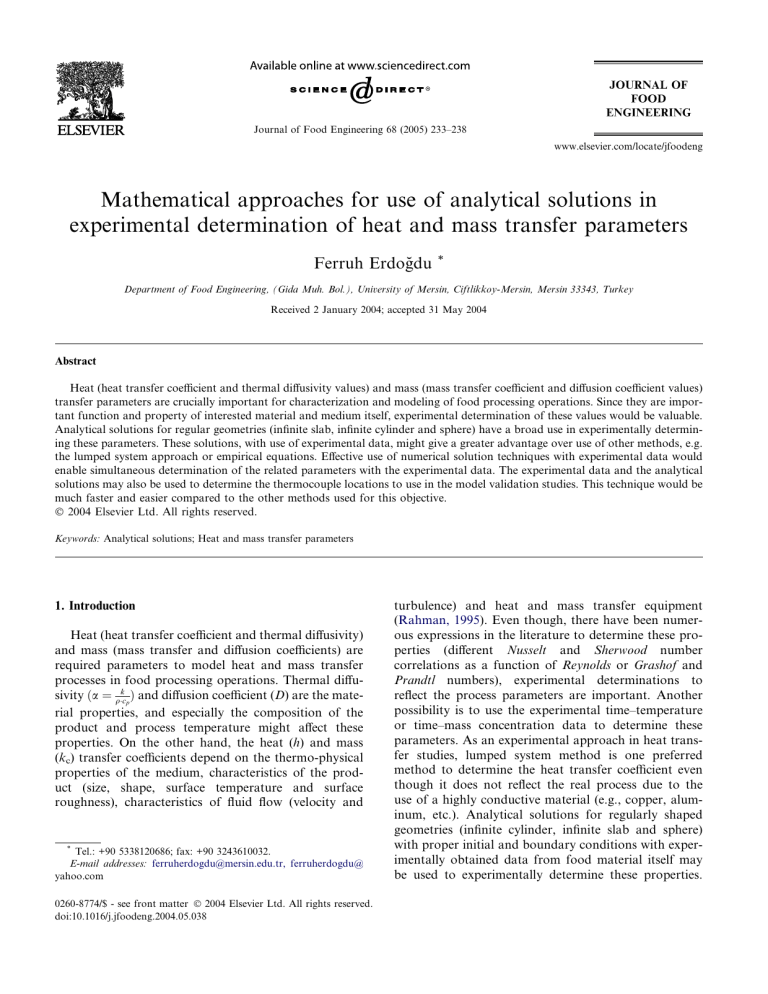

Journal of Food Engineering 68 (2005) 233–238 www.elsevier.com/locate/jfoodeng Mathematical approaches for use of analytical solutions in experimental determination of heat and mass transfer parameters Ferruh Erdoğdu * Department of Food Engineering, (Gida Muh. Bol.), University of Mersin, Ciftlikkoy-Mersin, Mersin 33343, Turkey Received 2 January 2004; accepted 31 May 2004 Abstract Heat (heat transfer coefficient and thermal diffusivity values) and mass (mass transfer coefficient and diffusion coefficient values) transfer parameters are crucially important for characterization and modeling of food processing operations. Since they are important function and property of interested material and medium itself, experimental determination of these values would be valuable. Analytical solutions for regular geometries (infinite slab, infinite cylinder and sphere) have a broad use in experimentally determining these parameters. These solutions, with use of experimental data, might give a greater advantage over use of other methods, e.g. the lumped system approach or empirical equations. Effective use of numerical solution techniques with experimental data would enable simultaneous determination of the related parameters with the experimental data. The experimental data and the analytical solutions may also be used to determine the thermocouple locations to use in the model validation studies. This technique would be much faster and easier compared to the other methods used for this objective. 2004 Elsevier Ltd. All rights reserved. Keywords: Analytical solutions; Heat and mass transfer parameters 1. Introduction Heat (heat transfer coefficient and thermal diffusivity) and mass (mass transfer and diffusion coefficients) are required parameters to model heat and mass transfer processes in food processing operations. Thermal diffusivity ða ¼ qck p Þ and diffusion coefficient (D) are the material properties, and especially the composition of the product and process temperature might affect these properties. On the other hand, the heat (h) and mass (kc) transfer coefficients depend on the thermo-physical properties of the medium, characteristics of the product (size, shape, surface temperature and surface roughness), characteristics of fluid flow (velocity and * Tel.: +90 5338120686; fax: +90 3243610032. E-mail addresses: [email protected], ferruherdogdu@ yahoo.com 0260-8774/$ - see front matter 2004 Elsevier Ltd. All rights reserved. doi:10.1016/j.jfoodeng.2004.05.038 turbulence) and heat and mass transfer equipment (Rahman, 1995). Even though, there have been numerous expressions in the literature to determine these properties (different Nusselt and Sherwood number correlations as a function of Reynolds or Grashof and Prandtl numbers), experimental determinations to reflect the process parameters are important. Another possibility is to use the experimental time–temperature or time–mass concentration data to determine these parameters. As an experimental approach in heat transfer studies, lumped system method is one preferred method to determine the heat transfer coefficient even though it does not reflect the real process due to the use of a highly conductive material (e.g., copper, aluminum, etc.). Analytical solutions for regularly shaped geometries (infinite cylinder, infinite slab and sphere) with proper initial and boundary conditions with experimentally obtained data from food material itself may be used to experimentally determine these properties. 