten install properly insert the floor on rear front its center con portion into BE033B and install and attaching bolts Fig BF 46 Removing center console BF034B Fig BF 47 Console with annrest SEAT SEAT BENCH SEAT DESCRIPTION There are two types of seats a semi separate bench seat for the standard wheelbase and long wheelbase models and a separate seat for the Deluxe Cab JJ models t CAUTION In qJ conforming 302 be sure polyethylene cushions seat with M Y s S No to remove the thin covers backs from seat and head 1 restraints at the time of a delivery Pre b Parts service 2 Seat assembly Seat slide 3 Seat slide lock handle 4 Seat slide lock wire BF474A replacement Fig BF 48 Bench 8F 19 seal Body Frame Removal and installation DESCRIPTION assembly 1 Remove four bolts slide assembly to retaining seat floor take out seat 2 To moval install seat reverse above re procedure s Head re5traint 2 Seat assembly 3 Reclining device 4 Seat slide outer 5 eat slide inner belt is three point type a lap shoulder consisting essentiaily belt and an inner lap belt The lap shoulder belt is fitted with an emergency locking retractor which senses the speed at which the webbing is being pulled and the deceleration of seat a of SEPARATE SEAT 1 The the vehicle The inner lap belt has buckle of the driver a s a buckle The seat belt includes switch which functions as a seat belt warning device J CAlJI10NS a In with M V S S conformity 302 be sure polyethylene to remove No the thin from seat belts covers at the time of j I delivery Pre 2 Parts service replacement b If the vehicle has overturned been BF0358 entire Fig BF 49 Separate seat c Remove two nuts attaching front Remove two bolts attaching of seat slide to floor Then remove seat with seat slides from the vehicle of seat slide to floor 2 3 rear 4 Installation is the reverse order of removal belt collision replace regardless assembly or the of If the condition of any component of a seat belt is questionable have entire belt assembly replaced rather than attempting to repair seat belt d If webbing is cut frayed or dam aged replace belt assembly e Do not inner SEAT BELT a nature of accident Removal and installation I in f spill lap drinks belt oil buckle etc on Never oil tongue and buckle Use only a genuine Nissan assembly seat belt REMOVAL AND INSTAUATION I Disconnect battery ground cable 2 Disconnect buckle switch harness at connector under seat Loosen bolt 3 retaining inner lap lap belt belt and remove inner 4 Remove bolt securing emergency locking retractor 5 Remove and remove shoulder anchor lap shoulder belt bolt assem bly Installation is the 1 Inner belt 6 2 Tongue stopper Emergency locking retractor Outer anchor plate belt shoulder Lap Shoulder through anchor removal 3 4 5 6 reverse Tightening torque Anchor bolts BF036B Fig BF 50 Seat belt BF 20 2 5 to 3 0 kg m 18 to 22 ft lb order of Body When installing locking retractor make is set vertically Note Frame INSPECTION OF BUCKLE SWITCH emergency sure that it @ The are g@ I contacts normally latches the of the buckle switch closed buckle tongue pushes the When tongue tip end of the push rod to open the switch contacts I Disconnect battery ground cable 2 Disconnect buckle switch wire harness 3 Using a test switch for proper light check buckle operation The light should go out when tongue of outer lap belt latches buckle when it unlatches buckle and go Replace on belt assembly if necessary When checking buckle switch operation make sure that power is Note held below 16 volts and 13 mA BF650A Fig BF 51 Seat belt anchorages 8F 21 SECTION BE BODY DATSUN PICK UP ELECTRICAL MODEL 620 SERIES SYSTEM I NISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN BODY ELECTRICAL WIRING BE 2 LIGHTING AND SIGNAL LAMP SYSTEM BE 3 METERS AND GAUGES BE 14 ELECTRICAL ACCESSORIES BE 21 EMISSION WARNING SYSTEM California models BE 43 Body Electrical System BODY ELECTRICAL WIRING DESCRIPTION Cables are covered with color coded vinyl for easy identification In the wiring diagram colors are indicated by one letters alphabetical two or before disconnected or fuse replacement In addition to fuses has been installed battery performing other than bulb any electrical service fusible link a protect wiring The fusible link functions almost the as same such parts to though its eharac slightly different than MAINTENANCE INSTRUCTIONS Fuse exhaust as The fuse block is installed under the instrument 8 Wiring is kept away from any rotating or working parts fan pulley fan belt panel the left hand on drive vehicle etc 9 Cables and moving parts between ftxed portions long enough to vibratory forces are withstand shocks and fuse a teristics temperature pipe It is recommended that the be 6 Each grounding bolt is firmly pbnted 7 Wiring is kept away from any adjacent parts with sharp edges or high are normal fuses Notes Before a starting to inspect and repair any part of electrical system or other parts which may lead to a CABLE COLORS short circuit disconnect cables at battery terminals Cable colors two are indicated by one or Disconnect alphabetical letters B Black Be terminal Brown G Green at positive R Red W White terminal be The main cable is generally coded with a single color coded with The others two tone a cables to battery connecting to clean terminals sure Fasten cable at rag positive terminal and then ground cable are color at as terminal Apply top of these terminals to When prevent Black with white stripe gR Light green with red stripe b from rust Never use a developing screwdriver tool to conduct c Inspect all electrical circuits refer ring to wiring or circuit diagrams use or another systematic problem before installing new a a nate cause of stalling fuse senrice or continuity test b an circuits under no 12V 3W or open circuit load Use a circuit tester new Use fuse of use Never ground lamp If fuse is blown be fuse sure to elimi before in problem specified rating Never of more than or specified rating test Co as a load Check condition of fuse holders If much rust or dirt is found thereon Circuits should be nuity or sandpaper tional test or low reading volt inspection of circuit lamp 2 often or terminal firmly in place shows any and free from rust and dirt 3 No evidence other 4 away 5 cable covering of cracks deterioration from Each any cable proper connector safe distance adjacent metal parts is or fastened terminal to voltage drop or and could result in improper circuit operation FUSE AND FUSIBLE LINK DESCRIPTION The fuse and fusible link at a to in the circuit or damage Each terminal is lead heating Each electrical component part or securely fastened to its con Each connection is grained metal to Poor contact in any fuse holder will cable is nector until proper metal contact is made that ensure I tested for conti short circuit with a conven Before of fuse clean metal parts with fine meter pro cause Notes on Use test leads INSPECTION reason one cedure to check and eliminate them BW for fuse has melted negative grease to follows Fuse block terminal Before a Fig BE 1 cable at negative Lg Light green with BE848A follows and then disconnect cable L Blue Y Yellow as its are protec Fusible link tive devices used in an electrical cir cuit When current increases beyond rated amperage fusible metal melts and the circuit is broken BE 2 Fusible starting cuits link charging protects and lighting accessory cir Electrical Body A melted fusible link be de can tected either by visual inspection or by feeling with finger tip If its condition Notes a If fusible link should supply or test circuit is shorted questionable use circuit tester or lamp as required to conduct continuity test This continuity test as be performed in the same carefully large current it c is power carrying In such a case check and eliminate cause of problem manner for any conventional fuse melt possible that critical circuit is can System b Never wrap periphery of fusible link with vinyl tape Extreme care should be taken with this link to ensure that it does not contact with any other ness or vinyl or come into BEB49A wiring har Fig BE 2 Fusible link rubber parts 1 LIGHTING AND SIGNAL LAMP SYSTEM CONTENTS DESCRIPTION LIGHTING BE SYSTEM CIRCUIT DIAGRAM BE INSPECTION 4 9 BE 10 LAMP BE 4 BE 5 BULB BE 5 LAMP BODY BE 5 8E 7 REMOVAL AND BE 7 INSPECTION BE 7 8E 7 REMOVAL AND BUL8 REPLACEMENT BE 7 INSPECTION REMOVAL AND INSTALLATION 8E 7 BE 8 BE B 8E 8 BE 8 REMOVAL AND INSTALLATION BE 11 8E 8 INSPECTION BE 11 8E 8 8E 8 BE 8 8E 8 TROUBLE BE 9 CORRECTIONS BE 9 HEAD LAMP REMOVAL AND INSTALLATION BE 9 TURN SIGNAL INSPECTION 8E 9 TAIL LAMP 8E 9 BACK UP LAMP 8E 9 HEADLAMP HEAD LAMP BEAM REPLACEMENT AIMING ADJUSTMENT FRONT COMBINATION BUL8 LAMP REPLACEMENT REMOVAL AND INSTALLATION SIDE MARKER ROOM BULB LAMP LAMP REPLACEMENT REMOVAL AND INSTALLATION REAR COMBINATION BULB LAMP REPLACEMENT REMOVAL AND INSTALLATION LICENSE LAMP BULB REPLACEMENT REMOVAL AND INSTALLATION ENGINE COMPARTMENT LIGHTING LAMP SWITCH ILLUMINATION REMOVAL CONTROL RHEOSTAT AND INSTALLATION KN08 ILLUMINATION TURN STOP DOOR BE 10 REPLACEMENT SIGNAL BE10 REPLACEMENT AND DIMMER SWITCH INSTALLATION BE 10 INSTALLATION BE 10 INSTALLATION BE 10 BE 11 INSPECTION BE 11 HAZARD SWITCH 8E 11 UNIT BE 11 REPLACEMENT BE 3 BE 10 BE 10 SWITCH REMOVAL AND 8ULB BE 10 BE 10 LAMP SWITCH FLASHER BE 10 SPECIFICATIONS BE 12 DIAGNOSES AND BE 12 BE 12 LAMP STOP BE 13 LAMP AND 8E 13 Body Electrical System DESCRIPTION LIGHTING SYSTEM CI RCUIT DIAGRAM Headlamp tail lamp and license lamp system FRONT SlOE lIIIARI ER LAMP IR H G REAR R 1 jSTOPBrURH STOP 8 TAIL I R H l HEAOLAMP LIGHTING SWITCH r H LllHTINIi 1121 I 1 BSAOC UP REAR COMBINATION LAMP R H x nn A TURN TAIL f ll lJ o CR SIDE MARKER LAMP j DIMMER SWITCH iNAnON 101 LAMP USl LE LINK LIU CIl CJ I LICE NSf J LAMP t ON 0 I I3 154 CJ BACIC TA CJ FUSE HEADl AMP 1 lOA CJ @ I r 8A UP L ST OP8TURN TAIL BLOCK STOP8TURN LH EA LAMP e H IL i LAMP I n 2 IR I REAR COMBINATION LAMP ILH METE ILLUMINATION fMP Q REAR SIDE NAR tAMP l BEBSOA Fig BE 3 Headlamp tail lamp and liceme lamp ay6t Turn signal hazard warning stop lamp and back lamp m lamp system up REAR COMBINATION LAMP R H BACK UP LAMP SWITCH BATTERY n TA I L 8ACK @ 4j FRONT COM8IfUl1ON LAMP H @ FUSIBLE LINK Jl P W E HAZARO FLASHER UNIT ON I a h FRONT COMBINATION LAMP L H FUSE HAIARD WA NING SWITCH 2 3 BLOCK G FUSE BACK FROM IGNITION SWITCH t UP J H LH EL U STOP 8 TURN N t JTA STOP8TURN TAIL CJ I TURN SIGNAL INDICATOR LAMP TU N SIGNAL FLASHER UNIT r UP I REAR COMelNATlON LAMP IL H I iH ij STOP TURN SIGNAL SWITCH BE851A Fig BE 4 Turn signal Juuard warning lamp stop lamp and back up lamp system 4 BE Body Electrical System Room lamp and engine compartment lamp system FUSE BLOC K 1 J QA C 6 I I I 2 I t1 CJ CJ Wf fi t ROOM 1 ROOM LAMP I I 0 1 SWITCt f HOOD LAMP C o lA II BATTERY ENGINE I J CJ C FUSIBLE LINK t 100 FUSE I DOOR I I SWITCH LH l I c SWITCHIR H l DOOR BE852A Fig BE 5 Room lamp and engine compartment lamp system connector from behind beam HEADLAMP Note Rubber back of is cover headlamp installed at beam The con nector is located in the cover 5 Change headlamp nect wiring 6 Place so that beam headlamp fit and 8 and in with three hollows on that on sign upper side headlamp retaining ring tighten retaining screws Place radIator grille in position tighten retaining screws lJ BE300 HEADLAMP BEAM REPLACEMENT Note Do not disturb aiming adjust screws Remove and sure Install Fig BE 6 Head amp screws behind AIMING ADJUSTMENT if I con beam in position three location tabs mounting ring Make Top of beam lens i 7 beam and connector to new beam radiator grille retaining grille headlamp retaining It may be unnecessary to 4 2 Loosen three ring screws remove screws radiator I 4 3 remove ii i Remove retaining ring by rotating it clockwise Remove headlamp beam from mounting ring and disconnect wiring 8E 5 l 1 J i Horiz tooi 4 Y nnn tal adjustment BE30l Fig BE 7 Aiming adjustment Electrical Body To screw to adjust vertical adjust screw on aim use adjusting upper side of headlamp on horizontal aim use Keep a and adjusting on the same no load in vehicle I Gasoline radiator and engine oil aimer an use screen or instructions operating refer aiming device headlamp tester of any respective operation to manuals supplied with the unit pan filled up to correct levels in foUowing performing headlamp aiming aiming wall For See that there is Before making headlarnp aiming ad the tester flat surface Notes When adjustment b Place vehicle and c observe tires inflated to correct pressures side of head lamp justment aU System 2 structions DRIVING BEAM HIGH Without passenger BEAM G L wt hi i iiI H 10 LOW PASSING BEAM 32 8 ft m 02 8 n BEAM 10 W2 m d 20 I h2 H2 02 10 m I I 32 8 ft f Driving All models I beam HI WI mm mm in in 715 780 28 15 30 71 High beam 01 CO 48 Passing hI H2 W2 mm mm mm in in 140 51 5 I 715 28 15 11 beam Low beam O2 h2 d 0 mm mm in in in 160 392 45 67 12018 is 349 43 13 74 BE302 Fig BE 6 BE 8 Aiming adjustment Body Electrical System FRONT COMBINATION LAMP BULB REPLACEMENT Remove two 1 retaining screws and lens 2 Push in bulb on turn it counter clockwise and remove it from socket 3 Insert bulb into socket press new it inward and rotate it clockwise Make sure that bulb is locked in its socket Place packing to lamp body in position and install lamp body with 4 lens packing and retaining two screws REMOVAL AND INSTALLATION To remove wiring disconnect lamp body at connector and remove wire grommet from panel Remove two retaining screws and lens and withdraw lamp body from vehicle Install new lamp assembly in the reverse 1 Screw 2 Lens 3 Bulb 4 Lamp body BE698B Fig BE 9 Front combinntion lamp sequence of removal SIDE MARKER LAMP BULB REPLACEMENT 1 two Remove retaining screws lens and rim Push in 2 on clockwise and 3 Insert bulb remove turn it counter it from socket bulb into socket press new it inward and rotate it clockwise Make sure that bulb is locked in its socket Place packing to lamp body in position and install lamp body with 4 and lens packing retaining two screws REMOVAL AND 2 INSTALLATION To two remove remove from lamp body wires lead at wire grommet disconnect connectors if so and equipped panel Remove two retaining and rim and withdraw screws lamp body lens from vehicle 2 Packing Lamp body 3 Rim 4 Bulb 5 Lens 6 Screw 5 BE699B Install reverse 1 new lamp assembly in the Fig BE IO Side marker lamp sequence of removal BE 7 Body Electrical System REMOVAL ROOM LAMP AND INSTALLATION BULB REPLACEMENT I wiring assembly Disconnect at cormector 2 Remove two nuts from combina tion lamp mounting 3 Dismount studs combination lamp as from vehicle sembly 4 Replace lamp assembly with a new one J Install 5 reverse new lamp assembly in the sequence of removal CD 1 Lens 2 Bulb 3 Lamp body 4 Screw O lux Cab 8E700B Fig HE ll Room lamp LICENSE LAMP BULB Remove lens from lamp housing Pull bulb forward and 2 remove it housing two wires at connectors Install from socket bulb into socket 3 Push 4 Install lens new REPLACEMENT from roof rail and disconnect reverse new in the lamp assembly sequence ofremoval REMOVAL AND INSTALLATION remove lamp assembly discon battery ground cable remove two retaining screws with lens removed from lamp housing dismount lamp To nect REAR COMBINATION LAMP BULB J i REPLACEMENT 1 Screw 2 Bracket 3 Lens 4 Bulb BE702B Fig HE 13 License Iomp 1 Remove lens retaining equipped 2 1 Screw 2 Lens 3 Bulb remove Pull out bulb and screw if so lens replace it with a new one 3 4 Rim 5 Lamp body @ and BE70tB Fig BE 12 Rear combination lamp Install lens REMOVAL AND I NSTALlATI ON 1 Disconnect lead wire at con nector 1 Remove six lens retaining screws it and lens 2 Push in on counterclockwise socket 3 bulb to and remove turn it it from Insert new bulb into socket inward Make sure and rotate it press clockwise that bulb is locked in its lamp bracket retaining lamp assembly Install new lamp assembly in the Remove screws 3 reverse socket 4 2 Place lens into position and install retaining screws 8E 8 and sequence of removal Body Electrical System ENGINE Removal and Installation INSPECTION Test COMPARTMENT Remove lighting switch from vehi LAMP continuity through using test lamp switch by cle following the procedures given in I TERMINAL 2 6 terminal 2 Bracket 3 Bulb SWITCH P I I 4 I 3 I 6 I T10N 2 F ICI I Screw ohm meter I 1 lighting or b I BE 7038 Fill BE 14 Engine compartment lamp Bulb can be replaced by pushing in bulb and turning it counterclock on 3 terminal wise 4 terminal replace engine compartment lamp assembly remove one SCrew retaining lamp bracket to upper dash panel and disconnect wires at connee To 1 terminal Switch position BE855A BE 15 Fig Lighting switch tors Engine compartment lamp switch be replaced by disconnecting lead ILLUMINATION tion CONTROL RHEOSTAT heater can wire at connector and assembly switch pulling out of its bracket To install This illumination control rheostat controls the brightness of the iliumina switch assembly to bracket clean dirt dust and rust from the opening groove of bracket and press down on switch lamps of the combination meter control wiper switch knob it and its can value is a and lighting variable resistor be controlled by a knob head until it fits in with bracket 0@ LIGHTING SWITCH REMOVAL AND BE 7048 INSTALLATION I Disconnect 2 Press in Fig battery ground switch knob counterclockwise and pull it out of REMOVAL AND INSPECTION INSTALLATION Test switch 3 Unscrew escutcheon and escutcheon and spacer remove I 2 Remove ring nut retaining switch meter to instrument multiple at connector from instrument harness wiring assembly and spacer and lighting switch 5 Install new remove switch in the reverse sequence of removal 3 4 panel Disconnect lead wires for switch Switch a When test lamp or two lead an ohm switch is in the OFF position continuity must not exist In the ON position resistance between the two lead wires must be between 0 body can be taken out from behind instrument panel 5 continuity between Pull out knob of switch wires with Reach up from underneath instru ment panel disconnect lighting switch 4 connector rhe08tat cable turn it BE 16 Illumination control Installation is in the quence of removal BE 9 reverse se and 3512 Body Electrical System KNOB ILLUMINATION LAMP The illumination lamp is located on 2 clip Unhook 7 Tighten that 8 Install shell 9 Connect wiring assembly from retains wiring assembly to panel lower instrument multiple Disconnect 3 and lead wire from instrument harness This lamp illuminates the knob of the wiper switch and lighting switch wiring with fiberscopes screws multiple connector and 10 Clip wiring assembly instrument panel II Upper and Remove shell covers 4 attaching covers lead wire to instrument harness connector the illumination control