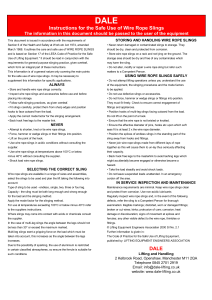

ASME B30.9 Slings Safety Standard: Selection, Use, Maintenance

Anuncio