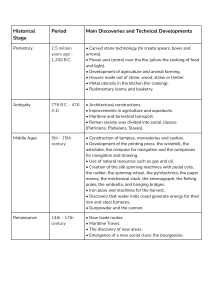

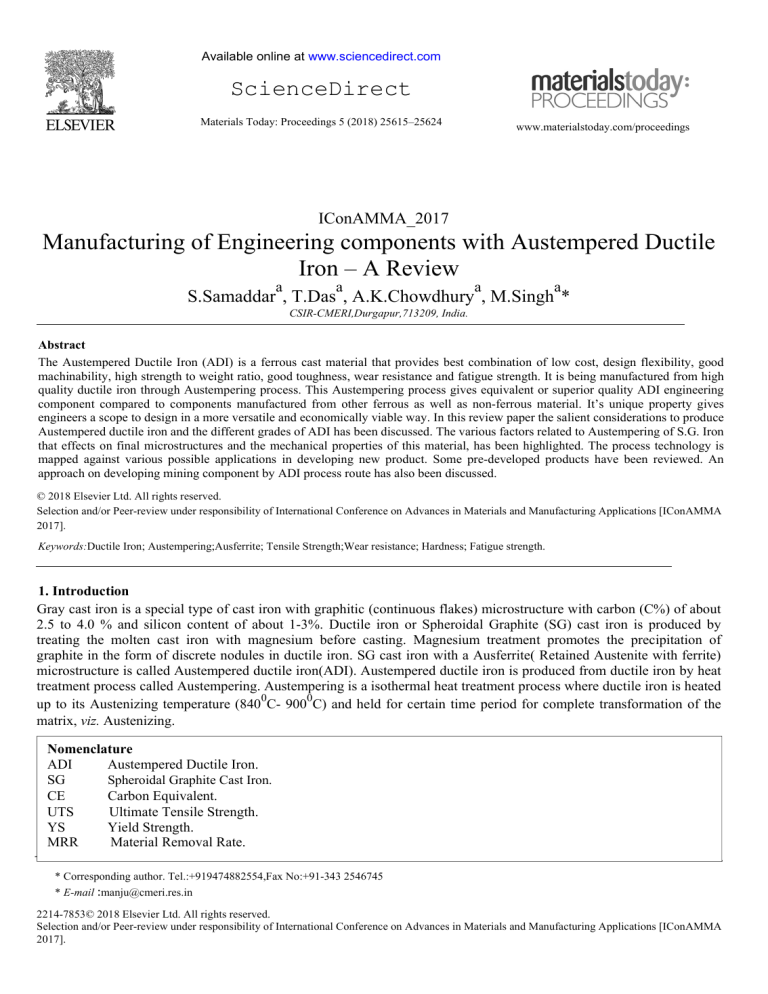

Available online at www.sciencedirect.com ScienceDirect Materials Today: Proceedings 5 (2018) 25615–25624 www.materialstoday.com/proceedings IConAMMA_2017 Manufacturing of Engineering components with Austempered Ductile Iron – A Review a a a a S.Samaddar , T.Das , A.K.Chowdhury , M.Singh * CSIR-CMERI,Durgapur,713209, India. Abstract The Austempered Ductile Iron (ADI) is a ferrous cast material that provides best combination of low cost, design flexibility, good machinability, high strength to weight ratio, good toughness, wear resistance and fatigue strength. It is being manufactured from high quality ductile iron through Austempering process. This Austempering process gives equivalent or superior quality ADI engineering component compared to components manufactured from other ferrous as well as non-ferrous material. It’s unique property gives engineers a scope to design in a more versatile and economically viable way. In this review paper the salient considerations to produce Austempered ductile iron and the different grades of ADI has been discussed. The various factors related to Austempering of S.G. Iron that effects on final microstructures and the mechanical properties of this material, has been highlighted. The process technology is mapped against various possible applications in developing new product. Some pre-developed products have been reviewed. An approach on developing mining component by ADI process route has also been discussed. © 2018 Elsevier Ltd. All rights reserved. Selection and/or Peer-review under responsibility of International Conference on Advances in Materials and Manufacturing Applications [IConAMMA 2017]. Keywords:Ductile Iron; Austempering;Ausferrite; Tensile Strength;Wear resistance; Hardness; Fatigue strength. 1. Introduction Gray cast iron is a special type of cast iron with graphitic (continuous flakes) microstructure with carbon (C%) of about 2.5 to 4.0 % and silicon content of about 1-3%. Ductile iron or Spheroidal Graphite (SG) cast iron is produced by treating the molten cast iron with magnesium before casting. Magnesium treatment promotes the precipitation of graphite in the form of discrete nodules in ductile iron. SG cast iron with a Ausferrite( Retained Austenite with ferrite) microstructure is called Austempered ductile iron(ADI). Austempered ductile iron is produced from ductile iron by heat treatment process called Austempering. Austempering is a isothermal heat treatment process where ductile iron is heated 0 0 up to its Austenizing temperature (840 C- 900 C) and held for certain time period for complete transformation of the matrix, viz. Austenizing. Nomenclature ADI Austempered Ductile Iron. SG Spheroidal Graphite Cast Iron. CE Carbon Equivalent. UTS Ultimate Tensile Strength. YS Yield Strength. MRR Material Removal Rate. * Corresponding author. Tel.:+919474882554,Fax No:+91-343 2546745 * E-mail :[email protected] 2214-7853© 2018 Elsevier Ltd. All rights reserved. Selection and/or Peer-review under responsibility of International Conference on Advances in Materials and Manufacturing Applications [IConAMMA 2017]. 25616 M.Singh / Materials Today: Proceedings 5 (2018) 25615–25624 o o This is followed by salt bath/oil quenching at temperature of about (250 C-370 C) [1]. Fig. 1.0 shows flow chart for manufacturing components with ADI. Fig. 1.0 Flow chart for manufacturing components from ADI Austempered Ductile iron, as material possesses very good strength to weight ratio, dynamic wear resistance properties, high toughness and fatigue, manufacturability and cast compatibility. Fig.1.1 (a)shows the comparison of ADI with different material w.r.t. relative weight per unit strength.Net shape manufacturing with Austempered Ductile Iron has been a trending technology that has been induced in the conventional manufacturing processes. It is driven by innovative product design and improved process technology, providing a competitive price. Fig.1.1 (b) shows the comparison of ADI with different material w.r.t. relative cost per unit weight.ADI material can be used to achieve design flexibility, maximum material utilization, minimum energy requirement, hence providing a better cost to benefit ratio with low cost production. This will be beneficial to wide spectra of user industry that includes automotive sector, mining sector, agricultural sector, Railway, etc. Fig.1.1.