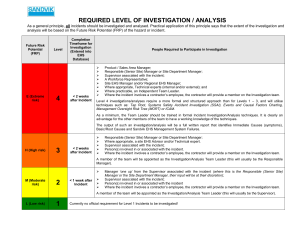

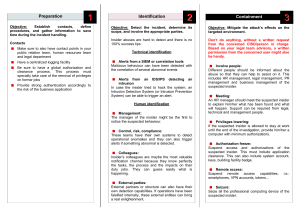

Introduction to Process Safety Management Training JOSEPH SURESH H A Z O P/LOPA C hai r ma n & Q R A S p e cia list P ro cess S af ety C o ns u ltant A n d H S E Tra i n er [email protected] www.ifluids.com • What is meant by Process Safety Management • Difference between Occupational safety and Process safety • Brief History- PSM • Elements of Process Safety Management (OSHA, CCPS-RBPS, OISD) • Elements Relevant to Major industries like Refineries • Brief introduction to each element and How they can be implemented [email protected] www.ifluids.com DEFINING PROCESS SAFETY Let’s Split the Terms [email protected] www.ifluids.com PROCESS PROCESS: Any activity or combination of activities concerning the use, storage, manufacturing, handling and movement of hazardous substances [email protected] www.ifluids.com SAFETY: Safety is a Quality of Mind – Being and Feeling Safe You can feel Safe due to the SAFETY • Systems present • Technology • Equipment • Procedures • Practices • People • Experience, etc., [email protected] www.ifluids.com WHAT IS PROCESS SAFETY? A blend of Engineering, Management and Operational Skills focused on preventing catastrophic incidents particularly explosions, fires and toxic releases associated with the use of chemicals and petroleum products [email protected] www.ifluids.com How is PSM different from Occupational Safety ? Process Safety: Pro-active and centered on the safety integrity of the process towards accident prevention. Occupational safety: Focuses more on injuries to workers – i.e., very much a Reactive focus. [email protected] www.ifluids.com What is PSM Process Safety Management ? [email protected] • Proactive Identification, Evaluation & Prevention of • Containment ( Material/Energy) loss in • A Chemical Process due to • Process/Equipment /Components Failure www.ifluids.com [email protected] www.ifluids.com WHY PROCESS SAFETY ? [email protected] www.ifluids.com Several catastrophic accidents have occurred, resulting in loss of life and significant property damage. Union Carbide: Bhopal, India (Dec 1984) Chernobyl: Ukraine (April 1986) Piper Alpha: North Sea (July 1988) BP: Texas City, TX (Mar 2005) Deepwater Horizon: TX (April 2010) [email protected] www.ifluids.com BP Texas Refinery, 2005 PSE – Process Safety Events involving fires, explosion, or toxic release https://youtu.be/goSEyGNfiPM https://www.youtube.com/watch?v=QiILbGbk8Qk https://youtu.be/3RFDKpwdbEA [email protected] www.ifluids.com INDIFFERENCE ➢Okaaaay ! ➢You think that will happen again? Here? ➢Incidents happen on an offchance. They don’t repeat ➢We have better systems. Don’t we? ➢We run better. [email protected] www.ifluids.com Human Impacts ADVERSE CONSEQUENCES Consumer Injuries Community Injuries On-site Personnel Injuries Unit Personnel Injuries Loss of Employment Psychological Effects • Off-Site Contamination • Air • Water • Soil • On-Site Contamination • Air • Water • Soil Environ. Impacts Economic Impacts [email protected] • • • • • • • • • • • • • Property Damage Inventory Loss Production Outage Poor Product Quality/ Yield Lost Market Share Legal Liability Negative Image www.ifluids.com Iceberg Safety Theory [email protected] www.ifluids.com PSM Rules -1992 After series of serious accidents ( like Bhopal gas Tragedy & Piper alpha, North Sea ) that occurred in 1980’s , OSHA developed Process Safety Management rules in 1992. These rules made mandatory for Chemicals handling , storing /processing chemicals above a Threshold quantity. [email protected] www.ifluids.com RULES & LEGISLATIONS ▪ U. S. Occupational Safety & Health Administration (OSHA) PSM RULE 29CFR 1910.119, 1992 ▪ COMAH (UK) ▪ U. S. OSHA 3132: Process Safety Management ▪ American Institute of Chemical Engineers (AIChE) Center for Chemical Process Safety (CCPS): Process Safety Leading & Lagging Metrics, 1998 ▪ UK Health Safety Executive (HSE) Guidelines HSEG254: Developing Process Safety Indicators, 2006 ▪ API 754: Process Safety Performance Indicators, 2008 ▪ OISD STD-206: Guidelines for Safety Management System in the Petroleum Industry ▪ CCPS Guidelines for Risk Based Process Safety [email protected] www.ifluids.com [email protected] www.ifluids.com Top Event CONTROL BARRIERS Supervisor RECOVERY MEASURES HSE CRITICAL TASK Staff INPUTS Business Activities Inspection Maintenance Operations Design & Construction Competency [email protected] STANDARDS & PROCEDURES HSE CRITICAL ACTIVITY OUTPUTS REPORTS Hazard CONSEQUENCE THREAT EFFECT ON BUSINESS KPI www.ifluids.com An effective Process Safety Management Program requires a systematic approach to evaluating the whole chemical process. [email protected] www.ifluids.com HOW? The OSHA PSM Rule introduced the concept of PSM through Elements. 