- Ninguna Categoria

Abrasive Wear by Hard Particles: Mechanisms & Resistance

Anuncio

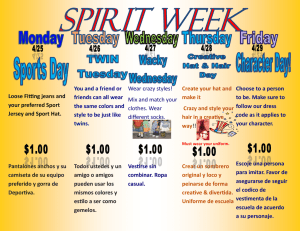

Tribology International Vol. 31, No. 10, pp. 587–596, 1998 1999 Elsevier Science Ltd. All rights reserved Printed in Great Britain 0301–679X/98/$19.00 ⫹ 0.00 PII: S0301–679X(98)00079–6 Wear by hard particles K.-H. Zum Gahr Abrasive wear can be caused by hard particles sliding on a softer solid surface and displaying or detaching material. Different types of interactions are distinguished between the sliding particles and the wearing surface of the solid. Frequently, resistance against abrasive wear is only considered as a function of hardness of the wearing material. However, a more general model shows that, depending on the interaction, the capability of deformation or the fracture toughness of the wearing material is very important in addition to hardness. Abrasive wear resistance can substantially be improved by second phases embedded in a hard or soft matrix. The theoretical models are supported by a lot of experimental results from studies on metallic or ceramic materials. 1999 Elsevier Science Ltd. All rights reserved. Keywords: abrasive wear, two-body abrasion, hardness Introduction Wear by hard particles occurs in many different situations such as on earth-moving equipment, slurry pumps or pipelines, rock drilling, rock or ore crushers, pneumatic transport of powders, dies in powder metallurgy, extruders or chutes. According to Fig 1, the wear processes may be classified by different modes depending on the kinematics and by mechanisms depending on the physical and chemical interactions between the elements of the tribosystem which result in detaching of material from the solid surfaces. Compared with unlubricated sliding wear, the value of the wear coefficient k, i.e. the dimensionless quotient of the amount of volumetric wear WV times the hardness of the wearing material H divided by the normal load FN and the sliding distance s, estimated from practical experience can be substantially greater in abrasive or erosive wear1–5. Fig 1 can only represent a very rough estimation of the wear coefficient because of wide variation of the wear mechanisms occurring in an actual tribosystem as a function of the operating conditions and properties of the triboelements involved, which can result in changes of the k value by some orders of magnitude. In abrasive wear, material is displaced or detached from a solid surface by hard particles, or hard particles between or embedded in one or both of the two solid surfaces in relative motion, or by the presence of hard University of Karlsruhe, Institute of Materials Science II and Karlsruhe Research Center, Institute of Materials Research I, P.O. Box 3640, 76021 Karlsruhe, Germany protuberances on a counterface sliding with the velocity v relatively along the surface. Two-body abrasion is caused by hard protuberances or embedded hard particles while in three-body abrasion the hard particles can move freely (roll or slide) between the contacting surfaces. According to Refs. 6–8, the rate of material removal in three-body abrasion can be one order of magnitude lower than that for two-body abrasion, because the loose abrasive particles abrade the solid surfaces between which they are situated only about 10% of the time, while they spend about 90% of the time rolling. Hard particles striking a solid surface either carried by a gas or a liquid stream can cause erosive wear whereby the wear mechanism depends strongly on the angle of incidence of the impacting particles. The interaction between hard particles and a solid surface can generally be accompanied by events of adhesion, abrasion, deformation, heating, surface fatigue and fracture. Fig 2 shows schematically some general trends of wear loss of materials depending on properties of the abrasive particles and the wearing materials as well as the operating conditions9. With increasing hardness of the abrasive particles, wear loss can increase by about one to two orders of magnitude from a low to a high level (Fig 2a). This transition depends on the ratio of the hardness of the abrasive particles to the hardness of the material being worn (Fig 2b). The increase from the lower to the higher wear level occurs for singlephase material when the hardness of the abrasive particles is equal to the hardness of the material worn. At equal bulk hardness of a multiphase material, the Tribology International Volume 31 Number 10 1998 587 Wear by hard particles: K.