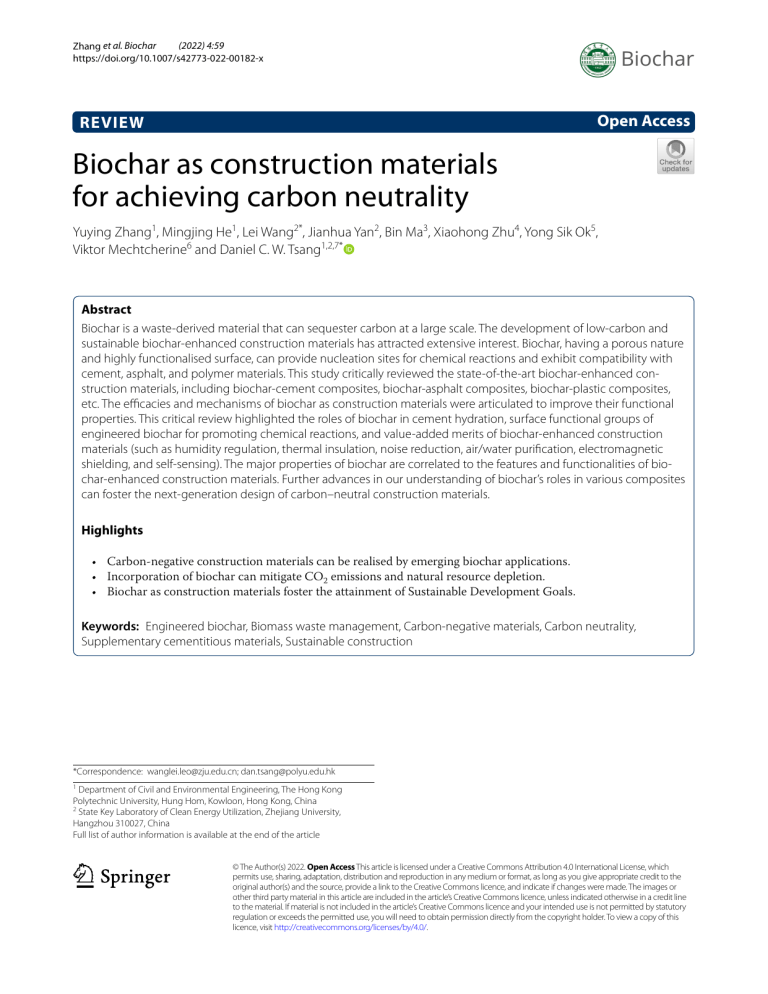

(2022) 4:59 Zhang et al. Biochar https://doi.org/10.1007/s42773-022-00182-x Biochar Open Access REVIEW Biochar as construction materials for achieving carbon neutrality Yuying Zhang1, Mingjing He1, Lei Wang2*, Jianhua Yan2, Bin Ma3, Xiaohong Zhu4, Yong Sik Ok5, Viktor Mechtcherine6 and Daniel C. W. Tsang1,2,7* Abstract Biochar is a waste-derived material that can sequester carbon at a large scale. The development of low-carbon and sustainable biochar-enhanced construction materials has attracted extensive interest. Biochar, having a porous nature and highly functionalised surface, can provide nucleation sites for chemical reactions and exhibit compatibility with cement, asphalt, and polymer materials. This study critically reviewed the state-of-the-art biochar-enhanced construction materials, including biochar-cement composites, biochar-asphalt composites, biochar-plastic composites, etc. The efficacies and mechanisms of biochar as construction materials were articulated to improve their functional properties. This critical review highlighted the roles of biochar in cement hydration, surface functional groups of engineered biochar for promoting chemical reactions, and value-added merits of biochar-enhanced construction materials (such as humidity regulation, thermal insulation, noise reduction, air/water purification, electromagnetic shielding, and self-sensing). The major properties of biochar are correlated to the features and functionalities of biochar-enhanced construction materials. Further advances in our understanding of biochar’s roles in various composites can foster the next-generation design of carbon–neutral construction materials. Highlights • Carbon-negative construction materials can be realised by emerging biochar applications. • Incorporation of biochar can mitigate ­CO2 emissions and natural resource depletion. • Biochar as construction materials foster the attainment of Sustainable Development Goals. Keywords: Engineered biochar, Biomass waste management, Carbon-negative materials, Carbon neutrality, Supplementary cementitious materials, Sustainable construction *Correspondence: [email protected]; [email protected] 1 Department of Civil and Environmental Engineering, The Hong Kong Polytechnic University, Hung Hom, Kowloon, Hong Kong, China 2 State Key Laboratory of Clean Energy Utilization, Zhejiang University, Hangzhou 310027, China Full list of author information is available at the end of the article © The Author(s) 2022. Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. Zhang et al. Biochar (2022) 4:59 Page 2 of 25 Graphical Abstract 1 Introduction Global ­CO2 emissions increased by 53% from 1990 to 2020 and reached nearly 31.5 giga-tonnes (International Energy Agency 2021), triggering climate change and adversely impacting the ecosystems. According to Global Alliance for Buildings and Construction, approximately 40% of energy-related ­ CO2 emissions result from construction and building activities (Global Alliance for Buildings and Construction 2017). The manufacture of cement (i.e., the most consumed construction material worldwide) accounted for ~ 36% of ­CO2 emissions in construction activities and ~ 8% of total anthropogenic ­CO2 emissions (Habert et al. 2020). To achieve ambitious goals of carbon neutrality on a global scale, it is imperative to take unprecedented actions for innovating the design and promoting the use of carbon-negative construction materials. Biochar, as a negative emission technology (NET) highlighted by the Intergovernmental Panel on Climate Change (IPCC), is a carbon-enriched material produced from the thermochemical conversion of various biomass waste in an oxygen-limited environment (Intergovernmental Panel on Climate Change 2018). The carbon present in biomass can be transferred into a more stable form in biochar, which persists one to two orders of magnitude longer than biomass precursor, resulting in long-term carbon sequestration (Fawzy et al. 2021; Lehmann and Stephen 2015). Recent literature indicated that the average ­CO2 footprint of biochar ranged from − 2.0 kg to − 3.3 kg of C ­ O2-eq per kg of biochar, relying on the locations and properties of feedstocks and the target applications (Azzi et al. 2019). Globally, biochar technology can reduce greenhouse gas emissions by 3.4–6.4 P ­ gCO2-eq, of which 1.7–3.7 ­PgCO2-eq (49–59%) is attributed to the C ­ O2 withdrawal from the atmosphere (Lehmann et al. 2021). Although there is variation in the total C ­ O2 reduction depending on different circumstances, extensive use of biochar is widely considered efficient for mitigating climate change and achieving net-zero emissions. Biochar can be converted from various waste biomass, such as wood waste, agro-waste, food waste, manure waste, and municipal/industrial sludge. The global generation of biomass waste (derived from agricultural and forestry practices) is estimated to be 140 giga-tonnes ­yr−1, causing severe greenhouse gas emissions and environmental pollution issues (Tripathi et al. 2019). It was estimated that producing 373 million tonnes ­yr−1 of biochar derived from agro-waste could sequester approximately 500 million tonnes of C ­ O2 ­yr−1, equivalent to 1.5% of total annual global C ­ O2 emissions (Windeatt et al. 2014; Yang et al. 2019). Carbon emissions would be further reduced when other types of biomass waste are transformed into biochar for carbon sequestration. In this context, converting various biomass wastes into biochar and expanding new applications of biochar could provide a win–win strategy for realising long-term decarbonisation and fostering a circular economy. Integrating biochar into innovative biochar construction materials could facilitate waste valorisation and reduce C ­ O2 emissions of construction materials. This strategy could also bring additional economic benefits through carbon trade, incentivising the construction and building industry to curtail overall C ­ O2 emissions (Wang et al. 2021a, b). Recent studies have reviewed the influences of incorporating biochar in concrete composites regarding workability, hydration, and mechanical properties (Akinyemi and Adesina 2020; Maljaee et al. 2021). Although it has often been overlooked in the construction-related literature, the Zhang et al. Biochar (2022) 4:59 feedstock of biomass and manufacturing technologies of biochar would significantly affect the properties of biochar construction materials, which should be critically investigated. To the best of our knowledge, no literature review has articulated the state-of-the-art knowledge about designing different types of engineered biochar as construction materials, especially for maximising their technical benefits, value-added functionality, and decarbonisation capacities. Hence, in this tutorial review, we firstly introduced different processes for biochar production and emphasised the efficacy of biochar construction materials in achieving carbon neutrality. We comprehensively evaluated the environmental impacts of biochar production and customisation as well as the decarbonisation capacity of biochar as filler and aggregate in comparison to conventional materials. Afterwards, we critically reviewed the manufacturing technologies of biochar construction materials, including biochar-cement composites, biochar-asphalt composites, biochar-plastic composites, etc. Lastly, we identified the grand challenges in employing biochar as supplementary cementitious materials, fine/coarse aggregate, and functional additives in the construction materials, and suggested the prospects for future research directions in this review. As illustrated in Fig. 1, we highlighted sustainable waste management towards a circular economy and Page 3 of 25 proposed a novel strategy for achieving carbon neutrality by adopting biochar construction materials. 2 Biochar production Biochar production processes can be divided into three categories: pyrolysis, gasification, and hydrothermal carbonisation (HTC). Figure 2 is a schematic diagram of the production processes for different types of biochar, with their yields following the order of HTC > pyrolysis > gasification. These biochars differ widely in chemical and physical properties due to their production conditions and feedstock selection. Factors such as pyrolysis temperature, heating rate, residence time, pyrolytic atmosphere, gas pressure, and types of biomass waste play critical roles in the yield and physicochemical characteristics of biochar for promoting the performance of biochar construction materials (including pore size distribution, specific surface area, cation exchange capacity, water retention capacity, etc.) (He et al. 2022; Leng and Huang 2018; Maljaee et al. 2021). Biochar is generally a product from partially carbonised biomass to highly refractory carbon with distinctive heterogeneity in physicochemical properties, primarily dependent on the feedstocks, production conditions, and various modification methods (Lehmann and Stephen 2015; Wang et al. 2020a, b). As an easily tuneable carbon-based material, biochar can be applied for a wide range of emerging applications, including additives and Fig. 1 Sustainable waste management towards circular economy and carbon neutrality by adopting biochar construction materials Zhang et al. Biochar (2022) 4:59 Page 4 of 25 Fig. 2 Pyrolysis and hydrothermal carbonisation of biomass for biochar production raw materials in construction materials, by engineering its porous structure, surface functionality, and aromatic/ graphitic carbon structure with fit-for-purpose designs (Chen et al. 2022b; Maljaee et al. 2021; Sajjadi et al. 2019). Different thermochemical treatments, including conventional pyrolysis (300–800 °C), gasification (> 700 °C with a fast-heating rate of tens of °C ­min−1), and HTC (180– 250 °C, 2–10 MPa), have been applied to produce biochar (or hydrochar from HTC) with the yields following the order of HTC > pyrolysis > gasification (Fig. 2) (Cao et al. 2021; Wang et al. 2020a, b; You et al. 2018). During biochar production, bio-oil and pyrolytic gas are the coproducts that can be applied for bioenergy applications or chemical upgrading (Tomczyk et al. 2020; Wang and Wang 2019). Overall, thermochemical technology should be customised depending on the nature of biomass waste (e.g., moisture content and carbon/mineral compositions) such that we can achieve the maximum reduction of ­CO2 emissions and upgrade the technical performance of biochar construction materials. 2.1 Pyrolysis biochar Conventional pyrolysis with a slow heating rate (5–10 °C ­min−1) in an oxygen-limited environment is the most widely adopted thermochemical technology to produce biochar owing to its technical simplicity of operation and economic feasibility for upscaling (Tripathi et al. 2016; Yang et al. 2021b). The physicochemical properties of pristine biochar are typically regulated by the compositions of feedstocks and the pyrolysis conditions, including temperature, duration, activation, and modification methods (Cha et al. 2016; Wang and Wang 2019). Pyrolysis temperature plays a critical role in the carbonisation process, which affects the energy value, yield, carbon stability, porous structure, and the pH value of biochar (He et al. 2021b). Increasing pyrolysis temperature could remarkably increase the pore volume and surface area of biochar due to the carbon phase change from amorphous to graphitic form and the driving off of pore-blocking substances (Lian and Xing 2017). For instance, by increasing the pyrolysis temperature, the specific surface area increased by 3.9-fold for sawdust-derived biochar (400–700 °C; 147.4–572.6 ­m2 ­g−1) (Zhu et al. 2019), 5.2-fold for rice straw-derived biochar (500– 700 °C; 22.4–115.5 ­m2 ­g−1) (Shen et al. 2019), and 29.5-fold for wood waste-derived biochar (650–950 °C; 10.5–309.2 ­m2 ­g−1) (He et al. 2021b). Longer residence time promotes the repolymerisation process and the development of the porous structure of biochar; slow pyrolysis with residence time longer than 1 h has been regarded as a dominant technology to produce biochar due to the higher economic feasibility and technological maturity (Chen et al. 2019c). Various activation or modification methods, including physical activation ­(CO2 or steam), chemical activation by acid, alkaline, and oxidising/reducing agents, have been conducted to augment the surface functionality of engineered biochar (Sajjadi et al. 2019; Xu et al. 2021; Wan et al. 2021). Appropriate specific surface area, pore structures, Zhang et al. Biochar (2022) 4:59 and surface functionalities of biochar can enhance the water holding and C ­ O2 storage capacity that would further promote the performance of biochar construction materials via internal curing and accelerated carbonation (Chen et al. 2020a, b; Praneeth et al. 2020). 2.2 Gasification biochar Gasification with a high reaction temperature (> 700 °C) in the presence of gasifying agents produces pyrolytic gas as the primary products (CO, ­H2, ­CO2, and ­CH4) and biochar with high aromaticity and porosity by four reaction stages, including drying (100–200 °C), pyrolysis (200–700 °C for fixed bed, 700–910 °C fluidised bed, and > 1400 °C for entrained flow), combustion (700– 1500 °C), and reduction (800–1000 °C) (You et al. 2018). The production of pyrolytic gas and biochar is typically controlled by the gasification conditions such as temperature, properties of feedstocks, gasifying agents (air, ­O2-enriched air, ­O2, ­CO2, and steam), and the gas pressure (Shayan et al. 2018). High temperature promotes the release of volatiles with a higher yield of pyrolytic gas at the expense of a lower biochar yield, facilitating the formation of micropores/mesopores with a higher specific surface area of biochar (Qi et al. 2021). Compared to the pyrolytic biochar, the gasification biochar with abundant pore structures might be a better choice as additives in construction materials for the sake of internal curing and accelerated carbonation. For the feedstocks with high ash content and alkali and alkaline earth metals (AAEMs) such as sewage sludge and food waste digestate, the solid–solid interaction between carbon and AAEMs (especially for ion-exchangeable ­Na+, ­Mg2+, and ­Ca2+) could weaken the C–C bond and improve the reactivity of gasification, hence enhancing the functionalisation of biochar (Mafu et al. 2018). 