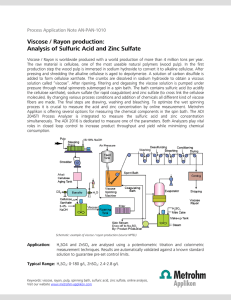

Cellulose (2014) 21:4349–4358 DOI 10.1007/s10570-014-0452-7 ORIGINAL PAPER Water redispersible cellulose nanofibrils adsorbed with carboxymethyl cellulose Núria Butchosa • Qi Zhou Received: 16 August 2014 / Accepted: 16 September 2014 / Published online: 25 September 2014 Ó Springer Science+Business Media Dordrecht 2014 Abstract Cellulose nanofibrils (CNFs) are difficult to redisperse in water after they have been completely dried due to the irreversible agglomeration of cellulose during drying. Here, we have developed a simple process to prepare water-redispersible dried CNFs by the adsorption of small amounts of carboxymethyl cellulose (CMC) and oven drying. The adsorption of CMC onto CNFs in water suspensions at 22 and 121 °C was studied, and the adsorbed amount of CMC was measured via conductimetric titration. The waterredispersibility of dried CNFs adsorbed with different amounts of CMC was characterized by sedimentation test. Above a critical threshold of CMC adsorption, i.e. 2.3 wt%, the oven dried CNF–CMC sample was fully redispersible in water. The morphology, rheological, and mechanical properties of water-redispersed CNF– CMC samples were investigated by field emission scanning electron microscopy, viscosity measurement, and tensile test, respectively. The waterN. Butchosa Department of Fibre and Polymer Technology, Royal Institute of Technology, 100 44 Stockholm, Sweden Q. Zhou (&) Wallenberg Wood Science Center, Royal Institute of Technology, 100 44 Stockholm, Sweden e-mail: [email protected] Q. Zhou School of Biotechnology, AlbaNova University Centre, Royal Institute of Technology, 106 91 Stockholm, Sweden redispersed CNFs preserved the original properties of never dried CNFs. This new method will facilitate the production, transportation and storage, and largescale industrial applications of CNFs. Keywords Cellulose nanofibrils Carboxymethyl cellulose Adsorption Redispersion Introduction Cellulose nanofibrils (CNFs), three orders of magnitude smaller than the micrometer scale intact plant fiber cells, have unique properties such as large specific surface area and high mechanical strength and toughness. The extraction process of CNFs from renewable resources like wood has been extensively investigated in the past decade (Pei et al. 2013). Typical processes include enzymatic (Henriksson et al. 2007; Pääkkö et al. 2007) and chemical (Pei et al. 2013; Saito et al. 2006) pretreatments on wood pulp followed by mechanical disintegration. Stora Enso has built a pre-commercial plant at Imatra, Finland for the production of CNFs. Other potential major producers of CNFs are UPM, Borregaard, and Daicel Corp. CNFs have been widely utilized as promising nanoscale building blocks in the fabrication of new materials such as nanopaper (Henriksson et al. 2008; Sehaqui et al. 2010a), hydrogel, aerogel (Jin et al. 2011; Sehaqui and Zhou 2011), and foam 123 4350 (Pääkkö et al. 2008; Sehaqui et al. 2010b), and as mechanical reinforcing nanoparticles in polymer composites (Hietala et al. 2013). CNF-based materials have demonstrated their suitability in a large range of applications such as substrates for solar cells (Fang et al. 2014), display substrates and organic lightemitting diode materials (Nogi and Yano 2008), transparent barrier coatings (Fukuzumi et al. 2009), polymer or metal-ion batteries (Hu et al. 2010; Nyström et al. 2009; Zhu et al. 2013), magnetic nanocomposites (Olsson et al. 2010), etc. However, CNFs are generally produced as aqueous suspensions with low solid content and very high viscosity due to the inherent hydrophilic nature of cellulose. Concentrated water suspensions of CNFs are difficult to prepare due to the irreversible agglomeration of cellulose during drying. This agglomeration process is known as hornification or co-crystallization (Newman 2004), and it is caused by strong hydrogen bonding between cellulose chains when they become in contact. To avoid hornification, CNFs must be kept in water suspension. This is a major drawback for CNFs in transportation, storage, and large-scale industrial applications in sectors such