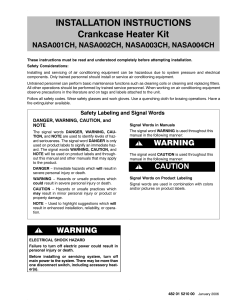

AC Series Air Conditioners Operating and Installation Instructions Professional Cooling Service Read this manual carefully before installing. and using this unit. Contents 1. Safety Notes 2. Product Description 2.1. Technical Specifications 5. Before using for the first time 5.1. Pre-operational checks 6. Operation 3. Receiving and Unpacking 6.1. Start-up and Self-Test 4. Installation 6.2. Operation Mode 6.3. Digital Display Panel 4.1. Choosing the installation site 4.2. Position of the components inside the enclosure 4.3. 4.4. Cutting out the enclosure Semi-embedded – Side or Door Mounting 4.5. Drainage consideration 4.6. Electrical installation 4.7. Protections 4.8. Door Switch Interlock 7. Setting up parameters 8. Troubleshooting 8.1. System Error Codes 8.2. Other Fault Conditions 9. Maintenance 10. Warranty 11. Storage and Disposal 2 1 Safety Notes Read this manual carefully before installing and using this unit. The installation and commissioning of this unit must only be performed by properly trained personnel who are familiar with the operation of cooling devices. Before connecting the unit, ensure that the electrical data on the nameplate matches the main electrical supply. The AC unit should not be tipped and it’s recommended to keep it in an upright position for at least 1 hour before attempting to operate it to allow proper lubrication of the compressor. Air inlets and outlets should not be obstructed inside or outside the cabinet. When installing the unit on a cabinet door, take into consideration that it could buckle. Make sure the cabinet is securely attached to its base so that it does not come out of balance when opening the door. The unit should always be moved or stored in an upright position. Do not repair or replace any part of the unit or attempt any servicing unless specifically recommended in these instructions. Faulty components must only be replaced with genuine spare parts from Huarui. 3 2 Product Description This unit is specifically designed for cooling electronic temperature sensitive equipment in challenging environmental conditions and is often used in outdoor enclosures in telecom, automation and IT equipment. The unit has a closed loop cooling circuit, which maintains internal cabinet temperature between 20o to 40oC and keeps air free of any contaminants from the environment. Huarui Air Conditioners are designed for continuous duty operation and manufactured with high quality components to ensure reliability for many years. 4 Product Design Features Digital Led display and keypad controller RS485 communication port (Modbus-RTU) Modbus protocol Dry contact alarm output, NO/NC Available Configuration Software Low dehumidification cooling function Optional heating element Optional hydrogen sensor Anti-theft design without the cowling Fit for harsh environment condition (T3), using R134a refrigerant Internal fan Controller Evaporator Heater External fan Compressor 5 2.1 Technical Data The unit label indicates the power rating, installation method and optional accessories. HRUC A 0* * / M / E / A / H* * HRUC: Outdoor enclosure cooling from Huarui A: Standard air conditioner 0* * : Cooling Capacity is **×100W(L35/L35) M: Series: M series; E: Installation: E: Semi-embedded Mounting A: Power: 230VAC 50/60Hz H* * : Heating Capacity is **×100W(L35/L35)。(When using optional installed heater) Remarks: Installation types for M series: E- Semi-embedded Mounting, D- Door Mounting, and S-Side Mounting; L and N series are standard NEMA 4 – IP55 and no additional cowling is required. All data sheets are available in our website at www.itenclosuresystems.com 6 3 Receiving and unpacking The air Conditioner unit is delivered in a wooden case. Before unpacking, please check that the box is not damaged, deformed, wet or the straps cut. The box and the unit contain electronic and electric components and it should be handled with care during transport, storage and manipulation. Pay attention to the packaging marks l Please make sure the air conditioner is always kept in upward position l Avoid excessive tilting l Protect from moisture, water and rain l Recycle when possible the packaging material l Do no step on the box or place heavy objects on top 7 4 Installation 4.1 Choosing the installation site When choosing an installation site for the enclosure, please observe the following: The installation site and the positioning of the cooling unit must be selected in such a way as to ensure good ventilation, distances between units and distances