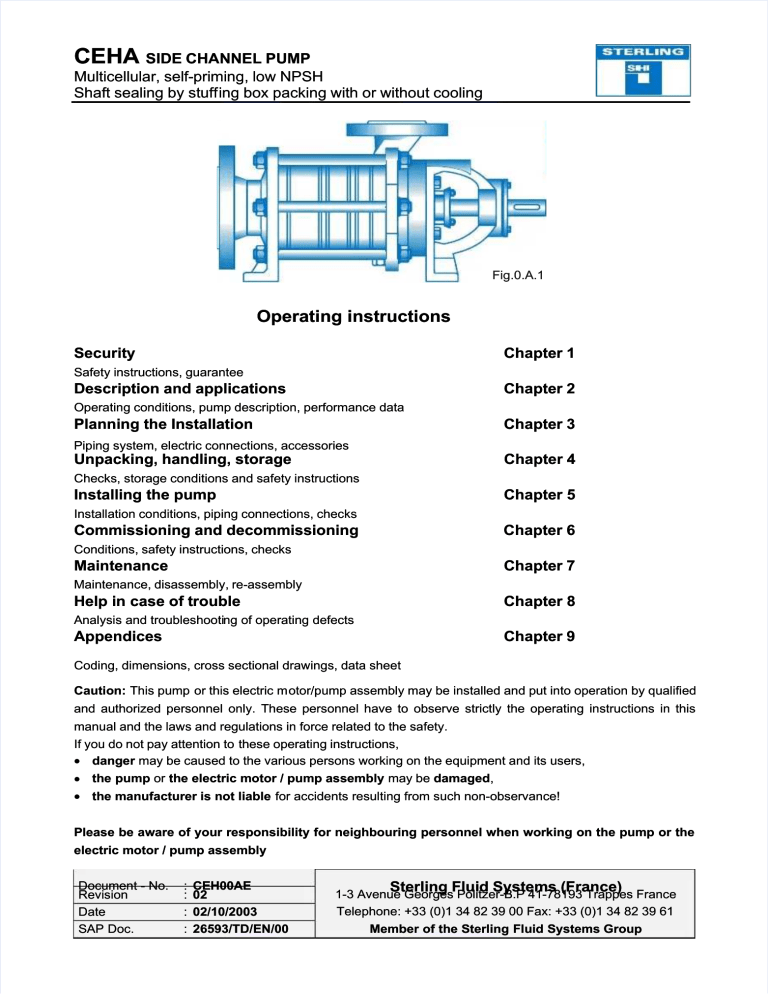

CEHA SIDE CHANNEL PUMP Multicellular, self-priming, low NPSH Shaft sealing by stuffing stuff ing box packing with or without cooling Fig.0.A.1 Operating instructions Security Chapter 1 Safety instructions, guarantee Description and applications Chapter 2 Operating conditions, pump description, performance data Planning the Installation Chapter 3 Piping system, electric connections, accessories Unpacking, handling, storage Chapter 4 Checks, storage conditions and safety instructions Installing the pump Chapter 5 Installation conditions, piping connections, checks Commissioning and decommissioning Chapter 6 Conditions, safety instructions, checks Maintenance Chapter 7 Maintenance, disassembly, re-assembly Help in case of trouble Chapter 8 Analysis and troubleshooting troubleshooting of operating defects Appendices Chapter 9 Coding, dimensions, cross sectional drawings, data sheet Caution: This pump or this electric motor/pump m otor/pump assembly may be installed and put into operation by qualified and authorized personnel only. These personnel have to observe strictly the operating instructions in this manual and the laws and regulations in force related to the safety. If you do not pay attention to these operating instructions, • danger may be caused to the various persons working on the equipment and its users, • the pump or the electric motor / pump assembly may be damaged damaged,, • the manufacturer is not liable for accidents resulting from such non-observance! Please be aware of your responsibility for neighbouring personnel when working on the pump or the electric motor / pump assembly Document - No. Revision : CEH00AE : 02 1-3 Avenue Georges Politzer-B.P 41-78193 Trappes France Date : 02/10/2003 Telephone: +33 (0)1 34 82 39 00 Fax: +33 (0)1 34 82 39 61 SAP Doc. : 26593/TD/EN/00 Sterling Fluid Systems (France) Member of the Sterling Fluid Systems Group Page 1 of 4 Safety 1.0 Safety Chapter 1 Authorized personnel for the use, maintenance, maintenance, This operating manual gives basic instructions inspection which are to be observed during installation, qualifications needed for th this is wo work. rk. operation and maintenance of the pump. responsibility, It is and assembly skills and must have the Scope of monitoring of the therefore imperative that this manual is read by personnel must be strictly controlled by the the fitter, personnel/operator in charge of set-up purchaser of the equipment. equipment. If the staff do not and commissioning, commissioning, as well as by by the user. This have the necessary knowledge, they must be manual is to be kept always available at the trained. The manufacturer or the supplier can installation site of the pump or electric motor- carry out this this training. In additio addition, n, the purchaser pump assembly. is to make sure that the competent personnel read and fully understood the contents of this 1.1 Meaning of safety symbols used in this manual manual. Safety instructions to be observed to avoid any danger to persons are shown by the symbol: 1.3 Non-compliance with safety instructions Non-compliance with safety instructions may cause danger to personnel, as well as to the environment and the machine. Electrical power risks are shown by the symbol: The manufacturer is such cases will not be held responsible. Non-observance of these safety instructions may cause in particular: Instructions where non-observance could cause damage to the machine, are shown by the word: Caution Failure of important functions of the machine or the installation, Failure of specified procedures for servicing and maintenance, Instructions where non-observance could cause supplementary risks when the pump is used in ‘’explosible atmosphères’’ are shown by the symbol: Exposure of people to electrical, mechanical and chemical hazards, Risks of pollution of the environment owing to hazardous substances being released. 1.4 Accident prevention The customer undertakes to respect the safety instructions shown in this manual, the national Signs affixed directly on the machine, such as the accident prevention regulations, as well as the arrow indicating the direction of rotation or the internal arrows indicating fluid suction and discharge conditions, the equipment operation and safety. regulations relating to the working connections must be observed and kept legible. 1.2 Qualification and training of personnel Doc.Num.: CL01E Rev.:01 Rev.: 01 Date: 01/04/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Page 2 of 4 Safety 1.5 Safety instructions for users Chapter 1 Pumps and electric motor-pump assemblies, This pump was designed in compliance with the which convey standard relating to the safety of the pumps. decontaminated. hazardous fluids must be Immediately after completion of work all safety Parts subject to temperature variations and and protective facilities must be re-installed and those where contact with them can be made operative again. dangerous must be protected by suitable After a service or other operation, the instructions devices. to re-start the machine given in paragraph 6 are to Safety devices against accidental contact with be observed. moving parts (e.g. coupling guards) must not be removed from the machine while in 1.7 operation. Use in Explosible Atmospheres The pump must never be started without these coupling guards. The instructions maintenance The coupling guard is a safety component designed for its function; in no case, it must never be used as a step or other support point. In no case, is this pump to operate without fluid. The destruction of the shaft outlet sealing which could result from such use would cause fluid leakage endangering the safety of persons and the environment. environment. Ensure that protection is provided against any hazard from electrical power (refer to regulations in force). 1.6 Safety instructions for maintenance, disassembly and assembly It is the customer’s responsibility to ensure that all maintenance, inspection and installation work is performed by qualified and authorized personnel who have studied this manual. Any work on the machine shall only be performed when it is at a standstill. It is imperative that the procedure for shutting down the machine described in this manual is to be followed. Doc.Num.: CL01E Rev.:01 Rev.: 01 Date: 01/04/2003 Manual for given supplied installation, throughout with the use the pump and Owner's must be scrupulously adhered to. This section gives additional information relevant to equipment use in explosible atmospheres. 1.7.1 Classification Classification of the Sterling side channel pumps as per EC Directive 94/9 "Explosible atmospheres" Group : II Category :2 Gas :G Build safety :c 1.7.2 Marking The nameplate of a Sterling side channel pump suitable for operation in explosible atmospheres carries the following indications: - Sterling's name and address, - the CE approval logo, - the serial number, - the year of manufacture, - the classification, e.g.: Information subjected to technical alterations due to engineering development II 2 G c. Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Page 3 of 4 Safety 1.7.3 Integration Chapter 1 The pump may only be integrated into an 1.7.5 Risks of Spark Production by External Shocks assembly intended for operation in explosible During atmospheres, in accordance with EC Directive operator shall see to it that external shocks on the 94/9 "Explosible atmospheres", if its nameplate pump or pump set components, which could includes the information defined in para. 1.7.2 produce sparks, are not likely to occur, otherwise, (pump marking). the necessary guards shall be installed. use in explosible atmospheres, the If the pump is integrated into a complete system, with other mechanical or electric components, this complete system may only be validated if all its 1.7.6 Technical Parameter Monitoring components comply with EC Directive 94/9 The "Explosible atmospheres". atmospheres". Only if this requirement maintenance is met will the use of the pump in an explosible Manual atmosphere (Group II, category 2) be authorized. scrupulously adhered to under all circumstances. NOTE: However, when the pump has to be used in an Particular attention shall be paid in checking that explosive atmosphere, the monitoring of the these requirements are complied with for every following parameters has to be reinforced component item of the complete system. significantly:: significantly instructions for given supplied installation, throughout with the use the and Owner's pump must be The use of a single component not meeting the requirements of EC Directive 94/9 "Explosible presence and correct operation of an atmospheres" entails that the pump cannot be used in explosible atmospheres, even though its emergency shutdown system, provided with an interlock preventing non-controlled nameplate includes the adequate symbols: untimely restarts, II 2 G c. conformity of the transmission coupling, presence and conformity of the coupling guard, 1.7.4 Conformity of the Pump Set conformity of the direction of rotation and impossibility of inadvertent reversal thereof, Coupling The transmission coupling shall be provided with adequate supply during operation, a system which prevents the two half-couplings to come into contact in case of abnormal wear of the sufficient fluid level in the pump at startup and use of the pump only within the authorized flexible transmission components. operating range (flowrate, water head, power, Coupling guard speed, NPSH, operation at zero flow without The coupling guard used in compliance with it shall be made of a non-sparking material instructions (carried (e.g. bronze, brass, aluminum, etc.), specific gravity, viscosity, startup intervals), atmospheres shall meet the following criteria: cr iteria: bypass is absolutely prohibited), explosible its mechanical design shall be such that it is conformity strong enough to resist any distortions likely temperature to result in a contact with a rotating part, even provided), in case of illegal use of the guard (e.g. use of the coupling guard as a step). the supplier's fluid, bearing (monitoring and service temperature, operating lubrication absence of vibrations and/or overheats due to poor drive coupling alignment or stresses on Motor the pump flanges, The drive motor shall meet the requirements of the CE Directive "Explosible atmospheres" it is subjected to. Doc.Num.: CL01E Rev.:01 Rev.: 01 Date: 01/04/2003 of the adjustment and control of the acceptable leaks, conformity of the shaft seal temperatures, Sterling Fluid Systems (France) Information subjected to technical Member of Group alterations due to engineering development Sterling Fluid Systems Page 4 of 4 Safety Chapter 1 check of sealing (shaft seal, body, plug, piping). 