as composites industries. Several approaches have been attempted to achieve water-redispersibility for CNFs and cellulose nanocrystals (CNCs) after drying. Dong and Gray (1997) first studied redispersibility of dried CNC film samples made from suspensions with different counterions. They discovered that salt-form samples were water-redispersible and turned into homogeneous suspensions, while CNCs with H? as counterion did not redisperse in water even with strong ultrasound treatment. Further study by Beck et al. (2012) revealed that the exchange of counterions of CNCs from H? to Na? significantly decreases the intermolecular hydrogen bonding generated from cellulose backbones, thus facilitates their redispersibility in water even when fully dried. In a similar fashion, Missoum et al. (2012) successfully prepared waterredispersible CNFs by freeze drying method after the addition of sodium chloride. In order to avoid intermolecular hydrogen bonds between fibrils and thus to obtain water-redispersible CNFs, both covalent and non-covalent surface modification methods have been exploited. Covalent surface carboxymetylation was found essential to obtain water-redispersible dry CNF powders (Eyholzer et al. 2010). The 123 Cellulose (2014) 21:4349–4358 irreversible non-covalent attachment of carboxymethylcellulose (CMC) onto different wood pulp fibers was first studied by Laine et al. (2000). The adsorbed CMC improved the mechanical properties of handsheets prepared from wood pulp and aided paper recycling (Duker et al. 2008). CMC adsorbed onto cotton fibers was used to increase the charge density and adsorption capacity for surfactant (Fras-Zemljic et al. 2006; Zemljic et al. 2008). Therefore, CMC has been successfully used as an anchoring polymer for surface modification of cellulosic materials including CNFs. Further CMC-assisted functionalizations such as sequential ‘‘click’’ reactions, conjugation of biomolecules, and PEGylation have been demonstrated (Filpponen et al. 2012). CMC has also been utilized to improve wet-strength of nanofibrillated cellulose/ CMC composites after ionic crosslinking with glycidyl trimethyl ammonium chloride (Pahimanolis et al. 2013). Redispersibile microcrystalline cellulose (MCC) products containing CMC as redispersing aid (Avicel RC-591 and CL-611) have been commercially available for decades. These products typically contains 8–18 wt% of CMC. Coating cellulose microfibrils with anionic polymeric additives such as CMC and polyacrylate have been found to form a watersoluble interfacial film around the cellulose microfibrils while drying, which allows the recovering of rheological properties after redispersion of dried samples (Lowys et al. 2001). However, a weight content of 30 % CMC was required in order to recover the rheological behavior of the initial CNF suspension. In order to prepare water-redispersible CNFs, we screened a series of hydrocolloids including cationic and anionic xyloglucan derivatives, water-soluble chitosan (50 % degree of acetylation), hydroxyethylcellulose, and CMC with similar molecular weight as the redispersing aids, and only CMC showed dispersing and stabilizing effect. In this work, the adsorption isotherm of CMC onto CNFs in water suspension at 22 and 121 °C was studied for the first time. The waterredispersibility of dried CNF samples adsorbed with CMC was investigated in order to discover the minimum amount of CMC required for redispersion. The morphology, viscosity, and mechanical properties of water-redispersed dried CNF samples, which were adsorbed with different amounts of CMC before drying, were investigated and compared to the never-dried CNFs. Cellulose (2014) 21:4349–4358 4351 Denmark. Subsequently, the pretreated pulp was passed 8 times through the microfluidizer (M-110EH, Microfluidics Ind., Newton, MA) at room temperature (21 °C), including first three passes through 400 and 200 lm chambers at a pressure of 900 bar and five last passes through 200 and 100 lm chambers at a pressure of 1,600 bar. A 2 wt% CNFs dispersion in water was thus obtained. Figure 1 shows the STEM image and width distribution profile of the