rheostat two wiring lower at Install steering wheel Lower The fiberscopes between the knobs and cap of the illumination lamp carry the light through their tubes with the inner reflective walJ 5 Loosen two switch assembly screws attaching steering column jacket and remove switch assembly 6 Position switch assembly to steer ing column jacket Make sure that a location tab to or screw INSPECTION ohm or meter hole of steering column jacket 3 lighting continuity through using test lamp Test switch by fits in with terminal 4 terminal 7 terminal Dimmer CID 1 Bulb socket 2 Screw 3 Lamp body 8E705B Fig BE 17 Knob illumination lamp BULB REPLACEMENT Ll Reach up from under the instru ment panel and pull out socket with I bulb from 12 I 2 j lamp body Pick up bulb and install a I new one 3 Installation is in the reverse 4JN l ER R se quence of removal r vt I RI PlOSITlON L n LASH STOP I I 91 9 I I JFRe II L I I III I 61616 11 161 II I BE706B LAMP Remove 1 Fig BE IS Turn signal and dimmer switch BODY REPLACEMENT illumination rheostat Refer to control section of illumina 2 illumination lamp Remove 3 body can 4 lead Disconnect wires for at connector leased REMOVAL open On the contrary contacts closed with plunger projected AND retaining lamp panel Lamp body then be taken out easily Installation is in the reverse se quence of removal Stop lamp switch bottom of pedal is mounted at the Door I Disconnect battery ground cable 2 Disconnect lead wires at REMOVAL AND DIMMER SWITCH 4 Steering both on coonee Loosen lock nut unscrew switch assembly and Install remove switch switch assembly assembly as de scribed under Brake Pedal in Section BR INSTALLATION I Disconnect battery 2 To lower 3 When assembly pull pillar ground switch assembly withdraw cable out switch of and wiring assembly INSPECTION section switch is installed H and R H front door pillars L TURN SIGNAL AND REMOVAL AND INSTALLATION DOOR SWITCH bracket 3 Remove steering wheel related Refer to the are and steering post tors I stop lamp switch INSTALLATION screw to instrument contacts are STOP LAMP SWITCH ti on control rheostat for removal plunger Disconnect lead wire at cannee tor is pressed into switch when brake 8El0 pedal is reo 4 Installation is in the quence of removal reverse se Electrical Body INSPECTION Test continuity switch by using test door through lamp or ohm 2 Remove shell covers 3 Remove assembly door open Contacts plunger is is pressed switch are into switch contacts Upper attaching Install verse There are two flasher units One is for hazard switch in the re signal turn and the other for hazard sequence of removal They are located at both sides of panel near steering column They can be distinguished from each other by their shape The large one is for turn signal the smaller for hazard See Figure BE 20 are instrument when closed FLASHER UNIT screws switch 4 plunger two switch to lower shell cover and remove meter When System projected HAZARD SWITCH INSPECTION Test REMOVAL AND switch INSTALLATION continuity through by using test lamp hazard or ohm meter 1 Disconnect multiple connector and lead wire from instrwnent harness wiring I I I ON 7 terminal TERMINAL SWITCH POSITION ON OFF li 2 I 5 I 4 I 5 I I 8 ill 1 Hazard flasher unit 2 Turn signal flasher unit BE707B Fig BE 20 Flasher unit I 7 REPLACEMENT To flasher unit 1 3 terminal 4 terminal I Disconnect 2 Disconnect connector fitted to bottom of unit terminal 3 5 battery ground cable terminal BE308 6 terminal 4 Fig BE 19 Hazard switch BE 11 Remove screw retaining flasher unit Installation is in the quence of removal reverse se Body Electrical System BULB SPECIFICATIONS Bulb Item Wattage Candlepower 4001 5W 37 Inner Headlamp SAE trade number 4002 5 S0W 37 Outer Front combination lamp Turn signal and parking lamp 1034 23 8W 32 3C Side marker lamp Front 8W Rear 8W 4C lamp signal lamp A Tail lamp B C 67 4C 67 Rear combination B Turn A B Stop lamp Back up lamp D A 23W 32C 1073 B 23j8W 32j3C 1034 C 8W 4C D 23W 32C 7 SW License plate lamp Engine compartment lamp 6W Room lamp 5W Combination meter illurnina iC 17W tion Knob illumination lamp Heater control illumination 89 6C 161 x3 3 4W 2C 158 4W 3 2C 158 lamp TROUBLEDIAGNOSE 67 1073 AND CORRECTIONS HEADLAMP Probable Condition Headlarnps do not light for both high and low beams High beam cannot Corrective action cause Burnt fuse Loose connection or open circuit or vice versa replace fuse Check wiring and or repair connection Faulty lighting switch Conduct continuity test and Faulty dimmer switch sary Faulty light relay Check light relay for proper operation and replace if necessary No ground Clean and Faulty dimmer switch Conduct continuity test and tighten ground replace if neces terminal replace if neces sary be switched to low beam Correct cause and Check light relay for proper operation and replace if necessary Faulty light relay BE12 Body Electrical System Condition Probable Partly discharged Headiamps dim or Corrective action cause faulty battery Measure Faulty charging system specific gravity of electrolyte and replace battery if necessary recharge or Measure voltage If it is less at headlamp terminals than 12 8V check charging system for proper operation Poor Clean and loose connection ground or side in only one lights headlamp Loose tighten Replace Burnt sealed beams Headlamp or connection Repair Damaged sealed beam Replace TURN SIGNAL LAMP Probable Condition Turn not signals Corrective action cause Correct Burnt fuse do operate Loose connection Faulty flasher Faulty turn or Check open circuit wiring and or repair connection Replace unit signal and replace cause Conduct switch continuity test and replace if neces sary Flashing cycle is too slow not go having wattage other wattage lamp Pilot Bulbs out does are than specified Replace with specified one with specified one used Burnt bulbs Replace Loose connection Repair or too fast Inoperative flasher Flashing cycle irregular is Burnt bulb Replace Loose connection Repair Bulb wa TAIL LAMP having wattage other than specified Replace ttage is used STOP LAMP AND BACK UP LAMP Probable Condition Both right and left lamps do not light Replace unit Corrective action cause and Burnt fuse Correct Inoperative stop lamp switch Conduct continuity test and cause replace replace if neces sary Conduct continuity test and replace if neces Falllty back up lamp switch sary Loose connection Lamp lights in only one side or open circuit Check wiring and or Burnt bulb Replace Loose bulb Repair lamp socket BE13 repair connection Body Electrical System METERS AND GAUGES CONTENTS COMBINATION METER COMBINATION METER BE 14 CHARGE CIRCUIT WARNING LAMP DIAGRAM BE 14 REMOVAL AND INSTALLATION BE 16 DESCRIPTION BE 16 HAND SPEEDOMETER REMOVAL AND INSTALLATION ODOMETER SWITCH REMOVAL AND INSTALLATION FUEL GAUGE AND WATER HAND METER AND WARNING 8ULB BE 18 SWITCH ILLUMINATION REMOVAL LAMP BE 18 BRAKE BE 16 8E 16 BE 17 BRAKE WARNING BE 16 TEMPERATURE GAUGE BE 17 DESCRIPTION 8E 18 INDICATOR BULBS 8E 18 AND INSTALLATION BE 18 BE 16 TROUBLE DESCRIPTION BE 16 CORRECTIONS REMOVAL BE 16 SPEEDOMETER 8E 17 WATER TEMPERATURE AND FUEL AND INSTALLATION OIL PRESSURE WARNING LAMP DESCRIPTION 01 L PRESSURE SWITCH BE 18 SPECIFICATIONS DIAGNOSES AND BE 18 BE 17 GAUGES BE 17 OIL PRESSURE BE 18 BE 19 AND CHARGE WARNING LAMPS BE 20 COMBINATION METER Meter illumination lamps COMBINATION METER Turn CIRCUIT DIAGRAM signal indicator lamp L H 9 9 R H iJ O l I rl8 i g o J OIL sq nal indicator lamp J lL Tj I M T only Turn Voltage regulator CHG TEMP 0 0 BEAM BRK FUEL C Q Speed switch BE856A @ I Speedometer 2 Thermometer 3 Fuel 4 Tachometer 5 Cluster lid 6 Speedometer cable Speed switch amplifier Manual transmission only 7 meter Option BE6828 Fig BE 21 BE 14 Cuit Ci1 diagram of combination meter Body Electrical System Circuit diagram of combination meter system IGNITION SWITCH BATTERY 1 lOA 0 FUSIBLE LINK r G 0 r g KG I I lOA r 15A t 15A i Jon HAZARD FLASHER 0 j UNIT J L Z a l J J I IIl ll Z ll Z LlJ LlJ J a J a Z2 lIa I LlJ IZ J Z az Z J z i g o I a ll I I 1 1 5a 7 LlJ I B z aa I 00 a a LlJLlJ ll ll a a u I I 2 I I 3 I J D 14 LIGHT 61 6 I 5 16 RELAY i2i I 9 76 mm S e ONI I 02 u3 OFF l I o FUEL TANK HAZAR D SWITCH I 04LlJ l1 S M ii I a Zza FROM AMP J I FLASHER UNIT l1 l1 CJ J J 00 TURN SIGNAL SWITCH LlJLlJ z z B COO CUT SOLENOID I lFLA n i OIL PRESSURE SWITCH IR R IR L IF IF R f THERMAL TRANSMITTER a I VOLTAGE REGULATOR HAND FROM BRAKE RELAY SWITCH J LIGHT RELAY TERMINAL TO L L RI I I I u u I I L1GHT DIMMER SWITCH IOFF 21 l B I I I X X LIGHT SWITCH BEB57 A Fig BE 15 BE 22 Circuit diagram of combination meter ayatt m Body Electrical System REMOVAL AND 2 INSTALLATION shadow cover and plate by removing clips and Remove meter front screws I Disconnect battery ground cable Working through meter openings 2 of cluster cluster retaining panel 3 lid remove From lid three screws instrument to underneath 3 The water temperature gauge con a gauge and thermal transmit sists of ter Remove located in the engine block thermal transmitter is equipped printed circuit housing and remove speedometer 4 Install speedometer in the reverse thermistor which sequence of removal tr screws retaining speed ometer to cooling a element water and ture gauge are arm follow etc the the procedures given in each section 5 From behind combination meter ODOMETER SWITCH disconnect REMOVAL AND cable speedometer at speedometer head and multiple con nector instrume nt wire assembly from printed circuit 6 On vehicle with clock disconnect wires at printed 7 connection on meter circuit assembly Remov screws retaining to cluster lid combination meter ter When is INSTALLATION I Remove under 2 speedometer installing assembly follow the reverse a bi metal bent and thus the bi metal the pointer gauges are the same A tolerance may odometer retaining temperature gauge source voltage fluctuation The voltage regulator is used to supply a constant screws Install and the heat coil is this heat outlined as Speedometer Remove coil With odometer in the reverse voltage sequence of removal so the water occur on or fuel gauge due to that the water temperature gauge and fuel gauge operate The operating part of the as consists of combination provided with connected to the bi metal arm is oper ated The characteristics of both sembly 9 heat heated arm 3 four Remove me ter 8 each to and heater coil When the ignition switch is set to ON current flows to Withdraw cluster lid slightly For to switches knobs thermal The fuel gauge and water tempera ment ccess the the gauge instrument panel remove one screw retaining me ter assembly to lower panel of instru 4 thus rtrols cUfTent flowing c t converts variation to temperature resistance The with a coil me turned on se quence of removal a When and bent contact is coil cools correctly regulator bi metal arm and a heater the ignition switch is the bi metal arm is heated by the coil Consequently interrupted opening the current to the As the bi metal the contact closes The repeti tion of this operation produces a pulsating voltage of 8 volts which is applied to the water temperature and BE342A Fig BE 24 Odometerswitch fuel gauges If both to Fig BE 23 Removing the water temperature gauge and fuel gauge become faulty at the same time this may be attributed problem in the voltage regulator eluster lid FUEL GAUGE AND WATER REMOVAL AND INSTALLATION TEMPERATURE GAUGE 1 Remove combination meter as sembly Follow the procedures under Removal and Installation in Combina DESCRI PTION SPEEDOMETER tion Meter The fuel gauge consists of REMOVAL AND Remove combination meter as Follow the procedures under Removal and Installation in Combina sembly tion Meter tank 2 Remove meter front cover unit located in the fuel tank and fuel shadow The tank unit detects fuel level with its float converts fuel level varia screws tion to back side of combination meter gauge INSTALLATION 1 a installed a resistance of slide resistor on the float base controls current flowing and thus to the fuel 3 Remove sembly and 4 retaining remove BE16 nuts at the as meter Install meter in the quence of removal gauge and plate by removing clips and reverse se Body Electrical System Fuse M OIL PRESSURE SWITCH Meter voltage regulator To YR lffi YW l B f Ignition r@ switch 1 Water temperature gauge oil pressure switch dis replace connect lead wire from switch termi nal and unscrew switch from engine cylinder block Prior to block Fuel gauge Y installing be to sure switch to cylinder conductive apply sealer to threads of new switch Fusible I link YW t L Thermal transmitter Fuel tank BE261 Fig BE 25 Circuit diagram offuel gauge and kg cm2 psi CHARGE WARNING LAMP is and oil reaches the DESCRIPTION above pressure the circuit opens and the light range charge warning lamp glows ignition switch is set to ON with the engine shut down or when the generator falls to charge with The when goes out BOX YR SA IGJ 4 to 0 6 0 Under normal opera stationary the ligh glows with the ignition switch turned on When the e gine is running whenever engine oil FUSE 5 8 when the engine tion The engine lubricating system in corporates an oil pressure warning glows 7to 5 DESCRIPTION which temperature gauge pressure falls below OIL PRESSURE WARNING LAMP lamp water the engine TO METER VOLTAGE REGULATOR I G TO OTHER lAMPS G ON the charge warning and closed the flows from current Fig YB YB rent opposes th current is into cur flowing from the warning lamp as the current N increases the solenoid is more FROM tl PRESSURE N comes the generator output operation BATTERY When the engine BE 27 1 started and the generator FUSIBLE LINK O J BROWN Fig is set to circuit is ignition switch to the warning lamp and grounds through the regulator Oil PRESSURE BE 26 ignition switch WARNING WARNING LAhlP I operated When the jt IGNITION SWITCH the energized PRESSURE and the pilot lamp relay contacts are open in effect it oreaks the warning circuit ground connection BE263 and the lamp goes out Circuit of oil prelSure warning system Fig BE 27 2 Fuse box Fuse box M Fusible link From From battery battery swllch ru A To ignition T tI I J v coil ge it WR IQlamps r Charge warning lamp j f lamp relay War I e g bt Generator Fig BE 27 1 YR other ft t r L warning hr witch i J To other A i Generator YR nu J T I M Ignition To battery Ig ition To battery Fusible link Glj I fCOil UTO warrung ignition WR Warning lamp relay lamps Charge warning lamp BE264 Voltage regulator Fig BE 27 2 Circuit ofcharge warning system BE17 Body Electrical System HAND BRAKE SWITCH HAND BRAKE WARNING LAMP To remove METER hand brake switch dis ILLUMINATION INDICATOR AND WARNING BULBS lead wire pull switch out of hand brake control bracket and with connect DESCRIPTION The hand brake draw switch and wiring assembly warning lamp glows when the hand brake is REMOVAL AND applied When the ignition switch is set ON current flows from the INSTALLATION to ignition To switch to the warning hand lamp When the applied hand brake is brake replace bulb turn bulb socket counterclockwise to dismount it from combination meter warning switch is closed and warning lamp glows connect lead wire printed circuit and if necessary dis connector from remove bulb from socket Fuse Ignition M 5 BULB SPECIFICATIONS I tch SAE Trade Item Bulb No Wattage Candle power W Fusible link Meter illumination YG 1 From battery 1 Hand brake sWitch BE314 Fig BE 28 Circuit of hand broke indicator 161 7I 1 161 7 1 I 17 I I signal High beam indicator lamp 161 Oil pressure warning lamp 161 I 7 Charge warning lamp 161 7 1 I Hand brake warning 158 34 2 158 4 3 2 Clock illumination lamp lamp lamp E DIAGNOSES AND CORRECTIONS SPEEDOMETER Condition Probable Speedometer pointer Loose speedometer cable union nut and odometer do not Coirective action cause Retighten Broken speedometer cable Replace operate Damaged speedometer drive pinion gear Replace Transmission side Inoperative speedometer Unstable speedometer Improperly tightened pointer cable union nut Unusual sound occurs in response to in crease in driving speed or Replace loose speedometer Retighten Faulty speedometer cable Replace Inoperative speedometer Replace ExceSjvelybent or cable inner wire lack of lubrication or x3 Turn warning Iystem TROUB lamp e twisted speedOmeter Inoperative speedometer Replace Replace 8El8 or lubricate Electrical Body Probable Condition Inaccurate speedometer System Corrective action cause Replace Inoperative speedometer indication Inaccurate odometer Improperly operation worn gears meshed second and third gear Replace speedometer to deformed odometer Replace speedometer Faulty feeding due and pinion carrier WATER TEMPERATURE AND FUEL GAUGES Probable Condition Both water temperature gauge and fuel gauge Corrective action cause Correct cause and Burnt fuse Inoperative gauge voltage regulator replace fuse Replace water temperature gauge Replace water temperature gauge do not operate Both water temperature gauge and fuel gauge Inoperative gauge voltage regulator pointer fluctuates excessively indicate Loose of poor inaccurately Gauge Gauge pointer connection Correct connector contact fluctuates slightly Correct conn Water temperature gauge Water temperature Faulty thermal transmitter gauge does not connection operate When wire is Faulty loose terminal thermal Replace transmitter or correct terminal connection thermal grounded water or yellow transmitter white gauge pointer fluctuates temperature gauge Replace wtater temperature gauge Open circuit Gauge indicates only maximum temperature Water temperature gauge does not Faulty thermal transmitter Gauge pointer returns to original position when ignition switch is turned off Replace thermal transmitter Faulty water temperature gauge Gauge pointer indicates maximum tempera ture even after ignition switch is turned off Replace Faulty water temperature gauge Faulty thermal transmitter water usn resistance between ther wire and transmitter yellow white Connect mal temperature gauge a ground When gauge indicates operate accurately 500C Loose or i220F approximately gauge is serviceable Correct gauge terminal contact poor connection BE 19 Body Electrical System Probable Condition Corrective action cause Fuel gauge Fuel gauge does not Faulty tank operate connection resistance F unit Replace tank or correct terminal con a half level when a 35U ground fuel gauge Replace Poor or loose cormection Conect connector terminal contact circuit pointer unit E lowers below tion switch Is turned unit Replace fuel gauge position when off F ignition switch is turned AND CHARGE WARNING Probable Condition Replace tank mark when igni off Faulty fuel gauge pointer still indicates OIL PRESSURE terminal is connected between tank unit wire and Faulty tank position unit Faulty fuel gauge Open