Trimteck Valve Training Module 3 - Severe Service Applications & Solutions

Anuncio

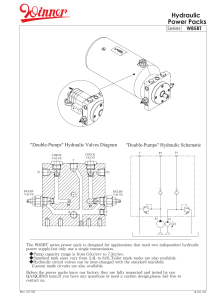

Trimteck-Optimux Control Valves Analysis of Severe Service Applications & Technologies Training Module 3 About Trimteck Trimteck is a family-owned American company with 15 years of experience in engineering, manufacturing, and marketing high-quality, cost-effective flow control solutions for critical processes. Our products are currently helping customers safely improve quality, optimize throughput, and reduce costs and emissions across an array of industries in more than 50 countries. Our applications engineers and certified representatives are committed to personalized customer service. Trimteck manufactures a comprehensive line of Optimux control valves – and a variety of actuators, positioners, severe service trims, and other accessories – that our applications engineers and representatives use to solve the most complex flow, pressure, and temperature control problems quickly and economically. Welcome to Trimteck. -1- Value Proposition As Trimteck grows, we are increasingly honing our value proposition to express that we are an innovative, agile organization that competitively offers a full control valve line of exceptional quality and proven design -2- Agenda I. Understanding Severe Service Problems II. Generic Guidelines for Valve Selection III. Specific Guidelines for Severe Service Valve Selection -3- Understanding Severe Service Problems 15% of valves are responsible for 85% of valve problems in any given industrial plant; and using the wrong valve in a severe service application can lead to costly premature failures -4- What Constitutes a Problem Valve? In general, there are three major categories of problems that can be predicted and addressed while sizing and specifying a control valve Problem Factors 1. Cavitation & Flashing • • • • • • • • • Excessive Fluid Energy Along Flow Path Inadequacies in Actuation System Pressure Drop Velocity Flow Rate Trim Selection Seat Leakage Consistency & Composition of Fluid Time of Exposure • • Consistency & Composition of Fluid Incorrect Material Selection 2. Noise & Vibration 3. Corrosion & Erosion -5- Background: Fluid Flow & Pressure Recovery Fluid Flow and Pressure Recovery in a Control Valve P1 Low Recovery Pressure P2 High Recovery Pvc Vena Contracta Valve Inlet Trim Inlet Trim Outlet -6- Valve Outlet Cavitation Explained Cavitation and flashing in control valves occur only with liquid media, and the principal factors responsible are fluid velocity and pressure drop. If upstream pressure is just above the vapor pressure, then the pressure may drop below the vapor pressure as the fluid flows through the valve. Cavitation will occur if the pressure recovers downstream of the valve to a pressure that is once again above the vapor pressure. Velocity Pressure -7- Background: Cavitating & Flashing Flow Liquid Flow Regimes in a Control Valve P1 Pressure Pv Cavitating Flow P2 Vapor Pressure Flashing Flow Pvc Vena Contracta Valve Inlet Trim Inlet Trim Outlet Valve Outlet -8- Flow Path Cavitation Damage Cavitation damage is a form of hyper-erosion that can destroy both control valves and piping, which can result in unacceptable process failures. The vapor bubbles created as a result of a pressure drop will implode – nucleate, grow, collapse, and rebound – as the vapor returns to liquid form. The implosion of vapor bubbles in the cavitation phenomenon inflicts damage in the form of small pits in the metal, which cumulatively wear away surfaces. Valve Plug with Cavitation Damage Implosion of Vapor Bubbles on Surfaces -9- Flashing Explained Similarly to cavitation, if upstream pressure is just above the vapor pressure, then the pressure might drop below the vapor pressure as the fluid flows through the valve. Unlike cavitation, however, flashing will occur if the pressure does not recover downstream of the valve, but rather remains below the vapor pressure. - 10 - Background: Cavitating & Flashing Flow Liquid Flow Regimes in a Control Valve P1 Pressure Pv Cavitating Flow P2 Vapor Pressure Flashing Flow Pvc Vena Contracta Valve Inlet Trim Inlet Trim Outlet Valve Outlet - 11 - Flow Path Flashing Damage In flashing service, the pressure drop will result in the process flashing from a liquid form to a gaseous form, carrying with it the liquid droplets at high velocity through the valve trim and into the downstream piping. Flashing damage is characterized by scalloping of the metal parts within the valve. - 12 - Noise & Vibration Explained As pressure drop is taken in a control valve, most of the resultant energy is lost as heat and the remainder is converted to noise. In liquid applications, both cavitation and flashing tend to cause hydrodynamic noise, however, in gaseous applications – gas or steam – a sudden pressure drop and high velocity cause turbulence