-H. Zum Gahr Fig. 1 Values of wear coefficient k as a function of wear mode and wear mechanism without lubricative media Fig. 2 Schematic representation of wear loss by hard particles as a function of material properties and operating parameters such as (a) hardness of abrasive particle; (b) ratio of hardness of abrasive particle and hardness of the wearing material; (c) abrasive particle size, normal load and impact velocity, and (d) impact angle without considering lubricative media matrix of the material containing hard reinforcing phases is softer than the matrix of the single-phase material. Hence, the transition from low to high wear level of the multiphase material starts and ends when the hardness of the matrix and the hardness of the reinforcing phase are respectively exceeded by the 588 hardness of the abrasive particles (Fig 2b). At the high wear level, the wear loss of the multiphase material can be greater than that of the single-phase material if the reinforcing phase can be detached from the matrix and acts abrasively on the matrix in addition. Important operating parameters are the average size of the abras- Tribology International Volume 31 Number 10 1998 Wear by hard particles: K.-H. Zum Gahr ive particles, the applied normal load, or during erosive wear the velocity of impinging hard particles. Wear loss of ductile and brittle materials depends on these parameters according to power laws exhibiting different values of the exponent n (Fig 2c). For ductile materials the velocity exponent can be expected to be between 2 and 3, while on brittle materials 3 to 4 are more likely. A transition from low to high wear level can occur on brittle materials such as alumina with increasing particle size and/or normal load or applied contact pressure, respectively. In general, spherical particles cause a lower amount of wear loss than angular particles at a given average particle size. However, the effect of particle shape should be smaller in threebody abrasion because the loose particles can reorient themselves during sliding and rolling contact compared with two-body abrasion. During erosive wear, the dependence of wear loss on the impact angle is influenced by the size of the impinging particles, the impact velocity and the target material. A trend has been observed that the wear loss increases, at a given impact angle, with increasing size and velocity of the impinging particles. Ductile metallic materials such as plain carbon steels exhibit their maximum wear loss at impact angles less of about 30° (Fig 2d). Brittle materials such as ceramics or hardened tool steels show increasing wear loss with increasing impact angles and frequently maximum values for normal incidence. Wear loss decreases continuously with increasing impact angle for materials of very high elasticity such as rubber. It has to be considered that Fig 2 can only represent general trends because in a given tribosystem many factors act in a complex manner simultaneously. Modelling of two-body abrasive wear Models for two-body abrasion have been developed to a substantially greater depth than for three-body abrasion. Penetration of a sliding abrasive particle into a metallic surface results in microploughing or microcutting depending on the attack angle10. Below a critical attack angle, the metallic material is mainly elastic– plastic deformed and flows around and beneath the sliding particle but no material is removed from the surface. Increasing the attack angle leads to a transition from microploughing to microcutting, i.e. material flows up the front face of the abrasive particle and it is detached from the wearing surface in the form of a chip. This model of a critical attack angle can be replaced by a criterion of a critical penetration depth of the abrasive particle or a rigid indenter. Using a spherical indenter, the degree of penetration as the ratio of penetration depth divided by the radius of contact is directly connected with the attack angle which increases with penetration depth. According to Refs. 5 and 11, the degree of penetration Dp as a function of the dimensionless shear strength f, i.e. the ratio between the shear strength at the contact interface and the shear yield stress of the wearing material, allows us to distinguish between different abrasive mechanisms (Fig 3a). Wedge formation means that a wedge prow forms at the front of the indenter and material is removed by propagation of a crack. Fig 3b