A Reproduced

Copy

OF

Reproduced

for NASA

by the

NASA

FFNo 672 Aug 65

Scientific

and

Technical

Information

Facility

"l

r

I

DESCRIPTION

By

.:

. .Lu

OF

STRESS-STRAIN

Walter

Ramberg

CURVES

and

William

BY

THREE

R,

PARAMETERS

0sgood

i

SUMMARY

A simple

formula

is suggested

for describing

the

stress-strain

curve

in terms

of three

parameters:

namely,

Young_s

modulus

and

two secant

yield

strengths.

Dimensionless charts

are derived

from

this

formula

for determining

the stress-strain

curve,

the tangent

modulus,

and the

reduced

modulus

of a material

for.which

these

three

parameters

are given.

Comoarison

with

the tensile

and compressive data

on aluminum-alloy,

stainless-steel,

and carbonsteel

sheet

in NACA

Technical

Note

No. 840

indicates

that

the formula

is adequate

for most

of these

materials.

The

formula

does

not describe

the behavior

of alclad

sheet,

which

shows

a marked

change

in slope

at low

stress.

It

seems

probable

that

more

than

three

parameters

will

be

necessary

to represent

such stress-strain,

curves

adequately.

INTRODUCTION

,_ _ ....

: ....

. .:= _

,q..

An assembly

of the tensile

and compressive

stressstrain

.curves

for sheet

materials

characteristic

of aircraft

construction

is being

obtained

at the National

Bureau

of Standards

as the principal

objective

of a research

project

for the National

Advisory

Committee

for

Aeronautics.

Stress-strain,

stress-devlation,

secantmodulus,

tangent-madulus,

and reduced-modulus

curves

have

° been presented

in reference

1. for various

grades

of sheet

materials

of aluminum

alloy,

carbon

steel,

and chromiumnickel

steel.

A second

objecti_e

of the

same research

project

is a search

for yield

parameter,a

that

give

a better

description

of the

stress-strain

curve

than

those

in use

at present.

The conventional

descripti-on

of

the s.tress-strain

curve

of metals

by the

two parameters,

Young_s

modulus

and

yield

strength,

iS .inadequate

for

the efficient

design

of

members

unless

the material

follows

Hooke's

law up to. a

2

"_/•

NACA

Technical

Note

No.

902

/.k

-

yiel_

point

at which

it yields

indefinitely

under

constant

stress.

This

special

behavior

is approached,

for

example,

by certain

steels

(fig.

l) and

by

certain

low-strength

magnesium

alloys,

but

it

is not

characteristic

of many

high-strength

alloys

for

aircraft.

p._

r

alloy

_

Examination

sheet

and

of the

stress-strain

chromium-nickel-steel

curves

sheet

for

given

aluminumin ref-

erence

1 shows,

particularly

for

the

compressive

stressstrain

curves

(figs.

2 and

3),

a gradual

transition

from

the

elastic

straight

line

for

low

loads

toward

the

horizontal

line

characterizing

plastic

behavior.

The

type

of

transition

varies

widely.

Hence

there

is no

hope

of reducing

all

stress-strain

curves

to a single

typ_

of curve

by

uniform

stretching,

or affine

transformation

of coordinates.

This

rules

out

the

possibility,

which

exists

for

affinely

related

stress-strain

curves

(reference

2),

of complete

description

in terms

of only

two

parameters,

Youngts

modulus

and

secant

yield

strength.

A minimum

of three

parameters

will

be

required

to describe

the

changes

in shape

for

different

materials.

i _

Several

proposals

have

been

made

stress-strain

curve

in terms

of

three

Donnell

(reference

5)

suggests

as

two

the

stresses

s I,

s_,

strain

curve

is equal

Young_s

modulus.

The

at which

to 3/4

E

stress-strain

the

and

for

describing

the

or more

parameters°

yield

parameters

slope

1/4

curve

of

E,

is

the

stresswhere

_

is

then

derived

from

these

two

parameters

on

the

assumption

that

the

slope

varies

linearly

with

the

stress.

This

procedure

gives

a good

descriotion

of many

tensile

stress-strain

curves

of aluminum

alloys,

but

it does

not

seem

adequate

for

the

highly

curved

tangent-modulus

curves

found

for

the

compressive

stress-strain

properties

in reference

l,

from

which

figure

4 is

taken.