that results in aerodynamic noise. Aerodynamic noise is a problem not only because of the noise pollution and possible damage to people within earshot, but because it indicates that there is turbulence and vibration in the valve and the downstream piping, which can cause physical damage to equipment. - 13 - Vibration Damage Shockwaves and turbulence, often caused by the control valves themselves, sometimes create vibration in the pipeline. If the plug stem is not rigid (i.e. is a two-piece threaded stem), properly aligned, and well-actuated, the plug could oscillate around the seat and eventually crack the stem. - 14 - Factors Explained - 15 - Corrosion & Erosion Explained Corrosion is the deterioration of a material resulting from a chemical or electrochemical reaction with its environment, such as a trim component in contact with the process fluid. General corrosion affects the entire surface of the exposed material uniformly, while localized corrosion can manifest itself by pits and cracking in specific locations. In control valves, erosion is generally defined as the wearing away of a material by any of many severe services: dirty process, cavitation, and flashing. In this discussion, we will limit our analysis of erosion to that caused by a dirty process – or particulates in suspension. There are cases when corrosion and erosion combine to cause significant damage. - 16 - Corrosion Damage Valve Stem and Yoke Corrosion Valve Plug Corrosion - 17 - Agenda I. Understanding Severe Service Problems II. Generic Guidelines for Valve Selection III. Specific Guidelines for Severe Service Valve Selection - 18 - Generic Requirements for Valve Selection The first step in combating severe service applications is selecting the correct valve for the service. Generic Selection Requirements Include: Valve Coefficient Flow Characteristic Rangeability Shutoff/Leakage Class Body Materials & Style Trim Materials & Design Soft Goods Materials Optimux OpGL Globe Control Valve - 19 - Valve Coefficients The measurement commonly applied to valves is the valve coefficient (CV) - also referred to as the flow coefficient - which is used to determine the valve size that will best allow the valve to pass the required flow rate while providing control of the process fluid One CV is defined as one U.S. gallon (3.78 liters) of 60°F (16°C) water that flows through an opening during 1 minute with a 1- psi (0.1-bar) pressure drop CV = Flow coefficient F = Flow rate (US GPM). SG = Specific Gravity fluid (Water = 1). ΔP = Pressure drop (psi). - 20 - OpGL Trim – Flow Characteristics Each valve has a flow characteristic, which describes the relationship between the valve coefficient (CV) and the valve stroke – as a valve opens, the flow characteristic—which is inherent to the design of the selected valve—allows a certain amount of flow through the valve at a particular percentage of the stroke, which allows the valve to control the flow in a predictable manner The three most common types of flow characteristics are equal percentage, linear, and quick-open - 21 - Flow Characteristics Continued Two rules of thumb for choosing the right flow characteristic: 1. If most of the pressure drop is taken through the valve and the upstream pressure is constant, a linear characteristic will provide better control 2. If the piping and downstream equipment cause significant resistance to the system, equal percentage will provide better control Control Valve Pressure Drop Recommended Inherent Flow Characteristic Constant ΔP Linear Decreasing ΔP with increasing load: ΔP at maximum load >20% of minimum load ΔP Linear Decreasing ΔP with increasing load: ΔP at maximum load <20% of minimum load ΔP Equal Percentage Increasing ΔP with increasing load: ΔP at maximum load <200% of minimum load ΔP Linear Increasing ΔP with increasing load: ΔP at maximum load >200% of minimum load ΔP Quick Open - 22 - Rangeability Rangeability is the ratio of maximum to minimum flow that can be acted upon by a control valve after receiving a signal from a controller High rangeability allows a valve to control flow from large to small flows, and it is imperative to select as broad of rangeability as possible in cavitating applications. Rangeability is affected by three factors: 1. Valve geometry – inherent rangeability due to the design of the body and the valve plug 2. Seat leakage – excessive seat leakage can cause instability as the valve lifts off of the seat 3. Actuator – diaphragm actuators are seldom accurate at less than 5% of the valve opening, whereas piston-cylinder actuators can provide control within 1% of valve lift due to the presence of air in two chambers - 23 - Shutoff Requirements Industry standards regarding the amount of permissible leakage of the process fluid through a valve’s seat. Leakage Class Designation Maximum Allowable Leakage Test Medium Test Pressure Test Procedure