1.8 Alter Alteration ation of the machi machine ne and of spare parts No alteration or modification may be undertaken without prior agreement of the manufacturer. Genuine spare parts and accessories specified by the manufacturer contribute to safety. The manufacturer of the machine cannot be held responsible in the event of accident related to the use of parts other than genuine parts. During the guarantee period, any repairs or modifications can be made only by our fitters or with our agreement. 1.9 Non-observanc Non-observance e of safety instructions Safety related to the correct operation of the machine can be guaranteed only if the instructions in this manual are respected, as well as the conditions and operational limits mentioned in the data sheet attached. 1.10 Warranty / guarantee The Sterling SIHI guarantee is satisfied only under the following conditions: The pump is installed and operated in perfect compliance with the instructions and under conditions approved by Sterling SIHI. All modifications will be submitted for Sterling SIHI's approval before implementation. implementation. Doc.Num.: CL01E Rev.:01 Rev.: 01 Date: 01/04/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Description and applications 2.0 Page 1 of 3 Equipment application Chapter 2 required NPSH, so that this pump can be used The pump is to be used only for the operating under very difficult suction conditions. conditions stated by the purchaser and confirmed Heating and cooling chambers for the pump hous- by the supplier. ing can be inserted in place of hydraulic stages. The guarantee conditions are defined as per our general conditions of sale. It is possible to add a retaining stage at the suc- The conditions of use are defined in the attached tion end of the pump. data sheet. The shaft outlet sealing can be adapted to suit the majority of operating conditions. The construction specifications are defined in 2.1 Safety instructions chapter 9. 2.4 Performance data Q(m3/h) – H(m) – P(kW) - NPSH (See following pages) You may use the pump only for the application stated in the data sheet as otherwise accidents to people and the environment may occur. Do not exceed the density and viscosity stated in the data sheet. Otherwise there is danger of damage to the pump. 2.2 The pump must not operate out of the output range defined by the minimum and maximum flow for each size. Accessories The accessories delivered with the pump or the electrical pump unit are indicated in the data sheet. The corresponding operating and installation instructions can also be found in the appendix. The installation of additional accessories may be carried out only after receiving approval from the manufacturer of the machine. 2.3 Construction and operation CEHA pumps are side channel, multicellular, selfpriming pumps designed with up to 8 stages, having a horizontal configuration and offering numerous metallurgical variants. They allow for the simultaneous pumping of gas and liquid. The use of a pre-compression turbine at the suction end makes it possible to obtain a very small Doc.No.: CEH02ABE Rev.: 01 Date: 02/04/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Description and applications Page 2 of 3 Chapter 2 Performance data CEH-Pumps n = 1450 rpm Design tolerances: Output ± 5% Density = 1kg/l Delivery height ± 5% Viscosity = 1mm²/s Power +10% NPSH 1 effective suction of a non gas-free liquid – NPSH 2 pumping under load Series Sizes 0.4 (1) H [m] 32 57 83 108 133 159 184 209 CEH 1201 CEH 1202 CEH 1203 CEH 1204 CEH 1205 CEH 1206 CEH 1207 CEH 1208 NPSH 1[m] NPSH 2[m] P [kW] 0.42 0.76 1.1 1.44 1.78 2.1 2.45 2.8 1.3 0.11 Q [m³/h] 0.6 H [m] 30 53 77 100 123 147 170 193 Measuring tolerances: DIN 1944 P [kW] 0.4 0.72 1.04 1.36 1.68 2 2.3 2.65 1.3 0.11 1.0 H P [m] [kW] 26 0.35 46 0.64 65 0.92 85 1.2 105 1.5 125 1.78 144 2.05 164 2.35 1.35 0.11 1.5 H [m] 20 36 52 68 83 99 115 130 P [kW] 0.29 0.53 0.77 1.02 1.26 1.5 1.74 1.98 1.4 0.11 2.5 (2) H P [m] [kW] 11.5 0.22 19.5 0.38 28 0.53 36 0.69 44 0.84 52 1 60 1.14 68 1.3 1.55 0.48 NPSH 1 effective suction of a non gas-free liquid – NPSH 2 pumping under load of a high vapor pressure liquid (1) CEH 3101 CEH 3102 CEH 3103 CEH 3104 CEH 3105 CEH 3106 CEH 3107 CEH 3108 NPSH 1[m] NPSH 2[m] 1.0 48 1.14 87 2.1 126 3.1 165 4.05 204 5 243 6 282 7 321 7.9 1.35 0.17 1.5 44 1.06 79 1.94 114 2.8 149 3.7 184 4.55 219 5.5 254 6.3 289 7.2 1.25 0.17 2.5 34 61 88 115 142 169 196 222 3.5 0.86 1.56 2.25 2.95 3.65 4.35 5.1 5.8 1.1 0.17 25 0.68 44 1.22 63 1.76 82 2.3 101 2.85 120 3.4 139 3.9 159 4.45 0.95 0.17 (2) 4.5 17 0.57 29 0.99 41 1.4 52 1.82 64 2.25 76 2.65 88 3.1 100 3.5 0.95 0.18 NPSH 1 effective suction of a non gas-free liquid – NPSH 2 pumping under load of a high vapor pressure liquid CEH 3601 CEH 3602 CEH 3603 CEH 3604 CEH 3605 CEH 3606 CEH 3607 CEH 3608 NPSH 1[m] NPSH 2[m] 3.5 (1) 35 1.2 63 2.2 91 3.15 119 4.15 147 5.1 175 6.1 203 7.1 231 8.1 0.95 0.17 4.5 28 0.99 50 1.82 72 2.65 94 3.45 117 4.25 139 5.1 161 5.9 5 .9 184 6.7 0.95 0.18 6.0 19 33 46 60 74 88 102 115 0.78 0. 78 1.4 2 2.6 3.25 3.85 4.45 5.1 1.1 0.19 7.5 (2) 9.5 0.59 16 1.02 22 1.46 28 1.9 34 2.35 41 2.75 47 3.2 53 3.65 1.4 0.21 NPSH 1 effective suction of a non gas-free liquid – NPSH 2 pumping under load of a high vapor pressure liquid (1) (2) : Minimum operating flow : Maximum operating flow Doc.No.: CEH02ABE Rev.: 01 Date: 02/04/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Description and applications Page 3 of 3 Chapter 2 Performance data CEH-Pumps n = 1450 rpm Design tolerances: Output ± 5% Density = 1kg/l Delivery height ± 5% Viscosity = 1mm²/s Power +10% NPSH 1 effective suction of a non gas-free liquid – NPSH 2 pumping under load Measuring tolerances: DIN 1944 Q [m³/h] Series Sizes CEH 4101 CEH 4102 CEH 4103 CEH 4104 CEH 4105 CEH 4106 CEH 4107 CEH 4108 NPSH 1[m] NPSH 2[m] 6.0 (1) H P [m] [kW] 37 2.05 67 3.65 98 5.3 128 6.9 159 8.6 189 10.2 220 11.8 250 13.4 0.85 0.22 7.5 H [m] 31 56 82 107 132 157 182 208 P [kW] 1.82 3.2 4.6 6.0 7.4 8.8 10.2 11.6 0.9 0.24 9.0 10.5 H P [m] [kW] 26 1.58 45 2.75 65 3.95 84 5.1 104 6.3 123 7.5 143 8.7 8. 7 162 9.8 0.95 0.28 H P [m] [kW] 19.5 1.36 33 2.3 46 3.3 60 4.25 73 5.2 86 6.2 99 7.1 113 8.1 1.05 0.35 12.0 (2) H P [m] [kW] 13.5 1.2 20 1.98 27 2.75 33 3.55 40 4.3 47 5.1 54 5.9 60 6.7 1.15 0.45 NPSH 1 effective suction of a non gas-free liquid – NPSH 2 pumping under load of a high vapor pressure liquid (1) CEH 5101 CEH 5102 CEH 5103 CEH 5104 CEH 5105 CEH 5106 CEH 5107 CEH 5108 NPSH 1[m] NPSH 2[m] 10.5 45 4.2 82 7.9 120 11.6 157 15.4 195 19.2 232 23 270 26.5 307 30.5 0.95 0.35 12.0 42 76 111 145 179 214 248 283 4.1 7.6 11 14.4 17.8 21.5 24.5 28 1.0 0.4 14.0 37 3.75 67 6.8 96 9.9 126 13 156 16 186 19.2 216 22 245 25 1.05 0.45 16.0 32 3.4 56 6.1 81 8.8 106 11.6 130 14.2 155 17 180 19.6 205 22.5 1.15 0.5 18.0 26 3.05 45 5.4 64 7.7 84 10 103 12.4 123 14.8 142 17 161 19.4 1.25 0.55 (2) 20.0 19 2.7 33 4.65 47 6.6 60 8.6 74 10.6 88 12.6 102 14.6 116 16.4 1.35 0.65 NPSH 1 effective suction of a non gas-free liquid – NPSH 2 pumping under load of a high vapor pressure liquid (1) CEH 6101 CEH 6102 CEH 6103 CEH 6104 CEH 6105 CEH 6106 CEH 6107 CEH 6108 NPSH 1[m] NPSH 2[m] 16.0 53 8 96 14.8 139 21.5 182 28.5 225 35 268 42 311 49 354 56 1.3 0.35 18.0 50 90 130 170 210 251 291 331 7.6 14.2 20.5 27 33.5 40 46.5 53 1.3 0.4 20.0 46 83 120 157 194 231 268 305 7.3 13.4 19.4 25.5 31.5 38 44 50 1.3 0.4 25.0 36 64 92 120 148 176 204 232 6.2 11.2 16.4 21.5 26.5 31.5 36.5 41.5 1.3 0.55 30.0 25 43 61 79 97 115 133 151 4.9 8.8 12.8 16.6 20.5 24.5 28.5 32.5 1.5 0.65 (2) 35.0 13 4 23 7.1 32 10.2 41 13.3 51 16.4 60 19.5 69 22.6 78 25.7 1.65 0.85 NPSH 1 effective suction of a non gas-free liquid – NPSH 2 pumping under load of a high vapor pressure liquid (1) (2) : Minimum operating flow : Maximum operating flow Doc.No.: CEH02ABE Rev.: 01 Date: 02/04/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Planning the installation Page 1 of 4 3.0 Planning of the Installation 3.1 Piping system Chapter 3 3.1.1 Installation diagram by-pass Caution Respect the direction of flow of the fluid flow normalizer (arrows on the pump flanges). The diameters of the pipes must not be smaller than the diameters of the Fig. 3.1 corresponding pump orifices (see data sheet). Check that cleaning of all pipes has been carried out prior to installation of the pump. Adjust the piping positioning to ensure it does not cause any stress on the pump orifices. Avoid abrupt changes of piping diameter and short radius pipe elbows. In case of change of diameter, use 1 – Gate-valve at the discharge 2 – Qmin-diaphragm or relief valve 3 – Qmax-diaphragm Qmax-diaphragm 4 – Pressure gauge 5 - Pressure gauge 6 – Gate-valve at the suction end asymmetrical (eccentric) convergent transition pieces in order to avoid the formation of air pockets in the pipes. Install a flow stabilising length before the 3.1.2 Suction line In case of effective suction lift operation: suction branch of the pump; it should have the same diameter as the pump and a length 10 to 20 times the diameter of the pump. The flow velocity in the suction line must not exceed 1m/s. The pipe holders and anchoring must be designed in such a way that thermal expansion in the pipe system does not have any effect on the pump flanges. and for filling of pump with liquid. Fig.3.2 Provide for connections for pressure gauges must slightly ascend to the pump. In critical applications, (liquids with impurities) the system must be protected by a finemeshed strainer. Doc.No.: CEH03ABE Rev.: 01 Date: 02/04/2003 The suction line is to be vertical and then If a foot valve is used, it must be installed at least 0.50 m below the lowest pumping level. Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Planning the installation Page 2 of 4 Chapter 3 flow normalizer In case of pumping under load: Fig.3.4 3.1.3 Discharge line Fig.3.3 The piping must slightly descend to the pump. above the axis of the suction line. Caution The liquid level must be kept at least 0.50 m In case of pumping in a vacuum tank, we recommend the installation of balance piping of Ø 25 to 50 mm (1" to 2") returning to the tank. Adjustment to the operating point of the pump is to be carried out by the means of a gate valve installed at the pump discharge line. If there is a risk of exceeding the working pressure, a protective device must be installed, such as a bypass line with diaphragm or a pressure relief valve. In both cases of pumping: working pressure = pressure at pump discharge with zero flow + suction pressure Caution Installing a slow-closing non-return check valve will prevent hammering in The gate valve in the suction line must be installations with long piping. kept completely open when starting, as well Use constant diameter piping. high pressure as during the operation of the pump. The suction line must be protected and 3.1.4 Installing a diaphragm insulated against heat. A filter must be installed in the piping in case of pumping of contaminated contaminated liquids. Its section must have at least three times the Caution diameter of the pipe section with a mesh size equal to 0.1 mm. Arrange a length of flow stabilising line just before the pump. pump. In case of ch changes anges in diameter, use an asymmetrical convergent transition piece to avoid the formation of gas pockets. - Q-max-diaphragm In order to avoid exceeding the permitted flow, a diaphragm should be fitted into the pump discharge line (see installation diagram). This will prevent any danger of operating with cavitation. - Q-min-diaphragm, relief valve Doc.No.: CEH03ABE Rev.: 01 Date: 02/04/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Planning the installation - Page 3 of 4 Chapter 3 The installation of a relief valve or a These accessories make it possible to check, for diaphragm in the by-pass piping will ensure example: that the required minimum flow for the pump The power load absorbed motor. A provide for sufficient cooling of the pump and absorbed by the motor. If this power iis s too avoid mechanical overloads. high, the motor is switched-off. The fluid measures the is present (see installation diagram). diagram). This will detector by the temperature power (PT100). 3.1.5 Pressure checking The PT100 probe is a resistance thermometer Pressure checks will be carried out by means of intended for checking the temperature of pressure gauges installed on the suction line and bearings or pumpe pumped d liquid liquid.. A thread threaded ed pipe on the discharge line of the pump (see installation connection is essential for it to be installed. diagram). The switch-off temperature has to be adjusted 10 C higher than the operating temperature. temperature. 3.1.6 Double envelope of or reheating casings cooling The level of the pumped liquid. To protect the pump from a possible lack of liquid in the course of operation, it is possible to use a level detector. The gradual starting of the motor. Caution The cooling or heating piping for the shaft sealing system will be connected to the ports provided for that purpose. 3.4 Pumping of liquefied gases and condensates For the pump to handle liquefied gases and condensates it is especially important that the design * and installation is carried out by specialists. Incorrect operations during starting – 15° 15° causing “dry” operation - lead to damage to pump parts. Please follow the instructions below: Fig.3.5 The loss of pressure must be reduced to a minimum in the suction line. *: Port in the double envelope of the case for bends, filter, gate-valve or changes in diameter cooling or heating fluid. Shut-off valves are to be installed in the inlet and outlet pipes. suction flange (see installation diagram). allow for a safety factor compared to the The connections and the protection system for the required NPSH. electric motor will be made in accordance with the 3.3 Various accessories can be installed to contribute to the safety of the equipment. Doc.No.: CEH03ABE Rev.: 01 Date: 02/04/2003 The by-pass piping is to return to the tank and not to the pump inlet. Accessories The available NPSH (net positive load at the suction flange) scheduled for the project must Electrical connections requirements and regulations regulations currently in force. A length of stabilizer pipe must be installed with a length 10-20 times the diameter of the 3.2 The suction must not be disturbed by The supply line must be as short as possible. With longer lines, which may be exposed to strong sunlight, correct insulation must be provided. Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Planning the installation Page 4 of 4 Chapter 3 As liquefied gases may give off oxides, suitable filters must be provided to prevent oxides from entering the pump. These must be cleaned at regular intervals. Degassing piping must be installed between the flow stabilizer piping and the gas phase of the tank at the suction end (see installation diagram). This piping must be 25 to 50 mm (1’’ to 2’’) in diameter If the pump is to be used for several tanks with various mixtures of liquefied gases and different vapour pressures, high performance non-return valves must be mounted on the pump discharge end. This is to prevent the liquid which is being pumped from returning to the suction end when gate-valves are actuated. When draining several tanks with only one pump, a device allowing for isolation of the empty tank must be installed, to prevent any gas from entering the other tanks. Before each start-up, make sure that the pump is filled with liquid. liquid. It is recommended recommended to fit a degassing lever valve below the outlet valve. When filling the pump this valve is kept open continuously, until the liquid comes out. In order to check the liquid level, a level detector must be installed to prevent the pump from dry operation operation.. A spe special cial d design esign exists whi which ch makes it possible to add a retention stage directly on the pump (CEH..../7). Keep the pressure balance line open at the end which supplies to the tank. When using the pump in explosion hazard areas,, make sure areas sure that the various various ancillaries ancillaries are in conformity with the current safety standard. At pump start-up, start-up, the outlet gate-valve is to remain half open. If this valve is fully opened, there is the danger that the pump will operate beyond its specification range and this leads to the formation of vapour in the pump. Doc.No.: CEH03ABE Rev.: 01 Date: 02/04/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Unpacking, handling, storage 4.0 Page 1 of 2 Unpacking, handling, storage Chapter 4 specific conditions). conditions). This protection is de designed signed for storage duration of 3 months. months . 4.1 Safety measures 4.3.1 Short-term storage, less than three months If the pump or the electric pump unit is not to be installed immediately after delivery, the equipment will have to be stored in a dry location and free Never stay below the suspended load. from vibrations, for a duration not exceeding three Keep a sufficient safety distance during trans- months. Moreover, it is advised to turn the pump pump port of the load. shaft over manually and periodically to avoid any Use only appropriate hoisting slings which are risks of seizing of mobile parts. in perfect condition. Adjust the length of the hoisting slings in such a way that the pump or the electrical pump 4.3.2 Long-term storage unit is suspended horizontally and stable. If the storage duration exceeds three months, in Do not use the eyebolts on the pump compo- addition to the precautionary measures specified nents or on the motor for lifting the assembled in 4.3.1, it is necessary to wash the pump with pump or the complete complete unit. They are intended intended fresh water and to re-apply the preserving fluid only for handling spare parts during assembling or dismantling. every three months. Make sure that the product used is compatible with the pump materials and Do not separate the documents attached to complies with the environmental protection and the pump. personnel safety regulations currently in force. Do not remove the protection caps from the pump flanges. Handle the pump or the pump-motor-base 4.3.3 Lengthy installation stoppage plate assembly with care and avoid impacts. In the event of installation stopping for more than 3 weeks (this period could be much more shorter in unfavorable climatic conditions), drain the pump, wash it with fresh water and spray the cor- 4.2 rosion-resistant agent agent inside. inside. Make sure that the Unpacking product used is compatible with the pump materiJust after taking delivery of the equipment and before unpacking, a visual control of the packing als and complies with the environmental protec- is recommended. recommended. If transport damage is visible, tion and personnel safety regulations currently in its extent is to be noted on the receipt or on the force delivery note. note. Possible claims are to be lodged immediately with the carrier. 4.4 Handling The electric motor-pump assembly weights, as 4.3 Preservation and storage well as those of the various components, are After platform testing, every pump is drained and specified on the drawings in the appendix at- an internal corrosion-resistant protection is ap- tached. plied (except for pumps in stainless material or Doc.No.: CEH04ABE Rev.: 00 Date: 03/10/2000 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Unpacking, handling, storage Page 2 of 2 Chapter 4 During slinging and handling of the pump or the unit, make sure that the hoisting ropes or slings cannot escape from the hook. sling, When using a single hoisting rope or sling, it is necessary to cross them in the hook to prevent them slipping and the load tipping during handling. Fig.4.1 Handling the pump Fig.4.3 Fig.4.2 Handling the pump unit Doc.No.: CEH04ABE Rev.: 00 Date: 03/10/2000 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Installing the pump 5.0 Page 1 of 6 Installing the pump 5.4 5.1 Chapter 5 Preconditions The pump or the electric motor-pump assembly must have been unpacked and transported in conformity with the recommendations shown in chapter 4. Tools The assembly and installation of the pump or of the electrical pump unit does not requir require e any speci special al tools,, only regular tools of a mechanical and tools electrical workshop are needed. 5.4.1 Environmental conditions 5.2 Personnel qualifications The work described in this chapter must be carried out by qualified and authorized personnel only. 5.3 The permissible ambient temperature is between – 20°C and + 60 °C. °C . The h humidity umidity of the air shou should ld be as low as possible in order to avoid corrosion. 