Pointer indicates only loose or nection indicates pointer yellow unit LAMPS Corrective action cause Oil pressure wamiug lamp Lamp does not light when ignition switch set to oil pressure switch switch terminal connection Inoperative is When ON switch yellow black wire is or loose Replace switch OJ correct terminal connee tion grounded warning lamp lights Burnt bulb Open Lamp does not go out while engine is being operated or Replace bulb loose bulb or correct bulb socket circuit Lack of engine oil Check oil level and add oil Oil pressure too low Inspect engine oil pressure system Inoperative oil pressure switch Replace oil pressure switch Burnt bulb Replace bulb as required OIarge warning lamp Lamp does not light when ignition switch is set to ON loose bulb Warning lamp regulator white Open Lamp does not go out when engine is started or does not light or correct bulb socket when voltage red wire is grounded circuit Inspect charging system Faulty charging system BE 20 Body Electrical System ELECTRICAL ACCESSORIES CONTENTS HORN DESCRIPTION REMOVAL AND INSTALLATION IGNITION SWITCH REMOVAL AND INSTALLATION HEATER BE 21 FAN BE 21 CONTROL ASSEMBLY 8E n ADJUSTMENT BE 22 SPECIFICATIONS BE 22 INSPECTION WINDSHIELD WIPER INSPECTION INSTALLATION REMOVAL AND ADJUSTMENT CLOCK BE 29 8E 29 BE 30 BE 30 BE 30 30 8E REPLACEMENT 8UL8 BE 23 RADIO BE 29 REPLACEMENT BE 23 REMOVAL AND INSTALLATION CORE MOTOR TACHOMETER BE 23 AND WASHER 8E 29 BE 21 SEAT 8ELT WARNING 8E 31 SYSTEM BE 31 BE 25 DESCRIPTION BE 25 REMOVAL AND INSTALLATION BE 31 BE 25 WARNING LAMP BULB REPLACEMENT 8E 31 BE 25 INSPECTION 8E 31 DIAGNOSES AND REMOVAL BE 25 TROUBLE I NST ALLATION BE 26 CORRECTIONS BE 33 BE 26 HORN 8E 33 DESCRIPTION BE 26 WINDSHIELD WIPER AND WASHER 8E 34 AIRFLOW BE 28 RADIO BE 35 HEATER HEATER BE 29 UNIT ASSEMBLY HORN horn button flow horn circuit includes a horn relay Current from the battery flows through the fusible link and fuse to the horn relay terminal B where it is shunted by the two circuits In one circuit terminal S supplied through ground supplied through is horn contacts and serves as a grounding the relay is pressed battery energizes the energized closed This the the allows the current to flow to the horn solenoid and contacts INSTALLATION Horn bracket the current flow is relay REMOVAL AND I As the solenoid is solenoid the Horn When the horn button current from the In the current other circuit terminal H DESCRIPTION The the to are 2 on Disconnect battery ground cable Disconnect horn wire at terminal horn body 3 Remove horn retaining bolt 4 Install in horn the reverse se quence of removal Horn relay The horn Fusible link H Qi Fu att Horn button Qm J t JJI L is installed on the 3 Remove retaining 4 Install horn relay in the sequence of removal HIBQ I relay hoodIedge on the right side of the engine compartment I Disconnect battery ground cable 2 Disconnect horn relay wire con nector at terminals on horn relay J Hornrelay BE859A Fig BE 29 Circuit diagram of horn sy tem BE 21 screws reverse Body Electrical System 1 Voltage regulator 2 Horn relay 3 Headlamp relay Ignition relay California only heater relay choke Auto Compressor relay Au conditioner equipped model Floor sensor relay California only Inhibitor relay Automatic tran5mission only 4 5 6 7 8 BE683B Fig BE 30 Horn switch INSPECTION The horn switch is signal turn integral with the switch and dimmer Remove switch assembly sembly Test as and Dimmer Signal outlined in Turn ContInuity test as switch continuity through ignition by using test lamp or ohm meter Switch BE861A Fig BE 3 I Removing ignition switch IGNITION SWITCH REMOVAL AND INSTALLATION C cable ground I Disconnect battery from battery 2 Unscrew and remove escutcheon R terminal from the front of ignition switch Withdraw ignition switch 3 wiring assembly 4 Disconnect from with spacer Figure shell cover as shown in wiring and BE 1G terminal TERMINAL connector A terminal ST terminal switch from the back of ignition 5 Replace ignition switch with KEY FOSITlON 0 A F F C C B terminal a B 1 o IG new one 6 Connect ignition switch to ignition switch to shell ST wiring Position cover u A connector 7 opening escutcheon and install secure and t 3 R tighten u j I I BE6848 ignition switch Fig to shell cover 8E 22 BE 32 Ignition witch Body Electrical System Washer pump WASHER WINDSHIELD WIPER AND The washer pump and washer fluid are integral parts and are serviced REMOVAL AND INSTALLATION tank as assembly an Caution for windshield waBher operation I Be only washing solu to use sure tion Never mix use powder soap or detergent with solution 1 2 3 Windshield wiper blade Windihield wiper arm 5 Wiper motor Wiper motor bracket Connecting rod 6 Pivot 4 2 Do not operate windshield washer continuously more than 30 seconds or without Fig BE 33 Wind hield wiper er should be less at I and 2 Remove Remove cowl top grille See Sec tion BF 3 Remove cowl top grille 3 Remove stop ring that connects wiper motor arm to connecting rod 3 Remove two flange nuts retaining pivot wiper linka e to cowl top Remove stop ring that retains 4 connecting rod to wiper motor arm 5 Remove wiper motor linkage as sembly 6 Install wiper motor linkage in the reverse I From disconnect connector 4 under panel instrument wiper on wiper Remove motor motor three harness at Install retaining screws wiper motor tank and motor reverse sequence of Install washer 4 the in removal Washer nozzele sequence of removal Access for washer nozzle removal is obtained by disconnecting vinyl tube and removing washer nozzle retaining from cowl top When washer nozzle is installed screw washer fluid fluid is sprayed Figure BE assembly Removing wiper linkage wiper arm in correct and blade sweeping angle See Figure BE 35 for correct installing dimensions I 25 mm 0 984 in j217 Press in switch counterclockwise and knob pull turn it Unit Unscrew escutcheon and remove disconnect wiper switch panel multiple connector Fig BE 35 Wip J from instrument harness wiring assembly and remove arm irutallation 4 Install new nun in BE863A BE 37 Waaher nozzle adjuatment Fif INSPECTION Wiper motor I Disconnect wiring connector from wiper motor spacer and switch BE862A J out of switch ment i r l 450 1772 it escutcheon and spacer 3 Reach up from underneath instru r that washer in range indicated in 1 1 2 JC sprayed direction by Ii 1 00 Li L L 1 3 94 270 to 63 Wiper and washer switch so not or 37 450 72 Fig BE 36 is nozzle adjust bending nozzle tube Install pump from tank bracket assembly properly 7 washer two Pull out washer tank and motor 3 in the reverse sequence of removal BE 34 or Remove hose from washer pump when Fig 10 seconds operated and drain washer fluid assembly body and pull out wiper motor forward 5 washer time one Disconnect 2 arm often This windshield lead wires at connectors Wiper motor wiper blade assembly from pivot I fluid operation Normally windshield wash BE685B Wiper linkage washer improper causes switch in the sequence of removal BE 23 reverse 2 Connect test lead between B ter minal on motor ide and battery posi Body Electrical System tive terminal or B terminal and blue red wire terminal in wiring connector plug 3 To check wiper low tion speed L terminal to connect with ground cable or opera Blue white ground connect L termi nal to black wire terminal make sure that wipers sweep at low speed 4 To check wiper high speed opera tion connect nal in the to H termi in 3 step that wipers sweep fast During low speed operation make 5 ground cable same manner as sure nect E terminal to con H tenninal o ground and conlect @ P and L terminals with lead wire as shown in Figure BE 38 At this time make sure that auto stop mechanism to stop wiper blade at the position specified 6 Wiper is in good condition if actuates above tests are made as C BE864A indicated Fig BE 38 Wipftrmotor Fusible link e Cl rt Battery Wiper and washer switch Ignition witch Continuity test Remove wiper switch from vehicle as WQ5hcr motor Fuse I motor Wiper B LR I 191 switch by O Y Dj Wiper box terminal y P tenninal L L terminal w H I rmjrW t r r J using test lamp wiper or ohm meter switch 1 21 b E terminal outlined in Wiper Switch Test continuity through 1 I II BE865A Fig BE 39 Circuit diagram of windshield wiperwtUher TERMINAL I SlOIT01 I OFF POSIl10N 2 I 2 I Z I Z I te7tl I 1 b sy ii I I I I 10 I I 2 4 5 Switch position m 3 2 BE686B Fig 8E 24 40 BE Wi r witch Body 2 RADIO Electrical Remove System holding radio nuts and washer from radio control shafts REMOVAL AND 3 INSTALLATION front of radio Remove 4 Radio From disconnect Removal 5 under bezel Remove from cable radio from lead and and speaker the panel instrument antenna power lead wires Pull radio knobs offradio control radio t lead instrument panel shafts BEB67 A Fig BE 42 Radio ant nna ADJUSTMENT Antenna trimmer When or a new radio receiver antenna Extend 2 Tune tween on completely antenna in the weakest station be 1 200 to 1 600KC 12 and 16 dial regard but dis generated it Turn trimmer antenna and left slowly and set it at aE323 antenna adjusted Noise may be 3 installed antenna feeder is trimmer should be right position highest to a where receiving sensitivity is Fig BE 41 Radio Installation Installation panel panel m behind Fr position radio to instrument 2 Install radio bezel to the front of 3 Install washers and nuts control shafts and tighten on them radio secure pillar Connect antenna cable and lead wires power lead and vehicle that is not 2 with SE133 Thread mounting stud of antenna clip opening 3 speaker lead equipped radio into ly Then install control knobs 4 antenna on radio plugs that cover mounting opening in front when installing radio antenna Remove rubber instrument upper antenna Fig BE 43 Adjwting antenna trimmer mountins Insert antenna cable into lower mounting opening and place nna base in position Install antenna base retaining antenna ant 4 Removal From behind instrument disconnect antenna cable at 2 Remove remove 3 pillar on Remove retaining antenna ont fr 5 Route antenna cable dash panel 6 Connect and antenna nector upper Remove battery 2 cable at con Remove instructions in ground cluster steps lid cable following I to 4 of Removal in Combination Meter tor 3 of screw cable along to radio antenna base and antenna base sembly from 4 plug panel conne REMOVAL screw Antenna and antenna cable CLOCK Disconnect three wire connectors clock printed as from combination meter circuit and instrument harnes wiring pillar 4 Unscrew antenna clip from front Remove three s rews clock from cluster lid if necessary BE 25 and remove Body Electrical System INSTALLATION I Position install three 2 clock cluster lid and screws Connect three wire connectors of clock to each connection combination meter to instrument h 3 to printed ness Install cluster two to circuit one wiring lid to instrument panel 4 Connect battery ground cable Fig BE 44 Clock HEATER DESCRIPTION @ Defroster nozzle L U 7 Ventilator knob 2 Deflortcr duct LR 8 Heater 3 Heater 9 4 Resistor 10 Conuol cable clip Heater cock 5 Heater motor 11 Defroster duct Heater 12 Defroster nozzle 1 6 control case core R H R H BE687B Fig BE 45 Heater comtruction BE 26 Body Electrical System of the heater is control Operation led by two control levers located on the instrument panel and a hand op erated knob on the center of the heater unit The AIR LEVER controls the air intake valve and lever operation of the fan motor When the lever is in the OFF position the water cock is flow into heater closed and the circulation of tion engine coolant through the heater core stops When the lever is slided to any other position than OFF control To fan motor opera pull the lever knob Two are for the fan motor provided speeds by using a three position switch the water air intake valve draws the fresh push or FUSE IOfF outside air from the cowl top grille and supplies the air into the heater 1 unit The room valve is located at the bottom of the heater unit The air to the room valve where the air is f distributed to the floor outlet and defroster outlets position of the depending room on or the valve is directly linked valve which provides fresh The VENT KNOB is to the vent air for the passenger Push the knob all the way in to open the valve The fresh ventilating air comes out of the heater rl FUSIBlE LINK BATTERY G HEATER UlwlHI t ON SWITCH coming through the air intake valve opening is forced through the heater core core the through the control cables ROOM The OFF positions valve by its DEFROST and or room cock opens in proportion to the lever setting and allow engine coolant to the heater unit and the other for the u HEATE R SWITCH luJ MOTOR center outlet The TEMP lever is H EATER dual pur is for regulating the a pose control one flow of engine coolant flowing into UN IT BE868A Fig BE 46 Circuit diagram of heater 8E 27 Body Electrical System AIRFLOW OFF VENTILATING Vent valve Push Heater core c IUl J n NlL fAl e u c Push u g Pull DEFROSTING VENTILATING HEATING Pull Push J tTIlsl 0 IU lI g IIt D WI I L I Pull DEFROSTING Pull HEATING IU I n C n HU J 11 Pull UIUI ff J CIl C JIlT Ill Pull BE397 Fig BE 47 Airflow 8E 28 Body Electrical System 2 UNIT ASSEMBLY HEATER Disconnect three lead wires from each connector 3 Removal Remove front of radio ground L Disconnect battery 2 3 Drain engine coolant Remove defroster hoses 4 Remove and clips three cable 4 cable retaining 5 cables BE869A fan motor lead Fig BE 48 Removing front cov r Disconnect two resistor lead wires from each connector core Remove Withdraw heater core from heater two retaining bolts and heater control assembly 6 Install control assembly in the sequence connecting control cock S Disconnect water hoses from 7 the Remove heater control knobs and reverse wires from each connector 6 from instructions heater bezel disconnect control Disconnect two bezel following in steps I to 3 in Removal of Radio from valves and water cock 5 plug radio adjust of removal When cables to valves and control cable length as outlined in Adjustment housing and water cock 8 three Remove mounting housing heater bolts and dismount heater unit from vehicle ADJUSTMENT AIR lever L Installation Fig unit securing bolts 2 Install water hoses 3 Position heater control cables to room BE870A and install three heater panel 6 valve air intake valve and water DEF air intake valve and connect control cable to air intake valve Position heater unit under instru 1 ment AIR lever to the Move position 2 Open BE 49 Removing heater Install heater core core 3 Clip control cable with cable re taining clip in the reverse sequence of removal cock Adjust control cable length for as outlined in Adjust proper operation 4 FAN MOTOR ment Connect 5 resistance fan wires wires motor to and from vehicle Install defroster hoses 6 Connect battery ground cable Fill cooling systeIT 7 8 Run engine AIR lever Make sure at in the that 2 000 rpm with HOT position engine coolant is fIlled as outlined in Removal of Heater Unit Assembly Fig BE 50 A iT intake valve spring clips disassemble heater housing 2 Remove 3 Remove fan from fan motor 4 Remove S stall nine fan motor and retaining 4 Assemble heater housing and in heater unit to vehicle in the Pull room valve upward and con nect control cable to room valve 5 and fan motor screws up to correct level heater unit assembly Dismount L plug 9 Removal and Installation each connector Clip control cable with cable re taining clip sequence of removal as out lined in Installation of Heater Unit reverse Assembly I HEATER CORE Removal and installation CONTROL ASSEMBLY L Drain engine coolant 2 Remove defroster hoses 3 Disconnect water hoses from inlet and outlet pipes of heater core 4 Remove cover four clips and Removal and Installation I front clips Remove and three disconnect from valves and cock BE 29 cable retaining control BE871A cables Fig BE 51 Room valve Body Electrical System TEMP lever 1 2 Move TEMP lever to the RG The red with green wire must OFF flat position 2 3 of water ock when water cock lever is pulled forward fully closed 3 cable control on stripe lead connected to terminal at back of combination meter Connect control cable to the lever Install plate be B The black lead wire must be connected to T shaped ter minal at back of combination water meter cock bracket with cable retaining clip 4 YR The yellow with red stripe lead wire must be connected BE872A Fig BE 52 Water cock pole to terminal at back of combination meter SPECIFICATIONS 6 Item General Extremely cold use weather Pass grommet tachllmeter on and connect use wires through hood lock control wire to negative terminal of ignition coil FAN MOTOR Notes Rated power consumption Revolution 12V less than 36W 3 600 rpm Fix grommet with a 12V less than SSW or a 2 SOO an adhesive tape sealing compound leakage to prevent water Fan dia mm in 110 433 110 33 4 b Attach tachometer wires to hood lock control wire with 3 TACHOMETER The is tachometer model HL620 It is an optional ignition system It counts pulses entering the ignition coil are connected to combination meter and tachometer on integral part the They of cable 4 remove tions 5 BULB REPLACEMENT Remove the and indicates the number of engine revolu three screws and then I tachometer from cluster lid Install in moval note the When sequence of re connecting lead wire reverse REPLACEMENT 1 BW 2 following The black with white striped Remove battery ground cable lead wire must be connected 2 Remve to following instructions iri steps I to 4 of Removal in Combination Meter identically chometer cable colored coming engine compartment ta from as previously Twist illumination bulh socket at back of tachometer I lid Remove tachometer described can cluster adhesive tape Disconnect four tachometer lead wire connectors an Bulb with socket then be easily removed 3 Remove bulb 4 Install new bulb in reverse se quence of removal Bulb wattage Tachometer illumination lamp 3 4W BE965 Fig BE 53 Tachometer BE 30 Electrical Body the to SEAT BELT WARNING SYSTEM lamp zer the lamp to ignition switch is turned position the warning ON on comes 8 seconds and remains The on sounds if the driver s seat belt is warning tion switch sounds for 4 to 8 seconds intermittent ly if the driver s seat belt is not fastened properly The seat belt warning system con sists of a driver s belt switch a warning buzzer a warning lamp a timer unit and an ignition switch on instru Remove cluster lid Disconnect lead wire at connee tor Remove two retaining screws Installation is in the reverse se quence of removal REMOVAL AND INSTALLATION Ignition switch Refer to page BE 22 for Removal and Installation WARNING LAMP BULB REPLACEMENT Timer unit is fIXed switch is turned I 2 4 For Canada ignition is located lamp body Timer unit When the Warning lamp panel