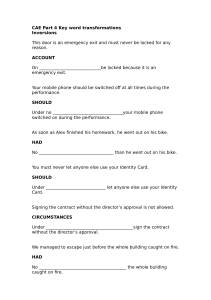

OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 1 / 23 Date : 2005-04-04 DCSS5 Starting Up Routine Authorization Date D1 : . . . 04. . . . Apr . . . . 2005 ......................... Running on PCB : . . . . . . . .GAA24350BD11 . . . . . . . . . . . . . . .or . . higher ............... Software Version : . . . . . . . .GAA . . . . .30328BAA ........................... Document Revision: Date 22-Dec-99 28.Nov.2000 05.July.2001 17. May 2002 18. May 2004 18. May 2004 04. Apr 2005 SCN GAA 30328AAA GAA30328AAC GAA30328AAD GAA30328AAE GAA30328AAF GAA30328AAG GAA30328BAA Author R. Löb M. Barten M. Barten R. Löb R. Löb R. Löb R. Löb Comment Original document AAC Release AAD Release AAE Release limited release for ADS CI 47-04-101 D2000-2 door Copyright 2001 OTIS GmbH Berlin No part of this document may be copied or reproduced in any form or by any means without the prior written consent of OTIS GmbH. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 2 / 23 Date : 2005-04-04 1 SCOPE 3 2 SAFETY REFERENCES 4 3 BEFORE THE INSTALLATION 4 3.1 Encoder 4 3.2 Power Supply 4 3.3 RS Board Interface Description 5 3.4 Electromagnetic Noise and Interference 5 4 CONNECTIONS 4.1 Motorcable and Power supply 5 4.2 Incremental Speed Encoder (at plug P3): 5 4.3 Controller Interface 6 4.3.1 Discrete 3-Wire Interface 4.3.2 Serial (Multidrop) Interface: 4.3.3 Relay-Controller with Interface Box 5 FIRST INSTALLATION 6 7 8 11 5.1 Starting Up Condition 11 5.2 SETUP Routine (Basic Installation) 12 5.2.1 5.2.2 5.2.3 Configuration of the DCSS5 environment: Automatic Basic Setup for the Profile Set 1 Automatic Setup for the Profile Set 2 5.3 Customer Specific Fine-tuning 6 5 13 15 17 17 5.3.1 Installation suggestions for heavy doors (200W motor) 19 SOFTWARE UPDATE FOR DO2000 DOORS 20 7 CONTROLLER INSTALLATION 21 7.1 Discrete 3-Wire Interface (LCBII/TCB) 21 7.2 Multidrop Interface (LMCSS) 23 8 PROFILE DESCRIPTION 23 OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 3 / 23 Date : 2005-04-04 1 Scope The Door Control Sub-System DCSS 5 is VF door drive with an unique hardware platform for the • D2000-2 (new Gien door family) • DO2000 • HPDS-VF (not available) • HSDS-VF • SIT door (China) • ADS door (only with limited release GAA30328AAF) application. The DCSS 5 substitutes the DCSS 4 system. In order to guarantee spare part support for elevator systems equipped with DCSS 4 a replacement kit will be available upgrading DCSS5 to be pin-compatible refereed to the DCSS 4. The DCSS 5 is an element of the Modular Elevator Control System (MCS). It interfaces as standard with the Motion Command Subsystem • MCSS in a MCS311/411 (if ICD51512_V21 is supported) • LMCSS in a MCS 321/413 • with the Limited Car Board (LCBII) in a MCS120/220/310/312 • with the TCB2 /TCBC for Gen2 • ADS door with SpecRevo controller (only with limited release GAA30328AAF) configuration. DCSS 5 is prepared to operate in cooperation with the CAN-bus based CarBus. The advanced door drive represents a microprocessor controlled frequency inverter suitable for AC motor application. The proposed 3-phase inverter is the power interface between the µP system and the motor. Ultrafast switching technology using a six pack module IGBT device leads to noiseless operation and low current ripple due to the high switching frequency of above 15kHz. A suitable gear reduces the speed of the motor shaft according to the requirements of the mechanical environment. The control and profile and PWM- pulse pattern generation are done by a microprocessor system. Position recognition, security and motor/inverter protection functions are implemented. Furthermore the µP system has to establish the communication via the serial link (Multidrop protocol or CAN-Bus) with the MCSS or via discrete information lines/RSL communication with the LCBII, from where it gets the door commands. The position could be is acquired by an incremental encoder providing two tracks with 4 pulses up to 500 pulses/round. All In- and Outputs for signal use are optically insulated and short circuit protected. To supply an alternate door an additional DCSS 5 system is necessary. The following will describe the basic configuration and function. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 4 / 23 Date : 2005-04-04 2 Safety References • Please ensure that the EDS button is reachable when a door movement is started. • Inside the DCSS dangerous high voltage (>310Vdc) is connected to several devices. The cover of the box must be closed before switching on the mains! • In case of reopening the box wait at least 1min. after switching off the power to be sure the main capacitor is discharged! 