5.4.2 Base and foundation Safety measures The pump or the electrical pump unit must be installed always on a horizontal floor or foundation not subject to external vibration. In case of doubt use vibration dampening feet. For the pumps equipped with shaft sealing by stuffing box, provide a seepage recovery pipe. Remove the caps from the pump flanges only when connecting the pipes. Connect the pipes carefully as to avoid any leakage when subjected to pressure. Make sure that the gate-valves at the suction end and at the discharge end are closed. Observe internal regulations concerning conditions of operation. Wash off the corrosion-resistant substance as shown in chapter 4 to prevent any contamination of the plant. Provide an electric motor control switch and protection system. 5.4.3 Space required The space required for installing the pump unit is shown in the overall dimensions drawing attached. Make sure there is easy access to the shut-off gates and valves as well as to the measuring instruments. 5.5 Checks before installation Caution Check that all electrical connections are free from voltage and ensure that the installation cannot be switched on inadvertently. Doc.No.: CEH05ABE Rev.: 02 Date: 02/10/2003 The following points must be checked before installing the pump or the electric motor-pump assembly: 1. Absence of voltage on the electrical connection and ensure that the installation cannot be switched on inadvertently. 2. Compatibility of the electric electric power cable with the power of the motor concerned. 3. Cleanliness and insulation insulation of the suction suction line and discharge line and of the other related pipes. 4. It should be possible possible to rotate the pump pump easily by hand. Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Installing the pump Page 2 of 6 Chapter 5 5. Observance of instructions, regulations and internal precautions to be observed when carrying out the installation. 5.6 Mounting the electric motor-pump assembly in the installation Caution The couplings are to be assembled on the shafts taking care to avoid any impact. They can be heated to facilitate assembly. assembly. The shaft ends must be perfectly aligned, and the distance between the two Sterling SIHI half-couplings must be 2 to 3 mm. Caution straight edge 1. Check that the general instructions given in 3.1 concerning piping are respected. 2. Make the unit perfectly level on its foundation block by using metal shims; take care that these shims are as close as possible to the anchoring points. 3. Carry out an even diagonal tightening of the unit retaining bolts on its foundation block, block, taking care not to cause deformation of the base. 4. Check and adjust if necessary, the pump/motor alignment (see 5.7). 5. Remove the protective caps from the pump flanges, taking care that no foreign body enters the pump. 6. Check and adjust if necessary, the positioning of the pipe flanges on the pump flanges; no stress must be applied to the pump flanges during positioning and tightening. tightening. When using temperature, take care in conditions of varying temperature, particularly to avoid the transfer of stresses to the pump flanges due to piping expansion. 7. Check the the presence presence and the correct positioning positioning of the seals between the flanges. Tighten the piping flanges evenly and diagonally on the pump. 9. Check the pump/motor alignment (see 5.7) and readjust it, if necessary, by loosening the flanges and starting again at point 4. 8. a b1 a1 2 to 3 mm a = a1 Coupling Doc.No.: CEH05ABE Rev.: 02 Date: 02/10/2003 b = b1 Fig.5.1 If couplings other than Sterling SIHI couplings are used, refer to the manufacturer's instructions. It is essential that the coupling is equipped with a guard in accordance with current regulations on the prevention of accidents and the protection of persons. 5.8 5.7 b Coupling in ATEX conform pumpsets Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Installing the pump Page 3 of 6 The following instructions for couplings need especially to be followed for pumpsets which are manufactured in conformity with Directive 94/9/EC for operations as category II equipment in hazardous areas. Limitations Only the coupling type BDS and HDS is released for pumpsets in conformity with 94/9/EC. These couplings are designed to be operated according the following parameters: o Max 25 starts per hour o Daily operating cycle up to 24 h o Operation within the specified alignment o Temperature range -30°C to +80°C in the immediate vicinity of the coupling Storage If coupling parts are stored as spare parts, the storage area must be dry and free from dust. The flexible elements must not be stored with chemicals, solvents, motor fuels, acids, etc.. Furthermore they should be protected against light, in particular direct sunlight and and bright artificial light with high ultraviole ultraviolett content. Chapter 5 Failure to observe these instructions may result in breakage of the coupling. Danger from flying fragments! The coupling then becomes an exlosion hazard. Mounting the coupling parts Before beginning installation, the shaft ends and the coupling parts must be carefully cleaned. Before cleaning the coupling parts with solvent the flexible elements must be removed. If necessary, heating the coupling parts (to max 150°C) will facilitate fittin fitting. g. With temperatures over 80°C the flexible elements must be removed from the coupling part s before heating. Coupling parts must be fitted with the aid of suitable equipment to avoid damaging the shaft bearings through axial joining forces. Always use a suitable lifting equipment. The shaft ends must not project from the inner sides of the hub. Axial securing is effected by means of the set screw. The storage area must not contain any ozone-generating equipment, e.g. fluorescent light sources, mercury vapour lamps, high voltage electrical equipment. Damp storage areas are unsuitable. Ensure that no condensation occurs. The most favourable atmospheric humidity is below 65%. Installation Type B and H couplings shall never be operated in pumpsets category II. The flexible elements are delivered in different materials and are then differently couloured or marked with stripes in different colours. Only elements of one type must be used in one coupling. When assembling a pumpset with a coupling, the fits of the bores and shafts must be checked, see table 5.c1 Table 5.C.1 Tolerances for coupling fit Fit Nominal Shaft Coupling diameter tolerance bore tolerance Shaft 50 mm k6 H7 tolerance > 50 mm m6 Tightening the set screws to a tightening torque in accordance with the table 5.C.3. Failure to observe these instructions may result in breakage of the coupling. Danger from flying fragments! The coupling then becomes an explosion hazard. After fitting the coupling parts onto the shafts the flexible elements, if previously removed must be fitted. Previously heated coupling parts must have cooled down again to a temperature below +80°C. It must be be ensured ensured that tthe he fl flexibl exible e element elements s are o off identical size and colour or have identical marking. Move together the components to be coupled. Danger of squeezing! Alignment The couplings connect the 2 shaft ends of the driver and the pump. The alignment of the shaft ends needs to be adjusted within the following tolerances. The errors of alignment are differentiated into: Doc.No.: CEH05ABE Rev.: 02 Date: 02/10/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Installing the pump o o o Page 4 of 6 Axial misalignment: misalignment: the allowable difference between maximum and minimum axial gap S between the two coupling halfes is given Table 5.C.2. Angular misalignment: misalignment: this can usefully be measured as the difference in the gap dimension S = Smax – Smin. The allowable values are given in Table 5.C.2 depending on coupling size and speed Radial misalignment is the radial offset between the shaft centers. The allowable values are the same s values like for the angular misalignment given in Table 5.C.2.. The method to adjust the alignment is: first correct the angular misalignment misalignment then correct the axial gap then correct the radial misalignment. The useful tool are a feeler gauge and a ruler as shown in figure 5.C.2. Table 5.C.2 Alignment dimensions Coupling type BDS Axial gaps mm 76 2–4 Angular and radial alignment S max in mm at speed 750 1/min 0,25 1000 1/min 0,2 1500 1/min 0,2 2000 1/min 0,15 3000 1/min 0,15 88 2–4 0,25 0,2 0,2 0,15 0,15 103 2–4 0,25 0,25 0,2 0,2 0,15 118 2–4 0,3 0,25 0,2 0,2 0,15 135 2–4 0,3 0,25 0,25 0,2 0,15 152 2–4 0,35 0,3 0,25 0,2 0,2 172 2–6 0,4 0,35 0,3 0,25 0,2 194 2–6 0,4 0,35 0,3 0,25 0,2 218 2–6 0,45 0,4 0,3 0,3 0,2 245 2–6 0,5 0,4 0,35 0,3 0,25 Fixing the coupling on the shaft. For fixing the coupling parts on the shaft there are set screws, which need to be locked with the following torque depending on coupling size: Table 5.C.3 5.C.3 Torque for for Set Screws Screws Size Torque Nm Size Torque Nm 76 4 172 15 88 4 194 25 Doc.No.: CEH05ABE Rev.: 02 Date: 02/10/2003 103 4 218 25 118 4 245 25 135 8 Chapter 5 Operation: If any irregularities are registered during operation (vibrations or noise) the pumpset is to be switched off immediately. Determine the cause of the fault fault usin using g the fault fault list in Ch Chapte apterr 8. This list list contains possible faults, their reasons and succested actions. If the analysis is not possible then contact the Sterling Service. Maintenance: regular control of the torsional backlash is necessary to prevent breakdown. The torsional backlash is to be measured in the following way: One coupling part is rotated against the other with no torque to a stop. Then this position of the two coupling halfes is marked as shown in the left had picture of figure 5.C.3. Then the coupling parts are rotated into the other direction as far as possible without torque. The distance between the two marks is the backlash measure delta sb. The maximum values for this measure are given in table 5.C.4 by coupling size. If this measure is exceeded, then the flexible elements need to be exchanged. the flexible elements must be replaced in sets (all elements of one coupling at once, independent of the individual wear) Only identically marked flexible elements must be used. Only spareparts from the original equipment manufacturer is allowed for replacement. Table 5.C.4 Torsional Backla Backlash sh measure Size Delta mm Size delts 76 7,0 88 5,0 103 7,0 194 8,0 218 7,0 245 6,5 118 9,0 135 10,5 152 11,5 172 9,0 152 8 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Installing the pump Page 5 of 6 Chapter 5 Figures: Figure 5.C.1 Measures for checking alignment Smax Smax •S Smin Smin •S = Smax - Smin Figure 5.C.2 Checking of alignment Ruler S Figure 5.C.3 Measurement Measurement of Torsional Backlash •Sb Doc.No.: CEH05ABE Rev.: 02 Date: 02/10/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Installing the pump 5.9 Page 6 of 6 Pump mounting for operation at high temperatur temperature e 5.12 Chapter 5 Hydrostat Hydrostatic ic pressure test When subjecting the piping system to a hydrostatic pressure test, exclude the pump from this test. Otherwise make that no foreign bodies can enter the pump. Caution If this pump is intended to convey a hot fluid, (with cooled shaft sealing), the retaining screws at the pump drive end are to be locked. The nuts and spring washers at the opposite end must allow for pump dilation in the longitudinall direction. longitudina The hydrostatic test pressure for the pump must not exceed 1. 