between the unit and the wall must be at least 500mm (20”). The Huarui cooling units N & L series are designed for indoor or outdoor use with a NEMA 4 – IP55 protection rating. No additional cowling is necessary. Do not block airflow to the unit. The M series could be fitted with cowling (rain hood) by the customer; make sure that inlet air and outlet air are not obstructed. This is critical to maintain the best cooling efficiency. The cooling unit must be installed and operated in a vertical position (maximum deviation: 3°). The site must be free from excessive contamination and moisture, corrosive or inflammable gases. The ambient temperature must not exceed 55°C and the humidity not higher than 95% To avoid condensation, make sure all openings in the enclosure are airtight. The unit is equipped with a drain hole and a nozzle, which could be connected to a hose (not provided). Make sure the unit has been in an upright position for at least 60 minutes before operation. 4.2 Position of the components inside the enclosure Do not position the components inside the cabinet too close to the air conditioner outlet in order to maintain an optimal cooling airflow at all times. Try to arrange the equipment inside the cabinet in order to ensure even air circulation. Do not direct the cool air directly to a warm air stream coming from an active electric device such a rectifier or inverter in order to prevent an air short-circuit condition. Air conditioner inlet and outlet openings should never be obstructed 8 4.3 Cutting out the enclosure • Using the dimension drawings (see the unit correspondent datasheet), identify the valid lines and dimensions for your installation type on the door or side of the cabinet. • Mark, drill and deburr the holes. • Make the cutout. The shadow part of the drawing should be cut off. Deburr the cutouts. Be careful as sharp edges of cutouts and holes could cause injuries! Example Datasheet drilling and cutout information example (Refer to the model datasheet for measurements correspondent to your unit) Please notice position of holes Please notice outer dimensions and Cutoff section marked as a shadow Install the unit in the cabinet using M4 screws 9 4.4 Semi embedded, Side or door mounting Follow this instructions for M series fitting 10 4.5 Drain consideration Huarui Air Conditioners are equipped with a drain hole at the outside bottom of the unit. A nozzle with screws is supplied with the unit. A hose could be connected to it. 11 4.6 Electrical Installation Prepare the electrical wiring according to the manual Terminal connector 电源端子二(已安装) Power Terminal --二(Installed) 电源端子一(可拆卸) Power Terminal --一(Dismountable) 1 2 3 4 5 6 7 8 9 10 Terminal descriptions. No. Symbol Description 1 L Live AC Power line 2 N Neutral line or L2 in 240V 3 phases AC power 3 PE Ground wire 4 T/R+ Positive pole of 485 Communication 5 T/R- Negative pole of 485 Communication 6 NO Normally open dry output contact 7 COM Common of dry output contact 8 NC Normally close dry output contact 9 and 10 I/O Input contact or optional hydrogen sensor contact 12 4.7 Protection Select a circuit breaker according to the maximum current indicated on the unit nameplate. 4.8 Door Interlock Switch Terminals 9 and 10 could be connected to a door switch in order to stop the compressor when opening the cabinet, this is recommended to avoid excessive moisture condensation. Terminals 9 and 10 could also be used for an optional hydrogen leak sensor circuit supplied by Huarui. 5 Before using for the first time 5.1 Pre-operational checks After the Air Conditioner is installed and the electrical connection is completed, please check the following: Table7-1 Pre-operational checks Serial number Check items 1 Ensure that all four screws are securely tightened 2 Air inlets and outlets are not obstructed inside and outside the cabinet and there is space for a good air flow 3 Power line is connected the right polarity Alarm signal cables are connected correctly 4 Use a multimeter to check that supply voltage is normal and consistent with the requirements on the nameplate 5 The unit has been in an upright position for at least 1 hour 13 6 Operation 6.1 Start-up and Self-test Once the air conditioner is running, if there is abnormal noise or vibration, please cut off power immediately and contact Huarui technical support. Once power is applied, the unit will initiate a self-test procedure for the first 30 seconds: internal fan operation, temperature sensor, heater will be checked. 