Furthermore

there

are

practical

sponding

quickly

difficulties

in determining

to

a tangent

modulus

of

8/4

from

the

stress-strain

curve.

Esser

stress-strain

and

Ahrend

curves

the

stresses

E

and

1/4

(reference

4)

noticed

for

many

materials

may

correE

that

the

be

approxi-

mated

by

two

straight

lines

when

they

are

clotted

• on loglog

paper.

They

orooosed

to

define

yield

strength

as

the

stress

at

the

intersection

of these

two

lines.

Description

of

strength

_ould

straight

line.

the

description

....

•

................................

the

stress-strain

curve

above

be

obtained

from

the

slope

of

The

proposal

is doubtless

an

by

an

offset

yield

strength.

.

•

.

.

................

the

yield

the

upper

advance

over

It has

the

NACA

..<

-

-

Technical

Note

No.

902

3

disadvantage,

however,

of requiring

the plotting

of sufficient

stress-strain

data

on log-log

paper

to determine

a straight

line

through

the points.

Furthermore

it gives

no informationabout

the shape

of the

important

transition

region

near

the intersection

of the two straight

lines.

c

• i_

¸.

,i

An analytical

expression

which

is suited

for theoretical

ling was proposed

by Nadai

in

expression

is

for the

stress-strain

studies

of plastic

1939

(reference

5).

-\

e = Ese

=

s'<

.....

S

ey-

>

Sp

s-

Sp

[

curve

buckThe

(i)

/

where

e

strain

s

stream

ey

strain

Sp

n

corresponding

proportional

to

yield

strength

Sy

limit

constan_

If the iogarithmof

both

sides

is

taken

in equation

(_),

it can be seen that

equation

(1) approaches

Esser

and

Ahrendls

two straight

lines

as asymptotes

for low and for

high

stress,

respectively.

The description

of the

transition region

is obtained

by increasing

the number

of parameters

from

three

to four.

k :i

In the

study

of plastic

bending,

the second

author

found

an analytical

expression

containing

three

parameters

that appeared

to be well

adapted

for representing

stressstrain

curves.

Further

examination

of the exoression

in

the light

of the data

given

in reference

1 confirmed

this

view.

I

4

NACA

Technical

ANALYTI

CAL

Note

EXPRE

Stress-Strain

No.

902

SSI ON

Curve

: • !ii

•ii

The

proposed

analytical

expression

E

where

becomes

K

and

the

n

same

is

(2)

•

are

constants.

as

equation

(2)

Sp=

Nadaits

if

expression

(1)

0

(3)

ey

that

the

is,

if

the

requirement

spond__ng

form

to

proportional

is

a

dropped

yield

The

expression

in terms

of

_

stress

the

=

K

limit

that

is

ey

taken

is

as

the

zero,

and

strain

corre-

dimensionless

(reference

6):

Sy.

(2)

may

be

follo_ving

written

variables

in

S I

(4)

S 1

J

,

•

r._

where

ordinate

of a

(fig.

Since

reduces

single

curve

sI

line

5),•

is the

secant

yield

strength,

equal

to

of the

intersection

with

the

stress-strain

through

the

origin

m I

being

a chosen

m I

is fixed,

all

affinely

curve.

The

abscissa

described

by

having

a

constant

slope

,

0

the

transformation

related

stress-strain

of the

intersection

equation

(2)

is

<

equal

ml <

(equation

curves

for

a

the

curve

to

i.

(_))

to a

stress-strain

m I

E

NACA Technical

ei

Note No. 90_

5

sl

-

+

mE

(5)

K

E

1

Inserting

equation

(4)

in

equation

Sl

From

equation

)n-I

gives

(6)

n

(5)

n-i

K

Inserting

(2)

V

equation

I ml

-

(7)

in

equation

i

= a +

(7)

mI

--

(6)

m I

gives

an

(8)

m I

f

Affinely

related

stress-strain

curves

that

by

equation

(8)

are

characterized

by having

of

n.

Figure

6 shows

a family

of

curves

different

values

of

n,

and

m I = 0.7.

Stress-Deviation

The

- ,. "-

stress-deviation

stress

against

elastic

strain

stress-strain

is

given

Curve

curve

difference

corresponding

curve

given

may

be described

the

same

value

for

a number

of

is

obtained

by

plotting

between

measured

strain

and

to

Hooke's

law.

