paper: hicks

Strength and ductility of headed stud connectors

welded in modern profiled steel sheeting

Synopsis

Push tests in Australia have suggested that studs welded in

modern trapezoidal decks possess lower resistances and slip

capacities than expected. This paper presents the results from

a comprehensive research programme consisting of full-scale

composite beam and companion push tests. The beams

exhibited excellent ductility, and the slip capacity at the shear

connection far surpassed the levels considered obtainable by

current British and European Standards. Comparisons of

load–slip performance show that any brittleness exhibited in

push tests is as a result of a deficiency in the standard push

specimen rather than the shear connection. For single studs,

the beam tests demonstrate that the current UK design

practice of using the shoulder height of the deck in BS 5950

to be the most appropriate. Conversely, the performance of

pairs of studs in the current research appears to be adversely

affected by longitudinal connector spacing. Interim design

guidance is proposed for studs in this arrangement.

equations that are multiplied by the design resistance of studs

embedded in solid concrete slabs. The reduction factor formulae in BS 5950-3.1 and Eurocode 4 have been empirically

derived from push tests, which have been revised and modified

as new deck profiles have been developed. It should also be

noted, however, that no advice is given in either of these

Standards on how to adapt the standard specimen in Fig 1(a)

when decking is present; this has led to a wide variation in specimen geometry for push tests with decking which, in part, may

be a reason for the high scatter in results observed in previous

calibration studies7,8. The reduction factor formula given by BS

5950-3.1 is as follows:

k = 0.85/√nr(b0/hp){(hsc/hp) – 1}

...(1)

but k ≤ 1.0 for nr = 1 and k ≤ 0.8 for nr = 2

where nr is the number of studs per rib, b0 is the breadth of

the concrete rib (which should be reduced to 2e when the studs

are welded in the unfavourable position), hp is the height of the

steel deck rib and hsc is the height of the stud (see Fig 2).

Introduction

Historically, the performance of shear connectors has been

established from small-scale specimens of the type shown in Fig

1(a). By applying a load to the top end of the steel-section, the

load–slip behaviour of the connectors can be determined. This

type of specimen is known as a ‘push test specimen’ in BS 59503.1: 19901 and BS EN 1994-1-1: 20042 (Eurocode 4) and, apart

from slight variations in its geometry, has hardly changed since

its inception in the early 1930s3.

a)

b)

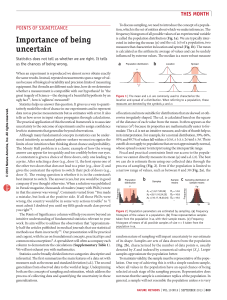

According to Eurocode 4, if three nominally identical tests are

carried out, and the deviation of any individual result from the

mean value does not exceed 10%, the characteristic resistance

of a shear connector PRk is defined as 0.9 times the minimum

failure load per stud (see Fig 1(b)). The ductility of a shear

connector is measured by the slip capacity δu, which is defined

in Eurocode 4 as the slip value at the point where the characteristic resistance of the connector intersects the falling branch

of the load-slip curve (see Fig 1(b)). The characteristic slip capacity δuk is taken as 0.9 times the minimum test value of δu.

Alternatively, the characteristic properties of a shear connector

can be determined by a statistical evaluation of all of the results

according to BS EN 1990: 20024.

The rules for partial shear connection given in BS 5950-3.1

and Eurocode 4 are based on extensive numerical analyses,

which considered composite beams over a wide range of spans

and section types5,6. To enable the designer to assume that all

of the studs are equally loaded at the ultimate limit state (i.e.,

the shear connection is fully plastic), the minimum degree of

shear connection in these Standards is based on an assumed

ductility limit. In Eurocode 4, a connector may be taken as

ductile if the characteristic slip capacity δuk is at least 6mm.

When stud connectors are welded within the ribs of profiled

steel decking, their resistance is reduced when compared to

studs embedded in solid concrete slabs. To account for this

reduction, BS 5950-3.1 and Eurocode 4 provide reduction factor

32|The Structural Engineer – 15 May 2007

9

In 1993 the SCI wrote an advisory desk article to clarify the

definition of deck height to be used when calculating the reduction factor for modern trapezoidal decks that possess a shallow

central stiffening rib on their crests (see Fig 2). The article

stated that, for trapezoidal decks of the form shown in Fig 2,

only the height to the shoulder hp,n needed to be considered

provided that: the stud projects at least 35mm above shoulder

height (i.e. hsc – hp,n ≥ 35mm); and the re-entrant portion is not

more than 15mm in height (i.e. hp,g – hp,n ≤ 15mm) and 55mm

in width. This gave less onerous reduction factors than those

based on the overall deck height hp,g.

There has been much publicity of push tests in Australia that

have suggested considerably lower resistances and slip capacities than expected for stud connectors welded in the troughs

of trapezoidal decks10,11. Proprietary solutions, such as special

reinforcement, which are now required in certain situations by

the Australian Standard12, are proposed to overcome these problems.