ment 3 for 4 buzzer Warning lamp body and the warning buz properly The seat belt warning system con sists of a driver s belt switch a warning buzzer a warning lamp and an igni Except Canada When the the warning position comes on not fastened DESCRIPTION to ON System ment behind glove on a reinforce box I Remove cluster lid 2 Twist with bulb Socket socket lamp warning then be taken can out 3 Pick up bulb from socket 4 Install new bulb in the reverse sequence of removal Bulb wattage Seat belt I 7W warning lamp INSPECTION Warning buzzer Apply BE282B BE688B Fig BE 54 Timer unit I Disconnect CD sounds 12V direct current between @ and or The buzzer must sound when battery ground cable @ 2 Remove glove box and 3 Disconnect timer unit connector circuit See 4 Remove buzzer timer unit two on retaining screws reinforcement can S Installation is in the Note is fIxed on a re BE967A inforcement behind glove box Refer to the power 55 for warning Make sure that negative Timer unit Warning buzzer buzzer Figure BE CD to terminal of power circuit is always connected to @ terminal reverse se quence of removal Warning connected are Timer then be taken out unit and check whether buzzer not preceding for Removal and Installation s ignition key to the ON Fig BE 55 Warning buzzer position The voltage between @ and ground must be 12V for 4 to 8 seat belt switch seconds and then go out See timer unit Driver Turn Figures BE 54 and BE 56 I Remove seat belt 2 Disconnect belt switch lead wire ecuring bolt Belt switch at connector 3 4 Seat belt can Installation then be taken out is in the quence ofremoval BE 31 reverse se Test continuity between two lead wires from seat belt switch with ohm meter or test lamp Body Electrical System Circuit diagram of seat belt warning system Non California modela except for Canada FUSE lOA FUSIBLE LINK p c DRIVER S o @ BATTERY @I f IGNITION SWITCH BELT TIMER UNIT I@ SWITCH 9 I WARNING fS LAMP 2 l BUZZER California modela IGNITION RELAY FUSIBLE LINK F lC 1 1 9 FUSE lOA ORIVE R S BELT SWITCH BATTERY f 9 IGNITION SWITCH WARNING LAMP r i J 2 I BUZZER Canada modela DRIVER S FUSIBLE BELT FUSE LINK lOA aP o BATTERY f SWITCH 9 c N IGN ITION SWITCH WARNING fS LAMP J 2 I Cf BUZZER BE689B Fig BE 56 Circuit diagram of seat belt warning system BE 32 Electrical Body System TROUBLE DIAGNOSES AND CORRECTIONS HORN Condition Horn does not operate Probable Corrective action cause Discharged battery Measure specific gravity of electrolyte Recharge Burnt fuse Correct Faulty horn button contact Repair horn button Horn sounds grounded when horn relay terminal s replace battery cause and replace fuse is Inoperative horn relay Horn sounds when or Replace horn relay B and H horn relay connected with a test lead tenninals are Damaged horn or loose horn terminal con nection Correct horn te inal Horn sounds Short circuited continuously button lead wire When light horn button and or horn Repair horn button green lead wire is disconnected from horn relay terminal s horn stops to sound Inoperative Reduced volume and or tone quality Loose or onnection horn horn Replace relay poor connector contact or horn button Repair Fuse relay horn and Damaged horn Replace BE 33 horn relay or its wiring or replace Body Electrical System WINDSHIELD WIPER AND WASHER Condition Probable Windshield wiper motor does not Correct Burnt fuse cause and replace fuse Replace wiper Damaged motor Check wiper motor operate Corrective action cause as outlined in motor Inspec tion Repair Loose connection and washer switch Faulty wiper Replace Test continuity through switch in is too slow Damaged Loose Seized or or circuit Wiper motor continues ground circuit on on motor Lubricate in windshield glass and operate wiper without load replace Clean windshield glass and Damaged Replace motor Remove stop operation stop device auto to run after switch relay is turned off or Clean dirty contacts bending if necessary wiper blades do not return to correct position replace wiper cover and check contacts Poor connection Repair Faulty switch Replace BE 34 or blade Replace auto or wiper blade Faulty wiper switch Faulty motor Repair rusted wiper linkage arm Repair Replace poor connection Wiper blades stick Raise or motor Humming occurs operating cycle Wiper speed cannot be changed correctly outlined Inspection Open power Wiper operating speed as or repair relay plate Body Electrical System RADIO Noise prevention Position vehicle in an open area control to maximum and set dial at away from steel a buildings run Condition Probable antenna to its maximum engine extend medium point without catching broadcasting length set volume wave Corrective action cause Ignition system Noise occurs is when engine op High tension wire Install new Install a high tension wire erated Ignition coil 0 51lF capacitor primary side to terminal of ignition coil Be careful not to install capacitor to secondary or primary breaker side other wise engine becomes improper Note Install bond strap Distributor Secure contact of carbon electric pole and rotor Eliminate sharp tip on rotor pole or cap pole by scrubbing with a screwdriver Check stagger between rotor and stator Charging system Sound of alternating current pre Alternator Install 0 a 51lF capacitor to charging termi nalA sents Note Do not use a larger capacitor If capacitor is installed to terminal F alternator coil will be damaged When accelerator or pedal is depressed Install Regulator 0 a 51lF capacitor IGN to terminal of voltage regulator released noise presents Supplement equipment When engine starts noise presents Noise still presents even after stop Operative noise of water tem Install O IIlF capacitor between terminal and perature and fuel gauges ground ping engine Note wire If a is used capacitor having a larger capacity indication of gauge will be de viated b Cut lead wire Notes a Be sure to locate as to noise parallel capacitor source as close and connect in c as short as possible Ground wire should be attached the body d Make on completely installation 35 BE and connection e securely Carefully identify or OUT mark IN to o Q m r0 C i Ql 1 CIl Il l3 @ @ D v only models H L 2 lamp B L type lamp marker combinat check headl mp conetr U C a l i f o r n a Californa models olenoid distrbuo California Non To To To To 37 38 39 40 cut L Low High sido front horn horn D D C B To To To To To To To resi tor only and tcrminal only coil coil models block igniton condesr igniton Californa only models 30 3t 32 33 34 3S 36 only models n California Non R 2 lamp 2 n 1 type type No lamp c o m b i n a t marker batery fusible engine altern o headlmp headlmp H link 1 R harnes R front transmiter B R side California Non solenid heater cut solen id only cut choke IS 16 17 18 1 20 1 L D ground thermal distrbuo models fuel auto headl mp D C 8 To To To To To To To To To To To To 9 type R 22 23 i4 is 26 To To To 27 28 29 only Can da only modeb models for lamp I j except relay CCaliforna aliforna only only harnes amplifer heater counter model relay relay relay models switch compart en mot r relay senor lamp relay regulator cable tinstrumen ransitor ho d washer igniton floor inhbitor voltage T A @ dri e engine det cor To To Californ a To To To To cauthokoe full To 1 2 3 4 S head horn Califunia Non 67 89 10 II 12 13 14 OJ m ll0 ll CDm Cl co ler To To To To To To To n e g t OJ l3 c oZ l tl lTI 6o III only ifornia 18 6 @ r A L @ f ca Non l8 @ DE1A jB @ onlY @ U Califotl a a AIL DEI 0 11 6 1 1 9 @ 13 @ BY omY ornta @ i ca on l B O onlY 0 @ DE1AIL @ otnia tll calit on t l too i1 l @ OJ 8il m OQ CIl II D 3 I OJ o Q I HARNES J n L ENGt E RO M TO cf w 0 r AlT AfT solenid switch Kickdown Inhibtor Oip 1 cable slinger cable Oip Engine Batery Engine Batery 23 45678 m ii bll m l if 3i to o c O Dl I lti 3 r LB solenid Transmi o switch Tranmiso switch Transmi o switch mot r harrnoesm Transmi o harrnoesm Transmi o kicdown Automaic rev se Manual inhbitor Automaic presu stare engine Manual engine Automaic BY RB 1 BW RB CJ BY B RB m r0 O WB @ RB@RB YB oil 2 RB To fOT To for To for To To To for To for Automaic Transmi o B YB 1 For Manual For Transmio 2 3 4 56 7 fBYB RB BY BY stripe stripe red white with with gre n gre n Transmio CODE Black Brown Gre n Blue Light Red White Yelow Black Light COL R B BI G L Lg R W Y LgR BW Automaic For LB Automaic Transmio For B Transmio Manual For m to l0c mW D l s Q3 Jo Q o m CD n Ql en I i3 @ I 1 1 I I lL flll I J peratuJe ilumnato lamp switch r lamp floor ilumnato light Olodels lamp te ilumnato warni g models R S U timer only AfT I E IT U California Non L I U comparten lamp switch switch lighter control control and models control warni g harnes mot r switch harnes wiper wiper cigar heater radio heater belt heater buz er belt indcator co ler wiptr door engine floor j II H R G 1 harnes A or I To lamp To To To To To To 19 20 21 22 23 24 25 Californa To To To To To To To To To 26 27 28 29 30 31 32 33 34 L @ U@ rL Can da Qj for switch except onlAfTy rheosta mode15 met r switch switch control unit only instrumen d i m e r flasher lamp switch and conetr Jamp switch brake mot r ro m light fuse tachomet r haz rd stop igniton haz rd check AMP CNonaliforna flasher kic down hand heater cable clock unit or switch switch T M tU @ combinat combinat To To To To To To To To To To To To 1 2345 6789 10 11 11 ilumnato To To To To To To 13 14 IS 16 17 18 m tot lQ mJ c E S CD o c m o O II fJl 13 engine J l To YA comparten harnes IIY Lt r wRfl G oIll R G RY ll L Ri l LIB G A GL only L T A B LW AL LW B @ y j onl T I BG Can da California Non except Can da R M L except G GR 13 california Non GW L GL R A GW ft t It BW B 4D 4 LR LW t4 LG @ lD m en l l ii b CD m l lD tp o c TS O l 13 rJl i lt L H R lamp tarnP H R y s @ haltl @ 8 d8 Gt QR 1ii ou switch lamp fo 1 To 0 1 To To L lamp harnesS sensor models belt unit marker instrUment co ler floorCalifornia driver tank Gt ll combinato combinato market amp e cens side reat 0 1 i rear side to To To 10 9 67 45 10 1 t 8 @ @ J G Q8 t 8 Gt Q t QR t LQR RB Gt 8 ill@ RB LQR 8 8 8 CD Q8 t G Bt c Body Electrical System EMISSION WARNING SYSTEM California models CONTENTS FLOOR TEMPERATURE WARNING SYSTEM California models BE 43 DESCRIPTION WARNING LAMP 43 BE TROUBLE 44 BE SHOOTING GUIDE 8E 43 FLOOR The warning lamp also comes on TEMPERATURE during operation WARNING SYSTEM California models permitting inspection of the lamp s condition The lamp goes out after the engine starts DESCRIPTION The floor of the starter motor 4 Installation is in the se Bulb wattage Floor temperature warning lamp Refer to Section EC for details temperature warning a floor temperature reverse quence of removaL 17W system consists of sensing switch installed floor a floor on the vehicle temperature floor temperature warning harnesses relay lamp abnormal level will come on the warning lamp to call the attention of the driver Lamp body replacement a and When the floor temperature rises to an WARNING LAMP Bulb replacement I 2 Remove cluster lid Twist ng warni Socket with bulb can Remove cluster lld Disconnect lead wire at connee tor lamp socket then be taken out 3 I 2 3 4 Pick up bulb from socket Remove two screws retaining lamp body Installation is in the reverse se quence of removal IGNITION RELAY FUSIBLE LINK I P i I l IGNITION BATTERY SWITCH FLOOR SENSOR RELAY f I I I FLOOR SENSOR ON FLOOR TEMPERATURE WARNING LAMP LOW OFF FLOOR TEMPERATURE HIGH 7 BE697B Fig BE 64 Circuit diagram of floor temperature warning system 43 BE Body Electrical System TROUBLE SHOOTING GUIDE Condition Warning lamp does not light in START posi tion of ignition switch Probable Corrective action cause Burnt or loose bulb Replace bulb Faulty f1o Conduct r temperature relay or correct bulb socket continuity test and repair place Refer Loose connection or open circuit 44 BE to Section EC Check wiring and or repair if necessary or reo SE B V I C E I M A N IuI A71i 1 SECTION AC W c i L AIR CONDITIONING DATSUN PICK UP MODEL 620 SERIES lmSSANJ NISSAN MOTOR CO TOKYO LTD JAPAN DESCRIPTION AC 2 TROUBLE DIAGNOSES AND CORRECTION AC 19 REMOVAL AND INSTALLATION AC 25 COMPRESSOR AC 33 SPECIAL SERVICE TOOLS AC 39 Air Conditioning DESCRIPTION CONTENTS OUTLINE OF AIR CONDITIONER AC 2 DESCRIPTION AC 5 AC3 MAIN AC 7 CONDENSER AC 3 FAN COMPRESSOR AC3 THERMO SWITCH RECEIVER AC4 PRESSURE SWITCH AC 7 AC4 COMPRESSOR AC 7 AC 5 F I C D REFRIGERATION SYSTEM COOLING DRYER UNIT ELECTRICAL CIRCUIT OUTLINE OF AIR CONDITIONER The sentially of condenser The three conditioner air a cooling receiver cooling brackets location ment consists es unit is a occupied by panel secured ttached the to with the package tray The compressor air directed into the passenger compart I 5 2 6 Cooling unit Expansion valve 3 Receiver dryer 4 Comressor three outlets at the serves to compress vaporized refrigerant and is attach ed through the bracket to the loca tion occupied by the mechanical fuel pump on the engine sed refrigerant AC 7 RELAY VALVE the radiator AC 7 in the engine compart ment The condenser cools the compres from the duct is AC 7 SOLENOID the in the dash The cooled SWITCH instrument unit compressor dryer and piping through the panel RELAY vapor sent pressor and is located on by the com the front of The receiver dryer serving reservoir for storage of the as liquid a sent by the condenser is located on the right in the engine compartment The piping consists of two flexible hoses and five copper tubes which connect various components of the air conditioning system Condenser Duct @ Flexible hose @ Copper tube AC724 Fig AC AC 2 1 Cooling system Air REFRIGERATION perature inside the box will drop This is because the alcohol is evaporated SYSTEM If you were to paint your finger with alcohol your finger would feel cold This is because the liquid alcohol from heat away your finger while it evaporates Ifa quickly evapo rating liquid such as alcoliol is placed takes in a container inside box a Conditioning the absorbing the box the heat from the air insidc If the gaseous alcohol collected and cooled with cold it will be changed absorption of back into heat its a is water liquid by by the cold pIe The liquid refrigerant the and then operates on this princi refrigerant back to in from dissipated liquid a to to a the outside refrigerant from a liquid refrigeration system is changing The The cooler is the The heat inside the passenger compartment is absorbed by changing water tem used R 12 the Figure AC a gas by gas shown 2 f V7777 High J l gas lLLLLL I I Low pressurt pressure 1 liquid Low pressure High pressure liquid L2 I gas Inside air Outside air U J6G1 1 t Condenser i i 11 t1 I I ilill li Compressor J u l i LlJ JJ r 7 t qIrJ U It Evaporator Receiver J 1 Blower motor J f dryer L ttLJ 9 d lUr I Expansion valve AC458 w t h Fig AC CONDENSER The condenser is installed to Refrigeration cycle COMPRESSOR the front of the radiator The heated and compressed refrigerant gas from 2 the compressor condenses to a liquid by being cooled by air passing between the fins of the condenser compressor is installed to the of the engine and is driven by crank pulley through a belt The refrig The side gas leaving the evaporator is forced out to the condenser by com erant 7 1 GJ pressor an plI electrical rpm is very compressed clutch Ac459 Fig AC 3 Condenser AC3 force idling Because engine low during idling clutch will not d1i 1il low pressure refrig to a high gas and high pressure temperature The driving force is transmitted by vlmnn iii and the is erant transmit thus ensuring the the driving smooth engine Air Conditioning AC728 Fig A C 4 Compressor RECEIVER DRYER The pose The receiver amount of the flowing through the dryer of storing the serves To ran ion e alve the system varies with operating condition conditioner the pur liquid refrigerant liquid refrigerant To be of the accurate air the receiver dryer stores excess amount of refrigerant when the heat load is lowered It also releases stored ant when additional cooling 5 From condenser refriger FJi c is needed i thus maintaining the optimum flow of refrigerant within the system The receiver dryer strainer and desiccant includes They have 1 a Z the job of removing moisture and foreign particles as the refrigerant circulates i 3 c I o within the system The pressure o switch is installed 3 L o beside sight glass of receiver dryer The 7 W purpose of the switch is to stop the compressor operation in the event an excessive system pressure builds up on the high pressure lines R o r J J t AC230 I Prc 2 Sight glass 3 Strainer 4 De kcant surc switch Fig AC 5 Receiver dryer COOLING The liquid UNIT refrigerant the The and rator the cooling cooling motor and an electrical unit a some unit includes an evapo expansion valve From the point of view consists resistor for fan of a blower speed control switches and relays the aid of the evaporator expansion valve Consequently the air drawn by the blower motor is cooled in passing through the evaporator The expansion valve restricts the liquid refrigerant as it passes through it and delivers sprayed refrigerant to the evaporator for evaporation 4 AC evaporates in with facilitating refrigerant Air The refrigerant within the Conditioning thermo bulb changes in pressure through the super heat condition of frigerant gas which vaporized re out of the comes evaporator causing the deflection of the diaphragm The lift of the ball attached to the diaphragm is changed by the deflection of the dia phragm thus controlling the amount of refrigerant passing the orifice valve Diaphragm Orifice Valve ball AC729 4 Sensing bulb Fig A C 6 Expansion value 000 l 1 Motor 8 Resistor 2 Fan 9 3 Lower case 10 Main relay Thermo switch 4 Cooler duct II Cable 5 Evaporator Expansion valve Upper case 12 Cable 13 Harness 6 7 clamp AC725 Fig AC 7 Cooling unit ELECTRICAL CIRCUIT The following wiring diagram pro vides a complete description of the pressure switch and compressor relay The blower motor fan speed is con DESCRIPTION whole circuit trolled by the fan switch and resistor The solenoid valve is also activated ignition switch and the fan switch are ON the main relay is When the The electrical circuit of the air conditioner consists of four switches two relays motor clutch and a a solenoid valve compressor a fan magnetic activated flow causing battery through power to the fan motor and the magnetic clutch The magnetic clutch is activated by the thermo switch AC 5 This in turn device speed causes F lC D the fast idle control to increase engine when the vehicle is at rest with the engine ON Air Conditioning J c BW BW 00 B n B L ELECTRIC L FUEL PUMP b@ tl ILLUMINATION CONTROL I GL RHEOSTAT GL1J lL t m oB 3 FROM LIGHT SWITCH ILLUMINATION LAMP I J c I MAIN RELAY FAN SWITCH 2 LW L fZP I rRL W I FUSE 15A r D CJ B J 1 6 1 RY THERMO