2.3 Hydrothermal carbonisation biochar (hydrochar) HTC exhibits advantages in dealing with wet and bulky biomass such as wet yard waste, food waste, and wastewater sludge, producing carbonised solids (hydrochar) without an energy-intensive drying pretreatment (Cao et al. 2021; Chi et al. 2021). The HTC is carried out in a subcritical water system; ~ 1000-fold of ionic products ­(Kw = ­[H+][OH−]) can be dissociated from water by increasing temperature from 25 °C to 250 °C, which makes water a suitable medium for base- or acid-catalysed reactions (Yang et al. 2021b). In the HTC process, the carbohydrates, protein, lipid, lignin, and humic substances from the feedstocks would be depolymerised to the intermediates by hydrolysis, dehydration, decarboxylation, deamination, and decomposition processes; then, the intermediates could form hydrochar by aromatisation, condensation, and polymerisation Page 5 of 25 (Liu et al. 2021). A higher heating rate was also found to facilitate feedstock decomposition while suppressing the formation of hydrochar; for instance, Wang et al. (2019a) found a decrease in hydrochar yield from 10.3% to 5.0% by increasing the heating rate from 8 °C ­min-1 to 50 °C ­min−1. It is noteworthy that higher levels of nutrients, AAEMs, transition metals, and polycyclic aromatic hydrocarbons (PAHs) may accumulate in the hydrochar, which should be carefully investigated and properly addressed before potential use in construction materials. 3 Carbon neutrality and biochar‑enhanced construction materials Carbon neutrality entails efficiently reducing greenhouse gas emissions and sequestering/capturing ­ CO2 from the atmosphere (Wang et al. 2021a). Biochar as a soil amendment to curtail C ­ O2 emissions and accomplish carbon sequestration has been intensively investigated since its first proposal nearly 15 years ago (He et al. 2022; Lehmann et al. 2021). More recently, biochar as a carbonnegative material has been employed in construction materials to enable buildings to become a carbon sink and facilitate the attainment of carbon neutrality targets (Danish et al. 2021; Maljaee et al. 2021). 3.1 Decarbonisation by biochar production 3.1.1 Decarbonisation by converting biomass waste into biochar The extent of carbon reduction by biochar is determined by its production conditions and application environment that would affect the amount of C ­ O2 emissions during the entire life cycle (Lehmann et al. 2021; Puettmann et al. 2020; Yang et al. 2021a, b). Meanwhile, the yield, carbon content, and stability of biochar, as well as the energy conversion efficiency of pyrolytic gas and bio-oil as renewable energy, are pivotal factors in determining the ­CO2 sequestration potential of thermochemical systems converting biomass into biochar (Yang et al. 2021a, b). The life cycle impacts of biochar systems also encompass ­CO2 emissions associated with the transport and storage of biochar, which could be kept minimum as a marginal contribution to the overall emissions (Matuštík et al. 2020). Notably, the large-scale deployment of converting waste biomass to biochar has been considered a ready-to-implement NET for achieving carbon neutrality targets (Azzi et al. 2019; Yang et al. 2021a, b). The pyrolytic gas and bio-oil generated by pyrolysis/gasification/HTC of biomass waste can be used for electricity, heat generation, and alternative fuels. More importantly, biochar/hydrochar can be used in the agriculture and construction industry to enhance their environmental performance and sequester carbon in the natural or built Zhang et al. Biochar (2022) 4:59 environment. The decarbonisation intensity (including fossil fuel offset) of pyrolysis systems varies from 36.6 ­CO2-eq to 136.5 g ­CO2-eq ­MJ−1 in accordance with different production processes and biochar applications (Roberts et al. 2010; Peters et al. 2015). Among them, the biomass intermediate pyrolysis poly-generation (BIPP) system, referring to multiple outputs of an integrated technology system, features the highest ­CO2 reduction capacity (Yang et al. 2021a, b). It is believed to be profitable without subsidies in China, reducing 61% carbon emissions per unit of gross domestic product and alleviating air pollution. Overall, converting biomass waste into biochar can foster resource circulation and the attainment of the United Nations’ Sustainable Development Goals (SDGs) and global carbon neutrality. 3.1.2 Decarbonisation of biochar customisation The engineered biochar exhibits an auspicious future due to its superior adsorptive, catalytic, and electrochemical characteristics after proper customisation (Klüpfel et al. 2014; Qiu et al. 2020; Kumar et al. 2020a; Xu et al. 2022). For instance, ball milling is a practical industry process which can now be assisted by automated technology minimising manual labour. As an emerging mechanochemical activation technology, ball milling has been widely employed in sustainable chemistry and, more recently, in customising biochar to increase its fineness, reactivity, and specific surface area (Kumar et al. 2020b). The ballmilled biochar with customised size, porosity, and surface functional groups can be adopted as fillers in cement composites and carbon-based modifiers in phase change materials (PCMs), which could facilitate their physicochemical performance based on the recent findings (Lyu et al. 2017). Featuring environmentally benign (e.g., ambient temperature, solvent-free), short duration and high reaction selectivity, the mechanochemical methods for customising biochar improve overall sustainability criteria (Lyu et al. 2017; Howard et al. 2018). For example, the electricity consumption associated with chopping and grinding of feedstocks ranged from 5 kWh ­t-1 to 200 kWh ­t−1 depending on their initial and targeted particle size, while the energy consumption related to biochar grinding should be minimal due to its brittle nature (Onarheim et al. 2015; Cheng et al. 2020). The C ­ O2 emissions from the biochar grinding process for manufacturing biochar-cement composites are negligible compared to the ­CO2 emissions from cement clinker production (Reis et al. 2020). Meanwhile, the ­CO2 emissions of biochar customisation can be compensated by the ability of biochar to enhance the C ­ O2 uptake capacity of cementitious materials. In recent studies, for example, incorporating 4 wt% tailored biochar in cement could store an Page 6 of 25 additional 0.12 kg of C ­ O2 and incorporating 8 wt% ballmilled biochar in cement could reduce ­CO2 emissions by 15% compared to plain cement (Praneeth et al. 2021; Tan et al. 2022). However, the commercial-scale application of ball-milled biochar is still in its infancy and requires extensive studies to validate the cost-effectiveness and environmental impacts. 3.2 Decarbonisation of biochar‑enhanced construction materials Cement and concrete are critical components widely applied in the construction industry, which inevitably present tremendous environmental impacts worldwide. In addition to particulate matter and potentially toxic elements that result in human health impacts, the most intractable environmental issue is the high level of C ­ O2 emissions associated with cement and concrete production, accounting for ~ 8% of the total anthropogenic ­CO2 emissions (Schneider 2015; Miller et al. 2018; Zou et al. 2018). In a newly constructed building, approximately 40% of C ­ O2 emissions come from concrete, and at least 70% of ­CO2 emissions of concrete come from cement, followed by the transport of raw materials and aggregate production (Habert et al. 2020). 3.2.1 Decarbonisation of biochar as a filler in cement systems The adoption of fillers as a partial clinker substitution is a promising method to reduce ­ CO2 emissions and energy consumption (John et al. 2018). Grinding is crucial for ensuring the high mechanical performance of fillers with high fineness, which together with raw material collection and transportation, contributes to ­CO2 emissions in filler production (Batuecas et al. 2021; Ige et al. 2021). The calcination of fillers (e.g., limestone) requires lower temperature and less energy, thereby less ­ CO2 emissions (John et al. 2018). The cement system incorporating 10% limestone and 5% silica fume as fillers can reduce ­CO2 emissions by more than 13% while having comparable mechanical strength with plain cement (Li et al. 2019). In recent years, biochar has been adopted as a filler in cement systems, demonstrating good performance owing to its internal curing effect and provision of nucleation sites. The lightweight and brittle nature of biochar can alleviate the burden on transportation and energy consumption compared to conventional fillers. Meanwhile, a high dosage of fillers (up to 60%) can make carbon-negative concrete feasible (Habert et al. 2020). Overall, biochar as a carbon-negative filler can revolutionise the construction industry by improving the properties of cement-based composites and environmental sustainability. Zhang et al. Biochar (2022) 4:59 3.2.2 Decarbonisation of biochar as aggregates in concrete systems It is estimated that approximately 17.5 Gt of aggregates are utilised to manufacture concrete each year, whose crushing and transportation induce considerable ­ CO2 emissions (Miller et al. 2018). The over-extraction of natural aggregates (e.g., sand and gravel) has already caused massive environmental damage with cascading effects that affect human well-being (Ioannidou et al. 2017; Aurora et al. 2017). Crushing the demolition waste into smaller particles for reuse as recycled aggregates is a sustainable approach to reducing the C ­ O2 emissions associated with natural aggregates (Zhan et al. 2018, 2020). The recycled aggregates with porous nature and increased surface area are suitable for C ­ O2 curing that can densify the matrix, enhance mechanical performance, and increase the lifetime ­ CO2 uptake (Zhan et al. 2019; Habert et al. 2020). Accelerated carbonation is a promising approach for C ­ O2 mineralisation and performance enhancement of cementitious materials (Chen and Gao 2019a, 2020; Pan et al. 2020). The ­CO2 utilisation potential of cementitious construction materials is expected to remove 100–1400 tonnes C ­ O2 by 2050 while generating the highest breakeven cost of US$70 per ton of C ­ O2 utilised (Hepburn et al. 2019). However, the carbonised areas are concentrated on the surface of cementitious materials due to the dense structure and closed pores, which under-utilises the decarbonisation potentials. When serving as aggregates, biochar with a hierarchical porous structure can improve the pore size distribution of the matrix and promote the deep carbonation of cementitious materials. The biochar pores can interlink with those in the cement systems, facilitating the diffusion and dissolution of C ­ O2 and enhancing carbonation progress. By incorporating biochar as aggregates, the biochar-enhanced concrete can sequester 59–65 kg ­CO2 ­ton−1 whilst delivering a maximum benefit of 41.1 USD ­m−3 (Chen et al. 2022b). The life cycle Page 7 of 25 analysis proved that the biochar incorporation significantly reduces the ­ CO2 emissions, whereas biocharenhanced concrete with 30 wt% biochar can be effectively converted into carbon-negative products (Chen et al. 2022b). However, the kinetics of ­ CO2 adsorption and water release of biochar in cementitious materials under ­CO2 curing lack investigations and sufficient understanding (Chen et al. 2019b; Chen and Gao 2019b). Future research should intend to tailor the adsorption and desorption kinetics of different engineered biochar to control the ­CO2 diffusion and regulate the crystalline forms of ­CaCO3 (i.e., calcite, aragonite, and vaterite) for desirable interfacial chemistry and optimal performance. 4 Biochar as construction materials Due to population growth and infrastructure development, increasing demand for construction materials is expected to cause substantial consumption of natural resources and greenhouse gas emissions (China Association of Building Energy Efficiency 2020). It is crucial to save the limited natural resources from manufacturing construction materials and reduce carbon emissions throughout the entire life cycle. Developing new and sustainable construction materials with low or even negative carbon footprint is an effective way to achieve carbon neutrality, which has increased interest in scientific and industrial communities (Churkina et al. 2020). To alleviate the issue of substantial ­CO2 emissions associated with cement and concrete, several research schemes such as the development of alkali-activated materials, limestone calcined clay cement ­(LC3) (Scrivener et al. 2018), waste utilisation for cement replacement (Yin et al. 2018; Maljaee et al. 2021), have been intensively investigated and practically applied in recent years. In the latest development, biochar as a carbon-negative material has been considered a promising candidate for cement and aggregate substitution in construction materials (Akinyemi and Adesina 2020). Figure 3 shows the conversion of Fig. 3 Upcycling of waste biomass into carbon-negative biochar construction materials Zhang et al. Biochar (2022) 4:59 waste biomass into biochar and the proposed biochar construction materials as a carbon sink. Fine-grained biochar can act as supplementary cementitious material, whilst coarse-grained biochar can partially substitute aggregate in concrete. 