CNFs. The nanofibril length is several micrometers and nanofibril ends are not apparent. The width of the cellulose nanofibrils was in the range from 5 to 22 nm as measured from the image by using imageJ (NIH, USA). Adsorption of CMC onto CNF Fig. 1 STEM image of CNFs and corresponding histogram showing the width distribution Experimental Materials Carboxymethylcellulose (CMC, sodium salt, Mw = 2.5 9 105, DS = 0.90) was purchased from SigmaAldrich. A commercial never-dried softwood sulphite pulp (Nordic Paper, Sweden) was used as a starting material for CNFs production. The wood pulp contains approximately 14 % of hemicelluloses, \1 % of lignin, and almost 86 % cellulose with a degree of polymerization (DP) of 1,200. CNFs were prepared from the wood pulp according to the method reported previously (Pääkkö et al. 2007; Henriksson et al. 2007; Sehaqui et al. 2010a). In brief, the wood pulp was first dispersed in water and subjected to a pretreatment step involving mechanical beating and enzymatic degradation. The enzyme used was an endoglucanase, FiberCare R, manufactured by Novozymes A/S, CMC was dissolved in deionized water (1 wt%) and stirred overnight. A series of CNF/CMC mixtures were prepared by the addition of different aliquots of CMC aqueous solution (1 wt%) to 40 g of 2 wt% CNFs water suspension. Additional water was added to each mixture to obtain a total weight of 80 g, i.e. a constant CNFs concentration of 1 wt%. The CNF/ CMC suspensions were mixed at 12,000 rpm using an Ultra-Turrax mixer (IKA, D125 Basic) for 2 min before storing at room temperature (RT) overnight. To study the effect of high temperature (HT) on the adsorption, the suspensions were autoclaved at 121 °C for 25 min after mixing and cooled down at room temperature overnight. Subsequently, CNFs adsorbed with CMC were precipitated by centrifugation (Avanti J-26 XP, Beckman Coulter, USA) at 25,000 rpm for 20 min with unbound CMC remaining in the supernatant. The precipitated CNFs were redispersed in water followed by centrifugation. This washing step was repeated 3 times in order to completely remove the unbound CMC. The modified CNFs samples were coded as either CNF–CMC–HT-x or CNF–CMC–RTx, where the initial amount of CMC in suspension was x mg per 1 g of CNFs at either high temperature (121 °C) or room temperature (22 °C), respectively. Drying and redispersion To obtain dry cellulose, the pure CNFs and CNFs adsorbed with CMC samples were simply dried from their water suspension in an oven at 80 °C until constant weight was reached. The dry samples were 123 4352 easily swelled and redispersed in water typically with a solid concentration of 1 wt% by stirring with a magnetic stirrer overnight followed by mixing with an Ultra-Turrax mixer for 15 min. Conductimetric titration The amount of CMC adsorbed onto CNFs was calculated from the carboxyl content as measured by the electric conductivity titration method. In brief, 100 mL of CNFs suspension with a solid content of 0.1 wt% was mixed with 0.1 M HCl to set the pH value in the range between 2.5 and 3. The suspension was titrated with 0.01 M NaOH at a rate of 0.2 mL/min up to pH 11, as measured by a pH station (FiveEasy, Mettler-Toledo). The conductivity of the suspensions was monitored with a conductimetric station (SevenCompact, Mettler-Toledo). The titration curve showed typical presence of strong and weak acid groups. The amount of strong acid corresponded with the added HCl, and that of weak acid corresponded with the carboxyl content (Araki et al. 2001; Perez et al. 2003). The amount of weak acid (0.099 mmol/g) from the pure CNFs was deduced to obtain the carboxyl content of the adsorbed CMC. The results of three independent titrations were averaged for each sample. Cellulose (2014) 21:4349–4358 Viscosity The viscosity measurements were performed on a con/ plate rheometer (RVDV-III, Brookfield) using a cone CP-40 with an angle of 0.8°. The shear viscosity of the water-redispersed CNFs and CNF-CMC suspensions (0.5 wt%) was monitored by decreasing the shear rate from 1,875 to 15 s-1 at 25 °C. Mechanical properties Cellulose nanopapers were prepared from