SWITCH COMPRESSOR RELAY COLOR I BA H UE 1 I I I i @ IC PRESSU 1 CODE B Black BW Black with white L Blue LW Blue with white stripe LR Blue with red W White G Green GL Green with blue stripe RL Red with blue stripe stripe stripe rlTCH IG D J oc c G F IC D m I SOLENOID f LR COMPRESSOR FUSE W O 0 J ov 0 OVJ I t1 n BW L IGNITION SWITCH BW I IG AC727 Fig A C B Wiring diagram of air conditioner system AC 6 Conditioning Air COMPRESSOR RERAY MAIN RELAY The main cooling relay is located on the unit tacts in the relay the electrical power from When the ignition switch and fan switch are both turned on the COll supplied to closed are The compressor relay is attached to Then battery is the blower motor and the electrical clutch for the compressor the receiver dryer bracket on the right side of the engine compartment This relay is actuated by the fan switch thermo switch and pressure switch to turn on off the and compressor magnetic clutch 1 1 @ Dc l@ cv IDe ID @ @e L J AC465 Fig A C 9 Main relay FAN SWITCH The fan switch set temperature it serving as a control automatically switch is by the control lever turns turned off When the off the unit is installed on the center console clutch is turned off of refrigerant inside the cooling system speed through used as a main the resistor It is also relay switch stopping 2 AC731 magnetic This switch controls the blower motor 1 Fig A C 11 the flow and increasing the cooling system Pressure switch and compressor relay tem perature the When determined air rises switch automatically way to temperature the pre F I C D SOLENOID VALVE the thermo turns on the temperature of the air dis charged from the cooling unit matically controlled as desired The In this is auto um to valve is at is ON supplies valve vacu the F I C D diaphragm through hose connected to the vacuum engine engine The pressure switch is turned off refrigerant pressure in the solenoid compartment This the PRESSURE SWITCH lC D F tached to the dash panel in the engine intake manifold when the is at idle and the cooling system thereby raising idle speed to the predetermined rpm 800 when Fig AC I0 Fan switch cooling system rises to an abnormally This high level 28 kg cm2 398 psi in turn The thermo switch is located on the kg cm2 trollever attached to the console box again designed that when the passing through the evaporator cooled down to the 341 Thus is pressure is predetermined s I the pressure switch psi turns on air core e pressure in the cooling system When the pressure drops to or below 24 upper side of the cooling unit and is controlled by the cable and the con so IW r compressor magnetic clutch actuating the com pressor relay and gradually decreasing THERMO SWITCH It is off the turns cooling system refrigerant automatically maintained at the proper value at all times AC 7 1 AC132 Fig AC 12 F l C D solenoid value Air Conditioning GENERAL SERVICE CONTENTS REFRIGERAiH R 12 AC 8 EVACUATING COMPRESSOR OIL AC 8 CHARGING REFRIGERANT MAINTENANCE AC 8 CHECKING HALIDE PERIODIC MAINTENANCE AND SEASON IN INSPECTION GENERAL SERVICE INSTRUCTION SAFETY PRECAUTIONS CHARGING EV ACUATlNG AND HANDLING SYSTEM MANIFOLD GAUGE ELECTRIC AC15 DETECTOR LEAK AC15 DETECTOR AC 8 AC 8 AC 9 SIGHT GLASS AC 9 PERFORMANCE TEST AC 9 AC16 REFRIGERANT LEVEL CHECK AC 16 AC16 AC 17 COMPRESSOR OIL LEVEL CHECK AC17 AC10 PERFORMANCE TEST AC 17 AC 11 REFRIGERANT LEAKS AC18 The CAN TAP used refrigerant conditioner 12 frigerant AC 12 the in is generally called R 12 No other erant than the above refrigerant MAINTENANCE air Re refrig This in refrigerant small a it is case can or PERIODIC MAINTENANCE liquefied available In either high pressure season Refrigerant evaporates easily has it can abSorb a of heat large Extreme vaporating e must be exercised when care the wherr amount handling refrigerant periodic maintenance and inspection are most essential Perform the following level through sight glass dryer topics For details under Refrigerant SUNISO 5GS or as Check the entire 2 of refrigerant for sign leaks Refer to relative The SUNISO refrigeration two is allowable lubricant should refrigeration be used to assure the successful than recommended with other chemical reaction viscosity or or oils or mixing of the would tacts the air phere for cause not an around connection indication that This condition fittings refrigerant can it is is and at a sure leaking easily be corrected by retightening the joints If any joint on line is suspected of small amount of leakage use a leak detector to locate leaking points 3 Check compressor drive belts for proper deflection lead to lowered deficient lubrication The oil absorbs moisture care com Use of oils other pressor operation for Leaks Checking Refrigerant Leaks as to expose it to atmos extended period of time tips following maintenance to allow the air conditioner normally in Keep the entire to operate the I system free from 8 AC at 1 500 rpm The servicing of the air conditioner only by well should be carried out trained servicemen next season This chapter de scribes essential points of servicing a Jarge enter the carried amount of dirt and sand they system will be refrigerant with and may scratch rotating clog the system or parts This points out the need for care in servicing the system That is disconnecting joints should be carried out in a dean place Water should not be allowed to get inside the system does not However readily the The refrigerant mix with water presence of even a minute amount of water will cause a chemical reaction at high tem produce Since HCl perature which will in turn hydrochloric Observe the compressor for 10 once a month by c ENERAL SERVICE acid hydrochloric Season off it con This points out the need least running the engine Jf sysiein If any trace of oil is noted lubricant Mixing of the Level Check COMPRESSOR OIL should be used receiver refer to relative topics under The refrigerant on the at INSTRUCTION checks Start engine and check and 351 give full performance a low evaporation point and moreover since the latent heat of the refrigerant in Turn minutes to enable the air conditioner to in the container large 2 INSPECTION Both usually under out of season should cylinder is a refrigerant leakage by periodically checking for refrigerant gas leak even AND SEASON IN be used for LEAKS LEAK HANDLING REFRIGERANT R 12 oil FOR AC12 AC 13 HANDLING SERVICE VALVE DISCHARGING SYSTEM is SYSTEM acid is highly sive to metals copper piping corroded and corro the aluminum and etc the will become refrigeration system will become clogged Conditioning Air Water in the system will ice the orifice when the high pressure re is will and obstruct the the of gas cause leakage Before connecting pipes be sure to give coating of compressor oil to the changed to low pressure refrigerant by expansion valve etc frigerant be may sea dent than Therefore training importance it is of first any other that personnel well trained serviceman should a not be allowed to handle the ting surfaces refrig erant refrigerant flow following The items instructions to be When I system line is discon nected plug the opening immediately a This is especially necessary moisture to condensation from line and in the to keep out dust It is also necessary line at and prevent forming dirt and keep surrounding above to at all the air When con times temperatures necting system lines do not attempt to remove the plug from the opening until ready for immediate use 2 Always keep the working place clean and dry and free from dirt and dust Wipe water off with a clean Since direct contact of the liquid refrigerant with your skin will cause be careful when frostbite always handling or the refrigerant Wear piece of cloth wrap a 3 Have all necessary tools in pre paration beforehand and have tools clean and dry The oil compressor will easily absorb moisture when exposed to air Immediateiy close the opening of the container after to observe the use It is also necessary following notes your eyes with cool water to raise the temperature gradually Apply Do not rub your eyes specialist Always glasses to protect working refrigerant oil from a should not be transfused container into another the failure will as possibly cause mois ture to mix with the oil b The used oil should not be returned into c container a The oil should not be used if its of state is preservation not clear enough 5 When connecting or disconnect ing pipes from the refrigeration tem use two used for sys wrenches One wrench is holding the fixing nut in place while the other for turning the mating flare nut Failure to do so may result in twisted a tube or may damage protec Consult wear your an apply a or Should strikes your body splash protective Also to the prior in to charging refrigerant service safe strength dled container However if han it wili incorrectiy explode always follow the instruc I ture Since the condensation tempera of the air is extremely low the air will not be condensed when air will form for to be condensed will be the volume of the air to air and in system a refrigerant a The hot location or drop refrigerant it above S20C from a high refrigerant aluminum copper hydrochloric iron materials in system may be affect the and not to seating surface gas is heavier than air and will lay close to the floor be especially careful when handling it in generated HANDLING MANIFOLD GAUGE The pressure at the on the seating surface low high and small confined spaces sides of system should be measured when evacuating and charging refrig 4 erant The refrigerant itself is nonflam mable However gas is and special a toxic gas produced when care phosgene it contacts fire is therefore required when checking for leaks in the system with a halide torch 5 Do tern not steam clean especially condenser on the sys since exces sively high pressure will build up in the system resulting in explosion of the and when diagnosing trouble in the system The manifold gauge is used for these purposes A manifold gauge has two pressure gauges a low pressure gauge and a high pressure gauge These gauges are connected to the high and low side service valves of system through flexible charging construction shown in of Figure hoses manifold The above in handling their strict are essential precautions of Refrigerant l 2 observation requires AC 9 and suffi and the center is is fully screwed path are path blocked When valve stem is backed off the opened The gauge AC 13 When valve stem system give scratches at connections other gas is odorless and colorless and breathing may become difficult due to the lack of oxygen Since the and produced are chemical reaction tions particular be effective of condenser The pressure rise will become When mixed area gas will be red uced and refrigerant refrigerant gas 2 the Consequently thermal transmission red ueed and thus remain in gaseous acid which will adversely never refrigerant gas is condensed in the condenser will the label In system refrigerant Air following delete Therefore on refriger new has the refrigerant to rious effects 2 The refrigerant be evacuated from must in system a caution into the valve is front seated and valve use care A small scratch ant proportional has use When air enters the system all film connection 6 During servicing keep air from getting eye when eyes EVACUATING AND CHARGING SYSTEM the goggles the system cool water and on 3 The a tive film to the eye to avoid infection l250F height a around service refrigerant should get into your eyes when charging the refrigerant splash stpre it in Notes gloves valve to protect your fingers against frostbite by refrigerant If any of the around cloth 4 SAFETY PRECAUTIONS observed in closely the system servicing I general are paths are Air Conditioning Low pressure gauge Compound pres lIrt c Back se High gaug 7 ure rHe g Uge I ted Full counter clockwise Ji Front seated Full clockwise J r gL rnF r rr1 W t 2 g To low side vacuum refrigerant rvicc valve pump OI can To high ide service lve va AC243 Fig AC 13 Manifold gauge HANDLING SERVICE VALVE Connection to service valve into The refrigerant gas wili be since check valve is discharged when open onto pressing charging hose service valve 3 loosen the connection fit of charging hose at manifold Next ting to purge gauge side for 2 to 3 seconds air hose inside charging by the any pressurized gas in system Disconnedion from service val v I Fully close both valves of mani fold gauge 2 Disconnect two from service valves charging hoses At this time the gas will be discharged until check valve is closed Therefore disconnect hose quickly Caution Work with fingers with cloth fant l fri against protected frostbite by re valve When this valve the valve is valve service nected to Remove caps from service valves Connect high and low pressure charg ing hoses to service valves in system service presses against the connection fitting that is when charging hose is con gauge 2 check valve is built An automatic Fully close both valves of mani fold gauge Connect high and low hoses to manifold pressure charging I When charging hose is discon nected the valve is closed automatical open To ly Always observe the following usage 2 during connection and disconnection of be using quickly while pressing charging hose Caution valve cap hoses nut of service valve Work with fingers protected against frostbite by re after 3 build up at the side of system and air low pressure dirt and in In addition may be sucked result enter the valve dust will gradually easily in flare frigerant install When high speed opera tion is per formed without valve cap a negative ing against charging with cloth service valve pressure will hoses and refrigerant will forcefully discharged Therefore charging connect and disconnect precautions Always Check valve will be half opened foreign matter entering the Since close contact between the thread of valve eap and the thread of valve will prevent gas leakage service these sections clean and free of keep scratches and damage 4 Since will be lost during long check packing prior ing hose system of charging hose packing to use always installing charg J 17 t 1 L j Close 1 5V Open Fig AC l0 t Cap 2 Service valve 3 Charging hose AC733 AC 14 Service oolve Conditioning Air HANDLING CAN TAP A wide available variety of The can terclockwise taps are following procedures up Attach 3 conventional can taps apply For the correct usage refer to the firmly manufacturer wise to instructions s that so the is needle pulled 4 tap can Turn can tap to make a to refrigerant handle hole in can fully clock refrigerant can 5 b r r Caution Use can tap of good quality Turn Connect I Fig A C 15 Service value center charging hose to the fitting of manifold gauge At this time fully turned in Turn 2 confirm that both stems are counter Refriger fitting will flow up to the of manifold gauge gas Loosen the 6 fitting center few seconds front seated tap handle fully can coun handle fully ant AC734 the clockwise to raise the needle ing hose connection center a t the of manifold gauge for purge air inside See Figure AC 16 to a charg Counterclockwise docK wise n s r r @ 1 Can tap handle 2 Charging 3 Needle 4 Refrigeran t hose can AC246 A rn air n Purging R I2 AC247 Fig AC 16 AC Can tap and pwging air q Conditioning Air DISCHARGING SYSTEM EVACUATING SYSTEM pressurized refrigerant gas Ul side system must be discharged to a atmospheric pressure approaching pressure prior to evacuating refrigerant 1 The This operation should permit safe re oval when inside system be made to replacing system components I and low pressure Close high valves of manifold gauge fully 2 Connect two charging hoses of manifold gauge to their respective service valves 3 Open both manifold gauge valves slightly and slowly discharge refriger ant from system See Figure AC 17 Connect hoses of manifold gauge to their respective service valves of sys Do not allow refrigerant to rush out be Otherwise compressor oil will discharged along with re frigerant and tern d ischarge Refer 3 Close utes from refrigerant Discharge System 2 When refrigerant has been dis charged to a pressure approaching at mospheric pressure connect center charging hose to a vacuum pump system of ascension of the low rate less than pressure gauge should be I in Hg in five min 2S mm Hg low pressure charging to both valves of manifold If the pressure rises negative pressure there is the or can not specified be obtained leak in the system a In this pump 4 Open low pressure valve and suck old refrigerant from See ystem immediately charge system with refrigerant and repair the leak de scribed in the following Confirm that both valves of I Figure AC 18 manifold gauge Then start fully gauge vacuum case fully closed charging are S When low pressure gauge reading then disconnect center has reached from mm Note and high b The Hg 20 in pressure valve approximately 500 slowly open high See Figure AC 19 to Hg When pressure inside system has dropped to 710 mm Hg 28 in Hg 6 of valves of manifold fully close both and stop gauge stand it state for 5 vacuum pump 10 minutes in this to confirm that and Let the reading in vacuum pump Connect center hose 2 of place refrigerant and hose vacuum to can to pump tap Attach can tap and can pass to manifold gauge refrigerant Loosen the connection of center 3 fitting of manifold gauge purge air to from center hose 4 Open low pressure valve of mani does not rise fold gauge and charge refrigerant Notes system After about 0 4 kg a The low pressure gauge reads lower by 2S mm Hg I in Hg per a 300 m 1 000 ft elevation Perform evacu ation according to the following Ib of close low pressure valve for refrigerant leakage Repair any leak Checking for with a leak detector found Refer Leaks and to Refrigerant Confirm 6 into I charged has been refrigerant into system 5 Check ages table one can that Leaks both valves of manifold gauge are fully closed and then change center charging hose from Elevation m 0 300 ft Vacuum of system mm 0 I 000 600 2 000 Hg Hg can tap to 7 Note Caution valves and operate Protect fingers the pressure in system has 26 710 low pressure gauge 25 suck it therefrom AC 12 refrigerant mm Hg 28 from in pump system Hg to When dropped to fully close both valves of manifold gauge The above operation completes Next charge system refrigerant Refer to Charging Refrig evacuation erant with cloth vacuum 27 Values show readings of the against frostbite by refrigerant when connecting the charging hose to the service valve or disconnecting pump and low pressure 68S 635 Fig AC 17 Discharging system high Open 28 7 AC735 vacuum 710 660 900 3 000 in of Air Conditioning 1 j jJ J J lJ I1 R i j J g ru AC736 Fig A C l8 Euacuating system j First step AC737 Fig AC 19 Euacuatingsystem Second