For

the

by

equation

(2)

the

deviation

d

by

d

=

e-

s_ =

(9)

K(S

E

\ _,J

or

. -

.

",L

log

that

is,

a log-log

be a straight

line.

sionless

form

as

d

=

log

K

+

plot

of deviation

The

deviation

6 - Sd

S

1

nlog

s_

E

(I0)

against

stress

would

may

be written

in dimen-

(ll)

6

From

NACA

Technical

(9).,

(4),

equations

Note

90,2

No.

(8)

and

-

n

m1

or

1

1

log

8

=

-

m 1

log

+

nlog

G

(13)

m I

The

family

values

of

of

straight

n

and

lines

to

mI

=

corresoonding

0.7

Tangent

the

The

slope

that

from

tangent

of the

stress.

equation

modulus

tangent

is

to

shown

in

various

figure

7.

Modulus

at

to

a given

stress

the

stress-strain

The

reciprocal

(2):

of

the

is

tangent

defined

curve

modulus

as

at

is

! = __ = 1 + nK shn

E,

d.

{

{]

This

may

be

of

equations

written

(7)

and

in dimensionl'ess

(4):

E = 1 +

-

- m_ )

E I

ml

the

tangent-modulus

form

by

making

use

c n-l

(15)

k

Figure

8

against

shows

stress

ratio

Reduced

..,..

-

n(1

(.14)

•

_,

Modulus

ratio

with

for

mI

=

E'/E

plotted

0.7.

Rectangular

Section

.

•k

The

exceeds

(reference

ulus

columns

mated

E

reduction

the

by

the

in

proportional

7, pp.

159

a

reduced

actual

buckling

stress

limit

and

274)

is

by

modulus

E r.

buckling

stress

when

the

frequently

replacing

Thus

sr

stress

estimated

Young's

modin

the

would

case

be

of

esti-

_

as

sr

_

-

Er

-E

se

(16)

•

i_

_ _

NACA

wh,ere_

se

is

the

Technical

Note

buckling

stress

theory

and,

for

columns

from

reference

8,

of

Er

No.

comouted

rectangular

=

equation

(17)

_EE'

by

E

mr =

Figure

9

against

shows

the

stress

with

mI

=

(16)

Let

gives

4E '/E

a

may

(_e

(18)

for

ratio

different

be

=

solved

Er/E

values

Se

--;

for

(_r --

S1

that

(17")

plotted

of

n

and

0.7.

Equation

so

elasticL

section,

2

reduced-mo'dulus

ratio

from

crGss

(4_ + Jgr)

Dividing

902

equation

(16)

Er/E

as

follows:

(19)

Sr

Sl

becomes

Or

Er

(20)

(_e

Thus,

the

desired

intersection

of

reduced

(n)

in

1/(_ e

with

modulus

question.

may

the

DERIVATION

The

on log-log

materials

a straight

be

Er/E

EMPIRICAL

on

the

is

line

conveniently

point

adequacy

paper

given

line

of

straight

curve,

equation

Straight

lines

drawn

proper

OF

value

the

E

(18),

w.ith

by

ordinate

=

O/(_ e

for

the

FROM

curve

of

with

the

the

the

material

given

slope

connecting

circular

CONSTANTS

the

Er/E

the

in

STRESS-STRAIN

origin

figure

9.

CURVE

of

equation

(2)

was

tested

by plotting

the

stress-deviation

curves

for

the

sheet

in reference

1.

The

points

should

lie

on

according

to equation

(10)

if

equation

(2)

r

i

8

is

r

•

!

3

NACA

an

accurate

From

the

constants

Technical

Note

description

slope

and

K

and

Straight

stress-deviation

of

intercept

n

can

be

lines

were

curves

No

the

stress-strain

of

such

de_ermined

obtained

and

for

902

a

curve°

straight

for

a

line

the

best

fit.

for

all

the

compressive

all

but

four

of the

ten-

sile

curves

for

stresses

greater

tlian

the

stress

at which

the

secant

modulus

was

equal

to 90 percent

of Young's

modulus.

The

exceptions

had

stress-strain

curves

which

had

a gradual

change

of

slope

throughout

their

entire

length.

Thim

indicates

that

any

value

of

mI

0.90

would

give

an

approximate

fit

to compressive

Strain

curves

and

to most

tensile

stress-strain

at

stresses

It

such

mate

above

appeared

that

the

the

widely

that

corresponding

desirable

secant

used

offset.