234 F. Erdoğdu / Journal of Food Engineering 68 (2005) 233–238 Nomenclature A a cp D E n h J0, J 1 k kc L k m l constant thermal diffusivity, m2/s specific heat, J/kg K diffusion coefficient, m2/s experimental data characteristic length, m heat transfer coefficient, W/m2 K the first kind 0th and 1st order Bessel functions thermal conductivity, W/m K mass transfer coefficient, m/s half-thickness for an infinite slab, m root of Eqs. (5)–(7) slopes of temperature or concentration ratio vs time curves, 1/s dynamic viscosity, kg/m s In fact, proper use of analytical solutions with the experimentally obtained data might give a greater advantage over the use of other methods, e.g. lumped system approach or empirical equations. The analytical solutions with the experimental data may also be used to find out the precise geometric location of the thermocouples placed in the samples to measure the temperature change. In fact, the precise thermocouple location is crucially important in model validation studies rather than in determining the heat and mass transfer parameters. Therefore, the objective of this study was to explain the methodologies to use analytical solutions of regularly shaped geometries with the experimentally obtained data to determine the heat and mass transfer parameters and thermocouple locations where the temperature measurement was taken. g X / /i /1 w w r, x R q m heat or mass transfer coefficient in heat or mass transfer cases thermal diffusivity or diffusion coefficient, m2/s temperature or mass concentration initial temperature or mass concentration medium temperature or mass concentration dimensionless temperature or mass concentration ratio volume average dimensionless temperature or mass concentration ratio distance from the center, m radius for an infinite cylinder or a sphere, m density, kg/m3 kinematic viscosity, m2/s cylinder, and n = 2 for sphere); and X is thermal or mass diffusivity (m2/s). Solutions for Eq. (1), for initial condition of uniform temperature or mass distribution and boundary conditions of central symmetry and convective boundary at the surface, are given for these geometries as follows (Carslaw & Jaeger, 1986). Infinite slab: / /1 /i /1 1 X 2 sin kn x 2 ¼ cos kn expðkn FoÞ L kn þ sin kn cos kn n¼1 w¼ ð2Þ Infinite cylinder: / /1 /i /1 1 X 2 J 1 ðkn Þ x 2 ¼ 2 k FoÞ expðk J 0 n n kn J 0 ðkn Þ þ J 21 ðkn Þ L n¼1 w¼ 2. Mathematical background Governing differential equations and solutions for infinite geometries (infinite slab, infinite cylinder and sphere) are given as follows with the mostly encountered initial (uniform distribution of temperature or mass concentration) and boundary condition (surface convection). Governing differential equation: 1 o 1 o/ n o/ x ð1Þ ¼ xn ox ox X ot where / is temperature or mass concentration; x is location in geometry to characterize temperature or mass concentration (m), distance from the center; n is a characteristic number (n = 0 for infinite slab, n = 1 for infinite ð3Þ Sphere: / /1 /i /1 1 X 2 ðsinkn kn coskn Þ sinðkn Rr Þ 2 ¼ expðkn FoÞ kn Rr kn sinkn coskn n¼1 w¼ Xt n2 ð4Þ where Fo Fo ¼ is Fourier number (n is L, halfthickness for an infinite slab and R, radius for an infinite cylinder or a sphere; X is thermal diffusivity or diffusion F. Erdoğdu / Journal of Food Engineering 68 (2005) 233–238 coefficient), and the knÕs are the roots of Eqs. (5)–(7) for infinite slab, infinite cylinder and sphere, respectively: Bi ¼ k tan k ð5Þ J 1 ðkÞ J 0 ðkÞ ð6Þ Bi ¼ k k Bi ¼ 1 ð7Þ tan k where Bi Bi ¼ gn is Biot number (g is heat or mass k transfer coefficient, and k is thermal conductivity or X, diffusion coefficient in a mass transfer case), and J0 and J1 are the first kind 0th and 1st order Bessel functions. In heat transfer related calculations, use of Eqs. (2)–(4) would be enough since the temperature change at a certain location inside the geometry is needed or