the waterredispersed samples of CNFs adsorbed with CMC according to a method developed previously (Henriksson et al. 2008; Sehaqui et al. 2010a). Tensile tests of the nanopapers were performed using an Instron universal material testing machine equipped with a load cell of 500 N at 50 % relative humidity and 23 °C. Samples were cut into rectangular strips of 5 mm width. The gauge length was 50 mm and the strain rate was 5 mm min-1. The results for each material were based on at least five specimens. The modulus was obtained from the slope at low strain and the tensile strength was determined as the stress at specimen breakage. Results and discussion Electron microscopy Adsorption of CMC on CNFs Field-emission scanning electron microscopy (FESEM) was conducted with a Hitachi S-4,800 SEM working at low acceleration voltage (1 kV) and short working distance (8 mm). A droplet of redispersed water suspension of CNFs and CNFs adsorbed with CMC with a solid content of 0.1 wt% was dried under vacuum on a specimen mount covered with carbon conductive tape. The vacuum dried samples were coated with a thin layer of platinum–palladium with a sputter coater (Cressington 208HR). To further characterize the size distribution of the never dried CNFs, 7 ll of very dilute sample suspension (0.005 wt%) was deposited on a carbon coated cooper grid and stained with 2 wt% uranyl acetate. After drying at ambient conditions, the sample was observed using a Hitachi S-4800 scanning electron microscope equipped with transmitted electron detector (STEM) to capture transmitted electron images. 123 The adsorbed amount of CMC onto CNFs as a function of added amount of CMC in water suspension of CNFs at room temperature 22 °C (RT) and high temperature 121 °C (HT) is plotted in Fig. 2. Following the classification of adsorption isotherms by Brunauer et al. (1940), the adsorption curve at RT shows a typical shape of type III isotherm, which is characteristic for unfavorable adsorption. Interestingly, the adsorption at HT follows a type II or BET isotherm, which is characteristic for multilayer adsorption on a non-porous material (Brunauer et al. 1938; Ebadi et al. 2009). The adsorption of anionic CMC onto slightly negatively charged CNFs is unfavorable due to charge–charge repulsion. The irreversible adsorption relies on the attachment of unsubstituted cellulose segments in CMC on cellulose chains exposed on the surface of CNFs by hydrogen bonding, similar to the adsorption of a nonionic Cellulose (2014) 21:4349–4358 4353 irreversible adsorption of CMC onto CNFs in water suspension at different temperatures. The adsorbed amount of CMC could be possibly further increased by tuning pH or by the addition of cations in the CNF water suspensions (Duker et al. 2007; Laine et al. 2000; Liu et al. 2011). Redispersion of dried CNF–CMC samples Fig. 2 Adsorbed amount of CMC onto CNFs as a function of the initial amount of CMC in CNFs water suspensions at room temperature 22 °C (RT) and high temperature 121 °C (HT) polymer, methylcellulose, onto wood pulp (Ishimaru and Lindström 1984). As shown in Fig. 2, such irreversible attachment was significantly strengthened by increasing temperature. At HT, almost all the CMC added in the suspension was adsorbed onto CNFs when the initial amount of CMC was lower than 20 mg/g CNFs. When the initial amount of CMC was gradually increased from 20 to 100 mg/g CNFs, the final amount of bound CMC slowly increased from 17 to 23 mg/g CNFs. Further increasing the initial amount to 200 mg/g CNFs did not increase the adsorption, indicating that the surface of CNFs was saturated with negative charges from bound CMC. To achieve an adsorption level of 23 mg CMC per gram of CNFs, the initial amount of CMC was only 100 mg at HT as compared to 300 mg at RT. After the saturation point achieved at HT, i.e. when the initial amount of CMC was higher than 200 mg/g CNFs, the adsorption became unfavorable, similar to the adsorption at RT in which the amount of bound CMC gradually increased with increasing initial amount of CMC. The amount of bound CMC was in the range of 23–59 mg/g CNFs by increasing the initial