3 Before the Installation 3.1 Encoder The DCSS5 requires an incremental speed encoder comply with the following specification: • two tracks with 500 pulses per rotation • phase shift between the tracks 90 ° +/- 45° • supply voltage 15V • Output: NPN Push Pull circuit or Open Collector (with internal Pull up resistors) • Shielded cable 3.2 Power Supply The supply will be provided in general directly by the main switch panel in the machine room. An automatic cut-off for each door system, located in the elevator controller, protects the traveling cable and the DCSS5 box. • DCSS5 requires a single phase 230Vac supply. In case that a neutral is not available, the elevator controller has to be equipped with an additional transformer. • In order to protect the traveling cable and the DCSS5 box only automatic cut-offs with class C characteristic and a limit within the range of 2.5A...4A are permitted. The DCSS ratings: Nom. Voltage: Output Voltage: Nom. Current: Output Frequency: Leakage Current: 1x230V-240V AC, 50/60Hz, -15% / +10% (195V..264) 3x 0..230Vac / 3-Phase 3x1.5Aac / 3-Phase (ED = 0.4) 0..128Hz / 3-Phase 13mA Electric Output Power: 550VA (Un=230V, In=1.5A, Ipeak=8A) the average continuous current at 100% duty cycle is < 350mA Mechanical Outp. Power: Appar.Outp.Power x Efficiency(ACmotor) x cosϕ = 550W x 0.5 x 0.6 = 165W OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 5 / 23 Date : 2005-04-04 3.3 RS Board Interface Description The DCSS can be set into operation only, if the TCI switch is set and this information is forwarded to the DCSS via LCBII/TCB and RSL board. Therefore the signal lines ST1, ST2 and ST3 must be wired and the LCBII/TCB and the remote station are installed and programmed accordingly. How to connect the signal lines see also item 4.1. A test check sequence, initiated by the SVTOOL -TEST-INTRFCHK menu, should be started before the SETUP routine, to check the correct connection and signaling. Before starting the check sequence be make sure that /TCI is set. If the connection is wrong an appropriate message will be displayed, to help to localize the error. If the message ‘No Response’ appears, please check the outputs DOL or DOS. Attention : The DCSS 5 I/O‘s are only designed to cooperate with the RS14. Applying other RS-boards can cause serious problems. The reversal device and the Door Open Button have to pull the DCSS 5 inputs (LRD, DOB) to HL2 in order to indicate an active status. Otherwise pull up resistors on the DCSS board force the signal lines to 24V. 3.4 Electromagnetic Noise and Interference The DCSS fulfills the requirements, given in EN 12015/16 under condition that: • closed cover • motor cable shield connected at motor body and cable gland of heat sink panel In order to avoid disturbances of the encoder signal apply only shielded encoder cables and connect the shield to plug pin P3.5. 4 Connections Before switching power to the door operator, the connections must be checked: 4.1 Motorcable and Power supply • Ground connection of the plug pin P1.2 and the heat sink • Mains supply 230Vac (1 phase, +10/-15%) at plug P1.1 and P1.3 • Motor connection via ready-made shielded cable: • Check that motor cable plug is fixed tight on the DCSS motor terminal • Noise sensitive wires (signal cables, serial link connections) should not installed close or in parallel to the motor or power supply cable to avoid any interference! 4.2 Incremental Speed Encoder (at plug P3): • • • • +15V on P3.1: T1 on P3.2: T2 on P3.3: GND on P3.4&5: Encoder supply. Encoder signal track 1. Encoder signal track 2. Ground and shield OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 6 / 23 Date : 2005-04-04 4.3 Controller Interface Depending on the main controller the user can configure the interface during the Installation Setup. The DCSS5 supports following controller interfaces: • 3Wire Interface (standard), (LCBII or TCB, door type = 12) • 3-Wire Interface w. DOB (extended or fast DOB), ), (LCBII or TCB, door type = 13) • Serial Multidrop Interface ((L)MCSS • Relay Interface (modernization, additional Relay Interface board is necessary) • Discrete Interface (TBD) 4.3.1 Discrete 3-Wire Interface Control signals ST1, ST2 and ST3 • Supply: • Input ST1: • Input ST2: • Input ST3: 24V at P5.1 ST1 at P5.4 (HL2 active) ST2 at P5.5.....(HL2 active) ST3 at P5.6.....