shows the increase of the wear coefficient k with increasing degree of penetration for metals under unlubricated sliding. Hardness of a material can be defined as the resistance to penetration by a hard indenter. Hence, hardness of the wearing material affects the penetration depth of abrasive particles but Fig 4 shows that it fails in predicting abrasive wear resistance of different materials. For example, cold working of metals can increase hardness substantially but not abrasive wear resistance and it may even reduce it. This general relation between abrasive wear resistance and hardness was measured in many studies12,13. The increment in abrasion resistance with increasing hardness of materials is substantially larger in pure metals than in heat treated steels or ceramics. Hardness fails in predicting wear resistance because it cannot characterise the interactions between abrasive particles and the wearing materials sufficiently, which, however, determine the formation of wear debris. According to an early model3, which predicts wear volume WV only depending on the attack angle ␣, the normal load FN, the hardness H of the material, the geometry of the indenter (in this case a conical indenter) and the sliding distance s, the wear volume W V 2·tan ␣ F N · ⫽ (1) s H can be calculated from the volume of the wear groove produced. However, it has to be considered that only a portion of the volume of a wear groove formed on a metallic surface is removed as wear debris and the remainder of the groove volume is plastically displaced to the sides of the groove14–16. Hence, a more general model9,17 was developed which describes abrasive wear by distinguishing four types of interactions between abrasive particles and a wearing material (Fig 5), namely microploughing, microcutting, microfatigue and microcracking. In the ideal case, microploughing due to a single pass of one abrasive particle does not result in any detachment of material from the wearing surface. A prow is formed ahead of the abrading particle and material is continuously displaced sideways to form ridges adjacent to the groove produced. Volume loss can, however, occur owing to the action of many abrasive particles or the repeated action of a single particle. Material may be ploughed aside repeatedly by passing particles and may break off by low cycle fatigue, i.e. microfatigue. Pure microcutting results in a volume loss by chips equal to the volume of the wear grooves. Microcracking occurs when highly concentrated stresses are imposed by abrasive particles, particularly on the surface of brittle materials. In this case, large wear debris is detached from the wearing surface owing to crack formation and propagation. Microploughing and microcutting are the dominant processes on ductile materials while microcracking becomes important on brittle materials. In a single scratch experiment, the ratio of volume of material removed as wear debris to the volume of the wear groove produced can be described by the fab value (Fig 5) which is defined9,17 as Tribology International Volume 31 Number 10 1998 589 Wear by hard particles: K.-H. Zum Gahr Fig. 3 Modes of interaction and wear coefficient k owing to a hard spherical indenter sliding on metallic materials as a function of (a) interfacial shear strength and (b) degree of penetration (from Hokkirigawa and Kato5,11) where s is the effective deformation on the wearing surface and lim is the capability of deformation of the wearing material before microfracture occurs locally during abrasion in a given tribosystem.  is a factor which describes the decay of deformation with increasing depth below the wearing surface and depends mainly on the work-hardening behaviour of the wearing material. Equation (3) is defined for s ⱖ lim only while for s ⬍ lim microploughing or elastic/plastic deformation occurs without any wear loss. Hence, the fab value is not only a material property but it is also a function of the operating conditions during abrasion which affect both s and lim. According to this model17 the linear wear intensity Wl/s defined as the change in the length of a pin specimen or the thickness of a plate per sliding distance is given by Fig. 4 Schematic drawing of abrasive wear resistance (two-body abrasion, W−1 of different materials v ) measured in the pin abrasion test as a function of their bulk hardness f ab ⫽ A V ⫺ (A 1 ⫹ A 2 ) AV (2) W l/s ⫽ ⌽ 1 ·f ab · p H def (4) or inserting Equation (3): 冋 冉 冊册 W l/s ⫽ ⌽ 1 1 ⫺ lim s 2/ · p H def (5) where AV is the cross-sectional area of the wear groove and (A1 ⫹ A2) represents the amount of material which is pushed to the groove sides by plastic deformation. In the case of microcracking, spalling occurs at the edges of the wear grooves (Fig 5) which leads to negative values of A1 and A2 and fab becomes greater than 1. The fab value becomes equal to unity for ideal microcutting and equal to zero for ideal microploughing. Values of fab ranging from 0.15 to 1.0 have been measured experimentally on about 30 different materials using metallographic taper sections9,18. where Hdef is the hardness of the highly deformed material, e.g. of wear debris, p is the applied surface pressure and ⌽1 is a geometrical factor which depends on the shape of the abrasive particles. From Equation (5) it follows that abrasive wear loss is strongly influenced by the capability of deformation (lim) and the work-hardening capacity ( ⬇ (H def /H) 1/3 as the first approximation) and Hdef of the wearing material in addition to the operating conditions (p, ⌽1 s). This theoretical model was strongly supported by a lot of experimental results9,17. A theoretical model9 for calculating the fab value owing to a combination of microploughing and microcutting results in Fig 6 shows a good agreement between experimental results measured on a lot of different metallic materials and the prediction of Equation (4). Abrasive wear resistance (Wl/s)−1 of these materials against flint abrasive grits (80 mesh) increased linearly with the ratio (fab/Hdef)−1 in the pin abrasion test used. The deviation f ab ⫽ 1 ⫺ 590 冉 冊 lim s 2/ (3) Tribology International Volume 31 Number 10 1998 Wear by hard particles: K.-H. Zum Gahr Fig. 5 Schematic representation of different interactions between sliding abrasive particles and the surface of materials, scanning electron micrograph of a wear groove on an austenitic steel and a draft of a taper section through a wear groove penetrating abrasive particles, and the type of internal notches. Using models of fracture mechanics, a critical applied load or surface pressure can be estimated, above which flaking of material occurs9,17. For a material containing cracks or thin graphite lamellae the critical surface pressure pcrit is given by p crit ⫽ ⌽ 2 · ·K 2IIc D 2ab ·H·2 (6) and for the linear wear intensity owing to microcutting (fab ⫽ 1) and microcracking it is obtained W l/s ⫽ ⌽ 1 · with Fig. 6 Abrasive wear resistance on pure metals, singlephase alloys, precipitation-hardened ferritic and austenitic alloys, austenitic and ferritic steels and plain carbon steels against 80 mesh flint measured in a pin abrasion test with p ⫽ 0.71 MPa contact pressure versus the ratio of hardness of wear debris to fab values measured in a scratch test by using a sliding diamond loaded by 2 N of the test data from the straight line at high ratios was caused by a change in wear mechanism from microploughing/microcutting to portions of microcracking on the steels of high hardness. Smaller or greater portions of microcracking can occur during abrasion of inherent brittle materials such as highly hardened steels or ceramics or materials containing internal notches such as cracks, pores, graphite lamellae, embrittled grain boundaries, inclusions or large carbides, which promote crack formation and/or crack propagation. The extent of cracking depends on the fracture toughness (KIc, KIIc) of the stressed material, loading conditions, the size and shape of the p3/2 ·H 1/2 2 p ⫹ ⌽ 3 ·A f ·D ab ·⍀ H def K 2Ic (7) 再 冉 冊冎 ⍀ ⫽ 1 ⫺ exp ⫺ p p crit 1/2 ⌽2 and ⌽3 are geometrical factors which depend on the shape of the abrasive particles and the shape of the cracking during abrasive wear. These factors can be calculated for special cases9. is the mean free path between and Af the area fraction or density of the inherent defects, e.g. cracks or graphite lamellae. is the coefficient of friction at the leading face of the abrasive particles, Dab is the effective size of the abrasive particles and KIc, KIIc the fracture toughness of the wearing material according to mode I (tension) or II (shear) loading. Other models19,20 using fracture mechanics for describing removal of material by lateral cracking result in similar equations for linear wear intensity such as W l/s ⫽ ⌽· 5/4 D 1/2 ab ·p 3/4 K c ·H 1/2 (8) where ⌽ is a constant. As many studies have shown, fracture toughness KIc decreases with increasing hard- Tribology International Volume 31 Number 10 1998 591 Wear by hard particles: K.