1.3 3 ttim imes es the no nomi mina nall pum pump p pressure.. (See the data sheet in the appendix). pressure After mounting the two spring washers in the opposing position shown, position the flat washer and screw the self-locking nut into contact (the washers must be able to be moved by hand). Then tighten the two self-locking nuts half a turn. pump foot retaining stud self-locking nut flat washer base spring washers Fig.5.2 5.10 Monitoring and regulation The monitoring / regulation accessories and instruments must be set up in accordance with their individual instructions (see appendix). 5.11 Final checks The following final checks must be carried out: Check all tightening that has been carried out during the mounting of the pump in the installation, particularly the tightening of the connecting flanges. Check that the pump can be rotated easily by hand (turn the motor fan for this). Check the alignment. Verify the presence and check the fastening of the coupling guard. Doc.No.: CEH05ABE Rev.: 02 Date: 02/10/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Commissioning and decommissioning Page 1 of 3 6.0 Commissioning and decommissioning 6.1 Preconditions Chapter 6 As soon as the rated speed is attained, the The pump or the electrical pump unit must have flow adjustment will be done by means of the been installed according to the directions and gate-valve placed at the discharge discharge end of of the instructions in chapter 5. pump. The gate-valve at the suction end must always be open during operation to prevent cavitation, both during effective suction and 6.2 Personnel qualification under load. The work described in this chapter must be carried out by qualified and authorized personnel only. 6.4 6.3 Filling the pump Safety measures Caution To preserve the installation from pollution by the anti-corrosion All electrical connections are to be carried out according to the rules of the trade, in accordance with current product and to avoid any compatibility problem with the pumped substance, the pump must be rinsed out. The anti-corrosio anti-corrosion n product is water-soluble. relevant requirements, laws and regulations. Only authorized and qualified personnel may Before the first start, the pump and the suction carry out this work. line, must be completely filled with the pumping liquid to prevent the pump running dry and to avoid the formation of air pockets and thermal shock. Fill the pump correctly in order to avoid any damage due to dry operation (the shaft sealing or sleeve bearings could be destroyed and 6.5 moving parts could seize). circuit diagram diagram in the termin terminal al box. (See safety safety Check the direction of rotation only after filling measures in 6.3). the pump and at the precise Electrical connection The motor has to be connected according to the moment described in 6.7. Fill the pump very slowly if hot pumping liquid 6.6 is used in order to avoid distortions or thermal The shock. accessories must be carried out in accordance When pumping explosive, harmful, hot, crystalline or corrosive products, ensure that persons and the environment are Accessories installation and connections of the with their attached commissioning instruction manuals. (See appendix). not endangered. Doc.No.: CEH06ABE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Commissioning and decommissioning 6.7 Page 2 of 3 Checking before switching-on Chapter 6 If the pumping pressure does not constantly rise with increasing speed, stop the motor again and bleed the pump carefully again. 5. After reaching operating speed, adjust the Caution operating point of the pump by means of the regulating gate-valve in the discharge line. Before switching-on the pump unit, ensure that nobody can be endangered by starting the pump unit. It is mandatory to check the following points: Caution 1. The pipelines are all all connected and the unions are leak proof. Operating with the gate-valve closed at the 2. The pump and pipes pipes are correctly filled and air air has been bled. discharge end, even for short durations, is possible only if the installation is equipped with a 3. The cooling system supply (if applicable) is open and its system has been bled. by-pass providing for circulation of the minimum flow necessary for the correct operation of the 4. If the installation is protected by by a relief valve pump. If not, operating with the gate gate-valve -valve closed make sure that its adjustment is correct, at the discharge end quickly causes destruction of particularly in accordance with the pressure the sealing and seizing of the moving parts. rating of the pump housing. 5. The regulating gate-valve at the the discharge discharge end is fully opened. 6.9 6. The gate-valve at at the suction end end is completely open. Frequency of switching on/off The CEHA pump may be switched on up to 15 times per hour. 7. The coupling alignment has been checked and is correct (see chapter 5). 8. The coupling coupling guard is in place place.. 6.10 Checks during operation 9. The motor is ready for operation. 10.At this point check the direction of rotation of the motor (short pressure on the switch), the Caution rotation of the CEHA pump is anti-clockwise when facing at the end of the pump drive shaft. During operation, the following points must be checked: 6.8 Commissioning discharge end. For commissioning proceed as follows: 1. Open the gate-valve gate-valve at the suction suction end fully. fully. 2. Open the discharge regulating end fully. gate-valve When at pumping Check the liquid level in the tank at the suction end. 3.4). The pump runs regularly, smoothly, and without vibration. the condensates, only half-open this valve (see Check the temperature of the pump bearing (maximum temperature 80 °C or 50 °C above 3. Switch on the motor. motor. the ambient temperature). 4. Check the pressure on the the pressure gauge at the discharge end. Constant rotation speed and pressure at the Check the temperature of the shaft sealing coolant. Doc.No.: CEH06ABE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Commissioning and decommissioning Page 3 of 3 Chapter 6 If shaft sealing is provided by a stuffing box, 10 6.11 Decommissioning to 20 drops per minute leakage is necessary When decommissioning the unit, proceed as and normal to avoid overheating of the sealing follows: system. 1. Shut-off the motor po power wer supply. If shaft sealing is provided by a rotating 2. Close mechanical seal, a slight leak is possible at the the regulating gate-valve at the discharge end. first startup; if the conditions allow it, let it run 3. Close the g gate-valve ate-valve at the the suction end. end. for 30 minutes so that the components take up 4. Close the sh shaft aft sealing coolant inle inlet. t. their positions. positions. If the leak persists, dismantle. dismantle. Drain the pump if there is a risk of freezing. Caution In the event of significant leakage, stop the pump as soon as possible, and check the shaft sealing. If draining the pump produces explosive, harmful, or crystalline measures to products, take protect the persons necessary and the environment. If the pump has to be dispatched elsewhere, it must be free of any dangerous product. In the event of prolonged stoppag stoppage e of the pump, it must be rinsed and then protected internally with a suitable anti-corrosion product. Doc.No.: CEH06ABE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Maintenance, disassembly, assembly 7.0 Page 1 of 5 Maintenance, disassembly, assembly Chapter 7 After 8 000 service hours, or at the latest 2 years after commissioning, check the inner sleeve bearing for wear. Replace it, if necessary. 7.1 Preconditions Shaft sealing The pump or the electric motor / pump assembly After prolonged use and frequent re-tightening, must be put out of operation in accordance with the stuffing-box packing rings can lose their origi- the instructions in chapter 6. nal elasticity, and must be renewed. After 2500 hours of operation, we advise you to 7.2 Personnel qualification check the packing rings; if settling of the rings is The work described in this chapter must be car- equal to 20% or has a value of a half ring, they ried out by qualified and authorized personnel must be changed. only. Rings replacement: see 7.7.4 Any work on electrical connections must be carried out by authorized skilled staff only. 7.5 7.3 7.5.1 Preparation for disassembly Safety measures Disassembly Proceed as follows: 1. Make sure that the pow power er supply is switchedoff and cannot be switched-on inadvertently during the operation. operation. 2. Disconnect the motor in the the terminal b box. ox. If the pump has conveyed explosive, hot, toxic, crystalline, etc. products, the necessary measures must be taken so that persons and the environment are not endangered. In the event of the pump being dispatched elsewhere, it must be free from any trace of pumped product. Since the pump could still contain pumped product, it must be rinsed out carefully prior to disassembly. 7.4 3. Shut off the isola isolation tion gate-valves at the suction and discharge ends, and carefully drain this part of the installation. 4. If necessary, disconnect and dismantle the measuring and checking instruments. 5. Disassemble the pum pump p flanges and disassemdisassemble the pump from the base plate. 6. Drain the pump pump,, and then rin rinse se it again, if n nececessary. 