In

other

appr o ximat

ely :

to

_'eld_

yield

choose

strength

strength

words,

sI

should

mI

=

the

value

than

stresscurves

0°90°

of

mI

sI

would

So. s

for

approxi0.2--oercent

be

to

chosen

satisfy

s

o.oo2 = e-

_!

i i_? _

; ....

to

less

(21)

E

[

where

(see

fig.

5)

e

S 1

-

(21a)

miE

inserting

1/m I

equation

(21a)

in

equation

(21)

and

solving

for

gives

r

1

--=

0.002

I

-

ml

Examination

ues

of

of

1

+

sl/E

tables

so.e/E

nickel

steels

1025

carbon

0.002

+

for

III

the

and

IV

aluminum

which

ranged

from

steel

in reference

of

its

relatively

value

was

low

_--

(21b)

So.alE

value

of

of

reference

alloys

1

and

1

the

gave

0.00258

to 0.00675;

was

not

included

this

ratio.

The

val-

chromiumthe

because

average

S

= 0.00486

(21c)

E

Substituting

for

mI ,

this

gives

average

_n

equation

(Ylb)

and

solving

"

.

• • "

,

L

•

.

NACA

Technical

No

Note

" 902

m I = 0.709

.. ..: .j:!

It

was

decided,

therefore,

to

(21d)

use

for

ml

the

value

m I = 0.7

for

determining

the

secant

(22)

yield

strength

s I.

W_nen

E

is known

and

sI

has been

determined,

it

is still

necessary

to know

the

shape

parameter

n

in

order

to establish

the

shape

of the

stress-strain

curve

according

to equations

(8) and

(4).

The

shape

parameter

n

is conveniently

the use

of a second

secant

yield

strength

sponding

to a second

secant

modulus

rosE,

In analogy

to equations

(5) and

(7),

e s -.

-

+

msE

derived

by

s2, correas follows.

(23)

K

E

•i

._-=

m 2

.

k

Solving

both

equations

(24)

z +z(,,.

(7)

and

(23)

for

K

gives

1

,; C<-,)

so

(25)

that

_i__

1

(26)

_h- l

m I

Solving

for

n

gives

m_

I-

mI

log

n =

1 +

mI

.......

log

1-m

s-kl

sm

s

(27)

l0

NACA

The

was

value

chosen

of

as

m s

Technical

for

the

second

=

ms

since

since

m =

tion

Note

up

most

Substituting

gives:

to

of

secant

(22)

(2)

=

1

is an

curves

(28)

=

+

in

1

relation

--

COMPARISON

_ITH

AND

The

describes

ues

to

of

13,

order

the

n

in

on

(29)

log

from

which

EXPERIMENTAL

to

data

ence

1.

The

approximation

practical

purposes.

In

were

obtained

from

the

puted

tion

s

A

from

between

equation

c

and

was

obtained

by

better

fit

would

been

determined

first

paragraph

procedure

used

cases.

than

S8

paper

is

STRESS-

TANGENT-MODULUS

3.08

the

-lO

log-log

of approximation

stress-strain

(27)

S 1

S 8

this

adequate

descripin reference

1.

equation

8 1

A plot

of

ure

10.

1.0

and

value

0.3853

+

log

strength

0.7

and

limiting

and

17

log-_

n

yield

(2,8)

between

of

the

which

equation

the

stress-strain

equations

902

0.85

this

value

lies

midway

it

is on the

safe

side

0.90

of

No.

given

in

fig-

STRAIN

CURVES

curve

w.ith which

equation

for

materials

with

c_

is brought

were

taken

at

out

in

random

(2)

val-

figures

ll

from

refer-

appears

to be

adequate

for

most

these

figures

E,

el,

and

ss

stress-strain

data,

and

n

was

com-

(27).

o,

Equation

and

the

multiplying

have

been

(8)

then

gave

relation

between

¢

by

obtained

sl/E

if

n

and

and

the

e

a

K

rela-.

and

by

had

s I.

from

a plot

of

the

data,

as

exolained

in

of the

preceding

section

(p.

7);

but

the

is simpler

and

probably

adequate

in most

A much

more

the

comparison

severe

with

test

the

of

the

adequacy

stress-strain

parison

with

the

tangent

modulus

- that

stress-strain

curve.

