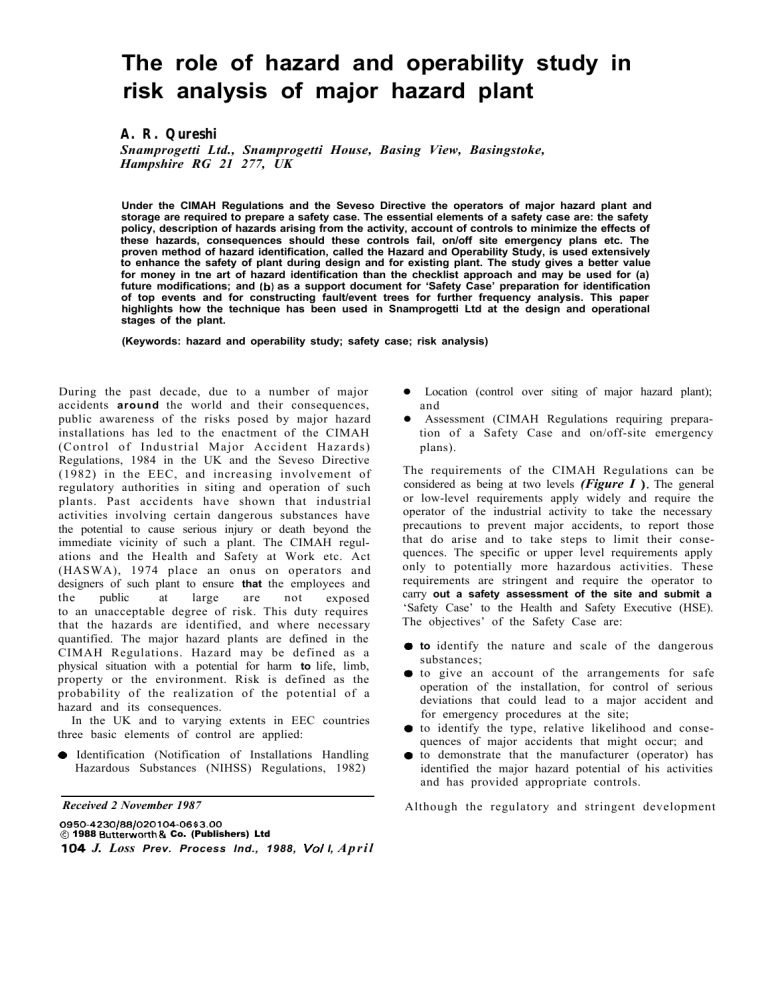

The role of hazard and operability study in risk analysis of major hazard plant A. R. Qureshi Snamprogetti Ltd., Snamprogetti House, Basing View, Basingstoke, Hampshire RG 21 277, UK Under the CIMAH Regulations and the Seveso Directive the operators of major hazard plant and storage are required to prepare a safety case. The essential elements of a safety case are: the safety policy, description of hazards arising from the activity, account of controls to minimize the effects of these hazards, consequences should these controls fail, on/off site emergency plans etc. The proven method of hazard identification, called the Hazard and Operability Study, is used extensively to enhance the safety of plant during design and for existing plant. The study gives a better value for money in tne art of hazard identification than the checklist approach and may be used for (a) future modifications; and lb) as a support document for ‘Safety Case’ preparation for identification of top events and for constructing fault/event trees for further frequency analysis. This paper highlights how the technique has been used in Snamprogetti Ltd at the design and operational stages of the plant. (Keywords: hazard and operability study; safety case; risk analysis) During the past decade, due to a number of major accidents around the world and their consequences, public awareness of the risks posed by major hazard installations has led to the enactment of the CIMAH (Control of Industrial Major Accident Hazards) Regulations, 1984 in the UK and the Seveso Directive (1982) in the EEC, and increasing involvement of regulatory authorities in siting and operation of such plants. Past accidents have shown that industrial activities involving certain dangerous substances have the potential to cause serious injury or death beyond the immediate vicinity of such a plant. The CIMAH regulations and the Health and Safety at Work etc. Act (HASWA), 1974 place an onus on operators and designers of such plant to ensure that the employees and the public at large are not exposed to an unacceptable degree of risk. This duty requires that the hazards are identified, and where necessary quantified. The major hazard plants are defined in the CIMAH Regulations. Hazard may be defined as a physical situation with a potential for harm to life, limb, property or the environment. Risk is defined as the probability of the realization of the potential of a hazard and its consequences. In the UK and to varying extents in EEC countries three basic elements of control are applied: 0 Identification (Notification of Installations Handling Hazardous Substances (NIHSS) Regulations, 1982) Received 2 November 1987 OS?04230/68~020104-06S3.00 0 1988 Butterworth & Co. (Publishers) Ltd 104 J. Loss Prev. Process lnd., 1988, Vol I, A p r i l l Location (control over siting of major hazard plant); and l Assessment (CIMAH Regulations requiring preparation of a Safety Case and on/off-site emergency plans). The requirements of the CIMAH Regulations can be considered as being at two levels (Figure I ). The general or low-level requirements apply widely and require the operator of the industrial activity to take the necessary precautions to prevent major accidents, to report those that do arise and to take steps to limit their consequences. The specific or upper level requirements apply only to potentially more hazardous activities. These requirements are stringent and require the operator to carry out a safety assessment of the site and submit a ‘Safety Case’ to the Health and Safety Executive (HSE). The objectives’ of the Safety Case are: to identify the nature and scale of the dangerous substances; to give an account of the arrangements for safe operation of the installation, for control of serious deviations that could lead to a major accident and for emergency procedures at the site; to identify the type, relative likelihood and consequences of major accidents that might occur; and to demonstrate that the manufacturer (operator) has identified the major hazard potential of his activities and has provided appropriate controls. Although the regulatory and stringent development Role of hazop in the risk analysis of major hazard plant: R. Qureshi Is my installation excluded (Reg 3) ? START HERE Is it an industrial activity within the meaning of Reg 2 ? NO ACTION Have I a dangerous substance within the meaning of Reg 2 ? NO ACTION Yes tI Is my activity I EITHER a use specified in Schedule 4 ? Does the dangerous substance come within the criteria NO ACTION OR isolated storage ? I I I I ACTION in the event of a major accident Reg 5 Notif major accident to HSE bf not notified under NADOR) Provide information to HSE on major accident I I Is the quantity large enough to render the operation capable of presenting major accident hazards ? No No , IS the dangerous substance listed in Schedule 2 ? 