1. Process Safety Information (PSI) 2. Operating Procedures (OP) 3. Training (TRG) 4. Contractor Safety Management (CSM) 5. Hot Work Permit (HWP)/safe work practices 6. Process Hazard Analysis (PHA) 7. Management of Change (MOC) 8. Pre-Startup Safety Review (PSSR) 9. Mechanical Integrity (MI) 10.Incident Investigation 11.Emergency Planning and Response (ERP) 12.Employee Participation 13.Compliance Audits (CA) 14.Trade secrets [email protected] www.ifluids.com PSM ELEMENTS OSHA PSM RULE (1910.119) [email protected] www.ifluids.com [email protected] www.ifluids.com CCPS-RBPS PSM ELEMENTS Commit to Process Safety • Process safety culture • Compliance with standards • Process safety competency • Workforce involvement • Stakeholder outreach Understand Hazards and Risks • Process knowledge management • Hazard identification and risk analysis (HIRA) [email protected] Manage Risk • Operating procedures • Safe work practices • Asset integrity and reliability • Contractor management • Training and performance assurance • Management of change • Operational readiness • Conduct of operations • Emergency management Learn from Experience • Incident investigation • Measurements and metrics • Auditing • Management review and continuous improvement www.ifluids.com [email protected] www.ifluids.com OISD-GDN-206 1. Safety Organisation 2. Employees Participation 3. Process Safety Information 4. Process Hazard Analysis 5. Operating Procedures 6. Training 7. Contractors 8. Pre-startup Safety Review 9. Mechanical Integrity 10. Work Permit [email protected] 11. Management of Change 12. Incident Investigation and Analysis 13. Emergency Planning and Response 14. Compliance Audit 15. Occupational Health 16. Off-the job Safety 17. Customers and Products 18. Road Transportation 19. Trade Secrets www.ifluids.com PSM elements 1.Safety organization 11.Management of Change (MOC) 2.Employee Participation (EP) 12.Incident Reporting & Investigation System (IRIS) 3.Process Safety Information (PSI) 13.Emergency Response Planning (ERP) 4.Process Hazard Analysis (PHA) 14.Compliance Audit (CA) 5.Operating Procedures (OP) 15.Measurement and metrics (Management Review) 6.Training & competency 7.Contractor Safety Management (CSM) 8.Pre-Start Up Safety Review (PSSR) 9.Mechanical Integrity (MI) 10.Work Permit System (HW&WPS) [email protected] www.ifluids.com PSM Elements Cross Functional Team - KICK OFF MEETING PSM cell NRL [email protected] www.ifluids.com [email protected] www.ifluids.com • Ensuring Safe Workplace for Workers. • Reduces Risk to nearby community. PSM Benefits • Reduces Risk to adverse environment impact. • Increase assets reliability with Reduced downtime & losses. • Reduction in Insurance Premium. • Business management with better controls. [email protected] www.ifluids.com RE-VISIT PSM ELEMENT– Why ? Hazards PROTECTIVE BARRIERS The protective barriers are nothing but PSM Elements WEAKNESSES OR HOLES ACCIDENT Holes are Gaps in systems/procedures execution When “Holes” aligns, Hazards turns into Accidents. [email protected] www.ifluids.com 1. Safety Organization •Safety Policy •Safety promotion •Safety committee •Enforcement of safety [email protected] www.ifluids.com Safety Culture 35 [email protected] www.ifluids.com Keys for Success 36 [email protected] www.ifluids.com • Managers and supervisors set the tone for your safety culture. The leadership team MUST “talk the talk” AND “walk the walk.” Management Commitment • The leadership team allocates resources – people, time, and invests money in their teammates, demonstrating their commitment to safety. Leaders know that safety adds value to the company. • Fastest way to destroy a safety culture’s credibility is through a leadership team’s disregard for the safety rules. 