An obvious question regarding shear connectors in push

specimens is whether their behaviour is comparable to that

which would occur in a full-scale beam. While many full-scale

beam tests have been undertaken in the past, there was insufficient instrumentation to determine the load–slip performance of the shear connectors in situ. As a consequence of this,

although the measured end slips were in excess of the required

ductility limits, it was impossible to know whether the stud

performance was much better in beam specimens or, as implied

by Australian push test results, whether the outer studs were

on the falling branch of the load–slip curve. Moreover, the

degree of shear connection provided in these tests was not low

enough to provoke a brittle failure had the studs possessed

insufficient slip capacity. In an attempt to answer these questions, full-scale composite beam and companion push specimens were constructed and tested to failure at Cambridge

Stephen Hicks

BEng(Hons),

PhD(Cantab)

Manager, Building

Engineering, The Steel

Construction Institute,

Silwood Park, Ascot,

Berks

Received: 08/06

Modified: 01/07

Accepted: 02/07

Keywords: Beams,

Composite construction,

Shear connectors, Studs,

Decks, BS 5950,

Eurocode 4, Testing,

Behaviour

© Stephen Hicks

Your comments on this

paper are welcome and

will be published online

as Correspondence.

Please send your

contribution to the Editor

within 3 months

Fig 1. (left)

Eurocode 4 (a)

standard push test

specimen and (b)

determination of

characteristic

resistance and slip

capacity from

load–slip curve

Fig 2. (below)

Dimensions of

profiled steel

decking and studs in

the (a) central (b)

favourable and

(c) unfavourable

position

paper: hicks

strengths fym presented in Table 1 were evaluated. As well as

being used in the predictions of moment resistance, the stressstrain behaviour of the material was used in the back-analysis

of the strain gauge readings.

The target mean compressive cube strength of the concrete

was 25N/mm², which was achieved by specifying a normal

weight C16/20 mix; this strength was chosen in an attempt to

provide the lowest degree of shear connection that is permitted

by the current Standards to obtain evidence of slip capacity. A

summary of the measured properties on the day of the beam

test is presented Table 2.

The shear connectors consisted of 19 × 100mm long headed

studs (95mm length-as-welded). To determine the mechanical

properties of the stud material, three coupons were machined

from finished studs. From tensile tests on these coupons, the

mean ultimate tensile strength of the stud material was found

to be fum = 513.5N/mm² with an elongation of between 15 to 16%.

University Engineering Department. The remainder of this

paper describes this research and its implications on design.

Fig 3. 10m span

composite beam

specimen

Composite beam specimen 1

The composite beam was simply-supported over a span of 10m,

and consisted of a 305 × 165 × 46kg/m UB (see Fig 3). To provide

the most unfavourable loading to the studs, the beam was

propped at third-points at the wet concrete stage so that the full

self-weight load was applied to the shear connection once the

props were removed. As well as pre-loading the studs, this

construction also ensured that the effects of ponding were

minimised to enable a constant slab thickness to be assumed

in the back-analysis of the test.

To gather as much information on the shear connection as

possible, two stud arrangements were used in the beam specimen. On the left hand side of the beam in Fig 3, seven pairs of

studs were through-deck welded in every other trough in the

‘favourable’ position (see Fig 2(b)); this arrangement was

adopted to enable the lowest degree of shear connection to be

provided, so as to gain information on the in situ load–slip

curves. (N.B. The longitudinal spacing provided was very close

to achieving the maximum spacing requirements given in BS

5950-3.1, Clause 5.4.8.1 of the smaller of 600mm or 4 × overall

slab depth; however, the spacing was compliant with the

requirements given in Eurocode 4, 6.6.5.5(3) of the lesser of 6 ×

the total slab thickness or 800mm). On the right hand side of

the beam in Fig 3, 14 studs were through-deck welded singly

in every trough in the ‘favourable’ position. This welding

arrangement meant that an equal number of studs were

provided in each half of the beam.

The steel used in the fabrication of the specimen was grade

S355. From coupons cut from the UB, the mean measured yield

Table 1: Measured steel properties

Top flange

Web

Bottom flange

fym (N/mm²)

368

378

388

Table 2: Measured concrete properties

Age (days)

fcm,cube

(N/mm²)

fck,cube

(N/mm²)

fcm

(N/mm²)

fck

(N/mm²)

Ecm

(kN/mm²)

42

25.3

16.5‡

20.4

12.4‡

26.1†

‡ characteristic value determined from BS EN 1992-1-1: 200413

† modulus of elasticity derived from beam bending stiffness

Table 3: Cross-sectional properties for 305×165×46 kg/m

UB

D

(mm)

B

(mm)

t

(mm)

T

(mm)

Root

radius

(mm)

Crosssectional

area

(mm²)

309.8

166.6

7.3

10.9

8.9†

5795

† Nominal value

To facilitate the back-analysis, the geometry of the steel section

was measured at each of the 16 instrumented cross-sections.