7.5.2 Spare parts Maintenance and inspection When ordering spare parts, note the information given on the pump identification plate, that is to say: 1. The exact type of pump. 2. The complete pump identification number. Caution Use the attached cross-sectional drawing to note the identification references of the items required. r equired. After commissioning this kind of pump requires The spare parts must meet the manufacturer’s only little maintenance. maintenance. technical requirements, and the guarantee is only For checks during operation refer to 6.10. valid when genuine original parts are used. Bearings Sterling SIHI will not admit liability in the event of The ball bearing is lifetime lubricated and does failure or accident related to the use of parts other not require any maintenance. Doc.No.: CEH07AE Rev.: 01 Date: 02/04/2003 than genuine parts. Sterling Fluid Systems (France) Information subjected to technical Member of Group alterations due to engineering development Sterling Fluid Systems Maintenance, disassembly, assembly Page 2 of 5 7.5.3 Disassembly of the pump Chapter 7 7. Disassemble the screws 9011 and the cap See the sectional drawing attached. 3600, then remove the circle 9320, and the The working surface must be clean, free from dirt, spacer 5051. 8. Separate the bearing casing 3500 from the filings etc. and be perfectly clear. 1. To facilitate later assembly assembly make marks along discharge flange 1070 and from the stuffing the whole length of the pump body and num- box casing 4510 by removing the screws ber the parts. 9012. 2. Disassembly starts at the suction end. 3. Remove the nuts nuts 9201, 9201, the flat washers washers 5500, the cup springs 9512 (only for model 501 with cooling casing), the tie bolts 9050 and extract the suction flange 1060. 9. Use a hub puller to extract the bea bearing ring casing 3500 with the ball bearing 3210 and the spacer 5050. 10.Remove the hexagonal nuts 9200; extract the gland 4520, slide the stuffing box casing 4510 along the shaft. Extract the stuffing box packing rings 4610, the stuffing box intensive cooling ring 4420 with its gaskets 4120 (only for model with cooling casing). The pump may still contain residues of pumped fluid or of rinsing rinsing product. product. Take precautions precautions to 7.6 Work after the disassembly contain any leakage. 7.6.1 Cleaning instructions 4. Release the lock washer 9310 and loosen the hexagonal nut 9220 while holding the shaft with a strap wrench or gripping it in a soft jaw vice. The use of some solvents requires special precautions. Refer to the supplier's recommendations CAUTION and to current regulations. The hexagonal nut 9220 has a left-hand thread Clean all parts using an appropriate solvent. 5. Disassemble successively the impellor 2310, A scraper can be used to remove the residue of the key 9402, the centrifugal body 1080 and adhesive on the mating faces of the bodies; take the shaft sleeve 5240 (only sizes 4100 – care not to damage the surface finish during this 6100). operation. 6. Then, disassemble the inlet body 1090, the vane impeller 2350, the key 9411 (9401) and the discharge body 1140. Repeat this procedure as many times as there are stages, (the last discharge body bears the number 1141). Doc.No.: CEH07AE Rev.: 01 Date: 02/04/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Maintenance, disassembly, assembly Page 3 of 5 Chapter 7 7.6.2 Repair instructions Caution The following parts must be checked carefully: 1. Ball bearing 3210 Since the bearing is lubricated for life, it does not 35° require any maintenance. maintenance. Check it for wear and change it if necessary. 2. Lip sealing ring 4210 Fig 7.1: drive end view If the shaft is marked at the corresponding location, change the lip sealing ring; pay attention to the correct mounting position to prevent the grease from escaping and to prevent dirt entering. 3. Stuffing b box ox packing rings 4610 4610 Change the rings in accordance with the directions given in 7.7.4. 4. Shaft 2100 Any pronounced mark on the shaft, at the stuffing box rings, at the lip sealing ring or bearing bush positions requires it to be changed. 5. Shell bearing 0241 In the event of severe wear on the shell bearing 0241 (play >0.2mm), carry out its replacement as follows: Extract the worn shell bearing. Degrease the bore of the body 1080 using a solvent. Spread adhesive adhesive on the parts accordaccording to the instructions of the adhesive manu- facturer (Loctite 640 or equivalent). Cold-press the bearing bush 0241 into the body 1080; ensure that the lubrication groove is correctly orientated (Fig 7.1). 6. Body 1090, 1140, 1141 Body surfaces in contact with the wheel may be re-machined to a max. of 0.5 mm with a plane plane parallelism defect of 10 µm in relation to the mating surfaces. The max. admissible roughness height of the re-worked surface will be Rt = 6 µm. The mating surface of the body 1090 has to be re-machined also, in such a way that the depth is greater by min. 0.10 mm to max. 0.13 mm (sizes 1200/3100/3600) and by min. 0.15 mm to max. 0.20 mm (sizes 4100/5100/6100) in relation to the thickness of the vane impellor. Since hydraulic perform- ance is linked to the depth of the bodies, do not re-machine more than necessary. N.B.: For multi-stage pumps and for a complete overhaul, it is preferable to mix new stages and old re-machined stages to avoid out-ofline keying, losses of efficiency or out-of-line pump mounting brackets in relation to the base plate mounting holes. 7. Vane impeller 2350 Re-machining the wheel produces uncontrolled changes in specifications and interchangeability is no longer guaranteed. 8. Body she shellll bearings bearings 0242 0242 (Sizes 4100 to 6100 only) In the event of severe wear, they must be changed. These shell bearings have to be cold-pressed and glued with a product like Loctite 640 or equivalent. Doc.No.: CEH07AE Rev.: 01 Date: 02/04/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Maintenance, disassembly, assembly Page 4 of 5 Chapter 7 cooling casing) and the stuffing box packing 9. Shaft sleeve 5240 rings 4610. (Sizes 4100 to 6100 only) 2. Position the gland 4520 and screw in the two In the event of severe wear, they must be nuts 9200 slightly. changed. 3. Assemble the bearing casing 3500, after 7.7 Assembly checking that the radial shaft seal ring 4210 is present, then fasten the assembly on the discharge flange 1070 using screws 9012. 7.7.1 Instructions before assembly 4. Pass the shaft 2100 through the assembly; Make sure that all the parts have been mount the spacer 5050 and the ball bearing checked and are perfectly clean (mating 3210 and and the spacer spacer 5051. Secure the shaft planes, faces of the bodies). by the circlip 9320, then fasten the cap 3600 Coat all sliding surfaces with molybdenum using the screws 9011. disulfide paste, except for carbon surfaces. Sealing of the mating surfaces on the hydrau- (drive shaft end downwards), wedge it or lic part bodies is done by: clamp the shaft end in an opening in the - Adhesive EPPLE 33 or equivalent for cast bench. 6. Assemble the discharge b body ody 1141 (1140 for iron pumps. 5. Position the assembly vertically on the b bench ench - Soft Teflon cord for stainless steel pumps (Ø the following stages), the key 9411 (9401), the 0.75 mm for sizes 1200, 3100, 3600 / Ø 1 mm for sizes 4100, 5100, 6100). vane impeller 2350 and the inlet body 1090. Repeat this procedure as many times as there It is mandatory to ensure that the bodies are are stages, until all stages are mounted; en- correctly orientated orientated to ensure ensure correct operaopera- sure that bodies are correctly orientated in ac- tion of the pump (use the bodies assembly dia- cordance with the location drawing attached. gram attached). The reference marks traced Then reassemble the shaft sleeve 5240 (only before disassembly simplify this aspect. sizes 4100 to 6100), the centrifugal body 1080 For pumps which require adhesive, immedi- (do not forget the positioning of the soft Teflon ately coat the mating faces of the bodies 1140, cord sealing for pumps which require it), the 1141, 1080, and 1090 so as to allow the adhe- key 9402 and the vane impeller 2310. sive to cure slightly before assembly. 7. Position the lock washer 9310. Tighten the wheel nut 9220 and secure it by bending the lock washer. 7.7.2 Tightening torque Nuts and bolts must be tightened using a torque CAUTION wrench. The following tightening torques torques must be applied: The hexagonal nut 9220 has a left-hand thread Rated Ø M5 M6 M8 M M10 10 M1 M12 2 M16 M16 M20 M20 Torque Nm 4.5 8.5 12 25 40 90 175 7.7.3 Assembling the pump 1. Mount the stuffing box casing 4510 on the discharge casing 1070, then place the stuffing box cooling ring 4420 with its O-rings 4120 on the stuffing box casing (only for models with Information subjected to technical Doc.No.: CEH07AE alterations due to engineering development Rev.: 01 Date: 02/04/2003 Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Maintenance, disassembly, assembly Page 5 of 5 Chapter 7 Skew cut Staggered cuts 8. Mount the suction flange 1060, the tie bolts 9050 with the spring washers 9512 (models with cooling casing) and the flat washers 5500. Tighten the nuts 9201 slightly. Grease the tie bolt ends, the washers and nuts for better Fig. 7.3 tightening torque distribution. Positioning the preformed rings 9512 9201 Caution When running, the stuffing box should not exceed a temperature which is bearable to the touch and should leak in small drops. 5500 9050 Fig.7.2 Location of spring washers at the suction end 7.8 Checking after assembly 9. Place the pump on a surface plate plate straighten the retaining lugs and gradually tighten the tie Caution bolt nuts 9210 9210 diagonally, diagonally, observing the tightening torques specified in 7.7.2. 10.Insert the key 9400 and the half-sleeve of the coupling, without hitting it; heat it if necessary. 1. Check that th the e pump rotates freely by by hand. 2. Check and if necessary correct th the e tightening torque on the tie bolt nuts. Leave th the e pump several hours before operating it (to allow the 7.7.4 Changing the stuffing box packing rings sealing compound to dry). 3. Perform a hydrostatic test under maximum pressure equal to 1.3 times the rated pressure Changing the stuffing box rings can be done with- (see the data sheet for the definition of the out disassembling the pump entirely. rated pressure). Choose a test liquid which is compatible with the pumped product. 1. Loosen the gland and move it out of the way. 2. Extract the worn rings, taking care not not to dam- 4. After the test, check the tightening torque of the tie-bolts, correct it if necessary. age the surface finish of the shaft. 3. The rings are preformed and precut; position the rings with their gaps staggered. 4. The rings must be pushed back using the stuffing box gland. 7.9 Installing in the plant When installing in the plant, follow the notes shown in chapter 5. 