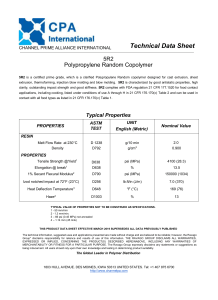

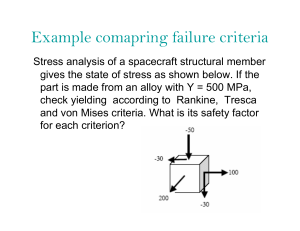

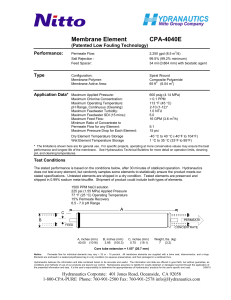

Parallel Type Air Gripper/2 Finger, 3 Finger, 4 Finger MHS Series ø16, ø20, ø25, ø32, ø40, ø50, ø63, ø80, ø100, ø125 MHZ MHF MHL MHR MHK MHS MHC MHT MHY MHW -X MRHQ MA D- 569 Lightweight, compact design with reduced height Smaller auto switch mountable High repeatability: ±0.01 mm Auto switch capable A wide variety of solid state auto switches can be mounted using the body’s side mounting grooves. Selections include 2-color indication and water resistant types. Smaller auto switches D-M9(V) D-M9W(V) D-M9A(V)L Easy alignment when mounting Positioning pin holes are provided on the top of the gripper. Can be mounted from two directions Using tapped holes Using through holes Employs wedge cam construction The wedge cam mechanism allows strong gripping force to be obtained from a compact design. 2-Finger Series Variations MHS2 Series Gripping of diverse workpieces Bore size (mm) 16 20 25 32 40 50 63 80 100 125 P.576 3-Finger MHS3 Series Axial gripping of cylindrical workpieces P.584 Long stroke MHSL3 Series 4-Finger Accommodates a wide range of workpiece diameters 570 P.618 MHS4 Series Positioning of square workpieces P.628 Ideal for gripping workpieces of different diameters MHSL3 Long Stroke P.618 Opening/Closing stroke more than twice the standard (MHS3) Gripping of different diameter workpieces The mounting pitch is compatible with the standard type. Weight (g) 43.5 80 46 135 49 180 58 370 64 550 77.5 d Height (mm) 930 89 1,550 116 2,850 135 5,500 175 11,300 lo se 16 20 25 32 40 50 63 80 100 125 10 (4) 10 (4) 12 (6) 16 (8) 20 (8) 28 (12) 32 (16) 40 (20) 48 (24) 64 (32) C Bore size (mm) O pe n Stroke (mm) Dia.: Open – Closed Standard inside ( )/MHS3 stroke MHZ MHS3 Variations With dust cover/MHSJ3 MHL Bore size (mm) 16 20 25 32 40 50 63 80 MHSJ3 MHSH3 P.594 Through-hole/MHSH3 MHF MHSHJ3 With dust cover Through-hole With center pusher (Cylinder type) With center pusher (Spring type) Through-hole with dust cover With dust cover/Center pusher (Cylinder type) With dust cover/Center pusher (Spring type) MHS3-X84 Single acting (Normally open, Normally closed) MHR MHK MHS MHC MHT MHY With dust cover/Center pusher P.602 Single acting/MHS3-X84 Symbol Single acting/Normally open: External grip Single acting/Normally closed: Internal grip -X The dust cover and center pusher assembly can be modularized for the through-hole MHSH3. Air blowing Pushing out a workpiece with external cylinder ø16, ø20, ø25, ø32, ø40, ø50, ø63 MHW MRHQ MA Center pusher assembly Dust cover Through-hole MHSH3 D- Spring type Cylinder type P.644 571 Added single acting (Made to Order -X84) to 3-finger type (MHS3 Series). ø16, ø20, ø25, ø32, ø40, ø50, ø63 Normally open or normally closed type can be selected. P.644 Port position can be changed according to installation conditions. Piping and auto switch wiring entries are one way. (For top ported) Space reduced through integration of air piping and auto switch wiring. The piping can be connected from the side port or top port of the body, which allows for improved piping flexibility. Air piping Auto switch wiring Top port Side port Series Variations Series Action Double acting MHS3 Single acting 572 Normally open Normally closed Bore size [mm] 16 20 25 32 40 50 63 80 100 125 V V V V V V V V V V V V V V V V V — — — MHS Series Model Selection Model Selection Selection Procedure Step 2 Confirmation of gripping point Step 1 Confirmation of gripping force Step 1 Confirmation of Gripping Force Confirmation of conditions Calculation of required gripping force Selection of model from gripping force graph MHS2-32D Example Gripping method: External gripping Number of fingers: 2 External Gripping Force Model selection criteria with respect to workpiece weight 150 • Although differences will exist depending on the coefficient of friction between attachments and workpieces, select a model which will provide a gripping force as shown in the table below. Note 1)Refer to the model selection illustration regarding multiples of the workpiece weight. Model Multiples of gripping force by workpiece weight MHS2 10 to 20 times or more Gripping force (N) Workpiece mass: 0.4 kg MHSJ3 7 to 13 times or more 5 to 10 times or more MHS4 • If high acceleration, deceleration or impact forces are encountered during motion, a further margin of safety should be considered. Example) When it is desired to set the gripping force at 20 times or more above the workpiece weight. Required gripping force = 0.4 kg x 20 x 9.8 m/s2 ≈ 78.4 N or more 0.3 MPa 0.2 MPa 60 0.1 MPa 10 20 30 40 50 Gripping point L (mm) • Selecting the MHS2-32D. A gripping force of 92 N is obtained from the intersection point of the gripping point distance L = 20 mm and a pressure of 0.4 MPa. •The gripping force is 23 times greater than the workpiece mass, and therefore satisfies a gripping force setting value of 20 times or more. Operating pressure: 0.4 MPa Note) For Step 2 , refer to the gripping point for the effective gripping force of each model. 574 0.4 MPa 0 MHSL3 Gripping point: 20 mm 0.5 MPa 92 90 30 MHS3 MHSH3 Pressure 0.6 MPa 120 Parallel Type Air Gripper 2 Finger, 3 Finger, 4 Finger MHS Series Model Selection Illustration When gripping a workpiece as in the figure to the left, and with the following definitions, n: Number of fingers F: Gripping force (N) µ: Coefficient of friction between attachments and workpiece m: Workpiece mass (kg) g: Gravitational acceleration (= 9.8 m/s2) mg: Workpiece weight (N) the conditions under which the workpiece will not drop are n x µF > mg F and therefore, F µxF mg F > ———— nxµ µxF mxg MHZ With “a” as the safety margin, F is determined as follows: MHF MHL a x mg F = ————— nxµ MHR Multiples of Gripping Force by Workpiece Mass MHK Number of fingers: When n = 2 • SMC performs calculations allowing for impacts which occur during normal transfer, etc., using a safety margin of a = 4. When µ = 0.2 F= mg 2 x 0.2 MHC When µ = 0.1 x4 = 10 x mg F= mg 2 x 0.1 MHS MHT x4 MHY = 20 x mg MHW 10 x workpiece weight -X 20 x workpiece weight Note) • Even in cases where the coefficient of friction is greater than µ = 0.2, for safety reasons, SMC recommends selecting a gripping force which is at least 10 to 20 times the workpiece weight. • If high acceleration, deceleration or impact forces are encountered during motion, a further margin of safety should be considered. MRHQ MA D- 575 Parallel Type Air Gripper/2-Finger Type MHS2 Series ø16, ø20, ø25, ø32, ø40, ø50, ø63 How to Order Bore size ø16 to ø25 MHS2 20 D M9BW Number of fingers 2 2 fingers Number of auto switches Bore size 16 16 mm 20 20 mm 25 25 mm Nil Auto switch S Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, Action refer to the table below. D Double acting 2 pcs. 1 pc. Made to Order Refer to page 577 for details. Applicable Auto Switches/Refer to pages 797 to 850 for further information on auto switches. Solid state auto switch Type Special function Electrical Indicator light entry — Diagnosis (2-color indicator) Grommet Yes Water resistant (2-color indicator) Wiring (Output) Load voltage 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 5 V, 12 V 12 V 5 V, 12 V 12V 5 V, 12 V 12 V DC 24 V Auto switch model In-line AC Perpendicular — M9NV M9PV M9BV M9NWV M9PWV M9BWV M9NAV∗∗ M9PAV∗∗ M9BAV∗∗ Lead wire length (m)∗ Pre-wired 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector M9N M9P M9B M9NW M9PW M9BW M9NA∗∗ M9PA∗∗ M9BA∗∗ Applicable load IC circuit IC circuit Relay, PLC IC circuit ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ············ Nil (Example) M9N ∗ Auto switches marked with a “” symbol are produced upon receipt of order. 1 m ············ M (Example) M9NWM 3 m ············ L (Example) M9NL 5 m ············ Z (Example) M9NZ Note) When using the 2-color indicator type, please make the setting so that the indicator is lit in red to ensure the detection at the proper position of the air gripper. Bore size ø32 to ø63 MHS2 50 D M9BW Made to Order Number of fingers Refer to page 577 for details. 2 2 fingers Number of auto switches Bore size 32 40 50 63 32 mm 40 mm 50 mm 63 mm Nil Action S D Double acting 2 pcs. 1 pc. Auto switch Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, refer to the table below. Applicable Auto Switches/Refer to pages 797 to 850 for further information on auto switches. Solid state auto switch Type Special function Electrical Indicator light entry — Diagnosis (2-color indicator) Water resistant (2-color indicator) Grommet Yes Wiring (Output) Load voltage 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 5 V, 12 V 12 V 5 V, 12 V 12 V 5 V, 12 V 12 V DC 24 V Auto switch model In-line AC Perpendicular — M9NV M9PV M9BV M9NWV M9PWV M9BWV M9NAV∗∗ M9PAV∗∗ M9BAV∗∗ M9N M9P M9B M9NW M9PW M9BW M9NA∗∗ M9PA∗∗ M9BA∗∗ Lead wire length (m)∗ Pre-wired 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector Applicable load IC circuit IC circuit Relay, PLC IC circuit ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ············ Nil (Example) M9NW ∗ Auto switches marked with a “” symbol are produced upon receipt of order. 1 m ············ M (Example) M9NWM 3 m ············ L (Example) M9NWL 5 m ············ Z (Example) M9NWZ Note 1) When using the 2-color indicator type, please make the setting so that the indicator is lit in red to ensure the detection at the proper position of the air gripper. Note 2) When ordering the air gripper with auto switch, auto switch mounting brackets are supplied with the air gripper having a bore size of ø32 to ø63. Note 3) When ordering the auto switch separately, auto switch mounting brackets (BMG2-012) are required. 576 MHS2 Series Parallel Type Air Gripper/2-Finger Type Model/Specifications Model MHS2-16D MHS2-20D MHS2-25D MHS2-32D MHS2-40D MHS2-50D MHS2-63D 16 20 25 32 40 50 63 Bore size (mm) Air Fluid Operating pressure (MPa) 0.1 to 0.6 0.2 to 0.6 -10 to 60 Ambient and fluid temperature (°C) ±0.01 Repeatability (mm) Max. operating frequency (c.p.m.) 60 120 Not required Lubrication Double acting Action External grip 21 37 63 111 177 280 502 Internal grip 23 42 71 123 195 306 537 Opening/Closing stroke (Both sides) (mm) 4 4 6 8 8 12 16 Weight (g) 58 96 134 265 345 515 952 Effective gripping force (N) at 0.5 MPa Note) Note) Values for ø16 to ø25 are with gripping point L = 20 mm, and for ø32 to ø63 with gripping point L = 30 mm. Refer to “Effective Gripping Force” data on pages 579 and 580 for the gripping force at each gripping position. Symbol Double acting: Internal grip MHZ Double acting: External grip MHF MHL MHR MHK Made to Order (Refer to pages 725 to 748 for details.) Symbol -X4 -X5 -X50 -X53 -X56 -X63 -X79 -X79A Specifications/Description Heat resistance (100°C) Fluororubber seal Without magnet EPDM seal/Fluorine grease Axial ported MHS Refer to pages 636 to 643 for the specifications of products with auto switches. MHC Auto switch installation examples and mounting positions Auto switch hysteresis Auto switch mounting Protrusion of auto switch from edge of body MHT MHY Fluorine grease MHW Grease for food processing machines, Fluorine grease Grease for food processing machines -X MRHQ MA D- 577 MHS2 Series Construction Closed condition Open condition !0 w !2 u t o !3 i r y e !1 q !4 Component Parts Material Material Note No. 1 Body Aluminum alloy Hard anodized 8 Magnet 2 Piston Aluminum alloy Hard anodized 9 Type C retaining ring 3 Cam Carbon steel Heat treated, Specially treated 10 Piston seal NBR 4 Finger Carbon steel Heat treated, Specially treated 11 Rod seal NBR 5 Cap Aluminum alloy Hard anodized 12 Gasket NBR 6 End plate Stainless steel 13 Gasket 7 Piston bolt Stainless steel 14 Cross recessed flat head screw Description No. Description Note — Carbon steel Phosphate coated NBR Carbon steel Zinc chromated Replacement Parts Description MHS2-16D MHS2-20D MHS2-25D MHS2-32D MHS2-40D MHS2-50D MHS2-63D Main parts Seal kit MHS16-PS MHS20-PS MHS25-PS MHS32-PS MHS40-PS MHS50-PS MHS63-PS !0!1!2!3 Finger P3316004 P3346104 P3316204 P3316304 P3316404 P3316504 P3316604 r Cam P3316023 P3316123 P3316223 P3316323 P3316423 P3316523 P3316623 e MHS-A1601 MHS-A2001 MHS-A2501 MHS-A3201 MHS-A4001 MHS-A5001 MHS-A6301 wui MHS-A2013-2 MHS-A2513-2 MHS-A3213-2 MHS-A4013-2 MHS-A5013-2 MHS-A6313-2 y!4 MHS-A2014 MHS-A2514 MHS-A3214 MHS-A4014 MHS-A5014 MHS-A6314 t Piston assembly End plate assembly MHS-A1613-2 Cap MHS-A1614 ∗ Order 2 pieces of fingers for one unit. Replacement part/Grease pack part no.: MH-G01 (30 g) 578 MHS2 Series Parallel Type Air Gripper/2-Finger Type Gripping Point • The workpiece gripping point distance should be within the gripping force ranges given for each pressure in the effective gripping force graphs below. • If operated with the workpiece gripping point beyond the indicated ranges, an excessive offset load will be applied to the sliding section of the fingers, which can have an adverse effect on the service life of the product. • If there is an overhang, please consult with SMC. Gripping point Gripping point L L External grip Internal grip L: Gripping point distance Effective Gripping Force External Grip Internal Grip MHS2-16D 30 MHS2-16D Pressure 0.6 MPa Pressure 0.6 MPa 30 0.5 MPa Gripping force (N) Gripping force (N) • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger, when both fingers and attachments are in full contact with the workpiece as shown in the figure below. 20 0.4MPa 0.3 MPa 10 0.2 MPa 0.5 MPa 20 0.4 MPa 0.3 MPa 10 0.2 MPa MHZ F 0 F 5 10 15 20 25 0 30 Gripping point L (mm) 60 Gripping force (N) Gripping force (N) Pressure 0.6 MPa 0.5 MPa 40 0.4 MPa 0.3 MPa 20 10 25 30 20 30 MHR MHK 0.5 MPa MHS 0.4 MPa MHC 0.3 MPa 20 0.2 MPa 0 40 10 20 30 MHT 40 Gripping point L (mm) MHS2-25D -X 100 Gripping force (N) Gripping force (N) 100 Pressure 0.6 MPa 0.5 MPa 60 0.4 MPa 40 0.3 MPa 0.2 MPa 0 Pressure 0.6 MPa MRHQ 80 0.5 MPa 60 MA 0.4 MPa D- 0.3 MPa 40 0.2 MPa 20 20 10 20 30 Gripping point L (mm) 40 0 10 MHY MHW MHS2-25D 80 MHF Pressure 0.6 MPa 40 Gripping point L (mm) Internal grip 20 MHL 0.2 MPa 0 F 15 MHS2-20D 60 F 10 Gripping point L (mm) MHS2-20 D External grip 5 20 30 40 Gripping point L (mm) 579 MHS2 Series Effective Gripping Force External Grip Internal Grip MHS2-32 D MHS2-32D Gripping force (N) 150 F Pressure 0.6 MPa 120 0.5 MPa 0.4 MPa 90 0.3 MPa 60 0.2 MPa 30 0 F 20 30 0.5 MPa 120 0.4 MPa 90 0.3 MPa 60 0.2 MPa 30 0.1 MPa 10 Pressure 0.6 MPa 150 Gripping force (N) • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger, when both fingers and attachments are in full contact with the workpiece as shown in the figure below. 