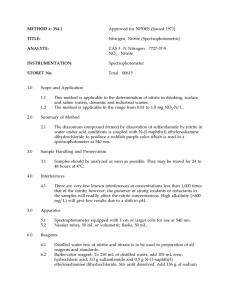

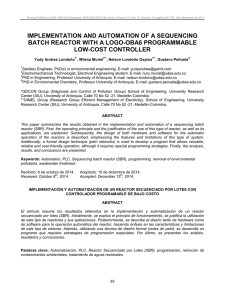

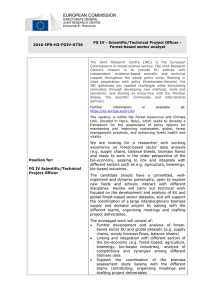

International Biodeterioration & Biodegradation xxx (2016) 1e13 Contents lists available at ScienceDirect International Biodeterioration & Biodegradation journal homepage: www.elsevier.com/locate/ibiod Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR G. Anjali, P.C. Sabumon* Environmental Engineering Division, School of Mechanical and Building Sciences, VIT University, Chennai Campus, Vandalur - Kelambakkam Road, Chennai 600127, India a r t i c l e i n f o a b s t r a c t Article history: Received 29 July 2016 Received in revised form 22 October 2016 Accepted 25 October 2016 Available online xxx The objective of this work was to develop simultaneous partial nitrification, anammox and denitrification (SNAD) process in a twenty liter non-aerated sequencing batch reactor (SBR). Flocculent type activated sludge sourced from a tannery common effluent treatment plant was used as seed biomass. The SBR was operated for 161 days in 23 cycles with initial feed concentrations of NH4-N and COD as 250 ± 14.9 mg l1 and 250 ± 4.6 mg l1, respectively. The process was developed in a non-mixing condition in a dark room with no temperature control, but the temperature in SBR varied between 30 C and 36 C. The average HRT was 10.5 d with SBR cycle time of 7 d. The last three cycles gave the best average removals of NH4-N (94%), COD (92%) and TN (82%). The conversion ratio Y(NO2-Nþ NO3-N)/(NH4-N) during the last 10 cycles remained below 0.11, confirming a stable SNAD process. Maximum specific substrate (NH4-N, COD and TN) utilization rates of SNAD biomass were determined as 185 mg NH4-N g1 MLVSS d1, 153 mg COD g1 MLVSS d1 and 172 mg N g1 MLVSS d1. These results contribute towards the application of SNAD process in shallow anoxic ponds/tanks/ditches in the absence of sunlight. © 2016 Elsevier Ltd. All rights reserved. Keywords: Partial nitrification Anammox Denitrification COD to NH4-N ratio Diffusion Catalase enzyme 1. Introduction AnAOB Simultaneous partial nitrification, anammox and denitrification (SNAD) process is evolving as an effective process for simultaneous removal of COD and NH4-N from effluents characterized with low COD to NH4-N ratio (Chen et al., 2009; Wang et al., 2010; Xu et al., 2010; Daverey et al., 2012; Anjali and Sabumon, 2015; Wang et al., 2016). The SNAD process works in an oxygen limited environment through the coordinated actions of ammonia oxidizing bacteria (AOB), anaerobic ammonia oxidizing bacteria (AnAOB), and heterotrophic denitrifying bacteria (HDB) as per Eqs. (1)e(3) (Koops et al., 1991; Strous et al., 1998; Sabumon, 2007). 1 þ NHþ 4 þ 1:5O2 !NO2 þH2 O þ 2H ; DG ¼ 275 kJ mol AOB (1) * Corresponding author. E-mail address: [email protected] (P.C. Sabumon). þ NHþ ! 1:02N2 4 þ 1:31NO2 þ 0:066HCO3 þ 0:13H þ 0:26NO3 þ 0:066CH2 O0:5 N0:15 þ 2:03H2 O; DG ¼ 357 kJ mol1 (2) HDB 2NO 3 þ 1:25CH3 COOH !N2 þ 2:5CO2 þ 1:5H2 O þ 2OH ; DG ¼ 946:16 kJ mol1 (3) By definition, the value of DG for a reaction measures the difference between the free energies of the reactants and the products when all components of the reaction are present in standard-state conditions (25 C and 1 atmospheric pressure). The negative values of DG indicate that all the reactions are feasible and spontaneous and can occur in any suitable eco-system. Also, the higher DG value in Eq. (3) as compared to that in Eq. (2) indicates that in the reduction of NO2-N and/or NO3-N to N2, HDB is more competitive compared to AnAOB. The competitive power of HDB can be regulated by limiting the supply of organic carbon (measured as COD). Therefore, it is imperative that during the growth of AnAOB and HDB together, the reactor and/or ecosystem should not have http://dx.doi.org/10.1016/j.ibiod.2016.10.047 0964-8305/© 2016 Elsevier Ltd. All rights reserved. Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 2 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 excessive organic carbon. The SNAD process works effectively when COD to NH4-N ratio is less than or equal to 1. The efficiency of the process decreases when the COD increases, especially in a suspended growth type reactor. When the COD increases, the growth of heterotrophs increases and causes an increase in washout of biomass from the reactor. This washout of biomass reduces the solids retention time (SRT) of AOB and AnAOB in the reactor. Since AOB and AnAOB are slow growing bacteria, minimum SRT of 12e15 days (Strous et al., 1998; Wang et al., 2010; Lan et al., 2011) is required for a sustainable process. This aspect makes SNAD process vulnerable to failures when conventional suspended growth systems are used because higher SRT can not be achieved. A comprehensive review of SNAD process using SBR configuration is given in Table 1. Other reactor configurations used for SNAD are reviewed by Anjali and Sabumon (2015). From the review, it is clear that SBR is a popular suspended growth type laboratory reactor used to retain the slow growing AOB and AnAOB. Even though SBR is a powerful reactor for developing SNAD, no attempt has been made earlier to develop SNAD in a nonaerated SBR. As mentioned earlier, SNAD can work in an oxygen limited environment by the harmonious existence of AOB, AnAOB and HDB. All the previous SBRs used for SNAD had external aeration to aid in partial nitrification and the process was developed in controlled conditions (Table 1). In developing countries, the cost and complexity involved in the process control of SNAD using SBR limit its application. Alternatively, provision of a shallow reactor with wastewater having both COD and NH4-N enables the diffusion of oxygen (air) from the head space. This creates low concentrations of dissolved oxygen (DO) conducive for SNAD to work when COD to NH4-N ratio is less than or equal to 1. The presence of COD and low concentrations of DO promote the growth of facultative organisms, including HDB and induces a stressed condition for the competitive growth of microbes. In this context, the limited DO for partial nitrification can be obtained in two ways: (i) by the diffusion of oxygen from the head space of the reactor and (ii) by the microbial production of oxygen through cleaving of H2O2 in the presence of catalase enzyme produced under stressed condition (Sabumon, 2007). Therefore, the objective of this study was to develop a nonaerated SBR capable of SNAD, which has not been reported earlier. In this study, an SBR was used for developing SNAD process using flocculent type activated sludge procured from a common effluent treatment plant (CETP) treating combined tannery effluents. The SBR was operated in a non-mixing condition in the absence of any process control for 161 days. The water temperature in SBR varied between 30 C and 36 C because of the summer season in Chennai, India. Biomass were drawn from the SBR at predetermined intervals to conduct separate batch studies: (i) to optimize the pH and the temperature of SNAD biomass, (ii) to estimate the kinetic parameters of ammonia removal and the maximum specific substrate utilization rates of SNAD biomass, and (iii) to confirm the involvement of anammox and denitrification in SNAD process. Results of this work are useful to promote the application of the SNAD process for the simultaneous removal of COD and NH4-N from wastewaters at ratios of COD to NH4-N less than or equal to one by means of shallow anoxic ponds/tanks/ditches. Such low-cost and maintenance-free treatment may be attractive to both developed and developing countries for treating wastewater containing low to moderate concentrations of NH4-N and COD. 2. Materials and methods 2.1. Mineral media and synthetic feed The mineral media and trace element composition used were same as reported by Sabumon (2007). Predetermined amount of NH4-N (3.82 g NH4Cl g1 NH4-N) and COD (0.78 g sucrose g1 COD) were added to the mineral media to make the synthetic feed having COD to NH4-N ratio equal to one. Analytical reagent (AR) grade chemicals supplied by ‘Thomas Baker’ (India) and clean glass wares (Borosil, India) were used in the study. 2.2. Seed biomass Twenty liters of flocculent type Mixed Liquor Suspended Solids (MLSS) was collected from the extended aeration process treating combined tannery effluent in a common effluent treatment plant (CETP) located in Ranipet (Vellore District, Tamil Nadu, India, www. ranitec.com) and brought to the laboratory. The initial characteristics of MLSS were: brown in appearance, pH (7.82), MLSS (5.67 g l1), Mixed Liquor Volatile Suspended Solids (MLVSS; 3.08 g l1), ratio of MLVSS/MLSS (0.54) and sludge volume index (SVI; 87 ml g1). The settled MLSS was washed several times using mineral media to remove higher concentrations of sulphides/sulphate and other toxic and refractory compounds present in the tannery effluent. The complex characteristics of tannery effluent are presented in Table 1 (supplementary information). Washing was carried out to avoid toxicity during the development of the process. Finally, 8 l of settled MLVSS was used as seed biomass. The seed biomass was selected based on the evidence of the earlier work by the authors, in which the same seed biomass was used in the development of enhanced SNAD process in a down-flow packed bed reactor (Anjali and Sabumon, 2015). 