(HL2 active) Outputs: /DOL and DOS signal • Output Door Open Limit: • Output Door Opening Signal: /DOL at P5.3 DOS at P5.2 Reversal Signal The reversal signal must be connected to the DCSS at plug P5.7 and to the RS to inform the controller (LCBII) about a reversal action. Because all inputs of the DCSS5 are low active (must pulled down to HL2), the REV signal must be pulled down to HL2 if the reversal device is active. For that reason the logic of the I/O signal of the LCBII/TCB must be eventually inverted by reprogramming the RS-address. Please check this point and test the REV signal state via SVTOOL Monitor Menu of the LCBII / TCB. DOB Signal In case that you intent to apply the 3-Wire Extended Interface connect the DOB in a similar way as the REV signal (DCSS terminal : P5.9). Applying the 3-Wire Standard interface then connect the DOB signal to the RS board only. SGS Signal: With the SW version GAA30328AAE a new input signal is operating as a Safety Gate Shoe at DCSS terminal- P5.8. It supports the single SGS. In case of double safety shoe one signal must be disabled by a mechanic switch to avoid a door opening, if the door reaches the nearly close position. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 7 / 23 Date : 2005-04-04 4.3.2 Serial (Multidrop) Interface: A twisted pair wiring for data-receive at P4.1 for RxA and P4.2 for RxB A twisted pair wiring for data-transmit at P4.3 for TxA and P4.4 for TxB Set Line terminator and DCSS address in INSTALLATION Menu: The setting of the Line Terminator depends on how many subsystems (DCSS and LWSS) will be connected to the serial bus (see table). DCSS /LWSS Unit 1 Unit 2 Unit 3 One Unit Two Units Three Units Line Terminator ON Line Terminator ON* Line Terminator OFF Line Terminator OFF Line Terminator OFF Line Terminator OFF *Physically Farthest !!! • Voltage supply: 24V at P5.1 • Safety Signal: /SO on P5.8 • Optional: (Pin re-assignment is done with installation set to serial interface) Pay attention that all signals must pulled down to HL2 to be active! • Door Open Button: DOB on P5.9 • Light Ray Device: LRD on P5.6 • Electronic Door Protector: EDP on P5.7 The plugged-in OTIS Service Tool must show to be in MCS mode. Proceed with pressing “3” to open the DCSS menu. A detailed description can be found in the Service Tool Manual. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 8 / 23 Date : 2005-04-04 4.3.3 Relay-Controller with Interface Box To control the DCSS by a Relay Controller an additional Interface Box is necessary to service the enhanced amount of inputs and outputs. All inputs are optically insulated and can be driven by AC or DC sources. The voltage level of the inputs ranges from 48V up to 240 Volts. The outputs are potential free relay contacts, which can be used either as a making or a braking contact. Interface Box: Signal conversion by INTERFACE BOX OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 9 / 23 Date : 2005-04-04 Inputs: Max. 8 input signals can be connected with a voltage range from 48V up to 230V AC or DC given by the various kind of installations. To cover this wide range of voltages the inputs are divided into two voltage ranges. One range operates from 48/-15% to 110 volt and covers the most used signals. The other range is used for voltages higher than 130V/-15% up to max. 240V/+10%. To select the specific voltage range, please set a jumper for each input signal separately. To connect these relay controller signals with the "DCSS" they must be adapted by the interface box to the appropriate voltage level of the inputs of the door system. These signals are: Interface Box Signals Name In EDS Emergency Doorstop 6.3 to 6.4 TCI Top of Car Inspection 6.1 to 6.2 E6 SGS reversal signal 5.11 to 5.12 E5 EFS Emergency Fireman 5.9 to Service 5.10 DO Door open signal 5.7 to 5.8 DC Door close signal 5.5 to 5.6 nd E2 2 speed profile / 5.3 to EFO(disable rev) note1) 5.4 E1 Nudging (forced closing) 5.1 to 5.2 Out 8.1 DCSS 5 : Input at: P5.4 8.2 P5.5 1.13 P5.7 note2) 1.12 P5.6 note3) 1.14 P5.9 1.15 P5.8 note 1) function depends on programming, if ENG Setup Parameter “EFS_OPERATION = 1 nd all reversal devices are disabled if input is activated, if parameter = 0 then a 2 speed profile is selected note2) this EFS signal disables only the SGS reversal signal note3) depends on jumper setting; the DO signal can operate as a single door open command if jumper S1 is set to “DO”, or as a combination of DO and DC signal if S1 is set to “DO/DC” The inputs for the SGS, 2nd PROF and NDG signal can be programmed either as 'high' active or 'low' active input in the Setup menu ‘ENG’. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 10 / 23 Date : 2005-04-04 Outputs: The interface box has 6 relay outputs which are controlled by two 30V output signals of the DCSS. The two outputs control an 8-Bit shift register, whereby one signal is the Data and the other the Clock signal. To bring a new data to the output the according data state is clocked into the shift register. If 6 data states are shifted in, the complete output information is stored in the shift register. With the 8th clock the contents of the shift register is latched to the output where a relay driver sets the 6 relays according to the state of the data. Simultaneous the shift register is cleared and is now ready to be written for the next data to be shifted in. This procedure needs max. 16x8.192ms = 131ms and the outputs are refreshed in this cycle time. The max. contact ratings are 230Vac / 8A. The outputs of the relay interface box: Name REL1 (DOL) REL2 (XMC) REL3 (GH) REL4 (SGL) REL5 (PMY) REL6 (SGSout) Brake cont. 1.7 - 1.9 Plug Make cont. 1.7 - 1.8 1.4 -1.6 1.4 -1.5 1.1 -1.3 1.3 -1.2 2.4 -2.7 2.5 -2.6 2.2 - 2.4 2.2 - 2.3 3.4 - 2.1 3.4 - 3.5 Description Position used as Door Open Limit switch close (DOL) set before door is fully closed (XMC) close (used for gearless elevator) used as door fully closed (DCL) close used as SGL signal open / (to weak the sensitivity of EDP) close set before door is fully closed (PMY) close (used for high speed main drive) door reopen signal with adjustable -----delay time (SGSout) The outputs are activated if the door panel has reached the programmed position. This position can be adjusted individually for each relay by setting a distance with the Service Tool in the 'SETUP-ENG Menu'. Except the output Relay6, which is not position controlled. This output will be activated if a reversal is requested by the SGS input signal and an adjustable time delay has timed out. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 11 / 23 Date : 2005-04-04 5 First Installation 5.1 Starting Up Condition Every time before starting a DCSS 5 setup go step by step through the following check list: Bring the car to floor level so that you can perform the setup with car and landing doors together. If the hoistway is equipped with different landing doors proceed as follows: • in case that the elevator controller supports one profile set only choose the floor with the heaviest landing door • if the elevator controller is able to differ between profile set 1 and profile set 2 commands assign to each of the two profile sets one type of landing door and start the installation at the corresponding floor level for profile set 1. • Mechanical checks : • • Ensure that the adjustment of the car and landing door is in compliance with corresponding Field Instruction Manual. • • Check the operation of the door lock • Ensure that the door panels are centered and that they are in fully open position in line with the door frame. • Prove that the encoder is well tightened Test that the doors can be moved by hand easily ( low friction, no scratching etc.). Safety Check: • Check that the Top of Car Inspection Box is switched to inspection and press in addition the TES emergency button. • Check if LCBII/TCB and RS board is set into operation before power on the DCSS5. • Power the DCSS only if nobody is in the area of moving and rotation parts of the door operator. • Plug the SVT to the DCSS and check under menu 3-1-1 ( Monitor -> Status) that the message appears: NOTSTOP DED . Release the TES and observe the SVT display again. The status line has to change to: SERVICE DED. If not, please check communication interface. • System Check: • Check type of interface, depends on controller setup (see 5.2.1) • Check type of motor (see 5.2.1) OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 12 / 23 Date : 2005-04-04 5.2 SETUP Routine (Basic Installation) For the first time to put the system into operation the DCSS must be configured to its specific electrical and mechanical environment. After that step the DCSS executes an automatic learn run to find the optimum values for the creeping distances (lock), the speed profiles and the respective torques. There are 2 independent speed profiles which must be set separately. In order to simplify the installation, the complete installation procedure is menu-driven and monitored on the Service Tool. The user only needs to follow the displayed instructions and has to confirm the requests. To start the installation the DCSS must be set into SERVICE mode by switching the TCI. If the Service Mode is not available, please check the communication interface of the DCSS and Controller. A 3-Wire-bit-coded interface can be checked easily by starting the InterfaceCheck-Sequence (SVTOOL-TEST-INTRFCHK). The installation starts if the system is set into the 'SERVICE' mode and the Service Tool Menu is set to 'SETUP-INST1-Config' by press the key sequence 3-3-1-1 with following display. Attention: After connecting the SVTOOL to DCSS for the first time, the SETUP-menu is hidden. It must be visible by pressing SHIFT 7. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine 5.2.1 DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 13 / 23 Date : 2005-04-04 Configuration of the DCSS5 environment: In the first steps the mechanical environment will be configured: Enter menu 3-3-1-1 (Config) On the SVT-display the cursor “>” points to the actual selected component. Declare a different one by scrolling through the lists using the GOON/GOBACK button and select a specific one pressing ENTER. Please configure: Interface: -3-Wire (standard, DOB is not connected to DCSS5), LCB/TCB door type = 12 -3-Wire w. DOB (extended or DOB_FAST) , LCB/TCB door type = 13 -Multidrop (with LMCSS setup door type = 2) -Relay Attention: If a 3-Wire Interface has been selected, please start the Interface Check Sequence (key 3-2-4) to be sure that the wiring and the addressing of the Remote Stations are OK. Only if this test was successful you should continue with the next installation step. Door System Type: D2000-2 TLD D2000-2 CO D2000-2 CO4 DO2000 TLD DO2000 CO SIT9692 TLD SIT9692 CO HSDS NY TLD HSDS NY CO AADS DOOR TLD AADS DOOR CO (200W motor) (200W motor) (Korea/Japan motor) (Korea/Japan motor) The selected door type declares the standard motor and the standard encoder for this kind of door: Door System Type D2000-2 TLD/ CO/CO4 DO2000 TLD / CO SIT9692 TLD / CO HSDS TLD / CO AADS Door TLD / CO Motor FBA24350AC1 (200W) FBA24350F1 (100W) FBA24350F1 (100W) FBA24350AC1 (200W) JAA24354ABV1 (for WW) JAA24354ABV2 (for Japan local) Encoder FAA633A2 (500 pulses per/round) FAA633A2 (500 pulses per/round) FAA633A2 (500 pulses per/round) FAA633A2 (500 pulses per/round) JAA633ABP1 (for WW) JAA633ABP2 (for ADS-K) JAA633ABP3 (for Japan local) OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 14 / 23 Date : 2005-04-04 If you like to derive from the setting above answer the question “ Start Auto Learn” with “NO” and declare the following configuration parameters manually: Motor: - DO2000 for the 100W motor (blue) HSDS for the 200W motor (black) Korea (for ADS door) Door width: Enter door width in millimeters Tacho Resolution: Enter the pulses per rotation Attention: Motor Identification: Please check the type of motor before start of installation. Generally the DO2000 will be equipped with a standard 100W motor for Techna or Prima door types, but in special cases, for example heavy glass doors, this type of doors is equipped with a 200W motor. Every time a 200W motor is used, you have to select a HSDS door system. The 200 W motor can be identified by the motor label which shows a nominal current of 1.7 A and a torque of 3.4 Nm. Unfortunately this type of motor looks very similar the 100 W version (nearly same size, same colour). In future the 200 W motor will be delivered in black colour for clear identification. After the declaration of the configuration the DCSS proceeds automatically to the automatic setup for profile set 1. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine 5.2.2 DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 15 / 23 Date : 2005-04-04 Automatic Basic Setup for the Profile Set 1 The automatic learn run consists of 5 elements: Step 1: Sense Test The DCSS learns the cabling sequence of the motor and the encoder. The DCSS tries to open or close the door. If the system does not detect within a certain time period a sufficient door movement its reverses automatically the direction. If there is no movement in both directions the torque will be increased and the test loop starts again. If even with the maximum torque no door movement takes place the installation routine aborts with the error message Sense Test Failed Step 2: Learn Door Way The DCSS learns the door width. DCSS ask you to confirm that the door is fully closed. Inspect the door and ensure that the door and the lock are really closed. After your confirmation that the door is fully closed DCSS opens the door and accumulates the received encoder pluses. When the DCSS detects a stopped door it asks to confirm that the door is fully opened. In case of fully opened the accumulated pulses represent the door width otherwise the DCSS restarts the test. Step 3: Learn Creep-Ways This step is only performed if the selected door type requires a locking segment. First