The average measured properties of the UB are presented in

Table 3.

The slab was 140mm thick, and was conventionally reinforced with one layer of A193 square mesh fabric, which was laid

directly on the deck (i.e. the top of the studs projected 11mm

above the mesh). A total slab width of 2500mm was provided,

which corresponds exactly with the effective width requirements given in current Standards of beam span/4.

To represent UK practice, a typical 60mm deep trapezoidal

deck was fixed perpendicular to the longitudinal axis of the

beam (comprising of a Multideck 60-V2 profile); this provided

an average concrete rib breadth b0 of 150mm, a ‘shoulder height’

hp,n of 60.9mm and an overall height hp,g of 69.9mm (see Fig 2).

Owing to the fact that the rules given in Eurocode 4 reduce the

stud resistance for sheet thicknesses less than or equal to

1.0mm, a 0.9mm gauge deck was used to provide the most

unfavourable case (thinner gauge decks are not currently in use

in the UK).

Instrumentation

Measured material properties

Location

Geometric properties

To enable the internal forces to be evaluated, the steel beam was

instrumented with strain gauges on the top and bottom flange

at cross-sections corresponding to the shear connector positions. As well as determining the build-up of axial force, the

internal bending moments were evaluated to check the reliability of the strain gauge readings. The slip distribution at the

shear connection was established from horizontally mounted

transducers, which monitored the relative displacement

between bars cast in the concrete behind the shear connector

positions and the top flange of the beam (see Fig 4). The internal load–slip curves for the shear connectors were therefore

evaluated by plotting the change in axial force at each crosssection against the corresponding slip.

Owing to the fact that two stud arrangements were provided,

the different load–slip characteristics for the shear connectors

meant that there was no position of symmetry. The steel beam

was therefore instrumented at 16 cross-sections along its entire

length, comprising 48 strain gauges and 30 displacement transducers (see Fig 3). The deflection was monitored by vertical

transducers at third-points and at mid-span of the beam. An

image of the instrumentation on the side with pairs of studs is

shown in Fig 4.

In an attempt to closely simulate the bending moment from

a uniformly distributed load, four equally spaced point-loads

were applied along the centre-line of the beam. The loading was

supplied by 60t jacks with a stroke of 300mm, which were

located at third points along the beam (see Fig 3).

To enable large deflections to be applied to the beam specimen, rollers were provided under the ram of the jacks as well

as to the ends of the spreader beams. The bearing plates were

plastered directly onto the concrete slab and, to eliminate any

question of the shear connection being assisted by horizontal

forces taken through the load system, horizontal sliders were

15 May 2007 – The Structural Engineer|33

paper: hicks

Fig 4. (left)

Instrumentation in

the vicinity of the

support on the side

with pairs of studs

Fig 6. (right)

Concrete pull-out

failure around pairs

of studs revealed

after separating the

slab from the deck

provided at the interface between the bearing plate and the

rollers to the spreader beam.

General behaviour of the beam

The props were left in place until the target compressive

strength of the concrete was achieved. Once the props were

struck, the self-weight loads on the composite cross-section

(which amounted to 74.5kN) resulted in a mid-span deflection

of 66mm. The end-slips indicated that there was a modest

asymmetry in the shear connector behaviour, with measured

values of 0.15 and 0.08mm for the side with pairs of studs and

single studs respectively.

Initially, the beam was subjected to three cycles of load up to

approximately 70% of the predicted ultimate load (which was

based on BS 5950-3.1, using mean measured material properties, and the shoulder height of the deck hp,n in Eq.(1)); this

loading was undertaken to ensure that the beam was elastic in

the initial stages and to identify the load level when first yield

occurred. The applied moment versus mid-span deflection plot

is presented in Fig 5.

As can be seen from Fig 5, for load Cycle 4 and 5 up to a midspan deflection of 300mm (equivalent to span/30), the specimen

exhibited excellent ductility. Significant slip was recorded on the

side with pairs of shear connectors and, at an end-slip of

26.5mm, it was felt that sufficient data had been collected,

which resulted in load Cycle 5 being terminated.

From test observations, it was clear that significant distress

was caused at the shear connector positions with pairs of studs.

By a visual inspection of the locations where the deck had

delaminated from the concrete slab during load Cycle 4, it

appeared that concrete pull-out had occurred, with pyramidal

shear cones of concrete clearly visible around the studs. Pullout failure was later confirmed when the concrete slab was

removed from the deck to reveal the failure surfaces shown in

Fig 6; this failure mode was similar to that experienced in the

companion push tests discussed below and reported elsewhere14. In addition to this, there was some evidence of uplift

at the unstudded concrete ribs adjacent to the positions where

studs were welded in pairs (see Fig 7). In an attempt to gain

further information on single studs, an end stop was welded to

the left end of the beam in Fig 3 to subject these connectors to

greater levels of longitudinal shear force.