amount of CMC from 200 to 400 mg/g CNFs at HT. Thus, the adsorbed amount of CMC on CNFs is in the range of 0.09–0.22 mg/m2, assuming an average diameter of 10 nm for the CNFs. This result is similar to the surface coverage of 0.33–0.34 mg CMC/m2 on regenerated cellulose films as studied by surface plasmon resonance at different electrolyte conditions (Liu et al. 2011). To our knowledge, we are the first to report the The stability of water-redispersed CNFs and CNF– CMC suspensions was qualitatively assessed by sedimentation test. As shown in Fig. 3A, the oven dried CNFs (b) and the four CNF–CMC samples, in which the initial contents of CMC were 20 (c, CNF– CMC–HT-20) and 50 (d, CNF–CMC–HT-50) mg/g of CNFs at 121 °C and 100 (f, CNF–CMC–RT-100) and 200 (g, CNF–CMC–RT-200) mg/g of CNFs at 22 °C, precipitated from water suspensions within 3 and 24 h. The two CNF–CMC samples with the initial content of CMC of 100 mg/g at 121 °C (e, CNF–CMC–HT-100) and 300 mg/g at 22 °C (h, CNF–CMC–RT-300) were stable for the whole studied period of time, i.e. 24 h, as compared to the never dried CNFs (a) sample. This indicates that the water-resdispersibility of dried CNFs relies on the adsorbed amount of CMC. When the surface of the CNFs was saturated with negative charges introduced by the adsorbed CMC, the agglomeration of CNFs induced by the intermolecular hydrogen bonding between cellulose upon drying was minimized, thus stable suspensions were obtained when fully dried CNF-CMC samples were redispersed in water. The required amount of adsorbed CMC to achieve a stable suspension after redispersion was 23 mg CMC/g CNFs, i.e. a total surface carboxyl content of 0.185 mmol/g on CNFs. This value corresponds to a degree of substitution (DS) of 0.03, which is lower than the DS (0.08–0.22) of water-redispersible nanofibrillated cellulose prepared by carboxymethylation and mechanical disintegration (Eyholzer et al. 2010). This indicates that the adsorption of CMC onto CNFs is rather homogeneous while covalent carboxymethylation is a heterogeneous reaction. Figure 3B shows the photograph of dried CNF–CMC– HT-100 sample, which was prepared by the addition of 100 mg CMC/g CNFs in suspension at 121 °C followed by careful washing of unbound CMC and oven drying. 100 mL of 1 wt% suspension was placed in a glass beaker in the oven at 80 °C with ventilation and dried overnight until constant weight was reached. The 123 4354 Cellulose (2014) 21:4349–4358 Morphology, viscosity and mechanical properties of redispersed CNF–CMC samples Fig. 3 A Sedimentation test for 0.2 wt% water suspensions of never dried CNFs (a) and redispersed oven dried CNFs (b), CNF–CMC–HT-20 (c), CNF–CMC–HT-50 (d), CNF–CMC– HT-100 (e), CNF–CMC–RT-100 (f), CNF–CMC–RT-200 (g), and CNF–CMC–RT-300 (h). B Photographs of oven dried and C water-redispersed CNF–CMC–HT-100 sample with a solid content of 5 wt% CNF–CMC sample was removed from the glass wall of the beaker and broken into pieces ready for redispersion. The dried sample contained only 23 mg CMC/g CNFs (i.e. 2.3 % by weight of CNFs). Interestingly, this sample could be redispersed in water even at a solid content as high as 5 wt%, and a homogeneous and stable hydrogel was prepared (Fig. 3C). Such procedure to prepare CNF suspensions with high solid content is much easier than the conventional method using high speed centrifugation or filtration to concentrate the typical 2 wt% suspension of never dried CNFs (Pääkkö et al. 2007; Sehaqui et al. 2010b). 123 Figure 4 shows FE-SEM images of vacuum dried CNFs water suspensions. The individualized nanofibers from never dried CNFs suspension formed a weblike structure (Fig. 4A). Due to the agglomeration of CNFs during drying, both redispersed CNFs (Fig. 4B) and CNF–CMC–HT-10 (Fig. 4C) showed large CNFs aggregates of more than 25 lm. With increasing initial added amount of CMC, the water-redispersed CNF– CMC–HT-20 sample (Fig. 4D) showed a web-like structure with fewer large CNFs aggregates, while the water-redispersed CNF–CMC–HT-100 sample (Fig. 4E) showed a web-like structure of individualized nanofibers without any aggregates, similar to that for never