5. Tighten the gland nuts until you feel a slight friction when turning the pump shaft by hand. 6. Loosen the gland again again and tighten it slightly. Doc.No.: CEH07AE Rev.: 01 Date: 02/04/2003 Information subjected to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Help in case of trouble Page 1 of 1 8.0 Troubleshooting 8.1 Personnel qualifications Chapter 8 Troubleshooting Troubleshoo ting must be carried out by qualified, authorized personnel only. Problem Poor performance Cause - Counter pressure too high. - Pump or pipe not full or not completely free of gas. - Suction lift too high or positive suction head too low. - Clearances too large due to wear. - Wrong direction of rotation. - Foreign body in pump. - Stuffing box too loose. - Air leakage between bodies or at flanges on the suction line. - Bodies, shaft sealing, foot valve or suction line leaking. Pump runs irregular or noisy - Suction lift too high or positive suction head too low. - Stresses on the pump or on the electric motor /-pump assembly. - Foreign body in the pump. - Leak between the bodies due to loose tiebolts. Pump leaking - Leak at mechanical seal. - Leak at stuffing box too large. - Pump or pipe not completely filled. High pump temperature - Suction lift too high or positive suction head too low. Motor protective circuit breaker opens - The pump operates with the discharge gate closed without by-pass or the minimum rated output is not respected. - Stresses on the pump or on the electric motor / pump assembly. - The specified operating point is not correct. - Absorbed current higher than the specified max. limit value of the thermal relay. - Stuffing box too tight. - Foreign body in the pump. Doc.No.: CL08E Rev.: 00 Date: 03/10/2000 Solution Check and readjust the operating point. Clean the pipes. Bleed and fill the pump and the suction line. Check the level of liquid in the tank; open the gate-valve at the suction end. Clean the filter at the suction end. Replace worn pump parts. Reverse two phase wires on the motor. Open and clean pump. Re-tighten the gland. Re-machine the bodies sealings. Replace the flange seals. Check the body seals. Check the shaft sealing. Check the flange mating. Check the liquid level in the tank; open the gate at the suction end. Clean the filter at the suction end. Check the mounting of the pump, the coupling alignment and the pipe coupling. Open and clean the pump. Check the tightening torque of the tie bolts nuts, if the leakage remains re-work the intermediate pieces sealing. Check the friction surfaces, replace the sealings if necessary. Adjust the stuffing box. Change the stuffing box packing rings. Bleed and fill the pump and the suction line. Check the liquid level in the tank; open the gate-valve at the suction end. Clean the filter at the suction end. Open the discharge gate-valve or install a by-pass, check the minimum output. Check the mounting of the pump, the coupling alignment and the pipe coupling. Check and adjust the operating point (see data sheet). Check the motor protective circuit breaker and the electrical connections. Adjust the stuffing box. Check the pump for free rotation, dismantle and clean the pump. Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes Page 1 of 11 Chapter 9 9.0 Appendices 9.1 Cross sectional drawing - CEHA pump – shaft sealing by stuffing box *only for sizes 4100 to 6100 as from 5-stage models - **only for sizes 4100 to 6100. ***flat key (9401) for sizes 5100 and 6100. Fig.9.1.a 0 0 1 2 0 0 4 9 1 1 0 9 0 6 3 1 5 0 5 9 0 1 2 3 0 5 0 5 0 0 2 9 0 2 0 9 0 0 5 3 2 1 0 9 0 1 2 4 0 1 6 4 0 2 5 4 0 1 5 4 1 1 4 9 * * * 1 0 4 9 * 2 4 2 0 0 4 1 1 * * 0 4 2 5 0 5 0 9 0 1 6 5 0 3 0 9 1 4 1 1 0 7 0 1 0 2 3 0 9 0 1 0 5 3 2 1 4 2 0 8 0 1 2 0 4 9 0 0 1 3 2 0 0 5 5 0 1 3 9 1 0 2 9 0 2 2 9 0 6 0 1 Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes Page 2 of 11 Chapter 9 9.2 Cross sectional drawing - CEHA pump – shaft sealing by cooled stuffing box *only for sizes 4100 to 6100 as from 5 stage models - ** only for sizes 4100 to 6100 *** flat key (9401) for sizes 5100 and 6100 Fig.9.2.a 0 0 4 9 1 1 0 9 0 0 6 3 0 2 3 9 0 1 2 3 1 5 0 5 0 0 2 9 0 5 0 5 0 2 0 9 0 0 5 3 2 1 0 9 0 1 6 4 0 1 5 4 0 1 2 4 0 4 0 9 0 1 3 7 0 3 0 9 1 4 1 1 0 7 0 1 1 1 4 9 0 2 1 4 * * * 1 0 4 9 0 5 3 2 * 2 4 2 0 0 4 1 1 2 5 0 5 0 9 0 9 0 1 0 6 0 1 1 4 2 0 0 8 0 1 2 0 4 9 0 1 3 2 2 1 5 9 0 0 5 5 0 2 5 4 0 1 6 5 0 2 4 4 * * 0 4 0 0 1 2 0 1 3 9 0 2 2 9 1 0 2 9 Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes 9.3 Page 3 of 11 Chapter 9 Appendix – Parts list CEHA pump – shaft sealing by stuffing box and cooled stuffing box 0241 0241 Bear Bearin ing g bush bush for for iint nter erme medi diat ate e piec piece e 1080 1080 02 0242* 42* Bearin Bearing g bush bush for for interm intermedi ediate ate piece piece 1140 1140 (si (sizes zes 410 4100 0 to 6 610 100 0 from from 5 stages stages)) 1060 Suction casing 1070 Discharge casing 1080 Intermediate piece 1090 1140 Intermediate piece Intermediate piece 11 1141 41 Inte Interm rmed edia iate te pi piec ece e (l (las astt inte interm rmed edia iate te be befo fore re d dis isch char arge ge casi casing ng)) 2100 Shaft 2310 Impeller 2350 Vane wheel impeller 3210 Ball bearing 3500 Bearing housing 3600 Bearing cover 4120 Seal for cooling insert 4420 4210 Sealing ring for ball bearing 3210 4420 Cooling insert 4510 4520 Stuffing box housing Gland 4610 Stuffing box packing ring (preformed "tefloned" rings) 5050 Spacer 5051 Spacer 52 5240* 40*** Bearin Bearing g bush bush (inter (interme media diate te casin casing g 108 1080), 0), for for sizes sizes 4100 4100 to 6100 6100 5500 Flat washer (tie bolt) 56 5610 10 Spline Splined d guid guide e pin pin (disch (discharg arge e fflan lange ge/st /stuff uffing ing bo box x casin casing/b g/bear earing ing hou housin sing) g) 9011 9011 Hexa Hexago gona nall s scr crew ew (b (bea eari ring ng co cove verr rret etai aini ning ng)) 90 9012 12 Hexag Hexagona onall screw screw (disc (discha harge rge fla flange nge/st /stuff uffing ing box cas casing ing/be /beari aring ng c casi asing ng rreta etaini ining) ng) 9020 Dowel p piin (stuffing b bo ox) 9030 Plug Plug (di (disc scha harg rge e fla flan nge dra rain in hole) le) 90 9040 40 9050 Plug Pluggi ging ng scr screw ew (di (disc scha harg rge e flan flange ge for for coo coole led d stuf stuffi fing ng box box ver versi sion on)) Tie bolt 9200 Hexagonal nu nut ((s stuffing b bo ox) 9201 Hexagonal n nu ut ((ttie b bo olt) 9220 9220 Hexa Hexago gon n nut nut ((sh shaf aft, t, le left ft-h -han ande ded d thre thread ad)) 9310 Lock washer fo for shaft nut 9320 Circlip ((b bearing) 9400 Flat key (motor drive) 9401*** 940 1*** Flat key (vane (vane wheel wheel impeller impeller drive, drive, size sizes s 5100 5100 a and nd 6100) 6100) 9402 Flat ke key (i (impellor 23 2310 d drrive) 94 9411 11 Disk Disk key key ((va vane ne whee wheell iimp mpel elle lerr d driv rive, e, size sizes s1 120 200 0 tto o 410 4100) 0) 95 9512 12 Spri Spring ng wash washer er (p (pum ump p eq equi uipp pped ed with with cool coolin ing g casi casing ng)) Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes 9.4 Page 4 of 11 Chapter 9 Appendix – Dimension drawing – CEHA pump f a uk Ød2 ØD Øk l dk6 DNA w u uk 15° ØkE t DNE c h h ue Ød2 e1 e2 s b q1 m2 n2 n1 m1 ue: draining hole - uk: Connection to the sealing cooled casing Dime Di mens nsio ions ns:: G1 G1/4 /4”” for for si size zes s 120 1200 0 to 51 5100 00 - G3 G3/8 /8”” for for si siz ze 61 6100 00 Fig.9.3 Sizes DNA DN b C e1 e2 f h1 h2 n1 n2 Q1 s d l t u w E 1200 20 40 35 10 44 41 171 100 100 100 105 113 13 14 25 16.1 5 176 31/3600 32 65 35 12 50 42 201 112 132 112 135 134 13 19 40 21.5 6 214 4100 40 80 40 15 52 43 195 132 140 132 155 140 13 24 45 26.9 8 238 5100 50 100 45 18 60 66 237 160 165 160 170 159 15 28 50 30.9 8 276 6100 65 100 50 20 64 63 262 180 180 180 195 172 15 32 65 35.3 10 300 (in models with stage cooling chamber or retaining stage, the latter take the place of a hydraulic stage) 1 stage 2 stages 3 stages 4 stages Sizes a m1 m2 a m1 m2 a m1 m2 a m1 m2 12.. 195 238 204 229 272 238 263 306 272 297 340 306 31/36.. 213 261 227 253 301 267 293 341 307 333 381 347 41.. 268 294 260 323 349 315 378 404 370 433 459 425 51.. 305 353 315 380 428 390 455 503 465 530 578 540 61.. 338 391 353 428 481 443 518 571 533 608 661 623 5 stages 6 stages 7 stages 8 stages Sizes a m1 m2 a m1 m2 a m1 m2 a m1 m2 12.. 331 374 340 365 408 374 399 442 408 433 476 442 31/36.. 373 421 387 413 461 427 453 501 467 493 541 507 41.. 488 514 480 543 569 535 598 624 590 653 679 645 51.. 605 653 615 680 728 690 755 803 765 830 878 840 61.. 698 751 713 788 841 803 878 931 893 968 1021 983 Flanges connection as per DIN 2501 PN40 DNA/E 20 32 40 50 65 80 100 Øk 75 100 110 125 145 160 190 ØD 115 140 150 165 185 200 235 Ød2 x n 14 x4 18 x4 18 x 4 18 x 4 18 x 8 18 x 8 22 x 8 Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes 9.5 Page 5 of 11 Chapter 9 Appendix – CEHA pump - Forces and permissible moments on the flanges MxA A y F FxA FxE E y F FzA FzE E x M Fig.9.4 If several individual forces are developed, developed, the components of the resultants of these forces should not exceed the acceptable values in each direction. The pump brackets must be fixed on a plane base plate with uniform tightening. If these conditions are not met, it is no longer possible to guarantee either the sealing or the general mechanical behaviour of the pump. Suction flange 1060 Discharge flange 1070 N N Nm Sizes FxE F Fy yE Fz FzE Fx FxA FyA FzA MxE MxA 1200 2500 4000 3000 2000 4000 2000 220 75 3100 3000 4500 3500 2500 4500 2200 320 120 3600 3000 4500 3500 2500 4500 2200 320 120 4100 3500 5000 4000 3000 5000 2400 400 160 5100 4000 6000 4500 3500 6000 2600 570 210 6100 4500 7000 4500 4000 7000 3000 660 290 Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes 9.6 Page 6 of 11 Chapter 9 Appendix – CEHA pump – Identification coding Position 1-3 4 5-8 Characteristic Code Type CEH Construction Sizes 9-10 11 12 Hydraulic Bearing A 1201-6108 Definition Self-priming,, multi-cellular, side channel pump, with low NPSH. Self-priming Early production stage. Size and number of stages. …/5 Pump for LPG. …/7 Pump for LPG with retaining stage A A First hydraulic stage. One grooved ball bearing to DIN 625 and one liquid surrounded sleeve bearing 1313-15 Shaf haft sea sealing 001 Stuffing box flushed from internal source 501 Stuffing box with intensive cooling. AAE Unbalanced standard mechanical seal, flushed from internal source Brand: SFS – Type: FN - Mat.: EBPGG. AA1 Unbalanced standard mechanical seal, flushed from internal source Brand: SFS – Type: FN – Mat.: GBVGG. AF3 Balanced standard mechanical