-H. Zum Gahr Fig. 7 Schematic drawing of the relation between fracture toughness and abrasive wear resistance (Wl/s)−1 of different metallic and ceramic materials (two-body abrasion, pin abrasion test) Fig. 8 Interactions between sliding hard or soft abrasive particles and reinforcing phases ness or yield stress of the materials tested, i.e. fracture toughness and hardness of a given material can be connected to each other. These models suggest that wear loss of brittle materials increases more rapidly than linearly with applied surface pressure or normal load (FN ⫽ p·A, where A is the area of contact) in accordance with Fig 2c. Fig 7 summarises the general effect of fracture toughness and hardness of materials on their abrasive wear resistance in a given tribosystem. Brittle materials such as ceramics show under severe wear conditions an increasing wear resistance with increasing fracture toughness despite simultaneously decreasing hardness. Surfaces of these materials worn by hard particles exhibit large or small portions of microcracking that can result in spalling of individual grains of the wearing material and in addition microcutting in accordance with Equation (7). Materials with values of fracture toughness greater than a critical value, which depends on the operating conditions (load, size and acuity of the abrasive grits, sliding speed etc.), are worn by a 592 combination of microploughing and microcutting. Hence, the wear loss of these materials is determined with others by the hardness (see Equation (5)) but is independent of fracture toughness. In this regime, wear resistance decreases with decreasing hardness due to enhanced penetration depth and experimentally a large variety of values of wear resistance can be measured on different materials but equal hardness owing to differences in the capability of deformation lim. The aim of the foregoing modelling of two-body abrasion is to exhibit the most important parameters influencing wear resistance of homogeneous materials but not calculating exact values of wear losses. The theoretical models discussed above do not consider the interaction between parallel scratches or grooves which can result in enhanced material removal22,23, temperature24 or liquid media25. It is evident and supported by many experimental results that hardness of a wearing material alone is insufficient for describing resistance to abrasive wear. Microstructural parameters such as grain size26–28 or reinforcing phases can substantially Tribology International Volume 31 Number 10 1998 Wear by hard particles: K.-H. Zum Gahr affect the amount of wear. Abrasive wear tests on different oxide ceramics showed an increase in wear resistance with an increase in the reciprocal of the square root of the grain size to a first approximation. Effect of second phases on abrasive wear Composites can offer the answer for achieving high hardness and sufficient fracture toughness to avoid brittle fracture. Second phases, e.g. hard ceramic particles or fibres, can be incorporated into a softer and more ductile matrix. The abrasive wear resistance of such composites depends on different microstructural parameters such as the hardness, shape, size, volume fraction and distribution of the embedded phases, the properties of the matrix and the interfacial bonding between the second phase and the matrix. Fig 8 shows different interactions between abrasive particles and a reinforcing phase. Hard and soft abrasive particles, i.e. harder or softer than the reinforcing phase and also small and large sizes of the reinforcing phase are distinguished. Hard abrasive particles can easily dig out small phases and cut or crack larger ones. Soft abrasive particles are able to dig out small phases or produce large pits. The indentation depth of soft abrasive particles is substantially reduced by hard reinforcing phases if the mean free path between them is smaller than the size of the abrasive particles. Large phases deficiently bonded to the matrix can be pulled out. However, large phases strongly bonded to the matrix can blunt or fracture soft abrasive particles. Fig 9 shows wear grooves caused by a sliding SiC tip (attack angle and wedge angle of 90°) on the surfaces of TiC and TaC steel composite layers which were produced on the die steel 90MnCrV8 (0.9% C) by laser cladding29. The reinforcing TiC (⬇ 2600 HV) and TaC (⬇ 1800 HV) particles were embedded in the martensitic steel matrix (810 HV30). The soft TaC phase was grooved (microcutting primarily) by the hard SiC tip (Fig 9a) and was smashed under high Fig. 9 Scanning electron micrographs of polished surfaces of heat treated composite layers scratched by a sliding silicon carbide tip: (a) 3 m TaC, FN ⫽ 1 N; (b) 3 m TaC, FN ⫽ 2 N; (c) 30 m TaC, FN ⫽ 5 N; (d) 3 m TiC, FN ⫽ 5 N; (e) 30 m TiC, FN ⫽ 1 N; (f) 30 m TiC, FN ⫽ 5 N Tribology International Volume 31 Number 10 1998 593 Wear by hard particles: K.