2.3. Development of SNAD process in a non-aerated SBR Development of SNAD process in a non-aerated SBR was done in a 20 l clean plastic cargo having a height of 300 mm. Initially, 8 l seed biomass (~23 g MLVSS) was added along with 10 l synthetic feed to have a working volume of 18 l. A water depth of 270 mm was maintained in the reactor, with 30 mm height as head space. The reactor was then closed and operated in an SBR mode, with a cycle time equal to 7 days under non-mixing condition. The cycle composed of negligible time (30 min) for feeding, settling and decanting compared to its reaction time (7 days). The reactor was manually mixed prior to 30 min of decanting operation and immediately after feeding. This mixing was carried out to get representative samples for analyses at the start and the end of each cycle. The SBR operation was continued for 23 cycles, extending over 161 days, by keeping the reactor in a dark room to avoid photosynthetic activity. Initial pH was set at 7 ± 0.02 using 1 M HCl in all cycles to minimize the escape of NH3-N to the head space. The initial NH4-N and COD in the reactor for all cycles were 250 ± 14.9 mg l1 and 250 ± 4.6 mg l1, respectively. The DO, oxidation-reduction potential (ORP) and the temperature in the SBR during the entire operation varied from 0.17 to 0.35 mg l1, 98 to 264 mV and 30 to 36 C, respectively. Low concentrations of DO (0.17e0.35 mg l1) in the reactor were maintained by the diffusion of DO from the head space and simultaneous consumption of DO by the microbial consortium. The temperature was not controlled in the reactor. The temperature in the SBR varied between 30 and 36 C. This variation in temperature was due to the summer season in Chennai, India, where the ambient temperature varied between 34 C and 43 C. Conducive ORP maintained for SNAD was due to the presence of COD and/or NH4-N in limited DO and lack of turbulence in the reactor. Representative samples were withdrawn at the start and the end of each cycle and were analyzed for pH, NH4N, NO2-N, NO3-N, and COD. Biomass (25 ml) was drawn at the start of the first cycle and the end of the 23rd cycle and then dried, powdered and stored in closed Eppendorf tubes for elemental Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 Type of reactor 1. NLR ¼ 0.961; OLR as BOD ¼ 0.362; HRT ¼ 0.5; DO ~ 1 to 1.5 (Periodic air supply); Temperature ¼ 30 C; pH ¼ 7.6 to 7.8; Uniform mixing SBR Landfill leachate at COD/NH4- NH4-N ¼ 295 to 700; NLR ¼ 0.118 to 0.28; OLR ¼ 0.1 to 0.2; N ¼ 0.55 to 0.85 COD ¼ 250 to 500 HRT ¼ 2.5; Cycle time 24 h; DO ~ 0.1; Temperature ¼ 35 C; Uniform mixing Labscale SBR reactor Synthetic wastewater at COD/ NH4-N ¼ 200; NLR ¼ 0.0667; OLR ¼ 0.011; HRT ¼ 3 to NH4-N ¼ 0.5 COD ¼ 100 9; DO ~ 0.5 to 1; Temperature ¼ 35 C; pH ¼ 7 to 8; Uniform mixing Labscale sequencing batch Swine digestor liquor at NLR ¼ 0.2 to 0.26; OLR ¼ 0.16 to 0.32; NH4-N ¼ 418; biofilm reactor (SBBR) COD/NH4-N ¼ 0.64 to 1.24 COD ¼ 437 HRT ¼ 1; DO ~ 0.2 to 2; Temperature ¼ 30 C; Labscale SBR Opto electronic industrial NH4-N ¼ 567; NLR ¼ 0.016 to 0.23; OLR ¼ 0.004 to wastewater at COD/NH4COD ¼ 100 0.04; Cycle time ¼ 24 h; HRT ¼ 2.5 to 5; DO ~ 0.1 to 5; Temperature ¼ 25 C N ¼ 0.18 e37 C; pH ¼ 7.8 to 8; Continuous mixing at 125 rpm Labscale SBR Anaerobic digested liquor of NH4-N ¼ 519; NLR ¼ 0.045 to 0.153; OLR ¼ 0.026 to swine wastewater at COD ¼ 288 0.236; HRT ¼ 2.5 to 5; d; Cycle time COD/NH4-N ¼ 0.75 24 h; DO ~ 0.5; Temperature ¼ 15 C e30 C; pH ¼ 7 to 8; Continuous mixing at 100 rpm Lab scale SBBR Synthetic wastewater at COD/ NH4-N ¼ 200 to 600; NLR ¼ 0.36; OLR ¼ 0.18; HRT ¼ 1.67; NH4-N ratio of 0.5 COD ¼ 100 to 300 Cycle time 24 h; DO ¼ 0.1 to 0.5; Temperature ¼ 25 C; pH 7 to 8; Continuous mixing at 150 rpm Lab scale SBR Synthetic wastewater at COD/ NH4-N ¼ 250; NLR ¼ 0.04; OLR ¼ 0.04; HRT ¼ 10.5; NH4-N ¼ 1 COD ¼ 250 Cycle time ¼ 7 d; DO ¼ 0.17 to 0.35 (No external supply of air); Temperature ¼ 30e36 C; pH ¼ 6 to 7.35; No mixing 2. 3. 4. 5. Biomass from aerobic activated sludge treating landfill leachate and biofilm from anammoxASBBR reactor Biomass from a full-scale landfill-leachate treatment plant Biomass from aeration tank of full scale landfill leachate treatment plant Autotrophic culture successfully enriched for CANON process Biomass from full scale landfill leachate treatment 6. Biomass from landfill leachate treatment system 7. Biomass was collected from a full-scale landfill leachate treatment plant 8. Biomass from aeration tank of CETP treating tannery effluent Labscale SBR reactor for treating landfill leachate Type of wastewater Influent parameter (mg l1) Loading Rate (g l1 d1); HRT (d); DO (mg l1); Temperature ( C); pH; Type of mixing Sl. No. Type of seed sludge Synthetic wastewater at COD/ NH4-N ¼ 1451; NH4-N ¼ 0.4 and raw landfill BOD ¼ 548 leachate % removal at Nature of sludge in References steady state the reactor NH4-N ¼ 97 Suspended growth TN ¼ 93 BOD ¼ 99 Xu et al., 2010 NH4-N ¼ 82 TN ¼ 78.2 COD ¼ 45 NH4-N ¼ 96 TN ¼ 50.7 COD ¼ 87 NH4-N ¼ 50 TN ¼ 48 COD ¼ 87 NH4-N ¼ 95 TN ¼ 93 COD ¼ 79 Suspended growth Wang et al., 2011 Suspended growth Lan et al., 2011 Attached growth Zhang et al., 2012 Suspended growth Daverey et al., 2012 NH4-N ¼ 96 Suspended growth TN ¼ 80 COD ¼ 76 Daverey et al., 2013 NH4-N ¼ 90 Mainly attached growth and slight TN ¼ 88 suspended growth COD ¼ 90 Daverey et al., 2015 NH4-N ¼ 94 Flocculant sludge in Present work COD ¼ 92 settled condition TN ¼ 82 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 Table 1 Comparison in performance of wastewater treatment using SNAD process in SBR. NLR: Nitrogen Loading Rate; OLR: Organic Loading Rate; TN: Total Nitrogen; HRT: Hydraulic Retention Time; CETP: Common Effluent Treatment Plant. 3 4 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 carbon analysis. Elemental carbon analysis was carried out as an indirect measure of biomass lysis during the operation. Additional biomass was also drawn from the SBR for conducting batch studies as described below. However, after completing the batch studies, biomass was put back into the SBR. 2.3.1. Optimization of pH and temperature Biomass was drawn on day 98 (end of 14th cycle) from SBR after thorough mixing and kept for settling for 15 min. The settled biomass (15 ml each) was added to six sets (in duplicates) of 50 ml Erlenmeyer flasks. Then, 20 ml synthetic feed having 250 mg l1 each of NH4-N and COD was added to every flask. The volume of biomass and synthetic feed were chosen to have approximately the same Food to Microorganism (F/M) ratio of SBR. The initial pH was adjusted to 4, 5, 6, 7, 8 and 9 (using 0.1 M HCl and 0.1 M NaOH) in each of the sets. The Erlenmeyer flasks were tightly plugged with cotton for a restricted entry of air during incubation. Batch reactors were incubated for 7 days at 32 ± 0.2 C in an orbital shaking incubator (CIS25 BL, Remi Instruments, India) at 120 ± 2 rpm. The temperature was chosen based on the average liquid temperatures observed in SBR until the 14th cycle of operation. Mixing was carried out to have optimal contact between the biomass and the substrates unlike in SBR. Analyses of pH, ORP, NH4-N, NO2-N, NO3N, and COD were done during the start and the end of the study. Temperature studies were conducted in a similar way as in pH studies except for the following changes: (i) adjustment of initial reactor pH to optimum pH (7 ± 0.02) and (ii) the incubation done at varying temperatures of 10, 20, 25, 30, 35 and 40 C using other incubators available in the laboratory (LT-orbitek, Scigenics Biotech, India). 2.3.2. Kinetics of ammonia removal and substrates utilization rates of SNAD biomass Biomass was drawn on day 150 (during the 21st cycle) from SBR after thorough mixing and kept for settling for 15 min. The settled biomass (15 ml each) was added to six sets (in duplicates) of 50 ml capacity Erlenmeyer flasks. Then, synthetic feed (20 ml) having 250 mg l1 each of NH4-N and COD was added to every flask. The initial pH was adjusted to optimum pH (7 ± 0.02) and the Erlenmeyer flasks were tightly plugged with cotton. The reactors were incubated for 7 days at optimum temperature (35 ± 0.2 C) in an orbital shaking incubator (LT orbitek, Scigenics Biotech, India) at 120 ± 2 rpm. Analyses of pH, ORP, NH4-N, NO2-N, NO3-N, COD, MLSS, and MLVSS were carried out on 0th, 1st, 2nd, 3rd, 5th, and the 7th day from each duplicate, respectively. Also, the biomass samples drawn from SBR and/or Erlenmeyer flasks were subjected to catalase tests as per the reported procedure (Sabumon, 2007). For a catalase test, a colony of bacteria was picked up from the enriched microbial culture and transferred to a clean microscope glass slide containing a drop of water. A few drops of 3% H2O2 were added to the culture and the bubble generation was observed for 20 s. If bubbles appear within 20 s, the organism shows positive catalase activity. A blank in similar conditions without bacterial cells was also tested. 