4.1 Biochar‑cement composites 4.1.1 Biochar as a filler in cement composites Biochar can be a promising filler in cement-based composites. The roles of biochar in cement composites have been investigated regarding rheology, cement hydration, and mechanical properties. For example, Gupta and Kua (2019) investigated the yield stress and plastic viscosity of biochar-cement composites by comparing coarse (2–100 μm) and fine (0.10–2 μm) biochar as a filler, where macroporous coarse biochar influenced the flowability and viscosity of cement paste to a greater extent than fine biochar. It was also found that fine biochar particles exhibited higher early strength (i.e., 1-day and 7-day) and better water tightness than macroporous biochar (Gupta et al. 2018a). Fine biochar would fill in pores and voids between solid particles in the cement system, enhancing the compactness and early strength of the biochar-cement composites. Compared with conventional fillers, biochar has a large pore volume that can retain the surrounding water. The retained water would slowly be released and contribute to internal curing, facilitating the hydration of biochar-cement composites (Wang et al. 2021b). Furthermore, the biochar exhibited a more pronounced enhancement in the long-term strength development via dry curing compared to water curing (Sirico et al. 2021). Nonetheless, excessive introduction of biochar would increase the overall porosity and compromise the mechanical strength and workability of biochar-cement composites. The effect of different curing schemes on the long-term mechanical performance of biochar-cement composites deserves further investigation. Biochar can facilitate ­CO2 diffusion and regulate moisture content in the biochar-cement composites during accelerated carbonation (Praneeth et al. 2020; Wang et al. 2020a). Wang et al. (2020a, b) suggested that the combination of biochar and C ­ O2 curing can enhance the properties of biochar-cement composites, which is especially effective for Mg-based cement. This is because Mg-based cement would expand after hydration and further fill in the pores of biochar, thus counteracting the adverse effects of large pores. This novel integration of biochar with ­CO2 curing can serve as a promising technique for producing sustainable construction materials. However, ­CO2 pre-saturated biochar displayed a detrimental effect on the development of compressive strength due to weak bonding between cement and C ­ O2 pre-saturated Page 8 of 25 biochar (Gupta et al. 2018a, b; Kua et al. 2020). Thus, the ­CO2 curing and pre-saturation schemes should be carefully designed to achieve the required mechanical performance and carbon sequestration capacity. The ability of biochar for internal curing and maintaining high relative humidity can also mitigate autogenous shrinkage and dry shrinkage, thus improving the durability of biocharcement composites. By combining biochar with MgO expansive additive, Mo et al. (2019) solved the autogenous shrinkage of cement and enhanced the compressive strength. The reduction of autogenous shrinkage could reach 16.3% at the age of 180 h with an addition of 2 wt% biochar into the cement. Similarly, a 6-week observation in another study proved that the autogenous shrinkage was eliminated using a combination of rice husk biochar and rice husk ash (Muthukrishnan et al. 2019). It should be noted that rice husk biochar is rich in active silica, which may facilitate pozzolanic reactions and further relieve the autogenous shrinkage. Benefiting from the abundant micropores/mesopores and high specific surface area of biochar, the water adsorption/retention capacity, thermal insulation, and temperature regulation ability of biochar-cement composites can be further enhanced. For instance, Gupta and Kua introduced 40 wt% rice husk biochar as a porous micro-filler in cenosphere-containing (10–40 wt%) lightweight cement mortar, demonstrating 15–20% higher strength retention and 9–25% lower permeability, giving evidence to the significant enhancement of thermal stability of biochar-cement composites at 450 °C (Gupta and Kua 2020). Meanwhile, the biochar-cement composites with 10–30 wt% silica fume exhibited a 28-day compressive strength of up to 66 MPa with a density of less than 2102 kg ­m−3. Nevertheless, the relatively high price of cenosphere and silica fume would unavoidably increase the cost of manufacturing lightweight biocharcement composites, and the density for lightweight concrete should be less than 1920 kg ­m−3 (ACI 213 2003; ACI 213R-03 2003). Therefore, it is necessary to reduce the consumption of cenosphere and silica fume in future studies, increase the biochar dosage, and improve the properties of engineered biochar for better composite performance. The biochar-cement composites were also tested at 550 °C, showing that the stability was still maintained due to the function of biochar in reducing capillary porosity and redistribution of water (Gupta and Kua 2020). Furthermore, biochar as a hygroscopic filler has been applied in pervious concrete to regulate the temperature and purify contaminated water, thus contributing to developing sponge cities. By incorporating 5% biochar, the total water adsorption of pervious concrete reached 117 kg ­m−3, and the enhancement of water adsorption, in Zhang et al. Biochar (2022) 4:59 turn, decreased the surface temperature of pervious concrete by 6 °C (Tan et al. 2021). Fine biochar (< 125 μm) as an alternative for cement was applied for manufacturing ultra-high performance concrete (UHPC) with lightweight and high strength (Dixit et al. 2019). It was found that biochar with internal curing and nucleation sites can improve the hydration and alleviate the brittle nature of biochar, making it feasible for manufacturing UHPC. Dixit et al. also found that the addition of 2 wt% and 5 wt% biochar reduced the autogenous shrinkage of calcined marine clay-based UHPC by 21% and 32%, respectively (Dixit et al. 2021). Using 5 wt% biochar in UHPC also contributed to carbon sequestration of approximately 115 kg C ­ O2 per ­m3 of UHPC (Dixit et al. 2021). Replacing cement partially with biochar is a win–win strategy in respect of sustainable waste management and carbon sequestration. Optimising the biochar dosage in the admixture would benefit the enhancement of compressive strength, flexural strength, toughness, ductility, and durability of biochar-cement composites. The optimal dosage of biochar recommended as a filler in the biochar-cement composites was 0.5–2 wt% in consideration of the improvement in mechanical performance (Maljaee et al. 2021). The incorporated dosage of biochar could be further increased to reduce the ­CO2 emissions associated with construction and buildings, even though this would lead to an inevitable strength loss (within an acceptable range). Biochar with a relatively large particle size was not recommended as a filler because it could not efficiently fill the pores, leading to low strength and high capillary pores (Akhtar and Sarmah 2018). Meanwhile, the O/C atomic ratio in biochar was strongly associated with its hydrophilicity, such that high ratios may ensure good water retention capacity and facilitate internal curing (Karnati et al. 2020). Few studies investigated the customisation of engineered biochar for improving the performance of biochar-cement composites. Engineered biochar can be tuned to possess hydrophilic functional groups, which may be compatible with cement and promote hydration reaction. The mineral-rich engineered biochar may be able to facilitate the pozzolanic reactions further. For example, the Si released from Si-enriched biochar could form additional C-S-H with Al and Ca in the cement system, densifying the structure and enhancing the mechanical performance (Wang et al. 2019b, d; Chen et al. 2022a). The composites of Mg/Al layered double hydroxides (Mg/Al-LDHs) impregnated biochar feature smaller crystallite sizes, larger interlayer spacing, higher surface area, and more exposed active sites (Peng et al. 2021), which could provide additional nucleation sites and promote the hydration rate. Meanwhile, the Mg/ Page 9 of 25 Al-LDHs impregnated biochar has the potential to be used as a corrosion control additive in concrete because free Cl can be captured in the interlayer of LDHs (Cao et al. 2017; Ye 2021). The engineered biochar can also be combined with Al-rich minerals (e.g., kaolinite) via cation bridging, ligand exchange, and Van der Waals attraction (Yang et al. 2018), enhancing the carbon stability of biochar in the composites. A modification of the electronegativity of biochar surface may also regulate the cement hydration process. Therefore, incorporating engineered biochar into cement composites exhibits a good research potential and warrants further investigations. 4.1.2 Biochar as an aggregate in concrete Biochar can be used to substitute for aggregate, especially in lightweight concrete. Previous research has investigated the application of hollow cenospheres, wood, and fibres (e.g., reed fibres and milled fibres) as low-density aggregate in construction sectors for achieving lightweight and high performance (Wang et al. 2016a; Shon et al. 2019; Chen et al. 2020a; Lu et al. 2021). Biochar can also be incorporated into the concrete as a porous and lightweight fine aggregate. It was found that replacing sand with 20% biochar with an average particle size of 26 μm could enhance the flexural strength by 26% while reducing the bulk density by 10% (Praneeth et al. 2021). Restuccia et al. adopted biochar derived from hazelnut shells and coffee powder as nano-aggregates (10–15 μm), where the rupture modulus and fracture energy of samples increased by 22% and 61%, respectively (Restuccia and Ferro 2016). These results indicated that biochar could provide a ductile behaviour and strengthen the interfacial transition zones, thus improving the bending strength and fracture energy. Carbon-negative concrete can also be developed by incorporating 30 wt% biochar as aggregates, providing both environmental benefits and economic profits, and revolutionising the development of the concrete industry (Chen et al. 2022b). Therefore, the application of biochar as an alternative aggregate and the associated environmental benefits (e.g., net-zero ­CO2 emissions, moisture regulation) are worth further substantiation. In the future, large-scale development of biocharcement composites should be achieved through advancing our scientific understanding of the interfacial reactions and further optimising the pore structure and physicochemical properties of engineered biochar. It is suggested that engineered biochar should be selected from an appropriate feedstock and can be reinforced with chemical additives or physical approaches to maximise the value-added performance of biochar-cement composites. Biochar-rubber composites 650; 700; 750 Residues miscanthus n.a n.a Ash content (%) < 4.5 900 800 Dried distillers’ grains Lignin 0.5 n.a n.a n.a 1.0–4.7 2–10 (diameter); n.a 30–50 (length) D50 = 35–40 10 Biochar particle size (μm) Arhar stalks and 800 Bael shell Cellulose; waste 400 cotton fibre 600; 1000 Maple tree Biochar-resin composites Pyrolysis temperature (℃) Feedstock Products 83.4 n.a n.a n.a n.a n.a Specific surface area ­(m2 ­g−1) 0–40 n.a 2; 4; 6 1; 2; 5; 10 20 1; 2; 4; 20 Filler ratio (wt.%) Table 1 Performance and characteristics of biochar and properties of biochar-polymer composites 3.8–9.9 15.6–21.4 30–50 15–28 n.a ~ 23 1.4–2.3 1.3–1.9 n.a 0.8–2.3 n.a ~1 Ref. Giorcelli et al. (2019a) Graphitic structure of biochar exhibited hydrophobicity resulting in a high affinity with rubber Jiang et al. (2020) Lower rolling Paleri et al. (2021) resistance and higher wet skid resistance; good for tire applications Tensile strength Minugu et al. increased by (2021) 183%, and flexural strength by 91% compared with neat epoxy (4% biochar added) Improvement of Bartoli et al. elongation (2020) Electrical properties of the composites increased as the ­CO2 activated biochar conductivity increased Tensile toughGiorcelli et al. ness of biochar- (2019b) resin composite (2% added) increased 11 times compared with pure resin Tensile Modulus (GPa) Remarks strength (MPa) Zhang et al. Biochar (2022) 4:59 Page 10 of 25 Biochar-plastic composites Products 900 700; 900 n.a Rice husk Date palm tree Mixed hardwood 1000 Coconut shell; wood pallets 700 (gasification) n.a Wood waste Spruce woodchips Pyrolysis temperature (℃) Feedstock Table 1 (continued) 22.9 20–50 150 n.a 0.1–10 ~1 Biochar particle size (μm) 15 20.57; 21.35 n.a 4.2 12.89; 4.06 2.41 Ash content (%) 45.4 283.62; 291.11 1.8–297.4 297 375; 137 n.a Specific surface area ­(m2 ­g−1) 8, 10, 12 0–15 50 44 0–40 15.2–16 Filler ratio (wt.%) n.a 32–35 26.3 (highest) n.a ~ 15 18–25 n.a 1.12–1.36 1.87 (highest) n.a n.a n.a Jong et al. (2014) Peterson and Kim (2020) Ref. PVA/biochar composite sensor was influenced by thickness and temperature Agglomeration and high ash content of biochar led to low conductivity Nan and DeVallance (2017) Poulose et al. (2018) Stiffness, Zhang et al. elasticity, creep (2020a) resistance, and stress relaxation improved Electrical Benedetti et al. conductiv(2021) ity reached 2 × ­10−3 S ­cm−1 Biochar-polymer interaction strength was lower than that of carbon black 15% biochar incorporation increased elongation and toughness by 31% and 24%, respectively Tensile Modulus (GPa) Remarks strength (MPa) Zhang et al. Biochar (2022) 4:59 Page 11 of 25 Products Pyrolysis temperature (℃) 500; 900 900 400; 450 Feedstock Perennial grasses Pine saw dust n.a Table 1 (continued) 425 n.a 16.1; 8.4 Biochar particle size (μm) 3.1–8.4 n.a n.a Ash content (%) 1.2–1.6 335 216.3; 8.4 Specific surface area ­(m2 ­g−1) 6; 12; 18; 24; 30 15; 20; 25 0; 10; 20 Filler ratio (wt.%) 19–25 ~ 25 ~ 20 2.8–3.6 ~ 3.5 1.2–1.5 Behazin et al. (2017) Ref. Higher flexural Das et al. (2015b) strength was found at 24 wt.% biochar Peak heat Das et al. (2017a) release rate and limiting oxygen index reached 318 kW ­m−2 and 23%, respectively Surface functional groups elimination and high specific surface area promoted compatibility Tensile Modulus (GPa) Remarks strength (MPa) Zhang et al. Biochar (2022) 4:59 Page 12 of 25 Zhang et al. Biochar (2022) 4:59 4.2 Biochar‑polymer composites The adoption of carbon-based fillers (nanotubes, graphene and its derivatives, graphite, activated carbon, and biochar) in polymer composites has gained great interest due to good interfacial bonding with polymer, availability in different forms, etc. Table 1 compares the performance and characteristics of biochar-polymer composites investigated in the latest studies. Incorporating biochar enhanced the mechanical performance (e.g., tensile strength, flexural strength, and elongation) and functional performance (e.g., electrical conductivity and rolling resistance) of biochar-polymer composites. 4.2.1 Biochar‑resin composites Biochar can be incorporated into epoxy resin to enhance its mechanical and electrical properties, extending resin composites’ applications in structural applications, surface coating, and laminating electronic circuit boards in industries such as automobiles and aerospace. Giorcelli et al. found that a low biochar dosage had no significant effect on the mechanical properties of the biochar-epoxy resin composites, whilst a high biochar dosage significantly enhanced the mechanical properties in terms of toughness and resilience 105. The electrical performance of the composites was also investigated, in which the degree of conductivity enhancement was associated with the carbon content of biochar (Giorcelli et al. 2019a, b). The shape (i.e., spherical and cylindrical) of biochar affects the mechanical properties of epoxy resin. The biochar-epoxy resin composites exhibited remarkable elongation properties (up to 8.2%) and low friction coefficients (reaching 0.37) when incorporating 2 wt% of spherical biochar, while the two parameters reached 4.0% and 0.22, respectively, when adopting 10 wt% of cylindrical biochar (Bartoli et al. 2020). Therefore, the pyrolysis procedure, types of feedstock, and characteristics of the resultant biochar primarily affected the performance of biochar-epoxy resin composites, especially for electrical properties. A thoughtful selection of suitable biochar is a prerequisite for effective incorporation. 