(a)Comparison of ADI with different material w.r.t. relative weight per unit strength[2]; .(b) comparison of ADI with different material w.r.t. relative cost per unit weight.[2] ADI is in the western market since 1972 and has been utilized to develop several components in the sector discussed above. Table 1 shows the ADI market share in North American and European professions. But this grade of ductile iron is relatively new and highly growing in the Indian market. In India CSIR-CMERI started research on developing ADI components since 2000.Other universities and laboratories, viz. NML, NIFFT, MSRIT Bangalore, JNUTH college of Engineering are also doing research work on process route development with ADI at laboratory scale. Table 1.The ADI market share in North American and European professions [3] Industry ADI ratio of the total production volume (%) Medium and heavy duty truck 2007 26 year North America 2010 25 year Europe (2007) 34 Light vehicle Building &Mining Agricultural machinery General machinery Railway 25 8 14 11 16 20 11 17 15 12 14 22 4 5 3 Energy &source 18 M.Singh / Materials Today: Proceedings 5 (2018) 25615–25624 25617 In this paper, the scope of suitability and sustainability of ADI in various engineering fields has been discussed briefly. This review analysis will help the designer to accumulate all data regarding manufacturing with ADI. Therefore, this paper aims at lucidification of the aspects of designing and manufacturing engineering components with ADI. 2. Process Technology to develop ADI 2.1. The Ductile Iron process Ductile iron is an iron-based alloy which contains a carbon content that is high enough to exceed its solubility in iron; resulting in the presence of pure carbon or graphite dispersed within an iron matrix. In the case of ductile iron, the shape of the graphite is spheroidal or round and is described as having graphite nodules. To get ADI, high quality ductile iron is required to be Austempered . For the purpose of Austempering, high quality 2 can be defined as: Minimum nodule count (100 per mm ); minimum nodularity of 80%;Porosity, carbide, inclusions and Micro shrinkage <1.5%; Throughout same chemical composition. High nodule count is important to minimize the segregation of alloy element which can promote the presence of carbides as well as delay the rate of Ausferrite transformation. Additionally, higher nodule count will prevent in the formation of porosity on micro shrinkage as well as promote the formation of small, round graphite nodule. [2] 2.1.1. Standard Grades of SG Iron. According to the tensile strength and elongation of the SG Iron , it can be classified in following grades shown in Table 2. These grades of SG Iron can ideally be transformed into Austempered Ductile Iron . Table 2. Grades of Ductile iron as per ASTM A536-84(2009) Standard Specification For Ductile Iron[4] Grade 60-40-18 65-45-12 80-55-06 100-70-3 UTS Yield Strength psi/ MPa psi/ MPa 60000/414 65000/448 80000/552 100000/689 40000/276 45000/310 55000/379 70000/483 %Elongation 18 12 6 3 2.2. The ADI Process ADI is produced from ductile iron through a heat treat process called Austempering. Austempering process is an isothermal heat treatment process. It generally consists of heating ductile iron to a temperature, called Austenising temperature, to produce Austenite. After Austenising, heat treated ductile iron is subjected to rapid quenching to avoid formation of Pearlite and other micro-constituents at a temperature above Martensite start(Ms) . This quenching temperature is called Austempering temperature. Fig 2.1shows the (a) Schematic representation of the Austempering process in ductile iron (b) Effect of Austenising temperature on carbon concentration in austenite. Ductile iron is quenched at the austempering temperature indicated in fig.2.1(a) for a sufficient time for complete transformation of the SG matrix into the Ausferrite structure.