37 [email protected] www.ifluids.com • Build TRUST! Do what you say Communication • Ensure timely and appropriate responses to identified hazards. • Proper safety techniques and procedures training • Celebrate the successes along the way! 38 [email protected] www.ifluids.com Continuous Improvement – Are we better than we were yesterday? ➢ Continuously review your own policies and procedures, especially after an incident. ➢ Re-train your teammates when deficiencies have been corrected. [email protected] www.ifluids.com 39 [email protected] 40 www.ifluids.com [email protected] 41 www.ifluids.com You just checked into your hotel, round the corner to head towards your room, and you see a guy standing on a bucket on the top rung of a ladder. What do you do? [email protected] 42 www.ifluids.com You see the General Manager of your company walking across the production floor and he is not wearing all of his PPE. What do you do? [email protected] 43 www.ifluids.com Provide Input on process 2.Employee Participation Consult with employees on process Data available to employee Training [email protected] www.ifluids.com • Standard operating procedures • Checklist for start/shutdown/critical operations • Safety observation • Safety suggestion • Hazop/LOPA (MOC) Employee Participation • Permit audit • Day/shift verification of KPI(process) • Preparation of Job safety analysis for critical activities, confined space, hot work • Confined space identification and document preparation • Training • Process safety information gap analysis (monthly) • Safety Logbook • Safety Meeting of each group of Plant [email protected] www.ifluids.com 3.PROCESS SAFETY INFORMATION [email protected] www.ifluids.com [email protected] www.ifluids.com 4.PSM Element – Process Hazard Analysis [email protected] www.ifluids.com ❑One of the most important elements ❑IDENTIFY and ANALYSE significance of POTENTIAL HAZARDS associated ❑Analyses potential CAUSES and CONSEQUENCES of Process Incidents ❑Reduces consequences of accidental releases of hazardous chemicals. ❑Focuses on equipment, instrumentation, utilities, human actions (routine and non-routine), and external factors that might affect the process. [email protected] www.ifluids.com ❑ There are multiple PHA methodologies/ techniques out there, viz. ➢Checklists ➢What-if Analysis ➢Hazard Identification (HAZID) ➢Hazard and Operability Study (HAZOP) ➢Failure Mode and Effects Analysis (FMEA) ➢Event Tree Analysis ➢Fault Tree Analysis ➢Layer of Protection Analysis (LOPA)/SIL ➢Quantitative Risk Analysis (QRA) Conceptual Design • What If Analysis [email protected] Preliminary Design • What If &/ • Checklist Final Design • HAZOP • FMEA • Fault-Tree Analysis Management of Change • What If • HAZOP Decommissioning • What If Analysis www.ifluids.com 5. Operating Procedures [email protected] www.ifluids.com OPERATING PROCEDURES ❑Describes: • Tasks to be performed, • Operating conditions to be maintained, • Safety and health precautions to be taken. ❑Need to be: • • • • Technically accurate, Understandable, and Revised periodically to reflect current operations It should be readily accessible to employees ❑Should be Reviewed Annually by Plant Operations Team CSB Video-15 min [email protected] https://www.youtube.com/watch?v=rjxBtwl8-Tc&feature=player_embedded www.ifluids.com ✓ INITIAL START-UP AND NORMAL START-UP ✓ NORMAL OPERATIONS, EMERGENCY OPERATIONS ✓ NORMAL AND EMERGENCY SHUT-DOWN ✓ TEMPORARY OPERATIONS ✓ OPERATING LIMITS AND CONSEQUENCES OF DEVIATION ✓ HAZARDS PRESENTED BY THE PROCESS ✓ INCLUDE SAFE WORK PRACTICES ✓ LOTO, CONFINED SPACE, CONTROL OVER ENTRANCE TO FACILITY, ETC [email protected] www.ifluids.com 6. WORK PERMIT SYSTEM /SAFE WORK PRACTICES CSB video-11 Min https://www.youtube.com/watch?v=PqskpvPejeU [email protected] www.ifluids.com Safe Working Practices (WPS) ➢Safe working practices provides a carefully planned system of procedure and/or permits involving checking and authorizations prior to executing non-routine work in progress areas for : ▪ Hot work ▪ Vessel Entry (confined