Fig 7. Slab uplift of

unstudded rib

adjacent to locations

where studs were

welded in pairs

(Position S7)

As can be seen from load Cycle 6 and 7 in Fig 5, the end stop

was successful in that, as well as significantly increasing the

stiffness, the beam was capable of taking further load. Under

this new set-up, load was applied until an end slip of 4.1mm was

achieved on the side with single studs welded in each trough.

At this point, bearing failure of the concrete in front of the end

stop occurred, which resulted in the test being terminated.

However, as can be seen from Cycle 6 and 7 in Fig 5, although

the test was stopped prematurely, the resistance corresponded

almost exactly with the BS 5950-3.1 predictions for the side

with single studs.

From observations made on the beam, it was clear that the

plateau observed in the moment–deflection plot during load

Cycle 4 and 5 was caused by a plastic hinge forming in the beam

on the side with pairs of studs. A visual inspection of the steel

beam confirmed this in that Lüders’ wedges were observed in

the web of the UB, adjacent to cross-section S3 on the side with

pairs of studs (see Fig 3).

Back-analysis of the beam

Fig 5. (below)

10m span beam

applied moment

versus mid-span

deflection

To enable the internal forces to be evaluated, a special version

of the SCI software ‘BFIRE’ was developed. At each instrumented cross-section, the steel beam was sub-divided into a

number of rectangular elements. The strain at the centroid of

each of these elements was calculated from the strain gauge

readings and compared to the stress–strain curves that had

been established from coupons cut from the UB. From the distribution of stresses on the cross-section, the internal forces and

moments within the steel beam were derived.

Load–slip performance of shear connectors

The load–slip curves for the pairs of studs closest to the support

(7th pair from mid-span) and 646mm from the support (6th pair

from mid-span) are presented in Fig 8. As can be seen from this

plot, the pairs of studs possessed a high initial stiffness until a

peak resistance of approximately 160kN was achieved at slips

of about 1mm. As the slip increases, the resistance reduces to

approximately 66 and 100kN (i.e., 33 and 50kN per stud);

beyond this point, the behaviour is very ductile indeed, and a

plateau is maintained up to a slip of 26mm.

The load–slip curves for the single studs closest to the

support (13th and 14th stud from mid-span) and 646mm from

the support (11th and 12th stud from mid-span) are presented

in Fig 9. As can be seen from this plot, the single studs possessed

34|The Structural Engineer – 15 May 2007

paper: hicks

Fig 8. (above top) Comparison of axial force in beam versus slip for 6th and 7th

pair of studs (Load Cycles 1 to 5)

loading comprised of two point loads applied to the beam.

Owing to the new beam configuration, the left hand side of the

beam had seven single studs welded in the unfavourable position (see Fig 2(c)); whereas, the right hand side of the beam had

seven single studs welded in the favourable position (see Fig

2(b)). To enable the load–slip curves for single studs to be determined in situ, two extra cross-sections were instrumented at

positions N1.5 and N7.5 (see Fig 10).

Because it was expected that the unfavourable studs would

have a lower resistance than the studs welded in the favourable

position, an extra centrally welded stud was provided over the

left hand support. A set of concrete cubes had been set aside

after the previous beam test, which were crushed on the day of

the test to determine the compressive cube strength of the

concrete. Although the age of the concrete was 106-days, it was

found that the concrete possessed exactly the same properties

as those presented in Table 2.

General behaviour of the beam

Fig 9. Comparison of axial force in beam versus slip for 13th and 14th single studs

together with 11th and 12th single studs (Load Cycles 1 to 7)

a much higher resistance than the pairs of stud connectors.

Assuming that the load was equally distributed between the

studs, a maximum resistance of about 113kN was achieved per

stud and was maintained with increasing slip. However, owing

to the fact that bearing failure of the concrete in front of the end

stop occurred, the magnitude of the slips were quite low for the

single studs in comparison with studs welded in pairs (4mm cf.

26mm). As a consequence of this, it was impossible to know

whether the single studs would have been able to maintain

their load for higher levels of slip or, in a similar way as for pairs

of studs, their resistance would have reduced. Furthermore,

the assumption that the load was equally distributed between

the studs may not be entirely correct.

The applied moment versus mid-span deflection plot for the

5.0m span beam specimen is presented in Fig 11. During the

first two load-cycles, much greater end slips were recorded on

the side with unfavourable studs (4.5mm cf. 2.4mm at the

maximum moment applied in load Cycle 1). At an end-slip of

12.9mm, the second load cycle was terminated as it was felt that

sufficient data had been collected for unfavourable studs. As can

be seen from Fig 11, the specimen exhibited excellent ductility

up to this point, which corresponded to a mid-span deflection

of 85mm (equivalent to span/59). Furthermore, the resistance

was 11% higher than the predictions from BS 5950-3.1.