step CHARGING REFRIGERANT I Install manifold gauge to system Refer to Manifold Handling Gauge Notes Be sure to purge air from the high and low pressure charging hoses b If air is mixed with refrigerant gas a in system evacuation of system should performed be Refer to Evacuating System 2 Attach center manifold charging hose of refrigerant can through can tap Break seal of refriger ant can to allow refrigerant to enter manifold gauge Loosen charging hose gauge at the center and purge hose Refer to fitting air AC738 Fig AC 20 Charging refrigerant slow of manifold gauge from water heated inside charging about Handling Can Tap 3 and low pressure Open high valves of manifold gauge and charge refrigerant to into system See Figure AC 20 immerse 400C note that is temperature of l040F However dangerous when Figure AC 21 R 121 Immerse in water Under any circumstances the refrig erant can must not be warmed in to a heated to about 400C 1040F Note that hot temperature of water is 520C l2S0F b A blow torch refrigerant charging speed in Cautions over When a can this is water heated a to water is hot See a Notes refrigerant be used to or warm stove must up the AC13 can never AC252 dangerous Fit AC 21 Heating refrigerant Air b When low pressure charging hquefied refrigerant After into the system lith the can turned upside time down it charge pressure to valve Conditioning 3 completion charging of the be turn compressor should always See ed Several times manually reduce charging only through high but not through When 5 he close fully refrigerant a Before valve can refrigerant can with one new Figure AC 22 empty Ives of manifold both gauge and replace is can to be charging opening manifold gauge charge refrigerant from new sure to purge air from inside hose Charge the specified amount of refrigerant into system by weighing charged refrigerant with scale Over charging will cause discharge pressure 6 to rise t Q UL v1ifl j AC739 Fig A C 22 ClUJrging refrigerant First step 4 If refrigerant charging down charge it speed slows Iunning the of charging After compressor for ease having taken the steps up to 3 above proceed with charging in the following order Shut off high pressure valve of manifold gauge I Caution Never back into while charge refrigerant pressure side of sys tem since this will force refrigerant through high may 2 refrigerant explode Run the engine can and can idling speeds at about 1 500 rpm Set 3 lever and the temperature fan switch at control AC255 Measure the amount of charged refrigerant with a scale Make a note of the amount charged from maximum can Fig AC 24 Measuring refrigerant cool and maximum speed respectively refrigerant while con 4 Charge trolling low pressure gauge reading at 8 kgfcm2 40 psi or less by turning 2 in or out low pressure valve of mani Refrigerant capacity fold gauge See Figure AC 23 Unit Minimum Refrigerant R 12 Note 0 7 15 lb kg Maximum 0 9 2 0 presence of bubbles in glass of receiver dryer is an The sight unsuitable method of amount of system The checking the refrigerant charged in state of the bubbles in sight glass should only be used for checking whether the amount of t AC740 Fig A C 23 Charging refrigerant AC 14 Second step charged refrigerant is small or not The amount of charged refrigerant can be correctly judged by means of discharge pressure Refer to Re frigerant Level Check Air After 7 the specified amount Conditioning Refrigerant is a colorless odorless leakage from system is diffi of I Discharge refrigerant in or one refrigerant has been charged into sys tem close manifold gauge valves Then gas and two seconds to ascertain that system cult to detect Accordingly the use of leak detector facilitates check for has detach a charging valves of system valve cap 8 to from hoses Be sure to service install checking with a leak detec tor Refer Checking for to Two methods of checking available service valve Confirm that there are no leaks in system by leaks employs one a kg I refrigerant if necessary 2 Light leak detector Adjust the height of the ilame between flame halide leak detector which burns propane gas or butane gas and the other is an electric adjusting type leak detector of combustion tube 3 Performance Test when which Dr a leak test whenever leak is of connection lines the at top and bottom plate A reaction fittings Place the end of sampling tube the point of the suspected leak in near Since the propane leak detector and butane leak detector are the same in system Notes a Since refrigerant gas is heavier than easily detect leak detector air small leaks can b The copper screen is heated by the burning of propane Refrigerant gas ed by decomposes suspected and conducting service operations are accompanied by disassembly loosening HALIDE LEAK DETECTOR respect to their operation this section describes the operation of the propane CHECKING FOR LEAKS of refrigerant with 04 will immediately become red hot Conducting a performance test prior to removing manifold gauge is ice sen a good operation Refer to Conduct needed for pressure Charge of lb are Leaks Note age sufficient a leak detection to color the flame when it contacts the heated screen placing sampling tube direct ly below the check point b Suitable ventilation is refrigerant The gas to be checked is drawn into the sampling surrounding tube and always sent out the burner to required is mixed with gas If the air leak detector will a response and detection of the actual leak will be A refrigerant leak can clearly be detected by variations in the color of the flame indicate difficult c Never bold at leak detector an angle Cautions a Never inhale the fumes produced by combustion of refrigerant gas since they are toxic b Never halide torch in use where combustible is present when there is no refrigerant gas being burned When there is ant gas leak yellowgreen age is blue 2 Copper reaction plate Flame adjusting lines 3 Burner 4 Sampling 5 Strainer AC010 tube 6 Gas bomb 7 Flame adjuster Fig A C 25 Checking for leak Pale blue SMALL LEAK Yellow Bright burned I Or Compressor Compressor shaft LARGE LEAK Purple Vivid green seal rotate the by hand plug Flexible hose connections cover and side cover gaskets Service valve 2 blue Since the color of the purple will be Rear Greenish blue refriger yellow when dust is there is aging scale on being copper reaction plate always keep the strainer of sampling tube and reaction plate clean 5 Major check points ilame Butane type NO LEAK small large the ilame will be brilliant or Oil filler type a the ilame will be green or When refrigerant gas leak compressor Propane place The ilame will be almost colorless 4 1 a explosive gas or Condenser Condenser pipe fitting Condenser inlet and outlet pipe connections AC 15 I Air 3 Piping Flared section of high pressure and Conditioning REFRIGERANT 2 LEVEL CHECK maximum low pressure flexible hose Pipe connections SIGHT GLASS rvice valve 4 Evaporator housing receiver Jnlet and outlet pipe connections ELECTRIC LEAK DETECTOR through operational procedures amount refer to the 3 Set blower 4 Check maximum speed to sight gla after the lapse is to the following table there is enough refrigerant in system is given by observing refrigerant flow Expansionvalve for glass sight However method is unsuitable for the instructions furnished with measuring level can judged be this the correct t e system pressures in cordance with the scribed judging of refrigerant The refrigerant each electric leak detector procedures by ac de Performance Test Start the engine and hold engine speed at 1 500 rpm AC741 I Amount to position of about five minutes Judge according provided at the top of dryer One guide for whether Sight glass Set temperature control lever Fig AC 26 Temperature control lever of refrigerant Almost no reftigerant Almost no difference Too much refri crant Suitable Insufficient Check item Temperature of high pressure and low pressure pipes between high pressure and low pressure side High pressure side is High pressure side hot and low pressure side is cold bubbles are seen intervals of 1 2 Almost transparent Bubbles may appear when engine speed is and High pressure side is abnormally hot is low pressure side is fairly cold warOl temperature State insightglass Bubbles flow continu ousty Bubbles will disappeu thing like a nd some mist The at seconds conditions r I AC256 High pressure side is abnormally loW Stop compressor and conduct check an M A A Repa ir seen No clear difference exists between these two is nearly gone Pressure of system be can raised and lowered will now when rerrigeran I No bubbles overall I II I AC258 AC257 and low Both pressures on high and low pressure sides are are Both pressures on high preSure sides slightly low normal Both pressures on high and low pressure sides are abnormally high Check for gas leakage Discharge reftgerant repair as required re plenish and charge from system AC 16 11 10 service valve of pressure side Air and high blower Notes The bubbles a glass seen the sight through influenced by the ambient Since the bubbles are are temperature hard show to up in comparatively low temperatures below 200C 6S0 that slightly larger amount of refrigerant would be filled if supplied according to the sight glass Be sure to recheck F it possible is a the amount when it exceeds 200C In higher temperature the 680F bubbles b Condit onin j are the When becomes dryer of pipe side the receiver considerably cold 2 compressor 2 Stop the engine and discharge refrigerant of system and then remove from the vehicle compressor Remove compressor fIller 3 plug Drain compressor oil from compres sor oil sump and measure the amount 4 the Compressor oil is satisfactory if following amount of oil remains in the compressor 6 the oz chips or clean oil 5ump with new oil Discard the used oil and fili with same amount of new oil Add oil if 5 Check for the in the system Set 6 uring pressure The correct the in range ance by side if pressure is within the For details at 1 500 rpm After the air conditioner has been S refer is Overcharging will show pressure on discharge side sure The oil used sor lubricate compres to circulates into system from the oil sump while c9mpressor is The efore correctly to operating com measure the amount of oil pressor oil flowing system must be considered If a considerable amount of leakage of to refrigerant gas happens oil compressor is the also 27 oil compressor pressor oil when or replacing any use the component part of the system following cilitates I service to return Operate idling speed com procedure This fa oil to compressor compressor 1 000 rpm at or engine below with controls set for maximum cooling of temperature Measure ambient temperature meter 3 ft away one sunlight Performance Chart If compressor is inoperative due to faulty compressor or heavy loss of refrigerant remove compressor and repair as necessary Then pour oil up to correct level and install on engine After above steps have been complet ed recheck oil drain level correct level if level is oil Notes The a pressure followi g will manner change in the with changes in conditions to When excessively high blower speed is low dis charge pressure will drop When the relative humidity of in take air is low discharge pressure will drop PERFORMANCE TEST The cooling level check is unnecessary When checking the level of grille the Measure Filler plug considered completely sealed system When system operates under satisfying the air at outlet ard pressure in leakage of a condition the temperature of dis Measure There will be no compressor oil leak age from side suction Check for any abnormalities by comparing the test results with stand Fig AC COMPRESSOR OIL LEVEL CHECK minutes 12 higher up in 10 about system pressures at high pres discharge side and low pressure measure direct specified Perform to for operated from condenser front Be careful not to expose dry buib and wet bulb to described later Test temperature control lever to and humidity the on maxi Start the engine and hold engine 11 meas discharge side amount of refrigerant lever to capin on system discharge be made control cool position 10 of refrigerant amount can Handling Manifold to fan Set charge PERFORMANCE TEST of the mum 9 found less than above amount high to Ga uge speed other foreign the hood Refer system the close Connect manifold gauge and low side service valves 7 3 to 4 Check the cleanliness of the oil If the oil contains material Open However 4 max S5 to 128 gr 5 3 of the windows the Open all fully doors to Residual oil appear even if the amount of refrig erant is normal In this case the outlet 15 oil in the receiver the bubbles will clogged is dryer to vehicle easy to show up screen for 10 speed minutes in order to return compressor performance of the air conditioner changes considerably with changes in surrounding conditions Testing correct must be performed method This test whether system is judge using is used The temperature will change in the following manner with changes in conditions When the ambient air is low the rectly in checking for problems Park the vehicle indoors guide If the in the the AC 17 reveals that there is any in system pressure isolate and repair by reference to Trouble Diagnoses and Cor cause rections shade test abnormality the or temperature the outlet air temperature will become low to operating cor and can also be used as a I b Air Condition ing REFRIGERANT LEAKS If leaks should should not are be be noticeable repaired leaky parts Then system filled with refrigerant Do operate compressor with level e loss of compressor oil If system atmosphere for has an been exposed to extended period of receiver are in system refriger cessively low If this caution is neglected a burnt compressor will result since heavy loss of refrigerant usually indicates heavy ant time If leaks To topics Here is dryer slight and add no refrigerant detect leaks be replaced must fitting has been retightened dis charge refrigerant from system discon as nect refer necessary to relative under Checking for Leaks how leaks are stopped I Check torque on the connection fitting and if too loose tighten to the proper torque Check for gas with a leak detector 2 If leakage leakage continues even after AC 18 the air is present the fittings and check its seating face for damage Always replace if damage is slight 3 even Check compressor oil and add oil if required 4 Charge for gas leaks evacuate refrigerant If no and recheck leaks are found and charge system Air Conditioning TROUBLE DIAGNOSES AND CORRECTION CONTENTS COOLING DIAGNOSES AC19 COMPRESSOR FUNCTION TEST AC 20 NOISE AC 20 BLOWER MOTOR PERFORMANCE STANDARD AC 22 DIAGNOSES AC23 DIAGNOSES AC24 DIAGNOSES AC21 PERFORMANCE TEST DIAGNOSES COOLING DIAGNOSES INSUFFICIENT COOLING I I Check amount of discharged air j No or insufficient IfOK discharged air 1 ChecK Check sight glass for bubbles I I I Many bubbles I I No or few bubbles If OK I Blower stops I I Check refrigeration line for leakage Note blower I If there are too many bubbles stop compressor and check for Refer to test on performance the following page leaks Then evacuate and Performance test recharge system I IfOK Discharge the system Evacuate and recharge lfleaks Repair leaks and recharge AC 19 Repair cooling Refer unit diagnoses to Blower motor Air Conditioning FUNCTION TEST STANDARD PERFORMANCE air conditioner The 620 has the below on TEMPERATURE the model acteristics when all systems are in Discharged Intake In the cabin performance char good Pressure air cm2 170 160C 61 OF 30C 37OF 12 kg ISoC 64OF 50C 4IOF 13 kgcm2 220C 72OF 70C 45OF 15 kg cm2 213 100C SOOF IS kg cm2 256 psi Pressure suction psi condition Compressor pressure is also indicated below 185 psi N E 24 j 23 22 270C SIOF psi 21 20 19 Note 18 Engine 17 FAN 16 TEMP 1 500 rpm 3 position Cold Max 15 14 13 I 12 u 0 6 0 5 0 40 3 0 2 0 10 20 25 30 35 40 45 Temperature of outside air REFRIGERANT PRESSURE ENGINE 1 FAN MAX TEMP Fun Cotd 500 rpm 0 a Oc 35 u Co Temperature outside Pressure 25 18 kg cm2 256 psi 1 0 300C S6OF 15 kg cm2 213 psi 2 kg 1 cm2 17 psi 350C 95OF 13 kg cm2 IS5 psi 1 4 kg cm2 20 psi 400C J05OF J2 kg cm2 170 psi 16 kg cm2 21 psi 20 IS 20 15 10 5 0 Temperature of dischuge kg cm2 14 psi 250C 77OF S 30 discharge Oc air AC 20 Air Conditioning PERFORMANCE TEST DIAGNOSES Probable Condition Discharge a Both air too warm discharge sure too Corrective action cause and suction pres Air mixed refrigerant with in Evacuate and charge system system high Overcharge of refrigerant Discharge some of refrigerant or check cooling to correct level fan Loose belt or engine over system heating b Both discharge and suction pres fan belt Adjust dirty condenser fins Clean exterior surface with water Obstructed or Insufficient refrigerant charge Add filling of compressor oil Drain oil and correct oil level refrigerant sure too low c Discharge pressure too high and Over Refer suction pressure too low to Compressor oil level check d Suction pressure too high and discharge pressure too low e compressor valve pack or ing Discharge pressure normal and suction pressure too Damaged Repair or replace compressor Refer to Compressor Loose compressor drive belt Adjust Clutch Repair Refer slippage to Compressor Reinstall sensing bulb correctly to Faulty expansion valve keep high it tight to pipe Replace pressure normal and luction pressure too low t Discharge valve strainer Clogged expansion Water has frozen at expansion Clean strainer Evacuate and charge system valve Faulty expansion g Suction pressure discharge pressure too h Both sure discharge normal and and suction pres conditioning properly Discharge air or too cold a Discharge a and h exist high normal Air Faults of both Replace valve from engine com Restricted air flow through evapo Air leaks Correct sealing partment is operating normal pressure normal suction pressure too low and Clean evaporator fins ratof Slow blower motor speed Check and repair blower motor and wiring AC 21 Air Conditioning COMPRESSOR DIAGNOSES I COMPRESSOR TROUBLE Turn the compressor dutch wheel by hand I I j If OK Will not turn I 12V direct current to compressor clutch Then check clutch engagement Apply Internal problem in compressor cylinder Repair or replace compressor I j I If OK Clutch does not engage I Check voltage oflead wire for compressor Clutch is damaged on cooler cable I Repair or replace dutch assembly I IfOK No voltage I Internal problem Repair or replace in compressor Check or repair wiring system for compressor clutch compressor AC 22 Air NOISE NOISY Conditioning DIAGNOSES I I I Set fan switch 2 Change the on engine rpm frequently Detect the source of noise I From cabin From engine compartment j Cooling unit j Check the resonant sound