1 Yes V the threshold in Schedule 3, column 2 ? 1 ACTION -4 Reg 4 Demonstrate safe operation at any time I No \ I I 7 Yes t c Does the quantity exceed the threshold in Schedule 2, column 2 ? 1 ACTIONS Reg 7 Provide notification to HSE (if activity not already notified under NIHHS Regs) Prepare &submit to HSE a written report (safety case) igure 1 Reg 8 Provide information to HSE on significant modifications Reg 9 Provide further information at request of HSE Reg 10 Prepare an on-site emergency plan Reg 11 Provide information to local authority to enable them to draw up an off-site emergency plan Reg 12 Inform the public about the major accident hazard Yes plus Reg 4 Demonstrate safe operation at any time A manufacturer’s guide to the CIMAH regulations (Ref.1) J. Loss Prev. Process Ind., 1988, Vol 1, April 105 Role of hazop in the risk analysis of major hazard plant: R. Qureshi controls are not universally applicable, incidents at Bhopal and Mexico City, among others, have shown that in future the designers and operators of such plant irrespective of their location would have to demonstrate that the plant offers a degree of safety comparable with those located in the Western world*. This paper deals with how a hazard and operability study differs from other hazard identification techniques and its role in risk analysis of major hazard plants for both the design and operational stages of a plant. Hazard identification techniques and their application Until recently, it has been customary to examine a project for inadequacies in design on an ad hoc basis and any one or a combination of the following techniques have been used for hazard identification either in a team or on an individual basis: Obvious: for example in the manufacture of ethyl oxide, oxygen and ethylene are mixed in proportions close to the explosive limit, it is also very toxic - the hazards are therefore obvious. 0 See what happens approach. l Checklist approach: the main disadvantages are that items not on the list are not considered and plants dealing with new design and chemicals not experienced before are inadequately covered. It is not possible to produce a checklist which could meet all situations. 0 A more effective way to identify potential hazards is to look at the design in a dynamic manner. The technique is known as a hazard and operability (hazop) study and is defined by the Chemical Industry Association (CIA) in their guide3 as follows: ‘The application of a formal systematic critical examination to the process and engineering intentions of the new facilities to assess the hazard potential of maloperation or malfunction of individual items of equipment and the consequential effects on the facility as a whole’. HAZARD AND Although the definition implies the use of this technique for ‘new facilities’ it is equally intended for existing plants, as will be demonstrated later on. It is not the intention to deal with the hazop study technique in detail here (for further guidance reference should be made to Ref. 3 and 4), but to describe its application. For the success of the study it is essential that a multi-disciplined team is selected under the chairmanship of an independent and experienced person. The team structure depends upon the type of plant being studied but would normally consist of the designer (process engineer when an existing plant is undergoing a hazop), client’s representative (for plant being designed), specialists (instrument/mechanical/safety advisor etc.), as and when required. It is best to start with the raw materials first and work towards the products. Each piping and instrument diagram (PID) is divided into meaningful sections, and each section is systematically examined using guide words how deviations from the desired intention of the design can occur and whether such deviations can lead to hazardous situations. Any means of protection against hazards are noted and if there are further requirements for qualitative and quantitative studies these are actioned on members of the study team. The need for further action depends upon the product of consequence and frequency of occurrence, and is determined by rough and ready evaluation. The procedure for study consists of the following steps: 1. definition of the objective and scope of the study; selection of team; preparation for the study; carrying out study and recording of results; and follow up. 2. 