4.2.2 Biochar‑rubber composites Carbon black is a conventional filler used in rubber composites representing approximately 90% of the rubber filler market (Fan et al. 2020). However, carbon black is a fossil fuel-derived product with considerable carbon emissions. Some researchers have replaced carbon black with renewable bioresources (e.g., starch, lignin, soy protein, and eggshell) in the rubber composites (Jong 2015; Barrera and Cornish 2016; Cao et al. 2018; Du et al. 2019), yet they exhibited low reinforcement efficacy on rubber owing to the brittle nature and strong hydrophilicity (Jiang et al. 2020). Page 13 of 25 Biochar with similar properties to carbon black has been applied to rubber composites. Jong et al. (2014) found that coconut shell biochar exhibited a fivefold increase in tensile modulus of the rubber composites compared to natural rubber. The importance of filler size and filler surface properties was emphasised for the strength enhancement of rubber (Jong et al. 2014). Biochar larger than 10 µm in diameter would introduce localised stress in the rubber composites, adversely influencing reinforcement properties. To address this issue, the reinforcement efficacy of particle size on the biocharrubber composites could be adjusted by using nano-silica as the co-milling material and controlling ball milling time (Xue et al. 2019; Peterson and Kim 2020). Both studies confirmed that smaller particle sizes (< 1 μm) improved the elongation and toughness properties of biochar-rubber composites. Generally, biochar as a filler incorporated into polymer could improve the mechanical, thermal, and electrical properties and concurrently reduce the production cost. However, some intrinsic drawbacks of biochar (e.g., relatively large particle size, low surface activity, variable components and properties) would require adequate and scientific designs before industrial applications. Therefore, the properties of polymer-composites can be further improved by tailor-making the biochar properties such as porous structure, surface functionalisation, chemical composition, mineral speciation/crystallinity, carbon structure/reactivity, etc. Such enhancement could strengthen the biochar-polymer interactions and impart superior properties for the composites. Recently, molecular dynamics simulations have been applied for evaluating the mechanical performance of carbon materials-polymer interfaces under different conditions (Zhou et al. 2015; Tam et al. 2019), which are also recommended for improving our scientific designs of the biochar-polymer composites. Combining the experimental analysis at the macro scale and computational simulations at both micro and nanoscale, a comprehensive understanding of the biochar-polymer composites can be achieved. In the future, the multi-scale investigation will be an essential study for next-generation biochar-polymer composites. 4.2.3 Biochar‑plastic composites Biochar was employed as a filler in wood-plastic composites (WPC) (Das et al. 2015a). By increasing the biochar content to 24 wt%, the tensile and flexural strength of biochar-modified WPC improved comparing with conventional WPC (Das et al. 2015b). This was attributed to the porous biochar, which allowed molten polypropylene to fill in and created a mechanical/physical interlocking (Das et al. 2016a). Zhang et al. Biochar (2022) 4:59 Page 14 of 25 Fig. 4 Biochar as a modifier for asphalt manufacture Destructions due to building fire highlight the importance of flame-retardant polymer composites. Biochar with a stable porous honeycomb structure and no flammable volatiles is qualified with considerable thermal resistance and can be used as excellent fire-resistance materials (Babu et al. 2020). The highest thermal stability was observed in the case of WPC with 18 wt% biochar incorporation (Zhang et al. 2020a). The biochar application into WPC would synergistically preserve mechanical properties and reduce flammability. Poultry litter biochar was found to impart the optimal tensile and flexural properties of composites due to the Ca-rich ash in poultry litter biochar (Das et al. 2016a). Besides, biochar addition could save production cost by approximately 18% as the dosage of coupling agent (i.e., maleic anhydride grafted polypropylene) could be reduced from 3 to 1 wt% without significant deterioration in mechanical performance (Das et al. 2016b). Conventional flame retardants (i.e., ammonium polyphosphate and magnesium hydroxide) were introduced into the biocharmodified WPC to further impede its flammability. Considering both enhancements of resistance to radiative heat and economic benefits, the loading amount of magnesium hydroxide was suggested to be 20 wt% (Das et al. 2017a, b). A higher dosage of flame retardants (e.g., magnesium hydroxide at a high loading rate of 50 wt%) may further strengthen the thermal stability of biochar-modified WPC; however, the excess flame retardants would be trapped in the biochar pores and obstruct the infiltration of polypropylene, which consequently reduced the mechanical bonding/interlocking between biochar and polypropylene (Das et al. 2017a). The employment of biochar for enhancing the flame resistance of WPC is a promising approach concerning both environmental sustainability and economics. The effect of biochar on the WPC manufacturing process (e.g., extrudability) requires further investigation before industrial applications. The electrical conductivity of biochar-plastic composites is also attracting extensive attention regarding their various applications, such as electrostatic dissipation materials, electromagnetic interference shielding materials, and semiconducting layers to prevent electrical discharge. Poulose et al. (2018) applied biochar to manufacture biochar polypropylene composites to enhance the electrical properties and tensile modulus, but the agglomeration and the high ash content of biochar would hamper the conductivity enhancement. In general, the integrated properties of the biochar-plastic composites are associated with the dispersion of biochar and the network formation in the polymer matrix (Khushnood et al. 2015). Other parameters (e.g., characteristics of biochar, polymer viscosity, and types of coupling agents) would affect the integrated properties of the biochar-plastic composites. The addition of coupling agents, wood and biochar was crucial for the tensile and flexural strength of composites but had little effect on the flammability (Ikram et al. 2016). Polar wood biochar exhibited no effect on the melting temperature of high-density polyethene, but it promoted the early crystallisation of biochar-plastic composites (Zhang et al. 2019b). Dynamic mechanical analysis revealed that biochar incorporation enhanced the stiffness, elasticity, creep resistance, and stress relaxation of the biochar-plastic composites (Zhang et al. 2020a). However, other properties of biochar, such as ash content, specific surface area, surface functional groups, etc., are not clearly stated regarding the performance of biochar-plastic composites and require further investigations. In future research, it is also necessary to identify the optimum levels of various factors to achieve the desirable properties of biochar-plastic composites for either mechanical performance or flammability. Zhang et al. Biochar (2022) 4:59 Page 15 of 25 Fig. 5 Environmental and technical advantages of biochar composites: a humidity regulation and urban microclimate; b thermal insulation and noise reduction; c contaminant immobilisation and indoor air quality improvement; d electromagnetic shielding; e biochar-added 3D printable concrete; f biochar-enhanced phase change materials; g self-sensing cement composites; h bacteria cargo for self-healing cement composites 4.3 Biochar‑asphalt composites Asphalt mixtures, consisting of asphalt binder and aggregates, are principal construction materials employed in the highway and pavements. Some carbon-based materials (e.g., carbon black, carbon fibre, and carbon nanotubes) have been introduced to improve the properties (e.g., rutting resistance, stripping resistance, and durability) of asphalt binders in previous studies (Cong et al. 2014; Wang et al. 2016b; Ziari et al. 2018). However, the high cost and limited enhancement of the aforementioned carbon-based materials inhibited their large-scale applications. A few researchers have adopted biochar Zhang et al. Biochar (2022) 4:59 as an economic modifier to enhance the properties of asphalt binders and mixtures, such as durability, temperature sensitivity, and fatigue performance (Fig. 4). Biochar was more effective in strengthening temperature susceptibility and rutting resistance of asphalt binders than carbon black or carbon fibre (Zhao et al. 2014a, b). Biochar with a particle size less than 75 μm could be a favoured asphalt binder modifier for achieving satisfactory rotational viscosity and low-temperature crack resistance (Zhang et al. 2018). The ageing of the asphalt binder would lead to cracking, fatigue, and raving (Nazari et al. 2018). Ageing also contributes to an increase in viscosity, affecting the stiffness of the asphalt binders and mixtures (Pasandín et al. 2015). Therefore, more interest has been gained in enhancing the ageing resistance and susceptibility of asphalt (Cong et al. 2014; Kumar et al. 2018; Dong et al. 2020). Pyrolysis biochar could primarily improve the ageing resistance of asphalt binders by mitigating the oxidative ageing of asphalt binder components rather than reducing the volatilisation of lightweight components (Dong et al. 2020). Furthermore, pyrolysis biochar, having carbon as the primary composition, can shield the surface of asphalt from ultraviolet light, prevent photo-oxidative ageing and improve the high-temperature stability of asphalt (Zhou and Adhikari 2019). Bio-oil, one of the by-products generated during pyrolysis of biochar, can also be applied as a rejuvenator for aged asphalt (Zhang et al. 2020b), enabling a combination usage of biochar and bio-oil for manufacturing sustainable asphalt. Hydrochar also exhibits good compatibility with asphalt owing to the micron-sized pits, voids and abundant functional groups on the surface. The high-temperature performance of asphalt was significantly improved by incorporating hydrochar. The optimum dosage of hydrochar was 6 wt% with rutting index reaching 76 °C and penetration and softening point reaching 31.7 (0.1 mm) and 54.7 °C, respectively (Hu et al. 2021). However, incorporating hydrochar hindered the workability of asphalt under low temperatures, which requires further investigation and improvement by adopting tailored hydrochar. 5 Environmental and technical advantages of biochar‑enhanced construction materials 5.1 Humidity regulation and cooling effect Excessive artificialisation of the ground (e.g., the extensive application of pavement) caused by the rapid urban expansion has disrupted the balance of moisture and heat transition between the ground and the atmosphere, leading to a series of thermal environment issues in urban (He et al. 2021a). For example, pavement materials involving concrete and asphalt mixtures would adsorb Page 16 of 25 and store solar energy and then release the stored energy into the city as sensible heat, contributing to the urban heat island effect (Qin et al. 2018). Pervious concrete features a porous structure that can provide channels for heat and moisture transfer in road pavement, enabling evaporative cooling and alleviating the urban heat island effect in hot seasons (Park et al. 2021a). Incorporating biochar into the pervious concrete could reduce albedo and increase water adsorption capacity, mitigating urban heat island issues (Park et al. 2021b). The biocharpervious concrete could absorb more solar radiation than plain pervious concrete, keeping cool through water evaporation and creating an urban microclimate. These findings were validated by Tan et al. (2021) by adopting a low-speed straight flow climatic wind tunnel to investigate the temperature regulation capacity of biocharpervious concrete. Their results demonstrated that the maximum temperature decreased by 6 °C for 18 h (Tan et al. 2021). Therefore, biochar is considered a promising hygroscopic filler for manufacturing humidity- and temperature- regulating construction materials, enhancing hygrothermal performance and alleviating the urban heat island issues (Park et al. 2021b). Figure 5a illustrates the mechanisms of humidity regulation and urban microclimate of biochar pervious concrete. The hygrothermal properties of biochar-pervious concrete should be optimised to enhance the capabilities for regulating humidity and temperature. 5.2 Thermal insulation and noise reduction Customised biochar possesses 3D porous and 2D flakelike structures, which contribute to the formation of additional pathways for heat transfer (Xiong et al. 2022). When porous biochar is uniformly distributed throughout the construction materials, it can induce scattered heat propagation, render the heat propagation routes multi-directional, and hinder the effect of unidirectional heat propagation (Jiang et al. 2022; Wu et al. 2022; Xiong et al. 2022). This phenomenon effectively slows the expected propagation of heat flow and inhibits the heat transfer through solids, enhancing the thermal insulation potential of biochar-cement composites (Fig. 5b). It was found that the addition of biochar decreased the thermal conductivity of biocharcement composites by 25% (Rodier et al. 2019). Similar results were also obtained in biochar-clay composites, where the maximum thermal conductivity decreased by 67% (Lee et al. 2019). The addition of 2 wt% biochar resulted in a low thermal conductivity [0.192 W (m·K)−1], and its incorporation also improved the acoustic performance of biochar-cement composites across the frequency range of 200–2000 Hz (Cuthbertson et al. 2019). The introduction of biochar can Zhang et al. Biochar (2022) 4:59 increase the porosity of cement-biochar composites. The pores in biochar would break the thermal bridging within the biochar-cement composites, which is responsible for the low thermal conductivity and thermal insulation improvement. Therefore, biochar with high porosity and 3D pore structure is more favoured for enhancing the thermal insulation and noise reduction of construction materials. 5.3 Contaminant immobilisation and indoor air quality improvement Biochar has been widely applied for water purification and soil remediation due to its peculiar and tuneable properties, such as high porosity, good stability, and high cation exchange capacity. Many studies have focused on incorporating biochar into construction materials to impart the functional properties (e.g., contaminant immobilisation and indoor air quality improvement) to the composites (Fig. 5c). For instance, the water purification process of biochar-pervious concrete was mainly controlled by adsorption ability and microbial degradation of biochar. Wang et al. also applied the biochar-modified binder for the contaminated sediment immobilisation, suggesting that biochar enhanced the immobilisation efficacy of potentially toxic elements (PTEs) and other organic contaminants in the sediment (Wang et al. 2019c). The environmental merits of biochar make the sediment products environmentally acceptable as construction materials, such as fill materials and paving blocks. Biochar cement is a climate-positive and robust binder for immobilising municipal solid waste incineration fly ash, where biochar promotes the hydration of cement, resulting in a denser matrix for encapsulation of PTEs (Chen et al. 2019a, 2022a). These studies provided new insights into adopting climate-positive binders to treat hazardous waste. As an economical and highly efficient adsorbent for volatile organic compounds (VOCs), biochar also has the potential to be applied in biochar particleboard for adsorbing VOCs from interior finishing, contributing to indoor air quality improvement (Zou et al. 2019; Xiang et al. 2020). However, very few studies concerning incorporating biochar into particleboard to eliminate VOCs were performed, requiring further relevant investigations. Asphalt pavement production would inevitably generate VOCs, posing health risks to construction labours (Cui et al. 2020). To solve this problem, some researchers introduced biochar for removing VOCs in asphalt. Biochar could reduce the VOCs emissions by half, and the adsorption mechanisms depend on the types of biochar (Zhou et al. 2020). For example, chemical adsorptions occurred between straw/wood-derived biochar and Page 17 of 25 VOCs, while physical adsorptions typically occurred with pig manure-derived biochar (Zhang et al. 2020b; Zhou et al. 2020). The adsorption capacity of biochar and biochar asphalt towards VOCs can be improved by increasing specific surface area, pore volume, and the amount of surface chemical functional groups but decreasing pore size (Li et al. 2020). Although biochar exhibits a promising perspective as a VOCs scavenger, few studies have considered the synergy of both VOCs removal efficiency and asphalt performance improvement by adopting biochar. 