40 0 50 0.1 MPa 10 20 250 Gripping force (N) Gripping force (N) 200 0.5 MPa 150 0.4 MPa 0.3 MPa 100 0.2 MPa 50 0 20 30 40 0.3 MPa 100 0.2 MPa 0 50 0.1 MPa 10 20 Pressure 0.6 MPa 300 0.5 MPa 0.4 MPa 200 0.3 MPa 0.2 MPa 100 Gripping force (N) 400 Internal grip 0.5 MPa 0.4 MPa 200 0.3 MPa 0.2 MPa 100 40 0 60 0.1 MPa MHS2-63 D 0.3 MPa 0.2 MPa 200 600 40 Gripping point L (mm) 60 0.5 MPa 0.4 MPa 400 0.3 MPa 0.2 MPa 200 0.1 MPa 0.1 MPa 580 60 Pressure 0.6 MPa Gripping force (N) Gripping force (N) 0.5 MPa 0.4 MPa 20 40 MHS2-63D Pressure 0.6 MPa 400 0 20 Gripping point L (mm) Gripping point L (mm) 600 50 Pressure 0.6 MPa 300 0.1 MPa 20 40 MHS2-50D 400 0 30 Gripping point L (mm) MHS2-50 D Gripping force (N) 0.4 MPa 150 Gripping point L (mm) F 0.5 MPa 200 50 0.1 MPa 10 50 Pressure 0.6 MPa 250 Pressure 0.6 MPa F 40 MHS2-40D MHS2-40 D External grip 30 Gripping point L (mm) Gripping point L (mm) 0 20 40 60 Gripping point L (mm) MHS2 Series Parallel Type Air Gripper/2-Finger Type Dimensions MHS2-16D to 25D øWA depth 1.5 2 x ø3.4 through 6.5 Counterbore depth SC (Mounting hole) RA AA RB øB XA depth XB NA NB øVA depth VB RB O RA AB 3 Q (Open DO) (Closed DC) 20° FY FZ CB 4 x M3 x 0.5 thread depth TB Thread for mounting attachment 2 x M4 x 0.7 thread depth 8 (Mounting thread) 20° FX 7 K Open EO Closed EC P (Finger opening port) MHZ J MHF 2H9 +0.025 0 MHL 2 P (Finger closing port) G 1 MHR MHK MHS Auto switch mounting groove dimensions (2 locations) MHS2-16D MHS2-20D MHC MHS2-25D MHT 5 5 6 5 ° 24 MHW 24 4.5 MHY ° 24 3 3 3 6.5 5 ° ø4 -X ø4 ø4 33° 33 ° 33° MRHQ MA D- Model MHS2-16D MHS2-20D MHS2-25D Model MHS2-16D MHS2-20D MHS2-25D AA 35 38 40 AB 32 35 37 B 30 36 42 CB 11 13 15 RA 18 24 26 RB SC 16 8 18 9.5 22 10 TB 5 6 6 DC 30 36 42 DO 34 40 48 VA 2H9 +0.025 0 2H9 +0.025 0 3H9 +0.025 0 EC 10 12 14 VB 2 2 3 EO 14 16 20 FX FY 12.5 11 14.5 13 17 14.5 WA 17H9 +0.043 0 21H9 +0.052 0 26H9 +0.052 0 FZ 3 3 5 XA 2H9 +0.025 0 2H9 +0.025 0 3H9 +0.025 0 G 25 27 28 1 4 5 5 J 10 12 14 K 4 5 6 NA 8 10 12 NB 0 5h9 -0.030 0 6h9 -0.030 0 6h9 -0.030 O 2 2.5 3 P M3 x 0.5 M5 x 0.8 M5 x 0.8 (mm) Q 6 7 8 XB 2 2 3 581 MHS2 Series Dimensions MHS2- 32D/40D 2 x øSA through RA AA SB counterbore 9 (Mounting hole) RA 6.4 AB 3 35° 35° 5 øVA depth VB RB XA depth XB øB 0 8h9 -0.036 RB NA 8 4.5 Q 20° 2 x UA thread depth UB (Mounting thread) 20° FY FZ (Open DO) FX (Closed DC) øWA depth 2 4 x M4 x 0.7 thread depth 8 Thread for mounting attachment CA CB Closed EC J 9 Open EO M5 x 0.8 (Finger opening port) L M5 x 0.8 (Finger closing port) G 1 2 Model MHS2-32D MHS2-40D Model MHS2-32D MHS2-40D 582 AA 44 47 AB 41 44 B 56 62 SB 8 9.5 UA M5 x 0.8 M6 x 1 CA 8 9 UB 10 12 CB 16 17 VA 3H9 +0.025 0 4H9 +0.030 0 DC 56 62 VB 3 4 DO 64 70 EC 16 20 EO 24 28 FX FY 23 20.5 26.5 23.5 WA XA 3H9 +0.025 34H9 +0.062 0 0 +0.062 4H9 +0.030 42H9 0 0 XB 3 4 FZ 5 6 G 30.5 32 1 6 7 J 20 21 L 2H9 3H9 +0.025 0 +0.025 0 NA 14 16 Q 11 12 RA 38 44 RB 25 28 (mm) SA 4.5 5.5 MHS2 Series Parallel Type Air Gripper/2-Finger Type MHS2- 50D/63D 4 x ø5.1 through 9.5 counterbore depth SC (Mounting hole) RA AA 6.4 AB AC RA 35° 35° 5 øVA depth VB RB NB XA depth XB øB NA RB YC O Q 20° FY FZ (Open DO) 4 x M5 x 0.8 thread depth 10 Thread for mounting attachment øWA depth WB M5 x 0.8 (Finger opening port) Closed EC MHZ MHF K Open EO FX CA CB (Closed DC) 4 x M6 x 1 thread depth 12 (Mounting thread) 20° J MHL L MHR M5 x 0.8 (Finger closing port) G 1 MHK M Model MHS2-50D MHS2-63D Model MHS2-50D MHS2-63D AA 55 66 AB 52 62 AC 3 4 B 70 86 CA 9 12 CB 20 22 DC 70 86 O 5 5.5 Q 14 17 RA 52 66 RB 34 38 SC 12 14 VA 4H9 +0.030 0 5H9 +0.030 0 DO 82 102 VB 4 5 EC 22 30 EO 34 46 WA 52H9 +0.074 0 65H9 +0.074 0 FX 31 38 WB 2 2.5 FZ 6 7 FY 28 34.5 XA 4H9 +0.030 0 5H9 +0.030 0 G 37.5 44 XB 4 5 J 24 28 1 9 11 K 10 11 L 4H9 +0.030 0 6H9 +0.030 0 NA 18 24 M 2 3 (mm) NB 0 10h9 -0.036 0 12h9 -0.043 MHY MHW MRHQ (E) øD F F -X E (B) h pt MA C øD F-F 2 x A screw depth B C MHC MHT YC 7 7.5 MHS2 Series Detailed dimensions of mounting portion of end plate de MHS D- (mm) Model MHS2-16D MHS2-20D MHS2-25D MHS2-32D MHS2-40D MHS2-50D MHS2-63D A B 5.5 M2 x 0.4 5.4 5.2 M3 x 0.5 8 C 11 13 15 18 21 24 32 øD 21 +0.1 0 24 +0.1 0 27 +0.1 0 32 +0.1 0 +0.1 38 0 42 +0.1 0 54 +0.1 0 E 0.5 0.6 0.8 1 583 Parallel Type Air Gripper/3-Finger Type MHS3 Series ø16, ø20, ø25, ø32, ø40, ø50, ø63, ø80, ø100, ø125 How to Order Bore size ø16 to ø25 MHS3 20 D M9BW Number of fingers 3 3 fingers Number of auto switches Bore size 16 16 mm 20 20 mm 25 25 mm Nil Auto switch S Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, Action D Double acting refer to the table below. 2 pcs. 1 pc. Made to Order Refer to page 585 for details. Applicable Auto Switches/Refer to pages 797 to 850 for further information on auto switches. Solid state auto switch Type Special function Electrical Indicator light entry — Diagnosis (2-color indicator) Grommet Yes Water resistant (2-color indicator) Wiring (Output) Load voltage 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 5 V, 12 V 12 V 5 V, 12 V 12 V 5 V, 12 V 12 V DC 24 V Auto switch model In-line AC Perpendicular — M9NV M9PV M9BV M9NWV M9PWV M9BWV M9NAV∗∗ M9PAV∗∗ M9BAV∗∗ Lead wire length (m)∗ Pre-wired 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector M9N M9P M9B M9NW M9PW M9BW M9NA∗∗ M9PA∗∗ M9BA∗∗ Applicable load IC circuit — IC circuit — Relay, PLC IC circuit — ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ············ Nil (Example) M9N ∗ Auto switches marked with a “” symbol are produced upon receipt of order. 1 m ············ M (Example) M9NWM 3 m ············ L (Example) M9NL 5 m ············ Z (Example) M9NZ Note) When using the 2-color indicator type, please make the setting so that the indicator is lit in red to ensure the detection at the proper position of the air gripper. Bore size ø32 to ø125 MHS3 50 D M9BW Number of fingers 3 3 fingers Action Bore size 32 32 mm 40 40 mm 50 50 mm 63 63 mm 80 80 mm 100 100 mm 125 125 mm Number of auto switch D Double acting Nil S n Port thread type Symbol Nil TN TF Type Cylinder bore M thread ø32 to ø63 Rc NPT ø80 to ø125 G 2 pcs. 1 pc. Made to Order Refer to page 585 for details. “n” pcs. Auto switch Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, refer to the table below. Applicable Auto Switches/Refer to pages 797 to 850 for further information on auto switches. Solid state auto switch Type Special function Electrical Indicator light entry — Diagnosis (2-color indicator) Water resistant (2-color indicator) Grommet Yes Wiring (Output) Load voltage 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 5 V, 12 V 12 V 5 V, 12 V 12 V 5 V, 12 V 12 V DC 24 V Auto switch model In-line AC Perpendicular — M9NV M9PV M9BV M9NWV M9PWV M9BWV M9NAV∗∗ M9PAV∗∗ M9BAV∗∗ M9N M9P M9B M9NW M9PW M9BW M9NA∗∗ M9PA∗∗ M9BA∗∗ Lead wire length (m)∗ Pre-wired 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector Applicable load IC circuit — IC circuit — Relay, PLC IC circuit — ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ············ Nil (Example) M9NW ∗ Auto switches marked with a “” symbol are produced upon receipt of order. 1 m ············ M (Example) M9NWM 3 m ············ L (Example) M9NWL 5 m ············ Z (Example) M9NWZ Note 1) When using the 2-color indicator type, please make the setting so that the indicator is lit in red to ensure the detection at the proper position of the air gripper. Note 2) When ordering the air gripper with auto switch, auto switch mounting brackets are supplied with the air gripper having a bore size of ø32 to ø125. Note 3) When ordering the auto switch separately, auto switch mounting brackets (BMG2-012) are required. 584 Parallel Type Air Gripper/3-Finger Type MHS3 Series Models/Specifications Model Cylinder bore size (mm) MHS3-16D MHS3-20D MHS3-25D MHS3-32D MHS3-40D MHS3-50D MHS3-63D MHS3-80D MHS3-100D MHS3-125D 16 20 25 32 50 40 Fluid 63 80 100 125 Air Operating pressure (MPa) 0.1 to 0.6 0.2 to 0.6 Ambient and fluid temperature (°C) –10 to 60 ±0.01 Repeatability (mm) Max. operating frequency (c.p.m.) 60 120 Lubrication 30 Not required Action Double acting External grip Effective gripping force (N) at 0.5 MPa Note 1) Internal grip 14 25 42 74 118 187 335 500 750 1,270 16 28 47 82 130 204 359 525 780 1,320 Opening/Closing stroke (mm) (dia.) 4 4 6 8 8 12 16 20 24 32 Weight (g) 60 100 140 237 351 541 992 1,850 3,340 6,460 Note 1) Values for ø16 to ø25 are with gripping point L = 20 mm, for ø32 to ø63 with gripping point L = 30 mm, and for ø80 to ø125 with gripping point L = 50 mm. Refer to “Effective Gripping Force” data on pages 587 to 589 for the gripping force at each gripping position. Symbol Double acting: Internal grip Double acting: External grip MHZ Made to Order: Individual Specifications MHF (For details, refer to pages 644 to 654.) Symbol -X84 Specifications/Description Single acting (ø16 to ø63) Refer to pages 636 to 643 for the specifications of products with auto switches. MHL Auto switch installation examples and mounting positions MHR Auto switch hysteresis Made to Order (Refer to pages 725 to 748 for details.) Symbol -X4 -X5 -X50 -X53 -X56 -X63 -X79 -X79A Auto switch mounting MHK Protrusion of auto switch from edge of body Specifications/Description MHS Heat resistance (100°C) MHC Fluororubber seal Without magnet MHT EPDM seal/Fluorine grease Axial ported MHY Fluorine grease Grease for food processing machines, Fluorine grease MHW Grease for food processing machines -X MRHQ MA D- 585 MHS3 Series Construction Closed condition !0 w !2 u i r Open condition t o !3 y e !1 q !4 Component Parts Material Material Note No. 1 Body Aluminum alloy Hard anodized 8 Magnet 2 Piston Aluminum alloy Hard anodized 9 Type C snap ring 3 Cam Carbon steel Heat treated, Specially treated 10 Piston seal NBR 4 Finger Carbon steel Heat treated, Specially treated 11 Rod seal NBR 5 Cap Aluminum alloy Hard anodized 12 Gasket NBR 6 End plate Stainless steel 13 Gasket 7 Piston bolt Stainless steel 14 Cross recessed flat head screw Description No. Description Note — Carbon steel Phosphate coated NBR Carbon steel Zinc chromated Replacement Parts MHS3-16D MHS3-20D MHS3-25D MHS3-32D MHS3-40D Main parts Seal kit MHS16-PS MHS20-PS MHS25-PS MHS32-PS MHS40-PS !0!1!2!3 Finger P3316004 P3316104 P3316204 P3316304 P3316404 r Cam P3316003 P3316103 P3316203 P3316303 P3316403 e MHS-A1601 MHS-A2001 MHS-A2501 MHS-A3201 MHS-A4001 wui End plate assembly MHS-A1613-3 MHS-A2013-3 MHS-A2513-3 MHS-A3213-3 MHS-A4013-3 y!4 Cap MHS-A16014 MHS-A2014 MHS-A2514 MHS-A3214 MHS-A4014 t Description Piston assembly MHS3-50D MHS3-63D MHS3-80D MHS3-100D MHS3-125D Main parts Seal kit MHS50-PS MHS63-PS MHS80-PS MHS100-PS MHS125-PS !0!1!2!3 Finger P3316504 P3316604 P3316704 P3316804 P3316904 r Cam P3316503 P3316603 P3316703 P3316803 P3316903 e MHS-A5001 MHS-A6301 MHS-A8001 MHS-A10001 MHS-A12501 wui MHS-A5013-3 MHS-A6313-3 MHS-A8013-3 MHS-A10013-3 MHS-A12513-3 y!4 MHS-A5014 MHS-A6314 MHS-A8014 MHS-A10014 MHS-A12514 t Description Piston assembly End plate assembly Cap ∗ Order 3 pieces of fingers for one unit. Replacement part/Grease pack part no.: MH-G01 (30 g) 586 Parallel Type Air Gripper/3-Finger Type MHS3 Series Gripping Point • The workpiece gripping point distance should be within the gripping force ranges given for each pressure in the effective gripping force graphs below. • If operated with the workpiece gripping point beyond the indicated ranges, an excessive offset load will be applied to the sliding section of the fingers, which can have an adverse effect on the service life of the product. Gripping point Gripping point L L External grip L: Gripping point distance Effective Gripping Force External Gripping Force MHS3-16D 25 25 20 Gripping force (N) Pressure 0.6 MPa Pressure 0.6 MPa 0.5 MPa 15 0.4 MPa 10 0.3 MPa 0.2 MPa 5 F 0 F Internal Gripping Force MHS3-16D Gripping force (N) • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. Internal grip 5 10 15 0.5 MPa 15 0.4 MPa 10 0.2 MPa 5 20 25 0 30 5 Gripping force (N) Gripping force (N) 0.5 MPa 25 20 0.4 MPa 15 0.3 MPa 10 0.2 MPa 0 30 MHL 0.5 MPa MHR MHK 0.3 MPa 20 15 MHS 0.2 MPa MHC 5 5 10 15 20 25 30 35 0 5 10 15 20 25 30 35 Gripping point L (mm) MHW 70 Gripping force (N) 50 0.5 MPa 40 0.4 MPa 30 0.3 MPa 20 Pressure 0.6 MPa 60 Pressure 0.6 MPa 0.2 MPa 10 50 -X 0.5 MPa 40 MRHQ 0.4 MPa 30 MA 0.3 MPa 20 0.2 MPa D- 10 10 20 30 40 Gripping point L (mm) 50 0 10 MHT MHY MHS3-25D 60 MHZ Pressure 0.6 MPa 10 MHS3-25D Gripping force (N) 30 0.4 MPa 25 Gripping point L (mm) 0 25 35 5 F 20 MHF 40 Pressure 0.6 MPa 30 F 15 MHS3-20D 35 External grip 10 Gripping point L (mm) MHS3-20 D Internal grip 0.3 MPa Gripping point L (mm) F F 20 20 30 40 50 Gripping point L (mm) 587 MHS3 Series Effective Gripping Force External Gripping Force MHS3-32 D MHS3-32D 120 Gripping force (N) 100 F Pressure 0.6 MPa 80 0.5 MPa 60 0.4 MPa 0.3 MPa 40 0.2 MPa 20 0 0.1 MPa 10 F 0.5 MPa 80 0.4 MPa 60 0.3 MPa 40 0.2 MPa 0.1 MPa 20 20 30 40 50 0 10 Gripping point L (mm) Gripping force (N) F Pressure 0.6 MPa 0.5 MPa 120 0.4 MPa 0.3 MPa 80 0.2 MPa 0 Pressure 0.6 MPa 0.1 MPa 10 20 30 40 0.5 MPa 120 0.4 MPa 0.3 MPa 80 0.2 MPa 40 0 50 0.1 MPa 300 250 Pressure 0.6 MPa 200 0 0.5 MPa 0.4 MPa 0.3 MPa 0.2 MPa Gripping force (N) Gripping force (N) 350 300 50 0.1 MPa 10 30 40 50 60 0.3 MPa 100 0.2 MPa 0.4 MPa 0.1 MPa 10 20 30 40 50 60 70 Gripping point L (mm) MHS3-63D 500 500 Pressure 0.6 MPa Pressure 0.6 MPa 400 Gripping force (N) Gripping force (N) 0.5 MPa 200 150 0 70 MHS3-63 D 0.5 MPa 300 0.4 MPa 0.3 MPa 200 0.2 MPa 100 20 40 60 80 400 0.5 MPa 300 0.4 MPa 0.3 MPa 200 0.2 MPa 100 0.1 MPa Gripping point L (mm) 588 50 Pressure 0.6 MPa Gripping point L (mm) 0 40 250 50 20 30 MHS3-50D 350 100 20 10 Gripping point L (mm) MHS3-50 D 150 50 160 Gripping point L (mm) Internal grip 40 200 160 40 F 30 MHS3-40D 200 External grip 20 Gripping point L (mm) MHS3-40 D F Pressure 0.6 MPa 100 Gripping force (N) F Internal Gripping Force Gripping force (N) • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. 100 0 0.1 MPa 20 40 60 80 Gripping point L (mm) 100 Parallel Type Air Gripper/3-Finger Type External Gripping Force Internal Gripping Force MHS3-80D MHS3-80D 700 700 Pressure 0.6 MPa Gripping force (N) Gripping force (N) Pressure 0.6 MPa 600 600 0.5 MPa 500 0.4 MPa 400 0.3 MPa 300 0.2 MPa 200 0.1 MPa 100 0 20 40 60 0.5 MPa 500 0.4 MPa 400 0.3 MPa 300 0.2 MPa 200 0.1 MPa 100 0 80 20 40 MHS3-100D MHS3-100D 1,000 1,000 Pressure 0.6 MPa 800 0.5 MPa 600 0.4 MPa 0.3 MPa 400 0.2 MPa 200 Gripping force (N) Gripping force (N) Pressure 0.6 MPa 40 60 80 800 0.5 MPa 600 400 0.2 MPa MHF 0 100 20 60 40 80 100 MHL Gripping point L (mm) MHS3-125D MHR MHS3-125D 1,800 1,800 1,600 Pressure 0.6 MPa 1,400 0.5 MPa 1,200 0.4 MPa 1,000 800 0.3 MPa 600 0.2 MPa 400 0.1 MPa 200 MHK Pressure 0.6 MPa 1,600 Gripping force (N) Gripping force (N) MHZ 0.1 MPa Gripping point L (mm) 0 0.4 MPa 0.3 MPa 200 0.1 MPa 20 80 60 Gripping point L (mm) Gripping point L (mm) 0 MHS3 Series 1,400 MHS 0.5 MPa 1,200 0.4 MPa 1,000 800 0.3 MPa 600 0.2 MPa 400 0.1 MPa MHC MHT MHY 200 20 40 60 80 100 Gripping point L (mm) 120 0 20 40 60 80 100 120 MHW Gripping point L (mm) -X MRHQ MA D- 589 MHS3 Series Dimensions MHS3 -16D to 25D CB 7 P (Finger opening port) P (Finger closing port) AA 6 x M3 x 0.5 thread depth TB Thread for mounting attachment AB øB 20° K 2H9 +0.025 0 FY J O (Open DO) (Closed DC) 20° øVA depth VB Open EO Closed EC 3 FX Q øWA depth 1.5 22.5° NA B th X dep 2 FZ NB XA G 3 x UA thread depth UB P.C.D.R (Mounting thread) 3 x øSA through SB counterbore depth SC P.C.D.R (Mounting hole) Auto switch mounting groove dimentions (2 locations) MHS3-16D MHS3-20D 5 33° Model MHS3-16D MHS3-20D MHS3-25D Model MHS3-16D MHS3-20D MHS3-25D 590 5 3 ° 5 6.5 6 ° 3 54 54 ° 54 ø4 5 5 ø4 MHS3-25D ø4 3 33° AA 35 38 40 AB 32 35 37 B 30 36 42 CB 11 13 15 DC 15 18 21 DO 17 20 24 SA 3.4 3.4 4.5 SB 6.5 6.5 8 SC 8 9.5 10 TB 5 6 6 UA M3 x 0.5 M3 x 0.5 M4 x 0.7 EC 5 6 7 UB 4.5 6 6 EO 7 8 10 FX FY 12.5 11 14.5 13 14.5 17 VA 2H9 +0.025 0 2H9 +0.025 0 3H9 +0.025 0 VB 2 2 3 FZ 3 3 5 33° G 25 27 28 WA 17H9 +0.043 0 21H9 +0.052 0 26H9 +0.052 0 4 5 5 XA 2H9 +0.025 0 2H9 +0.025 0 3H9 +0.025 0 J 10 12 14 XB 2 2 3 K 4 5 6 NA 8 10 12 NB 0 5h9 -0.030 0 6h9 -0.030 0 6h9 -0.030 O 2 2.5 3 P M3 x 0.5 M5 x 0.8 M5 x 0.8 Q 6 7 8 (mm) R 25 29 34 Parallel Type Air Gripper/3-Finger Type MHS3 - 32D to 80D CB MHS3 Series CA P (Finger opening port) P (Finger closing port) AA AC AB 20° 20° øWA depth WB K FX O øB Open EO Closed EC (Open DO) (Closed DC) 6 x TA thread depth TB Thread for mounting attachment 22.5° øVA depth VB L M FZ G NA B th X J Q FY NB XA dep 3 x UA thread depth UB P.C.D.R (Mounting thread) 3 x øSA through SB counterbore depth SC P.C.D.R (Mounting hole) MHZ MHF MHL Auto switch mounting groove dimensions (4 locations) MHR MHS MHC ° 40 40 ° 10° 10° MHK MHT 4 Y 5 6. MHY MHW -X MRHQ Model MHS3-32D MHS3-40D MHS3-50D MHS3-63D MHS3-80D Model MHS3-32D MHS3-40D MHS3-50D MHS3-63D MHS3-80D AC 3 3 3 4 5 AA 44 47 55 66 82 AB 41 44 52 62 77 O 4.5 4.5 5 5.5 6 P M5 x 0.8 M5 x 0.8 M5 x 0.8 M5 x 0.8 Rc 1/8 (G 1/8, NPT 1/8) B 52 62 70 86 106 Q 11 12 14 17 20 CA 8 9 9 12 13.5 R 44 53 62 76 95 CB 16 17 20 22 27 SA 4.5 5.5 5.5 6.6 6.6 DC 28 31 35 43 53.5 SB 8 9.5 9.5 11 11 EC 8 10 11 15 21.5 EO 12 14 17 23 31.5 TA M4 x 0.7 M4 x 0.7 M5 x 0.8 M5 x 0.8 M6 x 1 TB 8 8 10 10 12 DO 32 35 41 51 63.5 SC 9 9 12 14 19 FX 22 26.5 31 38 47.5 FY 19.5 23.5 28 34.5 43.5 UA M4 x 0.7 M5 x 0.8 M5 x 0.8 M6 x 1 M6 x 1 FZ 5 6 6 7 8 UB 6 7.5 10 9 12 G 30.5 32 37.5 44 56 6 7 9 11 12 VA 3H9 +0.025 0 4H9 +0.030 0 4H9 +0.030 0 5H9 +0.030 0 +0.030 6H9 0 J 20 21 24 28 32 VB 3 4 4 5 6 K 9 9 10 11 12 WA 34H9 +0.062 0 42H9 +0.062 0 52H9 +0.074 0 65H9 +0.074 0 +0.087 82H9 0 L 2H9 3H9 4H9 6H9 8H9 +0.025 0 +0.025 0 +0.030 0 +0.030 0 +0.036 0 WB 2 2 2 2.5 3 M 2 2 2 3 4 XA 3H9 +0.025 0 4H9 +0.030 0 4H9 +0.030 0 5H9 +0.030 0 +0.030 6H9 0 NA 14 16 18 24 28 XB 3 4 4 5 6 (mm) NB 0 8h9 -0.036 0 8h9 -0.036 0 10h9 -0.036 0 12h9 -0.043 0 14h9 -0.043 Y 6 8 7 7.5 9 591 MA D- MHS3 Series Dimensions MHS3 - 100D/125D CB CA P (Finger opening port) P (Finger closing port) 22.5° AA 6 x TA thread depth TB Thread for mounting attachment AB øB øWA depth WB K O L Q FY (Open DO) (Closed DC) J 20° FX NB 20° øVA depth VB Open EO Closed EC AC XA B th X dep M FZ NA G 3 x UA thread depth UB P.C.D.R (Mounting thread) 3 x øSA through SB counterbore depth SC P.C.D.R (Mounting hole) Auto switch mounting groove positions (4 locations) 40 ° 40 ° 40 40 ° 10° 10° 10° MHS3-125D 10° MHS3-100D ° 5 5 4 6. 0 1 13 Model MHS3-100D MHS3-125D Model MHS3-100D MHS3-125D 592 AA 96 122 AB 90 114 AC 6 8 O 7.5 10.5 Rc 1/4 (G 1/4, NPT 1/4) Rc 3/8 (G 3/8, NPT 3/8) P B CA CB 134 18 30.6 166 23.5 38 Q 23 31 R 118 148 SA 9 11 DC 66 82 SB 14 17.5 DO 78 98 SC 21 34 EC 28 30 EO 40 46 TA M8 x 1.25 M10 x 1.5 FX 59 74 TB 16 20 FY 54 68 FZ 10 12 UA M8 x 1.25 M10 x 1.5 G 63 84 15 18 UB VA 8H9 +0.036 16 0 20 10H9 +0.036 0 15 90 ° 7 12 5 4 6. 