-H. Zum Gahr normal loads (Fig 9c). Resulting debris of the TaC were impressed into the matrix under the sliding SiC tip (Fig 9b). The harder TiC particles of an average size of about 30 m were not or only moderately grooved by the SiC (Fig 9e,f). With increasing normal loads, the large TiC particles were broken. TiC particles of a size smaller than that of the wear groove were dug out of the matrix (Fig 9d). The effects of size and volume fraction of a hard reinforcing phase were studied on SiC dispersoides of varying size (5–200 m) which were galvanically embedded in a nickel matrix. Fig 10 shows the wear intensity (amount of linear wear divided by length of the wear path) of the composites related to that of the pure nickel matrix as a function of the volume fraction of the SiC reinforcing dispersoides. Wear intensities were measured using 80 mesh (grit size of about 200 m) SiC abrasive paper. Small dispersoides were easily dug out and resulted in enhanced wear loss with increasing volume fraction owing to their own abrasive action as loose particles. At a given volume fraction, wear intensity decreased with increasing size of the dispersoides. A minimum of wear intensity was measured for 15 and 120 m SiC dispersoides as a function of volume fraction. Microcracking connected with spalling of dispersoides occurred at high volume fraction. Composites containing the large 200 m SiC dispersoides exhibited continuously decreasing wear intensity with increasing volume fraction. In this case, the ratio of size of wear grooves to size of the dispersoides had been substantially smaller than unity. In agreement with the results of Fig 10, studies on SiC or Al2O3 particle reinforced aluminium alloys showed decreasing abrasive wear loss with increasing volume fraction and size of the reinforcing particles30,31. In studies on a polyester resin which was reinforced by continuous steel fibres perpendicularly oriented to the wearing surface, wear intensity decreased also continuously with increasing area fraction of the reinforcing fibres up to about 45 vol%32. However, in other studies on polymeric composites containing dispersed Al2O3 particles33 or short fibres34 of glass or carbon, wear loss decreased only below a critical volume fraction or increased even continuously with increasing amount of reinforcing phase. From the foregoing results and also studies on white cast irons9,35 it follows that under mild operating conditions abrasive wear loss decreases with increasing volume or area fraction of the reinforcing phase. This means that the reinforcing phase is strongly embedded in the matrix and spalling does not occur. However, under severe conditions with microcracking and spalling of the reinforcing phase, wear loss can increase with increasing volume fraction of reinforcing particles or short fibres. These conclusions are also in agreement with orientation effects of fibre reinforced materials. Fibres perpendicular oriented to the wearing surface of polymeric composites lead to the lowest wear loss34. Fibres parallel to the surface may be dug out more easily than those perpendicular to it, if the indentation depth of the abrasive particles is larger than about a half of the fibre diameter. For brittle materials such as ceramics, resistance to severe abrasion is influenced with others by fracture toughness of the wearing material according to Equations (6)–(8), Fig 7 and experimental results9,20,21,36. Fracture toughness of brittle materials can generally be enhanced by mechanisms of energy dissipation. Such toughening mechanisms are stress-induced phase transformation, stress-induced microcracking, crack pinning Fig. 10 Relative linear wear intensity (related to that of pure nickel) of SiC dispersion-hardened galvanic nickel versus SiC volume fraction. Average size of SiC dispersoides 5, 15, 120 and 200 m 594 Tribology International Volume 31 Number 10 1998 Wear by hard particles: K.