2.3.3. Confirmation of anammox and denitrification Biomass was collected (after thorough mixing) after completing the 23rd cycle on day 161 to determine MLVSS at the end of the operation. Also, biomass was tested separately in batch studies to confirm the involvement of anammox and denitrification processes. For this, 15 ml each of settled biomass was added to six serum bottles of 70 ml capacity. The mineral media containing NH4-N (60 ± 5.6 mg l1) and NO2N (79.2 ± 11.29 mg l1) according to the anammox stoichiometry (Strous et al., 1998) was purged with nitrogen and was added to three serum bottles (in triplicates containing 15 ml biomass each) to its full capacity. Few drops of resazurin indicator were added to all the serum bottles. All serum bottles were purged again with nitrogen for 2 min and sealed using rubber septums and aluminium crimp caps to ensure anoxic condition. The study was conducted in an SBR mode for three cycles with cycle time equal to 7 days, settling time equal to 10 min and negligible time for decanting and filling operation. Confirmation of denitrification process was conducted in the remaining three serum bottles (in triplicates) containing 15 ml of biomass each. The nitrogen purged mineral media was supplemented with COD (564 ± 32 mg l1) and NO2-N (150 ± 2.52 mg l1) in the ratio of 3.76 (COD to NO2-N) as substrates. NH4-N (50 ± 1.42 mg l1) was also added in the mineral media as a nitrogen source for cell synthesis. This mineral media were added to the full capacity of the three serum bottles and were tightly closed with rubber septums and aluminium crimp caps. SBR operation was carried out for three cycles, with a cycle time of 2 days and negligible time for decanting, filling and 30 min for settling. In both studies, incubation was carried out at 120 ± 2 rpm in a temperature controlled (32 ± 0.2 C) orbital shaker (LT orbitek, Scigenics, Biotech, India). Analyses for pH, ORP, DO, NH4-N, NO2-N, NO3-N, and COD were carried out at the end of each cycle. 2.4. Analytical techniques All the physicochemical analyses were conducted as per Standard Methods (APHA, 1998). The DO and the pH were measured using DO meter (YSI 55 model, USA) and pH meter (SenTix 42, WTW inoLab pH 720, Germany), respectively. The ORP was measured using double junction platinum ORP electrode connected to a calibrated WTW inoLab pH (720) meter in mV mode. ORP electrode (Pt-Ag/AgCl) was calibrated using RH 28 supplied by WTW, Germany. Ion Chromatography (Basic IC plus 883, Metrohm) was used for the analyses of aqueous nitrogen species with conductivity detector and the results were processed using integrated magic net software. NH4-N was analyzed using cationic column (Metrosep C4-150/4.0) and cationic mobile phase consisting of 1.7 mM nitric acid and 0.7 mM diplocolinic acid with organic carbon suppressor (acetonitrile; 100 ml l1). NO2-N and NO3-N were analyzed using anionic column (Metrosep A Supp5-250/4.0) and anionic mobile phase consisting of Na2CO3 (0.3487 g l1) and NaHCO3 (0.084 g l1) along with organic carbon suppressor (acetonitrile; 100 ml l1). COD analysis was carried out by the closed reflux method using COD digester (WTW-CR 3200, Germany). Elemental carbon analysis of dried biomass samples was carried out using Perkin-Elmer 2400 series CHNS/O analyzer. 2.5. Calculations The removals of NH4-N, COD and total nitrogen (TN) were calculated using the following equation: % removal ¼ . o n Ci 100 Ci Cf (4) Where, Ci is the concentration of NH4-N (or COD, TN) in the reactor after the instant fill phase; and Cf is the concentration of NH4-N (or COD, TN) in the effluent after 7 days; TN is the sum of the aqueous concentrations of NH4-N, NO2-N and NO3-N. The conversion ratio Y(NO2-NþNO3-N)/NH4-N used in evaluating the performance of SNAD was calculated using the Eq. (5). Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 5 Fig. 1. Performance history during development of SNAD in a non-aerated SBR [(a): Average removal of NH4-N, COD, TN and ratio of COD to NH4-N (removed); (b) NO2-N profile in SBR; (c) NO3-N profile; (d) pH profile and ratio of COD removed to input NH4-N; (e) Ratio of accumulation of NO2-N and NO3-N to NH4-N consumed]. Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 6 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 YðNO2 N þ NO3 NÞ fEffluent ðNO2 N þ NO3 NÞe Initial ðNO2 N þ NO3 NÞg ¼ NH4 N ðInitial NH4 N e Effluent NH4 NÞ 3. Results and discussion 3.1. Development of SNAD process The results obtained during the development of the SNAD process are shown in Fig. 1 (a, b, c, d and e). Fig. 1 (a) shows the average removal of NH4-N, COD, TN and ratio of COD to NH4-N (removed) in the SBR. Fig. 1 (b) and 1 (c) show the NO2-N and NO3N profiles in SBR. Fig. 1 (d) shows the pH profile and the ratio of COD removed to input NH4-N. Fig. 1 (e) shows the ratio of accumulation of NO2-N and NO3-N to NH4-N consumed. The results of the development of SNAD process are discussed in 3 parts. (i) Cycle 1 to cycle 5 The average removals of NH4-N, COD and TN during the first two cycles were 38%, 70% and 35%, respectively (Fig. 1 (a)). This shows the capability of the seed biomass for simultaneous removal of NH4-N and COD in limited DO (0.17e0.35 mg l1) conditions. The higher COD removal during first two cycles could be due to the action of facultative heterotrophs present in the seed sludge. In the 3rd cycle, the effluent NH4-N was 314 mg l1 which was 26% more than the initial NH4-N. The COD removal was also less, compared to the earlier cycles. This could be due to the death and intense cell lysis of non-adaptive microorganisms when subjected to low concentrations of the DO compared to the high DO available to them in the extended aeration process in CETP. This intense cell lysis was evident from the settled volume (after 30 min settling time) of biomass, which was reduced to 6 l from an initial volume of 8.5 l. Another reason for the less removal of NH4-N up to 5th cycle was due to the drop in pH (Fig. 1 (d)) in the range between 6.1 and 6.8. This is due to the enhanced fermentation of lysed cell components in low concentrations of DO by facultative anaerobes present in the mixed culture. Xu et al. (2010) observed similar effect of cell lysis while developing a SNAD process for treating landfill leachate in SBR using an inoculum consisting of aerobic activated sludge and anammox bacteria. Tyagi and Lo (2013) reported that the lysate of activated sludge contains 50e55% carbon and 10e15% nitrogen. Hence, cell lysis can result in the addition of COD and NH4-N and thereby affect the removals of COD and NH4-N, when calculated with respect to initial concentrations. Further, the cell lysis leads to fermentation and fermentation leads to the formation of organic acids, which in turn dissociate and reduce the pH. Several previous studies have reported that nitrification rate reduces when pH is below 7 because of inorganic carbon limitations caused by stripping of CO2 (Wett and Rauch, 2002; Guisasola et al., 2007). The profiles of NO2-N (Fig. 1 (b)) and NO3-N (Fig. 1 (c)) up to 5th cycle, show the evidence of nitritation and/or nitrification. The low DO (<0.5 mg l1) was suitable for partial nitrification as nitrite oxidizing bacteria (NOB) could be washed out under oxygenlimited condition. Formation of NO3-N in the initial cycles might be due to the oxidation of NO2-N by the NOB present in the seed biomass. However, the survival of NOB was difficult in low DO and in high temperature and correspondingly there was a decrease in the formation of NO3-N when the cycle progressed (Fig. 1 (c)). V azquez-Padín et al. (2009) reported that NOB has a lower (5) oxygen affinity than AOB and oxygen-limited condition (DO < 0.5 mg l1) inhibits NOB. In another study, Guisasola et al. (2005) reported that the oxygen saturation constant of AOB is 0.25e0.5 mg l1 and NOB is 0.72e1.84 mg l1, hence at low concentrations of DO, there would be a higher accumulation of NO2-N. Hellinga et al. (1998) reported that the maximum specific growth rate of AOB is higher than that of NOB at a temperature above 30 C. Hence, in low DO and in the high temperature maintained in the SBR, the activity of NOB would be more distinctly affected than that of AOB. The limited DO (<0.5 mg l1) in the SBR could easily create anaerobic zones within the flocculent biomass. For example, Chen et al. (2008) accomplished the simultaneous nitrification and denitrification in a continuously-aerated pilot scale submerged membrane reactors (SMBRs) by controlling ambient DO concentration between 0.6 and 1.2 mg l1. This oxygen diffusion limitation resulted in the formation of an anoxic micro-zone inside the biological flocs, where the denitrification occurred. In this work, the anaerobic zone formed could enhance the growth of HDB and AnAOB and creates a chance for the competition in the reduction of NO2-N produced by AOB. Since HDB are thermodynamically competitive compared to AnAOB as per Eqs. (2) and (3), the growth rate of HDB would be higher. However, at a ratio of COD to NH4-N equal to one, enough organic carbon will not be available for the HDB to overpower the AnAOB. This is because according to Bernat et al. (2008), a minimum of 3.5e4 g COD g1 N is necessary for denitrification after nitritation. Therefore, in conditions of effective nitritation in limited DO and at COD to NH4-N ratio less than or equal to 1, the anoxic zone could provide a winewin situation for both HDB and AnAOB in the reduction of NO2-N. During the initial 5 cycles, the TN removal might have occurred mainly through denitrification in low pH as per Eq. (3) because of higher COD available by cell