90 ° J 38 52 K 15 21 VB 6 8 L 8H9 +0.036 0 10H9 +0.036 0 WA 102H9 +0.087 0 130H9 +0.100 0 M 4 6 NA 34 40 WB XA 8H9 +0.036 4 0 6 10H9 +0.036 0 (mm) NB 0 18h9 -0.043 0 22h9 -0.052 XB 6 8 Parallel Type Air Gripper/3-Finger Type MHS3 Series MHS3 Series Detailed Dimensions of Mounting Portion of End Plate 3 x A screw depth B P.C.D. C øD h pt de E F F MHZ MHF (B) MHL øD MHR MHK MHS (E) MHC MHT F-F MHY MHW -X (mm) Model MHS3-16D MHS3-20D MHS3-25D MHS3-32D MHS3-40D MHS3-50D MHS3-63D MHS3-80D MHS3-100D MHS3-125D A B 5.5 M2 x 0.4 5.4 5.2 M3 x 0.5 8 M4 x 0.7 9.5 C 12.5 15 17 21 22 26 33 40 54 62 øD 18H8 +0.027 0 21H8 +0.033 0 23H8 +0.033 0 27H8 +0.033 0 +0.039 31H8 0 +0.039 35H8 0 42H8 +0.039 0 52H8 +0.046 0 +0.046 70H8 0 +0.054 82H8 0 E 0.5 MRHQ 0.6 0.8 MA 1 D- 1.5 593 Parallel Type Air Gripper 3-Finger Type with Dust Cover MHSJ3 Series ø16, ø20, ø25, ø32, ø40, ø50, ø63, ø80 How to Order MHSJ 3 32 D M9BW Made to Order With dust cover Refer to page 595 for details. Number of auto switches Number of fingers Nil S 3 3 fingers Bore size 16 20 25 32 40 50 63 80 2 pcs. 1 pc. Auto switch 16 mm 20 mm 25 mm 32 mm 40 mm 50 mm 63 mm 80 mm Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, refer to the table below. Dust cover type Nil F S Chloroprene rubber (CR) Fluororubber (FKM) Silicone rubber (Si) Port thread type Symbol Nil TN TF Type Cylinder bore M thread ø16 to ø63 Rc NPT ø80 G Action D Double acting Applicable Auto Switches/Refer to pages 797 to 850 for further information on auto switches. Solid state auto switch Type Special function Electrical Indicator light entry — Diagnosis (2-color indicator) Water resistant (2-color indicator) Grommet Yes Wiring (Output) Load voltage 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 5 V, 12 V 12 V 5 V, 12 V 12 V 5 V, 12 V 12 V DC 24 V Auto switch model In-line AC Perpendicular — M9NV M9PV M9BV M9NWV M9PWV M9BWV M9NAV∗∗ M9PAV∗∗ M9BAV∗∗ M9N M9P M9B M9NW M9PW M9BW M9NA∗∗ M9PA∗∗ M9BA∗∗ Lead wire length (m)∗ Pre-wired 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector Applicable load IC circuit — IC circuit — Relay, PLC IC circuit — ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ············ Nil (Example) M9NW ∗ Auto switches marked with a “” symbol are produced upon receipt of order. 1 m ············ M (Example) M9NWM 3 m ············ L (Example) M9NWL 5 m ············ Z (Example) M9NWZ Note) When using the 2-color indicator type, please make the setting so that the indicator is lit in red to ensure the detection at the proper position of the air gripper. 594 Parallel Type Air Gripper 3-Finger Type with Dust Cover MHSJ3 Series Models/Specifications Model Cylinder bore size (mm) MHSJ3-16D MHSJ3-20D MHSJ3-25D MHSJ3-32D MHSJ3-40D MHSJ3-50D MHSJ3-63D MHSJ3-80D 16 20 25 32 40 50 63 80 Air Fluid 0.2 to 0.6 Operating pressure (MPa) 0.1 to 0.6 Ambient and fluid temperature (°C) –10 to 60 ±0.01 Repeatability (mm) Max. operating frequency (c.p.m.) 60 120 30 Not required Lubrication Double acting Action External grip Effective gripping force (N) at 0.5 MPa Note 1) Internal grip 9 21 36 62 97 155 280 400 16 28 47 82 130 204 359 525 Opening/Closing stroke (mm) (dia.) 4 4 6 8 8 12 16 20 Weight (g) 95 150 230 440 620 1,050 1,800 3,200 Note 1) Values for ø16 to ø25 are with gripping point L = 20 mm, for ø32 to ø63 with gripping point L = 30 mm, and for ø80 with gripping point L = 50 mm. Refer to “Effective Gripping Force” data on pages 597 to 599 for the gripping force at each gripping position. Symbol Double acting: Internal grip Double acting: External grip MHZ MHF Made to Order (Refer to pages 725 to 748 for details.) Symbol -X4 -X5 -X50 -X53 -X56 -X63 -X77A -X77B -X78A -X78B -X79 -X79A Specifications/Description Heat resistance (100°C) Fluororubber seal Auto switch installation examples and mounting positions Without magnet Auto switch hysteresis EPDM seal/Fluorine grease Axial ported MHL Refer to pages 636 to 643 for the specifications of products with auto switches. MHR MHK Auto switch mounting MHS Protrusion of auto switch from edge of body Fluorine grease MHC Dust cover adhesion MHT Dust cover adhesion (Finger part only) Dust cover caulking MHY Dust cover caulking (Finger part only) Grease for food processing machines, Fluorine grease MHW Grease for food processing machines -X MRHQ MA D- 595 MHSJ3 Series Construction i ø16 to ø25 Closed condition !2 w t !1 Open condition !3 !4 q u !6 !0 !2 r y e !5 o ø32 to ø80 Open condition !7 Component Parts No. Material Note No. Description Material Note Aluminum alloy Hard anodized 9 10 11 12 13 14 15 16 17 Hexagon socket head bolt Carbon steel Zinc chromated Description 1 Body 2 Piston 3 4 5 6 7 8 Cam ø16 to ø25: Stainless steel ø32 to ø80: Aluminum alloy Hard anodized Carbon steel Heat treated, Specially treated Carbon steel Heat treated, Specially treated Cap Aluminum alloy Hard anodized End plate Stainless steel Guide Aluminum alloy Finger Hard anodized — Magnet Parallel pin Stainless steel Type C retaining ring Carbon steel Gasket NBR Gasket NBR Piston seal NBR Rod seal Nickel plated NBR Dust cover CR/FKM/Si Cross recessed flat head screw Carbon steel Zinc chromated Replacement Parts Description Dust cover Material Seal kit CR MHSJ3-16D MHSJ3-20D MHSJ3-25D MHSJ3-32D Main parts MHSJ16-PS MHSJ20-PS MHSJ25-PS MHSJ32-PS !2!3!4!5 MHSJ3-J16 MHSJ3-J20 MHSJ3-J25 MHSJ3-J32 FKM MHSJ3-J16F MHSJ3-J20F MHSJ3-J25F MHSJ3-J32F Si MHSJ3-J16S MHSJ3-J20S MHSJ3-J25S MHSJ3-J32S Finger P3316054 P3316154 P3316254 P3316354 Cam (J) P3316093 P3316193 P3316293 P3316393 e Piston assembly MHS-A1603 MHS-A2003 MHS-A2503 MHS-A3203 wi End plate assembly MHSJ-A1613 MHSJ-A2013 MHSJ-A2513 MHSJ-A3213 y!7 Cap MHSJ-A1614 MHSJ-A2014 MHSJ-A2514 MHSJ-A3214 t Description Dust cover Finger Cam (J) Material Seal kit CR !6 r MHSJ3-40D MHSJ3-50D MHSJ3-63D MHSJ3-80D Main parts MHSJ40-PS MHSJ50-PS MHSJ63-PS MHSJ80-PS !2!3!4!5 MHSJ3-J40 MHSJ3-J50 MHSJ3-J63 MHSJ3-J80 FKM MHSJ3-J40F MHSJ3-J50F MHSJ3-J63F MHSJ3-J80F Si MHSJ3-J40S MHSJ3-J50S MHSJ3-J63S MHSJ3-J80S P3316454 !6 P3316554 P3316654 P3316754 P3316493 P3316593 P3316693 P3316793 e Piston assembly MHS-A4003 MHS-A5003 MHS-A6303 MHS-A8003 wi End plate assembly MHSJ-A4013 MHSJ-A5013 MHSJ-A6313 MHSJ-A8013 y!7 Cap MHSJ-A4014 ∗ Order 3 pieces of fingers for one unit. MHSJ-A5014 MHSJ-A6314 MHSJ-A8014 t Replacement part/Grease pack part no.: MH-G01 (30 g) 596 r Parallel Type Air Gripper 3-Finger Type with Dust Cover MHSJ3 Series Gripping Point • The workpiece gripping point distance should be within the gripping force ranges given for each pressure in the effective gripping force graphs below. • If operated with the workpiece gripping point beyond the indicated ranges, an excessive offset load will be applied to the sliding section of the fingers, which can have an adverse effect on the service life of the product. Gripping point Gripping point L L External grip Effective Gripping Force • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. Internal grip L: Gripping point distance Internal Gripping Force External Gripping Force MHSJ3-16D MHSJ3-16D 25 Pressure 0.6 MPa 0.5 MPa 10 0.4 MPa 0.3 MPa 5 0 5 10 15 20 0.5 MPa 15 0.4 MPa 10 0.3 MPa 0.2 MPa 25 0 30 5 MHSJ3-20D External grip 35 40 30 35 Gripping force (N) Gripping force (N) 25 0.5 MPa 20 15 0.3 MPa 10 0.2 MPa 0.4 MPa 5 0 5 10 15 20 25 30 30 25 MHL MHR MHK 0.4 MPa 0.3 MPa 20 15 MHS 0.2 MPa 10 MHC 5 15 20 25 30 35 60 50 Pressure 0.6 MPa 40 0.5 MPa 30 0.4 MPa 20 0.3 MPa 0.2 MPa 10 20 30 40 Gripping point L (mm) 50 Gripping force (N) 70 MHW Pressure 0.6 MPa 50 -X 0.5 MPa 40 MRHQ 0.4 MPa 30 MA 0.3 MPa 20 0.2 MPa D- 10 0 10 MHT MHY MHSJ3-25D 60 10 10 Gripping point L (mm) 70 MHZ MHF 0.5 MPa 30 0 35 MHSJ3-25D Gripping force (N) 25 Pressure 0.6 MPa Gripping point L (mm) 0 20 5 F Internal grip 15 MHSJ3-20D Pressure 0.6 MPa F 10 Gripping point L (mm) Gripping point L (mm) F F Pressure 0.6 MPa 20 5 0.2 MPa F F Gripping force (N) Gripping force (N) 15 20 30 40 50 Gripping point L (mm) 597 MHSJ3 Series Effective Gripping Force • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. External Gripping Force Internal Gripping Force MHSJ3-32D MHSJ3-32 D 120 100 Pressure 0.6 MPa 80 0.5 MPa 60 0.4 MPa 0.3 MPa 40 0.2 MPa 20 F 0 F Pressure 0.6 MPa Gripping force (N) Gripping force (N) 100 0.1 MPa 10 20 30 40 0.4 MPa 60 0.3 MPa 40 0.2 MPa 20 0.1 MPa 0 50 0.5 MPa 80 0.4 MPa 0.3 MPa 0.2 MPa 40 Gripping force (N) Gripping force (N) Pressure 0.6 MPa 120 0.1 MPa 0 10 F 20 30 40 0.5 MPa 120 0.4 MPa 0.3 MPa 80 0.2 MPa 40 0 50 0.1 MPa 10 20 30 40 50 Gripping point L (mm) MHSJ3-50D MHSJ3-50D 350 250 Pressure 0.6 MPa 0.5 MPa 150 0.4 MPa 0.3 MPa 100 0.2 MPa 50 Gripping force (N) 300 200 Gripping force (N) 50 Pressure 0.6 MPa 160 Gripping point L (mm) 0.1 MPa 0 10 20 Pressure 0.6 MPa 250 200 150 0.3 MPa 100 0.2 MPa 30 40 50 60 0 70 10 20 30 40 50 60 70 Gripping point L (mm) MHSJ3-63D MHSJ3-63D 400 500 Pressure 0.6 MPa Pressure 0.6 MPa 400 Gripping force (N) 300 0.5 MPa 0.4 MPa 200 0.3 MPa 0.2 MPa 100 0.1 MPa 0 0.5 MPa 0.4 MPa 0.1 MPa 50 Gripping point L (mm) Gripping force (N) 40 200 External grip Internal grip 30 MHSJ3-40D 160 F 20 Gripping point L (mm) MHSJ3-40D 20 40 60 80 Gripping point L (mm) 598 10 Gripping point L (mm) F F 0.5 MPa 80 100 0.5 MPa 300 0.4 MPa 0.3 MPa 200 0.2 MPa 100 0 0.1 MPa 20 40 60 80 Gripping point L (mm) 100 Parallel Type Air Gripper 3-Finger Type with Dust Cover External Gripping Force Internal Gripping Force MHSJ3-80D MHSJ3-80D 700 500 0.5 MPa 400 0.4 MPa 300 0.3 MPa 200 0.2 MPa 0.1 MPa 100 20 40 60 Gripping point L (mm) Pressure 0.6 MPa 600 Pressure 0.6 MPa Gripping force (N) Gripping force (N) 600 0 MHSJ3 Series 0.5 MPa 500 0.4 MPa 400 0.3 MPa 300 0.2 MPa 200 0.1 MPa 100 80 0 20 40 60 80 Gripping point L (mm) MHZ MHF MHL MHR MHK MHS MHC MHT MHY MHW -X MRHQ MA D- 599 MHSJ3 Series Dimensions MHSJ3-16D to 25D 6 x M3 x 0.5 thread depth TB Thread for mounting attachment 3 x M4 x 0.7 thread depth 8 P.C.D.R (Mounting thread) ° øB 30° 20° 20 øHB ø3H9 +0.025 depth 3 0 K øHA Q øWA depth 1.5 NB P (Finger closing port) 2 2H9 +0.025 0 SD FX J O SD CB CA Open EO Closed EC (Open DO) (Closed DC) P (Finger opening port) AD 3 AE AA (Counterbore depth 4) 3 x ø3.2 through SB Counterbore depth 4(See section SD-SD) P.C.D.R (Mounting hole) A (Counterbore dia. SB) (3 x ø3.2) Section SD - SD Auto switch mounting groove dimensions (2 locations) MHSJ3-16D MHSJ3-20D ø4 ø4 5 MHSJ3-25D 6 ø4 20° 3 20° 5 6.5 5 3 3 5 5 90 90 ° 20° Model MHSJ3-16D MHSJ3-20D MHSJ3-25D Model MHSJ3-16D MHSJ3-20D MHSJ3-25D 600 AA 46 49 55 AD 16 18 20 AE 27 28 32 R 24 29 34 SB 6 6.5 6.5 TB 5 6 6 A 39 42 47 B 30 36 42 WA 17H9 +0.043 0 21H9 +0.052 0 26H9 +0.052 0 CA 7 7 7.5 CB DC DO 14 17.5 19.5 14 20 22 17.5 23.5 26.5 ° 20° EC 7.5 8 9.5 20° EO 9.5 10 12.5 FX 12 15 18 HA 46 52 62 HB 36 42 50 J 10 12 14 K 4 5 6 NB 0 5h9 -0.030 0 6h9 -0.030 0 6h9 -0.030 20° O 2 2.5 3 P M3 x 0.5 M5 x 0.8 M5 x 0.8 (mm) Q 6 7 8 Parallel Type Air Gripper 3-Finger Type with Dust Cover MHSJ3 Series MHSJ3-32D to 80D 6 x TA thread depth TB Thread for mounting attachment CB 3 x UA thread depth UB P.C.D.R (Mounting thread) FX 3 x YA thread depth YB P.C.D.R P (Finger opening port) CA Q SD 20° øB Open EO K Closed EC øHA øHB øVA depth VB J O SD (Open DO) (Closed DC) 30° ° 20 øWA depth WB L NB 3 x øSA through SB Counterbore depth SC (See section SD-SD) P.C.D.R (Mounting hole) P (Finger closing port) M AC AD AE AA MHSJ3-40D ø4 90 3 5 ° 5 20° 20° 90 ° 20° (3 x øSA) MHF 3 90 A ° 7.5 5 3 MHZ ø4 7 7 ø4 5 (Counterbore dia. SB) MHSJ3-50D 5 (Counter boredepth SC) Auto switch mounting groove dimensions (2 locations) MHSJ3-32D 5 20° MHL 20° MHR 20° MHK Section SD - SD MHSJ3-63D MHSJ3-80D MHS MHC MHT ø4 3 90° MHY 5 11 5 10 ø4 5 3 MHW 90 ° 5 -X 20° Model MHSJ3-32D MHSJ3-40D MHSJ3-50D MHSJ3-63D MHSJ3-80D Model MHSJ3-32D MHSJ3-40D MHSJ3-50D MHSJ3-63D MHSJ3-80D AD 24 26 31 37 46 AA 63 66 80 91 108 AC 3 3 3 4 5 O 4.5 4.5 5 5.5 6 P M5 x 0.8 M5 x 0.8 M5 x 0.8 M5 x 0.8 Rc 1/8 (G 1/8, NPT 1/8) AE 36 37 46 50 57 Q 11 12 14 17 20 20° 20° 20° A 54 57 70 79 93 R 44 52 63 78 98 B 54 62 74 92 112 SA 4.2 4.2 5.1 6.6 6.6 CA 9.5 10.5 11.5 13 14 SB 8 8 9.5 11 11 DO 35.5 40 48 59 73 CB 19 19 26.5 28 31 DC 31.5 36 42 51 63 SC 7 7 8 8 8 TA M4 x 0.7 M4 x 0.7 M5 x 0.8 M5 x 0.8 M6 x 1 EC 11.5 15 18 23 31 TB 8 8 10 10 12 EO 15.5 19 24 31 41 FX 22 26 32 40 50 UA M5 x 0.8 M5 x 0.8 M6 x 1 M8 x 1.25 M8 x 1.25 HA 80 90 109 133 168 UB 10 10 12 16 16 HB 65 75 88 106 130 VA 4H9 +0.030 0 4H9 +0.030 0 5H9 +0.030 0 6H9 +0.030 0 6H9 +0.030 0 J 20 21 24 28 32 VB 4 4 5 6 6 K 9 9 10 11 12 MRHQ L 2H9 +0.025 0 3H9 +0.025 0 4H9 +0.030 0 6H9 +0.030 0 8H9 +0.036 0 WA 34H9 +0.062 0 42H9 +0.062 0 52H9 +0.074 0 65H9 +0.074 0 82H9 +0.087 0 WB 2 2 2 2.5 3 M 2 2 2 3 4 MA (mm) NB 0 8h9 -0.036 0 8h9 -0.036 0 10h9 -0.036 0 12h9 -0.043 0 14h9 -0.043 YA M4 x 0.7 M4 x 0.7 M5 x 0.8 M6 x 1 M6 x 1 D- YB 8 8 10 12 12 601 Parallel Type Air Gripper 3-Finger Type Through-hole Type MHSH3 Series ø16, ø20, ø25, ø32, ø40, ø50, ø63, ø80 How to Order MHSH Through-hole Dust cover Nil J 40 50 63 80 40 mm 50 mm 63 mm 80 mm Symbol Nil TN TF M9BW Number of auto switches Made to Order Center pusher Nil A B Port thread type Bore size 16 mm 20 mm 25 mm 32 mm D Number of fingers 3 3 fingers None With dust cover Note) ø16, ø20 and ø25 are not available with dust cover. 16 20 25 32 3 32 Without center pusher Cylinder type Spring type Note) ø16, ø20 and ø25 are not available with center pusher. Type Cylinder bore M thread ø16 to ø63 Rc NPT ø80 G Dust cover type (with dust cover only) Action D Double acting Nil F S Chloroprene rubber (CR) Fluororubber (FKM) Silicone rubber (Si) Applicable Auto Switches /Refer to pages 797 to 850 for further information on auto switches. 2 pcs. Nil 1 pc. S n Note) “n” pcs. Refer to page 603 for details. Note) Symbol entry examples when mounting auto switches on air gripper with cylinder type center pusher } 1. Air gripper unit ············ 1 pc. Nil Center pusher unit ······ 1 pc. Total of 2 pcs. MHSH3-32DA-M9N 2. Air gripper unit ············ 2 pcs. Enter “4” Center pusher unit ······ 2 pcs. Total of 4 pcs. MHSH3-32DA-M9N4 } Auto switch Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, refer to the table below. Lead wire length (m)∗ Pre-wired Load voltage Auto switch model Applicable load AC DC Perpendicular In-line 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector 3-wire (NPN) M9NV M9N 5 V, IC circuit 3-wire (PNP) — M9PV M9P 12 V — 2-wire M9BV M9B 12 V 3-wire (NPN) M9NWV M9NW 5 V, IC Relay, Diagnostic circuit 3-wire (PNP) 24 V — Grommet Yes M9PWV M9PW 12 V (2-color indicator) PLC — 2-wire 12 V M9BWV M9BW 3-wire (NPN) 5 V, M9NAV∗∗ M9NA∗∗ IC Water resistant circuit 3-wire (PNP) 12 V M9PAV∗∗ M9PA∗∗ (2-color indicator) — 2-wire 12 V M9BAV∗∗ M9BA∗∗ ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ····· Nil (Example) M9NW ∗ Auto switches marked with a “” symbol are produced upon receipt of order. 1 m ····· M (Example) M9NWM Note) When using the 2-color indicator type, please make the setting so that the indicator 3 m ····· L (Example) M9NWL is lit in red to ensure the detection at the proper position of the air gripper. 5 m ····· Z (Example) M9NWZ Special function Electrical Indicator light entry Wiring (Output) Solid state auto switch Type Center pusher assembly MHSH 3 A 50 A M9BW Through-hole Number of fingers 3 3 fingers Center pusher assembly Number of auto switches Bore size 32 40 50 63 80 32 mm 40 mm 50 mm 63 mm 80 mm Nil S Center pusher A B Cylinder type Spring type Applicable Auto Switches /Refer to pages 797 to 850 for further information on auto switches. Made to Order Refer to page 603 for details. 2 pcs. 1 pc. Auto switch (Cylinder type only) Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, refer to the table below. Load voltage Lead wire length (m)∗ Pre-wired Wiring Auto switch model Applicable (Output) load AC DC Perpendicular In-line 0.5 (Nil) 1(M) 3 (L) 5 (Z) connector 3-wire (NPN) M9NV M9N 5 V, IC circuit 3-wire (PNP) — M9PV M9P 12 V — 2-wire M9BV M9B 12 V 3-wire (NPN) M9NWV M9NW 5 V, IC Relay, Diagnostic circuit 3-wire (PNP) Grommet Yes 24 V — M9PWV M9PW 12 V (2-color indicator) PLC — 2-wire 12 V M9BWV M9BW 3-wire (NPN) 5 V, M9NAV∗∗ M9NA∗∗ IC Water resistant circuit 3-wire (PNP) 12 V M9PAV∗∗ M9PA∗∗ (2-color indicator) — 2-wire 12 V M9BAV∗∗ M9BA∗∗ ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ····· Nil (Example) M9NW ∗ Auto switches marked with a “” symbol are produced upon receipt of order. 1 m ····· M (Example) M9NWM Note) When using the 2-color indicator type, please make the setting so that the indicator 3 m ····· L (Example) M9NWL is lit in red to ensure the detection at the proper position of the air gripper. 