dried CNFs. This further indicates that negative charges on the surface of CNFs are essential for a complete redispersion in water after drying. The addition of 100 mg CMC/g CNFs at HT to achieve an adsorption level of 23 mg/g is necessary to prepare water-redispersible dry CNF–CMC sample, as also indicated by the sedimentation test. The viscosities as a function of shear rate for suspensions of never dried CNFs and water-redispersed dry CNFs and CNF–CMC samples with a solid content of 0.5 wt% were investigated. As shown in Fig. 5, all samples showed a non-Newtonian behavior, with a large decrease of viscosity with increasing shear rate, i.e. shear thinning. This pseudoplastic behavior is typical for water suspensions of cellulose nanocrystals (Araki et al. 1998) and CNFs (Pääkkö et al. 2007). It is caused by the breakage of entanglements between cellulose particles and their alignment when shear rate increases. The viscosity of water-redispersed dry CNFs at shear rate of 15 s-1 was 4.2 9 10-2 Pa s, almost 3 times lower than that of never dried CNFs (1.1 9 10-1 Pa s). The viscosity of the water-redispersed CNF–CMC suspensions increased with the adsorbed amount of CMC on CNFs. For the CNF–CMC–HT-100 sample with 2.3 wt% CMC adsorbed on CNFs, the viscosity was 1.0 9 10-1 Pa s at shear rate of 15 s-1, similar to that of never dried CNFs suspension. This is a remarkable improvement since a weight content of 30 % CMC was required in order to recover the rheological behavior of the initial CNFs suspension as reported previously (Lowys et al. 2001). Cellulose (2014) 21:4349–4358 4355 Fig. 4 FE-SEM images of suspensions of never dried CNFs (A, A0 ) and water-redispersed CNFs (B), CNF–CMC–HT-10 (C), CNF– CMC–HT-20 (D, D0 ), and CNF–CMC–HT-100 (E, E0 ) observed at a magnification of 92,000 and 920,000 Furthermore, water-redispersed CNFs and CNF– CMC samples were used to prepare nanopapers. Typical stress–strain behavior in uniaxial tension and associated mechanical property data of the CNFs and CNF–CMC nanopapers are presented in Fig. 6 and Table 1, respectively. The tensile strength and strainto-break of the nanopaper prepared from waterredispersion of dried CNFs were significantly lower 123 4356 Cellulose (2014) 21:4349–4358 Table 1 Mechanical properties of nanopapers from never dried CNFs and water-redispersed CNF and CNF–CMC samples Sample Fig. 5 Viscosity versus shear rate for never dried CNFs suspension, water-redispersed CNFs and CNF–CMC suspensions with a solid content 0.5 wt% Modulus (GPa) Tensile strength (MPa) Strain-tobreak (%) CNFs never dried 11.4 ± 0.2 197.9 ± 6.1 7.4 ± 0.4 CNFs dried CNF–CMC–HT-50 10.3 ± 0.6 10.0 ± 0.3 125.5 ± 8.3 189.8 ± 7.8 4.5 ± 0.5 9.2 ± 0.7 CNF–CMC–HT-100 10.5 ± 0.3 190.8 ± 12.9 7.9 ± 0.8 CNFs adsorbed with CMC were slightly higher than that for never dried CNFs. This might be caused by the higher charge on the surface of CNFs, which could assist the sliding of the nanofibrils during plastic deformation as shown for carboxylated CNFs prepared by TEMPO-mediated oxidation (Sehaqui et al. 2012). Conclusions Fig. 6 Typical stress–strain curves of nanopapers prepared from never dried CNFs and water-redispersed CNFs and CNF– CMC samples than those of never dried CNFs while the modulus was maintained. Cellulose nanofibrils were not individualized when redispersed in water from fully dried CNFs sample, thus failed to form a continuous nanofiber network structure in the nanopaper. As the water redispersibility of CNFs increased with increasing amount of adsorbed CMC, the tensile strength of the nanopapers also increased compared to the dried CNFs without CMC. The CNF–CMC–HT-100 sample with only 2.3 wt% adsorbed CMC had tensile strength and modulus values rather similar to those for never dried CNFs, indicating good redispersibility in water after drying. The strain-to-break of nanopapers from 123 We have shown that water-redispersible dried CNFs can be simply prepared by the adsorption of 2.3 wt% CMC onto CNFs before oven drying. The irreversible adsorption of 2.3 wt% CMC was achieved with the addition of only 100 mg CMC/g CNFs in water suspension followed by