experimentally obtained. However, for mass transfer related calculations, these equations should be integrated through the whole volume since the mass transfer experimental results would generally be obtained through the whole volume rather than at a certain location. Integration of Eqs. (2)–(4) through the whole volume results in Eqs. (8)–(10) for infinite slab, infinite cylinder, and sphere, respectively: Infinite slab: / /1 /i /1 1 X 2 sin2 kn 2 expðkn FoÞ ¼ kn ðkn þ sin kn cos kn Þ n¼1 w¼ diffusion coefficient is constant, this first term approach may be easily used to determine these parameters with the known heat or mass transfer coefficient value. 3. Methods 3.1. Determination of constant thermal diffusivity or diffusion coefficient value Let us assume that the temperature change at a certain location of a spherical object in a highly agitated medium was recorded to determine the thermal diffusivity. Due to the agitation, heat transfer coefficient and hence the Biot number may be assumed to be infinite. Then, roots of Eq. (7) may be determined to be (p, 3p, . . . and so on). The roots would be p 2p, 3p 5p ; ; ; . . . for an infinite slab or (2.4048, 5.5200, 2 2 2 8.6537, . . .) for an infinite cylinder when the Biot number is infinite. Due to the fact that the temperature ratio //1 becomes linear after a certain time (Fo > 0.2), /i /1 the first term of Eq. (4) in case of sphere is then used to characterize the linear change in that region. When the natural logarithm of both sides of Eq. (4) is taken with the first term approximation (n = 1), following equation is obtained (k1 = p): / /1 k2 X p2 X t ð11Þ ln ¼ A1 1 2 t ¼ A 1 /i /1 R R2 where, ð8Þ Infinite cylinder: / /1 w¼ /i /1 " # 1 X 4 J 21 ðkn Þ 2 expðkn FoÞ ¼ 2 2 2 n¼1 kn J 0 ðkn Þ þ J 1 ðkn Þ 235 ð9Þ Sphere: / /1 /i /1 " # 2 1 X 6 ðsin kn kn cos kn Þ 2 ¼ expðkn FoÞ 3 kn sin kn cos kn n¼1 kn w¼ ð10Þ As seen in Eqs. (2)–(4) and (8)–(10), it is important to know how many terms of the infinite series solutions are required to obtain a correct solution. It is a general knowledge that use of the first term would be enough when the Fourier number is greater than 0.2 since the temperature or mass ratio change after that certain time would be linear. As long as the thermal diffusivity or the 2 ðsin k1 k1 cos k1 Þ sin k1 Rr A1 ¼ ln k1 sin k1 cos k1 k1 Rr r sin p R ¼ ln 2 p Rr ð12Þ As seen in Eq. (11), slope (m) of the temperature ratio vs 2 k2 X time curve would be equal to m ¼ R1 2 ¼ pRX 2 . Then, with the known slope and radius of the spherical material, thermal diffusivity value may be determined. As one realizes, this method does not require the knowledge of the location in the material where the experimental data is recorded since, regardless of the location, temperature ratio curves have the same slope after the linearization starts (Chau, 1995–2000). Eq. (11) also shows that the slope is independent of the location. Fig. 1 shows the change in simulated temperature ratios obtained using the analytical solution at different locations (Rr ¼ 0, Rr ¼ 0:5 and Rr ¼ 0:97) of a spherical object (30 mm in radius) cooked in agitated boiling water. Rr ¼ 0 is the center while Rr ¼ 0:97 is the location just underneath the surface. As seen in Fig. 1, temperature ratios become linear after a certain time (e.g. t > 1000 s for the center), and slopes are equal for each location. The same approach may also be easily applied to determine the 236 F. Erdoğdu / Journal of Food Engineering 68 (2005) 233–238 ln(Temperature Ratio) 0 -1 r/R=0 r/R=0.5 -2 r/R=0.97 -3 -4 -5 -6 -7 -8 0 500 1000 1500 2000 Time (s) 2500 3000 3500 Slopes of the linear parts for each curve are: - 0.0013 1/s Fig. 1. Simulated temperature ratios taken in