Such

a comparison

able

since

the

tangent

modulus

must

be

ing

the

reduced

modulus

in compression.

of

curve,

equation

is a

the

(2),

com-

is,

the

slope

of

the

seems

to be adviscomputed

for

evaluat(See

equation

(17).)

NACA

The

• i

tangent

Technical

moduli

in

Note

No.

compression

ll

902

of

reference

1

are

plotted

on a dimensionless

basis

in figures

14 to 21

together

with

computed

moduli

as given

by

figure

8.

The

value

of

n

from

equation

(29)

for

each

material

is given

in figures

14 to 21.

The

computed

moduli

are

shown

for

integral

values

of

n

and

for

n = 2.5.

To

appreciate

the

closeness

of fit,

therefore,

it

is necessary

to

interpolate

of

n

curves

values

between

the

curves

by using

the

particular

value

applying

to

the

plotted

data.

Except

for

the

with

a very

sharp

knee

(n

> 10)

the

experimental

of tangent

modulus

for

stresses

below

the

secant

yield

strength

sI

differ

less

than

_0.07

E

from

the

values

corresponding

to equation

(15).

In the

case

of the

values

with

the

sharp

knee

(fig.

21)

the

maximum

difference

was

considerably

greater.

These

differences

do not

detract

seriously

from

the

usefulness

of

equation

(2),

however,

since

the

region

in which

the

agreement

is not

good

comprises

a limited

this

range

the

difference

the

computed

values

of

of tangent

modulus

are

stress

range.

between

the

O

corresponding

small.

Consequently,

experimental

to a given

in

and

value

The

comparison

was

confined

to

the

materials

in reference

l, which

did

not

include

alclad

aluminum

alloys.

In the

alclad

aluminum

alloys

a change

in

slope

at

low

stress

is

observed

which

corresponds

to

the

yielding

of

the

aluminum

coating.

It

seems

probable

that

inclusion

of this

effect

will

require

the

addition

of at

least

one

more

parameter

EXAMPLE

to

FOR

the

three

APPLICATION

Computations

contained

0F

based

on

in

equation

THREE-PARAMETER

elastic

theory

(2).

METHOD

give

a

value

of

S

se

/

=

87

×

l0

pounds

for

the

critical

compressive

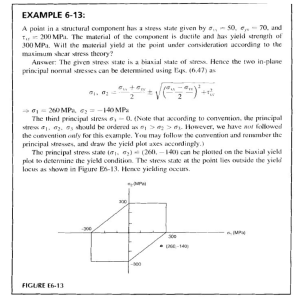

The

material

of the

specimen

strain

curve

shown

in

figuA'e

mine

the

stress:

per

inch

e

stress

of

a given

has

the

compressive

22.

It

is desired

specimen.

stressto deter-

Er

Sr

--

Se

E

which

account

is

an

estimate

of the

olastic

for

the

critical

stress

after

yielding

of

the

material.

taking

12

NACA

,

From

strengths

figure

Technical

22

are

Note

obtained

No.

the

902

two

secant

yield

|

so

s_

=

43.0

X 103

pounds

per

ss

= 38.0

x i03

poundsper

inch s

inch s

that

S1

-

I. 132

S_

From

figure

i0

this

corresponds

n=

Entering

ratio

figure

9 with

to

a

shaPe

parameter

8.15

this

value

of

n

and

with

th_

I

s_1

- _

se

43.0

87.0

_ 0.494

gives

_ 0.473

_E

E

so

that

the

corrected

critical

stress

3

sr

=

0.473

× 87

National

Bureau

Washington,

× lO

is

2

3"

=

41.2

of Standards,

D. C., April

X lO

8,

1943.

pounds

per

inch

NACA

Technical

Note

REFERENCE

i.

Aitchison,

C.

Pack

Alloy,

T.N.

2.

and

R. :

A

Jour.

13

902

S

Miller,

Compressive

Tests

of

1025

Carbon

Steel,

No.

840,

NACA,

1942.

0sgood,

W.

A.S.M.E.

pp.

S.,

No.

James

Some

and

A.:

Tensile

and

Sheets

of Aluminum

Chremium-Nickel

Steel.

Rational

Definition

App.

Mech.,

vol.

7,

of Yield

Strength.

no.

2, June

1940,

A61-A62.

•j

3.

Donnell,

L. H.:

tional

Limit

vol.

60,

no.

_.

Esser,

?

L

Suggested

and

Yield

ll,

Nov.

New

Definitions

for

ProporPoint.