-H. Zum Gahr Fig. 11 Volumetric wear loss in the abrasive wheel test against 120 mesh SiC abrasive and hardness versus the volume fraction of a soft eutectic phase of an Al2O3 ceramic surface alloyed by HfO2 with crack deflection, crack bridging or pullout of reinforcing phases. However, all tribologically induced interactions between abrasive particles and the ceramics are concentrated on a relatively thin surface zone. Hence, some of these toughening mechanisms can fail under tribological contact because they act in larger volumes only. Also an appropriate fracture toughness value of the relevant surface zone of the wearing material which can differ from the bulk value has to be inserted in the theoretical models. Laser surface alloying of ceramics can be very effective in increasing fracture toughness and wear resistance of brittle ceramics37,38. Fig 11 shows the volumetric wear of a HfO2 alloyed alumina measured using an abrasive wheel covered with 120 mesh SiC abrasive paper and sliding back and forth across the ceramic surface. The alloyed alumina surface contained a cellular eutectic HfO2–Al2O3 phase with a hardness only about half of that of the alumina crystallites. The volume fraction of this soft phase was varied up to an amount of about 50%. Despite decreasing hardness of the composite, the volumetric wear loss decreased substantially with increasing amount of the soft phase. This behaviour can be explained by enhanced fracture toughness compared with that of the monolithic alumina owing to grain refinement, elimination of porosity and introduction of the soft phase between the hard and brittle Al2O3 crystallites. Rules of mixtures may offer a simple method for a first estimation of wear resistance of multiphase structures or composites if the reinforcing constituents are strongly fixed in the matrix and are not pulled or dug out by abrasively acting particles. Fig 12 displays wear resistance of two-phase structures as a function of the volume fraction of the reinforcing constituent. Wear resistance of structures of type B increases strongly with volume fraction of the reinforcing constituent Fig. 12 Schematic representation of abrasive wear resistance of two-phase structures as a function of volume fraction of a reinforcing phase even at small volume fractions. In contrast, wear resistance of structures of type A is substantially increased only by large volume fractions of the reinforcing phase. In the case of type B, the reinforcing constituent determines wear behaviour predominantly and the phases are worn consecutively. The effect of the reinforcing phase depends on the identity, size and the distribution of this phase and also on size and identity of abrasive particles used or more generally on the wear system. The rule of mixtures of type B is supported by experimental results on polyester resin reinforced by continuously steel fibres and the rule of mixtures of type A by results on ferritic–perlitic steels9. Experimental values of wear resistance of multiphase Tribology International Volume 31 Number 10 1998 595 Wear by hard particles: K.-H. Zum Gahr structures are frequently measured between the boundaries given by both rules of mixtures. References 1. Burwell, J. T. and Strang, C. D., Metallic wear. Proc R Soc, 1952, A212, 470–477. 2. Archard, J. F., Contact and rubbing of flat surfaces. J Appl Phys, 1953, 24, 981–988. 3. Rabinowicz, E., Friction and Wear of Materials. John Wiley, New York, 1965. 4. Hutchings, I. M., Tribology: Friction and Wear of Engineering Materials. Edward Arnold, London, 1992. 5. Hokkirigawa, K., Advanced techniques for in-situ observations of microscopic wear processes. In Proceedings of Surface Modification Technologies VIII, eds T. S. Sudarshan and M. Jeandin, Institute of Materials, London, 1995, pp. 93–105. 6. Rabinowicz, E., Dunn, L. A. and Russell, P. G., A study of abrasive wear under three-body conditions. Wear, 1961, 4, 345–355. 7. Fang, L., Kong, X. L., Su, J. Y. and Zhou, Q. D., Movement patterns of abrasive particles in three-body abrasion. Wear, 1993, 162–164, 782–789. 8. Xie, Y. and Bushan, B., Effects of particle size, polishing pad and contact pressure in free abrasive polishing. Wear, 1996, 200, 281–295. 9. Zum Gahr, K. H., Microstructure and Wear of Materials. Tribology Series 10, Elsevier, Amsterdam, 1987. 10. Mulhearn, T. O. and Samuels, L. E., The abrasion of metals: a model of the process. Wear, 1962, 5, 478–498. 11. Hokkirigawa, K. and Kato, K., An experimental and theoretical investigation of ploughing, cutting and wedge formation during abrasive wear. Tribology International, 1988, 21, 51–57. 