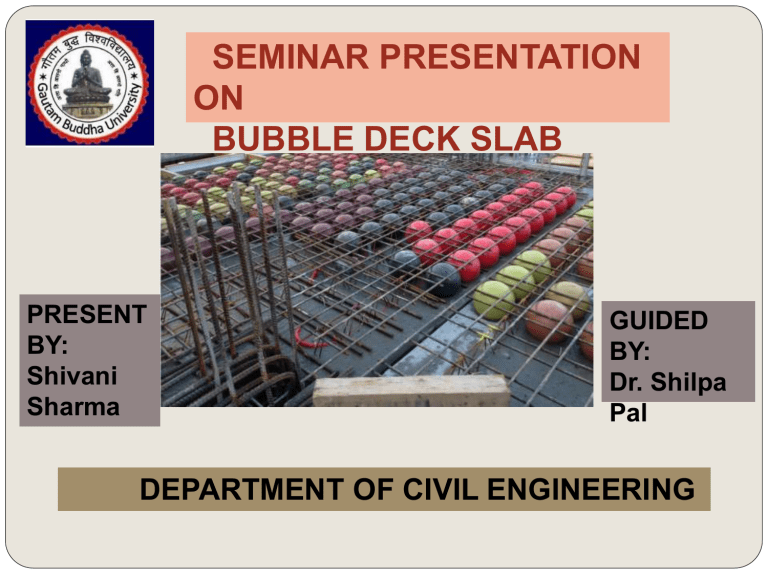

SEMINAR PRESENTATION ON BUBBLE DECK SLAB PRESENT BY: Shivani Sharma GUIDED BY: Dr. Shilpa Pal DEPARTMENT OF CIVIL ENGINEERING CONTENTS S.No Topic . 1. 1.1 1..2 1.3 2 3 4 5 6 7 8 Introduction Solid slab Hollow core slab Bubble deck slab Example of Project Materials Advantages and Disadvantages Literature Review Conclusion Scope of future use Reference NEED OF BUBBLE DECK SLAB 1. SOLID SLAB INACTIVE CONCRETE (Central portion of RCC solid slab) Problems with inactive concrete• Large amount of concrete consumption • Span limitation • Material wastage Solution 2. HOLLOW CORE SLAB Pre fabricated one way spanning concrete elements with hollow cylinders, replacing inactive concrete. PROBLEMS The elements are usually large and heavy. Rigid design and no flexibility of adaptation in the field. Large hoisting and erection costs. INTRODUCTION 3. BUBBLE DECK SLAB The best solution for above two problems is Bubble Deck Slab. This slab is invented by Jorgen Breuning in Denmark 1990’s. It’s a method of virtually eliminating all concrete from the middle of a floor slab, which is not performing any structural function, thereby dramatically reducing structural dead weight. MATERIALS PLASTIC SPHERES (hollow spheres made from recycled High Density Polyethylene). Enough strength (90% of solid slab) & rigidity. STEEL ( Steel reinforcement is of MS or HYSD can be used ). CONCRETE Concrete is made up of Standard Portland Cement with max WORKING PROJECT OF BUBBLE DECK SLAB Longer span, fewer columns Source- Google ADVANTAGES DISADVANTAGE S •Concrete usage is reduced as 1Kg of recycled plastic replaces 100kg of concrete. Hence this technology is green technology. •Reduces the overall dead load of structure & leads to 30 %to 50% lighter slab which reduces load on columns , walls and foundations. •Larger spans. •Lower the cost of total •Punching shear capacity is low. •Skilled labour required. •Conventional slab is less deflect than bubble deck slab. •Load carrying capacity is less than conventional slab. LITERATURE REVIEW S.N O. TITLE 1. 2. AUTHOR ABSTRACT CONCLUSION An experimental Nagesh study on bubble Hanche and deck slab system Arati Shetkar with hollow elliptical balls. The author studied the use of Hollow plastic balls in the reinforced concrete slab and its effects. •They founded that 50% dead weight reduction compared to solid slab , less CO2 emission. • Less concrete required . •Load carrying capacity of slab is depend on arrangements of bubbles. Experimental study on bubble deck slab To determine load bearing capacity and to estimate amount of concrete saved. •Results shows bubble deck slab carried less load due to stiffness reduction because of plastic balls introduce in to the slab. • 10.55-25% of concrete saved as compare to solid slab. Prof. Nishant Rajoria , Muhammad Shafiq Mushfiq (IRJET) S.N O. TITLE AUTHOR 3. An Neeraj Tiwari , experimental Sana Zafar study on bubble deck slab. ABSTRACT CONCLUSION To increase the strength of slab by using continuous and alternative bubble arrangement in the slab and to determine the deformation and failing mechanisms. • Continuous arrangement of bubbles increase the strength compare to alternate bubble arrangement. • volume of concrete in bubble deck ( continuous ) are less required i.e. 25% approx. •Conventional slab is less deflect . By using ANSYS SOFTWARE S.NO . TITLE AUTHOR ABSTRACT CONCLUSION 4. Punching shear Reshma strength Mathew, development of Binu.P bubble deck slab using GFRP (Glass fiber reinforced polymer) stirrups. This paper compared the punching shear behavior of bubble deck slab to solid slab by using ANSYS software. •Compared to solid slab punching shear capacity of bubble deck slab is less . • They used GFRP strips with various orientation as a strengthening system which increase load carrying capacity up to 20%. 5. Finite element analysis of voided slab with high density polypropylene void formers Analysis is performed using ANSYS software on 6 specimens in which 3 are solid and others voided. •Voided slabs performed similar to that of solid slab , either by plate analysis or finite element analysis. •Voided slab V30 Subramania n, K* and Bhuvaneshw ari , P CONCLUSION Weight reduction is 50% compared to solid slab. Concrete usage reduced up to 10.55-25% as 1Kg of recycled plastic replaces 100 Kg of concrete, reduces CO2 emission. Obtain large span with less supporting columns. Punching shearing capacity is less so GFRP(Glass Fiber Reinforced Polymer) stirrups with various orientation is used as a strengthening system for bubble deck slab. Reducing material consumption made it possible to make the construction time faster and overall costs are reduced by 8-10%. SCOPE OF FUTURE USE Used for constructing all types of building especially Sky Scrappers. Best of larger span halls like theatres and auditoriums. Pedestrain bridge decks. Used in parking areas as less number of columns are required. REFRENCES Bhagyashri G. Bhade and S.M Barelikar An Experimental study on two way bubble deck slab with spherical hollow balls International Journal Of Recent Scientific Research ISSN: 0976- 3031 Volume: 7(6) June -2016. Churakov A.G., “Biaxial hollow slab with innovative types of voids”, Construction of Unique Buildings and Structures, ISSN 23004-6295.No.6(21).2014. Saifee Bhagat “ parametric study of R.C.C voided and solid slab ” IOSR Journal of Mechanical and Civil Engineering , Volume 11, Issue2, pp 11-21,2010. Kitjapat Phuvoravan and Elisa, D.Sotelino. “Nonlinear Finite Element for Reinforced Concrete Slabs”. J. Struct. Eng. 131(4).pp. 643-649. 2005.