5 m ····· Z (Example) M9NWZ Solid state auto switch Type 602 Special function Electrical Indicator light entry Parallel Type Air Gripper 3-Finger Type Through-hole Type MHSH3 Series Model/Specifications Without center pusher Center pusher/Spring type Center pusher/Cylinder type Air Gripper Specifications MHSH3-16D MHSH3-20D MHSH3-25D MHSH3-32D MHSH3-40D MHSH3-50D MHSH3-63D MHSH3-80D Model 16 Cylinder bore size (mm) 20 25 32 40 50 63 80 Air Fluid 0.1 to 0.6 0.2 to 0.6 Operating pressure (MPa) – 10 to 60 Ambient and fluid temperature (°C) ±0.01 Repeatability (mm) 60 120 Max. operating frequency (c.p.m.) 30 Not reguired Lubrication Double acting Action 9 21 36 62 97 155 280 15 26 45 77 118 187 329 490 ø3H10 +0.040 0 ø3H10 +0.040 0 ø4H10+0.048 0 ø6H10+0.048 0 ø10H10 +0.058 0 ø12H10 +0.070 0 ø16H10 +0.070 0 ø20H10 +0.084 0 4 4 6 8 8 12 16 20 Effective gripping force (N) (Note 1) External hold at 0.5 MPa Internal hold Through hole diameter (mm) Opening/Closing stroke (dia.) (mm) 400 Weight (g) 90 140 220 410 570 970 1,650 2,920 Note 1) Values for ø16 to ø25 are with gripping point L = 20 mm, for ø32 to ø63 with gripping point L = 30 mm, and for ø80 with gripping point L = 50 mm. Refer to “Effective Gripping Force” data on pages 606 to 609 for the gripping force at each gripping position. Center Pusher (Cylinder type) Specifications Symbol Double acting: Internal grip Double acting: External grip MHSH3-32DA MHSH3-40DA MHSH3-50DA MHSH3-63DA MHSH3-80DA Model Pusher cylinder bore size (mm) 12 20 25 Operating pressure (MPa) 60 Symbol -X4 -X5 -X50 -X53 -X56 -X63 -X77A -X77B -X78A -X78B -X79 -X79A Specifications/Description Heat resistance (100°C) Not reguired Action Double acting Pusher stroke (mm) Fluororubber seal Pusher thrust (N) at 0.5 MPa Without magnet Weight (g) EPDM seal/Fluorine grease Axial ported Fluorine grease Dust cover adhesion Dust cover adhesion (Finger part only) Dust cover caulking Dust cover caulking (Finger part only) Extention Model Pusher stroke (mm) Pusher spring force (N) Weight (g) MHSHJ3-D Refer to pages 636 to 643 for the specifications of products with auto switches. Center pusher (cylinder type) with dust cover Auto switch installation examples and mounting positions Auto switch hysteresis Auto switch mounting Protrusion of auto switch from edge of body Center pusher (spring type) with dust cover MHSHJ3-DA MHSHJ3-DB MHR MHS 5 5 10 10 15 MHT 45 130 204 335 524 MHY 530 770 1,330 2,300 4,000 MHSH3-32DB MHSH3-40DB MHSH3-50DB MHSH3-63DB MHSH3-80DB 5 5 10 10 15 6 to 10 11 to 15 20 to 25 29 to 34 49 to 59 500 740 1,290 2,250 4,000 ø32 ø40 ø50 ø63 ø80 430 600 1,020 1,710 3,040 550 800 1,380 2.360 4,120 520 770 1,340 2.310 4.120 Weight Through-hole with dust cover MHL MHC Center Pusher (Spring type) Specifications Grease for food processing machines, Fluorine grease Grease for food processing machines 30 Lubrication MHF MHK – 10 to 60 Pusher maximum operating frequency (c.p.m.) (Refer to pages 725 to 748 for details.) 40 0.1 to 0.6 0.2 to 0.6 Ambient and fluid temperature (°C) Made to Order 32 Air Fluid MHZ 603 MHW -X MRHQ MA D- MHSH3 Series Construction Closed condition q i !6 !1 o r !2 y t !4 u !8 e !3 !7 w ø16 to ø25 Open condition ø32 to ø80 Open condition !5 !0� !3 Component Parts Description No. 1 Body 2 Piston 3 Cam (A) 4 5 Material Note Aluminum alloy Hard anodized ø16 to ø25: Stainless steel ø32 to ø80: Aluminum alloy Hard anodized Carbon steel Heat treated, Specially treated Finger Carbon steel Heat treated, Specially treated Cap (A) Aluminum alloy Hard anodized 6 End plate (A) Stainless steel 7 Tubing Stainless steel 8 Guide Aluminum alloy 9 Magnet 10 Hexagon socket head bolt 11 Parallel pin 12 Type C retaining ring Hard anodized — Carbon steel Zinc chromated Stainless steel Carbon steel Nickel plated !8 13 14 15 16 17 18 19 !9 Description No. Material Gasket NBR Gasket NBR Gasket NBR Piston seal NBR Rod seal NBR Rod seal Note NBR Dust cover CR/FKM/Si Replacement Parts Description Dust cover Material Seal kit MHSH3-16D MHSH3-20D MHSH3-25D MHSH3-32D MHSHJ3-32D Main parts MHSH16-PS MHSH20-PS MHSH25-PS MHSH32-PS !3!4!5!6!7!8 — — — MHSHJ3-J32F MHSHJ3-J32 CR FKM !9 MHSHJ3-J32S Si Finger P3316054 P3316154 P3316254 P3316354 Cam (A) P3316053 P3316153 P3316253 P3316353 e MHS-A1603 MHS-A2003 MHS-A2503 MHS-A3203 wo MHSH-A1614 MHSH-A2014 MHSH-A2514 MHSH-A3214 t MHSH3-40D MHSHJ3-40D MHSH3-50D MHSHJ3-50D MHSH3-63D MHSHJ3-63D MHSH3-80D MHSHJ3-80D Main parts MHSH40-PS MHSH50-PS MHSH63-PS MHSH80-PS !3!4!5!6!7!8 Piston assembly Cap Description Seal kit r MHSHJ3-J50 MHSHJ3-J63 MHSHJ3-J80 MHSHJ3-J40F MHSHJ3-J50F MHSHJ3-J63F MHSHJ3-J80F Si MHSHJ3-J40S MHSHJ3-J50S MHSHJ3-J63S MHSHJ3-J80S Finger P3316454 P3316554 P3316654 P3316754 Cam (A) P3316453 P3316553 P3316653 P3316753 e MHS-A4003 MHS-A5003 MHS-A6303 MHS-A8003 wo MHSH-A4014 MHSH-A5014 MHSH-A6314 MHSH-A8014 t Material MHSHJ3-J40 FKM Dust cover Piston assembly Cap CR ∗ Order 3 pieces of fingers for one unit. Replacement part/Grease pack part no.: MH-G01 (30 g) 604 !9 r Parallel Type Air Gripper 3-Finger Type Through-hole Type MHSH3 Series Construction Center pusher/Cylinder type r t y o !2 w No. Material Note o !1 1 Push holder (P) Aluminum alloy Hard anodized 2 Piston (P) Aluminum alloy Hard anodized 3 Rod holder Aluminum alloy Hard anodized 4 Bumper Urethane rubber 5 Push rod (P) 6 Rubber magnet 7 Hexagon socket head bolt Carbon steel Zinc chromated 8 Type C retaining ring Carbon steel Nickel plated 9 Steel balls 10 Gasket NBR 11 Gasket NBR 12 Piston seal NBR 13 Rod seal NBR q u !0 !3 i e Component Parts Description Stainless steel Hard chromed Synthetic rubber Stainless steel Replacement Parts: Seal Kit (Center pusher/Cylinder type) Part no. MHSH3-A32A MHSH3-A40A MHSH3-A50A MHSH3-A63A MHSH3-A80A MHSH32A-PS MHSH40A-PS MHSH50A-PS MHSH63A-PS MHSH80A-PS MHZ Description MHF A set of the above nos. !0, !1, !2 & !3 MHL MHR MHK ∗ Seal kits are sets consisting of items !0, !1, !2 and !3, and can be ordered using the kit number for each cylinder bore size. Replacement part/Grease pack part no.: MH-G01 (30 g) MHS MHC Construction MHT Center pusher/Spring type MHY w i q r u y t e MHW Component Parts -X Material Note 1 Push holder (S) Aluminum alloy Hard anodized 2 Cap (S) Stainless steel 3 Spring holder Stainless steel 4 Spring Stainless steel 5 Push rod (S) Stainless steel Hard chromed 6 Hexagon socket head bolt Carbon steel Zinc chromated 7 Hexagon socket head bolt Carbon steel Zinc chromated 8 Type C retaining ring Carbon steel Nickel plated Description No. MRHQ MA 605 D- MHSH3 Series Gripping Point Gripping point • The workpiece gripping point distance should be within the gripping force ranges given for each pressure in the effective gripping force graphs below. • If operated with the workpiece gripping point beyond the indicated ranges, an excessive offset load will be applied to the sliding section of the fingers, which can have an adverse effect on the service life of the product. Gripping point L L External grip Internal grip L: Gripping point distance Effective Gripping Force • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. External Gripping Force Internal Gripping Force MHSH3-16D MHSH3-16D 25 Pressure 0.6 MPa F Gripping force (N) Gripping force (N) 15 Pressure 0.6 MPa 0.5 MPa 10 0.4 MPa 0.3 MPa 5 F 0 5 10 15 20 25 0.5 MPa 15 0.4 MPa 10 0.3 MPa 5 0.2 MPa F 20 0 30 0.2 MPa 5 Gripping point L (mm) 35 Gripping force (N) Gripping force (N) 25 0.5 MPa 20 0.4 MPa 15 0.3 MPa 10 0.2 MPa 5 30 5 10 15 20 25 30 0.3 MPa 15 10 15 20 25 30 35 MHSH3-25D 70 70 60 60 50 Pressure 0.6 MPa 40 0.5 MPa 30 0.4 MPa 20 0.3 MPa 0.2 MPa 10 5 Gripping point L (mm) 20 30 40 Gripping point L (mm) 50 Gripping force (N) Gripping force (N) 0.2 MPa 10 0 35 MHSH3-25D 10 606 0.4 MPa 20 Gripping point L (mm) 0 0.5 MPa 25 5 F Internal grip Pressure 0.6 MPa 35 Pressure 0.6 MPa 0 30 40 30 F F 25 20 MHSH3-20D MHSH3-20D External grip 15 10 Gripping point L (mm) Pressure 0.6 MPa 50 0.5 MPa 40 0.4 MPa 30 0.3 MPa 20 0.2 MPa 10 0 10 20 30 40 Gripping point L (mm) 50 Parallel Type Air Gripper 3-Finger Type Through-hole Type MHSH3 Series Effective Gripping Force • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. External Gripping Force Internal Gripping Force MHSH3-32D MHSH3-32D 120 100 100 F Gripping force (N) Gripping force (N) F 0.5 MPa 60 0.4 MPa 0.3 MPa 40 0.2 MPa 20 10 20 30 0.5 MPa 80 0.4 MPa 60 0.3 MPa 40 0.2 MPa 20 0.1 MPa F 0 Pressure 0.6 MPa Pressure 0.6 MPa 80 40 0 50 0.1 MPa 10 Gripping point L (mm) Gripping force (N) Gripping force (N) Pressure 0.6 MPa 120 0.5 MPa 80 0.4 MPa 0.3 MPa 0.2 MPa 40 10 20 30 160 40 0 50 20 30 40 50 0.5 MPa 150 0.4 MPa 0.3 MPa 0.2 MPa MHR MHK 0.1 MPa 10 20 30 40 50 60 Pressure 0.6 MPa 200 0.5 MPa 0.3 MPa 100 0.2 MPa 50 0.1 MPa 0 70 MHS 250 150 Gripping point L (mm) 10 20 0.4 MPa 30 40 50 60 70 -X 500 MRHQ Gripping force (N) Gripping force (N) Pressure 0.6 MPa 300 0.5 MPa 0.4 MPa 200 0.3 MPa 0.2 MPa 100 0 20 40 60 80 Gripping point L (mm) Pressure 0.6 MPa 400 100 MA 0.5 MPa 300 0.4 MPa 0 D- 0.3 MPa 200 0.2MPa 100 0.1 MPa 0.1 MPa 20 MHY MHW MHSH3-63D 400 MHC MHT Gripping point L (mm) MHSH3-63D MHF MHL 300 Pressure 0.6 MPa Gripping force (N) Gripping force (N) 10 350 200 0 MHZ 0.2 MPa 0.1 MPa MHSH3-50D 250 50 0.3 MPa Gripping point L (mm) MHSH3-50D 100 0.5 MPa 0.4 MPa 80 Gripping point L (mm) Internal grip Pressure 0.6 MPa 120 40 0.1 MPa 0 50 200 F F 40 MHSH3-40D 160 F 30 Gripping point L (mm) MHSH3-40D External grip 20 40 60 80 100 Gripping point L (mm) 607 MHSH3 Series Effective Gripping Force F Internal Gripping Force MHSH3-80D MHSH3-80D 600 700 500 Pressure 0.6 MPa 400 0.5 MPa 0.4 MPa 300 0.3 MPa 200 0.2 MPa 100 0.1 MPa 0 External grip 20 40 60 Pressure 0.6 MPa 600 Gripping force (N) F F External Gripping Force Gripping force (N) • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. 500 0.5 MPa 400 0.4 MPa 0.3 MPa 300 0.2 MPa 200 0.1 MPa 100 0 80 20 Gripping point L (mm) F 40 60 80 Gripping point L (mm) F F Internal grip Effective Thrust of Center Pusher Spring Type Cylinder Type Note) MHSH3-32DB MHSH3-32DA 11 60 PA PA: Pusher thrust 10 PA Spring force (N) Pusher thrust (N) 50 40 30 20 10 PB 0 8 7 6 0.1 0.2 0.3 0.4 0.5 0 0.6 1 Supply pressure (MPa) PB: Spring force 4 5 6 16 150 15 PA Spring force (N) Pusher thrust (N) 3 MHSH3-40DB 180 120 90 60 PB 14 13 12 11 30 0 2 Pusher stroke (mm) MHSH3-40DA 0.1 0.2 0.3 0.4 0.5 0.6 0 Supply pressure (MPa) Note) The thrust of the cylinder type is on extension of the push rod. 608 PB 9 1 2 3 4 5 Pusher stroke (mm) 6 Parallel Type Air Gripper 3-Finger Type Through-hole Type MHSH3 Series Effective Thrust of Center Pusher Spring Type Cylinder Type Note) MHSH3-50DB MHSH3-50DA 300 PA 200 150 100 50 PB 0 PB 24 PA Spring force (N) Pusher thrust (N) PA: Pusher thrust 25 250 23 22 21 20 0.1 0.2 0.3 0.4 0.5 0 0.6 2 Supply pressure (MPa) 4 6 8 10 12 Pusher stroke (mm) PB: Spring force MHSH3-63DA MHSH3-63DB 600 34 PA 400 300 200 100 0 PB 33 Pusher thrust (N) Pusher thrust (N) 500 32 31 30 MHZ 29 0.1 0.2 0.3 0.4 0.5 0.6 0 2 Supply pressure (MPa) MHSH3-80DA 8 10 12 MHR PB Spring force (N) 57 PA 600 450 300 MHK MHS 55 53 MHC 51 MHT 49 150 0.1 0.2 0.3 0.4 0.5 0.6 0 Supply pressure (MPa) MHF MHL 59 750 Pusher thrust (N) 6 MHSH3-80DB 900 0 4 Pusher stroke (mm) 3 6 9 12 15 18 Pusher stroke (mm) MHY MHW Note) The thrust of the cylinder type is on extension of the push rod. -X MRHQ MA D- 609 MHSH3 Series Dimensions MHSH3-16D to 25D P (Finger opening port) 30 ° 20 ° øBC øBB øBA +0.025 0 depth 3 K J ø3H9 øWA, depth 1.5 øZA +0.025 0 Q NB P (Finger closing port) BD 2 G 2H9 NA 3 x M4 x 0.7, thread depth 8 P.C.D.R (Mounting thread) FX ° 20 Closed EC Open EO (Closed DC) CB CA O (Open DO) 6 x M3 x 0.5, thread depth TB Thread for mounting attachment AC 3 x ø3.2 through, SB counterbore depth 4 P.C.D.R (Mounting hole) AD AE AA Auto switch mounting groove dimensions (2 locations) MHSH3-16D MHSH3-20D ø4 ø4 5 MHSH3-25D 6 ø4 20° 3 20° 5 6.5 5 3 3 5 5 90 ° 90 ° 20° 20° Model MHSH3-16D MHSH3-20D MHSH3-25D Model MHSH3-16D MHSH3-20D MHSH3-25D 610 AA 46 49 55 AC 7 7 8 AD 10.5 12 13 O 2 2.5 3 P M3 x 0.5 M5 x 0.8 M5 x 0.8 AE 28.5 30 34 BA 30 36 42 BB 30.5 36.5 42.5 Q 6 7 8 R 24 29 34 SB 6 6.5 6.5 BC 34 40 47 TB 5 6 6 BD 27 28 32 CA 7 7 7.5 WA 17H9 +0.043 0 21H9 +0.052 0 26H9 +0.052 0 CB DC DO 17.5 19.5 14 14 20 22 17.5 23.5 26.5 ZA 3H10 +0.040 0 3H10 +0.040 0 4H10 +0.048 0 20° 20° EC 7.5 8 9.5 EO 9.5 10 12.5 FX 12 15 18 G 32 34 38 4 5 5 J 10 12 14 K 4 5 6 NA 8 10 12 (mm) NB 0 5h9 -0.030 0 6h9 -0.030 0 6h9 -0.030 Parallel Type Air Gripper 3-Finger Type Through-hole Type MHSH3 Series MHSH3-32D to 80D 6 x TA, thread depth TB 3 x øSA through, SB, counterbore depth SC P.C.D.R (Mounting hole) CB 3 x UA thread depth 6 UB P.C.D.R FX 3 x YA, thread depth YB P.C.D.R P (Finger opening port) CA ° NA 20° øBC øVA depth VB øWA depth WB øZA L NB øBB øBA Open EO K Closed EC ZC J O Q (Open DO) (Closed DC) øZB 30° 20 BD P (Finger closing port) G M AC AD AE AA Auto switch mounting groove dimensions (2 locations) MHSH3-32D MHSH3-40D ø4 MHSH3-50D MHZ ø4 3 5 3 5 90 ° 90 ° 20° MHF 5 3 7.5 5 5 7 7 ø4 MHL 5 90 20° MHR ° 20° 20° 20° MHSH3-63D 20° MHK MHSH3-80D MHS MHC MHT 5 11 3 5 90 ° ° 20° 20° MHSH3-32D MHSH3-40D MHSH3-50D MHSH3-63D MHSH3-80D Model MHSH3-32D MHSH3-40D MHSH3-50D MHSH3-63D MHSH3-80D AA 63 66 80 91 108 MHW 3 5 90 Model MHY ø4 5 10 ø4 AC 9 9 10 12 15 P M5 x 0.8 M5 x 0.8 M5 x 0.8 M5 x 0.8 Rc 1/8 (G 1/8, NPT 1/8) AD 15.5 17.5 21 26 31.5 AE BA BB BC 38.5 54 54.5 62 39.5 62 62.5 72 74 74.5 84 49 92 92.5 102 53 61.5 112 112.5 125 Q 11 12 14 17 20 R 44 52 63 78 98 -X BD 36 37 46 50 57 CA 9.5 10.5 11.5 13 14 CB 19 19 26.5 28 31 SA SB SC TB TA 4.2 8 8 7 M4 x 0.7 4.2 8 8 7 M4 x 0.7 5.1 9.5 8 M5 x 0.8 10 6.6 11 8 M5 x 0.8 10 6.6 11 12 8 M6 x 1 DC 31.5 36 42 51 63 DO 35.5 40 48 59 73 EC 11.5 15 18 23 31 EO 15.5 19 24 31 41 UA UB VA M5 x 0.8 10 4H9 +0.030 0 M5 x 0.8 10 4H9 +0.030 0 M6 x 1 12 5H9 +0.030 0 M8 x 1.25 16 6H9 +0.030 0 M8 x 1.25 16 6H9 +0.030 0 FX 22 26 32 40 50 VB 4 4 5 6 6 G 6 43.5 7 45 9 55.5 11 61 12 72 WA 34H9 +0.062 0 42H9 +0.062 0 52H9 +0.074 0 65H9 +0.074 0 82H9 +0.087 0 MRHQ 20° 20° L J 20 21 24 28 32 K 9 9 10 11 12 WB 2 2 2 2.5 3 YA M4 x 0.7 M4 x 0.7 M5 x 0.8 M6 x 1 M6 x 1 2H9 +0.025 0 3H9 +0.025 0 4H9 +0.030 0 6H9 +0.030 0 8H9 +0.036 0 YB 8 8 10 12 12 M 2 2 2 3 4 NA 14 16 18 24 28 ZA 6H10 +0.048 0 10H10 +0.058 0 12H10 +0.070 0 16H10 +0.070 0 20H10 +0.084 0 NB 0 8h9 -0.036 0 8h9 -0.036 0 10h9 -0.036 0 12h9 -0.043 0 14h9 -0.043 ZB 7.4 11.4 13.4 17.4 21.4 (mm) O 4.5 4.5 5 5.5 6 ZC 9 9 10 12 15 611 MA D- MHSH3 Series Dimensions: Center Pusher/Cylinder Type MHSH3-32DA to 80DA M5 x 0.8 (Pusher retraction port) Thread depth UD FX CC CC 3 x UC øZD ZE øBE øBF øBG Pusher extended ZF Pusher retracted ZG ZJ øVA depth VB AH ZH, thread depth Z AJ M5 x 0.8 (Pusher extension port) AG (AF) Center pusher auto switch mounting groove dimensions (2 locations) MHSH3-32DA MHSH3-40DA MHSH3-50DA ø4 ø4 3 2.7 5 12 3 5.8 5.7 5 8.8 3 3.3 6.3 ø4 12 6 16 MHSH3-63DA MHSH3-80DA ø4 6 3 8.2 11.2 3 7.2 10.2 ø4 6 21 18 Note) For dimensions, refer to the MHSH3-32 to 80D dimensions on page 611. Model MHSH3-32DA MHSH3-40DA MHSH3-50DA MHSH3-63DA MHSH3-80DA 612 AF 35 36 44 48 58 AG 26 27 33 35 45 AH 9 12 15 18 20 AJ 9 9 11 13 13 BE 30 38 48 58 68 BF 0 32h9 -0.062 0 40h9 -0.062 0 50h9 -0.062 0 60h9 -0.074 0 70h9 -0.074 BG 53.5 61.5 73.5 91.5 111.5 CC FX 9.5 22 13.5 26 17.5 32 20 40 25 50 UC M5 x 0.8 M5 x 0.8 M6 x 1 M8 x 1.25 M8 x 1.25 UD 10 10 12 16 16 UE 5.5 5.5 6.6 8.6 8.6 VA 4H9 +0.030 0 4H9 +0.030 0 5H9 +0.030 0 6H9 +0.030 0 6H9 +0.030 0 VB 4 4 5 6 6 ZD 6 10 12 16 20 ZE 5 8 10 14 17 ZF 20 21 28 32 41 ZG 15 16 18 22 26 ZH M3 x 0.5 M5 x 0.8 M6 x 1 M8 x 1.25 M10 x 1.5 Z 6 10 12 16 20 (mm) ZJ 3.5 4.5 5 7 8 Parallel Type Air Gripper 3-Finger Type Through-hole Type MHSH3 Series Dimensions: Center Pusher/Spring Type MHSH3-32DB to 80DB Thread depth UD FX 3 x øUE Pusher extended ZF Pusher retracted ZG ZE øZD øBE øBF øBG 3 x UC øVA depth VB ZJ øWC depth WD AH ZH, thread depth Z AJ AG (AF) øBF øBG MHZ MHF MHL AH MHR AF MHK MHSH3-32DB, 40DB MHS MHC Note) For dimensions, refer to the MHSH3-32 to 80D dimensions on page 611. Model MHSH3-32DB MHSH3-40DB MHSH3-50DB MHSH3-63DB MHSH3-80DB Model MHSH3-32DB MHSH3-40DB MHSH3-50DB MHSH3-63DB MHSH3-80DB AF 18 21 30 35 48 AG — — 19 22 35 ZH M3 x 0.5 M5 x 0.8 M6 x 1 M8 x 1.25 M10 x 1.5 AH 9 12 15 18 20 AJ 9 9 11 13 13 Z 6 10 12 16 20 ZJ 3.5 4.5 5 7 8 BE — — 48 58 68 BF 0 32h9 -0.062 0 40h9 -0.062 0 50h9 -0.062 0 60h9 -0.074 0 70h9 -0.074 BG 53.5 61.5 73.5 91.5 111.5 FX 22 26 32 40 50 UC M5 x 0.8 M5 x 0.8 M6 x 1 M8 x 1.25 M8 x 1.25 UD 10 10 12 16 16 UE 5.5 5.5 6.6 8.6 8.6 VA 4H9 +0.030 0 4H9 +0.030 0 5H9 +0.030 0 6H9 +0.030 0 +0.030 6H9 0 VB 4 4 5 6 6 WC 20 +0.1 0 24 +0.1 0 32 +0.1 0 42 +0.1 0 +0.1 52 0 WD 1.5 1.5 1.5 2 2 ZD 6 10 12 16 20 ZE 5 8 10 14 17 ZF 20 21 28 32 41 MHT MHY (mm) ZG 15 16 18 22 26 MHW -X MRHQ MA D- 613 MHSH3 Series