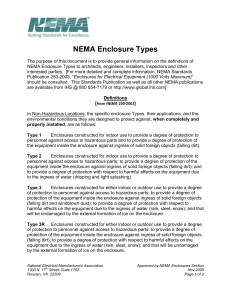

NFPA 496-2003 Purged and Pressurized Enclosures for Electrical Equipment

Anuncio