Once the load had been removed, an end stop was welded to

the left end of the beam in Fig 10, in an attempt to subject the

side with single favourable studs to greater levels of longitudinal shear force. As can be seen from load Cycle 3 in Fig 11, under

this new set-up further load and deflection was applied to the

beam specimen. Once an end slip of 24.6mm was achieved on

the side with studs welded in the favourable position, the test

was terminated at a mid-span deflection of 174mm (equivalent

Composite beam specimen 2

Owing to the fact that there was little evidence of a permanent

set within the UB until the plastic hinge position adjacent to

cross-section S3 (see Fig 3), it was decided to gather more data

on single studs by cutting the specimen in half to form a 5.0m

span beam. The tests on this shorter specimen are described

below.

As can be seen from Fig 10, unlike the previous test, the

Fig 10. (below) 5m span composite beam specimen

Fig 11. (above) 5m span beam applied moment versus mid-span deflection

to span/29) owing to concerns over the stability of the test rig

from the large curvatures.

In a similar way as the behaviour exhibited in the early

stages of the test, the applied moment–deflection plot for load

Cycle 3 showed that the specimen possessed excellent ductility.

Moreover, the performance of the studs welded in the

favourable position was much better than that assumed by

current Standards, which resulted in a resistance that was 12%

higher than that predicted by BS 5950-3.1. Failure was caused

by a plastic hinge forming in the beam adjacent to the load position near instrumented position N3 (see Fig 10), which was

confirmed by Lüders wedges being clearly observed in the web

of the UB.

15 May 2007 – The Structural Engineer|35

paper: hicks

normal force to the face of the slab15,16.

Discussion

Characteristic properties of stud connectors from beam

tests

Back-analysis of the beam

Load–slip performance of shear connectors

The load–slip curves for single studs in the favourable, central

and unfavourable position are presented in Fig 12. As can be

seen from these plots, much less slip was needed for the stud

in the unfavourable position to achieve its peak resistance

compared to the favourable and centrally welded studs (2.8mm

cf. 7.9mm and 9.6mm respectively). In terms of the slip requirements given by the current Standards, significant ductility was

achieved for all of the stud arrangements; in particular, for

studs welded in the favourable position (see Fig 2(b)), where a

plateau was maintained up to a slip of approximately 25mm.

Companion push tests

To provide a link between the behaviour of studs in a beam

compared to that achieved in a push test, six push specimens

were constructed using exactly the same batch of concrete that

was used in the beam specimen. These specimens varied

slightly from standard test given in Eurocode 4, in that the steel

section was split to form two structural ‘tees’ (see Fig 13). The

advantage of this set-up was that the casting process was

greatly simplified and the same concrete used in the beam

specimen could be used for both test slabs (thereby reducing the

variation in the results from different concrete mixes).

The load–slip curves from the beam tests compared to the

push tests are shown in Fig 14 and Fig 15; these curves represent the lowest results obtained from each test type for a particular stud arrangement. As can be seen from these plots, with

the exception of initial stiffness, there appears to be no similarity between the performance of studs in these two types of

specimen. It might be argued that the peak resistance achieved

in the push test is comparable with the plateau exhibited by the

studs in the beam specimen. However, the slip measured in the

push test is well below the levels achieved in the beam specimen and, if considered in isolation, would suggest that the

ductility of the shear connectors was lower than required by the

current Standards for partial shear connection design. It is felt

that the reason for the poor performance in push tests is due to

the absence of a curvature and normal force, which exists in real

composite beams from the floor loading. Brittle failures in push

tests have also been observed elsewhere, which has led some

researchers to modify the standard specimen by applying a

36|The Structural Engineer – 15 May 2007

Fig 12. (above)

Comparison of axial

force in beam versus

slip for single studs

in the favourable,

central and

unfavourable

position

Fig 13. ( below left)

Companion push

test specimen

Fig 14. ( below)

Load–slip curve for

single studs in the

favourable position –

Beam test versus

push test

Fig 15. (below right)

Load–slip curve for

pairs of studs in the

favourable position –

Beam test (7th pair)

versus push test

Based on the load–slip curves evaluated from the beam tests for

studs in the favourable, central and unfavourable position, the

characteristic resistances PRk presented in Table 4 have been

taken to be 0.9 times the minimum failure load per stud Pe. To

examine the performance of the current Standards, predictions

based on BS 5950-3.1 and Eurocode 4 (EC 4) are presented for

comparison purposes; in these comparisons, predicted stud

resistances based on the deck shoulder height, PRk,n and overall

deck height, PRk,g are considered. As can be seen from Table 4,

the characteristic resistance of 96kN for single centrally welded

studs compares well with the predictions for PRk,n using BS

5950-3.1. Moreover, the characteristic slip capacity of the stud

in this position out-performs the Eurocode 4 requirements for

ductile connectors by almost a factor of two. However, the

predictions for PRk,n using Eurocode 4 appear to be overly

conservative for single studs.