Mech.

Engineering,

1938,

pp.

837-38.

•

Hans,

durch

werden.

eine

1939-40,

and

Ahrend,

H.:

Kann

die

ubereinkommenfreie

Arch.

f. Eisenhu_tenw.,

pp.

Grenze

13,

ersetzt

no.

10,

425-428.

5.

Holmquist,

J.

L.,

and

N_dai,

A.:

A Theoretical

and

Exoerimental

Approach

to

the

Problem

of Collapse

of •Deep-Well

Casing.

Paper

presented

at 20th

Annual

Meeting,

Am.

Petroleum

Inst.,

Chicago,

Nov.

1939.

6.

0sgood,

Nat.

pp.

W. R.:

Bur.

of

Column

Curves

and

Stress-Strain

Standards

Jour.

Res.,

vol.

9,

Diagrams.

Oct.

1932,

571-82.

7o

Timoshenko,

Hill

Book

S.:

Co.,

8.

von

Th.:

Karman,

Theory

Inc.,

of Elastic

New

York,

Untersuchungen

Stability.

N.

Y.,

1936.

uber

_._iitteilungen

uber

Forschungsarbeiten.

Ing.,

Heft

81,

1910.

r•

0.2%

Dehngrenze

vol.

McGraw-

Knickfestigkeit,

Ver.

deutsch.

NACA Technical

30

Note

No. 902

Figs.

(I bloc k °-10/50'1

8O

"]

.

7O

.

cb SO

c_-40

¢]

<O

09

q)

o) 3O

L.

¢3"

C

Ill

2O

0

_T

C

0

/0

•

09

C

0

L

0

.O0 /

.002

Sfroin

.003

.OOW

(D

II

8O

Figure

2.-

Sfr-ess-st-roin

blunt

knee,

our-ves

with

aluminum-alloy

CD

0

._Q

5O

24S-T,

thickness

0:064

incb._l__

_i_

y._-_-x

b"

%

%

_ 3O

<

/

o_"

ro

• 20

.

..

,

-.

/0

0

/

+

/

.001

o

X

•002

Troms

verse

fens/On

.... L omq/fud/mo/oompness/on-Tmclns verse

"

.003

.004 .OOE

S fr o/)o

.OOG

.007

--

.008

.008

1,2

NACA Technica

No-l-e No. 902

(:,sz/ot-_olq x)

\

%

%

J t < "' ¸

%

.,

.,

..

•

- ,

,

.,-

-.,

NACATechnical

ZOO

k

Note

!

No.

902

, .... .

Figs.

\

\:..- -Fconsverse coM,oress/on

\

\

• I

compress/on

i>!i_i

_

_.50

_

_1

0

.50

ZOO

/.

S/8 _td

Figure

4.-

thickness

Non-linear

variation

of tangent modulus with

stress; chromium-nickel

steel, full-hard,

0.020 inch.

56

/

/

iI

S=_e

l

/

!

J

I

I

40

l1///

_3z

_ee

I

16

/

I

//

,/.

o

.002

.004

.006

.008

S_rain

Figure

5.- Determination

of secant

yield strength.

4,5

NAC

. .-

F;q. 6

A Tli,chnlcal

, ,!#.

#

"'8

_)

__

+

_o

_D

II

O)

©

>

o

¢)

• ,-_ -_

U)

,7

_

|

II

,d

(D

%

0

°,-4

"<

\

X

\

I

L0 ,

_S'/S = p

\

NACA

Technical

Note

No.

Fig.

902

-.,

:J

•

r

/:

r

7

1

I!

7

I

_ACA

..

I

Technical

'io

No.90_

k

8

__

m

II --

M

Cb

l,n

--

II -

t

,

L

--- ----_------

I

/

._

--7

.....-.-

fJ

/

11

;/l//'/ ,////

"///,/,

4-3

o)

///// /¢//

;4

//A/ ,

II/,/ /

/

////

//,

i I-,.-I

or2

I=I

,-44-3...-..

• ,-4

/

/

.r.-I

["r _

/

block

-

10/32")

>

4-3

c_

(1

//2

c:)

0.

C

....

:

.............

."

.....................

I

NACA

.

•

_

................

I

Technical

ii

" !

"

:

":

/,,

i -i/

"

"

:-

NACA

•

Technical

Note

No.

Fig.