12. Richardson, R. C. D., The maximum hardness of strained surfaces and the abrasive wear of metals and alloys. Wear, 1967, 10, 353–382. 13. Moore, M. A., Abrasive wear. In Fundamentals of Friction and Wear, ed. D. A. Rigney, ASM, Metals Park, OH, 1980, pp. 73–118. 14. Stroud, M. F. and Wilman, H., The proportion of the groove volume removed as wear in abrasion of metals. Br J Appl Phys, 1962, 13, 173–178. 15. Zum Gahr, K. H., Formation of wear debris by the abrasion of ductile metals. Wear, 1981/82, 74, 353–375. 20. Moore, M. A. and King, F. S., Abrasive wear of brittle solids. Wear, 1980, 60, 123–140. 21. Evans, A. G. and Marshall, D. B., Wear mechanisms in ceramics. In Fundamentals of Friction and Wear of Materials, ed. D. A. Rigney, American Society of Metallurgy, Columbus, OH, 1981, pp. 439–452. 22. Jacobson, S., Wallen, P. and Hogmark, S., Fundamental aspects of abrasive wear studied by a new numerical simulation model. In Wear of Materials, ed. K. C. Ludema, ASME, New York, 1987, pp. 595–606. 23. Xu, H. H. K., Jahanmir, S. and Wang, Y., Effect of grain size on scratch interactions and material removal in alumina. J Am Ceram Soc, 1995, 78(4), 881–891. 24. Berns, H., Fischer, A. and Kleff, J., Scratch tests on iron-, nickel- and cobalt-based alloys at elevated temperatures. Wear, 1993, 162, 585–589. 25. Backmark, U., Wear testing in water slurries. Wear, 1993, 162, 1029–1032. 26. Rice, R. W., Micromechanics of microstructural aspects of ceramic wear. Ceramic engineering and science. Proceedings of the 9th Annual Conference on Composites and Advanced Ceramic Materials, American Ceramics Society, Westerville, OH, 1985, pp. 940–945. 27. Mukhopadhyay, A. K. and Mai, Y. Q., Grain size effect on abrasive wear mechanisms in alumina ceramics. Wear, 1993, 162, 258–268. 28. Davidge, R. W. and Riley, F. L., Grain-size dependence of the wear of alumina. Wear, 1995, 186, 45–49. 29. Axén, N. and Zum Gahr, K.-H., Verschlei von TaC- und TiCLaserdispersions-schichten durch weiche und harte Abrasivstoffe. Mat-wiss u Werkstofftech, 1992, 23, 360–367. 30. Zamzam, M. A., Abrasive wear of aluminium–matrix composites. Metall, 1991, 45, 250–254. 31. Garcia-Cordovilla, G., Narciso, J. and Louis, E., Abrasive wear resistance of aluminium alloy/ceramic particulate composites. Wear, 1996, 192, 170–177. 32. Zum Gahr, K.-H., Einflu des Makroaufbaus von Stahl/PolymerFaserverbund-werkstoffen auf den Abrasivverschlei. Z Werkstofftech, 1985, 16, 297–305. 33. Lu, X.-Ch., Wen, S. Z., Tong, J., Chen, Y.-T. and Ren, L.-Q., Wettability, soil adhesion, abrasion and friction wear of PTFE (⫹ PPS) ⫹ Al2O3 composites. Wear, 1996, 193, 48–55. 34. Friedrich, K., Wear of reinforced polymers by different abrasive counterparts. In Friction and Wear of Polymer Composites, ed. K. Friedrich, Elsevier, Amsterdam, 1986, pp. 233–287. 16. Moore, M. A. and Swanson, P.A., The effect of particle shape on abrasive wear: a comparison of theory and experiment. In Wear of Materials, ed. K. C. Ludema, ASME, New York, 1983, pp. 1–11. 35. Zum Gahr, K.-H. and Eldis, G. T., Abrasive wear of white cast iron. Wear, 1980, 64, 175–194. 17. Zum Gahr, K.-H., Modelling of two-body abrasive wear. Wear, 1988, 124, 87–103. 18. Zum Gahr, K. H. and Mewes, D., Severity of material removal in abrasive wear of ductile metals. In Wear of Materials, ed. K. C. Ludema, ASME, New York, 1983, pp. 130–139. 37. Zum Gahr, K. H. and Schneider, J., Multiphase Al2O3 ceramic with high resistance to unlubricated sliding wear. Proceedings of the International Tribology Conference, Yokohama, 1995, Vol. 1, Japanese Society of Tribologists, Tokyo, 1996, pp. 397–402. 19. Evans, A. G. and Wilshaw, T. R., Quasistatic particle damage in brittle solids. I. Observations, analysis and implications. Acta Metall, 1976, 24, 939–956. 38. Zum Gahr, K. H., Bogdanow, Ch. and Schneider, J., Friction and wear reduction of Al2O3 ceramics by laser-induced surface alloying. Wear, 1995, 181, 118–128. 596 36. Yamamoto, T., Olsson, M. and Hogmark, S., Three-body abrasive wear of ceramic materials. Wear, 1994, 174, 21–31. Tribology International Volume 31 Number 10 1998

Anuncio

Documentos relacionados

Descargar

Anuncio

Añadir este documento a la recogida (s)

Puede agregar este documento a su colección de estudio (s)

Iniciar sesión Disponible sólo para usuarios autorizadosAñadir a este documento guardado

Puede agregar este documento a su lista guardada

Iniciar sesión Disponible sólo para usuarios autorizados