(Bainitic for steel and Ausferrite for Ductile iron). The quenching time is solely dependent on the cross section of the sample to be heat treated. Heat treatment temperature and time can be varied along with cross section of the sample. As the section size increases the quenching time also increases. Austempering technique include nitrate salt quench, hot oil quench.To avoid high temperature reaction products, salt bath quench severities can be increased with water addition or with alloying elements (such as Copper, Nickel, Magnasium or Molybdenum) that enhance Pearlite hardenability. 25618 M.Singh / Materials Today: Proceedings 5 (2018) 25615–25624 a. b. Fig 2.1 (a) Schematic representation of the Austempering process in ductile iron (b) Effect of Austenising temperature on carbon concentration in Austenite .[5] Table 3.depicts the different grades of ADI that can be produced by heat treating SG Iron.It is clear from the table that an Austempering treatment applied to the SG grade of Ductile Iron can improve its UTS ,YS and Elongation. By variation of Austempering Tempering temperatures and Quenching durations, Six standard grades of ADI can be produced given in Table 3. So,the designer can choose the required property as per the component to be developed. Table 3. Standard Grades of ADI as designated by ASTM A897-A897M-06 [6] Grade UTS Mpa/ksi Yield Strength %Elongation Impact Energy 500/70 11 110 241-302 Mpa/ksi J Hardness BHN 750-500-11 750/110 900-650-9 900/130 650/90 9 100 269-341 1050-750-7 1050/150 750/110 7 80 302-375 1200-850-4 1200/175 850/125 4 60 341-444 1400-1100-2 1400/200 1100/155 2 35 388-477 1600-1300-1 1600/230 1300/185 1 20 402-512 3.Properties of ADI Material . The property of ADI is dependent on the heat treatment temperature and quenching time. As a result varying the temperature and time ADI material exihibit wide range of properties shown in Table 4. It shows the comparison of yield strength(σy), fracture toughness(KIC), flaw tolerance between ADI, Conventional and austenitic Ductile Irons, Quenched and Tempered (Q&T) steels. 3.1. Fatigue strength 0 A high Austempering temperature (400 C) produces ADI with high ductility, yield strength in the range of 0 500Mpa with good fatigue and impact strength. A lower transformation temperature (260 C) results ADI with high yield strength (1400Mpa), high Hardness, Excellent wear resistance and contact fatigue strength. The modulus of elasticity for ADI lies in the range of 155-163Gpa. Fig3.1(a). Shows comparison of fatigue strength of ADI and other steel. Fig.3.1(b) shows Fatigue strength at different Austempering temperature. M.Singh / Materials Today: Proceedings 5 (2018) 25615–25624 25619 Table 4. Comparison of ADI alloy (A-2,B-5,C-1,C-3,C-5) ,Ductile Iron and Steel(Heat Treated) properties. [7][8] Alloy Heat A--2 850oC, 1 hr Salt Quench B--5 o 850 C, 1 hr Salt Quench Treatment 260oC* 300oC 350oC 400oC 430oC 260oC 300oC 350oC 400oC 1205.4 1107.4 989.8 744.8 744.6 1029.0 980.1 793.7 756.0 KIC (MPam1/2) 73.49 68.62 72.10 72.91 74.52 75.18 75.40 73.68 76.01 1151.5 86.00 C--1 850oC, 1 hr Salt Quench 300oC C--3 o 850 C, 1 hr salt/quench o C--5 850oC, 1 hr salt/quench 300 C 350oC 400oC 300oC Ductile Iron, Ferritic, 1.55% Si, 1.5% Ni, 1.2% Ni Ductile Iron, Ferritic, 3.6% C, 2.5% Si, 0.38% Ni, 0.35% Mo Ductile Iron Pearlitic, 0.5% Mo Ductile Iron, 80--60--03 Ductile Iron, D7003 Ductile