5.4 Electromagnetic shielding Electromagnetic radiation caused by wireless and communication devices is an increasing public concern. The ability to attenuate or hinder electromagnetic interferences is defined as electromagnetic shielding. The shielding performance of cement composites is expected to be increased by incorporating carbon-based materials, such as graphene and carbon nanotubes (Chen et al. 2015; Nam et al. 2018). The graphene and carbon nanotubes qualified with high specific surface area, low density, and high electrical conductivity could enhance the electromagnetic shielding efficacy (Zhou et al. 2018). However, the high cost and agglomeration of graphene and carbon nanotubes limit their large-scale applications in cement composites. Biochar as a cost-effective material was proposed for improving the electromagnetic interference shielding efficacy of cement-based composites (Fig. 5d). A maximum increase of shielding effectiveness was up to 353% at 1.56 GHz frequency by incorporating 0.5 wt% biochar compared to plain cement (Khushnood et al. 2015). The electromagnetic shielding performance of a sustainable lightweight biochar-cement-gypsum composite was facilitated by increasing biochar content, which became more pronounced at frequencies above 4 GHz (Natalio et al. 2020). The biochar composite exhibited high shielding efficacy in the microwave range; the mechanisms behind it were not interpreted clearly but attributed to some conventional reasons, such as natural alignment of carbon ultrastructure (e.g., lignin), dissipation of surface currents and polarisation in the electric field. 5.5 Biochar‑enhanced 3D concrete printing The three-dimensional (3D) concrete printing involving layer-by-layer concrete deposition by a 3D printer without framework support or vibration processes has gained tremendous interest in recent years. Construction materials plus 3D printing could reduce construction waste by 30–60%, labour expense by 50–80%, and production time by 50–70% (Zhang et al. 2019a). However, the high-efficiency 3D concrete printing requires excellent Zhang et al. Biochar (2022) 4:59 pumpability, extrudability, and buildability, making conventional cement-based materials difficult to satisfy the requirements (De Schutter et al. 2018). The appropriate dosages of polymeric fibres and nano-sized additives (e.g., nano-silica, graphene-based materials, and nanoclay) could improve the thixotropy and buildability of 3D concrete printing (Sikora et al. 2022). For instance, the nano graphene-based materials at the dosage of 1 wt% enhanced the flexural strength of composites by 89% and compressive strength by 28% whilst demonstrating excellent shape retention and buildability (Chougan et al. 2020). Lightweight concrete with a porous structure is a versatile material applicable for specific structural and insulating purposes. Recently, 3D printing of lightweight foam concrete with a density ranging from 800 to 1200 kg ­m−3 was manufactured for exterior wall elements without an extra thermal insulation layer (Markin et al. 2021). The stability of foam significantly affected the properties of 3D concrete printing, and future work should emphasise further reducing the density and maintaining adequate load-bearing capacity. Wood sawdust and phase change materials were added to enhance the thermal insulation capacity and reduce the density of 3D concrete printing (De Schutter et al. 2018). Carbon-negative biochar was also incorporated to improve the thixotropy of 3D concrete printing, which can provide a new direction for versatile 3D concrete printing (Fig. 5e). The addition of biochar can reduce the density of 3D printing of lightweight concrete and enhance extrudability and buildability. Developing appropriate mixture compositions for high-performance 3D concrete printing has become an opportunity yet a grand challenge. Incorporating biochar into 3D concrete printing has a promising perspective regarding property enhancement and carbon neutrality. 5.6 Biochar phase change materials Phase change materials (PCMs) with high latent heat storage capacity are novel and sustainable materials for energy storage and conversion (Mohamed et al. 2017). Recent studies have applied PCMs in construction materials to facilitate energy efficiency and decrease the energy consumption of construction (Song et al. 2018; Wi et al. 2021). However, the large-scale applications of PCMs are limited by several drawbacks, such as seepage above the normal melting temperature, insufficient heat transfer performance, inadequate thermal energy absorption and release characteristics. Nano-sized carbonbased materials, including graphite, graphene, porous carbons, and carbon nanotubes, have been applied as supporting materials for improving the performance of PCMs (Atinafu et al. 2018, 2021a; Chen et al. 2020b; Wi et al. 2020). Although these materials can effectively Page 18 of 25 enhance the heat transfer performance of PCMs, their prices are prohibitive for large-scale applications, and the modification processes are often chemically intensive. Biochar, as a low-cost carbon-negative material, has recently been adopted as a supporting scaffold for enhancing the performance of PCMs (Fig. 5f ) (Jeon et al. 2019a; Kim et al. 2021). The biochar-PCMs displayed negligible leakage, good thermal insulation capacity, high chemical compatibility, exudation stability, and shape stability whilst reducing building energy consumption of the referenced building model (up to 531 kWh ­year−1) (Jeon et al. 2019b). Engineered biochar could significantly prevent the leakage of PCMs, and the corresponding biocharPCMs achieved fusion enthalpies of 108.3 and 138.1 J ­g−1, respectively, whilst maintaining the chemical structure and thermal reliability after 1000 heating/cooling cycles (Hekimoğlu et al. 2021). The intermolecular interactions between PCM and biochar (i.e., hydrogen bonding), as well as the characteristics of biochar (e.g., surface functionality, specific surface area, and pore size distribution), were crucial factors influencing the performance of biochar PCMs (Atinafu et al. 2021c). An interconnected network and the high degree of graphitisation of biochar microparticles are essential for enhancing the specific heat capacity and providing nucleation sites to reduce the sub/super-cooling phenomenon of biochar-PCMs (Yang et al. 2019; Yuan et al. 2021). The engineered biochar integrating with multiwalled carbon nanotube exhibited a high loading capacity of PCMs up to 70.2%, exhibiting a high heat storage capacity of 127.4 J ­g−1 due to the favourable microstructure and interconnected framework of the engineered biochar (Atinafu et al. 2021b). Therefore, engineered biochar with sufficient specific surface areas, pore volumes, and functional groups would be favoured for developing high-performance biochar-PCMs. Overall, the biochar-PCMs with low cost and improved performance can be utilised for diverse thermal energy storage applications, e.g., waste heat recovery and passive cooling of climate-positive design. 5.7 Self‑sensing biochar‑cement composites The structural health monitoring of civil engineering infrastructures has received increasing attention nowadays, which involves controlling the functional reliability of infrastructure by using computer software. Underlying this new technique is a self-sensing cement composite combining sensors with electrically conductive additives loaded cement. A substantial amount of research has adopted carbon fibres, carbon black particles, carbon nanotubes, and graphene nanoplatelets as additives for manufacturing self-sensing cement composites (D’Alessandro et al. 2016; Monteiro et al. 2017; Belli et al. 2018). Biochar has been investigated as a potential Zhang et al. Biochar (2022) 4:59 alternative to graphene nanoplatelets in self-sensing cement composites (Fig. 5g). The addition of biochar at a dosage of 1% (v/v) to cement significantly reduced the electrical resistivity (− 42%) whilst maintaining good mechanical properties (Mobili et al. 2021). Engineered biochar at the dosage of 5% incorporated in self-sensing cement composites, exhibiting a 70% reduction in the water adsorption, a 23% increase in electrical conductivity, and an approximately 45% reduction in embodied carbon footprint (Haque et al. 2021). In future studies, the engineered biochar is recommended to enhance the performance of self-sensing biochar-cement composites. 5.8 Bacteria cargo for self‑healing cement composites Cracks formed in concrete allow aggressive chemicals to penetrate the structure, thereby accelerating the damage to the concrete and jeopardising its durability and service life. Self-healing treatment involves autogenous healing, incorporating polymeric materials and calcium carbonate precipitation by microbial species, a promising concrete crack remediation technique (Vijay et al. 2017). Calcium carbonate production through biomineralisation is an efficient and sustainable pathway for sealing cracks, which can hinder the crack development and fill the deep microcracks (Seifan et al. 2016). Biochar has been adopted as a carrier for bacteria spores in cement composite to seal cracks. A crack of 700 μm in maximum can be sealed by combining bacteria-doped biochar with superabsorbent polymers and polypropylene microfibers (Gupta et al. 2018c). Meanwhile, incorporating bacteria-doped biochar could enhance the strength of biochar-cement composites by 38% and reduce the water penetration and absorption by 65% and 70%, respectively, compared with the direct incorporation of spores (Gupta et al. 2018c). This modified system also maintained the crack sealing efficacy after multiple damage cycles. Biochar as bacteria cargo for self-healing composites can boost the sealing of cracks (Fig. 5h). This provides a relatively low-cost and sustainable solution for solving the crack issue in concrete, which is also beneficial for expanding the life span and durability of concrete. Further study is required to improve the survival rate of bacteria exposed to alkaline conditions of concrete. 6 Future perspectives (1) Advancing the scientific understanding of the interfacial reactions in biochar-construction materials with the assistance of cutting-edge technologies such as micro-computed tomography, nanoindentation, and transmission electron microscopy is required to promote the performance development of biochar-construction materials. Page 19 of 25 (2) The application of atomistic simulations could further improve the understanding of molecular-level interfacial properties between biochar and asphalt/ polymer/cementitious materials under different conditions. The models developed by molecular dynamics simulation also can be adapted to evaluate the bonding strength of biochar/asphalt/polymer/cementitious materials under different chemomechanical interactions and form the basis for predicting long-term performance. (3) Comprehensive regulation of biochar regarding quality, safety, and properties should be carried out to ensure the proper selection and utilisation of biochar in construction materials. For example, detailed requirements should be defined from raw materials selection to biochar production processes in order to ensure biochar performance. Standardized assessments of biochar construction materials should also be established to safeguard long-term use and human/environmental health. Meanwhile, modifications of biochar would benefit the biochar quality and expand the applications of functional biochar construction materials in respect of technical and environmental performance. (4) Environmental and technical advantages of biochar construction materials, such as hygrothermal regulation, electromagnetic shielding, contaminant immobilisation, indoor air quality improvement, self-healing capacity, and acoustic insulation, are still in their infancy and should be further explored to demonstrate their value-added and superior performance. (5) A combination of multiple techniques is promising to provide comprehensive information on the advantages and disadvantages of biochar construction materials. For instance, the synchronous use of biochar and C ­ O2 curing would enhance the performance of the construction materials whilst achieving deeper carbon sequestration compared with single technique utilisation. (6) A holistic techno-economic analysis and life cycle assessment should be carried out prior to commercial applications. This would provide an insight into the sustainability of biochar construction materials and their impact on the environment. 