different locations of a spherical object. diffusion coefficient during mass transfer phenomena (e.g., diffusion coefficient of moisture during drying) via the use of Eq. (10) when the changes in volume are known. As explained, it is very easy to determine the thermal diffusivity or diffusion coefficient as long as the experimental data is available in the range of high Fourier number (Fo > 0.2). For the heat transfer case, it is relatively easy to obtain the data in this range since the thermal diffusivity values are much higher than the diffusion coefficient values. For example, thermal diffusivity value of unfrozen red meat is in the range of 1.2–1.3 · 107 m2/s (Rahman, 1995) while the diffusion coefficient value; e.g. for sodium tripolyphosphates (prepared as 2% solution, w/v) in the red meat, is in the range of 1011 m2/s. The required times for Fo > 0.2 for red meat of 20 mm in thickness (infinite slab shaped) may be determined as 2.5 min for the heat transfer case and more than 500 h for mass transfer case (Ünal, Erdoğdu, Ekiz, & Özdemir, 2004). In the latter case, it would not seem to be possible to determine the diffusion coefficient value from the slope of the concentration ratio vs time curves. In this case an alternative approach must be used. Let us assume that the concentration of sodium tripolyphosphates were determined experimentally in red meat while the meat sample is dipped in the solution for 30 min. As explained, it is not possible to get a higher Fourier number in this case. To solve this problem, Eq. (8) can be written as: / /1 /i /1 2 2 2 Xt ¼ A1 exp k1 2 þ A2 k1 k n 2 X t exp k22 2 þ n w¼ for n ¼ 1; 2; . . . " 1 X 2 kn t 2 Xt 0 An exp kn 2 f ðXÞ ¼ n2 n n¼1 Xnþ1 ¼ Xn f ðXn Þ f 0 ðXn Þ # ð16Þ ð17Þ In this method, just knowing the concentration ratio (or temperature ratio in the heat transfer case) at any time would be enough to determine the diffusion coefficient value instead of using a set of experimental data. The constant diffusion coefficient value assumption may also be checked with this procedure using the experimental data obtained at different times. 3.2. Determination of variable thermal diffusivity or diffusion coefficient value The variable thermal diffusivity is not common. However, Ünal et al. (2004) reported variable diffusion coefficient values in the case of sodium tripolyphosphate diffusion in red meats. The variability of the diffusion coefficient may be tested using the procedure explained above (Eqs. (15)–(17)). If the variation continues through the whole process, it may be easier to determine an averaged value to describe the whole process, or numerical finite difference techniques should be used to take the variability into account. In this case minimization of sum of squares (S) of the differences between the experimental data and results of the analytical solutions may be used to minimize Eq. (18) as follows: S¼ n X 2 ðw EÞi ð18Þ i¼1 ð13Þ where A values are given by: sin2 kn An ¼ kn þ sin kn cos kn In Eq. (13), the only unknown is the diffusion coefficient value (X) assuming the mass transfer coefficient of the medium, therefore the Biot number and the k values through Eq. (5), is known. In this case Eq. (13) should be solved to determine the X value. Newton–Raphson or any other numerical technique may be applied to solve this equation. When the Newton–Raphson method is applied, the iterative solution of Eqs. (15)–(17) give the result for X value. 