Iron, Ni--Resist D-5B a. y (MPa) (KIC/sy)2 (mm) 5.58 3.72 3.84 5.30 9.58 10.00 5.34 5.92 8.62 10.08 1199.5 900.3 908.8 118.2 78.20 61.60 59.40 85.74 4.25 4.68 4.27 5.88 269 42.8 25.3 331 48.3 21.3 483 432 717 324 48.3 27.1 51.7 64.1 10.0 3.9 5.2 39.1 Alloy (KIC/sy)2 (mm) 1449 1587 1518 KIC (MPam1/2) 43.80 55.00 55.60 1380 1449 65.05 57.25 2.22 1.56 204oC 246oC 323oC 348oC 200oC 280oC 350oC 400oC 1380 1449 1414.5 1393.8 1345 1504.2 1497.3 1449.0 89.12 72.64 53.30 58.46 65.38 66.81 87.69 100.22 4.18 2.52 1.42 1.76 2.36 1.97 3.43 4.78 246oC 280oC 1380.0 1393.8 90.55 69.01 4.31 2.45 Heat Treatment AISI 4140 870oC, 1 hr Oil Quench 204oC 280oC 396oC 1100oC, 1 hr., Oil Quench 1200oC, 1 hr., Oil Quench 204oC 246oC 870oC, 1 hr Oil Quench AISI 4340 y (MPa) 1200oC, 1 hr., Oil Quench 843oC, 1 hr., OQ Tempered 260oC 427oC 1642.2 1421.4 48.79 84.47 .92 1.2 1.34 .88 * Isothermal Transformation Time: 1 hour. b. Fig.3.1 (a) Comparison of fatigue strength of ADI and other steel [9]; (b) Fatigue strength at different Austempering temperature [9] ADI is heat treated to produce high strength has a static fracture toughness of 55-70Mpa, which is greater than that of Ductile iron matrix of tempered Martensite or Pearlite. ADI heat treated to lower strength grade has fracture toughness in excess of 100Mpa [10]. ADI component at 30 to 40 RC will wear comparably lower to a quenched and tempered steel component. 25620 M.Singh / Materials Today: Proceedings 5 (2018) 25615–25624 3.2. Strength The strength of Austempered ductile iron is solely dependent on the relative amount of Ferritic and Pearlitic structure present in the ADI matrix. The Ferritic volume in the matrix is inversely proportional to the strength i.e. as the Ferrite volume in S.G microstructure increases the strength decreases. The Pearlite provides hardness to the matrix and contribute in Ausferrite structure formation after heat treatment. Now the ferrite structure being soft provide higher hardness to the Ausferrite structure along with nodular graphite, as shown in Fig.3.2 provide unique tensile strength & elongation % , that is equivalent to steel, employed to design components above 500Mpa yield strength. Fig. 3.2. Microstructure of ADI showing nodular Graphite and ausferrite structure[10] Fig. 3.3 Tensile Strength- Toughness curve for ADI versus ASTM standards.[11] Since ADI provided a greater strength to toughness value as shown in Fig 3.3. It can be considered as an alternative material for application in areas seeking such criteria, viz. Steering knuckles, Crank shafts, Gudgeon pin. etc considering high strength, ADI has very good toughness. Toughness of ADI is much greater than that of conventional ductile iron and equivalent or superior to competitive cast and forged steel as shown in Fig. 3.3.Like other properties of ADI, its toughness is strongly dependent on microstructure. 3.3. Dynamic Performance Another salient feature of the material that a mechanical designer must consider in order to design a component is the fatigue life & toughness of the material and its behavior under dynamic loading. Owing to the unique Ausferrite structure the ADI material provides, high strength to toughness combination. Therefore it provide itself superior to ductile iron with Martensitic structure. Table 5.shows comparison between Forged steel, Pearlitic Ductile Iron and ADI grade 1050-750-7. Table 5. Comparison of Forged steel Mechanical Properties Pearlitic Ductile Iron & ADI[12] MATERIAL Forged steel Yield Strength; ksi (MPa) 75(520) Tensile strength; ksi (MPa) 115(790) Pealitic Ductile Iron 70(480) 100(690) Grade 150/100/7 ADI 120(830) 160(1100) Elongation % 10 3 10 Hardness ;BHN 262 262 286 Impact Strength; (J) 175 55 165 3.4.Abrasion Resistance The application that requires longer life of the component when subjected to abrasive forces, ADI suits the best. As compared to heat treated and surface hardened steel, Austempered ductile