incubation at 121 °C for 25 min. The rheological and mechanical properties of CNFs were conserved after completely dried and water-redispersed. Interestingly, water suspensions of CNFs with concentration as high as 5 wt% can be readily prepared by redispersion from dry sample. A homogenous coverage of negative charges on the surface of the CNFs induced by the adsorbed CMC is essential to avoid the agglomeration of CNFs upon drying, thus cellulose nanofibrils can be easily redispersed in water without aggregates observed. With this new method, water-redispersible dried CNFs can be prepared without sophisticated chemical modification or drying process. Hence, CNFs transportation and storage can be optimized, leading to an easier implantation of CNFs in traditional polymer sectors such as packaging and composites industries. Acknowledgments The authors thank the Swedish Research Council Formas (CarboMat, 2009-1687) and the Wallenberg Wood Science Center for supporting this work. Cellulose (2014) 21:4349–4358 References Araki J, Wada M, Kuga S, Okano T (1998) Flow properties of microcrystalline cellulose suspension prepared by acid treatment of native cellulose. Colloids Surf A 142:75–82. doi:10.1016/S0927-7757(98)00404-X Araki J, Wada M, Kuga S (2001) Steric stabilization of a cellulose microcrystal suspension by poly(ethylene glycol) grafting. Langmuir 17:21–27. doi:10.1021/La001070m Beck S, Bouchard J, Berry R (2012) Dispersibility in water of dried nanocrystalline cellulose. Biomacromolecules 13:1486–1494. doi:10.1021/Bm300191k Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60:309–319. doi:10.1021/ja01269a023 Brunauer S, Deming LS, Deming WE, Teller E (1940) On a theory of the van der Waals adsorption of gases. J Am Chem Soc 62:1723–1732. doi:10.1021/ja01864a025 Dong XM, Gray DG (1997) Effect of counterions on ordered phase formation in suspensions of charged rodlike cellulose crystallites. Langmuir 13:2404–2409. doi:10.1021/La960724h Duker E, Brannvall E, Lindström T (2007) The effects of CMC attachment onto industrial and laboratory-cooked pulps. Nord Pulp Pap Res J 22:356–363. doi:10.3183/NPPRJ2007-22-03-p356-363 Duker E, Ankerfors M, Lindström T, Nordmark GG (2008) The use of CMC as a dry strength agent—the interplay between CMC attachment and drying. Nord Pulp Pap Res J 23:65–71. doi:10.3183/NPPRJ-2008-23-01-p065-071 Ebadi A, Mohammadzadeh JSS, Khudiev A (2009) What is the correct form of BET isotherm for modeling liquid phase adsorption? Adsorption 15:65–73. doi:10.1007/s10450009-9151-3 Eyholzer C, Bordeanu N, Lopez-Suevos F, Rentsch D, Zimmermann T, Oksman K (2010) Preparation and characterization of water-redispersible nanofibrillated cellulose in powder form. Cellulose 17:19–30. doi:10.1007/S10570009-9372-3 Fang ZQ et al (2014) Novel nanostructured paper with ultrahigh transparency and ultrahigh haze for solar cells. Nano Lett 14:765–773. doi:10.1021/Nl404101p Filpponen I, Kontturi E, Nummelin S, Rosilo H, Kolehmainen E, Ikkala O, Laine J (2012) Generic method for modular surface modification of cellulosic materials in aqueous medium by sequential ‘‘click’’ reaction and adsorption. Biomacromolecules 13:736–742. doi:10.1021/Bm201661k Fras-Zemljic L, Stenius P, Laine J, Stana-Kleinschek K (2006) The effect of adsorbed carboxymethyl cellulose on the cotton fibre adsorption capacity for surfactant. Cellulose 13:655–663. doi:10.1007/S10570-006-9071-2 Fukuzumi H, Saito T, Wata T, Kumamoto Y, Isogai A (2009) Transparent and high gas barrier films of cellulose nanofibers prepared by tempo-mediated oxidation. Biomacromolecules 10:162–165. doi:10.1021/Bm801065u Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43:3434–3441. doi:10.1016/j.eurpolymj.2007.05.038 Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. 