Dimensions: Through-hole with Dust Cover MHSHJ3-32D to 80D 6 x TA thread depth TB Thread for mounting attachment CA FX 3 x YA, thread depth YB P.C.D.R Q SD øB K Closed EC øHA Open EO øHB J O SD (Open DO) (Closed DC) 20° 20 ° CB 3 x UA thread depth 6 UB P.C.D.R (Mounting thread) P (Finger opening port) øVA depth VB øWA depth WB øZA L NB 3 x øSA, through SB, counterbore depth SC (See section SD-SD) P.C.D.R (Mounting hole) P (Finger closing port) M AC AD AE AA MHSHJ3-32D MHSHJ3-40D ø4 5 90 ° 20° A 20° 5 3 5 90 ° (3 x øSA) ø4 7.5 7 3 5 5 (Counterbore dia. SB) MHSHJ3-50D ø4 7 Counterbore depth SC Auto switch mounting groove dimensions (2 locations) 3 5 90 ° 20° 20° 20° 20° MHSHJ3-63D MHSHJ3-80D Section SD - SD ø4 11 3 5 5 10 ø4 5 3 90 5 90 ° ° 20° Model MHSHJ3-32D MHSHJ3-40D MHSHJ3-50D MHSHJ3-63D MHSHJ3-80D Model MHSHJ3-32D MHSHJ3-40D MHSHJ3-50D MHSHJ3-63D MHSHJ3-80D 614 AA 63 66 80 91 108 AC 3 3 3 4 5 AE 36 37 46 50 57 AD 24 26 31 37 46 P O 4.5 M5 x 0.8 4.5 M5 x 0.8 M5 x 0.8 5 5.5 M5 x 0.8 6 Rc1/8(G1/8, NPT1/8) Q 11 12 14 17 20 R 44 52 63 78 98 20° 20° A 54 57 70 79 93 B 54 62 74 92 112 CA 9.5 10.5 11.5 13 14 SA SB SC 7 4.2 8 7 4.2 8 5.1 9.5 8 8 6.6 11 8 6.6 11 CB 19 19 26.5 28 31 DC 31.5 36 42 51 63 TA M4 x 0.7 M4 x 0.7 M5 x 0.8 M5 x 0.8 M6 x 1 DO 35.5 40 48 59 73 TB 8 8 10 10 12 EC 11.5 15 18 23 31 UA M5 x 0.8 M5 x 0.8 M6 x 1 M8 x 1.25 M8 x 1.25 EO 15.5 19 24 31 41 UB 10 10 12 16 16 FX 22 26 32 40 50 HA 80 90 109 133 168 VA 4H9 +0.030 0 4H9 +0.030 0 5H9 +0.030 0 6H9 +0.030 0 +0.030 6H9 0 HB 65 75 88 106 130 VB 4 4 5 6 6 J 20 21 24 28 32 K 9 9 10 11 12 20° L 2H9 3H9 4H9 6H9 8H9 WB WA 2 34H9 +0.062 0 2 42H9 +0.062 0 2 52H9 +0.074 0 +0.074 2.5 65H9 0 +0.087 3 82H9 0 +0.025 0 +0.025 0 +0.030 0 +0.030 0 +0.036 0 M 2 2 2 3 4 (mm) NB 0 8h9 -0.036 0 8h9 -0.036 0 10h9 -0.036 0 12h9 -0.043 0 14h9 -0.043 YB YA ZA 8 6H10 +0.048 M4 x 0.7 0 8 10H10 +0.058 M4 x 0.7 0 M5 x 0.8 10 12H10 +0.070 0 12 16H10 +0.070 M6 x 1 0 +0.084 12 20H10 0 M6 x 1 Parallel Type Air Gripper 3-Finger Type Through-hole Type MHSH3 Series Dimensions: Center Pusher with Dust Cover/Cylinder Type MHSHJ3-32DA to 80DA Thread depth UD øZD ZE øBE øBF 3 x UC CC FX CC øBG Pusher extended ZF Pusher retracted ZG 3 x øUE M5 x 0.8 (Pusher retraction port) ZH, thread depth Z ZJ øVA depth VB AH AJ M5 x 0.8 (Pusher extension port) AG (AF) MHZ Note) For dimensions, refer to the MHSHJ3-32 to 80D dimensions on page 614. For auto switch mounting groove, refer to MHSH3-32 to 80DA on page 612. MHF MHL MHR Model MHSHJ3-32DA MHSHJ3-40DA MHSHJ3-50DA MHSHJ3-63DA MHSHJ3-80DA AF 35 36 44 48 58 AG 26 27 33 35 45 AH 9 12 15 18 20 AJ 9 9 11 13 13 BE 30 38 48 58 68 BF BG 0 32h9 -0.062 53.5 0 40h9 -0.062 61.5 0 50h9 -0.062 73.5 0 60h9 -0.074 91.5 0 70h9 -0.074 111.5 CC 9.5 13.5 17.5 20 25 FX 22 26 32 40 50 UC UD M5 x 0.8 10 M5 x 0.8 10 M6 x 1 12 M8 x 1.25 16 M8 x 1.25 16 UE 5.5 5.5 6.6 8.6 8.6 VA 4H9 +0.030 0 4H9 +0.030 0 5H9 +0.030 0 6H9 +0.030 0 6H9 +0.030 0 VB 4 4 5 6 6 ZD 6 10 12 16 20 ZE 5 8 10 14 17 ZF 14 15 21 24 31 ZG 9 10 11 14 16 ZH M3 x 0.5 M5 x 0.8 M6 x 1 M8 x 1.25 M10 x 1.5 Z 6 10 12 16 20 (mm) ZJ 3.5 4.5 5 7 8 MHK MHS MHC MHT MHY MHW -X MRHQ MA D- 615 MHSH3 Series Dimensions: Center Pusher with Dust Cover/Spring Type MHSHJ3-32DB to 80DB Thread depth UD Pusher extended ZF Pusher retracted ZG FX øBE øBF øBG 3 x øUE 3 x UC ZE øZD ZH, thread depth Z ZJ øVA depth VB øWC depth WD øBF øBG AH AG (AF) AJ AH AF MHSHJ3-32DB, 40DB Note) For dimensions, refer to the MHSHJ3-32 to 80D dimensions on page 614. (mm) Model MHSHJ3-32DB MHSHJ3-40DB MHSHJ3-50DB MHSHJ3-63DB MHSHJ3-80DB Model MHSHJ3-32DB MHSHJ3-40DB MHSHJ3-50DB MHSHJ3-63DB MHSHJ3-80DB 616 AH 9 12 15 18 20 AF 18 21 30 35 48 AG — — 19 22 35 ZG 9 10 11 14 16 ZH M3 x 0.5 M5 x 0.8 M6 x 1 M8 x 1.25 M10 x 1.5 AJ 9 9 11 13 13 Z 6 10 12 16 20 BE — — 48 58 68 ZJ 3.5 4.5 5 7 8 BF 0 32h9 -0.062 0 40h9 -0.062 0 50h9 -0.062 0 60h9 -0.074 0 70h9 -0.074 BG 53.5 61.5 73.5 91.5 111.5 FX 22 26 32 40 50 UC M5 x 0.8 M5 x 0.8 M6 x 1 M8 x 1.25 M8 x 1.25 UD 10 10 12 16 16 UE 5.5 5.5 6.6 8.6 8.6 VA 4H9 +0.030 0 4H9 +0.030 0 5H9 +0.030 0 6H9 +0.030 0 +0.030 6H9 0 VB 4 4 5 6 6 WC 20 +0.1 0 24 +0.1 0 32 +0.1 0 42 +0.1 0 +0.1 52 0 WD 1.5 1.5 1.5 2 2 ZD 6 10 12 16 20 ZE 5 8 10 14 17 ZF 14 15 21 24 31 Parallel Type Air Gripper/3-Finger Type Long Stroke MHSL3 Series ø16, ø20, ø25, ø32, ø40, ø50, ø63, ø80, ø100, ø125 How to Order Bore size ø16 to ø25 MHSL3 20 D M9BW Made to Order Number of fingers Bore size 3 3 fingers Action 16 16 mm 20 20 mm 25 25 mm Refer to page 619 for details. Auto switch D Double acting Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, refer to the table below. Number of auto switches Nil Solid state auto switch Type Special function Electrical Indicator light entry — Diagnosis (2-color indicator) Grommet Yes Water resistant (2-color indicator) Wiring (Output) Load voltage 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 5 V, 12 V 12V 5 V, 12 V 12 V 5 V, 12 V 12 V DC 24 V Auto switch model In-line AC Perpendicular — M9NV M9PV M9BV M9NWV M9PWV M9BWV M9NAV∗∗ M9PAV∗∗ M9BAV∗∗ 2 pcs. 1 pc. S Applicable Auto Switches/Refer to pages 797 to 850 for further information on auto switches. Lead wire length (m)∗ Pre-wired 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector M9N M9P M9B M9NW M9PW M9BW M9NA∗∗ M9PA∗∗ M9BA∗∗ Applicable load IC circuit — IC circuit — Relay, PLC IC circuit — ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ············ Nil (Example) M9NW ∗ Auto switches marked with a “” symbol 1 m ············ M (Example) M9NWM are produced upon receipt of order. 3 m ············ L (Example) M9NWL 5 m ············ Z (Example) M9NWZ Note) When using the 2-color indicator type, please make the setting so that the indicator is lit in red to ensure the detection at the proper position of the air gripper. Bore size ø32 to ø125 MHSL3 50 D M9BW Made to Order Number of fingers 3 3 fingers Refer to page 619 for details. Action Bore size D Double acting 32 32 mm 40 40 mm 50 50 mm 63 63 mm 80 80 mm 100 100 mm 125 125 mm Port thread type Symbol Nil TN TF Type Cylinder bore M thread ø32 to ø63 Rc NPT ø80 to ø125 G Number of auto switch Nil S n 2 pcs. 1 pc. “n” pcs. Auto switch Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, refer to the table below. Applicable Auto Switches/Refer to pages 797 to 850 for further information on auto switches. Solid state auto switch Type Special function Electrical Indicator light entry — Diagnosis (2-color indicator) Water resistant (2-color indicator) Grommet Yes Wiring (Output) Load voltage 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 5 V, 12 V 12 V 5 V, 12 V 12 V 5 V, 12 V 12 V DC 24 V Auto switch model In-line AC Perpendicular — M9NV M9PV M9BV M9NWV M9PWV M9BWV M9NAV∗∗ M9PAV∗∗ M9BAV∗∗ M9N M9P M9B M9NW M9PW M9BW M9NA∗∗ M9PA∗∗ M9BA∗∗ Lead wire length (m)∗ Pre-wired 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector Applicable load IC circuit — IC circuit — Relay, PLC IC circuit — ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ············ Nil (Example) M9NW ∗ Auto switches marked with a “” symbol 1 m ············ M (Example) M9NWM are produced upon receipt of order. 3 m ············ L (Example) M9NWL 5 m ············ Z (Example) M9NWZ Note 1) When using the 2-color indicator type, please make the setting so that the indicator is lit in red to ensure the detection at the proper position of the air gripper. Note 2) When ordering the air gripper with auto switch, auto switch mounting brackets are supplied with the air gripper having a bore size of ø32 to ø125. Note 3) When ordering the auto switch separately, auto switch mounting brackets (BMG2-012) are required. 618 Parallel Type Air Gripper/3-Finger Type MHSL3 Series Models/Specifications Model Cylinder bore size (mm) MHSL3-16D MHSL3-20D MHSL3-25D MHSL3-32D MHSL3-40D MHSL3-50D MHSL3-63D MHSL3-80D MHSL3-100D MHSL3-125D 16 20 25 32 40 Fluid 50 63 80 100 125 Air Operating pressure (MPa) 0.2 to 0.6 0.1 to 0.6 Ambient and fluid temperature (°C) –10 to 60 Repeatability (mm) ±0.01 Max. operating frequency (c.p.m.) 60 120 Lubrication 30 Not required Action Double acting External grip Effective gripping force (N) at 0.5 MPa Note 1) Internal grip 14 25 42 74 118 187 335 500 750 1,270 16 28 47 82 130 204 359 525 780 1,320 Opening/Closing stroke (mm) (dia.) 10 10 12 16 20 28 32 40 48 64 Weight (g) 80 135 180 370 550 930 1,550 2,850 5,500 11,300 Note 1) Values for ø16 to ø25 are with gripping point L = 20 mm, for ø32 to ø63 with gripping point L = 30 mm, and for ø80 to ø125 with gripping point L = 50 mm. Refer to “Effective Gripping Force” data on pages 621 to 623 for the gripping force at each gripping position. Symbol Double acting: Internal grip Double acting: External grip MHZ Made to Order MHF (Refer to pages 725 to 748 for details.) Symbol -X4 -X5 -X50 -X53 -X56 -X63 -X79 -X79A Specifications/Description Heat resistance (100°C) Fluororubber seal Without magnet EPDM seal/Fluorine grease Axial ported Refer to pages 636 to 643 for the specifications of products with auto switches. MHL Auto switch installation examples and mounting positions Auto switch hysteresis Auto switch mounting Protrusion of auto switch from edge of body MHR MHK MHS Fluorine grease Grease for food processing machines, Fluorine grease MHC Grease for food processing machines MHT MHY MHW -X MRHQ MA D- 619 MHSL3 Series Construction Closed condition Open condition !3 o t !2 u w !0 q i e !1 y r !4 Component Parts Material Note No. 1 Body Aluminum alloy Hard anodized 8 Magnet 2 Piston Aluminum alloy Hard anodized 9 Type C retaining ring 3 Cam Carbon steel Heat treated, Specially treated 10 Piston seal NBR 4 Finger Carbon steel Heat treated, Specially treated 11 Rod seal NBR 5 Cap Aluminum alloy Hard anodized 12 Gasket NBR 6 End plate Stainless steel 13 Gasket 7 Piston bolt Stainless steel 14 Cross recessed flat head screw No. Description Description Material Note — Carbon steel Phosphate coated NBR Carbon steel Zinc chromated Replacement Parts Description MHSL3-16D MHSL3-20D MHSL3-25D MHSL3-32D MHSL3-40D Main parts Seal kit MHSL16-PS MHSL20-PS MHSL25-PS MHSL32-PS MHSL40-PS !0!1!2!3 Finger P3316034 P3316134 P3316234 P3316334 P3316434 r Cam P3316033 P3316133 P3316233 P3316333 P3316433 e Piston assembly MHS-A1601 MHS-A2001 MHS-A2501 MHS-A3201 MHS-A4001 wui End plate assembly MHSL-A1613 MHSL-A2013 MHSL-A2513 MHSL-A3213 MHSL-A4013 y!4 Cap MHS-A1614 MHS-A2014 MHS-A2514 MHS-A3214 MHS-A4014 t Description MHSL3-50D MHSL3-63D MHSL3-80D MHSL3-100D MHSL3-125D Main parts Seal kit MHSL50-PS MHSL63-PS MHSL80-PS MHS100-PS MHSL125-PS !0!1!2!3 Finger P3316534 P3316634 P3316734 P3316834 P3316934 r Cam P3316533 P3316633 P3316733 P3316833 P3316933 e Piston assembly MHS-A5001 MHS-A6301 MHS-A8001 MHS-A10001 MHS-A12501 wui End plate assembly MHSL-A5013 MHSL-A6313 MHSL-A8013 MHSL-A10013 MHSL-A12513 y!4 Cap MHS-A5014 MHS-A6314 MHS-A8014 MHS-A10014 MHS-A12514 t ∗ Order 3 pieces of fingers for one unit. Replacement part/Grease pack part no.: MH-G01 (30 g) 620 Parallel Type Air Gripper/3-Finger Type MHSL3 Series Gripping Point Gripping point • The workpiece gripping point distance should be within the gripping force ranges given for each pressure in the effective gripping force graphs below. • If operated with the workpiece gripping point beyond the indicated ranges, an excessive offset load will be applied to the sliding section of the fingers, which can have an adverse effect on the service life of the product. Gripping point L External grip L: Gripping point distance Effective Gripping Force External Gripping Force MHSL3-16D 25 25 Pressure 0.6 MPa 20 Gripping force (N) Pressure 0.6 MPa 0.5 MPa 15 0.4 MPa 10 0.3 MPa 0.2 MPa 5 F 0 F Internal Gripping Force MHSL3-16D Gripping force (N) • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. L Internal grip 5 10 15 0.5 MPa 15 0.4 MPa 10 0.2 MPa 5 20 25 0 30 5 40 Pressure 0.6 MPa 20 0.4 MPa 15 0.3 MPa 10 0.2 MPa Gripping force (N) Gripping force (N) 0.5 MPa 25 5 F 0 30 30 Pressure 0.6 MPa MHL 0.5 MPa MHR MHK 0.3 MPa 20 15 5 10 15 20 25 30 MHS 0.2 MPa 10 0 35 MHC 5 10 15 20 25 30 35 Gripping point L (mm) MHW 70 60 50 Gripping force (N) Pressure 0.6 MPa 0.5 MPa 40 0.4 MPa 30 0.3 MPa 20 0.2 MPa 10 Pressure 0.6 MPa 50 -X 0.5 MPa 40 MRHQ 0.4 MPa 30 MA 0.3 MPa 20 0.2 MPa D- 10 10 20 30 40 Gripping point L (mm) 50 0 10 20 MHT MHY MHSL3-25D 60 MHZ MHF 5 MHSL3-25D Gripping force (N) 25 0.4 MPa 25 Gripping point L (mm) 0 20 35 30 F 15 MHSL3-20D 35 External grip 10 Gripping point L (mm) MHSL3-20 D Internal grip 0.3 MPa Gripping point L (mm) F F 20 30 40 50 Gripping point L (mm) 621 MHSL3 Series Effective Gripping Force MHSL3-32 D 120 Pressure 0.6 MPa 80 0.5 MPa 60 0.4 MPa 0.3 MPa 40 0.2 MPa 20 0 F 0.1 MPa 10 0.4 MPa 60 20 30 40 50 40 0 Gripping force (N) Pressure 0.6 MPa 0.5 MPa 0.4 MPa 0.3 MPa 80 0.2 MPa 10 20 30 40 50 0.5 MPa 0.2 MPa 20 10 30 40 50 MHSL3-50D 350 300 250 Pressure 0.6 MPa 200 0.5 MPa 0.4 MPa 0.3 MPa 100 0.2 MPa 50 0.1 MPa 20 0.1 MPa Gripping point L (mm) 300 10 0.4 MPa 0.3 MPa 80 0 50 Gripping force (N) Gripping force (N) 40 120 350 0 30 Pressure 0.6 MPa 40 0.1 MPa MHSL3-50 D 150 20 160 Gripping point L (mm) Internal grip 10 MHSL3-40D 120 0 0.1 MPa 200 160 40 F 0.2 MPa Gripping point L (mm) 200 F 0.3 MPa 20 MHSL3-40 D F 0.5 MPa 80 Gripping point L (mm) External grip Pressure 0.6 MPa 100 Gripping force (N) F MHSL3-32D 100 Gripping force (N) F Internal Gripping Force External Gripping Force Gripping force (N) • Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. 30 40 50 60 Pressure 0.6 MPa 250 0.3 MPa 100 0.2 MPa 50 0.1 MPa 0 70 0.5 MPa 200 150 Gripping point L (mm) 10 20 0.4 MPa 30 40 50 60 70 Gripping point L (mm) MHSL3-63 D MHSL3-63D 500 500 400 0.5 MPa 300 0.4 MPa 0.3 MPa 200 0.2 MPa 100 0 20 40 60 80 622 400 0.5 MPa 300 0.4 MPa 0.3 MPa 200 0.2 MPa 100 0.1 MPa Gripping point L (mm) Gripping force (N) Gripping force (N) Pressure 0.6 MPa Pressure 0.6 MPa 100 0 0.1 MPa 20 40 60 80 Gripping point L (mm) 100 Parallel Type Air Gripper/3-Finger Type Internal Gripping Force External Gripping Force MHSL3-80D 700 MHSL3-80D 700 Pressure 0.6 MPa Gripping force (N) Gripping force (N) Pressure 0.6 MPa 600 600 0.5 MPa 500 0.4 MPa 400 0.3 MPa 300 0.2 MPa 200 0.1 MPa 100 0 20 MHSL3 Series 40 0.5 MPa 500 0.4 MPa 400 0.3 MPa 300 0.2 MPa 200 0.1 MPa 100 60 0 80 Gripping point L (mm) 20 40 80 60 Gripping point L (mm) MHSL3-100D MHSL3-100D 1,000 1,000 Pressure 0.6 MPa 800 0.5 MPa 600 0.4 MPa 0.3 MPa 400 0.2 MPa 200 0 Gripping force (N) Gripping force (N) Pressure 0.6 MPa 40 60 80 0 100 0.2 MPa MHZ 0.1 MPa MHF 20 60 40 80 100 MHL Gripping point L (mm) MHSL3-125D MHR MHSL3-125D 1,800 1,600 1,800 Pressure 0.6 MPa 1,400 0.5 MPa 1,200 1,000 0.4 MPa 800 0.3 MPa 600 0.2 MPa 400 0.1 MPa 200 MHK Pressure 0.6 MPa 1,600 Gripping force (N) Gripping force (N) 0.4 MPa 0.3 MPa 400 Gripping point L (mm) 0 0.5 MPa 600 200 0.1 MPa 20 800 1,400 MHS 0.5 MPa 1,200 0.4 MPa 1,000 800 0.3 MPa 600 0.2 MPa 400 MHC MHT 0.1 MPa MHY 200 20 40 60 80 100 Gripping point L (mm) 120 0 20 40 60 80 100 120 MHW Gripping point L (mm) -X MRHQ MA D- 623 MHSL3 Series Dimensions MHSL3 -16D to 25D CB 7 P (Finger closing port) 6 x M3 x 0.5, thread depth TB (Thread for mounting attachment) (AA) 3 x øSA, through SB, counterbore depth SC P.C.D.R (Mounting hole) øVA depth VB AB 2H9 +0.025 0 øBA XA NA BD AD 2 H pth XB NC G Auto switch mounting groove dimensions (2 locations) MHSL3-16D FZ NB 3 x UA thread depth 6 P.C.D.R (Mounting thread) , de J K (Closed DC) O Q B øWA, depth 1.5 20° FY øB 22.5° 20° FX (Open DO) Open EO Closed EC 3 øBC P (Finger opening port) Mounting hole counterbore dimensions MHSL3-20D / 25D MHSL3-16D 6.1 Co un ter ø4 bo re de pth 5 ° 48 3 33° MHSL3-20D 5 ° 3 7.1 Co un 5 6. 5) 54 4.5 ø4 ter 6( 36° bo re Dimensions inside ( ) are for ø25. de pth 8 Note) The counterbore configuration differs only for the mounting hole section between the auto switch mounting grooves. (ø16, ø20 only) Model MHSL3-16D MHSL3-20D MHSL3-25D Model MHSL3-16D MHSL3-20D MHSL3-25D 624 AA AB AD 43.5 40.5 28 46 43 29 49 46 31.5 NC 5 7 7 O 2 2.5 3 BA 30 36 42 P M3 x 0.5 M5 x 0.8 M5 x 0.8 BB 40 45 52 BC 30.6 36.6 42.6 BD 12 16 19 CB DO DC EO 23.5 18.5 13.5 14 14 26 21 14 16.5 30 24 16 Q 6 7 8 R 25 29 34 SA 3.4 3.4 4.5 SB 6.5 6.5 8 SC 5 8 8 TB 5 6 6 EC FX FY 8.5 12.5 11 9 14.5 13 14.5 10 17 UA M3 x 0.5 M3 x 0.5 M4 x 0.7 VA 2H9 +0.025 0 2H9 +0.025 0 3H9 +0.025 0 FZ 3 3 5 G H 30.5 7 32 8 34.2 7.8 4 4 4.5 VB 2 2 3 WA 17H9 +0.043 0 21H9 +0.052 0 26H9 +0.052 0 XA 2H9 +0.025 0 2H9 +0.025 0 3H9 +0.025 0 J 10 12 14 K 4 5 6 XB 2 2 3 NA 8 11 13 (mm) NB 5h9 - 00.030 6h9 - 00.030 6h9 - 00.030 MHSL3 Series Parallel Type Air Gripper/3-Finger Type MHSL3 - 32D to 80D P (Finger opening port) CB CA P (Finger closing port) 3 x øSA, through SB, counterbore depth SC P.C.D.R (Mounting hole) 6 x TA thread depth TB Thread for mounting attachment (AA) AB øBA K Open EO Closed EC pth , de XA XB L J (Closed DC) B 20° 20° FY øB 3 x UA depth UB P.C.D.R (Mounting thread) 22.5° FX Q O (Open DO) øB C AC øVA depth VB øWA depth WB NA AD G H BD FZ M NB NC MHZ MHF Auto switch mounting groove dimensions (4 locations) MHL Mounting hole counterbore dimensions MHR MHSL3-32D MHK 10° 10° MHC MHT 5 Y 4 MHS R7 40 ° ° 40 6. 