3. 4. 5. The proceedings of the study are recorded on ‘working sheets’ (a specimen is shown in Figure 2), and the follow up is recorded on another sheet (Figure 3). The designer and the operator have very important roles to play in the hazop study which are crucial to its success. The designer explains the design intention and OPERABILITY STUDY WORKING S H E E T S TITLE ..,_................................. DATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . REFERENCE DOCUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TEAM MEMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N O D E S ; PARAMETER , DEVIATION , I I I I I I I I I I I I I Figure 2 I I I I I I I I I ; POSSIBLE CAUSE ; CONSEQUENCES I I I I I I I I I i I I Hazard and operability study working sheets 106 J. Loss Prev. Process Ind., 1988, VoJ 1, April SHEET ,......_........ of . . . . . . . . . . . . . . . . . . 1 PROTECTION MEANS I I I I I I I I I I I I ; NOTES I I I I I I I I I I I I & ACTIONS REQD. Role of hazop in the risk analysis of major hazard plant: .R. Qureshi SHT .......... OF .......... VENUE ......................... DATE ............... THOSE PRESENT ................................................................................ HAZ. OP. SHEET P.I.D. Figure 3 , I ; DESCRIPTION OF ACTION REQUIRED ; ; I RESPONSE ; ACTION BY I Action/response on hazop study the operator elaborates the operational philosophy/ constraints and historical data relevant to the plant, as such information is not readily available. In their absence one may have to spend a lot of time going through operating instructions, management philosophy etc., and even then the quality of information would not be the same. Risk analysis General risk analysis consists of the following steps: (a) the likelihood of a specified undesired event occurring within a specified period or in specified circumstances. It may be either frequency (number of occurrences per unit time) or probability (scale O-l) depending on circumstances5; (b) estimating the consequences to employees, members of the public and plant/profits; and (c) comparing the results of (a) and (b) with a target or set criteria to decide the appropriate course of action. The information for items (a) and (b) may be derived from hazop, incident and failure rate and chemical data banks, meterological conditions etc. Information on random failure and the extent of gaseous and liquid releases can be generated from well-documented hazop study working sheets. An experienced chairman, using his subjective judgement, can eliminate the need for numerical analysis in a large proportion of events. Application of hazop in Snamprogetti Ltd As mentioned earlier, hazop can be conducted on a plant under design or on an existing plant. Snamprogetti Ltd has applied the technique on both categories of plants and our experience is briefly described in this section. In our experience, contrary to common belief, hazop does not take any longer than reviews based on the checklist approach, provided it is conducted under the Chairmanship of an experienced and independent person and the team members are proficient in their discipline. It does. however, take time in producing typed versions of the hazop working sheets. To process Ammonium FCV NO nitrate solution NO W Demin water make up Ammonia Nitric acid KEY. * Added as a result of HAZOP BJ G NO,NC FCV,LCV QVI ,QV2 TV Figure 4 A Valve with actuator and failure mode shown Pumps (working/standby) Normally open/closed Flow and level control valves Quench valves Trip valve Ammonium nitrate reactor quench water System J. Loss Prev. Process Ind., 1988, Vol I, April 107 Role of hazop in the risk analysis of major hazard plant: R. Qureshi l-l UncontrollexJ temperature rise in reactor evcntslvear pi$Egg$qpj&iq Figure 5 Basic fault tree for uncontrolled temperature rise in ammonium nitrate reactor Application of hazop to plant under design While conducting hazop on a fertilizer plant design in which the client representative