Space) ▪ Heavy lifts & crane operations ▪ Vehicle access ▪ Scaffolding, Excavations etc. [email protected] www.ifluids.com 7. Contractor Safety Management [email protected] www.ifluids.com Contractor Safety Process ▪ Tendering ▪ Pre-Selection & Bidding ▪ Contractor Evaluation – Checklist ▪ Selection – Vendor Presentations including procedures and safety requirements, Safety Officer evaluation ▪ Field Deployment – Induction Training (to all), Fire Training, Tool-Box Talks, Spot Training - Skill Development Centre for contractors' supervisors and workers ▪ Performance Evaluation – Checklists, Appreciation, Monthly Performance Reports, Audits, Violations, Disciplinary Action ▪ Appraisal for extension ▪ Contractor Safety Audits [email protected] www.ifluids.com 8.Training & Competency [email protected] www.ifluids.com ▪ Induction Training ▪ Job specific training including safe work practices ▪ Refresher training ▪ Keep training records . [email protected] www.ifluids.com ❑Evaluate training programs periodically to see if necessary skills, knowledge, and routines are properly understood and implemented. ❑Ensure that employees, including maintenance and contract employees, receive current and updated training. If changes are made to a process, affected employees must be trained in the changes and understand the effects of the changes on their job tasks. [email protected] www.ifluids.com Training – PSM Awareness For knowledge sharing: ❑Safety Moment – Every Meeting ❑CCPS Beacons ❑Key Incident Learnings ❑Process Safety Incident Videos ❑Concept Videos ❑SLIPS (Simple Learnings in Process Safety) [email protected] www.ifluids.com 9.Management of Change [email protected] www.ifluids.com ▪ Definition of “Change” ✓Any Change/Modification in Machine, Material and Method. [email protected] www.ifluids.com MANAGEMENT OF CHANGE (MOC) ➢Change includes all modifications to equipment, procedures, raw materials, and processing conditions other than "replacement in kind”. ➢Changes in process technology can result from changes in: ➢production rates, ➢new equipment, new product development, ➢change in catalysts, and ➢changes in operating conditions to improve yield or quality. [email protected] www.ifluids.com ➢Equipment changes can be in: ✓materials of construction, ✓equipment specifications, ✓alarms and interlocks. ➢Establish means to detect both technical and mechanical changes. ➢Where the impact of the change is minor and well understood, a check list reviewed by an authorized person, with proper communication to others who are affected, may suffice. ➢For a more complex or significant design change, however, a hazard evaluation procedure with approvals by operations, maintenance, and safety departments may be appropriate. -> HAZOP/ HAZID based on Risk Ranking [email protected] www.ifluids.com Changes in documents, as below, should be noted so that these revisions can be made permanent when the drawings and procedure manuals are updated. Copies of process changes must be kept in an accessible location to ensure that design changes are available to operating personnel as well as to PHA team members when a PHA is being prepared or being updated. [email protected] www.ifluids.com Change of Personnel (OISD-GDN-178) ❑ Introduction of new personnel may introduce new hazards. ❑ Each employee shall be trained in an overview of the process and in the operating procedures BEFORE field deployment ❑ Training shall emphasize on specific safety and health hazards, emergency operations including shutdown, safe work practices applicable to employees' job task. ❑ The employer shall ensure that each employee involved in operating a process has received and understood the required training. COMPETENCY ❑ A record shall be prepared containing the identity of the employee, date of training and the means used to verify that the employee understood the training. [email protected] www.ifluids.com 10. Pre-Start up Safety Review [email protected] www.ifluids.com Pre - Startup Safety Review ▪ PSSR facilitates the safe transfer of projects from the construction stage to operation stage. ▪ A PSSR must be performed for new facilities and for modified facilities. ▪ PSSR must confirm that : • Construction and equipments are in accordance with design specifications; • Safety, operating, maintenance, and emergency procedures/system are in place and are adequate. [email protected] www.ifluids.com ➢Follow-up PHA Reviews/ HAZOP Recommendations ➢Field Rounds – Technical HSE Site Reviews ➢Document Reviews ➢Specific Equipment/ Loop – detailed Checklists ➢Punch Points ➢Cat. A = “HOLD”. Complete before commissioning ➢Cat. B = complete parallel to commissioning; ➢Cat. C = complete after commissioning as per agreed upon action plan ➢Resolution of Punch Lists - Monitoring & Tracking Implementation [email protected] www.ifluids.com 11. Mechanical Integrity [email protected] www.ifluids.com ❑ Is a “Breakdown” Philosophy used? ❑ Requires that a Mechanical Integrity Program be in place to ensure the continued integrity of process equipment. ❑ Elements of a mechanical integrity program include: ➢ Identifying And Categorizing Equipment And Instrumentation, ➢ Inspections And Tests And Their Frequency; ➢ Maintenance Procedures; ➢ Training Of Maintenance Personnel; ➢ Criteria For Acceptable Test Results; ➢ Documentation Of Test And Inspection Results; And ➢ Documentation Of Manufacturer Recommendations For Equipment And Instrumentation. [email protected] www.ifluids.com 12.Incident Reporting & Investigation System [email protected] www.ifluids.com Incident Reporting and Investigation System ▪ Each credible incident must be investigated [email protected] www.ifluids.com Incident Reporting and Investigation System ➢ Incident Reporting & Investigation System (IRIS) ➢ Online Reporting ➢ Incident categorization based on consequence matrix ➢ Investigation Team & Reporting times dictated based on Incident Levels ➢ Identification of Intermediate & Root Causes ➢ Event Sequencing/ Timeline study ➢ Root Cause Analysis (RCA) by Fault Tree Analysis done; 5-Whys trained personnel available ➢ Area Manager authority for approval and formation of Investigation Teams ➢ Investigation Completion Time restraints 5-WHYS TECHNIQUE [email protected] www.ifluids.com ➢ An incident investigation team must thoroughly investigate and analyze the incident. ➢ The incident report must be made available to all employees as well as contractors. ➢ Key leanings to be communicated to all. [email protected] www.ifluids.com 13.Emergency Response Planning https://www.youtube.com/watch?v=R2Ez7lkjg1Y [email protected] www.ifluids.com ▪ An Emergency Action Plan (EAP) must be developed to ensure the safe evacuation of employees. ▪ Plan must address all foreseeable emergency situations (e.g., fire, weather, chemical releases, etc.) ▪ Plan must address the means and methods necessary to protect employees responding to an uncontrolled release of a process chemical [email protected] www.ifluids.com 14.Compliance Audit [email protected] www.ifluids.com 15.Measurements & Metrics- KPI [email protected] www.ifluids.com Performance Indicators (Leading Indicators) • Number of observation received and target no (%) • No of work permit audit conducted Vs target • No of safety suggestions received and target no (%) • Percentage of process safety training completed vs. plan • Number of unplanned safety system activations for valid reasons • % of deviations in key operating parameters recorded and corrected • % of planned maintenance activities of critical instruments completed on time • % of planned maintenance activities of critical equipments completed on time • % of planned PSV testing completed on time [email protected] www.ifluids.com Performance Indicators (Lagging) • Percentage of near misses and incidents identified as being caused by unsafe acts or shortcuts • Number of critical instruments/alarms that fail to operate as designed, either in use or during testing • Number of unexpected loss of containment incidents • Number of times, plant operations (Start‐up / Shutdown) does not proceed as planned due to human errors • Number of incidents involving plant breakdown, loss of containment of hazardous material where deficiency in plant maintenance • No of work permits with serious deficiencies observed during audit [email protected] www.ifluids.com Training Academy [email protected] [email protected]