seal, flushed from internal source Brand: SFS – Type: Sterling GNZ – Mat.:Q1AEGG. AF8 Balanced standard mechanical seal, flushed from internal source AF4 Brand: SFS – Type: Sterling GNZ – Mat.:Q1BEGG. Balanced standard mechanical seal, flushed from internal source Brand: SFS – Type: Sterling GNZ – Mat.:Q1Q1EGG. AFU Balanced standard mechanical seal, flushed from internal source Brand: SFS – Type: Sterling GNZ – Mat.:Q1AVGG. AFJ Balanced standard mechanical seal, flushed from internal source Brand: SFS – Type: Sterling GNZ – Mat.:Q1BVGG. AFS Balanced standard mechanical seal, flushed from internal source Brand: SFS – Type: Sterling GNZ – Mat.:Q1Q1VGG. AFV Balanced standard mechanical seal, flushed from internal source Brand: SFS – Type: Sterling GNZ – Mat.:Q1AM1GG. AFK Balanced standard mechanical seal, flushed from internal source Brand: SFS – Type: Sterling GNZ – Mat.:Q1BM1GG. AFT Balanced standard mechanical seal, flushed from internal source Brand: SFS – Type: Sterling GNZ – Mat.:Q1Q1M1GG. AS3 Cooled, balanced standard mechanical seal, flushed from internal source. Brand: SFS – Type: Sterling GNZ – Mat.:Q1AEGG. ASJ Cooled, balanced standard mechanical seal, flushed from internal source. Brand: SFS – Type: Sterling GNZ – Mat.:Q1BV1GG AST Cooled, balanced standard mechanical seal, flushed from internal source. Brand: SFS – Type: Sterling GNZ – Mat.:Q1Q1M1GG BF3 Unbalanced standard mechanical seal, flushed from internal source. Brand: Burgmann – Type: M7N – Mat.:Q1AEGG BFJ Unbalanced standard mechanical seal, flushed from internal source. Brand: Burgmann – Type: M7N – Mat.:Q1BVGG Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes 13 - 15 Shaft sealing Page 7 of 11 BFT Chapter 9 Unbalanced standard mechanical seal, flushed from internal source. Brand: Burgmann – Type: M7N – Mat.:Q1Q1TGG BG3 Balanced standard mechanical seal, flushed from internal source. Brand: Burgmann – Type: H7N – Mat.:Q1AEGG BGJ Balanced standard mechanical seal, flushed from internal source. Brand: Burgmann – Type: H7N – Mat.:Q1BVGG BGT Balanced standard mechanical seal, flushed from internal source. CAK Brand: Burgmann – Type: H7N – Mat.:Q1Q1M1GG Unbalanced standard mechanical seal, flushed from internal source. Brand: Crane – Type: CR59B – Mat.:BQ1TGG CBK Balanced standard mechanical seal, flushed from internal source. Brand: Crane – Type: CR59B – Mat.:BQ1TGG DAJ Unbalanced standard mechanical seal, flushed from internal source. Brand: Pacific – Type: PA600 – Mat.:Q1BVGG DBJ Balanced standard mechanical seal, flushed from internal source. Brand: Pacific – Type: PA610 – Mat.:Q1BVGG DAK Unbalanced standard mechanical seal, flushed from internal source. Brand: Pacific – Type: PA600 – Mat.:Q1BTGG DBK Balanced standard mechanical seal, flushed from internal source. Brand: Pacific – Type: PA610 – Mat.:Q1BTGG DBG Balanced standard mechanical seal, flushed from internal source. Brand: Pacific – Type: PA610 – Mat.:SAVGG 16-17 18 Material Casing seal 0A Main parts in GG, impeller in brass 0B Main parts in GG, impeller in stainless steel 0F Main parts in GG, impeller in PAEK 1A Main parts in GGG, impeller in brass 1B Main parts in GGG, impeller in stainless steel 1F Main parts in GGG, impeller in PAEK 4B Main parts in CrNiMo-steel or cast 4F Main parts in CrNiMo-steel or cast, impeller in PAEK 0 Liquid sealing compound 4 Soft Teflon cord. 19 20 Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes 9.7 9.7 Page 8 of 11 Chapter 9 Ap Appe pend ndix ix – CE CEHA HA pu pump mp – As Asse semb mbli ling ng bo bodi dies es Mark (exte (external rnal side side)) Groove Suction body 1090 Discharge body 1140 / 1141 Fig.9.5 The suction bodies 1090, and discharge bodies 1140 and 1141, together with a vane impellor, form a stage. The foundry marks I, II, III, IV, are visible on the external sides of the bodies. bodies. Assembly is carried out by juxtaposing the marks with the upper generating generating line as indicated on the assem assembly bly drawing; for this purpose, use the foundry groove visible visible outside the bodie bodies. s. The foundry groove in body 1080 is always located located opposite the foundry groove in body 1090 which precedes it. CAUTION If the specified angular position of the stages, as defined, is not respected, pump performance will be adversely affected. CEHA pumps can comprise up to 8 stages in regular models. In models with a cooling chamber or a retaining stage, the latter take the place of a hydraulic stage, so the pump will be able to take only 6 or 7 hydraulic stages (depending on the case concerned); this fact must be taken into account when evaluating the desired specifications. Discharge flange Discharge flange 1141 1090 1080 1141 1090 1140 1090 Discharge flange 1080 Suction flange 1141 1090 1140 1090 1140 1090 1080 Suction flange Suction flange 1-sta e um 2-stag 2-s tage e pum pump p 3-sta e um Fig.9.6 Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes Page 9 of 11 Chapter 9 9.7.1 Appendix – CEHA pump – Assembling bodies sc arge flange sc arge flange 1141 1090 1140 1090 1140 1090 1140 1090 1141 1090 1140 1090 1140 1090 1140 1090 1080 1140 1090 1080 Suction flange 4-stage pump Suction flange 5-stage pump Fig.9.7 Discharge flange 1141 1090 1140 1090 Discharge flange 1140 1090 1140 1090 1141 1090 1140 1090 1140 1090 1140 1090 1140 1090 1140 1090 1140 1090 1140 1090 1140 1090 1080 1080 Suction flange 6-stage pump 7-stage pump Suction flange Fig.9.8 Discharge flange 1141 1090 1140 1090 1140 1090 1140 1090 1140 1090 1140 1090 1140 1090 1140 1090 1080 8-sta e um Suction flange Fig.9.9 Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes 9.8 Page 10 of 11 Chapter 9 Appendix – Technical data summary When using CEHA pumps, the following technical data must be taken into account. Self-priming pump Direction of rotation: anti-clockwise facing the end of the pump drive shaft RP: 40 bars Max. admissible P*: 40 bars at 120°C / 32 bars at 180°C Test Pressure: 52 bars (1.3 times the rated r ated pressure) Max. admissible viscosity*: 300 mm²/s Max. n*: 1800 rpm *These limits are not valid for for all products or all types of construction. construction. For use in conformity conformity and complete safety, take into account the existing requirements requirements (standards) concerning the type of sealing and cooling. Number of stages: 1 to 8 stages maximum (if a retaining stage is used, it takes the place of a hydraulic stage). Connecting flanges: as per DIN 2501, PN 40, (positions and dimensions: see dimension drawing). Bearings: plain bearing at the pump end, ball bearing at the drive end Bearing Sizes according to DIN 625 1200 6302 3100 6304 3600 6304 4100 6305 5100 6306 6100 6307 Lubrication: 1 plain bearing at the pump end lubricated by the pumped product, 1 ball bearing at the drive end lubricated for life. Weight of the pump: Approximate weight in kg Sizes 1-stage pump weight Cast iron Stainless steel Add per additional stage Cast iron Stainless steel 1200 18 19 2.0 2.2 3100 31 33 3.5 4.0 3600 31 33 3.5 4.0 4100 41 43 6.0 6.5 5100 60 63 10.0 10.0 11.0 6100 79 83 12.5 12.5 13.5 Minimum / maximum output: Refer to Chapter 2 Temperature limits Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems Annexes Page 11 of 11 Minimum temperature temperatur e of pumped liquid = - 40 °C * Maximum temperature temperatur e of pumped liquid = 120 °C * Chapter 9 180°C for high temperature execution * **These limits are not valid for all products products or all types of construction. For use in conformity conformity and complete safety, take into account the existing requirements requirements (standards) concerning the type of sealing and cooling. Maximum permissible temperature of pumping liquid The highest temperatures usually occur on the pump casing surface, on the bearing housing in the area of the anti-friction bearings and on the casing cover near the mechanical seal. A dry running must be prevent. The temperature occurring on the pump casing is almost the same as that of the liquid handled A maximum temperature temperature of 80°C, 80°C, if grease lubricated, lubricated, can be expe expected cted in the area of the anti-friction bearings, provided the requirements for appropriate pump operation are met and regular maintenance on the bearings is provided. Insulation of the bearing housing is not permissible. If the pump is adequately adequately filled with liquid, the temperature of the liquid handled in the shaft seal area should not increase by more than 15°C for dead end operation with a single acting mechanical seal. Thus, the following theoretical maximum temperature of the liquid handled as a function of the temperature class according to EN 13463-1 is obtained. The maximum operating temperature temperature of the pump as well as the operating limits of the mechanical seal must be observed (if there is any doubt, please contact Sterling SIHI or the mechanical seal manufacturer). Temperature class Max. temperature of acc. EN 13463-1 pumping liquid T5 85 °C T4 120 °C T3 185 °C T2 285 °C T1 350 °C Doc.No.: CEH09AE Rev.: 01 Date: 02/04/2003 Information subject to technical alterations due to engineering development Sterling Fluid Systems (France) Member of Group Sterling Fluid Systems S.A. Sterling Fluid Systems France) Zone Industrielle de Trappes-Elancourt 1-3, Avenue Georges Politzer B.P.41 - 78193 Trappes Cedex, France Téléphone: +33 (0)1 34 82 39 00 Télécopie: +33 (0)1 34 82 39 61 Declaration of Conformity for bare shaft pump In the sense of the EU Directive 98/37/EC, Appendix II B Herewith we declare that the pump type: CEH In the version supplied by us complies with the following relevant regulations: EU Machine Directive 98/37/EC, Appendix I No. 1 EU Directive 94/9/EC, Group II, category 2 And that is destined for installation in a machine / assembly with other machines to fform orm a single machine and that it may not be commissioned until it has been determined that the machine in which this pump is to be installed or with which this pump is to be assembled complies with the clauses of the EU Machine Directive in the version of 98/37/EC and 94/9/EC. Harmonised standards used, in particular: EN 809 EN 292 part 1 EN 292 part 2 EN 13463 - 1 prEN 13463 - 5 In the actual version. National technical standards and specifications used, in particular: Unauthorised alterations of the pump unit and any use not in accordance with valid regulations and / or intended use result in a loss of validity of this declaration. Notification of Pump: Operation Manager II 2 G c T1-T5 Business Unit Manager Dr R. EHL O. LOESER Membres du groupe Sterling Fluid S Systems ystems