lysis. The ratio of COD to NH4-N (removed) during the initial cycles was greater than 1 indicating the action of HDB to be dominant in the reduction of NO2-N (Fig. 1 (a)). Fig. 1 (e) also supports intense cell lysis during the cycles 2 and 3 and availability of more COD. Huang et al. (2011) reported a moderate rate of denitrification in the pH range 4.8e6.2 in the presence of acetic acid as the carbon source. Acetic acid can be formed as a result of fermentation. Therefore, the cell lysis and fermentation during the initial 5 cycles helped in getting the total nitrogen removal mainly by HDB. Tang et al. (2013) reported that the organics released from cell lysis could be used as the electron donors for nitrite reduction (denitrification). However, the rate would be controlled based on nitrite concentration in the influent. (ii) Cycle 6 to cycle 15 The average removals of NH4-N, COD and TN during 6th to 15th cycle were 79%, 67% and 71%, respectively, which indicate acclimatization of SNAD biomass (Fig. 1 (a)). After acclimatization, the formation of NO2-N (Fig. 1 (b)) was more compared to NO3-N (Fig. 1 (c)) indicating effective nitritation in low DO. This nitritation could have occurred as a result of Eqs. (1) and (6). In the stressed conditions, facultative bacteria produce H2O2 as a result of complex metabolism. The H2O2 formation is possible in the presence of trace Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 amount of oxygen (oxidative stress) by the use of oxidative enzymes of facultative organisms. The production of H2O2 takes place when facultative anaerobes use the aerobic respiratory pathway during degradation of substrates for energy production. This H2O2 is a highly reactive oxygen species formed as a direct byproduct of oxygen reduction (Fu et al., 2015). The bacterial cells protect themselves from the attack of H2O2 by producing the catalase enzyme which cleaves the H2O2 and produces oxygen as per Eq. (6). The oxygen produced could be used for nitritation as per Eq. (1). The contribution of nitritation/nitrification by diffused DO and by catalase enzyme route was not quantified in the present study because of the complexity in performing such experiments. However, the presence of the catalase enzyme in the SNAD biomass was confirmed by qualitative tests (Sabumon, 2007) performed as per the procedure described in Section 2.3.2. More detailed research is required for the quantification of H2O2 along with the bacterial growth in the SBR to evaluate the proportion of nitritation by Eq (6). Catalase 2H2 O2 ! 2H2 þO2 (6) During nitritation/nitrification, the formed NO2-N/NO3-N was converted to nitrogen gas by anammox as per Eq. (2) and denitrification as per Eq. (3). The analysis of the results showed that the ratio of COD to NH4-N (removed) (Fig. 1 (a)) varied from 0.62 to 1.15 from 6th cycle to 15th cycle. This ratio indicates that COD was insufficient for entire nitrogen removal by heterotrophic denitrification using externally added sucrose. On the other hand, not much NO2-N/NO3-N was accumulated corresponding to the amount of NH4-N removed, indicating effective denitrification. This denitrification could have occurred either in the presence of organic acids (produced as a result of fermentation of cell components) acting as electron donors or through anoxic ammonia oxidation by anammox where NO2-N/NO3-N acted as electron acceptors. During cycle 6 to cycle 15, the average removal of COD was 67%, which was less and not in concurrence with 71% of TN removed. For example, for removing 71% TN by denitrification, the required COD is around 621 mg l1 by considering the requirement of 3.5 g COD g1 N. But synthetic feed contained an average COD of 250 mg l1 equivalent to the removal of around 29% TN only. From this, it is clear that balance nitrogen removal must have occurred via denitrification using the organic carbon in the cell lysate and/or anammox. An estimate of anammox as per Eq. (2) during this period based on maximum NO3-N (3.4 mg l1) formed shows that the TN removal by anammox was 5%. Therefore, around 37% of TN removal was through denitrification using the COD available through cell lysis. The presence of residual NO2-N and NO3-N in the reactor after 7 days indicates that the residual COD available in the reactor (64e120 mg l1) was not readily biodegradable and might have contained difficult to degrade residual cell components of lysate. The pH in the reactor during this period increased from 6.7 to 7.3 (Fig. 1 (d)). Such an increase in pH is possible as a result of effective denitrification as per Eq. (7) (Hellinga et al., 1999). Eq. (3) shows that as a result of denitrification alkalinity is created, which acts as a buffer against the reduction of alkalinity by the nitritation as per Eq. (1). The alkalinity added in the synthetic feed was around 527 mg l1 as HCO 3 which was lesser than the required alkalinity for nitrification. For example, the alkalinity required for 79% of NH4N removal is around 830 mg l1 as HCO 3 . This shows that as a result of SNAD process, the external requirement of alkalinity could be reduced. þ 2NO 2 þ 6H þ 6e /N2 þ 2OH þ 2H2 O (7) Fig. 1 (e) shows the values of conversion ratio Y(NO2-Nþ NO3-N)/ i.e., the ratio of accumulation of NO2-N and NO3-N to NH4-N (NH4-N), 7 consumed in each cycle. For an efficient SNAD process, this conversion ratio should be less than 0.11 because the accumulated NO2-N and NO3-N would be consumed by HDR while removing COD (Daverey et al., 2015). The reason for Y(NO2-Nþ NO3-N/NH4-N) greater than 0.11 during the few cycles in the initial operation of SBR could be due to extra NO2-N formed as a result of oxidation of additional NH4-N produced by cell lysis. From the results, it is clear that SNAD biomass was acclimatized; though anammox process got hindered due to cell lysis. (iii) Cycle 16 to cycle 23 Results from 16th to 23rd cycle (Fig. 1 (a)) showed good average removals of NH4-N (92%), COD (81%) and TN (83%). Such high TN removal is not possible by denitrification alone. For example, to get 81% of COD removal by denitrification alone (considering 3.5 g COD g1 N), the NO2-N and/or NO3-N reduction could have been 58 mg l1 which corresponds to only 23% of TN removal. Therefore, there is a discrepancy of 60% in TN removal. There could be a contribution by heterotrophic denitrification using the organic carbon available through cell lysis of non-adaptive bacteria as described above. But, this contribution of denitrification promoted by cell lysis would decrease as the cycle progresses and in long time operation, this contribution becomes insignificant. Therefore, during the last cycles of the SNAD process, the enhanced removals of NH4-N and TN could have occurred via anammox reaction. This was evident from the increase of the average concentration of NO3-N (5.6 mg l1) as compared to that during earlier phases (from 6 to 14 cycles; 1 mg l1). Also, the DO inside the reactor was very low and this would have reduced the growth of NOB as they need high DO (greater than 1 mg l1) for oxidizing NO2-N to NO3-N. Hence, the increased NO3-N accumulation during later cycles might have occurred mainly via anammox as per Eq. (2). There was an increase of pH in the last cycles, compared to that in the earlier cycles and that shows clear indications of effective anammox and denitrification processes as per Eqs. (2) and (3). Also, the residual COD in the last 3 cycles, was lesser than 32 mg l1 which indicates low degree of cell lysis. The Y(NO2-Nþ NO3-N)/(NH4-N) values in the last cycle as well indicate an effective SNAD process. Altogether, the results show that the development of the SNAD process is possible in a non-aerated SBR using synthetic feed at COD to NH4-N ratio equal to one and using flocculent activated sludge from a tannery CETP as seed biomass. The increase in the removals of COD during the later cycles shows that as the cycle progressed, the extent of cell lysis decreased. This is evident from the improvement of the ratio of COD removed to input NH4-N (Fig. 1 (d)) when cycles progressed as a result of less availability of nonbiodegradable cell lysate. Therefore, during the last 3 cycles, the ratio of COD to NH4-N (removed) was closer to one which indicates the maximum utilization of sucrose (COD) and minimum cell lysis (Fig. 1 (a)). Therefore, the average data of the last 3 cycles were used for calculating the mass balance of nitrogen (N) in the SBR per cycle as per Eq. (8). The total mass of N fed to SBR ¼ The total mass of N escaped with the effluent from the SBR þ Total mass of N removed from the SBR during a cycle (8) It is to be noted that the analyses of the gas phase in SBR were not carried out. The assumptions considered while calculating the mass balance were: (i) the NH4-N loss due to volatilization was negligible as the final pH was 7.37 ± 0.07, (ii) the pH and molar concentrations of phosphorous and magnesium were not Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 8 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 conducive for magnesium ammonium phosphate (struvite) precipitation in SBR, and (iii) the nitrogen used for cell growth was balanced with the nitrogen generated by cell lysis. The above-listed assumptions simplified the solution of Eq. (8). Therefore, the total average mass of N removed