- Ninguna Categoria

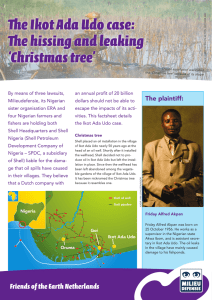

Shell DEP Specification: Global Technical Standards Procedure

Anuncio