Class I N/A N/A N/A No Test Class II 0.5% of rated capacity Air or water at 50 - 125o F(10 52oC) Lower of 45 - 60 psig or maximum operating differential Lower of 45 - 60 psig or maximum operating differential Class III 0.1% of rated capacity As above As above As above Class IV 0.01% of rated capacity As above As above As above Class V 0.0005 ml per minute of water per inch of port diameter per psi differential Water at 50 to125oF (10 to 52oC) Maximum service pressure drop across valve plug not to exceed ANSI body rating Maximum service pressure drop across valve plug not to exceed ANSI body rating Class VI Not to exceed Class VI standard per port diameter Air or nitrogen at 50 to 125o F (10 to 52oC) 50 psig or max rated differential pressure across valve plug whichever is lower Actuator should be adjusted to operating conditions specified with full normal closing thrust applied to valve plug seal - 24 - Shutoff Requirements Continued In severe service applications, tight shutoff is imperative and an actuator that provides the appropriate seat load is necessary. Furthermore, when pneumatic actuation is required, a piston-cylinder actuator with accessories for velocity control will provide the end-user with more accurate control of the process and more thrust for tighter shutoff. Trimteck-Optimux Anti-Surge Valve with OpTK Piston Cylinder Actuator - 25 - Body Materials Common practice dictates that the end-user specify the body material, especially with special or severe service valves General service valves are specified with commonly found materials to match the pipe material Standard Materials Carbon Steel Stainless Steel Chrome-moly A Word on Investment Casting … Control valve bodies are either cast, forged, or machined from bar stock, with standard sand casting as the most commonplace method Trimteck elects to use an advanced investment casting method as its standard for control valve bodies between .5” and 4” Investment casting offers the following benefits: Special Alloys Hastelloy B and C Titanium Monel Bronze Consistent and repetitive close tolerances Superior integrity and no porosity Fatigue performance equal to that of forgings Minimal need for machining - 26 - Trim Materials Valve parts – body, bonnet, bonnet bolting, plug, ball, disk, wedge, and/or drainage plug – exposed to pressure, process fluid, corrosion, and other effects of the service are required by regulation to be manufactured from approved metals In applications requiring elevated material hardness levels and resistance to corrosion and abrasion, Trimteck has pioneered the use of CVD-5B Trim Material Characteristics - 27 - Gaskets A gasket is a malleable material, which can be either soft or hard, that is inserted between two parts to prevent leakage between that joint Common Gasket Materials and Types Type Gasket Material Max Temp (oF/oC) Min Temp (oF/oC) Max Pressure (psi/bars) Flat Virgin PTFE 350/175 -200/-130 6000 – 1000 psi 415 – 70 bar Flat Reinforced PTFE 450/230 -200/-130 6000 – 500 pis 415 – 35 bar Flat CTFE 200/95 -423/-250 6000 – 500 psi 415 – 35 bar Flat FEP 400/205 -423/-250 6000 – 500 psi 415 – 35 bar Spiralwound AFG 1500/815 -20/-30 6250 psi 430 bar Spiralwound 316SS/PTF E 350/176 -200/-130 6000 – 500 psi 415 – 35 bar Spiralwound 316/Graphit e 1500/815 -423/-250 6250 psi 430 bar Hollow Oring Inconel X750 1500/815 -20/-30 15000 psi 1035 bar - 28 - Agenda I. Understanding Severe Service Problems II. Generic Guidelines for Valve Selection III. Specific Guidelines for Severe Service Valve Selection - 29 - Specific Requirements for Severe Service Valve Selection The next step in combating severe service applications is to control for the following elements: Problem Requirements 1. Cavitation & Flashing • Control Velocity: • 2. Noise & Vibration 3. Corrosion & Erosion • Liquids: Inlet shouldn’t exceed 60 ft/s (18 m/s); Outlet shouldn’t exceed 100 ft/s (30 m/s) Gases: Trim exit shouldn’t exceed head velocity of 70 psi (480 kPa) • Stage Pressure Reduction • Reduce Noise to 85 dBa at 3 ft (1m) from the valve (un-insulated) • Ensure appropriate material selection • Examine Fluid Composition • Ensure appropriate material selection - 30 - Severe Service Solutions by Technology In order to solve the various valve problems discussed in Section I, differing methods and technologies exist; all involve one or more of the following: Utilization of low recovery trim packages, which break down the mass flow into a multiplicity of small flow streams Introduction of multi-stage pressure-reducing trims, which create a torturous path to further reduce velocity, pressure, and energy levels Optimization of actuation and flow direction to take further advantage of the design mechanics Selection of appropriate materials, some of which are more resistant to cavitation, flashing, erosion, and corrosion than others - 31 - Sigma (σ): The Cavitation Index