7 Conclusions Biochar is demonstrating its tremendous promise for applications in carbon neutral/negative construction materials and is contributing to the achievement of carbon neutrality targets. The incorporation of biochar derived from waste biomass in construction materials Zhang et al. Biochar (2022) 4:59 can mitigate ­CO2 emissions and natural resource depletion whilst improving the mechanical performance and providing value-added merits for biochar construction materials. Biochar construction materials also offer environmental and technical advantages, such as hygrothermal regulation, electromagnetic shielding, contaminant immobilisation, indoor air quality improvement, selfhealing capacity, and acoustic insulation. The versatility of biochar gives biochar construction materials the potential to revolutionise the industrial manufacture of conventional construction materials and become an advocate of sustainable and green development. We also highlight that tailoring the favourable physicochemical properties of engineered biochar based on adequate and scientific designs and advancing the scientific understanding of interfacial reactions in biochar construction materials would facilitate the large-scale development and widespread applications of biochar construction materials. Acknowledgements The authors appreciate the financial support from the Hong Kong Green Tech Fund (GTF202020153), Hong Kong Environment and Conservation Fund (Project 104/2021), and the Alexander von Humboldt Foundation (AvH) for this study. Author contributions YZ: conceptualization, methodology, literature collection and analysis, writing; MH: literature collection and analysis, writing; LW: conceptualization, methodology, supervision, review and editing; JY: review and editing; BM: methodology, review and editing; XZ: methodology, review and editing; YSO: review and editing; VM: review and editing; DCWT: conceptualization, methodology, project administration; supervision, review and editing. All authors read and approved the final manuscript. Funding This work was supported by the Hong Kong Green Tech Fund (GTF202020153) and Hong Kong Environment and Conservation Fund (Project 104/2021). Availability of data and materials Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study. Declarations Competing interests All authors declare no conflict of interest. Author details 1 Department of Civil and Environmental Engineering, The Hong Kong Polytechnic University, Hung Hom, Kowloon, Hong Kong, China. 2 State Key Laboratory of Clean Energy Utilization, Zhejiang University, Hangzhou 310027, China. 3 Laboratory for Waste Management, Nuclear Energy and Safety, Paul Scherrer Institute, 5232 Villigen, Switzerland. 4 School of Civil Engineering, University of Leeds, West Yorkshire, Leeds, UK. 5 Korea Biochar Research Center, APRU Sustainable Waste Management Program & Division of Environmental Science and Ecological Engineering, Korea University, Seoul, Korea. 6 Institute of Construction Materials, Technische Universität Dresden, 01062 Dresden, Germany. 7 Research Centre for Resources Engineering towards Carbon Neutrality, The Hong Kong Polytechnic University, Hung Hom, Kowloon, Hong Kong, China. Received: 10 June 2022 Accepted: 23 September 2022 Page 20 of 25 References Akhtar A, Sarmah AK (2018) Novel biochar-concrete composites: manufacturing, characterization and evaluation of the mechanical properties. Sci Total Environ 616–617:408–416. https://doi.org/10.1016/j.scitotenv. 2017.10.319 Akinyemi BA, Adesina A (2020) Recent advancements in the use of biochar for cementitious applications: a review. J Build Eng 32:101705. https://doi. org/10.1016/j.jobe.2020.101705 American Concrete Institute (ACI) 213 (2003) Guide for structural lighweight concrete. Aci 213R 0–39 American Concrete Institute (ACI) 213R-03 (2003) Guide for structural lightweight aggregate concrete Atinafu DG, Dong W, Huang X et al (2018) Introduction of organic-organic eutectic PCM in mesoporous N-doped carbons for enhanced thermal conductivity and energy storage capacity. Appl Energy 211:1203–1215. https://doi.org/10.1016/j.apenergy.2017.12.025 Atinafu DG, Chang SJ, Berardi U et al (2021a) Potential utility of HKUST1-graphite nanocomposite to endow alkane with high thermal properties and low electrical resistivity. J Hazard Mater 402:123695. https://doi. org/10.1016/j.jhazmat.2020.123695 Atinafu DG, Wi S, Yun BY, Kim S (2021b) Engineering biochar with multiwalled carbon nanotube for efficient phase change material encapsulation and thermal energy storage. Energy 216:119294. https://doi.org/10. 1016/j.energy.2020.119294 Atinafu DG, Yun BY, Wi S et al (2021c) A comparative analysis of biochar, activated carbon, expanded graphite, and multi-walled carbon nanotubes with respect to PCM loading and energy-storage capacities. Environ Res 195:110853. https://doi.org/10.1016/j.envres.2021.110853 Aurora T, Jodi B, Kristen L, Jianguo L (2017) A looming tragedy of the sand commons. Science 357:970–971. https://doi.org/10.1126/science.aao05 03 Azzi ES, Karltun E, Sundberg C (2019) Prospective life cycle assessment of large-scale biochar production and use for negative emissions in Stockholm. Environ Sci Technol 53:8466–8476. https://doi.org/10.1021/ acs.est.9b01615 Babu K, Rendén G, Mensah RA et al (2020) A review on the flammability properties of carbon-based polymeric composites: state-of-the-art and future trends. Polymers 12:1–19. https://doi.org/10.3390/polym12071 518 Barrera CS, Cornish K (2016) High performance waste-derived filler/carbon black reinforced guayule natural rubber composites. Ind Crops Prod 86:132–142. https://doi.org/10.1016/j.indcrop.2016.03.021 Bartoli M, Rosso C, Giorcelli M et al (2020) Effect of incorporation of microstructured carbonized cellulose on surface and mechanical properties of epoxy composites. J Appl Polym Sci 137:48896. https://doi.org/10.1002/ app.48896 Batuecas E, Liendo F, Tommasi T et al (2021) Recycling ­CO2 from flue gas for ­CaCO3 nanoparticles production as cement filler: a life cycle assessment. J CO2 Util 45:101446. https://doi.org/10.1016/j.jcou.2021.101446 Behazin E, Misra M, Mohanty AK (2017) Sustainable biocarbon from pyrolyzed perennial grasses and their effects on impact modified polypropylene biocomposites. Compos Part B Eng 118:116–124. https://doi.org/10. 1016/j.compositesb.2017.03.003 Belli A, Mobili A, Bellezze T et al (2018) Evaluating the self-sensing ability of cement mortars manufactured with graphene nanoplatelets, virgin or recycled carbon fibers through piezoresistivity tests. Sustainability 10:4013. https://doi.org/10.3390/su10114013 Benedetti V, Scatto M, Baratieri M, Riello P (2021) Valorization of biomass gasification char as filler in polymers and comparison with carbon black. Waste Biomass Valoriz 12:3485–3496. https://doi.org/10.1007/ s12649-020-01243-7 Cao Y, Dong S, Zheng D et al (2017) Multifunctional inhibition based on layered double hydroxides to comprehensively control corrosion of carbon steel in concrete. Corros Sci 126:166–179. https://doi.org/10. 1016/j.corsci.2017.06.026 Cao L, Huang J, Chen Y (2018) Dual cross-linked epoxidized natural rubber reinforced by tunicate cellulose nanocrystals with improved strength and extensibility. ACS Sustain Chem Eng 6:14802–14811. https://doi. org/10.1021/acssuschemeng.8b03331 Zhang et al. Biochar (2022) 4:59 Cao Y, He M, Dutta S et al (2021) Hydrothermal carbonization and liquefaction for sustainable production of hydrochar and aromatics. Renew Sustain Energy Rev 152:111722. https://doi.org/10.1016/j.rser.2021.111722 Cha JS, Park SH, Jung SC et al (2016) Production and utilization of biochar: a review. J Ind Eng Chem 40:1–15. https://doi.org/10.1016/j.jiec.2016.06. 002 Chen T, Gao X (2019a) Effect of carbonation curing regime on strength and microstructure of Portland cement paste. J CO2 Util 34:74–86. https:// doi.org/10.1016/j.jcou.2019a.05.034 Chen T, Gao X (2019b) How carbonation curing influences ca leaching of Portland cement paste: mechanism and mathematical modeling. J Am Ceram Soc 102:7755–7767. https://doi.org/10.1111/jace.16684 Chen T, Gao X (2020) Use of carbonation curing to improve mechanical strength and durability of pervious concrete. ACS Sustain Chem Eng 8:3872–3884. https://doi.org/10.1021/acssuschemeng.9b07348 Chen J, Zhao D, Ge H, Wang J (2015) Graphene oxide-deposited carbon fiber/ cement composites for electromagnetic interference shielding application. Constr Build Mater 84:66–72. https://doi.org/10.1016/j.conbu ildmat.2015.03.050 Chen L, Wang L, Cho DW et al (2019a) Sustainable stabilization/solidification of municipal solid waste incinerator fly ash by incorporation of green materials. J Clean Prod 222:335–343. https://doi.org/10.1016/j.jclepro. 2019.03.057 Chen T, Gao X, Qin L (2019b) Mathematical modeling of accelerated carbonation curing of Portland cement paste at early age. Cement Concrete Res 120:187–197. https://doi.org/10.1016/j.cemconres.2019.03.025 Chen W, Meng J, Han X et al (2019c) Past, present, and future of biochar. Biochar 1:75–87. https://doi.org/10.1007/s42773-019-00008-3 Chen L, Wang L, Tsang DCW et al (2020a) Efficacy of green alternatives and carbon dioxide curing in reactive magnesia cement-bonded particleboards. J Clean Prod 258:120997. https://doi.org/10.1016/j.jclepro.2020. 120997 Chen R, Huang X, Deng W et al (2020b) Facile preparation of flexible eicosane/ SWCNTs phase change films via colloid aggregation for thermal energy storage. Appl Energy 260:114320. https://doi.org/10.1016/j.apenergy. 2019.114320 Chen L, Wang L, Zhang Y et al (2022a) Roles of biochar in cement-based stabilization/solidification of municipal solid waste incineration fly ash. Chem Eng J 430:132972. https://doi.org/10.1016/j.cej.2021.132972 Chen L, Zhang Y, Wang L et al (2022b) Biochar-augmented carbon-negative concrete. Chem Eng J 431:133946. https://doi.org/10.1016/j.cej.2021. 133946 Cheng F, Luo H, Colosi LM (2020) Slow pyrolysis as a platform for negative emissions technology: an integration of machine learning models, life cycle assessment, and economic analysis. Energy Convers Manag 223:113258. https://doi.org/10.1016/j.enconman.2020.113258 Chi NTL, Anto S, Ahamed TS et al (2021) A review on biochar production techniques and biochar based catalyst for biofuel production from algae. Fuel 287:119411. https://doi.org/10.1016/j.fuel.2020.119411 China Association of Building Energy Efficiency (CABEE) (2020) China building energy consumption study report 2020 Chougan M, Hamidreza Ghaffar S, Jahanzat M et al (2020) The influence of nano-additives in strengthening mechanical performance of 3D printed multi-binder geopolymer composites. Constr Build Mater 250:118928. https://doi.org/10.1016/j.conbuildmat.2020.118928 Churkina G, Organschi A, Reyer CPO et al (2020) Buildings as a global carbon sink. Nat Sustain 3:269–276. https://doi.org/10.1038/s41893-019-0462-4 Cong P, Xu P, Chen S (2014) Effects of carbon black on the anti aging, rheological and conductive properties of SBS/asphalt/carbon black composites. Constr Build Mater 52:306–313. https://doi.org/10.1016/j.conbuildmat. 2013.11.061 Cui P, Schito G, Cui Q (2020) VOC emissions from asphalt pavement and health risks to construction workers. J Clean Prod 244:118757. https://doi.org/ 10.1016/j.jclepro.2019.118757 Cuthbertson D, Berardi U, Briens C, Berruti F (2019) Biochar from residual biomass as a concrete filler for improved thermal and acoustic properties. Biomass Bioenergy 120:77–83. https://doi.org/10.1016/j.biombioe. 2018.11.007 D’Alessandro A, Rallini M, Ubertini F et al (2016) Investigations on scalable fabrication procedures for self-sensing carbon nanotube cement-matrix Page 21 of 25 composites for SHM applications. Cement Concrete Compos 65:200– 213. https://doi.org/10.1016/j.cemconcomp.2015.11.001 Danish A, Ali Mosaberpanah M, Usama Salim M et al (2021) Reusing biochar as a filler or cement replacement material in cementitious composites: a review. Constr Build Mater 300:124295. https://doi.org/10.1016/j.conbu ildmat.2021.124295 Das O, Sarmah AK, Bhattacharyya D (2015a) Structure-mechanics property relationship of waste derived biochars. Sci Total Environ 538:611–620. https://doi.org/10.1016/j.scitotenv.2015.08.073 Das O, Sarmah AK, Bhattacharyya D (2015b) A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag 38:132–140. https://doi.org/10.1016/j.wasman.2015.01.015 Das O, Bhattacharyya D, Hui D, Lau K-T (2016a) Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Compos Part B Eng 106:120–128. https://doi.org/10.1016/j.compositesb.2016. 09.020 Das O, Sarmah AK, Bhattacharyya D (2016b) Biocomposites from waste derived biochars: mechanical, thermal, chemical, and morphological properties. Waste Manag 49:560–570. https://doi.org/10.1016/j.wasman.2015.12.007 Das O, Kim NK, Kalamkarov AL et al (2017a) Biochar to the rescue: balancing the fire performance and mechanical properties of polypropylene composites. Polym Degrad Stab 144:485–496. https://doi.org/10.1016/j. polymdegradstab.2017.09.006 Das O, Kim NK, Sarmah AK, Bhattacharyya D (2017b) Development of waste based biochar/wool hybrid biocomposites: flammability characteristics and mechanical properties. J Clean Prod 144:79–89. https://doi.org/10. 1016/j.jclepro.2016.12.155 De Schutter G, Lesage K, Mechtcherine V et al (2018) Vision of 3D printing with concrete—technical, economic and environmental potentials. Cement Concrete Res 112:25–36. https://doi.org/10.1016/j.cemconres.2018.06. 001 Dixit A, Gupta S, Pang SD, Kua HW (2019) Waste Valorisation using biochar for cement replacement and internal curing in ultra-high performance concrete. J Clean Prod 238:117876. https://doi.org/10.1016/j.jclepro. 2019.117876 Dixit A, Verma A, Pang SD (2021) Dual waste utilization in ultra-high performance concrete using biochar and marine clay. Cement Concrete Compos 120:104049. https://doi.org/10.1016/j.cemconcomp.2021. 104049 Dong W, Ma F, Li C et al (2020) Evaluation of anti-aging performance of biochar modified asphalt binder. Coatings 10:1–19. https://doi.org/10. 3390/coatings10111037 Du X, Zhang Y, Pan X et al (2019) Preparation and properties of modified porous starch/carbon black/natural rubber composites. Compos Part B Eng 156:1–7. https://doi.org/10.1016/j.compositesb.2018.08.033 Fan Y, Fowler GD, Zhao M (2020) The past, present and future of carbon black as a rubber reinforcing filler—a review. J Clean Prod 247:119115. https://doi.org/10.1016/j.jclepro.2019.119115 Fawzy S, Osman AI, Yang H et al (2021) Industrial biochar systems for atmospheric carbon removal: a review. Environ Chem Lett 19:3023–3055. https://doi.org/10.1007/s10311-021-01210-1 Giorcelli M, Savi P, Khan A, Tagliaferro A (2019a) Analysis of biochar with different pyrolysis temperatures used as filler in epoxy resin composites. Biomass Bioenergy 122:466–471. https://doi.org/10.1016/j.biombioe. 2019.01.007 Giorcelli M, Khan A, Pugno NM et al (2019b) Biochar as a cheap and environmental friendly filler able to improve polymer mechanical properties. Biomass Bioenergy 120:219–223. https://doi.org/10.1016/j.biombioe. 2018.11.036 Global Alliance for Buildings and Construction (GABC) (2017) Towards a zeroemission, efficient, and resilient buildings and construction sectorGlobal status report 2017 Gupta S, Kua HW (2019) Carbonaceous micro-filler for cement: effect of particle size and dosage of biochar on fresh and hardened properties of cement mortar. Sci Total Environ 662:952–962. https://doi.org/10.1016/j. scitotenv.2019.01.269 Gupta S, Kua HW (2020) Application of rice husk biochar as filler in cenosphere modified mortar: preparation, characterization and performance under Zhang et al. Biochar (2022) 4:59 elevated temperature. Constr Build Mater 253:119083. https://doi.org/ 10.1016/j.conbuildmat.2020.119083 Gupta S, Kua HW, Pang SD (2018a) Biochar-mortar composite: manufacturing, evaluation of physical properties and economic viability. Constr Build Mater 167:874–889. https://doi.org/10.1016/j.conbuildmat.2018.02.104 Gupta S, Kua HW, Low CY (2018b) Use of biochar as carbon sequestering additive in cement mortar. Cement Concrete Compos 87:110–129. https:// doi.org/10.1016/j.cemconcomp.2017.12.009 Gupta S, Kua HW, Pang SD (2018c) Healing cement mortar by immobilization of bacteria in biochar: an integrated approach of self-healing and carbon sequestration. Cement Concrete Compos 86:238–254. https:// doi.org/10.1016/j.cemconcomp.2017.11.015 Habert G, Miller SA, John VM et al (2020) Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat Rev Earth Environ 1:559–573. https://doi.org/10.1038/s43017-020-0093-3 Haque MI, Khan RI, Ashraf W, Pendse H (2021) Production of sustainable, lowpermeable and self-sensing cementitious composites using biochar. Sustain Mater Technol 28:e00279. https://doi.org/10.1016/j.susmat. 