For single studs in the unfavourable position, the predicted

resistance given by BS 5950-3.1 is conservative in comparison

with that achieved in the beam tests (see Table 4). Furthermore,

the Eurocode 4 requirement that studs should be welded alternately on the two sides of the trough throughout the length of

the span (when it is not possible to place studs centrally within

the trough), seems to be appropriate in that the average of the

favourable and unfavourable resistances corresponds almost

exactly with the resistance of the centrally welded stud.

For pairs of studs, the characteristic resistance is 73kN per

stud. Although this resistance is close to the value of PRk,n calculated with BS 5950-3.1, owing to the shape of the load–slip plot

(see 7th pair in Fig 12), the corresponding slip capacity is only

0.7mm. This is well below the 6mm requirement given in

Eurocode 4 for cases when a connector may be taken as ductile.

In order to achieve a slip capacity of 6mm, the characteristic

resistance has been down-rated to 49kN per stud in Table 4; this

resistance is close to the value of PRk,n calculated according to

paper: hicks

Table 4: Characteristic properties of studs in the Favourable (F), Central (C) and

Unfavourable position (U) evaluated from beam test

nr

Stud

position

Pe

PRk

PRk/PRk,Central

δuk

(mm)

BS 5950

PRk/PRk,n

BS 5950

PRk/PRk,g

EC 4

PRk/PRk,n

EC 4

PRk/PRk,g

1

F

123

111

1.16

9.6

1.27

(87.3)

1.94

(57.2)

2.19

(50.6)

2.88

(38.5)

1

C

107

96

1.00

11.9

1.10

(87.3)

1.68

(57.2)

1.90

(50.6)

2.49

(38.5)

1

U

89

76*

0.79

6.0

1.32

(57.6)

2.36

(32.2)

–

–

2

F

80

49*

0.51

6.0

0.70

(69.8)

1.21

(40.4)

1.18

(41.7)

1.80

(27.2)

†PRk,Central is the characteristic resistance of the centrally welded studs

* down-rated to achieve a slip capacity of 6mm

( ) calculated characteristic resistance in kN

Table 5: Characteristic resistance of studs welded in the

favourable position evaluated from the standard push test

nr

Stud

PRk

δuk BS 5950

position (kN) (mm) PRk/PRk,n

BS 5950

PRk/PRk,g

EC 4

PRk/PRk,n

EC 4

PRk/PRk,g

1

F

76.2

2.6

0.87

(87.3)

1.33

(57.2)

1.51

(50.6)

1.98

(38.5)

2

F

46.1

2.4

0.66

(69.8)

1.14

(40.4)

1.11

(41.7)

1.69

(27.2)

( ) calculated characteristic resistance in kN

Eurocode 4.

Characteristic properties of stud connectors welded in

the favourable position from the companion push tests

Based on the load–slip plots from the companion push tests (see

Fig 14 and Fig 15), the characteristic values presented in Table

5 were calculated according to the requirements given in Annex

B of Eurocode 4.

By comparing Table 5 with Table 4, the single studs in the

beam test out-performed those in the push test both in terms

of resistance and ductility (by 46% and 269% respectively).

However, when pairs of studs are considered, the characteristic resistance of 46.1kN agrees well with the value given in

Table 4.

Design resistance of through-deck welded studs

Based on BS 5950-3.1, the ratio of the stud reduction factors for

pairs of studs to single studs is 0.6/0.85 = 0.71. From the present

investigation, the ratio of the characteristic resistance for pairs

of studs to single studs is 49/111 = 0.44 for the beam tests, and

46.1/76.2 = 0.60 for the companion push tests. From this

comparison it can be concluded that, if results from push tests

can be regarded as basically comparative, the resistance of the

pairs of studs from the beam test is lower than expected.

However, from the observed uplift at the unstudded concrete

ribs adjacent to the positions where studs were welded in pairs

(see Fig 7), it is believed that performance of the studs in this

arrangement was adversely affected by their relatively high

longitudinal spacing.

Although the effect of stud spacing will be examined in future

research, the poor performance of the pairs of studs in the

current investigation suggests that the reduction factor given

in BS 5950-3.1 is too high. Moreover, the current code assumption that the resistance of pairs of studs is proportional to 1/√nr

(where nr is the number of studs per rib), does not appear to be

appropriate. As an interim measure, it is suggested that for nr

= 2 the factor of 0.85 /√2 = 0.6 in Eq. (1) should be reduced to

0.37 (i.e. 0.85 × 0.44 = 0.37) to give the following reduction

factor equation:

k = 0.37(b0 /hp){(hsc /hp) – 1} but k ≤ 0.75 for nr = 2

...(2)

where b0 is the breadth of the concrete rib, hp is the depth of

the profiled steel sheet (provided that the stud projects at least

35mm above the shoulder of the deck, using the ‘shoulder

height’ hp,n as defined in Fig 2) and hsc is the height of the stud.