8 pth de re ) rbo ions e t n it cou pos (2 8.3 MHY Auto switch mounting groove dimensions Model MHSL3-32D MHSL3-40D MHSL3-50D MHSL3-63D MHSL3-80D Model MHSL3-32D MHSL3-40D MHSL3-50D MHSL3-63D MHSL3-80D Model MHSL3-32D MHSL3-40D MHSL3-50D MHSL3-63D MHSL3-80D AA AB 58 55 64 61 77.5 74.5 89 85 116 111 AC 3 3 3 4 5 L 2H9 +0.025 0 +0.025 3H9 0 +0.030 4H9 0 6H9 +0.030 0 8H9 +0.036 0 M 2 2 2 3 4 WA 34H9 +0.062 0 42H9 +0.062 0 52H9 +0.074 0 +0.074 65H9 0 82H9 +0.087 0 WB 2 2 2 2.5 3 AD 35.5 38.5 46.5 51 70 NA 16 18 20 26 30 BA 52 62 70 86 106 NB 0 8h9-0.036 0 8h9-0.036 0 10h9-0.036 0 12h9-0.043 0 14h9-0.043 XA 3H9+0.025 0 4H9+0.030 0 4H9+0.030 0 5H9+0.030 0 6H9+0.030 0 XB 3 4 4 5 6 BB BC 72 52.6 82 62.6 104 70.6 120 86.6 140 106.6 NC 10 10 12 14 16 O 4.5 4.5 5 5.5 6 Note) The counterbore configuration differs only for the mounting hole section between the auto switch mounting grooves. (ø32 only) BD 24 30 32 40 50 CA 8 9 9 12 14 P M5 x 0.8 M5 x 0.8 M5 x 0.8 M5 x 0.8 Rc 1/8 (G 1/8, NPT 1/8) CB 20 22 29 30.5 37.5 Q 11 12 14 17 20 DO 42 47.5 60 70 80.5 R 44 53 62 76 95 DC 34 37.5 46 54 60.5 SA 4.5 5.5 5.5 6.6 6.6 EO 22 26.5 36 42 48.5 SB 8 9.5 9.5 11 11 EC 14 16.5 22 26 28.5 SC 8 11 14.5 17 23 FX 22 26.5 31 38 47.5 FY 19.5 23.5 28 34.5 43.5 TA M4 x 0.7 M4 x 0.7 M5 x 0.8 M5 x 0.8 M6 x 1 TB 8 8 10 10 12 FZ 5 6 6 7 8 G 39.6 42.5 51.3 58.5 78.5 UA M4 x 0.7 M5 x 0.8 M5 x 0.8 M6 x 1 M6 x 1 H 10.4 13.5 17.7 19.5 23.5 UB 6 10 10 12 12 5 7 8 10 11 J 20 21 24 28 32 VA 3H9 +0.025 0 4H9 +0.030 0 +0.030 4H9 0 5H9 +0.030 0 6H9 +0.030 0 (mm) K 9 9 10 11 12 VB 3 4 4 5 6 Y 6 8 7 7.5 9 625 MHW -X MRHQ MA D- MHSL3 Series Dimensions MHSL3 - 100D/125D CB CA P (Finger opening port) P (Finger closing port) øBA K Open EO Closed EC (Closed DC) 22.5° 20° 20° øWA depth WB XA L J O (Open DO) Q øB øVA depth VB AB FY øB (AA) AC FX C B 3 x øSA through SB counterbore depth SC P.C.D.R (Mounting hole) 6 x TA thread depth TB (Thread for mounting attachment) FZ M NB AD G NA H BD B th X dep NC 3 x UA thread depth UB P.C.D.R (Mounting thread) MHSL3-100D MHSL3-125D 10° ° ° 40 40 ° 40 40 ° 10° 10° 10° 5 6. 4 90 ° Model MHSL3-100D MHSL3-125D Model MHSL3-100D MHSL3-125D Model MHSL3-100D MHSL3-125D 626 AA 135 175 AB 129 167 L 8H9 +0.036 0 10H9 +0.036 0 VB 6 8 5 5 13 10 AC 6 8 M 4 6 WA 102H9 +0.087 0 130H9 +0.100 0 AD BA 78 134 102 166 NA 37 43 BB BC 184 134.6 234 166.6 NB 0 18h9 -0.043 0 22h9 -0.052 NC 21 25 XA WB 8H9 +0.036 4 0 6 10H9 +0.036 0 XB 6 8 BD 56 66 O 7.5 10.5 CA 18 24 CB 44.5 54 P Rc 1/4 (G 1/4, NPT 1/4) Rc 3/8 (G 3/8, NPT 3/8) Q 23 31 DO 103 132 DC 79 100 R 118 148 12 7 4 15 6. 90 ° EO 65 80 SA 9 11 EC 41 48 SB 14 17.5 FX 59 74 SC 31 32 FY 54 68 TA M8 x 1.25 M10 x 1.5 FZ 10 12 TB 16 20 G 86 112 H 31 43 UA M8 x 1.25 M10 x 1.5 14 17 UB 16 20 J 38 52 (mm) K 15 21 VA 8H9+0.036 0 10H9+0.036 0 Parallel Type Air Gripper/3-Finger Type MHSL3 Series MHSL3 Series Detailed Dimensions of Mounting Portion of End Plate 3 x A screw depth B P.C.D. C øD depth E F F MHZ (B) MHF MHL øD MHR MHK (E) MHS MHC F-F MHT MHY MHW -X (mm) Model MHSL3-16D MHSL3-20D MHSL3-25D MHSL3-32D MHSL3-40D MHSL3-50D MHSL3-63D MHSL3-80D MHSL3-100D MHSL3-125D A B 5.5 M2 x 0.4 5.4 5.2 M3 x 0.5 8 M4 x 0.7 9.5 C 12.5 16 18.5 25 27 35 44 54 70 80 øD 18 +0.2 +0.1 21.5 +0.2 +0.1 24 +0.2 +0.1 34 +0.2 +0.1 37 +0.2 +0.1 44 +0.2 +0.1 56 +0.2 +0.1 70 +0.2 +0.1 90 +0.2 +0.1 110 +0.2 +0.1 E 0.5 MRHQ 0.6 0.8 MA 1 D- 1.5 627 Parallel Type Air Gripper/4-Finger Type MHS4 Series ø16, ø20, ø25, ø32, ø40, ø50, ø63 How to Order Bore size ø16 to ø25 MHS4 20 D M9BW Number of fingers 4 4 fingers Number of auto switches Bore size 16 16 mm 20 20 mm 25 25 mm Nil Auto switch S Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, Action refer to the table below. D Double acting 2 pcs. 1 pc. Made to Order Refer to page 629 for details. Applicable Auto Switches/Refer to pages 797 to 850 for further information on auto switches. Solid state auto switch Type Special function Electrical Indicator light entry — Diagnosis (2-color indicator) Grommet Yes Water resistant (2-color indicator) Wiring (Output) Load voltage 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 5 V, 12 V 12V 5 V, 12 V 12 V 5 V, 12 V 12 V DC 24 V Auto switch model In-line AC Perpendicular — M9NV M9PV M9BV M9NWV M9PWV M9BWV M9NAV∗∗ M9PAV∗∗ M9BAV∗∗ Lead wire length (m)∗ Pre-wired 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector M9N M9P M9B M9NW M9PW M9BW M9NA∗∗ M9PA∗∗ M9BA∗∗ Applicable load IC circuit — IC circuit — Relay, PLC IC circuit — ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ············ Nil (Example) M9NW ∗ Auto switches marked with a “” symbol are produced upon receipt of order. 1 m ············ M (Example) M9NWM 3 m ············ L (Example) M9NWL 5 m ············ Z (Example) M9NWZ Note) When using the 2-color indicator type, please make the setting so that the indicator is lit in red to ensure the detection at the proper position of the air gripper. Bore size ø32 to ø63 MHS4 50 D M9BW Made to Order Number of fingers Refer to page 629 for details. 4 4 fingers Number of auto switches Bore size 32 40 50 63 32 mm 40 mm 50 mm 63 mm Nil Action S D Double acting 2 pcs. 1 pc. Auto switch Without auto switch (Built-in magnet) Nil ∗ For the applicable auto switch model, refer to the table below. Applicable Auto Switches/Refer to pages 797 to 850 for further information on auto switches. Solid state auto switch Type Special function Electrical Indicator light entry — Diagnosis (2-color indicator) Water resistant (2-color indicator) Grommet Yes Wiring (Output) Load voltage 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire 5 V, 12 V 12 V 5 V, 12 V 12 V 5 V, 12 V 12 V DC 24 V Auto switch model In-line AC Perpendicular — M9NV M9PV M9BV M9NWV M9PWV M9BWV M9NAV∗∗ M9PAV∗∗ M9BAV∗∗ M9N M9P M9B M9NW M9PW M9BW M9NA∗∗ M9PA∗∗ M9BA∗∗ Lead wire length (m)∗ Pre-wired 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector Applicable load IC circuit — IC circuit — Relay, PLC IC circuit — ∗∗ Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. ∗ Lead wire length symbols: 0.5 m ············ Nil (Example) M9NW ∗ Auto switches marked with a “” symbol are produced upon receipt of order. 1 m ············ M (Example) M9NWM 3 m ············ L (Example) M9NWL 5 m ············ Z (Example) M9NWZ Note 1) When using the 2-color indicator type, please make the setting so that the indicator is lit in red to ensure the detection at the proper position of the air gripper. Note 2) When ordering the air gripper with auto switch, auto switch mounting brackets are supplied with the air gripper having a bore size of ø32 to ø125. Note 3) When ordering the auto switch separately, auto switch mounting brackets (BMG2-012) are required. 628 MHS4 Series Parallel Type Air Gripper/4-Finger Type Models/Specifications Model Cylinder bore size (mm) MHS4-16D 16 MHS4-20D MHS4-25D MHS4-32D MHS4-40D 20 25 32 MHS4-50D MHS4-63D 40 50 63 Air Fluid Operating pressure (MPa) 0.1 to 0.6 0.2 to 0.6 –10 to 60 Ambient and fluid temperature (°C) ±0.01 Repeatability (mm) Max. operating frequency (c.p.m.) 60 120 Not required Lubrication Double acting Action External grip Effective gripping force (N) at 0.5 MPa Note 1) Internal grip 10 19 31 55 88 140 251 12 21 35 61 97 153 268 Opening/Closing stroke (mm) 4 4 6 8 8 12 16 Weight (g) 66 110 154 300 390 590 1,095 Note 1) Values for ø16 to ø25 are with gripping point L = 20 mm, for ø32 to ø63 with gripping point L = 30 mm. Refer to “Effective Gripping Force” data on pages 631 and 632 for the gripping force at each gripping position. Symbol Double acting: Internal grip Double acting: External grip MHZ Made to Order (Refer to pages 725 to 748 for details.) Symbol -X4 -X5 -X50 -X53 -X56 -X63 -X79 -X79A Specifications/Description Heat resistance (100°C) Fluororubber seal Auto switch installation examples and mounting positions Without magnet Auto switch hysteresis EPDM seal/Fluorine grease Auto switch mounting Axial ported MHF Refer to pages 636 to 643 for the specifications of products with auto switches. MHL MHR MHK Protrusion of auto switch from edge of body MHS Fluorine grease Grease for food processing machines, Fluorine grease MHC Grease for food processing machines MHT MHY MHW -X MRHQ MA D- 629 MHS4 Series Construction Closed condition Open condition !0 w !2 u t o !3 i r q y e !1 !4 Component Parts Description Description Material Material Note No. 1 Body Aluminum alloy Hard anodized 8 Magnet 2 Piston Aluminum alloy Hard anodized 9 Type C retaining ring 3 Cam Carbon steel Heat treated, Specially treated 10 Piston seal NBR 4 Finger Carbon steel Heat treated, Specially treated 11 Rod seal NBR 5 Cap Aluminum alloy Hard anodized 12 Gasket NBR 6 End plate Stainless steel 13 Gasket 7 Piston bolt Stainless steel 14 Cross recessed flat head screw No. Note — Carbon steel Phosphate coated NBR Carbon steel Zinc chromated Replacement Parts MHS4-16D MHS4-20D MHS4-25D MHS4-32D MHS4-40D MHS4-50D MHS4-63D Main parts Seal kit MHS16-PS MHS20-PS MHS25-PS MHS32-PS MHS40-PS MHS50-PS MHS63-PS !0!1!2!3 Finger P3316004 P3316104 P3316204 P3316304 P3316404 P3316504 P3316604 r Cam P3316043 P3316143 P3316243 P3316343 P3316443 P3316543 P3316643 e Piston assembly MHS-A1601 MHS-A2001 MHS-A2501 MHS-A3201 MHS-A4001 MHS-A5001 MHS-A6301 wui End plate assembly MHS-A1613-4 MHS-A2013-4 MHS-A2513-4 MHS-A3213-4 MHS-A4013-4 MHS-A5013-4 MHS-A6313-4 y!4 MHS-A1614 MHS-A2014 MHS-A2514 MHS-A3214 MHS-A4014 MHS-A5014 MHS-A6314 t Description Cap ∗ Order 4 pieces of fingers for one unit. Replacement part/Grease pack part no.: MH-G01 (30 g) 630 Parallel Type Air Gripper/4-Finger Type MHS4 Series Gripping Point Gripping point • The workpiece gripping point distance should be within the gripping force ranges given for each pressure in the effective gripping force graphs below. • If operated with the workpiece gripping point beyond the indicated ranges, an excessive offset load will be applied to the sliding section of the fingers, which can have an adverse effect on the service life of the product. Gripping point L L External grip Internal grip L: Gripping point distance Effective Gripping Force External Gripping Force Internal Gripping Force MHS4-16D MHS4-16D 15 0.4 MPa 0.3 MPa 5 0.2 MPa Gripping force (N) 0.5 MPa 10 Pressure 0.6 MPa 15 Pressure 0.6 MPa Gripping force (N) • Indication of effective gripping force The gripping force shown in the tables represents the gripping force of one finger when all fingers and attachments are in contact with the workpiece. The gripping force of MHS4 series is the same as MHS2 series while one pair of opposite fingers is used to grip the workpiece and the other pair of fingers is used for positioning. 0.5 MPa 10 0.4 MPa 0.3 MPa 5 MHZ 0.2 MPa F 0 F 5 10 15 20 25 30 0 Gripping point L (mm) 5 10 15 20 25 30 Gripping point L (mm) MHL F MHS4-20 D F MHS4-20D 30 30 F 0.4 MPa 0.2 MPa 0 F 0.3 MPa 10 10 20 30 Gripping force (N) Gripping force (N) External grip 0.5 MPa 20 MHS 20 0.4 MPa MHC 0.3 MPa 10 Gripping point L (mm) F MHK 0.5 MPa 0 40 MHR Pressure 0.6 MPa Pressure 0.6 MPa 0.2 MPa 10 20 30 MHT 40 Gripping point L (mm) -X 50 50 Gripping force (N) Internal grip 0.5 MPa 30 0.4 MPa 20 0.3 MPa 0.2 MPa 10 0 10 20 30 Gripping point L (mm) 40 Gripping force (N) Pressure 0.6 MPa 40 F Pressure 0.6 MPa MRHQ 0.5 MPa MA 40 30 0.4 MPa D- 0.3 MPa 20 0.2 MPa 10 0 10 MHY MHW MHS4-25D MHS4-25D MHF 20 30 40 Gripping point L (mm) 631 MHS4 Series Effective Gripping Force External Gripping Force Internal Gripping Force MHS4-32D MHS4-32 D 75 0.5 MPa 0.4 MPa 45 0.3 MPa 30 0.2 MPa 15 F 0 F Gripping force (N) 60 0.1 MPa 10 20 30 40 Pressure 0.6 MPa 75 Pressure 0.6 MPa Gripping force (N) • Indication of effective gripping force The gripping force shown in the tables represents the gripping force of one finger when all fingers and attachments are in contact with the workpiece. The gripping force of MHS4 series is the same as MHS2 series while one pair of opposite fingers is used to grip the workpiece and the other pair of fingers is used for positioning. 0.5 MPa 60 0.4 MPa 45 0.3 MPa 30 0.2 MPa 15 0 50 Gripping point L (mm) 0.1 MPa 10 20 30 40 50 Gripping point L (mm) F MHS4-40 D F MHS4-40D External grip F Pressure 0.6 MPa 125 0.5 MPa 100 100 75 0.4 MPa 0.3 MPa 50 0.2 MPa 25 0 Gripping force (N) Gripping force (N) 125 20 30 40 0.4 MPa 0.3 MPa 50 0.2 MPa 25 0.1 MPa 10 0.5 MPa 75 0 50 Gripping point L (mm) F Pressure 0.6 MPa 0.1 MPa 10 20 30 40 50 Gripping point L (mm) F MHS4-50D MHS4-50 D 200 200 Pressure 0.6 MPa Internal grip 150 0.5 MPa 0.4 MPa 100 0.3 MPa 0.2 MPa 50 Gripping force (N) F Gripping force (N) Pressure 0.6 MPa 0.5 MPa 150 0.4 MPa 100 0.3 MPa 0.2 MPa 50 0.1 MPa 0.1 MPa 0 20 40 0 60 Gripping point L (mm) 0.4 MPa 200 0.3 MPa 0.2 MPa 100 Gripping force (N) 300 0.5 MPa 0.5 MPa 0.4 MPa 200 0.3 MPa 0.2 MPa 100 0.1 MPa 0.1 MPa 20 40 Gripping point L (mm) 632 60 Pressure 0.6 MPa Pressure 0.6 MPa 300 0 40 MHS4-63D MHS4-63 D Gripping force (N) 20 Gripping point L (mm) 60 0 20 40 60 Gripping point L (mm) Parallel Type Air Gripper/4-Finger Type MHS4 Series Dimensions MHS4-16D to 25D øWA, depth 1.5 2 x ø3.4, through 6.5 counterbore depth SC (Mounting hole) AA RA RA AB 3 RB øB XA depth XB O NA NB RB øVA depth VB Q (Open DO) (Closed DC) 20° FY FZ CB 8 x M3 x 0.5, thread depth TB Thread for mounting attachment 2 x M4 x 0.7, thread depth 8 (Mounting hole) 20° FX 7 Open EO Closed EC P (Finger opening port) MHZ J K MHF 2H9 +0.025 0 MHL P (Finger closing port) 2 G MHR MHK MHS Auto switch mounting groove dimensions (2 locations) MHS4-16D MHS4-20D 5 5 MHY ° 6 5 24 ° 24 ° 24 4.5 MHT 3 6.5 5 3 3 MHC MHS4-25D MHW ø4 ø4 ø4 33° 33° 33° -X MRHQ MA D- Model MHS4-16D MHS4-20D MHS4-25D Model MHS4-16D MHS4-20D MHS4-25D AA 35 38 40 AB 32 35 37 B 30 36 42 CB 11 13 15 DC 33 39 48 DO 37 43 54 RA 18 24 26 RB 16 18 22 SC 8 9.5 10 TB 5 6 6 VA 2H9 +0.025 0 2H9 +0.025 0 3H9 +0.025 0 EC 13 15 20 VB 2 2 3 EO 17 19 26 FX FY 12.5 11 14.5 13 17 14.5 WA 17H9 +0.043 0 21H9 +0.052 0 26H9 +0.052 0 XA 2H9 +0.025 0 2H9 +0.025 0 3H9 +0.025 0 FZ 3 3 5 G 25 27 28 4 5 5 J 10 12 14 K 4 5 6 NA 8 10 12 NB 0 5h9 -0.030 0 6h9 -0.030 0 6h9 -0.030 O 2 2.5 3 P M3 x 0.5 M5 x 0.8 M5 x 0.8 (mm) Q 6 7 8 XB 2 2 3 633 MHS4 Series Dimensions MHS4- 32D/40D 2 x øSA through SB counterbore depth 9 (Mounting hole) RA AA RA 6.4 AB 3 35° 5 35° øVA depth VB RB XA depth XB øB 8h9 0 -0.036 RB NA 8 4.5 20° Q FY FZ (Open DO) (Closed DC) CB 2 x UA, thread depth UB (Mounting hole) 20° FX CA øWA depth 2 M5 x 0.8 (Finger opening port) 8 x M4 x 0.7, thread depth 8 J 9 Open EO Closed EC Thread for mounting attachment M5 x 0.8 (Finger closing port) L G 2 (mm) Model MHS4-32D MHS4-40D Model MHS4-32D MHS4-40D 634 AA 44 47 AB 41 44 B 56 62 SB 8 9.5 UA M5 x 0.8 M6 x 1 CA 8 9 UB 10 12 CB 16 17 VA 3H9 +0.025 0 4H9 +0.030 0 DC 60 66 VB 3 4 DO 68 74 EC 20 24 EO FX FY 28 23 20.5 32 26.5 23.5 WA XA 34H9 +0.062 3H9 +0.025 0 0 +0.062 42H9 0 4H9 +0.030 0 XB 3 4 FZ 5 6 G 30.5 32 6 7 J 20 21 L 2H9 +0.025 0 3H9 +0.025 0 NA 14 16 Q 11 12 RA 38 44 RB 25 28 SA 4.5 5.5 MHS4 Series Parallel Type Air Gripper/4-Finger Type MHS4- 50D / 63D 4 x ø5.1 through 9.5 counterbore depth SC (Mounting hole) RA AA RA 6.4 AB AC 35° 35° 5 øVA depth VB RB øB NB XA depth XB NA RB YC O 20° Q (Open DO) (Closed DC) 4 x M6 x 1, thread depth 12 (Mounting hole) 20° FY FZ FX øWA depth WB 8 x M5 x 0.8, thread depth 10 Thread for mounting attachment CB CA M5 x 0.8 (Finger opening port) Open EO Closed EC MHF K MHZ MHR J MHL MHK M5 x 0.8 (Finger closing port) MHS L G M Model MHS4-50D MHS4-63D Model MHS4-50D MHS4-63D AA 55 66 AB 52 62 AC 3 4 B 70 86 CA 9 12 CB 20 22 DC 74 91 O 5 5.5 Q 14 17 RA 52 66 RB 34 38 SC 12 14 VA 4H9 +0.030 0 5H9 +0.030 0 DO 86 107 VB 4 5 EC 26 35 FX 31 38 EO 38 51 WA 52H9 +0.074 0 65H9 +0.074 0 FZ 6 7 FY 28 34.5 WB XA 4H9 +0.030 2 0 2.5 5H9 +0.030 0 G 37.5 44 XB 4 5 J 24 28 9 11 K 10 11 L 4H9 +0.030 0 6H9 +0.030 0 M 2 3 NA 18 24 (mm) NB 0 10h9 -0.036 0 12h9 -0.043 YC 7 7.5 MHW E -X de pth MRHQ øD F MA (B) F D- C øD (E) F C F øD F-F 2 x A screw depth B 2 x A screw depth B C C ø16 to ø25 ø32 to ø63 MHT MHY MHS4 Series Detailed Dimensions of Mounting Portion of End Plate E depth MHC Model MHS4-16D MHS4-20D MHS4-25D MHS4-32D MHS4-40D MHS4-50D MHS4-63D A B 5.5 M2 x 0.4 5.4 5.2 M3 x 0.5 8 C 11 13 15 18 21 24 32 øD 21 +0.1 0 24 +0.1 0 +0.1 27 0 +0.1 32 0 38 +0.1 0 42 +0.1 0 +0.1 54 0 E 0.5 0.6 0.8 1 635 MHS Series Auto Switch Installation Examples and Mounting Positions Various auto switch applications are possible through different combinations of auto switch quantities and detecting positions. 