iron provides a unique work hardening characteristics that allows the design engineer to deploy the material in highly abrasive environment. From Fig 3.4 (a) & (b), it is found that the ADI material with higher hardness grades have less volume loss and relatively high abrasion resistance compared to steel. This property is due to, strain induced transformation of stabilized Austenite which occur when the surface of an ADI component is subjected to deformation. M.Singh / Materials Today: Proceedings 5 (2018) 25615–25624 25621 With increasing the Austempering temp, the bulk hardness increases hence the stabilized Austenite increases. o o This increases the abrasion resistance. So with optimum Austempering temperature of about 330 C-380 C a unique combination of high strength and abrasion resistance is produced that suits various engineering application. a. AUSTEMPERED STEEL Q & T STEEL Q&T DUCTILE IRON ADI b. . Fig 3.4 (a)Volume loss of different material at different hardness (Pin on Disc Test) ;(b) Relative Abrasion resistance of ADI vs. Steel.[13] 3.5.Machining properties Due to high strength and ductility of ADI, cutting tool often suffer flank wear and crater wear during machining of ADI. Therefore cutting tools need to have high wear resistance but require the use of cutting fluids. Pgrade tools can be used in dry cutting.Al2O3 ceramics are successful for continuous cut process.Si3N4 and PCBN cutting tools are not suggested for machining ADI. Fig. 3.5 shows the effect on (a) Tool Life,(b)MRR By different Hardness grade of ADI[14]. The following points should be considered while machining ADI material: (i) Machining ADI at 50% less speed than that of material with similar hardness, with a 50% deeper cut.(ii)For ADI type 900-650-9 (302BHN) cutting speed must be around 300feet/min.(iii)Al2O3 ceramics and K –grade carbide tool with cutting fluid for continuous machining process.(iv)MRR will be similar to that of RC30 steel. a b. Fig. 3.5.Effect On (a)Tool Life ;(b)MRR By different Hardness Grade Of ADI.[14] 4. A few case studies of components developed at CSIR-CMERI. Austempered Ductile Iron can be developed in five available grades with standardized process technology discussed previously. Since standardized process technology can improve the manufacturability that includes machinability, near net shape production process reliability and dimensional repeatability. ADI open up a huge area for the designer to consider this new material for application in various Engineering fields. The basic consideration that every designer should follow in the decision making process includes: Strength (UTS, YS); Dynamic Performance; Wear Resistance; Application oriented properties (Damping, Corrosion resistance); Ease of manufacturability; Cost efficiency. The above stated properties of ADI find it suitable to compete with other available materials like Steel and in some case it has proved itself either superior or equivalent to the available materials. 25622 M.Singh / Materials Today: Proceedings 5 (2018) 25615–25624 Till date CSIR-CMERI already developed following ADI components, shown in Fig.4.1.These components are successfully installed and tested in various industrial machineries. The components are listed below: • Crankshaft Fig.4.1(a) shows crankshaft developed at CSIR-CMERI. Crankshaft has intrigue design and requires higher degree of precision for manufacturing. A crankshaft made of ADI has been deployed in 35HP Sonalika Tractor Engine and have successfully passed 500hrs of Engine test. This proved that proper process control of the ADI component can replace forged steel crankshaft yielding very high profit margin along with desirable mechanical properties like fatigue strength, endurance towards bending, torsion & shear. • Rotavator Blade Fig.4.1(b) shows Rotavator blade developed at CSIR-CMERI. Rotavator blade is an agriculture component that is used to till the field, and