from the SBR during a cycle is equal to the difference in the total average mass of N fed to SBR and escaped with the effluent from the SBR. The total average mass of N fed to SBR was 4.670 g (4.510 g NH4-N þ 0.146 g NO2-N þ 0.014 g NO3-N) whereas the total average mass of N escaped with the effluent from the SBR was 0.839 g (0.276 g NH4-N þ 0.448 g NO2-N þ 0.115 g NO3N). Therefore the difference of 3.831 g N (4.670e0.839) could have escaped as forms of nitrogen into the gas phase and considered as the total nitrogen removed from the reactor. Therefore, the best average removals of NH4-N and TN were approximately 94% and 82%, respectively. The average COD removal during the last 3 cycles was 92%. Throughout the enrichment studies, there was a decrease in volume of settled sludge as the cycle progressed. The maximum reduction in sludge volume was observed from cycle 1 to cycle 15 and sludge volume was 5.5 l at the end of cycle 15. Moreover, at the end of the study, the total biomass inventory in the reactor was 11.79 g MLVSS. This shows that the final active SNAD biomass were only 51.3% compared to the initial flocculent seed biomass (23 g MLVSS). The reason for such a reduction in sludge quantity could be due to the higher values of the average hydraulic retention time (HRT) 10.5 d and SRT, which might have induced cell lysis by endogenous respiration. The SRT in SBR was very high because (i) no biomass was wasted during the entire operation, and (ii) there was a negligible escape of Suspended Solids (SS) during decanting operation. Such high SRT was the reason for effective removal of NH4-N, COD and TN by the coordinated actions of AOB, AnAOB and HDB. The cell lysis was confirmed by the elemental carbon analysis of biomass done before and after enrichment of biomass for SNAD process. The carbon content decreased by 53.3% indicating cell lysis during enrichment and development of SNAD biomass. A similar result of the reduction in carbon content was reported during enrichment study of anaerobic ammonia removal using SBR (Sabumon, 2007). Table 1 shows the comparison of performance of other SNAD processes in SBR to the present work. The removals of NH4-N and TN at steady state in the present study were comparable with the SNAD process developed for swine wastewater treatment at COD to NH4-N ratio equal to 0.75 (Daverey et al., 2015). The nitrogen loading rate (NLR) and organic loading rate (OLR) of their work are comparable with those in the present work. The less removal of COD (76%) compared to the high removal of COD (92%) obtained in the present work is because of the presence of non-biodegradable COD in the anaerobic digested liquor of swine wastewater. The present work required an average HRT of 10.5 d compared to 2.5 d HRT of their work. The requirement of longer HRT in the present work is due to the non mixing condition in contrary to the continuous mixing at 100 rpm in their work. This indicates that the non-aerated SBR requires a larger volume for the treatment, whereas no energy is required for aeration and mixing. Another important observation was that, when COD to NH4-N ratio was greater than or equal to 0.5, the suspended growth based SBR could not operate at NLR and OLR greater than 0.3 g l1 d1. In such cases, for attaining higher NLR and OLR using SNAD process, other reactor configurations are to be used (Anjali and Sabumon, 2015). In short, the results of this study demonstrate that the development of SNAD is feasible in a non-aerated shallow SBR using flocculent activated sludge as seed; when wastewater is treated at very low NLR and OLR. However, the SBR requires a minimum of 10 d HRT to achieve around 90% removals of NH4-N and COD without any sludge removal. 3.1.1. Optimization of pH and temperature The plots with average values are shown in Fig. 2. The results of optimization of pH are shown in Fig. 2 ((a) and (b)). The ORP profile and the final pH profile with respect to initial pH are shown in Fig. 2 (a). The initial and the final ORP were in the range of 42.7 to 283.9 mV and 20.5e51.8 mV, respectively. There was a decrease of ORP as the pH increased. The ORP values indicate that the reactors were maintained in limited DO. The highest percentage removals of NH4-N (97%), COD (88.3%) and TN (82.2%) were obtained at pH 7 (Fig. 2 (b)). Also at pH 7, the final ORP was 20.5 mV indicating the anoxic condition for effective anammox and denitrification. There was a good overall removal at pH 8 too. Therefore, the optimal pH of the developed SNAD process could be considered between 7 and 8. Many researchers (Lan et al., 2011; Daverey et al., 2013, 2015) also reported higher COD and nitrogen removal efficiencies at the same pH range for SNAD process. The higher performance in this batch study compared to the performance in the 14th cycle of SBR (biomass drawn during this cycle) could be due to Fig. 2. Optimization of pH and temperature of SNAD biomass [Fig. 2 (a and b): Results of optimization of pH studies: (a) ORP and pH profile; (b) Average removals of NH4-N, COD and TN; Fig. 2 (c and d): Results of optimization of Temperature studies: (a) ORP and pH profile; (b) Average removals of NH4-N, COD and TN]. Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 the mixing provided and thereby increasing optimal contact between substrates and flocculent biomass. The removal efficiencies at pH 4 and pH 5 showed a negative removal of NH4-N and a positive removal of COD. The negative removal of NH4-N could be due to cell lysis at acidic pH in anoxic condition. The positive removal of COD could be due to fermentation and the action of other facultative heterotrophs on the oxidation of organic matter. This is evident from the increase of final pH. There are other reports of moderate rates of denitrification at the pH range between 4.8 and 6.2 in the presence of acetic acid as the carbon source and denitrification at pH 4 by a soil derived rhodanobacter dominated community (van den Heuvel et al., 2010; Huang et al., 2011). The removal of NH4-N at pH 9 was 80%. This removal is not considered optimum as the actual percentage of NH4-N oxidized by AOB could be very less due to free ammonia (FA) toxicity towards AOB at high pH as per Eq. (9) (Xue et al., 2009). The FA was calculated as 148.5 mg l1 as NH3-N at a temperature of 32 C and this concentration inhibits AOB (Jenson et al., 2008). The increase in the percentage removal of NH4-N was due to the escape of more than 50% of NH4-N as free ammonia (FA) by volatilization at pH 9 and at temperature 32 C. FA mgl1 ¼ 17=14 n total ammonia as nitrogen mgl1 10pH . . o e 6344 ð273 þ T CÞ þ 10pH (9) The results of optimization of temperature studies are given in Fig. 2 ((c) and (d)). The final pH and the ORP profiles are shown in Fig. 2 (c). The final ORP (4 mV to 104 mV) indicates anoxic condition suitable for SNAD. Maximum percentage removals of NH4-N (98%), COD (90%) and TN (85%) were obtained at temperature 35 C (Fig. 2 (d)). Daverey et al. (2013) observed very low TN (<50%) and COD removal (<20%) efficiencies when the operating temperature of SNAD was between 15 C and 20 C. But, when the 9 average temperature raised above 27 C the average values of NH4N, TN and COD removal efficiencies were 93%, 79% and 77%, respectively. Several researchers have reported that the optimum temperature for AOB, anammox and denitrifiers is approximately 35 C (Strous et al., 1999; Lalucat et al., 2006; Kim et al., 2006; Gu et al., 2012). Even though the biomass can grow between 15 C and 30 C, their specific growth rate and activities are reported to be higher at higher temperatures. The maximum specific growth rate of NOB is higher than AOB at temperature below 25 C. While denitrifiers grown at 20 C exhibited 75-times lesser levels of cnorB gene expression compared to the same grown at 30 C. The sensitive anammox process is reported to work well within an optimum pH range of 6.7e8.5 and temperature range from 20 C to 35 C (Strous et al., 1998; Reginatto et al., 2005). Based on the overall performance in this study, the optimum range of temperature for simultaneous removal of NH4-N and COD is from 25 C to 35 C. The final pH varied from 7.14 to 7.20 in the optimal range of temperature indicating coexistence of anammox and denitrifiers as there is an increase in final pH from initial pH (Anjali and Sabumon, 2014). Optimization studies showed that the developed microbial culture can perform SNAD very effectively between pH 7 and pH 8 and temperatures between 25 C and 35 C. Also, the observed results indicate that the process is workable between pH 6 and pH 8 and temperatures between 20 C and 35 C. The ability to work in such a wide range of temperature and pH is advantageous when the process is employed in the field. 3.1.2. Kinetics of ammonia removal and substrates utilization rates of SNAD biomass Kinetic studies were conducted using enriched SNAD biomass at 35 C temperature and at pH 7 and the data is shown in Fig. 3. Kinetics of ammonia removal in the SNAD biomass was studied by monitoring removals of NH4-N with time and these studies confirmed the presence of AOB too. However, it is not clear how much was the ammonia oxidation by autotrophs and heterotrophs as microbial identification was not attempted in this work. The results (Fig. 3 (a)) show that when the substrate concentration (NH4-N) was higher, the rate of reaction was higher. For example, Fig. 3. Kinetics of SNAD biomass {Maximum specific substrate utilization rates are shown in the plots} [(a): NH4-N, COD and MLVSS profile; (b) NO2-N, NO3-N and pH profile]. Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 10 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 the initial concentration of NH4-N (250 mg l1) reduced to 38 mg l1 in 2 days; indicating a second order reaction with a rate constant of 0.0167 l mg1 d1 (R2 ¼ 0.9735). Such a high rate of ammonia oxidation was possible because of simultaneous removal of the formed NO2-N by AnAOB or HDB as per Eqs. (2) and (3) (Fig. 3 (b)). This prevented NO2-N inhibition to AOB and AnAOB. Though HDB has thermodynamic advantage compared to AnAOB, their activity is limited at lower COD to N ratio in utilizing NO2-N. The COD removal was observed in a similar manner for the first two days and later there was no change in the removal of COD (final COD was 32 mgl-1) with time. From the data of COD removal, it is clear that AnAOB must have used some part of COD while oxidizing NH4-N. There are reports of AnAOB using organic carbon for oxidizing NH4-N by anammox process. Anammox species like Candidatus “Anammoxoglobus propionicus” and Candidatus “Brocadia fulgida” have been reported to have the capability of organotrophic nitrate reduction (Kartal et al., 2007; Winkler et al., 2012). Also, it has been observed in earlier studies that mixed culture dominant in anammox could enable anaerobic ammonia oxidation in the presence of externally added organic carbon and in the absence of oxidized forms of nitrogen (Anjali and Sabumon, 2014). In this study, the enhanced rate of removals of NH4-N and COD observed during the initial 2 days could be due to the combined action of AOB, AnAOB and HDB present in the enriched SNAD biomass. The evidence of anammox process was confirmed by the accumulation of NO3-N (11.7 mg l1) in 1 day as shown in Fig. 3 (b). As the NOB were inhibited in the enriched SNAD biomass, the chances of NO2-N conversion to NO3-N were negligible. Also, the concentration of COD (250 mg l1) was tolerable for the anammox species (AnAOB) to work. Jin et al. (2012) has reviewed various inhibitory levels of organic carbon for anammox and reported that the concentration of COD (as glucose) from 90 to 540 mg l1 does not inhibit AnAOB. The concentration of COD dropped from 250 to 32 mg l1 within two days after which there was lesser COD available for effective denitrification. The maximum specific substrate utilization rates of the enriched SNAD biomass were 185 mg NH4-N g1 MLVSS d1, 153 mg COD g1 MLVSS d1 and 172 mg N g1 MLVSS d1, respectively. These rates show that AOB, AnAOB and HDB work together in harmony at competitive rates for the simultaneous removal of COD and NH4-N. The COD to N ratio during maximum removal was 1.03, which shows that externally added COD was consumed completely within two days. However, this ratio was not good enough to have a dominating denitrification. Xu et al. (2010) reported that the maximum activities of AOB and AnAOB reached 0.79 and 0.18 (g NH4-N g1 MLVSS d1) after operating for 86 days in a process controlled completely mixed SBR maintained in DO 1e1.5 mg l1 (during the aeration phase). In their work, the feed COD to NH4-N ratio was 0.4 and the process was developed with a mixture of active seed biomass of anammox and activated sludge (80% w/w). The ammonia removal capacity of SNAD biomass in this work is comparable to the anammox culture in their work. Considering the simple SBR operation without using acclimatized seeding, the SNAD biomass performance attained in 5 months in this work is appreciable. Five days were taken to reduce NH4-N from 38 mg l1 to 6 mg l1 and the data followed first order reaction with reaction rate constant equal to 0.3376 d1 (R2 ¼ 0.9966). From 3rd to 7th day, ammonia removal might have occurred via anammox by first order reaction (Fig. 3 (a)) because of limitation of organic carbon for Fig. 4. (a) Confirmation of the anammox process using SNAD biomass {The final values of pH, DO, and ORP, respectively, is shown above the plots} [Top figure: Average removals of NH4-N, NO2-N, TN and Ratio of NO2-N to NH4-N (consumed); Bottom figure: Profile of NH4-N, NO2-N and TN] (b) Confirmation of the denitrification process using SNAD biomass {The final values of pH, DO, and ORP, respectively, is shown above the plots} [Top figure: Average removals of NH4-N, NO2-N and COD; Bottom figure: Profile of NH4-N, NO2-N and COD]. Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 11 Fig. 4. (continued). effective denitrification. The pH decreased during first two days (7.11e6.95) and then slowly increased to 7.2 by the 7th day. The ORP values were in the range of 50.2 mV to 46 mV. Suneethi and Joseph (2011) reported that the anammox process functions at an ORP range of 104 mV to 50 mV and therefore the positive values of ORP in the SNAD process did not inhibit the anammox process. Lackner and Horn (2012) found that anammox tolerated positive ORP up to 125 mV in a single stage nitritation-anammox SBR. 3.1.3. Confirmation of anammox and denitrification The enriched SNAD biomass was tested separately for confirmation of anammox and denitrification, respectively. The results of 3 cycles of SBR studies for confirmation of anammox process are shown in Fig. 4 (a). The average percentage removals of NH4-N, NO2-N and TN in first cycle were 66%, 99.9% and 74%, respectively. The average ratio of NO2-N to NH4-N removed was very high (2.11) compared to the reported stoichiometry ratio (1.32) of anammox (Strous et al., 1998). Similar results were reported by Ke et al. (2015) where NH4-N reduction and nitrite consumption were observed for 6 h to explain the anammox activity in the granular sludge. The ratio of NO2-N to NH4- N removed was 1.54, indicating that some nitrite was reduced not only by the anammox reaction but also by denitrification. Their work also proved that granular sludge was composed of AOB, AnAOB and HDB by direct molecular evidence. This shows that whenever HDB is involved, stoichiometry ratio (1.32) of anammox is not satisfied. Tang et al. (2010) also reported that the anammox stoichiometric ratio gets affected by denitrification. There was no residual NO2-N in cycle 1 in proportion to residual NH4-N. This denotes that NO2-N reduction could have happened by denitrification with stored carbon as the electron donor. There are reports of denitrification using internally stored carbon when externally added electron donor is unavailable (Third et al., 2003). Also, Monballiu et al. (2013) reported negligible accumulation of NO3-N when compared to the formation of NO3-N during anammox metabolism. The less accumulation of NO3-N was explained as the occurrence of denitrification using carbon from the lysis of the biomass. In this work the stored carbon might have been available with the SNAD biomass as the biomass was sourced from SBR working at 250 mg l1 COD. To re-confirm the presence of anammox in SNAD biomass, the SBR studies were continued for two more cycles. The results of the last two cycles showed average removals of NH4-N (76.2%), NO2-N (94.4%) and TN (77.3%). The average ratio of removal of NO2-N to NH4-N was 1.52 which became closer to the reported stoichiometry ratio (1.32) of anammox (Strous et al., 1998) as the cycle progressed. Moreover, the average ratio of NO3-N produced to NH4-N consumed was 0.28 which is closer to the reported stoichiometric ratio of anammox (0.26) as per Eq. (2). The presence of residual NO2-N indicates the reduced effect of heterotrophic denitrification. The final pH (7.15e7.22) for all cycles increased from initial pH (7.00 ± 0.02) indicating either anammox or denitrification as per Eqs. (2) and (3). A similar increase in pH trend was observed by Monballiu et al. (2013) in an anaerobic CSTR exhibiting stable and reliable anammox performance for more than 2 years of operation. The average influent pH was 7.8 ± 0.2 while effluent pH was 8.3 ± 0.1. The DO varied between 0.22 and 0.35 mg l1 which is within the tolerable range of anammox bacteria (Jenson et al., 2008). The negative values of ORP (20.8 to 106.3 mV) ensured anoxic condition for anammox by AnAOB. Confirmation of the denitrification process in the SNAD biomass Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 12 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 was done in three cycles and the results are shown in Fig. 4 (b). The average removals of NO2-N and COD were 86.1% and 84.1%, respectively, confirming the presence of denitrifiers (HDB) in the SNAD biomass. There was 12.5 ± 3% removal of ammonia in the first cycle, indicating anammox process in the biomass, but the removals got decreased as the cycles progressed and became negative in the last cycle. Therefore, the results of NH4-N removal indicate that the HDB overpowers AnAOB in the presence of COD especially at higher ratios of COD to NH4-N. When NO3-N concentrations are high, denitrifiers or other facultative species, under anoxic conditions, promote dissimilatory reduction of NO3-N to NH4-N known as dissimilatory nitrate reduction to ammonia, (DNRA) and release NO2-N as a free intermediate (Dalsgaard et al., 2005). The increase of NH4-N in the last cycle could be due to the dissimilatory nitrate reduction to NH4-N. The final values of pH, DO and ORP in all cycles show conducive environment for effective denitrification. 