the door will be moved into the fully closed position. After that, the Setup routine starts the detection of the creep ways. Therefore the distance is investigated which the car door has to move until the landing door is driven by the car door. This needs only a couple of test runs where the DCSS closes and opens the door slowly. This procedure is able to find the optimal values for the following parameters: P1:OpenCreepTorque, P1:CloseCreepDist, P1:IniStartOpenDist, P1:StartOpenDist P1:LockDistance P1:IniCloseCreepDis If the detected locking distance is not within the range: 2% of door way < locking distance < 12 % of door way then the error message: Learn Creep Ways failed will be displayed OTIS Software Basic Data Engineering Center Berlin Starting Up Routine Step 4: DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 16 / 23 Date : 2005-04-04 Learn Torques First the door will be moved into the fully closed position. The system continues with a torque setting procedure. The DCSS tries to open the door and increases the torque as long as it is not possible to reach the fully opened position within a calculated time. The affected parameters are: P1:OpenCreepTorque, P1:IniTorque P1:CloseCreepTorque, P1:CloseTorque, P1:NudgingTorque If the DCSS is not able to drive the door accurately even with the highest tolerable torque the error message ERR: Chk Operator will be displayed. Attention: The installation procedure continues with the next step but obviously a performance degradation has to be expected. Due to this the DCSS remains after finalized installation in the reduced mode executing slow profiles only. Step 5: Learn Forward Gain First the DCSS opens the door. Then the system starts a closing test run observing the breaking behavior. If the breaking distance is longer than calculated the door opens again and starts another closing test run with modified control parameter. This loop happens until the optimal control parameters are investigated. Affected parameters: P1: FeedUp-Gain P1: FeedDown-Gain In case of insufficient breaking behavior the error message ERR: Gain Setting will be displayed . Attention: The installation will be continued but due to the failed installation step which results in a degradation of performance DCSS remains after finalized installation in the reduced mode e.g. only slow profiles will be executed OTIS Software Basic Data Engineering Center Berlin Starting Up Routine 5.2.3 DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 17 / 23 Date : 2005-04-04 Automatic Setup for the Profile Set 2 If you wish to have a second profile, you have to repeat step 4 to 5 to learn the specific parameter at that landing door, you like to run the profile. The procedure is the same. In order to start the learn run for the second profile enter menu 3-3-2 (Inst2) 5.3 Customer Specific Fine-tuning The automatic setup together with well defined default parameter yields to an excellent door performance. However field experience shows that job-site specific conditions and customer expectation on door operation needs sometimes fine tuning measures. It has been shown, that especially heavy glass doors, equipped with 200W motor, needs some fine tuning. For this type of doors you find a table of suggested values appended. • Set Stalled Door Protection Sensitivity Try to stop the car door manually and assess the stalled door functionality. Enter menu 3-3-4-4 and scroll to item PassProtLimit. Decrease the parameter in order to get better sensitivity or set a higher value to prevent undesired reversals. Keep in mind that the change of Passenger Protection value will be effective at least after several complete door runs, because of the adaptation algorithm of the internal PP. Heavy doors (200W motor): To reduce the kinetik energy to activate the PP (<707N), it is advisable to reduce the closing torque (see table page 19) • Set Idle Torques In fully opened or fully closed position the motor has to provide sufficient torque to keep the door under any condition in the end position. Enter menu 3-4-1 and perform a profile set 1 opening operation. As soon as the door is fully opened try to move the door into the closed direction. Enter menu 3-3-3-1 and scroll to item P1:OpenIdle Torque. Increase the parameter to achieve a higher motor torque. Please consider that high Idle torques have an impact on the motor heating. Due to this find a compromise guaranteeing to keep the door open with a minimum of motor heating. Now enter again menu 3-4-1 and execute a profile set 1 closing operation. Set the P1:CloseIdle Torque under menu 3-3-3-1 in a similar way. In case that the profile set 2 will be used do the same procedure for the Idle torques of profile set 2 . Find the P2 OpenIdle Torque and the P2:CloseIdle Torque under menu 3-3-3-2. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine • DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 18 / 23 Date : 2005-04-04 Set Creep Torques The creep torques are learned during the automatic setup. However if the customer requires more force or less force during the creeping to fully opened or fully closed enter menu 3-3--4-1 or menu 3-3-4-2 and modify the parameters Px:OpenCreepTorq or the Px:CloseCreepTorq. Take care that with the new parameter setting the end-positions can be achieved. • Set Reversal Stop Distance After detection of a reversal event the DCSS first stops the door. The distance necessary to stop the door can be adjusted entering menu 3-3-4-4 scrolling to the item StopDistance. Short stop distances can cause a higher noise and vibration level - find the best compromise. • Set Cls-Locking Speed After the landing door is fully closed the final creeping of the car door or the closing of the lock can be done with a higher speed in order to shorten the time needed to contact the DCL switch. To reduce the overall close time you can increase the ClsLockSpeed from 5Hz to 8Hz if the resulting noise of the lock is acceptable. The default value is equal to the Close Creep Speed. Enter menu 3-3-4-4 and scroll to list item Cls:Lock Speed to modify the locking behavior.. In case that the door mechanism has a fix vane you can skip the locking profile segment by setting the P1:Lock Distance to zero (3-3-4-4). •Set Opening and Closing Times Set the normal opening and closing times in ms according to the customer specification. Enter Menu 3-3-1 and scroll to the list items Px:OpenRunTime or Px:CloseRuneTime. Attention: Pay attention that the setting of door closing time is in line with the EN81 regulation: Paragraph 7.5.2.1.1.2 The kinetic energy of the landing door and all mechanical elements to which it is 1 rigidly connected ( e.g. car door, linkage, gear, motor ), calculated or measured at the average2 of the closing speed shall not exceed 10J. Note1: Measured using, for example, a device consisting of a graduated piston action on a spring with a spring constant of 25 N/cm… Note2: The average closing speed of a sliding door is calculated over the whole travel less: 25 mm at each end of the travel in case of centrally closing doors; 50 mm at each end of the travel in case of side closing doors OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 19 / 23 Date : 2005-04-04 In order to prove the compliance with the EN81 use a spring gauge as described under note 1 and measure the kinetic force at three points 1/3, 12 and 2/3 of closing travel. Ensure that the average of the three data is less than 707 N, which is the equivalent to 10J. 5.3.1 Installation suggestions for heavy doors (200W motor) • Max. Close Torque according to EN81 Especially for heavy doors with a 200W motor it is important to check the max Close torque, which is defined in the EN81 as a static force of 150Newton a door panel is pressing. To measure that close force you must block the door with disabled reversal devices and Passenger Protection to avoid a re-opening. The best way to do it to enter a CLOSE command by the ServiceTool under Menu Tools (key 3412). Enter the CLOSE command and bring the running door to stop by blocking it. Now measure the static force with a Newton Meter (gauged spring). If the measured force is higher than 150N, than reduce the parameter Px:NudgingTorque (key3341). This table should give a general installation suggestion to help adjusting heavy glass door types driven with a 200W motor. 1) Fine-adjusting of the torques, which are learned during the installation, to reduce the forces at the door panel during closing and to avoid overcurrents. With reduced forces the Passenger Protection will react much better. Parameter ClsTorque NudgingTorque IniTorque learned value 90-100% 85-90 100-110 adjust to-… 60-70% 65-70 80-90 remarks to improve PP and to avoid overcurrent to reduce static force <150N acc. EN81 to reduce the torques during opening adjust to-… 6Hz 50mm remarks to accelerate the start opening to accelerate the start opening adjust to-… 5000 mA remarks increases the mot Current limit 2) Adjusting of the Creep Profile If start of opening is to slowly: Parameter OpnCrpSpeed StartOpnDist learned value 4 Hz 70-75mm 2) To avoid Motorprotection Errror: Parameter maxMotorCurrent learned value 4000 mA OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 20 / 23 Date : 2005-04-04 6 Software Update for DO2000 doors When updating DCSS5 Software, pay attention that with the SW Version GAA30328AAE the ClsLockSpeed has been increased from 5Hz to 8Hz, to shorten the over all close time for DO2000 door types. This higher speed works fine with the revised DO2000 Techna door, which is available since April 2002. If you update the SW at older DO2000 door types, the higher CLsLockSpeed can produce noises during the last mm of door run. In that case, reduce the ClsLockSpeed to 5Hz. Other door types than DO2000 are not affected. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 21 / 23 Date : 2005-04-04 7 Controller Installation 7.1 Discrete 3-Wire Interface (LCBII/TCB) Table of Parameter setting of LCBII / TCB Generally the controller parameter are pre-installed by the factory and must not be adjusted. Anyhow before performing the installation of the DCSS start the interface check (32-4) while the elevator is in inspection mode In case that the check fails ensure that the setup of the TCB or LCB II complies to the following instruction. Attention: Setup information only valid for SW versions: LCBII : GAA30082CAA or higher TCB : GAA30084AAD or higher Enter menu 1-3-1and set door operator parameter: group 5-DOORS parameter DOOR REAR value 3-Wire Standard : 12 3-Wire Extended (fast DOB): 13 remark DOB is connected to DCSS5 3-Wire Standard: 12 (only if rear door exist) 3-Wire Extended (fast DOB): 13 (only if rear door exist) 10-TEST F:DO-TYP F:DC-TYP F:EN-ACG F:EN-DCL F:DOL-D 0 0 0 0 0 R:DO-TYP R:DC-TYP R:EN-ACG R:EN-DCL R:DOL-D 0 0 0 0 0 CM-TYP TRO-TYP 0 0 (TCB) 1 (LCB2) DEBUG DEBUG1 0 0 DOB is connected to DCSS5 OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 22 / 23 Date : 2005-04-04 Enter menu 1-3-2 and set RSL I/O addresses: Nr 0 1 2 27 544 546 605 606 607 608 691 694 695 783 787 991 992 993 994 995 996 name DOL DOB EDP NDG RDOL REDP DOS / SGS RDOS / RSGS LRD RLRD TCI DCL RDCL TCIB DCM DOOR_ST1 DOOR_ST2 DOOR_ST3 DOOR_ST1R DOOR_ST2R DOOR_ST3R description Door Open Limit Door Open Button Electronic Door Protection Nudging Rear Door Open Limit Rear Electronic Door Protection Door Opening Signal Rear Door Open Signal Light Ray Device Rear Light Ray Device Top of car Inspection Switch Door Close Limit Switch Rear Door Close Limit Switch Top Of Car Inspection Button Door Closing Management ST1 for front DO-5 ST2 for front DO-5 ST3 for DO-5 ST1 for rear DO-5 ST2 for rear DO-5 3-Wire Standard: ST3 for rear DO-5 3-Wire Extended: ST3 for rear DO-5 MCS120 17,1 4.1 00,0 00,0 19,1 00,0 17,4 19,4 17,3 19,3 16,3 01,0 01,0 01,0 00,0 17,3 17,4 16,3 19,3 19,4 00,0 MCS220 Gien-99 Gen2_A Gen2_B 17,1 17,1 17,1 13,1 4.1 4.1 4.1 4.1 00,0 00,0 00,0 00,0 00,0 00,0 00,0 00,0 19,1 19,1 19,1 00,0 00,0 00,0 00,0 00,0 17,4 17,4 17,4 13,4 19,4 19,4 19,4 00,0 17,3 17,3 17,3 13,3 19,3 19,3 19,3 00,0 16,3 16,3 16,3 12,3 01,0 01,0 01,0 01,0 01,0 01,0 01,0 01,0 01,0 01,0 01,0 01,0 00,0 00,0 00,0 00,0 17,3 17,3 17,2 13,2 17,4 17,4 17,3 13,3 16,3 16,3 17,4 13,4 19,3 19,3 19,2 00,0 19,4 19,4 19,3 00,0 00,0 00,0 19,4 00,0 16,4 16,4 16,4 Gen2 Option A: front and rear doors up to 16 openings Gen2 Option B : only front doors up to 21 openings LRD/RLRD or DOB/RDOB are low-active signals. Some older LCB2/TCB software versions expect high-active signals so that the I/O must be inverted manually. The invert bit must be reset again when the software is updated to a corrected version. Use M-1-1-2 to check both LRD and DOB inputs. If one of the inputs is shown in uppercase letters while the corresponding reversal device is not active, you have to invert the I/O: Press M – 1 – 3 – 2 – <io-number> – ENTER – <address> – ON – ENTER Note that you have to enter the address again even if it is already shown in the display. OTIS Software Basic Data Engineering Center Berlin Starting Up Routine DCSS 5 No :GAA30328BAA_STR Scn : GAA30328BAA Page : 23 / 23 Date : 2005-04-04 7.2 Multidrop Interface (LMCSS) For elevator main controller (like MCS311/413 etc.) which are using a LMCSS board, the enhanced multidrop protocol for DCSS5 (ICD51512_V21) is supported by the software version GBA30085JAA and higher. The general Installation Parameter ‘Door Type’ must be set to 2. For more information see Field Component Manual JAA26801AAFVIIIc_FC1. 8 Profile Description The detailed description of the different velocity and torque profiles can be found in the FCM –Guideline. An example of a general velocity and torque profile: Profile 2 3 4 5 1 t Start Creep Idle OPN Velocity Torque Main Profile Stop Creep Idle CLS