it is subjected to high amount of abrasion force. The Rotavator blade made from ADI have successfully replaced steel blades proving itself better with respect to life,that has been incresed upto 200hrs compared to previously used steel blades. As well as it can be proved that ADI Rotavator blade price is cheaper than steel blade. • Gudgeon Pin Fig.4.1(c) shows Gudgeon pin developed at CSIR-CMERI. Gudgeon Pin of compressor which is made of steel has been replaced by ADI gudgeon pin. The ADI gudgeon pin has successfully run 600 hrs of test. Hence ADI can endure high amount of shearing and bending load equivalent to steel components. • Ore crushing Hammer Fig.4.1(c) shows ore crushing hammer developed at CSIR-CMERI. The giant ore crushing hammer are subjected to high amount of impact strength and abrasion. Owing to its huge size, defect free casting is a challenge. As ADI having unique matrix that reduces shrinkage and also due to its high wear resistance, it can withstand the abrasive environment better than hardened steel. Hammer, which is made from ADI have successfully completed 158 hrs of field trial at Mcnally Bharat Pvt. Ltd. proving itself more long lasting and tough than steel. a. b. c d. Fig.4.1 Components made with ADI (a) crankshaft,(b) Rotavator blade, (c) Gudgeon pin,(d) Ore crushing hammer[15] 5. Experimental details for manufacturing of Mining Component (Excavator tooth point) with ADI. In mining industry sharp digger teeth are essential for ground penetration. At present digger teeth are manufactured from cast steel material. In this experiment efforts have been made to replace the digger teeth material with Austempered ductile iron. Manufacturing process of ADI digger teeth as per Fig. 1.0. Considering end application of this component, composition of the melt, process parameter of casting and Austempering process were appropriately designed as given below. • The raw material should be charged initially bi-layer with MS scrap and carburizer (graphite) one upon another. • The heating rate should be low until the scrap melts. So that the carbon diffuses in the ferrous matrix uniformly • The CE value (4.3-4.5) should be fixed as per the required section thickness to the cast. • Alloying is done as per requirement to stabilize the iron-carbon pearlitic phase i.e. Ni, Mo and Cu may be added. • The percentage of S (<0.025), Mn ( <0.4), & P (<0.1) must be closely controlled to achieve S.G iron properties. The inoculation should be done to achieve spherical structure of Carbon (Graphitization). M.Singh / Materials Today: Proceedings 5 (2018) 25615–25624 25623 6. Results and Discussion Firstly SG Iron test blocks were casted as per ASTM A897 standards and the chosen chemical composition of the S.G. Iron is shown in Table 6. The microstructure of the S.G Iron test block is shown in Fig.5.1 (a) before etch (b) after etch with 2% nital. The Figure shows spherical structure of that will neutralize the shrinkage during solidification. The Figure also indicates sufficiently high nodule count resulting in minimization of porosity and carbide. Microstructure of S.G.Iron showing Nodule count is shown in Fig.5.2. Table 6. Chemical composition of S.G Iron. %C 3.15 a. %Mn %Si 0.30 1.65 %S 0.07 %P 0.26 b. Nodular Graphite Fig 5.1. S.G Iron Microstructure (a) before etch ; (b) after etch with 2% nital. Fig.5.2. Nodule Count of S.G iron Microstructure shown in Fig. 5.1. Tensile samples were developed from S.G. Iron test blocks as per ASTM A897 standard. The test sample were subjected to heat treatment cycle as depicted in Fig 5.3. Excavator Tooth point shown in Fig.5.4 was chosen for development through the ADI Process route. a. b. Fig.5.3. (a)Cycle 1;(b)Cycle 2 of the Austempering process done on samples(Dimension: 130mmx130mmx130mm) The Fig. 5.5 shows the complete transformation of S.G. matrix into Ausferrite structure. Table 7. and Table 8. show the various result of