3.2. Prospects in industrial applications Discharge of nitrogen containing effluents from landfills, food processing and agricultural industries is a growing concern to the water environment because of the eutrophication on a global scale. Therefore, recent research has contributed for more effective methods of nitrogen abatement. Anammox has emerged as an effective method of nitrogen removal in full-scale plants (van der Star et al., 2007). However, when anammox is involved, industries are looking for a treatment system which involves easy start-up, less complex process control, lower investment costs, reduced risk in inhibition of AnAOB by nitrite at higher concentrations of NH4-N, and lastly less residual sludge treatment and disposal. To address these issues, SNAD is evolving as a practical method for simultaneous removal of NH4-N and COD, especially when the ratio of COD to NH4-N is less than or equal to 1. Contrary to the use of acclimatized seed biomass in earlier studies reported in Anjali and Sabumon (2015), the results of this study indicate that SNAD could be successfully developed using flocculent type activated sludge, which was employed for treating tannery effluents containing both COD and NH4-N. The scale-up of the reactor used in this study could be easily done in the field by means of shallow ponds/tanks/ditches (400 mm liquid depth) resulting in a very minimum energy footprint for simultaneous removal of NH4-N and COD. However, it is important to keep the reactor in anoxic condition (in limited DO) and devoid of sunlight to avoid photosynthetic activity. One of the limitations of the nonaerated SBR is that higher loading rates are not possible in nonmixing conditions. But, the batch study results indicate that higher removal rates are feasible if the SNAD biomass is maintained in mixing condition without settling and in low DO. In short, the application of non-aerated SBR, having a shallow depth enabling the diffusion of air and disabling photosynthetic activity can abate nitrogen pollution to a great extent from effluents having low to medium concentrations of COD and NH4-N. Application of non-aerated SBR by means of shallow ponds/ tanks/ditches is very much suitable for developing countries in Asia, Africa and Latin America. These countries have year-round warm climates and thereby support a good microbial activity which is very much essential to get a stable performance. Pond systems are generally employed in such countries due to the advantages such as: (i) they are easy to construct, (ii) require low capital and maintenance costs, (iii) effluent does not require disinfection (iv) capable of handling a variety of hydraulic loads, (v) ideal for small communities, (vi) completes sludge treatment, (vii) handles varying wastewater types (industrial or municipal), (viii) BOD, fecal coliform and helminth removal is higher than by other treatment methods such as activated sludge, biological filters, and rotational biological contactors (Butler et al., 2015). The ammonia removal from pond systems are reported (USEPA, 2011) by means of volatilization, deposition, adsorption, nitrification and denitrification. Such combined removals associated with varying process conditions do not give consistent removal. Also, the change in organic loading rates and seasonal variations often make the pond systems anaerobic. This anaerobic environment releases methane and hydrogen sulphide, which are not acceptable to the environment. For example, methane increases global warming potential while hydrogen sulphide creates odour problem. Due to these issues, the promotion of pond systems is discouraged. In contrast, the shallow anoxic ponds envisaged in this work may not create anaerobic conditions when COD to NH4-N ratio is less than or equal to 1. Therefore, effluent/wastewater having COD to NH4-N ratio less than or equal to 1 can be treated by employing SNAD process in shallow anoxic ponds/tanks/ditches and thereby ensuring biological conversion of NH4-N to N2 without compromising the listed advantages of pond system. 4. Conclusions Flocculent type activated sludge drawn from a tannery effluent treatment can be used as a seed biomass for developing SNAD process in a shallow non-aerated SBR using a synthetic feed composed of 250 mgl1 each of COD and NH4-N. The DO (0.35 mg l1) required for partial nitrification was obtained through (i) diffusion of air from the head space in the reactor, and (ii) cleaving of H2O2 by catalase enzyme produced in cells under stressed conditions. Simultaneous removals of NH4-N (94%), COD (92%) and TN (82%) was achieved by the SBR with a cycle time of 7 days. Maximum specific substrates utilization rates of SNAD biomass for NH4-N, COD, and TN were 185 mg NH4-N g1 MLVSS d1, 153 mg COD g1 MLVSS d1, and 172 mg N g1 MLVSS d1, respectively. SNAD works effectively between pH 7.2 and pH 7.5 and temperatures between 30 C and 36 C. This research showed that application of non-aerated SBR operation in shallow anoxic ponds/ditches/tanks could remove COD and NH4-N simultaneously when wastewater has a ratio of COD/NH4-N equal to one in low to moderate concentrations. Acknowledgements This work was supported by the Department of Science and Technology (DST), Government of India, through the Grant-in-aid project (DST/TM/WTI/2K11/275). The authors also want to appreciate the anonymous reviewers and the editor for their significant contribution to improve the manuscript. Appendix A. Supplementary data Supplementary data related to this article can be found at http:// dx.doi.org/10.1016/j.ibiod.2016.10.047. References Anjali, G., Sabumon, P.C., 2014. Unprecedented development of anammox in presence of organic carbon using seed biomass from a tannery common effluent treatment plant (CETP). Bioresour. Technol. 153, 30e38. http://dx.doi.org/10. 1016/j.biortech.2013.11.061.24333699. Anjali, G., Sabumon, P.C., 2015. Development of enhanced SNAD process in a downflow packed bed reactor for removal of higher concentrations of NH4-N and COD. J. Environ. Chem. Eng. 3, 1009e1017. http://dx.doi.org/10.1016/j.jece.2015. 02.022. APHA, AWWA, WPCF, 1998. Standard Methods for Water and Wastewater Examination, twentieth ed. (Washington D.C, USA). ska, A., 2008. Denitrification with Bernat, K., Wojnowska-Baryła, I., Dobrzyn endogenous carbon source at low C/N and its effect on P (3HB) accumulation. Bioresour. Technol. 99, 2410e2418. http://dx.doi.org/10.1016/j.biortech.2007.05. Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047 G. Anjali, P.C. Sabumon / International Biodeterioration & Biodegradation xxx (2016) 1e13 008. Butler, E., Hung, Y., Ahmad, M.S.A., Yeh, R.Y., Liu, R.L., Fu, Y., 2015. Oxidation pond for municipal wastewater treatment. Appl. Water Sci. open access at Springerlink. com http://dx.doi.org/10.1007/s13201-015-0285-z. Chen, Z., Hua, D., Ren, N., Zhang, Z., 2008. Simultaneous removal of organic substances and nitrogen in pilot-scale submerged membrane bioreactors treating digested traditional Chinese medicine wastewater. Int. Biodeterior. Biodegrad. 62, 250e256. http://dx.doi.org/10.1016/j.ibiod.2008.01.010. Chen, H., Liu, S., Yang, F., Xue, Y., Wang, T., 2009. The development of simultaneous partial nitrification, ANAMMOX and denitrification (SNAD) process in a single reactor for nitrogen removal. Bioresour. Technol. 100, 1548e1554. http://dx.doi. org/10.1016/j.biortech.2008.09.003. Dalsgaard, T., Thamdrup, B., Canfield, D.E., 2005. Mini-review: anaerobic ammonium oxidation (anammox) in the marine environment. Res. Microbiol. 156, 457e464. http://dx.doi.org/10.1016/j.resmic.2005.01.011. Daverey, A., Su, S., Huang, Y., Lin, J., 2012. Nitrogen removal from opto-electronic wastewater using the simultaneous partial nitrification, anaerobic ammonium oxidation and denitrification (SNAD) process in sequencing batch reactor. Bioresour. Technol. 113, 225e231. http://dx.doi.org/10.1016/j.biortech.2011.12.004. Daverey, A., Hung, N., Dutta, K., Lin, J., 2013. Ambient temperature SNAD process treating anaerobic digester liquor of swine wastewater. Bioresour. Technol. 141, 191e198. http://dx.doi.org/10.1016/j.biortech.2013.02.045. Daverey, A., Chen, Y., Dutta, K., Huang, Y., Lin, J., 2015. Start-up of simultaneous partial nitrification, anammox and denitrification (SNAD) process in sequencing batch biofilm reactor using novel biomass carriers. Bioresour. Technol. 190, 480e486. http://dx.doi.org/10.1016/j.biortech.2015.02.064. Fu, H., Yuan, J., Gao, H., 2015. Microbial oxidative stress response: novel insights from environmental facultative anaerobic bacteria. Arch. Biochem. Biophys. 584, 28e35. http://dx.doi.org/10.1016/j.abb.2015.08.012. Gu, S., Wang, S., Yang, Q., Yang, P., Peng, Y., 2012. Start up partial nitrification at low temperature with a real-time control strategy based on blower frequency and pH. Bioresour. Technol. 112, 34e41. http://dx.doi.org/10.1016/j.biortech,2011.12. 028. Guisasola, A., Jubany, I., Baeza, J.A., Carrera, J., Lafuente, J., 2005. Respirometric estimation of the oxygen affinity constants for biological ammonium and nitrite oxidation. J. Chem. Technol. Biotechnol. 