1) Detection when Gripping Exterior of Workpiece Detection example 1. Confirmation of fingers in reset position Position of fingers fully opened Position to be detected Operation of auto switch 2. Confirmation of workpiece held Position when gripping a workpiece 3. Confirmation of workpiece released Position of fingers fully closed Auto switch turned ON when fingers return. (Light ON) Auto switch turned ON when gripping a workpiece. (Light ON) Step 1) Fully open the fingers. Step 1) Position fingers for gripping a workpiece. When a workpiece is not held (Abnormal operation): Auto switch to turn ON (Light ON) ∗ One position, any of q, w and e can be detected. Two auto switches ∗ Two positions of q, w and e can be detected. Pattern Detection combinations One auto switch How to determine auto switch installation position A B C Step 1) Fully close the fingers. Also, in case of lead wire entry from the At no pressure or Step 2) Insert the auto switch into the auto switch finger direction, installation should be from low pressure, installation groove in the direction shown in the the direction shown in the drawing. connect the auto following drawing. switch to a power supply, and follow the directions. Step 3) Slide the auto switch in the Step 3) Slide the auto switch in the direction of the arrow until the indicator light direction of the arrow until the indicator illuminates. Move the switch further 0.3 to 0.5 mm in the direction of the arrow and light illuminates. fasten it. Position where light turns ON Step 4) Slide the auto switch in the direction of the arrow until the indicator light goes out. 0.3 to 0.5 mm Step 5) Move the auto switch in the opposite direction until the indicator light illuminates. Move the switch further 0.3 to 0.5 mm beyond the position where the indicator light illuminates and fasten it. Position to be secured Position where light turns ON 0.3 to 0.5 mm Position to be secured Note 1) It is recommended that gripping of a workpiece be performed close to the center of the finger stroke. Note 2) When holding a workpiece close at the end of open/close stroke of fingers, detecting performance of the combinations listed in the above table may be limited, depending on the hysteresis of an auto switch, etc. 636 Prallel Type Air Gripper MHS Series Various auto switch applications are possible through different combinations of auto switch quantities and detecting positions. 2) Detection when Gripping Interior of Workpiece Detection example Position to be detected Operation of auto switch 1. Confirmation of fingers in reset position 2. Confirmation of workpiece held 3. Confirmation of workpiece released Position of fingers fully closed Position when gripping a workpiece Position of fingers fully opened Auto switch turned ON when fingers return. (Light ON) Auto switch turned ON when gripping a workpiece. (Light ON) When a workpiece is not held (Abnormal operation): Auto switch to turn ON (Light ON) ∗ One position, any of q, w and e can be detected. Two auto switches ∗ Two positions of q, w and e can be detected. Pattern Detection combinations One auto switch A B C How to determine auto switch installation position At no pressure or low pressure, connect the auto switch to a power supply, and follow the directions. Step 1) Fully close the fingers. Step 1) Position fingers for gripping a workpiece. Step 2) Insert the auto switch into the auto switch installation groove in the direction shown in the following drawing. Step 3) Slide the auto switch in the direction of the arrow until the indicator light illuminates. Move the switch further 0.3 to 0.5 mm in the direction of the arrow and fasten it. Step 1) Fully open the fingers. Also, in case of lead wire entry from the finger direction, installation should be from the direction shown in the drawing. Step 3) Slide the auto switch in the direction of the arrow until the indicator light illuminates. MHZ MHF MHL MHR MHK Position where light turns ON Step 4) Slide the auto switch further in the direction of the arrow until the indicator light goes out. MHS MHC MHT 0.3 to 0.5 mm Position to be secured Step 5) Move an auto switch in the opposite direction and fasten it at a position 0.3 to 0.5 mm beyond the position where the indicator light illuminates. MHY MHW -X Position where light turns ON MRHQ MA 0.3 to 0.5 mm Position to be secured D- Note 1) It is recommended that gripping of a workpiece be performed close to the center of the finger stroke. Note 2) When holding a workpiece close at the end of open/close stroke of fingers, detecting performance of the combinations listed in the above table may be limited, depending on the hysteresis of an auto switch, etc. 637 MHS Series Auto Switch Hysteresis Auto switches have hysteresis similar to micro switches. Use the table below as a guide when adjusting auto switch positions, etc. Hysteresis Switch operating position (ON) Auto switch reset position (OFF) MHS/MHSL Series Auto sw moditch Air gripper el model MHS - 16D MHSL3 MHS - 20D MHSL3 MHS - 25D MHSL3 MHS - 32D MHSL3 MHS - 40D MHSL3 MHS - 50D MHSL3 MHS - 63D MHSL3 MHSJ/MHSH Series (mm) (mm) Hysteresis (Max. value) Auto sw moditch Air gripper el D-M9(V) D-M9W(V) D-M9A(V) model MHSJ3 -16D MHSH3 0.5 0.5 MHSJ3 -20D MHSH3 0.5 0.5 MHSJ3 -25D MHSH3 0.5 0.6 MHSJ3 -32D MHSH3 0.6 0.6 MHSJ3 -40D MHSH3 0.6 0.6 MHSJ3 -50D MHSH3 0.6 0.6 0.6 0.6 MHS - 80D MHSL3 0.6 MHSJ3 -80D MHSH3 MHS -100D MHSL3 0.6 MHS -125D MHSL3 0.6 (mm) Air gripper model Hysteresis (Max. value) D-Y59/Y69/Y7P(V) D-Y7W(V)/Y7BA MHS - 32D MHSL3 0.7 MHS - 40D MHSL3 0.5 MHS - 50D MHSL3 0.5 MHS - 63D MHSL3 0.5 MHS - 80D MHSL3 0.5 MHS -100D MHSL3 0.5 MHS -125D MHSL3 0.5 Note) The actual mounting position should be adjusted after confirming the auto switch performance. 638 D-M9(V) D-M9W(V) D-M9A(V) 0.5 MHSJ3 -63D MHSH3 Auto sw moditch el Hysteresis (Max. value) Prallel Type Air Gripper MHS Series Auto Switch Hysteresis Center pusher/Cylinder type (mm) Air gripper model Auto switc modeh l MHSH3-32DA MHSH3-40DA MHSH3-50DA MHSH3-63DA MHSH3-80DA Hysteresis Hysteresis (Max. value) D-M9(V) D-M9W(V) D-M9A(V) 0.3 0.3 0.2 0.4 0.3 Note) The actual mounting position should be adjusted after confirming the auto switch performance. Switch operating position (ON) Switch reset position (OFF) MHZ MHF MHL MHR MHK MHS MHC MHT MHY MHW -X MRHQ MA D- 639 MHS Series Protrusion of Auto Switch from Edge of Body The projection of an auto switch from the edge of the body is shown in the table below. Use the table as a guideline for mounting. The MHSJ3 and MHSH3 series are described on another page. Mounting with lead wire on side opposite the fingers (mm) Mounting with lead wire on same side as the fingers L In-line electrical entry type L Direction of auto switch mounting on air gripper In-line electrical entry type F Perpendicular electrial entry type Perpendicular electrial entry type L Lead wire type Auto swit Fin ch m ger ode pos Air gripper l itio n model In-line entry D-M9 D-M9W D-M9A L Perpendicular entry D-M9V D-M9WV D-M9AV In-line entry D-M9 D-M9W D-M9A Perpendicular entry D-M9V D-M9WV D-M9AV Open — — 1 — 1 3 — MHS-16D Closed 5 5 7 3 — — — Open — — — — — — — MHS-20D Closed 5 5 7 3 — — — Open — — — — — 1 — MHS-25D Closed 3 3 5 1 — — — Open — — 1 — — — — MHSL3-16D Closed 5 5 7 3 — — — Open — — — — — — — MHSL3-20D Closed 5 5 7 3 — — — Open — — — — — — — MHSL3-25D Closed 3 3 5 1 — — — Open — — — — — — — MHS-32D Closed 5.5 5.5 7.5 3.5 — — — Open — — — — — — — MHS-40D Closed 5 5 7 3.5 — — — Open — — — — — — — MHS-50D Closed 4.5 4.5 6.5 2.5 — — — Open — — — — — — — MHS-63D Closed 2.5 2.5 4.5 0.5 — — — Open — — — — — — — MHS-80D Closed — — — — — — — Open — — — — — — — MHS-100D Closed — — — — — — — Open — — — — — — — MHS-125D Closed — — — — — — — Open — — — — — — — MHSL3-32D Closed 5.5 5.5 7.5 3.5 — — — Open — — — — — — — MHSL3-40D Closed 5 5 7 3.5 — — — Open — — — — — — — MHSL3-50D Closed 4.5 4.5 6.5 2.5 — — — Open — — — — — — — MHSL3-63D Closed 2.5 2.5 4.5 0.5 — — — Open — — — — — — — MHSL3-80D Closed — — — — — — — Open — — — — — — — MHSL3-100D Closed — — — — — — — Open — — — — — — — MHSL3-125D Closed — — — — — — — Note 1) There is no protrusion for sections of the table with no values entered. Note 2) When mounted with lead wires on the finger side, be sure that attachments and workpieces, etc., do not touch switch units or lead wires. Note 3) The actual mounting position should be adjusted after confirming the auto switch performance. 640 1 — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — Prallel Type Air Gripper MHS Series Protrusion of Auto Switch from Edge of Body The projection of an auto switch from the edge of the body is shown in the table below. Use the table as a guideline for mounting. (mm) Mounting with lead wire on side opposite the fingers Mounting with lead wire on same side as the fingers L In-line electrical entry type L Direction of auto switch mounting on air gripper In-line electrical entry type F Perpendicular electrial entry type Perpendicular electrial entry type L Lead wire type Auto swit Fin ch m ger ode pos Air gripper l itio n model In-line entry D-Y59 D-Y7P D-Y7W D-Y7BA L Perpendicular entry D-Y69 D-Y7PV D-Y7WV In-line entry D -Y59 D-Y7P D-Y7W D -Y7BA Perpendicular entry D -Y69 D-Y7PV D-Y7WV Open — — — — 5 — Closed 6 9 — 4 — — Open — — — — 2.5 — MHS-40D Closed 5.5 8 — 4 — — Open — — — — — — MHS-50D Closed 5 7.5 — 3 — — Open — — — — — — MHS-63D Closed 3 5 — 1 — — Open — — — — — — MHS-80D Closed — — — — — — Open — — — — — — MHS-100D Closed — — — — — — Open — — — — — — MHS-125D Closed — — — — — — Open — — — — — — MHSL3-32D Closed 6 9 — 4 — — Open — — — — — — MHSL3-40D Closed 5.5 8 — 4 — — Open — — — — — — MHSL3-50D Closed 5 7.5 — 3 — — Open — — — — — — MHSL3-63D Closed 3 5 — 1 — — Open — — — — — — MHSL3-80D Closed — — — — — — Open — — — — — — MHSL3-100D Closed — — — — — — Open — — — — — — MHSL3-125D Closed — — — — — — Note 1) There is no protrusion for sections of the table with no values entered. Note 2) When mounted with lead wires on the finger side, be sure that attachments and workpieces, etc., do not touch switch units or lead wires. Note 3) The actual mounting position should be adjusted after confirming the auto switch performance. MHS-32D MHZ MHF MHL MHR MHK MHS MHC MHT MHY MHW -X MRHQ MA D- 641 MHS Series Protrusion of Auto Switch from Edge of Body The projection of an auto switch from the edge of the body is shown in the table below. Use the table as a guideline for mounting. (mm) In-line electrical entry type L F Perpendicular electrial entry type L Lead wire type Fin ger Air gripper model Auto pos swit c hm itio ode n l In-line entry D-M9 D-M9W Perpendicular entry D-M9A D -M9V D -M9WV D-M9AV MHSJ3 -16D MHSH3 Open 2 4 — 2 Closed 5.5 7.5 3.5 5.5 MHSJ3 -20D MHSH3 Open 2 4 — 2 Closed 5 7 3 5 MHSJ3 -25D MHSH3 Open — 3 — — Closed 5 7 3 5 MHSJ3 -32D MHSH3 Open — 1 — — Closed 4.5 6.5 2.5 4.5 MHSJ3 -40D MHSH3 Open — — — — Closed 3 5 1 3 MHSJ3 -50D MHSH3 Open — — — — Closed 1.5 3.5 — 1.5 MHSJ3 -63D MHSH3 Open — — — — Closed — 2 — — MHSJ3 -80D MHSH3 Open — — — — Closed — 1 — — Note 1) Indicates the amount of protrusion from the mounting surface F. There is no protrusion from the finger side. Note 2) There is no protrusion for sections of the table with no values entered. Note 3) When mounted with lead wires on the finger side, be sure that attachments and workpieces, etc., do not touch switch units or lead wires. Note 4) The actual mounting position should be adjusted after confirming the auto switch performance. Protrusion from Edge of Push Holder (P) The amount of auto switch protrusion from the push holder (P) end surface is shown in the table below. Use this as a standard when mounting, etc. Center Pusher/Cylinder Type (mm) In-line electrical entry type Lead wire type Fin Air gripper model ger Auto pos MHSH-40DA MHSH-50DA Perpendicular electrial entry type hm itio MHSH-32DA L swit c MHSH-63DA MHSH-80DA n ode D-M9 D-M9W Perpendicular entry D-M9A D -M9V D -M9WV D-M9AV Extended 4 2 2 4 Retracted 9 7 7 9 Extended 3 — 1 3 Retracted 8 6 6 8 Extended — — — — Retracted 7.5 5.5 5.5 7.5 Extended — — — — Retracted 7 5 5 7 Extended — — — — Retracted 4 2 2 4 L Note) The actual mounting position should be adjusted after confirming the auto switch performance. 642 l In-line entry MHS Series Prallel Type Air Gripper Auto Switch Mounting Applicable models: MHS2-16, 20, 25 MHS3-16, 20, 25 MHSJ3-16, 20, 25, 32, 40, 50, 63, 80 MHSH3-16, 20, 25, 32, 40, 50, 63, 80 MHSH3-A32, 40, 50, 63, 80 MHSL3-16, 20, 25 MHS4-16, 20, 25 To set the auto switch, insert the auto switch into the installation groove of the gripper from the direction indicated in the following drawing. After setting the position, tighten the attached auto switch mounting set screw with a flat head watchmaker’s screwdriver. Applicable models: MHS2-32, 40, 50, 63 MHS3-32, 40, 50, 63, 80, 100, 125 MHSL3-32, 40, 50, 63, 80, 100, 125 MHS4-32, 40, 50, 63 (1) To set the auto switch, insert the auto switch into the installation groove of the cylinder as shown below and set it roughly. (2) Insert the auto switch into the auto switch bracket installation groove. (3) After confirming the detecting position, tighten the set screws (M2.5) attached to the auto switch and set it. (4) Be sure to change the detecting position in the state of (2). ø5 to ø6 ø5 to ø6 Flat head watchmaker’s screwdriver Flat head watchmaker’s screwdriver Auto switch mounting screw M2.5 x 4L Auto switch mounting screw M2.5 x 4L Auto switch mounting brackets MHZ Auto switch Auto switch Note) Use a watchmaker’s screwdriver with a grip diameter of 5 to 6 mm to tighten the auto switch mounting screw. The tightening torque should be about 0.05 to 0.15 N·m. Auto Switch Mounting Bracket Part No. Auto switch model D-M9(V) D-M9W(V) D-M9A(V) Auto switch mounting bracket part no. MHF MHL BMG2-012 MHR Note) Use a watchmaker’s screwdriver with a grip diameter of 5 to 6 mm to tighten the set screw (M2.5). The tightening torque should be 0.05 to 1 N·m. It should be turned about 90° beyond the point at which tightening can be felt. MHK MHS MHC MHT MHY MHW -X MRHQ MA D- 643 MHS3 Series Made to Order: Individual Specifications Symbol 1 Single Acting (Normally open, Normally closed) Piping from two directions are possible -X84 Piping and auto switch wiring entries are one way. (For top ported) Air piping Auto switch wiring Top port Side port How to Order MHS3 20 S M9BW X84 Number of fingers 3 Single acting 3 fingers Number of auto switches Nil S n Bore size 16 20 25 32 40 50 63 16 mm 20 mm 25 mm 32 mm 40 mm 50 mm 63 mm 2 pcs. ø16 to ø63 1 pc. “n” pcs. ø32 to ø63 Auto switch Nil Without auto switch (Built-in magnet) * For the applicable auto switch model, refer to the table below. Action S C Single acting (Normally open) Single acting (Normally closed) Applicable Auto Switches/Refer to pages 797 to 850 for further information on auto switches. Solid state auto switch Type Special function Electrical Indicator light entry — Diagnostic indication (2-color Grommet indicator) Water resistant (2-color indicator) Wiring (Output) 3-wire (NPN) 3-wire (PNP) 2-wire 3-wire (NPN) Yes 3-wire (PNP) 2-wire 3-wire (NPN) 3-wire (PNP) 2-wire Load voltage DC 24 V 5 V, 12 V 12 V 5 V, 12 V 12 V 5 V, 12 V 12 V Auto switch model In-line AC Perpendicular — M9NV M9PV M9BV M9NWV M9PWV M9BWV M9NAV** M9PAV** M9BAV** M9N M9P M9B M9NW M9PW M9BW M9NA** M9PA** M9BA** Lead wire length (m)* Pre-wired 0.5 (Nil) 1 (M) 3 (L) 5 (Z) connector V V V V V V v v v V V V V V V v v v V V V V V V V V V v v v v v v v v v v v v v v v v v v Applicable load IC circuit — IC circuit — Relay, PLC IC circuit — ** Water resistant type auto switches can be mounted on the above models, but in such case SMC cannot guarantee water resistance. * Lead wire length symbols: 0.5 m ············ Nil (Example) M9N * Solid state auto switches marked with “p” are produced upon receipt of order. 1 m ············ M (Example) M9NWM 3 m ············ L (Example) M9NL 5 m ············ Z (Example) M9NZ Note 1) When using the 2-color indicator, please make the setting so that the indicator is lit in red to ensure the detection at the proper position of the air gripper. Note 2) When ordering the air gripper with auto switch in MHS3-32S to 63S series, auto switch mounting brackets are required (shipped together). In addition, when ordering the auto switch separately, auto switch mounting brackets (BMG2-012) are required. 