2021.e00279 He B-J, Wang J, Liu H, Ulpiani G (2021a) Localized synergies between heat waves and urban heat islands: implications on human thermal comfort and urban heat management. Environ Res 193:110584. https://doi.org/ 10.1016/j.envres.2020.110584 He M, Xu Z, Sun Y et al (2021b) Critical impacts of pyrolysis conditions and activation methods on application-oriented production of wood waste-derived biochar. Bioresour Technol 341:125811. https://doi.org/ 10.1016/j.biortech.2021.125811 He M, Xu Z, Hou D et al (2022) Waste-derived biochar for water pollution control and sustainable development. Nat Rev Earth Environ 3:444–460. https://doi.org/10.1038/s43017-022-00306-8 Hekimoğlu G, Sarı A, Kar T et al (2021) Walnut shell derived bio-carbon/methyl palmitate as novel composite phase change material with enhanced thermal energy storage properties. J Energy Storage 35:102288. https:// doi.org/10.1016/j.est.2021.102288 Hepburn C, Adlen E, Beddington J et al (2019) The technological and economic prospects for CO2 utilization and removal. Nature 575:87–97. https://doi.org/10.1038/s41586-019-1681-6 Howard JL, Cao Q, Browne DL (2018) Mechanochemistry as an emerging tool for molecular synthesis: what can it offer? Chem Sci 9:3080–3094. https://doi.org/10.1039/C7SC05371A Hu C, Feng J, Zhou N et al (2021) Hydrochar from corn stalk used as bioasphalt modifier: high-temperature performance improvement. Environ Res. https://doi.org/10.1016/j.envres.2020.110157 Ige OE, Olanrewaju OA, Duffy KJ, Obiora C (2021) A review of the effectiveness of life cycle assessment for gauging environmental impacts from cement production. J Clean Prod 324:129213. https://doi.org/10.1016/j. jclepro.2021.129213 Ikram S, Das O, Bhattacharyya D (2016) A parametric study of mechanical and flammability properties of biochar reinforced polypropylene composites. Compos Part A Appl Sci Manuf 91:177–188. https://doi.org/10. 1016/j.compositesa.2016.10.010 Intergovernmental Panel on Climate Change (IPCC) (2018) Global warming of 1.5°C International Energy Agency (IEA) (2021) Global energy review 2021. Paris Ioannidou D, Meylan G, Sonnemann G, Habert G (2017) Is gravel becoming scarce? Evaluating the local criticality of construction aggregates. Resour Conserv Recycl 126:25–33. https://doi.org/10.1016/j.resconrec. 2017.07.016 Jeon J, Park JH, Wi S et al (2019a) Characterization of biocomposite using coconut oil impregnated biochar as latent heat storage insulation. Chemosphere 236:124269. https://doi.org/10.1016/j.chemosphere. 2019.06.239 Jeon J, Park JH, Wi S et al (2019b) Latent heat storage biocomposites of phase change material-biochar as feasible eco-friendly building materials. Environ Res 172:637–648. https://doi.org/10.1016/j.envres.2019.01.058 Jiang C, Bo J, Xiao X et al (2020) Converting waste lignin into nano-biochar as a renewable substitute of carbon black for reinforcing styrene-butadiene rubber. Waste Manag 102:732–742. https://doi.org/10.1016/j.wasman. 2019.11.019 Jiang D, Qin J, Zhou X et al (2022) Improvement of thermal insulation and compressive performance of A ­ l2O3–SiO2 aerogel by doping carbon Page 22 of 25 nanotubes. Ceram Int 48:16290–16299. https://doi.org/10.1016/j.ceram int.2022.02.178 John VM, Damineli BL, Quattrone M, Pileggi RG (2018) Fillers in cementitious materials—experience, recent advances and future potential. Cement Concrete Res 114:65–78. https://doi.org/10.1016/j.cemconres.2017.09. 013 Jong L (2015) Influence of protein hydrolysis on the mechanical properties of natural rubber composites reinforced with soy protein particles. Ind Crops Prod 65:102–109. https://doi.org/10.1016/j.indcrop.2014.12.004 Jong L, Peterson SC, Jackson MA (2014) Utilization of porous carbons derived from coconut shell and wood in natural rubber. J Polym Environ 22:289–297. https://doi.org/10.1007/s10924-013-0637-4 Karnati SR, Høgsaa B, Zhang L, Fini EH (2020) Developing carbon nanoparticles with tunable morphology and surface chemistry for use in construction. Constr Build Mater 262:120780. https://doi.org/10.1016/j.conbu ildmat.2020.120780 Khushnood RA, Ahmad S, Savi P et al (2015) Improvement in electromagnetic interference shielding effectiveness of cement composites using carbonaceous nano/micro inerts. Constr Build Mater 85:208–216. https://doi. org/10.1016/j.conbuildmat.2015.03.069 Kim YU, Yun BY, Nam J et al (2021) Evaluation of thermal properties of phase change material-integrated artificial stone according to biochar loading content. Constr Build Mater 305:124682. https://doi.org/10.1016/j. conbuildmat.2021.124682 Klüpfel L, Keiluweit M, Kleber M, Sander M (2014) Redox properties of plant biomass-derived black carbon (biochar). Environ Sci Technol 48:5601– 5611. https://doi.org/10.1021/es500906d Kua H, Gupta S, Koh S (2020) Review of biochar as a sustainable mortar admixture and evaluation of its potential as coating for PVA fibers in mortar. In: Tagliaferro A, Rosso C, Giorcelli M (eds) Biochar: emerging applications 1.01–1.014. IOP Publishing, Bristol. https://doi.org/10.1088/ 978-0-7503-2660-5ch10 Kumar A, Choudhary R, Narzari R et al (2018) Evaluation of bio-asphalt binders modified with biochar: a pyrolysis by-product of Mesua ferrea seed cover waste. Cogent Eng 5:1–15. https://doi.org/10.1080/23311916. 2018.1548534 Kumar M, Xiong X, Sun Y et al (2020a) Critical review on biochar-supported catalysts for pollutant degradation and sustainable biorefinery. Adv Sustain Syst 4:1900149. https://doi.org/10.1002/adsu.201900149 Kumar M, Xiong X, Wan Z et al (2020b) Ball milling as a mechanochemical technology for fabrication of novel biochar nanomaterials. Bioresour Technol 312:123613. https://doi.org/10.1016/j.biortech.2020.123613 Lee H, Yang S, Wi S, Kim S (2019) Thermal transfer behavior of biochar-natural inorganic clay composite for building envelope insulation. Constr Build Mater 223:668–678. https://doi.org/10.1016/j.conbuildmat.2019.06.215 Lehmann J, Stephen J (2015) Biochar for environmental management: science, technology and implementation. Routledge, London Lehmann J, Cowie A, Masiello CA et al (2021) Biochar in climate change mitigation. Nat Geosci 14:883–892. https://doi.org/10.1038/ s41561-021-00852-8 Leng L, Huang H (2018) An overview of the effect of pyrolysis process parameters on biochar stability. Bioresour Technol 270:627–642. https://doi. org/10.1016/j.biortech.2018.09.030 Li C, Wu M, Yao W (2019) Eco-efficient cementitious system consisting of belite-ye’elimite-ferrite cement, limestone filler, and silica fume. ACS Sustain Chem Eng 7:7941–7950. https://doi.org/10.1021/acssuschem eng.9b00702 Li X, Zhang L, Yang Z et al (2020) Adsorption materials for volatile organic compounds (VOCs) and the key factors for VOCs adsorption process: a review. Sep Purif Technol 235:116213. https://doi.org/10.1016/j.seppur. 2019.116213 Lian F, Xing B (2017) Black carbon (biochar) in water/soil environments: molecular structure, sorption, stability, and potential risk. Environ Sci Technol 51:13517–13532. https://doi.org/10.1021/acs.est.7b02528 Liu H, Basar IA, Nzihou A, Eskicioglu C (2021) Hydrochar derived from municipal sludge through hydrothermal processing: a critical review on its formation, characterization, and valorization. Water Res 199:117186. https://doi.org/10.1016/j.watres.2021.117186 Lu J-X, Shen P, Zhang Y et al (2021) Early-age and microstructural properties of glass powder blended cement paste: improvement by seawater. Zhang et al. Biochar (2022) 4:59 Cement Concrete Compos 122:104165. https://doi.org/10.1016/j. cemconcomp.2021.104165 Lyu H, Gao B, He F et al (2017) Ball-milled carbon nanomaterials for energy and environmental applications. ACS Sustain Chem Eng 5:9568–9585. https://doi.org/10.1021/acssuschemeng.7b02170 Mafu LD, Neomagus HWJP, Everson RC et al (2018) The carbon dioxide gasification characteristics of biomass char samples and their effect on coal gasification reactivity during co-gasification. Bioresour Technol 258:70–78. https://doi.org/10.1016/j.biortech.2017.12.053 Maljaee H, Madadi R, Paiva H et al (2021) Incorporation of biochar in cementitious materials: a roadmap of biochar selection. Constr Build Mater 283:122757. https://doi.org/10.1016/j.conbuildmat.2021.122757 Markin V, Krause M, Otto J et al (2021) 3D-printing with foam concrete: from material design and testing to application and sustainability. J Build Eng. https://doi.org/10.1016/j.jobe.2021.102870 Matuštík J, Hnátková T, Kočí V (2020) Life cycle assessment of biochar-to-soil systems: a review. J Clean Prod 259:120998. https://doi.org/10.1016/j. jclepro.2020.120998 Miller SA, John VM, Pacca SA, Horvath A (2018) Carbon dioxide reduction potential in the global cement industry by 2050. Cement Concrete Res 114:115–124. https://doi.org/10.1016/j.cemconres.2017.08.026 Minugu OP, Gujjala R, Shakuntala O et al (2021) Effect of biomass derived biochar materials on mechanical properties of biochar epoxy composites. Proc Inst Mech Eng Part C J Mech Eng Sci. https://doi.org/10.1177/ 0954406221990705 Mo L, Fang J, Huang B et al (2019) Combined effects of biochar and MgO expansive additive on the autogenous shrinkage, internal relative humidity and compressive strength of cement pastes. Constr Build Mater 229:116877. https://doi.org/10.1016/j.conbuildmat.2019.116877 Mobili A, Giosuè C, Bellezze T et al (2021) Gasification char and used foundry sand as alternative fillers to graphene nanoplatelets for electrically conductive mortars with and without virgin/recycled carbon fibres. Appl Sci 11:1–16. https://doi.org/10.3390/app11010050 Mohamed SA, Al-Sulaiman FA, Ibrahim NI et al (2017) A review on current status and challenges of inorganic phase change materials for thermal energy storage systems. Renew Sustain Energy Rev 70:1072–1089. https://doi.org/10.1016/j.rser.2016.12.012 Monteiro AO, Cachim PB, Costa PMFJ (2017) Self-sensing piezoresistive cement composite loaded with carbon black particles. Cement Concrete Compos 81:59–65. https://doi.org/10.1016/j.cemconcomp.2017.04.009 Muthukrishnan S, Gupta S, Kua HW (2019) Application of rice husk biochar and thermally treated low silica rice husk ash to improve physical properties of cement mortar. Theor Appl Fract Mech 104:102376. https://doi.org/ 10.1016/j.tafmec.2019.102376 Nam IW, Choi JH, Kim CG, Lee H-K (2018) Fabrication and design of electromagnetic wave absorber composed of carbon nanotube-incorporated cement composites. Compos Struct 206:439–447. https://doi.org/10. 1016/j.compstruct.2018.07.058 Nan N, DeVallance DB (2017) Development of poly(vinyl alcohol)/woodderived biochar composites for use in pressure sensor applications. J Mater Sci 52:8247–8257. https://doi.org/10.1007/s10853-017-1040-7 Natalio F, Corrales TP, Feldman Y et al (2020) Sustainable lightweight biocharbased composites with electromagnetic shielding properties. ACS Omega 5:32490–32497. https://doi.org/10.1021/acsomega.0c04639 Nazari H, Naderi K, Moghadas Nejad F (2018) Improving aging resistance and fatigue performance of asphalt binders using inorganic nanoparticles. Constr Build Mater 170:591–602. https://doi.org/10.1016/j.conbuildmat. 2018.03.107 Onarheim K, Solantausta Y, Lehto J (2015) Process simulation development of fast pyrolysis of wood using aspen plus. Energy Fuels 29:205–217. https://doi.org/10.1021/ef502023y Paleri DM, Rodriguez-Uribe A, Misra M, Mohanty AK (2021) Preparation and characterization of eco-friendly hybrid biocomposites from natural rubber, biocarbon, and carbon black. Express Polym Lett 15:236–249. https://doi.org/10.3144/expresspolymlett.2021.21 Pan SY, Chen YH, Fan LS et al (2020) CO2 mineralization and utilization by alkaline solid wastes for potential carbon reduction. Nat Sustain 3:399–405. https://doi.org/10.1038/s41893-020-0486-9 Park JH, Kim YU, Jeon J et al (2021a) Effect of eco-friendly pervious concrete with amorphous metallic fiber on evaporative cooling performance. Page 23 of 25 J Environ Manag 297:113269. https://doi.org/10.1016/j.jenvman.2021. 113269 Park JH, Kim YU, Jeon J et al (2021b) Analysis of biochar-mortar composite as a humidity control material to improve the building energy and hygrothermal performance. Sci Total Environ 775:145552. https://doi.org/10. 1016/j.scitotenv.2021.145552 Pasandín AR, Pérez I, Oliveira JRM et al (2015) Influence of ageing on the properties of bitumen from asphalt mixtures with recycled concrete aggregates. J Clean Prod 101:165–173. https://doi.org/10.1016/j.jclepro. 2015.03.069 Peng Y, Sun Y, Hanif A et al (2021) Design and fabrication of exfoliated Mg/ Al layered double hydroxides on biochar support. J Clean Prod 289:125142. https://doi.org/10.1016/j.jclepro.2020.125142 Peters JF, Iribarren D, Dufour J (2015) Biomass pyrolysis for biochar or energy applications? A life cycle assessment. Environ Sci Technol 49:5195–5202. https://doi.org/10.1021/es5060786 Peterson SC, Kim S (2020) Reducing biochar particle size with nanosilica and its effect on rubber composite reinforcement. J Polym Environ 28:317–322. https://doi.org/10.1007/s10924-019-01604-x Poulose AM, Elnour AY, Anis A et al (2018) Date palm biochar-polymer composites: an investigation of electrical, mechanical, thermal and rheological characteristics. Sci Total Environ 619–620:311–318. https://doi.org/ 10.1016/j.scitotenv.2017.11.076 Praneeth S, Guo R, Wang T et al (2020) Accelerated carbonation of biochar reinforced cement-fly ash composites: enhancing and sequestering ­CO2 in building materials. Constr Build Mater 244:118363. https://doi. org/10.1016/j.conbuildmat.2020.118363 Praneeth S, Saavedra L, Zeng M et al (2021) Biochar admixtured lightweight, porous and tougher cement mortars: mechanical, durability and micro computed tomography analysis. Sci Total Environ 750:142327. https:// doi.org/10.1016/j.scitotenv.2020.142327 Puettmann M, Sahoo K, Wilson K, Oneil E (2020) Life cycle assessment of biochar produced from forest residues using portable systems. J Clean Prod 250:119564. https://doi.org/10.1016/j.jclepro.2019.119564 Qi Q, Sun C, Cristhian C et al (2021) Enhancement of methanogenic performance by gasification biochar on anaerobic digestion. Bioresour Technol 330:124993. https://doi.org/10.1016/j.biortech.2021.124993 Qin Y, He Y, Hiller JE, Mei G (2018) A new water-retaining paver block for reducing runoff and cooling pavement. J Clean Prod 199:948–956. https:// doi.org/10.1016/j.jclepro.2018.07.250 Qiu Y, Xu X, Xu Z et al (2020) Contribution of different iron species in the iron-biochar composites to sorption and degradation of two dyes with varying properties. Chem Eng J 389:124471. https://doi.org/10.1016/j. cej.2020.124471 Reis DC, Abrão PCRA, Sui T, John VM (2020) Influence of cement strength class on environmental impact of concrete. Resour Conserv Recycl 163:105075. https://doi.org/10.1016/j.resconrec.2020.105075 Restuccia L, Ferro GA (2016) Promising low cost carbon-based materials to improve strength and toughness in cement composites. Constr Build Mater 126:1034–1043. https://doi.org/10.1016/j.conbuildmat.2016.09. 