when the engine rpm is Blower motor makes noise changed I Replace or repair blower I No resonant sound Compressor Resonant sound itself makes noise Repeat compressor clutch ON and OFF This checking can be performed by changing engine rpm while fan switch is set at ON Noisy only when clutch is Retighten compressor bracket bolt Ifpiping is resonating add clip engaged Noisy when clutch is not engaged I Check drive belt for slackness Remove compressor belt then turn compressor Check for loose compressor mounting bolts pulley by I I If OK If loose Compressor Repair hand pressor clutch or itself makes noise replace Retighten or compressor Nl1 adjust If noise is heard repair com Air Conditioning BLOWER MOTOR DIAGNOSES Blower motor inoperative Check fuse In fuse block fuse Single 15AW cooling 15A at unit I j mown fuse IfOK Check the continuity and fitting Replace offan switch I j I If If OK Connect fan switch 2 Turn the ignition switch ON IG 3 Set fan switch at ON 1 2 or 3 Check the voltage to Voltage Replace wiring harness fan switch position grounding No voltage I I Check the continuity and fitting of resistance Replace on cooling unit I If OK I Replace I for blower motor Blue lead wire is poweI source Blue wire with white stripe is for I I damaged I I I I fuse blower motor Ifdamaged I Replace resistance AC 24 main relay Air Conditioning REMOVAL AND INSTALLATION CONTENTS AC 25 REMOVAL AND INSTALLATION AC29 REMOVAL AC25 INSPECTION AC29 INSTALLATION AC26 COMPRESSOR WIRING AC 27 MAINTENANCE REMOVAL AND INSTALLATION AC27 MAIN INSPECTION AC 27 COMPRESSOR FAN BELT TENSION ADJUSTMENT AC31 AC31 FAN RESISTOR FOR DISASSEMBLY AND ASSEMBLY AC 2B THERMO SWITCH INSPECTION AC 29 DRYER AND PIPING SOLENOID SWITCH AC32 AC32 AC 32 VALVE fixing plate high pressure flexible hoses from compressor I Remove 2 Disconnect compressor lead wire battery Loosen idler pulley lock nut then bolt Remove drive belt from compressor Y Notes a Use two wrenches when disconnect b ing pipe joints Plug flexible hose and compressor joint openings immediately after at connector adjusting D C AC31 FAN Remove flexible hose and disconnect low and REMOVAL SWITCH AC 29 5 COMPRESSOR AC31 RELAY AC 27 RECEIVER AC30 RELAY AC27 I F AC30 DIAGRAM REMOVAL AND INSTALLATION COOLING UNIT 3 HARNESS AND COMPONENTS AC 27 IDLER PULLEY WIRING compressor pulley 1 L disconnection to prevent entry of dust moisture laden air etc AC744 7 Remove four bolts securing com pressor to its bracket Compressor and attachment can now be detached as an assembly Notes a AC477 There on Fig AC 28 Removing drive belt Discharge system Refer to Dis charging System under General Service 6 section to compressor attachment with Remove bolts securing fuel AC 25 tube total of four bolts two lower side of compreSsor Loosen upper bolts and remove lower bolts When removing upper bolts 4 a upper side of bracket and two on Fig AC 29 Disconnecting ftexible hoses from compressor are securely one hold compressor hand b When installing upper bolts bolts temporarily tighten tighten lower then Air Conditioning 2 5 R C7 c L 1 PJJ Compressor Compressor attachment 2 3 Compressor bracket 4 AHernator 5 Idler pulley bracket I AC745 8 Fig AC 31 Removing compressor INSTALLATION a J c l i Flexible hose to compressor To install compressor reverse the order of removal Observe the follow e trorf 1001 nhlJo vom R ing in3 used new O blj llllt l F 1 aQ t31 Jt r1tIU ifm Cheo t oressor l9Wul CJiJi fb necessary 1 I of 3 l Ighten I l e not 210 I d l11fd J 7 V 4l di No Yl y j orflexibie use t iI f J remoV Whenever J compres r make t8 C6itiu tUa t st idie 1rJ i mV rit and adjustril 0 immediate ectioo Servic F be su I engine IJgs remove r l u re refrigerant Refer to and Evacuating Charging System under m 3U llif then with charge Gen efal f 1l before ready for beJf tension adjwt yv r 9 s 1Y h r v For a tOoling 1 b diive compressor belt and fan belt tensions refer to Ildlet cS Yt WI j Cheok refrigerant t q if leakage neces iturn sary correct Wheniiinstallingccomptess it serWfiPtiffies When W l 5 3 42 D 1i6 5 ti WIf nl lL lil g ncn d et botts if l i 1Ttio illpuntinl qqlJ M re fI 11 f 3 ltlod UfO rt 16 Evacuate cooling system Lbolts aGket r s r n al S 31U VI ra Dons 11 irlUI JIVU IQ oriti o15g fo IbP o20 iil f6i J no qqll bnM kldf rlT 013 5 undeF HClJI1f qt ft 910 es r 2 mpdi x fler ot oldm 1Ilf i Orb m n s bi2 bffik kuanM Jli oln L il 1o compressor Hw f boc 19 bB1rllo e 1 Tf l d rnl v previously owt l dlt kg J efuouiitITof b11 1fasitlult sam tiiel Oil capacity 111 0 linpt fiil Wheliqli liiAniitg witlil 6 Tightening torque rp 9mPr JU compressor joints connecting flexible hose ssor UI SlOt v a coat apD t 2JIUU l1Il 1 0 1n to of Hfresh r uOHltl fl to aHn lurfaces of 1l11 fs JJ f J PJU Ht UlUJ jJ AC26 dO I iVl 2 i wl l Twl n U l rt bnu f 1 r2 1Z2 gf ign rb nojJ 2 Air IDLER PULLEY FAN The standard compressor drive belt between 0 47 in when depressed with thumb pressure midway between the crankshaft and compressor pulleys ADJUSTMENT is and 32 0 BELT TENSION tension Conditioning 12 8 and mm If necessary turn adjusting bolt to move idler pulley up or down until belt tension is correct AC766 Fig AC 34 Removing cooling unit cover Idler 7 pulley Remove three ducts from cooling unit Crankshaft pulley AC480 AC456 Fig AC 32 Adjustment of bolt tension Note Be to loosen sure before turning it after tighten locking adjusting bolt adjustment nut 3 Re pipes to their proper engine compartment Connect low and high pressure i in positions j l 3 INSTALLATION Remove drive belt To before this do loosen locking loosening adjusting nut bolt Drive Be sure c Be careful valve 2 heat Remove idler pulley from bracket r J1evM t jiwT9ff or king nut llil reverse rerr oval jldJ the order to use two wrenches when connecting pipe joints b Plug pipe opening immediately after pipe disconnection belt will then be detached by I Notes REMOVAL AND not to break expansion wrapped with This valve is insulating tape 11 AC767 Fig A C 35 Removing cooler ducts Remove 8 cable from thermo switch control connector Remove cooling unit and bracket 9 as an assembly of 1 t Jldr J I INSPECTiON Oheck idler pulley for smooth rota tion llfHt H Y H 1 t u i dler Check W n l 0 G pulley ot l H Jrk bracket for 0 cracks J arts iffound damaged flOJ gD IlI J l gtt flvlnv nOj IH q g Replace c cll dE JWu J J m Ufl I 1 COOLING UNIT X oM1 REMOVAL AND A1lIONI INSTALl 19qm91 crft gnillslUli 3 6rn llU2 n dW C ni DiScoimecprlY ferY lgroUR hable 2 tem Disbhargiou y iRefrflsll Qis chargingrSystemiillidenGeneral S ervicel 10 9 2 fl 1U fIlO 1i 1UJ qJ j Jwm v J51d 1Ii n 2 oj liD 4q v J 8 t l2u n AC768 C765 gnjlcfu2fIJ flip 1h at 3duJ y j 1 lc rf 1551 tqnPff i2n Wfi lsIliqrJ wlrv n lIJAh Cr FIg V1c ip i irWfiqX Gl0ql f01 pj sectiom5qiq lEldgJ ld 2 1 bm m e tworgromllets from dash Remo panel lots glovelbox lBl 5 lRemove 6 Detach cooling unit AC ZA n1 oT cover r rbtivl2 H f L vehicleG bn y 2tl n fi 7 vmg emo n I1iBITJ Ofm olIJgjjJpn IIfj IOJni nectars from vorr r coo mg um 0HJ Jl t l51 l wom with five i 51 rews r Jv O a I ld f tc SH 1I J n 0 Icyom 36 R j ani qiq 1 P a8f1l1 q 1 51 nc b twonleadliwif eUcon 1 iuo s UHf QisconnecEf cooling unitqiq Conditioning Air To install cooling unit 11 I refrigerant leakage if neces repair Refer to Checking for d Check reverse the order of removal sary Leaks under General Service Notes a Apply coat of fresh compressor a sealing surfaces necting pipe joints oil to when COD Tightening torque Copper tube joint nut High pressure side 2 5 to 3 5 kg m 18 to 25 ft lb b Use two wrenches when connecting cooling pipes c o Evacuate cooling system chaJge with refrigerant Refer fo then Disconnectirt re 5 to 4 0 kg 2 see 18 3 8 in I 2 in Low pressure side Evacuating and Charging System under General Service Fig AC 37 sec tion m to 29 ft lb tion connector 3 DISASSEMBLY AND ASSEMBLY 9 00 L 1 Motor 2 Fan 3 Lower case Cooler duct 4 Evaporator Expansion valve Upper case 5 6 7 8 9 Resistor 10 Main relay Thermo switch 11 Cable 12 Cable Harness 3 c mp AC725 Fig A C 38 Disassembling cooling unit I Remove connector resistor bracket and lead wire main motor relay thermo switch etc from cooling unit Remove five screws and duct 3 Remove main relay 4 Remove thermo switch Remove three screws springs securing upper case Unfasten and five case and outlet pipes Expansion valve tightening torque can now 5 8 Remove motor and fan as evaporator remove Notes a When installing expansion evaporator make pipe Remove 10 36 ft Ib Peel heat expansion valve from evap proper To install reverse removal AG28 the order of b sure valve on that temper capillary tube is position on outlet side oensing ature orator inlet kg m an insulating tape from ex pansion valve and unfasten clip secur ing expansion valve capillary tube to lower fittings securing cases separated 9 and rear bracket 6 be Upper and lower assembly Also 2 5 7 in its Apply a coat of fresh compressor oil to sealing surfaces of pipes Air Conditioning Notes INSPECTION a Evaporator Tightening torque Apply a oil sealing to coat of fresh compressor surfaces when Flare nut for copper tube from compressor con necting cooling pipes Check evaporator for leakage or damage If damaged replace Refer to Evacuating and i8 Checking refrigerant leakage if neces sary repair Refer to Evacuating and Charging a System under General Service b When cooler disconnecting and connecting pipes be sure to use two wrenches See Apply tion to c To prevent due to I Disconnect battery ground cable Disconnect battery ground cable Discharge system Refer to Dis 2 2 Discharge system Refer to Dis charging System under General Service 3 pipes at charge joints clean condenser not Always use cold water cooling system then re refrigerant Evacuating and Charging General Service sec System under radiator explosion with Refer to and of cold compressed air d Evacuate Remove radiator grille Remove radiator shroud 5 cooling or Drain engine coolant 4 at connector do with steam section Disconnect compressor lead wire possibility con high pressure within cooling system charging System under General Service section of fresh compressor coat a oil sealing surfaces when necting cooler pipes Condenser Receiver dryer to 25 ft lb Notes d Check REMOVAL AND INSTAUATION dryer kg m sec tion RECEIVER DRYER AND PIPING Disconnect to receiver re 2 5 to 3 5 System under General Service expansion valve If damaged replace 4 then charge with refrigerant Check expansion valve for leakage clogging If clogged clean filter in 3 Flare nut for copper tube Evacuate cooling system c to 29 ft Ib i8 cooling pipes Expansion valve or 5 to 4 0 kg m 2 b Use two wrenches when connecting tion On automatic transmission models Check e disconnect both torque converter oil sary hoses refrigerant leakage if neces to Checking for repair Refer Leaks under General Service Note While cooling water is hot take precautions against scalding 6 Disconnect two pipes from con denser remove two screws securing INSPECTION RecelYer dryer Check condenser Condenser can now sec tion for refrigerant leakage or damage be removed Check for proper connection of lead wires running to pressure switch two Fig AC 39 Diaconnecting Acno If any component part ing pipes damaged replace receiver pressure switch an dryer and assembly coo as is found Notes a Plug after Condenser all piping joints immediately pipe disconnection to prevent entry of dust or into dryer receiver I and moisture laden air air aJOdi or tioning system AC485 b Use two wrenches when dIsconnect Remove receiver dryer four Notes a screws securing bracket to vehicle body and detach compressor relay and pres sure switch as an assembly 6 To piping install reverse er place parts if damaged or leaky 2 Clogged condenser fins or air sages may reduce receiver dryer and the order of removal Use two wrenches when disconnect ing pipe joints b 7 areas of with dry air Piping Plug openings immediately disconnecting pipes To install compressed pas cooling efficiency condenser Clean these ing cooling pipes 5 Fig AC 40 Removing conden Check inlet and outlet pipe joints sealing surfaces for damage Re reverse removal AC 29 after the order Check piping for occurs of at connecting persists leakage connections nuts If leakage retighten Replace if leakage Conditioning Air WIRING HARNESS AND COMPONENTS WIRING DIAGRAM J c BW BW k ii gg gg La FUEL PUMP B 1 liii J B i Ii l 1 ILLUMINATION CONTROL RHEOSTAT @ GL FROM ELECTRIC LIGHT SWITCH Id CJ L f 8W lW @ rRl I FUSE 15A D CJ B J 1 B W I o 1t Ll1 l THERMO SWITCH I I COLOR CODE J B noc i y no I jqt vi yldru 1 ao jblr 11 0 J mcl J H y B Black BW Black with white stripe L Blue LW Blue with white LR Blue with red stripe W White riC O1 GreeMnQ stripe tll G WJ1 l J stripe GL Green with blue RL Red ith blue r stripe 201011 br 2f q lH iot tH f1 1 rf l h II JI1 GH 10 lHohfth l IiJl J Jdf I hi I s n tfli Jq r i tl 19 b I J t IO wt b t Jl l JIIgiJ f 8 rj fjI i i 1I0U dj J l1 11 ltll i mflu J A jll ii l tllU lJU d 1 il I I HInO to l lo 1I l VFJ l Y1 lStO I bn llnio I J O lnl htTin I rjJ I gm 1 J Jh nI IEvUID i21 MN 11 lIno tl 0 W WIJIJJOO ni fiq held l nq LnJ JI 1 l b ns lfi j 1 fJb fI IO l vomoC Iuul l vi Jlb ia 1 tnd 15 YI W llt le ibGt L mpHO luil tldmoGl i d ni Q IGNITION SWITCH 1 f w W tflt fli r1 U If OW I QI U tsH Ub l J YR FUSE IG Jlt I IJ VUlt l0H2 tJ lUll o II nlWI i Ji IJ J ggo lUb Jl 1 m W r d t gniJuo to I TGJ w G J lIt i l f DDj i It U I t dt ll i hm o t r nG III l l lb D rbliw7 tHO 1 mtlm ljg h54 MjVj J AC727 0I pi IJC Wi1q Air When MAINTENANCE Replace wiring harness which any deteriorated cracked is in poorly or a Conditioning 12 volt d points 3 and points I and 4 2 sulated Always replace wire with those of the same diameter Do not use wire of c is applied across continuity between should also exist CD @ smaller diameter Where securely retain clips or tapes so be frayed or worn 00 necessary ID ul I CDe IDe JOO wire harnesses with they will by vibration that not @e L Notes a AC465 Repair or replace any electrical part which is questionable or likely to cause a short circuit When disconnecting battery cables always disconnect ground cable be positive cable Clean battery and terminals before connecting fore cables then connect ground Apply a coat and positive in that cable COMPRESSOR RELAY order of grease to terminals prevent rust formation Do not attempt to conduct a con tinuity test with a screwdriver or service tools always use test lead Inspection Using Removal and installation a test lamp or an ohmmeter make sure that compressor Disconnect compressor relay lead cable to b Fig AC 42 Main relay wires at connector 2 Remove two screws pressor relay securing dryer com receiver to detach compressor relay 3 To install compressor relay verse and tacts close con relay con tinuously Continuity always exists between points 3 and 4 When current flows through points 3 and 4 points 1 and reo open and flow 2 This causes current to close through 1 and 2 the order of removal wires c Do always or terminals ground not circuits use 12V lamp test a circuit tester as a when unloaded or open are 3W load MAIN RELAY v t iJ Removal and Installation The main relay is attached to the cooling unit I Disconnect battery 2 Disconnect main relay lead wires ground cable AC489 Fig AC 43 Compressor relay at connector 3 Remove Refer to cooling Removal unit and assembly Installation FAN SWITCH under Cooling Unit Remove the 4 relay relay 5 to cooling screw securing main Removal and installation unit and detach main To install main relay reverse the Disconnect Remove screws box order of removal battery ground cable securing console 1 2 Withdraw console box forward and disconnect lead wire connector Inspection To circuit meter and 4 check use a continuity test lamp in relay or an ohm Continuity between points should exist 3 3 Detach switch knob 4 From remove remove 5 rear screws side of console box securing switch and switch To install fan switch order of removal AC 31 reverse the AC771 Fif AC 44 Removing fan switch Air 5 Inspection continuiry in fan switch circuit with a test lamp or an ohm Check Conditioning Remove assembly from resistor unit Resistor is upper side of cooling inserted into case 6 install To resistor for fan switch reverse the order of removaL meter Inspection I Fully move thermo swirch lever to COLD 2 Test between continuity minals with a test tamp or ter ohm an Continuity should exist Dip capillary tube end into water Test continuity between meter 3 Inspection Test continuity between resistor and fuse ice ter minals Continuity should not exist 4 Replace if switch is found dam aged F I C D SOLENOID VALVE Removal and installation I ICD 011 I 2 THERMO SWITCH 3 Removal and installation Tt tt Disconnect battery ground cable AC772 3 Fig AC 45 Fan switch 4 Disconnect thermo switch control Removal and Installation I Disconnect battery 2 Remove glove box 3 Remove Disconnect lead wires and Installation 5 to under Remove two screws securing sole noid valve and remove solenoid valve cooling unit Remove thermo switch Note ground 3 vacu tube cable and lead wires Capillary lube is fitted into groove in cooler unit cable cooling unit Refer and 1 Remove glove box Remove duct from RESISTOR FOR FAN SWITCH Removal Disconnect battery 2 um 2 cable ground I 6 To install thermo switch reverse the order of removal Cooling Unit 4 Disconnect resistor lead wires at connector AC77 4 Fig @ AC 48 Removing lC D F solenoid valve 4 To install solenoid valve reverse the order of removal Inspection 1 3n I O sn I I Test circuit with AC492 AC773 Fig AC 47 Removing thermo switch Fig AC 46 Resistor for fan switch AC 32 lamp or an ohm on Run engine at idle and check to be sure that vacuum is present in line between solenoid valve and diaphragm 3 @ test Turn both fan switch and thermo switch 00 a in solenoid valve meter 2 CD continuity Air Conditioning COMPRESSOR CONTENTS DESCR IPTIDN AC33 COMPRESSOR CLUTCH AC34 SHAFT SEAL ASSEMBLY AC36 REMOVAL AC36 REMOVAL AC34 INSTAllATION AC36 INSTAllATION AC34 INSPECTION AC37 DISASSEMBLY AC35 ASSEMBLY AC 35 REMOVAL AC37 AC35 INSTAllATION AC37 INSPECTION CYLINDER HEAD AND VALVES AC37 DESCRIPTION Model CF206 compressor a crank light weight type with specially designed minimum size and on is for use compact vehicles The compressor crankshaft is driven by a belt from the crankshaft pulley through the electromagnetic clutch Two pistons positioned in line are actuated by connecting rods coo nected to the crankshaft and Discharge suction valves are mounted in the valve liner between the crankcase and As used a cylinder lubricant head SUNlSO NO Simplified positive lubrication utilizes existing differential between suction 5 is pressure pressure intake provide a film of lubricating oil to bearings All internal components