Eq. (2) gives similar resistances to those calculated from

Eurocode 4, when the shoulder height of the deck is inserted

within the reduction factor formula. From the tests conducted in

this investigation, it is also recommended that pairs of studs

should not be arranged in line (i.e. in the favourable and

unfavourable position within the same trough). A more beneficial

arrangement is to have the studs arranged side-by-side, with the

maximum transverse spacing that may be practically achieved.

Owing to the very good agreement with the characteristic

resistance achieved in the beam tests it is recommended that,

for single studs through-deck welded in trapezoidal decks (i.e.

nr = 1), the current practice of using the deck shoulder height

in Eq. (1) should be maintained.

Minimum degree of shear connection

The minimum degree of shear connection permitted in BS 59503.1 and Eurocode 4 is 40%. However, the definition of the point

on the beam where the degree of shear connection should be

calculated is unclear in both of these Standards. According to

BS 5950-3.1, the critical cross-section that should be considered

in positive moment regions is defined by the point of maximum

moment. This definition was used in the initial design of the test

specimens, in that the critical cross-section was considered to

be at mid-span (i.e. the maximum moment comprised of the self

weight moment plus the moment applied by the jacks).

At maximum moment, the axial forces derived from the strain

gauge readings indicated that the critical cross-sections should

have corresponded to the point load positions closest to mid-span

(i.e. at position N3 and S3 in Fig 3). As a consequence of this, very

low levels of shear connection were actually provided. For

example, for the 10m span beam specimen with studs provided

in pairs, only 24% shear connection was achieved (it is believed

that this low level of shear connection is one of the reasons why

the moment resistance was below the predictions given by BS

5950-3.1, in that the connectors became fully loaded long before

the steel beam was fully yielded). It is therefore recommended

that when a beam is subjected to concentrated loads, the critical cross-section that should be considered in design should

correspond to the point load positions.

Standard push test

From comparisons of the load–slip curves it is clear that, for

the deck type considered in this investigation, any brittleness exhibited in the push test is as a result of a deficiency

in the standard specimen rather than the shear connection.

As a consequence of this, some caution should be shown

towards any new products that are claimed to increase the

ductility of stud connectors since, if these devices were developed using push specimens, the improvements to the

performance could be artificial.

Although the tests presented in this paper have shown

that the performance of studs in typical UK decks are

ductile, there remains the problem that, if new floor decks

are developed, it is difficult to identify cases when the behaviour could be brittle unless beam tests are undertaken.

Furthermore, should the performance of studs in particular

decks be better than that suggested by the current

Standards (which have been developed from push test

results) it is difficult to quantify the improvements in terms

of design rules without a standardised specimen that better

reflects the conditions that exist in a real beam.

In the absence of a new specimen, it is recommended that,

when decking is employed, the push test arrangement shown

in Fig 16 should be adopted. Although this specimen does not

solve the problem of brittleness, this arrangement appears

to eliminate an artificial mode of failure caused by the rotation of the last studded rib at the top of the specimen17,

which has sometimes been described as ‘back-breaking’. It is

also recommended that edge trim from pressed strips of thin

galvanised steel, which are normally used to form the floor

edge in buildings, should be removed from the push specimens prior to testing to reduce the scatter in results (from

earlier comparison tests, it was found that the coefficient of

15 May 2007 – The Structural Engineer|37

paper: hicks

variation for specimens with and without edge trim was

9.98 and 4.4% respectively).

Conclusions

Two full-scale composite beam tests have been undertaken with

a trapezoidal deck positioned perpendicular to the longitudinal

axis of the beam (i.e. a secondary beam), and through-deck

welded shear connectors. Unlike typical UK practice, the specimens were propped during construction to apply the most

unfavourable loading to the shear connectors. This form of

construction, together with other unfavourable combinations of

variables, was adopted to demonstrate the slip capacity that can

be achieved in a beam, together with the level of safety that

exists in current design Standards. Both specimens exhibited

excellent ductility in terms of overall load–deflection performance as well as slip capacity at the shear connection, which far

Fig 16. Standard

push test with

profiled steel

decking

surpassed the levels of slip assumed in the development of the

rules for partial shear connection given in BS 5950-3.1 and

Eurocode 4.

The performance of the beams with single studs welded in the

troughs of trapezoidal decking demonstrated that the current

design practice of using the shoulder height of the deck in

BS 5950-3.1 should be maintained. However, for pairs of studs

in the favourable position, the performance in the beam test was

lower than anticipated. Although it is felt that the performance

of the studs in this arrangement was adversely affected by their

longitudinal spacing, a modified reduction factor formula has

been presented as an interim measure. It is believed that

research, which is currently underway, will enable this proposed

design equation to be relaxed.