101 Roberts KG, Gloy BA, Joseph S et al (2010) Life cycle assessment of biochar systems: estimating the energetic, economic, and climate change potential. Environ Sci Technol 44:827–833. https://doi.org/10.1021/ es902266r Rodier L, Bilba K, Onésippe C, Arsène MA (2019) Utilization of bio-chars from sugarcane bagasse pyrolysis in cement-based composites. Ind Crops Prod 141:111731. https://doi.org/10.1016/j.indcrop.2019.111731 Sajjadi B, Chen W-Y, Egiebor NO (2019) A comprehensive review on physical activation of biochar for energy and environmental applications. Rev Chem Eng 35:735–776. https://doi.org/10.1515/revce-2017-0113 Schneider M (2015) Process technology for efficient and sustainable cement production. Cement Concrete Res 78:14–23. https://doi.org/10.1016/j. cemconres.2015.05.014 Scrivener K, Martirena F, Bishnoi S, Maity S (2018) Calcined clay limestone cements (LC3). Cement Concrete Res 114:49–56. https://doi.org/10. 1016/j.cemconres.2017.08.017 Seifan M, Samani AK, Berenjian A (2016) Bioconcrete: next generation of selfhealing concrete. Appl Microbiol Biotechnol 100:2591–2602. https:// doi.org/10.1007/s00253-016-7316-z Zhang et al. Biochar (2022) 4:59 Shayan E, Zare V, Mirzaee I (2018) Hydrogen production from biomass gasification: a theoretical comparison of using different gasification agents. Energy Convers Manag 159:30–41. https://doi.org/10.1016/j.enconman. 2017.12.096 Shen Z, Hou D, Jin F et al (2019) Effect of production temperature on lead removal mechanisms by rice straw biochars. Sci Total Environ 655:751– 758. https://doi.org/10.1016/j.scitotenv.2018.11.282 Shon CS, Mukashev T, Lee D et al (2019) Can common reed fiber become an effective construction material? physical, mechanical, and thermal properties of mortar mixture containing common reed fiber. Sustain 11:903. https://doi.org/10.3390/su11030903 Sikora P, Chougan M, Cuevas K et al (2022) The effects of nano- and microsized additives on 3D printable cementitious and alkali-activated composites: a review. Appl Nanosci 12:805–823. https://doi.org/10. 1007/s13204-021-01738-2 Sirico A, Bernardi P, Sciancalepore C et al (2021) Biochar from wood waste as additive for structural concrete. Constr Build Mater 303:124500. https://doi.org/10.1016/j.conbuildmat.2021.124500 Song M, Niu F, Mao N et al (2018) Review on building energy performance improvement using phase change materials. Energy Build 158:776– 793. https://doi.org/10.1016/j.enbuild.2017.10.066 Tam L, Zhou A, Wu C (2019) Nanomechanical behavior of carbon fiber/ epoxy interface in hygrothermal conditioning: a molecular dynamics study. Mater Today Commun 19:495–505. https://doi.org/10.1016/j. mtcomm.2019.04.002 Tan K, Qin Y, Du T et al (2021) Biochar from waste biomass as hygroscopic filler for pervious concrete to improve evaporative cooling performance. Constr Build Mater 287:123078. https://doi.org/10.1016/j. conbuildmat.2021.123078 Tan K, Qin Y, Wang J (2022) Evaluation of the properties and carbon sequestration potential of biochar-modified pervious concrete. Constr Build Mater 314:125648. https://doi.org/10.1016/j.conbuildmat.2021. 125648 Tomczyk A, Sokołowska Z, Boguta P (2020) Biochar physicochemical properties: pyrolysis temperature and feedstock kind effects. Rev Environ Sci Bio/technology 19:191–215. https://doi.org/10.1007/ s11157-020-09523-3 Tripathi M, Sahu JN, Ganesan P (2016) Effect of process parameters on production of biochar from biomass waste through pyrolysis: a review. Renew Sustain Energy Rev 55:467–481. https://doi.org/10.1016/j.rser. 2015.10.122 Tripathi N, Hills CD, Singh RS, Atkinson CJ (2019) Biomass waste utilisation in low-carbon products: harnessing a major potential resource. Npj Clim Atmos Sci. https://doi.org/10.1038/s41612-019-0093-5 Vijay K, Murmu M, Deo SV (2017) Bacteria based self healing concrete—a review. Constr Build Mater 152:1008–1014. https://doi.org/10.1016/j. conbuildmat.2017.07.040 Wan Z, Xu Z, Sun Y et al (2021) Critical impact of nitrogen vacancies in nonradical carbocatalysis on nitrogen-doped graphitic biochar. Environ Sci Technol 55:7004–7014. https://doi.org/10.1021/acs.est.0c08531 Wang J, Wang S (2019) Preparation, modification and environmental application of biochar: a review. J Clean Prod 227:1002–1022. https://doi. org/10.1016/j.jclepro.2019.04.282 Wang L, Chen SS, Tsang DCW et al (2016a) Recycling contaminated wood into eco-friendly particleboard using green cement and carbon dioxide curing. J Clean Prod 137:861–870. https://doi.org/10.1016/j. jclepro.2016.07.180 Wang Z, Dai Q, Porter D, You Z (2016b) Investigation of microwave healing performance of electrically conductive carbon fiber modified asphalt mixture beams. Constr Build Mater 126:1012–1019 Wang C, Zhu W, Zhang H et al (2019a) Char and tar formation during hydrothermal gasification of dewatered sewage sludge in subcritical and supercritical water: influence of reaction parameters and lumped reaction kinetics. Waste Manag 100:57–65. https://doi.org/10.1016/j. wasman.2019.09.011 Wang L, Chen L, Cho DW et al (2019b) Novel synergy of Si-rich minerals and reactive MgO for stabilisation/solidification of contaminated sediment. J Hazard Mater 365:695–706. https://doi.org/10.1016/j.jhazm at.2018.11.067 Wang L, Chen L, Tsang DCW et al (2019c) The roles of biochar as green admixture for sediment-based construction products. Cement Page 24 of 25 Concrete Compos 104:103348. https://doi.org/10.1016/j.cemco ncomp.2019.103348 Wang Y, Xiao X, Xu Y, Chen B (2019d) Environmental effects of silicon within biochar (Sichar) and carbon-silicon coupling mechanisms: a critical review. Environ Sci Technol 53:13570–13582. https://doi.org/10.1021/ acs.est.9b03607 Wang L, Chen L, Tsang DCW et al (2020a) Biochar as green additives in cement-based composites with carbon dioxide curing. J Clean Prod 258:120678. https://doi.org/10.1016/j.jclepro.2020.120678 Wang L, Ok YS, Tsang DCW et al (2020b) New trends in biochar pyrolysis and modification strategies: feedstock, pyrolysis conditions, sustainability concerns and implications for soil amendment. Soil Use Manag 36:358–386. https://doi.org/10.1111/sum.12592 Wang F, Harindintwali JD, Yuan Z et al (2021a) Technologies and perspectives for achieving carbon neutrality. Innovation. https://doi.org/10.1016/j. xinn.2021.100180 Wang L, Chen L, Poon CS et al (2021b) Roles of biochar and ­CO2 curing in sustainable magnesia cement-based composites. ACS Sustain Chem Eng 9:8603–8610. https://doi.org/10.1021/acssuschemeng.1c02008 Wi S, Berardi U, Di LS, Kim S (2020) Microstructure and thermal characterization of aerogel–graphite polyurethane spray-foam composite for high efficiency thermal energy utilization. J Hazard Mater 397:122656. https:// doi.org/10.1016/j.jhazmat.2020.122656 Wi S, Yang S, Yeol Yun B, Kim S (2021) Exterior insulation finishing system using cementitious plaster/microencapsulated phase change material for improving the building thermal storage performance. Constr Build Mater 299:123932. https://doi.org/10.1016/j.conbuildmat.2021.123932 Windeatt JH, Ross AB, Williams PT et al (2014) Characteristics of biochars from crop residues: potential for carbon sequestration and soil amendment. J Environ Manag 146:189–197. https://doi.org/10.1016/j.jenvman.2014. 08.003 Wu S, Chen D, Zhao G et al (2022) Controllable synthesis of a robust sucrosederived bio-carbon foam with 3D hierarchical porous structure for thermal insulation, flame retardancy and oil absorption. Chem Eng J 434:134514. https://doi.org/10.1016/j.cej.2022.134514 Xiang W, Zhang X, Chen K et al (2020) Enhanced adsorption performance and governing mechanisms of ball-milled biochar for the removal of volatile organic compounds (VOCs). Chem Eng J 385:123842. https://doi.org/ 10.1016/j.cej.2019.123842 Xiong T, Ok YS, Dissanayake PD et al (2022) Preparation and thermal conductivity enhancement of a paraffin wax-based composite phase change material doped with garlic stem biochar microparticles. Sci Total Environ 827:154341. https://doi.org/10.1016/j.scitotenv.2022.154341 Xu Z, He M, Xu X et al (2021) Impacts of different activation processes on the carbon stability of biochar for oxidation resistance. Bioresour Technol 338:125555. https://doi.org/10.1016/j.biortech.2021.125555 Xu Z, Yu Y, Xu X et al (2022) Direct and indirect electron transfer routes of chromium(VI) reduction with different crystalline ferric oxyhydroxides in the presence of pyrogenic carbon. Environ Sci Technol 56:1724–1735. https://doi.org/10.1021/acs.est.1c06642 Xue B, Wang X, Sui J et al (2019) A facile ball milling method to produce sustainable pyrolytic rice husk bio-filler for reinforcement of rubber mechanical property. Ind Crops Prod 141:111791. https://doi.org/10. 1016/j.indcrop.2019.111791 Yang F, Xu Z, Yu L et al (2018) Kaolinite enhances the stability of the dissolvable and undissolvable fractions of biochar via different mechanisms. Environ Sci Technol 52:8321–8329. https://doi.org/10.1021/acs.est.8b00306 Yang J, Tang LS, Bai L et al (2019) High-performance composite phase change materials for energy conversion based on macroscopically threedimensional structural materials. Mater Horizons 6:250–273. https://doi. org/10.1039/c8mh01219a Yang Q, Mašek O, Zhao L et al (2021a) Country-level potential of carbon sequestration and environmental benefits by utilizing crop residues for biochar implementation. Appl Energy 282:116275. https://doi.org/10. 1016/j.apenergy.2020.116275 Yang Q, Zhou H, Bartocci P et al (2021b) Prospective contributions of biomass pyrolysis to China’s 2050 carbon reduction and renewable energy goals. Nat Commun 12:1698. https://doi.org/10.1038/s41467-021-21868-z Ye H (2021) Autogenous formation and smart behaviors of nitrite- and nitrate-intercalated layered double hydroxides (LDHs) in Portland Zhang et al. Biochar (2022) 4:59 cement-metakaolin-dolomite blends. Cement Concrete Res 139:106267. https://doi.org/10.1016/j.cemconres.2020.106267 Yin K, Ahamed A, Lisak G (2018) Environmental perspectives of recycling various combustion ashes in cement production—a review. Waste Manag 78:401–416. https://doi.org/10.1016/j.wasman.2018.06.012 You S, Ok YS, Tsang DCW et al (2018) Towards practical application of gasification: a critical review from syngas and biochar perspectives. Crit Rev Environ Sci Technol 48:1165–1213. https://doi.org/10.1080/10643389. 2018.1518860 Yuan M, Xu C, Wang T et al (2021) Supercooling suppression and crystallization behaviour of erythritol/expanded graphite as form-stable phase change material. Chem Eng J 413:127394. https://doi.org/10.1016/j.cej. 2020.127394 Zhan BJ, Xuan DX, Poon CS (2018) Enhancement of recycled aggregate properties by accelerated ­CO2 curing coupled with limewater soaking process. Cement Concrete Compos 89:230–237. https://doi.org/10. 1016/j.cemconcomp.2018.03.011 Zhan BJ, Xuan DX, Zeng W, Poon CS (2019) Carbonation treatment of recycled concrete aggregate: effect on transport properties and steel corrosion of recycled aggregate concrete. Cement Concrete Compos 104:103360. https://doi.org/10.1016/j.cemconcomp.2019.103360 Zhan BJ, Xuan DX, Poon CS, Scrivener KL (2020) Characterization of interfacial transition zone in concrete prepared with carbonated modeled recycled concrete aggregates. Cement Concrete Res 136:106175. https:// doi.org/10.1016/j.cemconres.2020.106175 Zhang R, Dai Q, You Z et al (2018) Rheological performance of bio-char modified asphalt with different particle sizes. Appl Sci. https://doi.org/10. 3390/app8091665 Zhang J, Wang J, Dong S et al (2019a) A review of the current progress and application of 3D printed concrete. Compos Part A Appl Sci Manuf 125:105533. https://doi.org/10.1016/j.compositesa.2019.105533 Zhang Q, Khan MU, Lin X et al (2019b) Temperature varied biochar as a reinforcing filler for high-density polyethylene composites. Compos Part B Eng 175:107151. https://doi.org/10.1016/j.compositesb.2019.107151 Zhang Q, Zhang D, Lu W et al (2020a) Production of high-density polyethylene biocomposites from rice husk biochar: Effects of varying pyrolysis temperature. Sci Total Environ 738:139910. https://doi.org/10.1016/j. scitotenv.2020.139910 Zhang X, Xiang W, Wang B et al (2020b) Adsorption of acetone and cyclohexane onto ­CO2 activated hydrochars. Chemosphere 245:125664. https:// doi.org/10.1016/j.chemosphere.2019.125664 Zhao S, Huang B, Shu X, Ye P (2014a) Laboratory investigation of biocharmodified asphalt mixture. Transp Res Rec 2445:56–63. https://doi.org/ 10.3141/2445-07 Zhao S, Huang B, Ye XP et al (2014b) Utilizing bio-char as a bio-modifier for asphalt cement: a sustainable application of bio-fuel by-product. Fuel 133:52–62. https://doi.org/10.1016/j.fuel.2014b.05.002 Zhou X, Adhikari S (2019) Flow-induced crystallization of biochar in bioasphalt under various aging conditions. Sci Total Environ 695:133943. https://doi.org/10.1016/j.scitotenv.2019.133943 Zhou A, Tam L, Yu Z, Lau D (2015) Effect of moisture on the mechanical properties of CFRP–wood composite: an experimental and atomistic investigation. Compos Part B Eng 71:63–73. https://doi.org/10.1016/j. compositesb.2014.10.051 Zhou E, Xi J, Guo Y et al (2018) Synergistic effect of graphene and carbon nanotube for high-performance electromagnetic interference shielding films. Carbon N Y 133:316–322. https://doi.org/10.1016/j.carbon.2018. 03.023 Zhou X, Moghaddam TB, Chen M et al (2020) Biochar removes volatile organic compounds generated from asphalt. Sci Total Environ 745:141096. https://doi.org/10.1016/j.scitotenv.2020.141096 Zhu K, Wang X, Geng M et al (2019) Catalytic oxidation of clofibric acid by peroxydisulfate activated with wood-based biochar: effect of biochar pyrolysis temperature, performance and mechanism. Chem Eng J 374:1253–1263. https://doi.org/10.1016/j.cej.2019.06.006 Ziari H, Amini A, Goli A, Mirzaiyan D (2018) Predicting rutting performance of carbon nano tube (CNT) asphalt binders using regression models and neural networks. Constr Build Mater 160:415–426. https://doi.org/10. 1016/j.conbuildmat.2017.11.071 Zou L, Ni Y, Gao Y et al (2018) Spatial variation of PCDD/F and PCB emissions and their composition profiles in stack flue gas from the typical cement Page 25 of 25 plants in China. Chemosphere 195:491–497. https://doi.org/10.1016/j. chemosphere.2017.12.114 Zou W, Gao B, Ok YS, Dong L (2019) Integrated adsorption and photocatalytic degradation of volatile organic compounds (VOCs) using carbon-based nanocomposites: a critical review. Chemosphere 218:845–859. https:// doi.org/10.1016/j.chemosphere.2018.11.175