1 X 2 Xt An exp k2n 2 ð15Þ w¼0 f ðXÞ ¼ kn n n¼1 ð14Þ where n is the number of experimentally obtained data, and E is the experimental data. To determine the diffuoS sion coefficient value, to minimize S, oX should be 0. When this is applied to Eq. (18), Eqs. (19) and (20) are obtained: n oS X ow ¼ 2 ðw EÞ ¼0 oX oX i i¼1 ð19Þ F. Erdoğdu / Journal of Food Engineering 68 (2005) 233–238 237 n i o n h oS X 2 þ k22 A2 exp k22 Xt þ E 2kn21 t A1 exp k21 Xt 2kn22 t A2 exp k22 Xt A1 exp k21 Xt ¼0 2 ¼ 2 2 2 2 k1 n n n n i oX i¼1 i ð20Þ oS From Eq. (20), it would be obvious that for oX to be 0: n X 2 k1 t Xt A1 exp k21 2 2 n n i¼1 2 k1 t 2 Xt A2 exp k1 2 ¼ 0 ð21Þ n2 n i and Eq. (21) may be easily solved using Newton– Raphson or any other numerical solution technique for X value. 3.3. Determination of constant heat or mass transfer coefficient Heat or mass transfer coefficient may also be determined using the analytical solutions when a thermal diffusivity- or diffusion coefficient-known material is used. In this case, using the slope (m) of the temperature ratio pffiffiffiffiffiffiffi vs time curve, k1 is determined (k1 ¼ n mXÞ, and it is then used to determine the Biot number (Bi) and therefore the heat or mass transfer coefficient. Of course, in addition to the thermal diffusivity, thermal conductivity of the experimental material must also be known in the heat transfer case. In spite of the easy use of this method, general approach in the literature is to assume an infinite heat or mass transfer coefficient and then to determine the thermal diffusivity or diffusion coefficient values. However, just knowing heat transfer coefficient may also enable to determine mass transfer coefficient and diffusion coefficients through the so-called analogy of Chilton–Colburn when a simultaneous heat and mass transfer is occurring (e.g. during drying process): kc ¼ 23 h Pr q cp Sc ð22Þ where kc is mass transfer coefficient (m/s), h is heat transfer coefficient (W/m2 K), q (kg/m3) and cp (J/kg K) are density and heat capacity of the heating medium, c l respectively, Pr ðPr ¼ pk Þ is Prandtl number where l is dynamic viscosity (kg/m s), and Sc ðSc ¼ Dm Þ is Schmidt number where m is kinematic viscosity (m2/s) and D is diffusion coefficient (m2/s). Basically, knowing mass transfer coefficient with experimental data to determine the diffusion coefficient leads to Eqs. (23) and (24). Then, solving this equation leads to the determination of k value (Eq. (23)) and therefore the diffusion coefficient value through the slope of the concentration ratio vs time curve (Eq. (24)). k1 kc R ¼ Bi ¼ 1 tan k1 m R2 =k21 m R2 ¼X k21 ð23Þ ð24Þ where R is the characteristic dimension (radius for sphere). The solution to determine the kc value is not as easy as it seems to be since the D value should also be known through the Sc (Schmidt) number. Therefore, assuming the D value is known, through the average temperature of surface and medium, using the following steps lead to determine the X value: 1. Determine kc value from Eq. (22), 2. Determine k1 value from Eq. (23) (Newton–Raphson or any other method for a nonlinear equation may be used), and 3. Determine X value from Eq. (24). As long as the Chilton–Colburn analogy may be used, this methodology should work without any problem. However, one should not forget that there are limitations on the use of heat-mass convection analogies. Heat-mass convection analogies are generally valid for low mass flux cases so that mass transfer does not affect the surface flow, and heat transfer correlations are developed for smooth and constant surface temperature situations. Therefore, an extra pre-caution should be taken to find out the given conditions before applying the heat-mass analogies for more accurate results. 