644 Made to Order: Individual Specifications MHS3 Series Models/Specifications Model Cylinder bore size (mm) MHS3-16-X84 MHS3-20-X84 MHS3-25-X84 MHS3-32-X84 MHS3-40-X84 MHS3-50-X84 MHS3-63-X84 16 20 25 32 Fluid Operating pressure (MPa) 0.35 to 0.6 50 63 0.25 to 0.6 Ambient and fluid temperature (°C) −10 to 60 ±0.01 Repeatability (mm) Max. operating frequency (c.p.m.) 120 60 Lubrication Not required Action Single acting: Normally open, Normally closed Opening/Closing stroke (mm)(dia.) Normally closed Normally open 40 Air External grip Note) (N) Near fully closed at 0.5 MPa Near fully opened 4 4 6 8 8 12 16 9.6 17.5 29.4 56 92 144 238 10.4 19 31.7 60 99 153 258 Internal grip Note) (N) Near fully closed Spring force only Near fully opened 4.1 7.4 12.5 17.5 25.8 42.2 68.4 3.3 6 10.3 13.5 19 33.6 49 Weight (g) 85 145 210 350 485 740 1330 Internal grip Note) (N) Near fully closed at 0.5 MPa Near fully opened 12.3 21.2 36.5 68 108 169 279 11.3 19.9 34.2 64 103 160 259 External grip Note) (N) Near fully closed Spring force only Near fully opened 3.6 6.2 10.3 13.5 21.2 33.6 49 4.6 7.4 12.5 17.5 26.6 42.2 68.4 Weight (g) 85 145 210 345 485 740 1280 Note) Values for ø16 to ø25 based on gripping point L = 20 mm, for ø32 to ø63 based on gripping point L = 30 mm. Refer to “Effective Gripping Force” data on pages 646 and 647 for the gripping force at each gripping position. Symbol Single acting/Normally open: External grip MHZ Single acting/Normally closed: Internal grip MHF MHL MHR MHK Replacement Parts: Seal kit (Piston seal, Rod seal, Gaskets) Description MHS3-16-X84 MHS3-20-X84 MHS3-25-X84 MHS3-32-X84 MHS3-40-X84 MHS3-50-X84 MHS3-63-X84 Normally open MHS16-PS-X84-S MHS20-PS-X84-S MHS25-PS-X84-S MHS32-PS-X84-S MHS40-PS-X84-S MHS50-PS-X84-S MHS63-PS-X84-S MHS Normally closed MHC MHS16-PS-X84-C MHS20-PS-X84-C MHS25-PS-X84-C MHS32-PS-X84-C MHS40-PS-X84-C MHS50-PS-X84-C MHS63-PS-X84-C Replacement parts/Grease pack part no.: MH-G01 (30 g) MHT MHY MHW -X MRHQ MA D- 645 MHS3 Series Gripping Point Gripping point The workpiece gripping point distance should be within the gripping force ranges given for each pressure in the effective gripping force graphs below. If operated with the workpiece gripping point beyond the indicated ranges, an excessive offset load will be applied to the sliding section of the fingers, which can have an adverse effect on the service life of the product. Gripping point L L External grip L: Gripping point distance External Effective Gripping Force MHS3-40S-X84 20 15 Pressure 0.6 MPa 10 0.5 MPa 0.4 MPa 5 0 0.35 MPa 5 10 15 20 25 30 160 0.5 MPa 80 0.4 MPa 0.3 MPa 40 0.25 MPa 0 35 Pressure 0.6 MPa 120 10 20 Gripping point L (mm) External grip External gripping force (N) MHS3-20S-X84 F 30 25 Pressure 0.6 MPa 20 0.5 MPa 15 0.4 MPa 10 0.35 MPa 5 5 10 15 20 25 30 35 200 0.5 MPa 0.4 MPa 100 0.3 MPa 50 0.25 MPa 10 20 Pressure 0.6 MPa 30 0.5 MPa 20 0.4 MPa 0.35 MPa 20 30 40 50 Gripping point L (mm) External gripping force (N) 100 Pressure 0.6 MPa 60 0.5 MPa 0.4 MPa 40 0.3 MPa 20 0.25 MPa 20 30 40 Gripping point L (mm) 646 50 60 70 400 Pressure 0.6 MPa 300 0.5 MPa 200 0.4 MPa 0.3 MPa 100 0.25 MPa 0 20 40 60 Gripping point L (mm) MHS3-32S-X84 80 External gripping force (N) External gripping force (N) 40 10 40 MHS3-63S-X84 50 0 30 Gripping point L (mm) 60 10 60 Pressure 0.6 MPa 150 0 40 MHS3-25S-X84 0 50 250 Gripping point L (mm) 10 40 MHS3-50S-X84 35 0 30 Gripping point L (mm) External gripping force (N) F F External gripping force (N) MHS3-16S-X84 External gripping force (N) Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. Internal grip 50 80 Made to Order: Individual Specifications MHS3 Series Internal Effective Gripping Force MHS3-40C-X84 20 15 Pressure 0.6 MPa 0.5 MPa 10 0.4 MPa 5 0 0.35 MPa 5 10 15 20 25 30 Internal gripping force (N) F MHS3-16C-X84 Internal gripping force (N) Indication of effective gripping force The effective gripping force shown in the graphs to the right is expressed as F, which is the thrust of one finger when all 3 of the fingers and attachments are in full contact with the workpiece as shown in the figure below. 160 0.5 MPa 80 0.4 MPa 0.3 MPa 40 0.25 MPa 0 35 Pressure 0.6 MPa 120 10 20 Gripping point L (mm) 40 50 60 MHS3-50C-X84 MHZ 30 25 Pressure 0.6 MPa 20 0.5 MPa 15 0.4 MPa 10 0.35 MPa 5 0 5 10 15 20 25 30 35 Internal gripping force (N) 35 Internal gripping force (N) 40 Pressure 0.6 MPa 200 MHL 150 0.5 MPa 0.4 MPa 100 0.3 MPa 50 0.25 MPa 10 20 Gripping point L (mm) 50 40 Pressure 0.6 MPa 30 0.5 MPa 20 0.4 MPa 0.35 MPa 10 40 50 60 70 20 30 40 50 Gripping point L (mm) 0.5 MPa 200 0.4 MPa 0.3 MPa 100 0.25 MPa 20 40 60 MA Pressure 0.6 MPa 0.5 MPa 60 0.4 MPa 40 0.3 MPa 0.25 MPa 20 -X D- 80 10 MHW MRHQ 80 Gripping point L (mm) 100 0 MHS MHY Pressure 0.6 MPa 300 MHS3-32C-X84 20 MHK MHT 400 0 MHR MHC MHS3-63C-X84 60 0 30 Gripping point L (mm) MHS3-25C-X84 10 MHF 250 0 Internal gripping force (N) Internal grip MHS3-20C-X84 Internal gripping force (N) F Internal gripping force (N) F 30 Gripping point L (mm) 30 40 50 Gripping point L (mm) 647 MHS3 Series Dimensions Breath port 20 Plug: Width across flats 5 M3 x 0.5 Finger closing port 20° 20° 11 ø16H9 ( +0.043 ) 0 MHS3-16S-X84: Single acting/Normally open 3 x ø3.3 through 6.5 counterbore depth 8 P.C.D. 25 (Mounting hole) When changed to axial piping 48 20° 20° 45 6 x M3 x 0.5 thread depth 5 (Attachment mounting thread) Plug: Width across flats 5 10 4 ø31 Open 7 Closed 5 (3) 2H9 (+0.025 ) 0 2 6 (Open 17) (Closed 15) 0 5h9 ( –0.030) 8 1.7 3 M3 x 0.5 Finger closing port 13 2 4 38 3 x M4 x 0.7 thread depth 8 P.C.D. 25 (Mounting thread) 3 5 5.5 54° ø30 ø4 4.6 33° Auto switch mounting groove dimensions 648 Made to Order: Individual Specifications MHS3 Series Dimensions ø20H9 (+0.052 ) 0 MHS3-20S/25S-X84: Single acting/Normally open Breath port CA Plug: Width across flats 7 M5 x 0.8 Finger closing port 20° 20° CB 3.5 CC M5 x 0.8 Finger closing port 3 x øSA through SB counterbore depth SC P.C.D. R (Mounting hole) AA AB 20° 20° Plug: Width across flats 7 K øB MHZ J MHF 2H9 (+0.025 ) 0 Q O Open EO Closed EC (3) (Open DO) (Closed DC) When changed to axial piping 0 6h9 (−0.030) NA 6 x M3 x 0.5 thread depth 6 (Attachment mounting thread) 2 MHL 3 x UA thread depth UB P.C.D. R (Mounting thread) G 5 MHR MHK MHS MHC ø4 5 33° MHT Y ° 54 3 5 MHY Auto switch mounting groove dimensions MHW -X MRHQ MA D- (mm) Model AA AB B CA CB CC DC DO EC EO G J K MHS3-20S-X84 55 52 36 24 13 2.2 18 20 6 8 44 12 5 MHS3-25S-X84 60 57 42 27 15 2 21 24 7 10 48 14 6 Model NA O Q R SA SB SC UB Y MHS3-20S-X84 10 2.5 7 29 3.3 6.5 MHS3-25S-X84 12 3 8 34 4.2 8 9.5 10 UA M4 x 0.7 8 M5 x 0.8 10 6 6.5 649 MHS3 Series Dimensions MHS3-32S to 63S-X84: Single acting/Normally open Breath port M5 x 0.8 Finger closing port 20° CA 20° øWA CB CC 3.5 M5 x 0.8 Finger closing port 3 x øSA through SB counterbore depth SC P.C.D. R (Mounting hole) When changed to axial piping AA AB Plug: Width across flats 7 20° K øB 20° J (BA) L O Q (Open DO) (Closed DC) Open EO Closed EC (AC) Plug: Width across flats 7 I NB G M NA 3 x UA thread depth UB P.C.D. R (Mounting thread) 6 x TA thread depth TB (Attachment mounting thread) 40 ° 10° 10° ° 40 4 Y 5 6. Auto switch mounting groove dimensions (mm) Model AA AB AC B BA CA CB CC DC DO EC EO G I J K L 2H9 ( +0.025 ) 0 MHS3-32S-X84 66 63 3 52 — 30 16 2.2 28 32 8 12 52.5 6 20 9 MHS3-40S-X84 66 63 3 62 — 28 17 2 31 35 10 14 51 7 21 9 3H9 ( +0.025 ) 0 MHS3-50S-X84 78 75 3 70 0.3 32 20 2 35 41 11 17 60.5 9 24 10 4H9 ( +0.030 ) 0 MHS3-63S-X84 92 88 4 86 — 38 22 2 43 51 15 23 70 11 28 11 6H9 ( +0.030 ) 0 Model M NA MHS3-32S-X84 2 14 0 8h9 ( −0.036 ) 0 ( −0.036 ) 0 ( −0.036 ) 0 ( −0.043 ) NB MHS3-40S-X84 2 16 8h9 MHS3-50S-X84 2 18 10h9 MHS3-63S-X84 3 24 12h9 650 O Q R SA SB SC TA TB UA UB WA 4.5 11 44 4.2 8 9 M4 x 0.7 8 M5 x 0.8 10 25H9 ( +0.052 ) 0 6 ( +0.052 ) 0 ( +0.062 ) 0 ( +0.062 ) 0 8 4.5 12 53 5.1 9.5 9 M4 x 0.7 8 M6 x 1 12 30H9 5 14 62 5.1 9.5 12 M5 x 0.8 10 M6 x 1 12 40H9 5.5 17 76 6.6 14 M5 x 0.8 10 M8 x 1.25 16 50H9 11 Y 7 7.5 Made to Order: Individual Specifications MHS3 Series Dimensions MHS3-16C-X84: Single acting/Normally closed Plug: Width across flats 5 M3 x 0.5 Finger opening port M3 x 0.5 Finger opening port 3 Breath port 3 x ø3.3 through 6.5 counterbore depth 8 P.C.D. 25 (Mounting hole) 22 9 20° 45 25° MHZ 4 ø31 Closed 5 Open 7 Plug: Width across flats 5 10 MHF 2H9 (+0.025 ) 0 2 6 (Closed 15) (Open 17) 0 5h9 (−0.030 ) When changed to axial piping 48 (3) 8 ø16H9 (+0.043 ) 0 20° 25° 2 2 27 4 38 MHL 3 x M4 x 0.7 thread depth 8 P.C.D. 25 (Mounting thread) MHR 6 x M3 x 0.5 thread depth 5 (Attachment mounting thread) MHK MHC MHT 5.5 ° 54 ø4 3 4.8 ø30 MHS 5 MHY 33° Auto switch mounting groove dimensions MHW -X MRHQ MA D- 651 MHS3 Series Dimensions MHS3-20C/25C-X84: Single acting/Normally closed Plug: Width across flats 7 M5 x 0.8 Finger opening port M5 x 0.8 Finger opening port CC CB Breath port 3 x øSA through SB counterbore depth SC P.C.D. R (Mounting hole) ø20H9 (+0.052 ) 0 20° 25° 3.5 11 AA AB 20° 25° K øB Plug: Width across flats 7 J 2H9 (+0.025 ) 0 Q O Closed EC Open EO (3) (Closed DC) (Open DO) When changed to axial piping 0 6h9 (−0.030) NA 6 x M3 x 0.5 thread depth 6 (Attachment mounting thread) 2 3 x UA thread depth UB P.C.D. R (Mounting thread) G 5 ø4 4.8 Y ° 54 3 5 33° Auto switch mounting groove dimensions (mm) Model AA AB B CB CC DC DO EC EO G J K MHS3-20C-X84 55 52 36 26 2.2 18 20 6 8 44 12 5 MHS3-25C-X84 60 57 42 31 2 21 24 7 10 48 14 6 Model NA O Q R SA SB SC UB Y MHS3-20C-X84 10 2.5 7 29 3.3 6.5 MHS3-25C-X84 12 3 8 34 4.2 8 652 9.5 10 UA M4 x 0.7 8 M5 x 0.8 10 6 6.5 Made to Order: Individual Specifications MHS3 Series Dimensions MHS3-32C to 63C-X84: Single acting/Normally closed M5 x 0.8 Finger opening port Plug: Width across flats 7 3.5 CB Breath port 20° øWA 20° 2 M5 x 0.8 Finger opening port CA When changed to axial piping 3 x øSA through SB counterbore depth SC P.C.D. R (Mounting hole) AA AB Plug: Width across flats 7 20° 20° øB MHZ J K MHF MHL L O Q (Closed DC) (Open DO) Closed EC Open EO (AC) I NB NA 3 × UA thread depth UB P.C.D. R (Mounting thread) G M MHR MHK 6 × TA thread depth TB (Attachment mounting thread) MHS MHT ° 40 40 ° 10° 10° MHC MHY 3 5 Y 4. 8 MHW Auto switch mounting groove dimensions -X MRHQ (mm) Model AA AB AC B CA CB CC DC DO EC EO G I J K L M MHS3-32C-X84 66 63 3 52 12 34 2.2 28 32 8 12 52.5 6 20 9 2H9 ( +0.025 ) 0 2 ( +0.025 ) 0 ( +0.030 ) 0 ( +0.030 ) 0 2 MHS3-40C-X84 66 63 3 62 11 34 2 31 35 10 14 51 7 21 9 3H9 MHS3-50C-X84 78 75 3 70 13 39 2 35 41 11 17 60.5 9 24 10 4H9 MHS3-63C-X84 92 88 4 86 13 47 2 43 51 15 23 70 11 28 11 6H9 Model NA MHS3-32C-X84 14 0 8h9 ( −0.036 ) MHS3-40C-X84 16 8h9 MHS3-50C-X84 18 10h9 MHS3-63C-X84 24 12h9 0 ( −0.036 ) 0 ( −0.036 ) 0 ( −0.043 ) NB 2 3 O Q R SA SB SC TA TB UA UB WA Y 4.5 11 44 4.2 8 9 M4 x 0.7 8 M5 x 0.8 10 25H9 ( +0.052 ) 0 5.7 ( +0.052 ) 0 ( +0.062 ) 0 ( +0.062 ) 0 7.5 4.5 12 53 5.1 9.5 9 M4 x 0.7 8 M6 x 1 12 30H9 5 14 62 5.1 9.5 12 M5 x 0.8 10 M6 x 1 12 40H9 5.5 17 76 6.6 14 M5 x 0.8 10 M8 x 1.25 16 50H9 11 6 7 653 MA D- MHS3 Series Protrusion of Auto Switch from Edge of Body The projection of an auto switch from the edge of the body is shown in the table below. Use the table as a guideline for mounting. (mm) Mounting with lead wire on side opposite the fingers L Mounting with lead wire on same side as the fingers L In-line electrical entry type In-line electrical entry type Direction of auto switch mounting on air gripper Perpendicular electrical entry type F Perpendicular electrical entry type L Lead wire type Auto swit Fin ch m ger ode pos l itio n Air gripper model MHS3-16S-X84 MHS3-20S-X84 MHS3-25S-X84 MHS3-32S-X84 MHS3-40S-X84 MHS3-50S-X84 MHS3-63S-X84 MHS3-16C-X84 MHS3-20C-X84 MHS3-25C-X84 MHS3-32C-X84 MHS3-40C-X84 MHS3-50C-X84 MHS3-63C-X84 Open Closed Open Closed Open Closed Open Closed Open Closed Open Closed Open Closed Open Closed Open Closed Open Closed Open Closed Open Closed Open Closed Open Closed In-line entry D-M9 D-M9W — — — — — — — — — — — — — — — 2.5 — — — — — — — — — — — — L Perpendicular entry D-M9A D-M9V D-M9WV — — — — — — — — — — — — — — — 4.5 — 2 — — — 0.5 — 1 — — — — — — — — — — — — — — — — — — — 0.5 — — — — — — — — — — — — In-line entry D-M9AV D-M9 D-M9W — — — — — — — — — — — — — — — 2.5 — — — — — — — — — — — — 1 — — — — — — — — — — — — — — — — — — — — — — — — — — — Perpendicular entry D-M9A D-M9V D-M9WV D-M9AV 3 — — — 1 — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — 1 — — — — — — — — — — — — — — — — — — — — — — — — — — — Note 1) There is no protrusion for sections of the table with no values entered. Note 2) When mounted with lead wires on the finger side, be sure that attachments and workpieces, etc., do not touch switch units or lead wires. Note 3) The actual mounting position should be adjusted after confirming the auto switch performance. 654 MHS Series Specific Product Precautions 1 Be sure to read this before handling the products. Mounting Air Grippers/MHS Series Possible to mount from 2 directions. How to Mount Air Gripper How to Mount Air Gripper Body tapped Body tapped L L Body through-hole Model Applicable Max. tightening Max. screw-in bolts torque N·m depth L mm MHS2-16D M4 x 0.7 MHS2-20D M4 x 0.7 MHS2-25D M4 x 0.7 2.1 8 MHS2-32D M5 x 0.8 4.3 10 MHS2-40D M6 x 1 7.3 12 MHS2-50D M6 x 1 7.3 12 MHS2-63D M6 x 1 7.3 12 2.1 2.1 8 8 MHS3, MHSL3 Series MHS3 -20D MHSL3 MHS3 -25D MHSL3 MHS3 -32D MHSL3 MHS3 -40D MHSL3 MHS3 -50D MHSL3 MHS3 -63D MHSL3 MHS3 -80D MHSL3 Applicable Max. tightening Max. screw-in bolts torque N·m depth L mm M3 x 0.5 M3 x 0.5 M4 x 0.7 M4 x 0.7 M5 x 0.8 0.88 0.88 2.1 2.1 4.3 6 6 M5 x 0.8 M6 x 1 M6 x 1 MHS3 -100D M8 x 1.25 MHSL3 MHS3 -125D M10 x 1.5 MHSL3 MHSJ3 -16D M4 x 0.7 MHSH3 2.1 8 MHSJ3 -20D M4 x 0.7 MHSH3 2.1 8 MHSJ3 -25D M4 x 0.7 MHSH3 2.1 8 MHSJ3 -32D M4 x 0.7 MHSH3 M5 x 0.8 2.1 8 3.2 10 MHSJ3 -40D M4 x 0.7 MHSH3 M5 x 0.8 2.1 8 3.2 10 MHSJ3 -50D M5 x 0.8 MHSH3 M6 x 1 3.2 10 7.3 12 MHSJ3 -63D M6 x 1 MHSH3 M8 x 1.25 7.3 12 18 16 M6 x 1 MHSJ3 -80D MHSH3 M8 x 1.25 7.3 12 18 16 6 6 10 4.3 7.3 7.3 10 12 12 MHSH Series (Center pusher) Model 18 36 16 20 MHS4 Series Model Applicable Max. tightening Max. screw-in bolts torque N·m depth L mm Model L Model MHS3 -16D MHSL3 MHS2 Series MHSJ3, MHSH3 Series MHS2 Series Applicable Max. tightening Max. screw-in bolts torque N·m depth L mm Applicable Max. tightening Max. screw-in bolts torque N·m depth L mm Model Applicable bolts MHS2-16D M3 x 0.5 MHS2-20D M3 x 0.5 MHS2-25D M3 x 0.5 M4 x 0.7 M5 x 0.8 MHS2-32D MHS2-40D MHS2-50D MHS2-63D M5 x 0.8 M5 x 0.8 0.88 0.88 0.88 2.1 4.3 4.3 4.3 MHZ MHS3, MHSL3 Series Model Applicable bolts Max. tightening torque N·m MHS3 -16D MHSL3 M3 x 0.5 0.88 MHS3 -20D MHSL3 M3 x 0.5 0.88 MHS3 -25D MHSL3 M4 x 0.7 2.1 MHS3 -32D MHSL3 M4 x 0.7 2.1 MHS3 -40D MHSL3 M5 x 0.8 4.3 MHS3 -50D MHSL3 M5 x 0.8 4.3 MHS3 -63D MHSL3 M6 x 1 7.3 MHS3 -80D MHSL3 M6 x 1 7.3 MHS3 -100D MHSL3 M8 x 1.25 18 M10 x 1.5 36 MHSH3-32DA MHSH3-32DB M5 x 0.8 3.2 10 MHS3 -125D MHSL3 MHSH3-40DA MHSH3-40DB M5 x 0.8 3.2 10 MHS4 Series MHSH3-50DA MHSH3-50DB 7.3 12 MHSH3-63DA M8 x 1.25 MHSH3-63DB 18 16 MHSH3-80DA M8 x 1.25 MHSH3-80DB 18 16 M6 x 1 Max. tightening torque N·m Model Applicable bolts MHS4-16D M3 x 0.5 MHS4-20D M3 x 0.5 MHS4-25D M3 x 0.5 M4 x 0.7 M5 x 0.8 M5 x 0.8 M5 x 0.8 MHS4-16D M4 x 0.7 2.1 8 MHS4-20D M4 x 0.7 2.1 8 MHS4-25D M4 x 0.7 2.1 8 MHS4-32D M5 x 0.8 4.3 10 MHS4-40D MHS4-40D M6 x 1 7.3 12 MHS4-50D MHS4-50D M6 x 1 7.3 12 MHS4-63D MHS4-63D M6 x 1 7.3 12 MHS4-32D MHF MHL MHR MHK MHS MHC MHT MHY MHW -X MRHQ MA Max. tightening torque N·m 0.88 0.88 0.88 2.1 4.3 4.3 4.3 655 D- MHS Series Specific Product Precautions 2 Be sure to read this before handling the products. Mounting Air Grippers/MHS Series How to Mount the Attachment to the Finger Make sure to mount the attachments on fingers with the tightening torque in thetable below by using bolts, etc., for the female threads on fingers. MHSJ3, MHSH3 Series Model Applicable bolts Max. tightening torque N·m MHSJ3 -16D MHSH3 M3 x 0.5 0.88 MHSJ3 -20D MHSH3 M3 x 0.5 0.88 MHSJ3 -25D MHSH3 M3 x 0.5 0.88 MHSJ3 -32D MHSH3 M4 x 0.7 2.1 MHSJ3 -40D MHSH3 M4 x 0.7 2.1 MHS-16D MHSJ3 -50D MHSH3 M5 x 0.8 4.3 MHSH3-25D MHSJ3 -63D MHSH3 M6 x 1 7.3 MHSJ3 -80D MHSH3 Female thread for mounting attachment Model MHSJ3-20D MHSL3-32D MHSL3-40D MHSL3-50D M6 x 1 7.3 MHSL3-63D MHSL3-80D MHSH Series (Center pusher) Model Applicable bolts Max. tightening torque N·m MHSH3-32DA MHSH3-32DB M4 x 0.7 2.1 MHSH3-40DA MHSH3-40DB M4 x 0.7 2.1 MHSH3-50DA MHSH3-50DB M5 x 0.8 4.3 MHSH3-63DA MHSH3-63DB M6 x 1 7.3 MHSH3-80DA MHSH3-80DB M6 x 1 7.3 Note) When using the through-holes to mount models MHSJ3 and MHSHJ3, first remove the dust cover from the product, and after screwing it into place, reinstall the dust cover. 656 Applicable bolts Max. tightening torque N·m M3 x 0.5 0.59 M4 x 0.7 1.4 M5 x 0.8 2.8 M6 x 1 4.8 MHSL3-100D M8 x 1.25 12 MHSL3-125D M10 x 1.5 24