The definition of the critical cross-section where the degree

of shear connection should be calculated is unclear in both

BS 5950-3.1 and Eurocode 4. Based on the behaviour of the test

specimens it is concluded that, when a beam is subjected to

concentrated loads, the critical cross-section that is considered

in design should correspond to the point load positions.

From comparisons of the load–slip curves from the beam

tests with push tests, it is clear that any brittleness exhibited

in the push test is as a result of a deficiency in the standard

push specimen rather than the shear connection. It is recommended that a standardised specimen, which better reflects the

conditions that exist in a real beam, should be developed. In the

absence of a new specimen, a standard push test arrangement

for slabs that use decking has been presented.

Acknowledgments

Financial support for this investigation was provided by the

Floor/Deck Group of the Metal Cladding and Roofing

Manufacturers Association (MCRMA), Corus Construction

Services & Development and Corus Strip Products UK. The

author wishes to thank the help and assistance of Dr R. E.

McConnel, M. R. Touhey and the technical staff of

Cambridge University Engineering Department whose

expertise ensured the success of the testing programme.

Thanks also go to Prof. R. P. Johnson of University of

Warwick for his support and advice, together with Dr J. W.

Rackham, Dr W. I. Simms and C. King of The Steel

Construction Institute.

REFERENCES

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

BS 5950-3.1: 1990 Structural use of steelwork in buildings: Part 3: Section 3.1: Code of practice for design of simple and continuous composite beams, London,

British Standards Institution

BS EN 1994-1-1: 2004 Eurocode 4. Design of composite steel and concrete structures. General rules and rules for buildings, London, British Standards

Institution

Roš, M.: ‘Les constructions acier-beton system Alpha’, L’Ossature Métallique, 3/4, 1934, p 195-208

BS EN 1990: 2002 Eurocode – Basis of structural design, London, British Standards Institution

Aribert, J. -M. : ‘Analyse et formulation pratique de l’influence de la nuance de l’acier du profile sur le degree minimum de connexion partielle d’une

pouter mixte’, Construction Métallique, 3, 1997, p 39-55

Johnson, R. P. & Molenstra, N.: ‘Partial shear connection in composite beams for buildings’, Proc. Inst Civ. Eng., 91/2, 1991, p 679-704

Roik, K., Hanswille, G. & Cunze-O. Lanna, A.: ‘Harmonisation of the European construction codes – Eurocode 2, 4 and 8/Part 3 – Report on Eurocode

4 Clause 6.3.2 Stud connectors’, Institut für Konstruktiven Ingenieurbau, Ruhr-Universitat-Bochum, Report EC4/8/88, 1989, p 89

Stark, J. W. B. & van Hove, B. W. E. M.: ‘Statistical analysis of push-out tests on stud connectors in composite steel and concrete structures: Part 3:

Composite steel and concrete slabs’, TNO report BI-91-163, Delft, 1991

Lawson, R. M.: ‘AD 147: Composite decking with additional re-entrant top stiffeners’, New Steel Construction, 1/6, 1993, p 36

Patrick, M: ‘Composite beam shear connection design and detailing practices for Australian steel decks’, University of Western Sydney, Report CCTRCBSC-001-04, 2004, p 15

Ernst, S., Patrick, M., Bridge, R. and Wheeler, A.: ‘Reinforcement requirements for secondary composite beams incorporating trapezoidal decking’, In:

Composite Construction in Steel and Concrete V (eds Leon, R. T. & Lange, J.), New York, Amer. Soc. Civ. Engrs, 2004, p 236-246

AS 2327-1. Australian composite structures standard. Part 1: Simply-supported beams. Standards Association of Australia, 1996

BS EN 1992-1-1: 2004 Eurocode 2. Design of concrete structures. General rules and rules for buildings, London, British Standards Institution

Johnson, R. P. and Yuan, H.: ‘Existing rules and new tests for stud shear connectors in troughs of profiled sheeting’. Proc. Instn Civ. Engrs, Structs and

Bldgs, 128, 1998, p 244-251

Gibbings, D. R., Easterling, W. S. & Murray, T. M. 1993. Influence of steel deck on composite beam strength. In: Composite Construction in Steel and

Concrete II, W. S. Easterling and S. M. Kim Roddis (eds), New York: ASCE, p 758-770

Bradford, M. A., Filonov, A., Hogan, T. J., Ranzi, G. & Uy, B.: ‘Strength and ductility of shear connection in composite T-beams’, 8th Int. Conf. Steel,

Space & Composite Structures, Kuala Lumpar, Malaysia, 15-17 May, 2006, p 15-26

Johnson, R. P.: ‘Shear connection in beams that support composite slabs – BS 5950 and EN 1994-1-1’, The Structural Engineer, 83/22, 2005, p 21-24

38|The Structural Engineer – 15 May 2007