have been designed to provide more than adequate lubrica tion to cylinder walls connecting rod bearings and seal assembly The result is improved lubrication lower seal reduced oil pumping temperatures and crankcase to and a reduction in the number AC728 Fig AC 49 Sectional view of compressor of moving parts AC33 Air 1 Clutch wheel 2 Snap ring bearing 3 Clutch wheel assembly 4 Magnet 5 6 Shaft seal assembly Service valve 7 Flange valve 8 Cylinder head 9 Cylinder 10 O ring head t7 gasket 16 Clutch 17 Compressor assembly 13 14 1 LV I 15 12 1foo 1t coil Cylinder gasket Valve plate assembly Base plate gasket Base plate Oring Oil filler plug 11 Conditioning assembly AC775 H @ COMPRESSOR @ CLUTCH 3 I most between Clearance and pulley should be 0 016 to clutch at all that there is screws electromagnetic coil Coil assembly can then be taken out easily hub 4 to 0 6 0 0 024 in Loosen four mounting likely source of problem is clutch slippage Factors are listed here Exercise ample care The Fig A C 50 Exploded view of compressor mm peripheral points 2 Make sure no oil or AC776 dirt on friction surfaces of clutch disc and pulley Remove oil clutch hub or Fig AC 51 Remouing bolt dirt with clean lint free cloth 3 Make sure magnetic coil is that terminal voltage above at 2 Bolt 5V IO Then using remove Clutch clutch Removing assembly from cmnkshaft Fig A C 53 Removing magnetic clutch INSTALLATION REMOVAL I Using Clutch hold clutch hub wrench remove Spanner Locate the Wrench the With suitable socket bolt correct housing retaining clutch electromagnetic position Then coil at on secure compressor four electro magnetic coil mounting screws hub to crankshaft Tightening torque Electromagnetic coil mounting screws Fig AC 52 Removing clutch AC34 0 7 kg m 1 ft Ib 5 Conditioning Air Install the clutch assembly 2 on the crankshaft ST02371000 Key should be set on crank shaft before installing clutch assem bly Note 3 Clutch Using Spanner Wrench With socket wrench hold clutch hub secure 9 clutch hub securing bolt Tightening torque Clutch hub securing bolt 5 1 kg m II AC502 clutch DISASSEMBLY They are Fig A C 57 Installing bearin 2 Remove two snap 1 bearing AC503 Fig AC 56 Removing V pulley from ft lb rings retaining Using Installer KV99100610 and Stopper ST33061000 press clutch wheel into V pulley 4 Install inner snap ring in groove 3 located inside of clutch wheel Install outer snap ring in groove of V pulley ASSEMBLY Press bearings into V pulley with Bearing Installer ST02371000 I of clutch wheel AC500 Installer t Fig AC 54 Removing snap rings 2 Using Clutch Wheel V pulley with Stopper ST33061000 AC504 Remover KV99100700 and conventional remove KV99100610 2 puller bearings from Fig AC 58 Installing clutch wheel clutch wheel INSPECTION Check friction surface of clutch for damage due to excessive heat grooving due excessive necessary V KV99100700 pulley replace as a to slippage replace Fig A C 55 Removing clutch wheel bearings Using Bearing 4 to 0 6 0 clutch wheel bly 3 pulley Remover ST33061000 press clutch wheel bear ings out from clutch wheel AC 35 Oil or assem dirt on friction surfaces of clutch wheel and V pulley should be cleaned with a clean lint free cloth or suitable solvent Check coil for shorted or opened lead wire Pay particular attention to grounding part of coil If there is no continuity 0 016 to 0 024 in If not AC501 3 4 set and clutch wheel should be mm If clutch wheel and The clearance between V 2 or coil replace electromagnetic Air Conditioning 3 jpL Y L i 0 I I I Push seal assembly except carbon over end of shaft with carbon ring ring retainer 4 Move seal on facing out assembly into position shaft 0 Ace07 wft Fig AC 61 Removing s key AC506 Fig AC 59 Grounding point of coil 4 Remove seal 1 plate I 5 If clutch assembly must lie re placed remember that break in opera Fig AC 64 Inserting wft ass tion is necessary The break in opera tion consists of engaging and disengag 5 the clutch some tirty times ing so The yet tight of a sealing AC80e of this simplified design long lasting and 5 With the pull out seal Compressor Seal gland and discard Puller a REMOVAL It is recommended that the for shaft seal I com Remove replacement oil filler plug with D lugs and be firmly seated in Install seal not use a re new D ring in groove of plate Note screwdriver to pry shaft seal from shaft as damage to Use refrigeration oil to make it adhere to surface 7 Space seal around ance plate with equal clear and shaft insert cap screws shaft may result ring 6 Discard all parts of the seal includ ing the O ring b Do removed from the vehicle edge driving tainer Fig AC 62 Removing seal plate Notes pressor be The indentions in outside of carbon ring must engage shaft seal assembley compressor is Place carbon ring in ring retainer lapped surface is facing outward Note SHAFT SEAL ASSEMBLY al mbly 8 and drain the compressor oil Tighten these screws Tightening torque Seal plate securing 0 7 to 1 0 kg evenly cap screws m 5 to 7 ft Ib AC809 Fig A C 63 Removing wft s eal Fig AC 60 Removing filler plug 2 Remove clutch Refer to Com pressor Clutch Removal 3 Remove shaft key INSTALLATION AC811 Fig AC 65 8pcing 01 plate and tightening cap screws 1 Clean shaft and seal cavity with clean lint free cloth 2 Dip seal gland in clean oil refrigerant 9 Install clutch Refer pressor Clutch Installation AC 36 to Com Air Conditioning INSTALLATION INSPECTION Check for gas leakage Plug high and I on 2 as Valves and valve plates follows low pressure ed joints I compressor with blind caps Connect charging hoses in lines between manifold gauge and high low pressure service valves Connect refrigerant can eration oil plug AC813 at head Fig A C 6 7 Removing cylinder side of compressor to purge air out of compressor 4 shaft Turn 5 or 6 turns that confirm pressure low pressure Then does not gauge If indicates a gauge pressure decrease there is a leak Conduct a leak test decrease on Under such then install a condition remove and bolts Remove 3 valve plate cylinder by prying from under of crankcase to be the and or plate oil to top and bottom valve to be covered by gaskets areas head tapping which extend ears eration from valve plate If head and valve plate adhere hold and tap valve plate head from head with parts again on area by cylinder gasket 2 Place cylinder gasket in position on cylinder so dowel pins in crankcase go through dowel pin holes in cylinder gasket 3 Apply a thin film of clean refrig to middle filler furnish covered and hose of manifold gauge 3 Open valve of can tap and charge refrigerant Loosen oil are only as a complete assembly Apply a thin film of clean refrig Do Note not ears away soft hammer a hit or tap head to separate head and valve plate be 3use damage to head may result CYLINDER HEAD AND VALVES Insufficient refrigerant compression by damaged head valves damaged gasket Prior to servicing the head and valve plate both service valves should be is likely to be caused or opened AC816 Fig A C 70 Applying clean refrigeration oil to free any gas pressure which may be in the compressor Fig AC 68 Removing valve plate REMOVAL I Remove and head the bolts from flanged type service valves using Torx Driver Bit 4 When removing the gaskets sharp edged Note The direction of flanged type service valves should be noted for reinstallation use a cylinder gasket ie semblies Notes a Place valve 4 knife removing head gasket be very careful not to damage machined In sealing b Do not reuse smaller diameter blies with restrainer are go surface in position discharge valve plate so facing up and through over valve on as assem reed locating dowel pins dowel pin holes in valve plate gaskets AC812 Fig AC 66 Removing service valves 2 Remove the head the remaining bolts AC815 in Fig A C 69 Removing gasket AC37 Fig A C 71 Placing valve plate Air 5 Place head gasket in position valve on dowel plate pins go through dowel pin holes in gasket 6 Apply a thin film of clean refrig so eration oil on the machined surface of cylinder gasket 7 Place gasket so head which head on matches head cylinder head dowel pins go into dowel pin 8 Apply Conditioning a thin fihn of clean eration oil to service valve 9 refrig flanges Place flange valve O ring in posi tion on cylinder head 10 Place service valves in position on proper service or discharge screws valve ports suction and insert two longer through service pads head valve plate holes in head AC 38 valve mountiing and into crank case 11 Insert remammg head screws screws until the heads and run in all make contact Tightening torque Head and service valve 2 1 to 3 2 15 kg m to 23 ft lb screws Air Conditioning SPECIAL SERVI CE TOOLS For Tool number Description No tool use Unit name KV99100700 To remove clutch wheel from V mm in pulley Reference page or Figure No 620 Fig AC 55 620 Fig AC 58 620 Fig AC 56 620 Fig AC 57 on Clutch wheel remover BE436 2 KV991006S0 To install clutch wheel into V pulley Clutch wheel 38 1 50 1 installer set KV99100610 Installer ST33061000 Stopper BE437 3 ST33061000 To remove clutch wheel bearing from V pulley Bearing 38 remover 50 1 BE438 4 ST02371000 To install clutch wheel bearing into V pulley Bearing installer 50 1 96 Co tJ AC 39 BE439 Air Conditioning Tool number For Description No tool 5 Unit name Clutch use mm in To hold clutch wheel when removing clurch wheel on Reference page or Figure Remarks No 51 620 Fig AC 620 Fig AC 52 126344 620 Fig AC 63 J 10549 620 Fig AC 66 124878 1 spanner wrench BE440 6 Clutch removing To remove V pulley from crankshaft bolt BE441 7 Compressor seal puller To remove shaft seal from crankshaft BE442 8 Torx driver bit To remove flange bolts 124392 B E443 9 Oil dip stick To inspect oil level 620 BE434 40 AC 110545 SECTION SE SERVICE EQUIPMENT DATSUN PICK UP MODEL 620 SERIES SERVICE EQUIPMENT I NISSAN I NISSAN MOTOR CO TOKYO LTD JAPAN SE 2 Service Equipment SERVICE EQUIPMENT GENERAL DESCRI PTION CLASS REMARKS Indicated in this column Special Tools role play in the maintenance These are rate and important very of vehicles essential to the safe ftg1lles in As classi accordance with regards special tools which are also applicable to models other than those Classification of Speciai Tool accu ith dealt coluITUl U inual m this those names this other models speedy servicing The working times listed in the col RATE TIME in umn under FLAT FLAT RATE puted fication are based SCHEDULE the on use are CLASSIFICATION OF SPECIAL TOOL com Classification of Special Tools General Important The identification code of mainte nance betical tools is made up of 2 Inspection I alpha and minor repairs 4 letters and 8 digital figures 11 The heading two letters roughly classify tools or equipment as fol General Ill Special disassembly lows and disassembly and assembly 2 5 assembly 3 6 A Important STOOOOOOOO 11 Special Tool a Exclusive with no alternative Tool b Parts will be KVOOOOOOOO Special EMOOOOOOOO Recently established Engine Overhauling damaged if repaired without special tool General Gauge HTOOOOOOOO Hand Tool B General I HOW TO READ SPECIAL TOOL LIST a b c Disassembly such To facilitate and assembly as engine transmission and differential a Machine GGOOOOOOOO disassembly 111 Special disassembly and assembly Gauges c General General disassembly such as of exclusive parts automatic transmission and electrical accessories servicing b Special work such Inspection and minor repairs Inspection and maintenance Unit replacement Minor unit disassembly as boring and welding c Work very rarely required APPLIED VEHICLE OR UNIT In this column word for tools applicable All is given to all vehicle mod els and unit types treated in this manu al for tools applicable only to particu lar models models or or unit units types those are vehicle indicated SPECIAL TOOL SET See attached tool list The is put in newly added tools this column shows for and body regard new and through 77 620NA KV00102000 This set is X available other dealers who must go initial preparation SET NEWLY ADDED set designed for the chassis of the 620 models without to their destination SE 2 SET 3N71B KV0010l000 This set is designed for use on the 3N71B automatic transmission It con sists of the same service tools as those previously available separately Service Equipment TOOL LIST ENGINE TOOL Tool Name Tool Number ST050 I SODa tST05011000 ST050 I 2000 Newly added 5 Engine stand assembly Engine Remarks Class FIO B2iO 610 710 S30 stand Base ST05260001 Engine attachment 5 610 710 STlOl20000 Cylinder head bolt wrench 2 610 710 S30 STl 0640001 Pivot adjuster I 610 710 S30 KVIOI039S0 Valve guide FiO B210 610 710 reamer STl1081 000 Reamer 12 2 STl1032000 Reamer 8 0 STl1320000 Drift 480 0 mffi mffi 3 set in dia S30 J 0 315 in dia STll650001 Valve seat cutter set 2 610 710 S30 STl2070000 Valve lifter 5 B210 610 710 S30 STl3030001 Piston pin press stand 2 610 710 S30 STl53 10000 Crankshaft 2 610 KVI01041S0 Crankshaft main bearing cap puller 2 610 710 S30 rear oil seal drift KVIOI04110 Crankshaft main bearing puller STl6512001 Adapter STl6701001 Adapter 710 S30 STl6610001 Pilot bushing puller 3 610 710 S30 STl7420001 Chain stopper 2 610 710 S30 STl9320000 Oil filter wrench STl9870000 Air pump test gauge STl98 10000 Hexagonal wrench 3 FIO STl9890000 Rotor adapter 2 FIO B210 610 710 STl9900000 Dummy shaft 2 FIO B210 610 710 STl99 10000 Bearing drift 2 FIO B210 610 710 STl9920000 Rotor stand 2 FIO B210 610 710 STl9930000 Bearing adapter 2 FIO B210 610 710 ST I 9940000 Bearing pressing tool 3 FIO B210 610 710 EM03470000 Piston ring compressor 2 FIO B210 610 710 S30 FI0 B210 610 710 SE 3 B2iO 610 710 FIO B210 610 710 S30 Service CHAssis AND BODY Equipment TOOL Applied No Tool Name Tool Number Ser 17 620NA Newly 1e vehic or unit Class Remarks added KYOO 1 02000 Clutch 2 5Tl 66 1000 I Pilot bushing puller All X 3 610 710 530 KV30100200 Clutch aligning bar All X 2 610 710 530 5T200500 10 Base plate All X 5 B210 610 710 530 5T20050100 Distance piece All X 5 B210 610 710 530 5T20050051 5et bolt All X 5 B210 610 710 530 5TZ0050240 Diaphragm adjusting All X 5 B210 610 710 530 GG943 10000 Flare nut torque wrench All X 2 5TZ2360002 DriftC All X 2 5T23540000 Fork rod pin punch All X 2 5T23800000 Transmission adapter All X 5T23810001 5etting plate adapter All X 5 530 5T22520000 Wrench All X 2 B2iO 530 5T23860000 Counter gear drift All X 2 530 KV311 00400 Transmission press stand All X 5 530 5T30031000 Bearing puller All X 2 KV32101330 Bearing puller wrench FIO B210 610 710 530 Manual transmission 3 B21O 530 FIO B210 610 710 530 2 FIO B210 610 710 530 FSSW71B X X FIO B210 610 710 530 2 B21O 530 Differential ST063 I 0000 Diff attachment All X 5 610 ST31530000 Drive All X 2 B210 610 710 S30 ST3306S001 Diff side bearing All X 2 610 S30 All X 2 610 S30 All X 2 610 All X 2 610 pinion flange wrench ST33051001 Puller ST3306 I 000 Adapter ST3090S000 Orive pinion rear puller bearing inner race replacer ST30031000 Puller ST30901000 Base ST33230000 Diff side bearing drift ST3194S000 Drive pinion setting gauge ST3l941000 Height 5T3l942000 Dummy shaft ass y gauge SE 4 Service Equipment Applied No Tool Name Tool Number ST30611000 ST30613000 ST3062 1000 KV311 00300 4 5 6 7 Drive pinion outer race drift bar Drive Solid unit pinion race outer race 610 X 2 610 X 2 drift adapter 610 X 2 drift adapter 610 X 2 610 710 S30 All X 2 B21O 610 710 S30 All X 2 610 All All All Preload gauge KV381025S0 Oil seal Remarks 2 All punch ST3127S000 Class fitting tool KVOO 102000 X All Collar Drive pinion outer Newly added or ST31970000 Ser 77 620NA vehicle Front axle ST35380000 Kingpin bushing drift All X 2 HT56802000 Kingpin bushing All X 2 ST36070000 Transverse link All X 2 ST35390000 Kingpin grease seal drift All X 2 ST38020000 Bearing lock All X 2 KV40101000 Rear axle stand All X 2 B210 ST36230000 Sliding hammer All X 5 B210 610 710 S30 HT72480000 Rear axle shaft All X 2 B210 610 710 S30 All X 2 B210 610 710 S30 reamer bushing replacer Rear axle nut wrench bearing puller 610 710 S30 Steering ST2902000 I Pitman arm ST27 180001 Steering wheel puller All X 2 HT72520000 Ball joint All X 2 ST3127S000 Preload gauge All X GG943 10000 Brake pipe torque wrench All X 2 B210 610 710 S30 ST08060000 Master Vac oil seal retainer drift All X 3 B210 610 710 S30 ST08080000 Master Vac wrench All X 3 B210 610 710 S30 puller remover FIO B210 610 710 S30 FIO B210 610 710 S30 FlO B210 610 710 S30 Brake SE 5 Service Equipment AUTOMATIC TRANSMISSION TOOL Applied Tool Number Tool Name Transmission ST2505S001 Oil pressure gauge ST25 I 60000 Newly Class added or ST07870000 Set 3N71B vehicle unit stand All X 3 set All X I Torque driver All X 3 ST2532000l Snap ring All X 3 ST25420001 Clutch spring compressor All X 3 ST25490000 Socket extension All X 3 ST2557000l Hex head extension All X 3 ST25580000 Oil pump All X 3 ST25850000 case remover assembling gauge Sliding hammers All X 3 GG930 I 0000 Torque wrench All X 3 HT6 I 000800 Hexagon wrench All X 3 HT62350000 Spinner handle All X 6 HT69860000 Snap ring All X 3 remover SE 6 Remarks KVOOlO1OOO 8210 610 710 S30 WIRING DIAGRAM IIIITSlDl AI ij L rn H r I i jil 11 rC IJ 11 J Jl o Il r 1 i 1 W U U fl Eel I 1 c 1 it rU T LillI QbJ 1I0Nr@J l a F j I i vIII FF l SE Joftl O tn I Mji C i II i L ml b WJ l i L L r Alr tl SfJ l C CAlIrCl I IA 1l0nfl i B I D f OUIOD 1 g H g WJ H l 1l00ELS W TlIl IIl ATIO E Jr ONlJ P 1 r I 1 1 j i L IIIPH I J M 1GHl JILlUMINAlION Rl lllU CON l r L l IM 1I0N OllH OS Jl JlI lllltlUlAII 11lII1T lDTF w d1 EI fH on 1 1II0NS LOlTGllI1 IURf l T SOlENOID r 1 g I II fn r rmn y NOI0 r Ulltlt UIl lfT l l MNIMG V l rUSE TilBlJ101 Ih w n 1 P IOCI t LI 3 1 t w 1S1 IDA iGI 151 E iElr ISA iO I CT e IIlAL ORIlAl ttOSlO l FIJrNIA OIHAur 1 ll lI l 1l00m F S II r OIlATlt HOUIUlTON ll HAAAD cP ISIQIj U fLAlI lllOI r 1 I I lSII CIlIr ll1t I P tlII till lSII WI aM ItlII PI I lo 1 lIool ts lo lli to a bo 1Jo UilTIOllS I TlOIswntH IIO wd rL llO SMI ItlUlCIJIjQIlICJO 1 o e COIl CCNlEClD 11 I l Ct lW C tlKlI JII tTD lIOC l f I ll l l J I 11 i Dill I t IlJi J lI CALlFO QlI L1CE J MI i 11 L mlSl II1 ICOIL IQCl TIO r L I 0 Ol J1J1 IlCl lJP II 1 1 JI 1171 r i J J 1 l J IIL J w Ull VLA1II rt P L lI1 SIST ITIO COll I I rL II J L I Ct SIOE llC I lAIIl i t G D in 0 @ Ii r J T I 1 1 I S Fll Gl @ I l r I mB M OISlATIO l U W1 IT I MhROlP IW 1 li 0 l 1 IllUMINJflON l J t JV L l W UFo1 f u I J I I t nrr nil fflI CC i Ir ii II 1 M O Q M L I E rBtr irK I rmIw E n l J l e o J lPUMP I E d t 1 IIO aU tie e w UNIT 1AN L 1 f E i JJ It 1 P J L E 3 k It O t 1 l ii ii l J I I r l 5 L C jro J r i h III I L 1 t T o GAUGE i rElI i IIrTllI oiiil o SWITCH MTlIlGSWlICH U lUUlJlXtlftO lIOOISQ DllO I Il Ult ll TI Wl UAllD LNISSA NISSAN MOTOR CO J LTD Tokyo Japan L sued September 1976 070795 Printed in Japan Publication No SM7E 0620liO t