Tensile test and Hardness of ADI sample respectively. The result of tensile test conducted on four ADI test samples gives average value of UTS 720 MPa and Hardness of 300 BHN respectively. Fig.5.4.Tooth point of Excavator being developed with ADI at CSIR-CMERI Fig.5.5 SEM Microstructure of ADI test Sample Captured at CSIRCMERI 25624 M.Singh / Materials Today: Proceedings 5 (2018) 25615–25624 Table 7. Tensile Properties of the ADI samples developed at CMERI Sample no UTS YS %El A 721.6 430.2 10.8 B C 720.5 719.4 441.5 440.7 10.5 11.2 Table 8. Hardness of the ADI test samples developed at CMERI Sample no A B C Hardness(BHN) 319 304 297 7. Conclusion The process route of manufacturing of engineering component with ADI material has been elaborately discussed. The salient features regarding heat treating ductile iron to get desirable mechanical properties has been reviewed. The case studies of components manufactured with ADI at CSIR-CMERI, Durgapur have been compared with conventionally used steel components. In this review paper it has been observed that ADI is suitable contender for mining applications with indigenous resources and the developed material can satisfy the acceptance criteria of International specifications (EN/ASTM). It is inferred from the study that ADI is better (or equivalent in some case) considering suitability and sustainability at particular applied field. Hence from the review it can be concluded that further development can be made in the manufacturing field to replace ferrous engineering conventional component with this new, efficient, cost effective and characteristically better Austempered ductile Iron. Acknowledgements The authors thankfully acknowledge the technical support provided by members of NNMT Group and AdMac Group of CMERI for their technical support and providing infrastructure for completion of this review work. The authors would also like to extend their acknowledgement to the Director,CMERI for encouragement and support to conduct various experiments. References [1] J.R.Keough K.L.Hayrynen, G.L.Pioszak, Designing with Austempered Ductile Iron, American Foundry Society, Schaumburg. IL U SA, 2010, pp. 10-129 J. [2] J.R.Keough, Ductile iron Data, Section-IV,August 1998. [3] Yicheng Zeng, Kerui Li, Xianlong Wu, Zhongchou Zhang,The new development of austempered ductile iron (ADI) in China; GB/T 24733— th 2009 was issued on Dec 30 , 2009. [4]ASTM Hanbook ASTM A536-84(2009) standard specification for Ductile iron. [5]D.Myszka,Austenite-Martensite Transformation in Austempered Ductile iron.Archives of Metallurgy and Materials ,Volume 52,Issue 5, 2007. [6] Karl B. Rundman,ASTM A897 ,Dept. of Metallurgical and Materials Enginnering, Michigan Technological University [7]Iron Casting Handbook, 1981. P357. [8]Damage Tolerance Design Handbook, Metals and ceramics Information,;Battle Columbus Laboratories, January,1975. [9] P.A. Blackmore, R.A.Harding, The effects of Metallurgical process variables on the properties of Austempered Ductile Irons, J.Heat treating, Vol. 3,No 4,Dec 1984. [10] Chamberlin and hill group,Uk www.ironfoundries.co.in [11] A. Chennakesava Reddy, Effects of Holding Temperature and Time for Austempering on Impact Toughness of Medium Carbon and High alloy steel,IJCNS vol.3 No.1 ISSN: 0975-8283. [12]”Ductile Iron” Foundry Management and Technology, September, 1989. [13]Polishetty,Ashwin,Sarat Singamneni,Guy Littlefair, A comparative Assessment of Austempered Ductile Iron as a Substitute in Weight reduction Applications, ASME 2008 , International Manufacturing Science and Engineering Confernce Vol 1, 2008. [14] Kristin Brandenberg,, Sucessfully Machining Austempered Ductile Iron, Applied Process Inc. Technologies Div-Livonia, October 2001. [15] A.K.Chowdhury,S.k.samanta,D.P.Chattoadhya,S.Kumar, T.Ray and S.S Sinha Roy,Near Net Shape of Austempered Ductile Iron(ADI) components,Indian Foundry Journal, August 2009,Vol-55, N0-8.