4357 Biomacromolecules 9:1579–1585. doi:10.1021/ Bm800038n Hietala M, Mathew AP, Oksman K (2013) Bionanocomposites of thermoplastic starch and cellulose nanofibers manufactured using twin-screw extrusion. Eur Polym J 49:950–956. doi:10.1016/j.eurpolymj.2012.10.016 Hu LB, Wu H, La Mantia F, Yang YA, Cui Y (2010) Thin, flexible secondary li-ion paper batteries. ACS Nano 4:5843–5848. doi:10.1021/Nn1018158 Ishimaru Y, Lindström T (1984) Adsorption of water-soluble, nonionic polymers onto cellulosic fibers. J Appl Polym Sci 29:1675–1691. doi:10.1002/app.1984.070290521 Jin H et al (2011) Superhydrophobic and superoleophobic nanocellulose aerogel membranes as bioinspired cargo carriers on water and oil. Langmuir 27:1930–1934. doi:10.1021/La103877r Laine J, Lindström T, Nordmark GG, Risinger G (2000) Studies on topochemical modification of cellulosic fibres Part 1. Chemical conditions for the attachment of carboxymethyl cellulose onto fibres. Nord Pulp Pap Res J 15:520–526. doi:10.3183/NPPRJ-2000-15-05-p520-526 Liu ZL, Choi H, Gatenholm P, Esker AR (2011) Quartz crystal microbalance with dissipation monitoring and surface plasmon resonance studies of carboxymethyl cellulose adsorption onto regenerated cellulose surfaces. Langmuir 27:8718–8728. doi:10.1021/La200628a Lowys MP, Desbrières J, Rinaudo M (2001) Rheological characterization of cellulosic microfibril suspensions. Role of polymeric additives. Food Hydrocoll 15:25–32. doi:10. 1016/S0268-005x(00)00046-1 Missoum K, Bras J, Belgacem MN (2012) Water redispersible dried nanofibrillated cellulose by adding sodium chloride. Biomacromolecules 13:4118–4125. doi:10.1021/Bm301378n Newman RH (2004) Carbon-13 NMR evidence for cocrystallization of cellulose as a mechanism for hornification of bleached kraft pulp. Cellulose 11:45–52. doi:10.1023/B: Cell.0000014768.28924.0c Nogi M, Yano H (2008) Transparent nanocomposites based on cellulose produced by bacteria offer potential innovation in the electronics device industry. Adv Mater 20:1849–1852. doi:10.1002/Adma.200702559 Nyström G, Razaq A, Strømme M, Nyholm L, Mihranyan A (2009) Ultrafast all-polymer paper-based batteries. Nano Lett 9:3635–3639. doi:10.1021/Nl901852h Olsson RT et al (2010) Making flexible magnetic aerogels and stiff magnetic nanopaper using cellulose nanofibrils as templates. Nat Nanotechnol 5:584–588. doi:10.1038/ Nnano.2010.155 Pääkkö M et al (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941. doi:10.1021/Bm061215p Pääkkö M et al (2008) Long and entangled native cellulose I nanofibers allow flexible aerogels and hierarchically porous templates for functionalities. Soft Matter 4:2492–2499. doi:10.1039/B810371b Pahimanolis N et al (2013) Nanofibrillated cellulose/carboxymethyl cellulose composite with improved wet strength. Cellulose 20:1459–1468. doi:10.1007/S10570-013-9923-5 Pei AH, Butchosa N, Berglund LA, Zhou Q (2013) Surface quaternized cellulose nanofibrils with high water 123 4358 absorbency and adsorption capacity for anionic dyes. Soft Matter 9:2047–2055. doi:10.1039/C2sm27344f Perez DD, Montanari S, Vignon MR (2003) TEMPO-mediated oxidation of cellulose III. Biomacromolecules 4:1417– 1425. doi:10.1021/Bm034144s Saito T, Nishiyama Y, Putaux JL, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691. doi:10.1021/Bm060154s Sehaqui H, Liu AD, Zhou Q, Berglund LA (2010a) Fast preparation procedure for large, flat cellulose and cellulose/inorganic nanopaper structures. Biomacromolecules 11:2195– 2198. doi:10.1021/Bm100490s Sehaqui H, Salajkova M, Zhou Q, Berglund LA (2010b) Mechanical performance tailoring of tough ultra-high porosity foams prepared from cellulose I nanofiber suspensions. Soft Matter 6:1824–1832. doi:10.1039/B927505c 123 Cellulose (2014) 21:4349–4358 Sehaqui H, Zhou Q, Berglund LA (2011) High-porosity aerogels of high specific surface area prepared from nanofibrillated cellulose (NFC). Compos Sci Technol 71:1593–1599. doi:10.1016/J.Compscitech.07.003 Sehaqui H, Mushi NE, Morimune S, Salajkova M, Nishino T, Berglund LA (2012) Cellulose nanofiber orientation in nanopaper and nanocomposites by cold drawing. ACS Appl Mater Interfaces 4:1043–1049. doi:10.1021/Am2016766 Zemljic LF, Stenius P, Laine J, Stana-Kleinschek K (2008) Topochemical modification of cotton fibres with carboxymethyl cellulose. Cellulose 15:315–321. doi:10.1007/ S10570-007-9175-3 Zhu HL et al (2013) Tin anode for sodium-ion batteries using natural wood fiber as a mechanical buffer and electrolyte reservoir. Nano Lett 13:3093–3100. doi:10.1021/Nl400998t