6.2 Operation mode After the self-test the air conditioner will operate in: standby, cooling, heating or alarm • Standby mode: The Huarui air conditioner is equipped with a temperature sensor, which constantly monitors and compares the inside cabinet temperature with the default set point, which is 35o C. When the temperature inside the cabinet is lower than the set point the compressor doesn’t run, the unit is in stand-by mode. Only the internal fan will run and the display will show the inside enclosure temperature. • Cooling mode: When the inside cabinet temperature is ≥ the set temperature, the compressor starts and the unit is in cooling mode. The external fan also runs and the display shows symbol symbol, the compressor runs for 60 seconds, and the is bright. When the cabinet temperature is ≤ the set temperature minus the compressor hysteresis (default value 5o), and the compressor uptime ≥ minimum running time (default 5 minutes), the systems stops cooling. At this point the compressor turns off and the external fan will stop after a few seconds. The external fan stops, the • symbol is off and when the symbol is off. Heating mode*: If the cabinet inside temperature is ≤ heater start temperature set point (0oC), the heater switches on and the symbol is bright. 14 When the cabinet temperature is ≥ heater set point (0oC), plus heater stop hysteresis temperature (5 oC), the heater stops and the symbol turns off. *If the unit is equipped with heater option • Alarm mode In case of alarm, the display shows alternately the temperature and the alarm code. Go to troubleshooting section for more information. 6.3 Digital Display Panel Figure 4-1 the display panel diagram Table 4-1 the meanings of lights on the display panel LED Description Flashing during self test or setting mode Light on when cooling Light on when heating Light on when external fan is running Flashing when alarm is present 15 7 Setting up parameters To enter the programming mode press and hold the “M” key for 5 seconds, then scroll up or down with the "!"" keys to select the parameter code, select a code and press “set” to read the parameter value, to set a new value use the "!"" keys and press “set” again to retain the new value. Pressing “set” again will display the current state. At any moment the “M” key could be depressed to exit the programming mode. Some parameters are password protected; please contact customer service to obtain one. Table 4-2 Setting Codes Code Parameter name Default Value Range F01 Compressor start temperature 35 20~50oC F02 Compressor stop hysteresis temperature 5 2~8 oC F03 Heater start temperature 0 -5~10 oC F04 Heater stop hysteresis temperature 5 1~5 oC F05 High temperature alarm 55 35~70 oC F06 Low temperature alarm -5 -15~15 oC F07 Communication address 1 1~255 Remarks This function is only applicable to models with heater option installed. Address of the unit in the Modbus network 16 8 Troubleshooting Under normal operation, the display shows the internal air temperature. In case of alarm, the display shows alternately the temperature and the alarm code as follows: 8.1 System error codes Table 4-3 Alarm Code Code number E01 Code Name Internal temperature sensor fault Description of fault Return air temperature sensor is short circuit or open circuit Procedure 1- Use a multimeter to check whether the return air temperature sensor is short circuit or open circuit. 2 - Check whether the return air temperature sensor is loose. E02 Evaporator temperature sensor alarm Evaporator temperature sensor is short circuit or open circuit Check whether the evaporator temperature sensor is short circuit or open circuit. E03 Condenser temperature sensor alarm Condenser temperature sensor is short circuit or open circuit Check whether the condenser temperature sensor is short circuit or open circuit. 1- The internal fan is not working properly. 1- Check Whether the internal fan cables are loose. 2 - The evaporator temperature has been below zero for more than 15 minutes. 2- Check whether there is a system refrigerant leak. E04 Internal fan alarm 1- The external fan is not working properly E05 External fan alarm 2 -The condenser temperature has been above 77oC for more than15 minutes. 1- Check Whether the external fan line is loose. 2 - Check whether there is a system refrigerant leak. 17 1- Lack of refrigerant E06 Refrigerant leakage alarm 2 - The evaporator temperature sensor is loose. 