90_

I0

i

/5.0

10.5

,9.0

\

\

8.0

\

4.0

25

/.5

I

/.0

/./

,

It

I

P J

i

I

llqilll

/.2

I

F I

/.,3

I

I

I

I

I

t

I

t

I

I

[I

It

/.4

II

tllltl

ILllll_l

/.5

/.6

_,/e=

Figure

I0.-

Relation

between

log

n=l_-

zog

i?

-V

n

and

Sl/S 2 .

/IJllllll

/.7

JlllillJl

/-8

]LLIIIII

/.9

at.O

Note

I

No. 902

I

I

Figure

II.-

Figs.

I

I

I

I

Experimental

200

and

stress-strain

Cr-Ni

steel,

0.020

inch.

I

fUlll-hord,

1,12

I

computed

.,,_..,-,<'_"

curves_

--_----

thicknessl_J

_"

X../r"

/--11

l

Technical

_

NACA

l

/

¢'

'

_

/X.;

'

'

'

I

150

<

.

II

2_

0

0

_s

"/00

. 7S° .:"

.E

5O

d

002

O,

. !

Tension,

Longitudinal

Fr'c/n$ verse.

Compression,

Long/ltud/no/

Ff or?svef

s8.

dr'ed

A

+

$z

"

n__

26,/20

8Z3 5Z4 208

29. 660 205. 6/62. 7 zl.81

o

x

004

_

1000/b/s#7 in.

2#,770 18#. 7/473

4.83

29,010 1800/32.7

zl.58

puled

.006

Strain

.OO8

.012

.010

I00

MeosFension,

L ongi fudino/

7tons

verse.

Compression

L ongi fud/nol

Tr'onsver-se.

80

ured

a

+

Cor_puled

o

x

_b

<.

uf

I

E

s,

s,

tt

/000

Ib/sq in.

IO..EO0 52.2

5/.8 121.4

10,430

4_

,#ll.6

10.93

/06#.0

I0, 710

43.2

48.0

39./

45.6

9..88

13.43

..X._..._;-

_-'_-

-

_

_.

-

:d:o _c

2O

/

A Jc2

a I um Inum

- Experimental

stress-strain

alloy

24S-T,

ancl computed-curves;

thickness

0.064

i r_ch.

I

0

.002

I

0O4

I

•006

S#-oin

.008

. OI 0

.012

.

.... :.... _ .: ........ :_:::

NACA

........ :i :,¸

Technical

Nofe

i

No.

!_._/::

:::

:L :

..__:, : ......................................

902

Figs.

/00

8O

.c

o

o3

II

2_

_f

0

0

_Q

Measb_ r

Tensi-_,

ured

Transverse.

Compression

Longitudinal

Longitudinal

-_

Campuled

+

.......

_

o

Transverse.

E

I000

_

sz

Iblsq

in.

n

--

-

3/,620

64/

GS,/

oo

- ..

30,060

30,780

32,660

62S

b_.b

G3.4

$38

61.0

63.3

oo

oo

oo

x

i

I

i

0

•O01

002

.003

.004

Sfruin

Figure

t3.-

Experimenfol

corbon-sfeel,

end compufed

fhickness=O.054".

sTress-sfroin

curves,

1025

q

ZOO

rl

o 292

Mu

Cr=/V/"

sfeel

far

/e I

,

full-hard

/nch

fh.

0.020

Iomq.

.8O

.8O

B"

,n =2

.40

0

.20

.40

.80

.80

LO0

lQO

/,40

G=S/8_

Figure

14.- Experimenfal

2<n<3.

ond compufed

fongenf

moduliin

compression,

13,14

<

,.. '

,.• LI

I

L

NACA

Technical

Note

No. 902

Figs.

I

,.!•7

i:-¸ L::•_

::i!:

LO0

_

I

o 3.48

+ 3.83

_

3.10

_ 3.08

.80

Mo fer

OczNi

......

,,

X

_a'_

I

"

I

/o I

steel

I

I

1/4 hard

....

"

"

.......

....

I

Inch

fh.

/12

......

314

full

......

"

"

"

"

I/4

I

15,16

I

0020

long.

'_

.024

.020

-

"

"

trans.

_\

CD

OD

.60

I

-E-

0

0

.40

_Q

_0

o_

.20

X

_

o

o

t

0

0

.20

Figure

t5.-

.40

._0

Experimenfa]

compPessiom,

0498

A 410

1.00 ---_=

.80

/.00

d=S/S,

and

comoufed

3<n<4.