80, 388e396. http://dx.doi.org/10.1002/ jctb.1202. Guisasola, A., Petzet, S., Baeza, J.A., Carrera, J., Lafuente, J., 2007. Inorganic carbon limitations on nitrification: experimental assessment and modeling. Water Res. 41, 277e286. http://dx.doi.org/10.1016/j.watres.2006.10.030. Hellinga, C., Schellen, A.A.J.C., Mulder, J.W., van Loosdrecht, M.C.M., Heijnen, J.J., 1998. The SHARON process: an innovate method for nitrogen removal from ammonium-rich waste water. Water Sci. Technol. 37, 135e142. http://dx.doi. org/10.1016/S0273-1223(98)00281-9. Hellinga, C., van Loosdrecht, M.C.M., Heijnen, J.J., 1999. Model-based design of a novel process for nitrogen removal from concentrated flows. Math. Comput. Model. Dyn. Syst. 5, 351e371. http://dx.doi.org/10.1076/mcmd.5.4.351.3678. Huang, B., Chi, G., Chen, X., Shi, Y., 2011. Removal of highly elevated nitrate from drinking water by pH-heterogenized heterotrophic denitrification facilitated with ferrous sulfide-based autotrophic denitrification. Bioresour. Technol. 102, 10154e10157. http://dx.doi.org/10.1016/j.biortech.2011.08.048. Jenson, M.M., Kuypers, M.M.M., Lavik, G., Thamdrup, B., 2008. Rates and regulation of anaerobic ammonia oxidation and denitrification in the black sea. Limnol. Oceanogr. 53, 23e36. http://dx.doi.org/10.2307/40006147. Jin, R., Yang, G., Yu, J., Zheng, P., 2012. The inhibition of the Anammox process: a review. Chem. Eng. J. 197, 67e79. http://dx.doi.org/10.1016/j.cej.2012.05.014. Kartal, B., Rattray, J., van Niftrik, A.L., van de Vossenberg, J., Schmid, M.C., Webb, R.I., Schouten, S., Fuerst, J.A., Damste, J.S., Jetten, M.S.M., Strous, M., 2007. Candidatus “Anammoxoglobus propionicus” a new propionate oxidizing species of anaerobic ammonium oxidizing bacteria. Syst. Appl. Microbiol. 30, 39e49. http://dx.doi. org/10.1016/j.syapm.2006.03.004. € rtz, I., Gu, J., Denecke, M., 2015. Microbial community of Ke, Y., Azari, M., Han, P., Go nitrogen-converting bacteria in anammox granular sludge. Int. Biodeterior. Biodegrad. 103, 105e115. http://dx.doi.org/10.1016/j.ibiod.2015.04.011. Kim, D., Lee, D., Keller, J., 2006. Effect of temperature and free ammonia on nitrification and nitrite accumulation in landfill leachate and analysis of its nitrifying bacterial community by FISH. Bioresour. Technol. 97, 459e468. http://dx. doi.org/10.1016/j.biortech.2005.03.032. Koops, H.P., Bottcher, B., Moller, U.C., Roser, A.P., Stehr, G., 1991. Classification of eight new species of ammonia oxidizing bacteria: Nitrosomonas communis sp. nov., Nitrosomonas ureae sp. nov.,Nitrosomonas aestuarii sp. nov., Nitrosomonas marina sp. nov,Nitrosomonas nitrosa sp. nov., Nitrosomonas eutropha sp. nov., Nitrosomonas oligotropha spa nov. and Nitrosomonas halophila sp. nov. J. Genet. Microbiol. 137, 1689e1699. Lackner, S., Horn, H., 2012. Evaluating operation strategies and process stability of a single stage nitritation-anammox SBR by use of the oxidation-reduction potential (ORP). Bioresour. Technol. 107, 70e77. http://dx.doi.10.1016/j.biortech. 2011.12.025. Lalucat, J., Bennasar, A., Bosch, R., Garcia-Valdes, E., Palleroni, N.J., 2006. Biology of Pseudomonas stutzeri. Microbiol. Mol. Biol. Rev. 70, 510e547. http://dx.doi.org/ 10.1128/mmbr.00047.05. Lan, C., Kumar, M., Wang, C., Lin, J., 2011. Development of simultaneous partial nitrification, anammox and denitrification (SNAD) process in a sequential batch reactor. Bioresour. Technol. 102, 5514e5519. http://dx.doi.org/10.1016/j. 13 biortech.2010.11.024. Monballiu, A., Desmidt, E., Ghyselbrecht, K., De Clippeleir, H., Van Hulle, S.W.H., Verstraete, W., Meesschaert, B., 2013. Enrichment of anaerobic ammonium oxidizing (anammox) bacteria from OLAND and conventional sludge: features and limitations. Sep. Purif. Technol. 104, 130e137. http://dx.doi.org/10.1016/j. seppur.2012.10.046. Reginatto, V., Teixera, R.M., Pereira, F., Schmidell, W., Furigo, A., Menes, R., Etchebehere, C., Soares, H.M., 2005. Anaerobic ammonium oxidation in bioreactor treating slaughter house wastewater. Braz. J. Chem. Eng. 22, 593e600. http://dx.doi.org/10.1590/S0104-66322005000400012. Sabumon, P.C., 2007. Anaerobic ammonia removal in presence of organic matter: a novel route. J. Hazard. Mater. 149, 49e59. http://dx.doi.org/10.1016/j.jhazmat. 2007.03.052. Strous, M., Heijnen, J.J., Kuenen, J.G., Jetten, M.S.M., 1998. The sequencing batch reactor as a powerful tool for the study of slowly growing anaerobic ammonium-oxidizing microorganisms. Appl. Microbiol. Biotechnol. 50, 589e596. http://dx.doi.org/10.1007/s002530051340. Strous, M., Kuenen, J.G., Jetten, M.S.M., 1999. Key physiology of anaerobic ammonium oxidation. Appl. Environ. Microbiol. 65, 3248e3250. Suneethi, S., Joseph, K., 2011. ANAMMOX process start up and stabilization with an anaerobic seed in Anaerobic Membrane Bioreactor (AnMBR). Bioresour. Technol. 102, 8860e8867. http://dx.doi.org/10.1016/j.biortech.2011.06.082. Tang, C., Zheng, P., Wang, C., Mahmood, Q., 2010. Suppression of anaerobic ammonium oxidizers under high organic content in high-rate Anammox UASB reactor. Bioresour. Technol. 101, 1762e1768. http://dx.doi.org/10.1016/j.biortech. 2009.10.032. Tang, C., Zheng, P., Chai, L., Min, X., 2013. Characterization and quantification of anammox start-up in UASB reactors seeded with conventional activated sludge. Int. Biodeterior. Biodegrad. 82, 141e148. http://dx.doi.org/10.1016/j.ibiod.2013. 02.014. Third, K.A., Burnett, N., Cord-Ruwisch, R., 2003. Simultaneous nitrification and denitrification using stored substrate (PHB) as the electron donor in an SBR. Biotechnol. Bioeng. 83, 706e720. http://dx.doi.org/10.1002/bit.10708. 12889035. Tyagi, V.K., Lo, S., 2013. Sludge: a waste or renewable source for energy and resources recovery? Renew. Sustain. Energy Rev. 25, 708e728. http://dx.doi.org/ 10.1016/j.rser.2013.05.029. United States Environmental Protection Agency (USEPA), 2011. Principles of Design and Operations of Wastewater Treatment Pond Systems for Plant Operators, Engineers, and Managers. Office of Research and Development, Cincinnati. EPA 600-R-11e088. http://www.epa.gov/ordntrnt/ORD/NRMRL/lrpcd/projects/ ponds.htm. van den Heuvel, R.N., van der Biezen, E., Jetten, M.S.M., Hefting, M.M., Kartal, B., 2010. Denitrification at pH 4 by a soil-derived Rhodanobacter-dominated community. Environ. Microbiol. 12, 3264e3271. http://dx.doi.org/10.1111/j. 1462-2920.2010.02301. van der Star, W.R.L., Abma, W.R., Blommers, D., Mulder, J.W., Tokutomi, T., Strous, M., Picioreanu, C., van Loosdrecht, M.C.M., 2007. Startup of reactors for anoxic ammonium oxidation: experiences from the first full-scale anammox reactor in Rotterdam. Water Res. 41, 4149e4163. http://dx.doi.org/10.1016/j.watres.2007. 03.044. zquez-Padín, J.R., Pozo, M.J., Jarpa, M., Figueroa, M., Franco, A., MosqueraVa ndez, R., 2009. Treatment of anaerobic sludge Corral, A., Campos, J.L., Me digester effluents by the CANON process in an air pulsing SBR. J. Hazard. Mater. 166, 336e341. http://dx.doi.org/10.1016/j.jhazmat.2008.11.055. Wang, C., Lee, P., Kumar, M., Huang, Y., Sung, S., Lin, J., 2010. Simultaneous partial nitrification, anaerobic ammonium oxidation and denitrification (SNAD) in a full-scale landfill-leachate treatment plant. J. Hazard. Mater. 175, 622e628. http://dx.doi.org/10.1016/j.jhazmat.2009.10.052. Wang, C., Kumar, M., Lan, C., Lin, J., 2011. Landfill-leachate treatment by simultaneous partial nitrification, anammox and denitrification (SNAD) process. Desalin. Water Treat. 32, 4e9. http://dx.doi.org/10.5004/dwt.2011.2175. Wang, G., Xua, X., Gong, Z., Gao, F., Yang, F., Zhang, H., 2016. Study of simultaneous partial nitrification, ANAMMOX and denitrification (SNAD) process in an intermittent aeration membrane bioreactor. Process Biochem. 51, 632e641. In: http://dx.doi.org/10.1016/j.procbio.2016.02.001. Wett, B., Rauch, W., 2002. The role of inorganic carbon limitation in biological removal of extremely ammonia concentrated wastewater. Water Res. 37, 1100e1110. http://dx.doi.org/10.1016/S0043-1354(02)00440-2. Winkler, M.K., Kleerebezem, R., Van Loosdrecht, M.C.M., 2012. Integration of anammox into the aerobic granular sludge process for main stream wastewater treatment at ambient temperatures. Water Res. 46, 136e144. http://dx.doi.org/ 10.1016/j.watres.2011.10.034. Xu, Z., Zeng, G., Yang, Z., Xiao, Y., Cao, M., Sun, H., Ji, L., Chen, Y., 2010. Biological treatment of landfill leachate with the integration of partial nitrification, anaerobic ammonium oxidation and heterotrophic denitrification. Bioresour. Technol. 101, 79e86. http://dx.doi.org/10.1016/j.biortech.2009.07.082. Xue, Y., Yang, F., Liu, S., Fu, Z., 2009. The influence of controlling factors on the startup and operation for partial nitrification in membrane bioreactor. Bioresour. Technol. 100, 1055e1060. http://dx.doi.org/10.1016/j.biortech.2008.07.052. Zhang, Z., Li, Y., Chen, S., Wang, S., Bao, X., 2012. Simultaneous nitrogen and carbon removal from swine digester liquor by the Canon process and denitrification. Bioresour. Technol. 114, 84e89. http://dx.doi.org/10.1016/j.biortech.2012.03. 006. Please cite this article in press as: Anjali, G., Sabumon, P.C., Development of simultaneous partial nitrification, anammox and denitrification (SNAD) in a non-aerated SBR, International Biodeterioration & Biodegradation (2016), http://dx.doi.org/10.1016/j.ibiod.2016.10.047