3.4. Determination of thermocouple locations In the heat transfer validation studies, the knowledge of thermocouple locations, where the experimental data, is extremely important to correlate the simulation results with the experimental data. Since it is not easy to find out where the tip of the thermocouple, it is a common way to take an X-ray of the material when the thermocouple is still in it and then determine the location (Anderson & Singh, 2002). The other way might be to cut thin slices from the material until the tip was caught (Erdogdu, Balaban, & Chau, 1998). Both these ways are time consuming. The analytical solutions may be an alternative approach to determine the thermocouple locations. If we go back to Fig. 1 again for this purpose, the intercepts of the three temperature ratios may be 238 F. Erdoğdu / Journal of Food Engineering 68 (2005) 233–238 determined as 0.6821, 0.2416, and 2.6727 for Rr ¼ 0, r ¼ 0:5 and Rr ¼ 0:97, respectively. Now, let us try to R determine the thermocouple locations ðRr Þ values from these data. Then, using Eq. (11) and applying linear regression to the linear part of the data points, the following relationship is obtained for the second point (Rr ¼ 0:5): sin p Rr A1 ¼ ln 2 ¼ 0:2416 ð25Þ p Rr Now, the objective is to determine the Rr value from this equation. When Newton–Raphson method was applied, the following equations are obtained to solve: r r r ð26Þ f ¼ 2 sin p p expð0:2416Þ R R R r r f0 ¼ 2 p cos p p expð0:2416Þ ð27Þ R R Then, the iterative solution of Eqs. (26) and (27), starting with the initial guess of 1, leads to find Rr value as 0.5. proaches, it is required that one of the parameters should be known to determine the other: heat or mass transfer coefficient should be known to determine the thermal diffusivity or the diffusion coefficient value. Therefore, it is still important to develop or optimize a procedure to determine the both parameters simultaneously. In addition to the heat and mass transfer parameters, the analytical solutions may also be used to determine the thermocouple locations to use in the further model validation studies. This method would be faster and easier compared to the other methods. Acknowledgment The author wishes to express his gratitude to Dr. Khe V. Chau at the University of Florida, Department of Biological and Agricultural Engineering for his valuable suggestions. References 4. Conclusions Heat (heat transfer coefficient and thermal diffusivity) and mass (mass transfer coefficient and diffusion coefficient) transfer parameters are important to characterize, to model and to optimize the heat and mass transfer processes. Different approaches for experimental determination of these parameters were explained in detail. Since these approaches with the analytical solutions require the experimental data obtained from the interested material, they give a greater advantage over the use of more preferred methods, e.g., the lumped system approach or use of empirical equations to determine heat or mass transfer coefficients. As seen in these ap- Anderson, B., & Singh, R. P. (2002). Air impingement heat transfer on a cylindrically shaped object. The IFT Annual Meeting and Food Expo. Presentation no; 91C-22. Carslaw, H. S., & Jaeger, J. C. (1986). Conduction of heat in solids. New York, NY: Oxford. Chau, K. V. (1995–2000). Personal Communication. Department of Biological and Agricultural Engineering, University of Florida, Gainesville, FL. Erdogdu, F., Balaban, M. O., & Chau, K. V. (1998). Modeling of heat conduction in elliptical cross section: II. Adaptation to thermal processing of shrimp. Journal of Food Engineering, 28, 241–258. Rahman, S. (1995). Food properties handbook. Boca Raton, FL: CRC Press Inc.. _ & Özdemir, Y. (2004). Experimental Ünal, B., Erdoğdu, F., Ekiz, H. I., theory, fundamentals and mathematical evaluation of phosphate diffusion in meats. Journal of Food Engineering, 65, 263–272.