Cr-/vi

......

steel

t_._.ge

-,-,_

/.40

fomc)enf

moduli

ful/-hord

1/2

"

+,<.18......

x,<.si '; ....

.80

/.20

0.0275

.0 0

3i4 ....

,'_ll ;;

..........

in

long.

trs.

.o2.+

,.

\\

E'

,,,,,"

20

v

0

.20

Figure

16.-

.40

.80

.80

ExpePimenfal

and

compnessioP,,

4<n<5.

/.00

compufed

.....

5

/20

fongen¢

140

moduli

in

Technical

/.00

,.

. =*..

: L L :..,.

#

Note

No.

-

902

Figs.

17, 18

.80

;i

.60

LO

.

OJ

0

-...

II

0

0

_Q

in

compression

6<n<7

%

(

.20

n

o 6.72

0

Mc/fe/-iol

Or--N/Sfeel

full-ho/-d

.20

.40

fh.

._0

.80

Inch

0.02 75 tr-ons.

ZOO

120

d = sis,

.

.._

ZOO

.80

._0

E'

a

o

-E-

71

Mafer/'al

Z82 Al-ol/oy

24S-T

7.60

"

fh. 0.08/

"

.032

Inch

/on_7"

.40

I

.2O

Figure 18.-Experimental

and

co.mputed tangent modu

in

0

I

compresslon.

20

7<n<8.

dO

60

d=s/sl

..Irl

=7

.80

zOO

120

NACA

.

.-<.

,

Technical

Note

No. 902

Figs.

I 9,20

r:

.80

_

n

8.59

LO

Od

AAofer/'d/

E'

o

AI-olloy

7_-

+ 8.32 "

x 8.01

8.20

24S-RTth.

long.

II

0

0

._0

_Q

v

I

Figure

.2O

19-Experimenta

puted

tangent

compression.

_<_<9

0

.20

4O

end commoduli

n

.-_ =8

60

#=s/s,

.80

ZOO I

i

.80

6O

E'

-E-

o

Mafer/al

Inch

A/-o//oy/TS-T fh.0.032 long.

x 9.07 .....

24S- T ......

-9.88 ..........

084 " "

+ 9.O7 ....

243-RT

......

4O

Figure

.20 --

0

20-Experimenfo

puted

tangent

compression.

9<n</O

•20

.40

and commoduli

n

6o

d--s/s,

.8o

I00

120

O_

c_

,s/s=p

09

Ii

O_l

00I

08

017"

0_

0

__'-00

,I

0_I

.

......

_0

. I_

uoqJ_O

...........

180

_90"

I _.0 "

,,

........

u

u

11

II

u

/#

ii

#

_gO

I@0

l_90"

<_g'O'

/_.co"

_0"

u

J.

0

sl

II

o

c_

6

Z

0

z

n

.!

.,j

_,_

,,

o

_

--

s#

#i

/#

II

...........

ii

cr

ii

u

I

0_ <

_01

0_<

_9_I

Z __l

0__I

01__1

"i

i

-_

ii

1_

ii

,4--

0_

P_ZI

,,

l_-S_g

,,

,,

,.......

.

......

,,

_.Z-..q'/7_ .

,........

,,

i -SZ I/o//o-/V

0_I

,,

P_,cO" . I

I_0"0

"L/¢

qOUl

,, i _'_I

_01

l<gZI

,, 6'_/

I0_1

6__I

-moo

-uo.l.

_<_

0

[] x

,3"

Og

_ _"

0_ < +

,-,.<.,,

_O_Ol O_C< o_

I-S//o//o-IV

_01

v

i ,o/_./a do/41

tx

I

o8

I

00/

0

u

C

U

A

<

Z

.

.,

"

• /,

.

_.

ID:I.UaW

-!,.Jadx_

_

I

I<U "UOlSSaad

u! ]lnpom J,.ue6

pa.l.ndmoo

puo

. ....

- ..........

-18

e.Jn6!g

NACA

-

Technical

Note No.

902

Fig.

•i!

5O

I

I

I

qO

_, 30

_O

,-M

0

O

O

• 85 Ee

.7 Ee

,_ 20 L

l0

i

r.

I

0

• J

.OO2

•004

Strain

.OO8

•006

.

Figure

22.- Compressive

stress-strain

curve.

22