The most widely-accepted and precise cavitation index used to quantify and predict cavitation in control valves is Sigma (σ). Simply put, Sigma is the ratio of the potential for resisting formation of vapor bubbles to the potential for causing formation of vapor bubbles. - 32 - Controlling Mild Cavitation: 1.5 < σ < 1.7 When mild cavitation is present in a process, specifying a hardened single-stage low recovery trim package may be sufficient. Instead of attempting to eliminate the cavitation, a single-stage trim uses mutual impingement technology to force the vapor bubbles to collapse against themselves in the center of the valve gallery – and prevents them from causing damage to critical metal trim or body components Mutual Impingement of Vapor Bubbles Trimteck ST-1 Anti-Cavitation Trim - 33 - Controlling Moderate to Severe Cavitation: 1.0 < σ < 1.5 In applications with more severe cavitation, the ideal solution is to reduce pressure gradually from the trim inlet to the trim outlet. By staging pressure reduction, the trim can prevent the process pressure from dipping below the vapor pressure – thereby preventing the formation of the damaging vapor bubbles altogether. Liquid Flow through a Four-Stage Pressure Reducing Trim Trimteck-Optimux ST-2 Multi-Stage Anti Cavitation Trim - 34 - Effects of a Staged Pressure Reducing Trim Staged Pressure Drop through a Control Valve Three Stage Low Recovery Valve Trim P1 1 2 3 Pressure Pv P2 Vapor Pressure Pvc Vena Contracta Valve Inlet Trim Inlet Trim Outlet Valve Outlet - 35 - Flow Path Controlling Flashing: σ < 1.0 No matter how many pressure stages are introduced into a valve, in flashing service the pressure drop will result in the liquid flashing from liquid form to a gaseous form – carrying with it erosive water droplets at high velocity. Therefore, if flashing is present in a service, then the damaging effects must be controlled by displacing the erosion to non-critical components in the system. One way to do this is with a hardened venturi-style seat in an angle-body valve, which will displace the effects of the flashing downstream of the valve. Trimteck-Optimux ST-5 Venturi Seat Trim for Flashing Service - 36 - Controlling Aerodynamic Noise & Vibration Similar to cavitating applications, the ideal solution for noise abatement is to reduce pressure gradually from the trim inlet to the trim outlet. By staging pressure reduction, the gas velocity and effects of expansion are reduced and noise is abated. To reduce the effects of vibration on valve equipment, select a robust single-piece plug, which is guided in the bonnet as opposed to within the cage. Multi-Stage Noise Abatement Trim - 37 - Trimteck-Optimux ST-3 Multi-Stage Noise Abatement Trim Controlling Corrosion & Erosion Some materials are inherently more resistant to corrosion than other materials. Alloys containing chromium get their corrosion resistance from a passive oxide layer on their surface, which acts as a barrier to further oxidation or corrosion. Most stainless steel and nickel alloys rely on this layer for their corrosion resistance. 316 Stainless Steel exhibits this type of protective film, and most control valve trim is manufactured from this material as a standard. In order to achieve increased protection from corrosion, the amount of nickel in the alloy can be increased. For example nickel alloy C, commonly known by the Haynes International trademark Hastelloy® C, exhibits excellent resistance to sulfuric, hydrochloric, and organic acids as well as ammonia, dry chlorine, and hydrogen sulfide. Nickel alloy 625, commonly known by the Special Metals trademark Inconel® 625, also has high corrosion resistance in a wide range of environments, and is commonly specified in the oil and gas industry for resistance to pitting, crevice corrosion, and SCC caused by high chloride levels, as well as resistance to sulfide stress cracking. - 38 - Controlling Corrosion & Erosion In applications requiring elevated material hardness levels and resistance to corrosion and abrasion, Trimteck has pioneered the use of CVD-5B CVD-5B is a chemical vapor diffusion process utilizing a hard wear-resistant metal mesh that deposits itself into the substrate material providing a Rockwell Hardness level of 72. Trim Material Characteristics - 39 - Trimteck’s Severe Service Philosophy Severe service applications vary in degree of severity, so without over-engineering, Trimteck offers its customers timely, cost-effective products to enhance performance while driving down operating costs Our rationale is simple: invest in a reasonably-priced custom-engineered solution and enjoy extended performance combined with a dramatic reduction in operation and maintenance costs caused by failures and untimely shutdowns - 40 - Thank you for your attention, and we hope you will give Trimteck the opportunity to solve your severe service applications.