1- Check whether there is a system refrigerant leak. 2 - Check whether the evaporator temperature sensor is loose. E07 Low temperature alarm The cabinet temperature is below the set value The heater is running until the alarm is cleared. E08 High temperature alarm The cabinet temperature is higher than the set value. Open the cabinet door until the alarm is cleared. 8.2 Other Fault Conditions Table8-4 other fault analysis and processing Fault state Possible causes Solutions Power on the switch, the cabinet temperature is too high but the air conditioner is not working. 1- Power failure or no power. The air conditioner is running but the cooling effect is not good. 1 - The cooling capacity of the air conditioner is not match with the load. 1 - To add or choose another air conditioner according to the load. 2 - The ambience temperature is too high. 2 - Ensure the machine is used in the correct range. 2 - The cooling set temperature is higher than the cabinet temperature. 3 - System fault. 1 - Check the power supply and the electric circuit. 2 - Set cooling temperature according to the needs. 3 - Please contact customer service 3 - Other system fault. 3 - Please contact customer service The machine is 1-The cabinet temperature greater than or stopping suddenly, equal to the cooling set temperature. and the electric 2 - Other system fault. system is normal. 1-Setting cooling temperature according to the needs. 2 - Please contact customer service 18 9 Maintenance Warning: Disconnect all electrical connections before any kind of maintenance. The unit is maintenance free; however, the components in contact with the outside air should be cleaned periodically. Depending on environmental conditions of the installation site, Huarui suggests the following verification points every six months. No. Check items Check methods Procedure 1- Turn off the supply power 1 Cable connections 2 - Pull gently the power line and other cables to check if any wires or terminal screws are loose. Tighten the screws. 2 Voltage Stability Use the multimeter to check if input voltage is within normal. If the voltage is not within the normal range, Please turn off the power supply immediately. 3 Mechanical check Use screwdriver to tighten the screws and verify the AC unit is solidly attached to the cabinet Tighten the screws. 4 Sealing It's important to seal the space between the air conditioner unit and the cabinet to prevent cool air from escaping and reduce the chance of hot outside air seeping into the cabinet. Check for leaks around the edges between the unit and the cabinet. 5 Fans Verify the fans, inlet and outlets for signs of dirt accumulation or other debris Be sure to caulk the gap between the unit and the cabinet to seal the space around it and reduce the chance of leaks. Fans could be cleaned with compressed air and/or a vacuum cleaner 19 10 Warranty Warranty Coverage and disclaimer Huarui warrants the Air Conditioner unit to be free of any manufacturing or workmanship defects for twelve (12) months from product up-running time or for a maximum of eighteen (18) months from the date of delivery. The warranty does not cover damage to Huarui units caused by erroneous application, inappropriate maintenance, abnormal environmental conditions, modifications or service done without authorization from Huarui, intentional misuse or ordinary wear. Huarui will repair or replace any unit that does not meet this warranty. The replacement or repair of the defective unit is the exclusive remedy; liability does not extend to any other damages, incidental, consequential or otherwise. In case of replacement a refurbished or new unit will be provided. In order to return a unit please contacts our service department to obtain a Return Authorization Number (RAM). The unit should be then returned in its original packaging or similar of same quality to our service center freight prepaid and covered by adequate transport insurance. 11 Storage and disposal During storage, the cooling unit must stand upright and ambient temperature should not exceed +70oC and relative humidity should not exceed 95%. Keep away from corrosive gases and dust. This AC unit contains refrigerant gas and at the end of the working life, the product must not be disposed of as urban waste; it must be taken to a special local authority differentiated waste collection center or to a dealer providing this service. Suzhou Huarui Thermal Control Technology Co.,Ltd IT Enclosure Systems BuildingA2 ,No.2, Tian’e’dang Rd. Wuzhong Dis. Suzhou China 8 Abri Du Bois, Chelsea, QC, J9B-1S7 http://www.huaruicooling.com Tel: +86 512 66570332 - Fax::+86 512 68792690 CANADA http://www.itenclosuresystems.com Tel: +1-819-866-3020 - Fax::+1-819-483-1630 20