was a team member it was discovered that the ammonium nitrate reactor was a critical item where runaway reaction could give disastrous consequences. By keeping operational parameters under control the situation could be avoided, but once realized, the only way the reaction can be arrested is by quick introduction of water. The water for this purpose was supplied from a demineralized water supply system which normally fed the process stream and the boiler. The system is shown in Figure 4 (the hazop recommendations are also marked). Because of the very serious nature of the problem the client requested a reliability analysis of the quench water to be carried out to ensure that is was within acceptable limits. It was found that the system availability was considerably enhanced by taking account of the recomendations of the hazop study (a basic fault tree is shown in Figure 5). It has been experienced time and time again that a properly conducted hazop improves considerably the plant design and saves time on detailed assessment. Application to existing plants Conducting a hazop study on existing plant could be an expensive and laborious exercise and it should, therefore, be selectively applied. It may be that part of the plant is giving problems or a number of incidents have occurred in certain parts of the plant to warrant hazop. The classification of units of major hazard plants can be done on the basis of an integrated method proposed 108 J. L OSS P r e v . P r o c e s s lnd., 7988, Vol I, A p r i l by Dow Chemical & TN0 and ICI Mond6 as a first analysis of major hazards and should not be a replacement for more detailed and sophisticated hazard assessment and consequence analysis. Either method can be used at any phase of design of a new plant or on an existing plant to highlight those areas where hazard levels are comparatively high and which require an in-depth study. The methods can be applied to a wide range of processes, storage installations, loading/ unloading operations, and failure of pipes handling flammable as well as toxic substances. The toxicity index does not take into account all the possible effects on the human body, therefore care should be exercised when formulating recommendations based on this methodology. The plant is divided into units. A unit is defined as part of a plant that can be readily and logically characterized as a separate entity. It may consist of a portion of the plant which is (or could be) separated from the remainder of the plant either by distance or by fire barriers, walls or bunds etc. The portion of the plant selected as a unit will normally be the area where a particular process and/or material hazard exists which is somewhat different to those present in other units nearby. There are two ways of ranking various units on a site Table 1 The Fire & Explosion and Toxicity Indices FEI TI less than 65 65-95 above 95 less than 6 6610 above 10 Hazard category Ill II I Kategory I being the most hazardous) Table 2 The Mond index Hazard category Index R Ill II I up to 500 between 500 and 2500 above 2500 (Category I being the most hazardous) The extent of safety analysis is determined as per Table 3 Table 3 Safety analysis to be applied Hazard categories Extent of safety analysis I Level 1 Level 2 Level 3 X II Ill X X The levels are defined as follows: Level 1: Qualitative (hazard and operability study) and quantitative treatment Level 2: Qualitative (hazard and operability study) and offset Mend Index R2 (Mend Index which takes into account operational aspects) Level 3: Offset Mond Index R2 only Role of hazop in the risk analysis of major hazard plant: R. Qureshi and these are briefly described as follows: (a) Using the Fire 8z Explosion Index (FEI) and Toxicity Index (TI). From the values of FE1 and TI (Table I), Hazard Categories are assigned and the extent of safety analysis to be applied is determined from Table 3 . (b) Using the Mond Index R6. This is a slightly longer method and the value of R determines the Hazard Category (Table 2) and the extent of the safety analysis to be applied is determined from Table 3 . Acknowledgements The author is grateful to Snamprogetti Ltd for the preparation and presentation of this paper and for providing secretarial and graphical services. References I Z 3 4 5 6 A guide to the Control of Industrial Major Accident Hazards Regulations, 1984, HS(R) 21 Qureshi, A. R. and Grille, P., Health and Safety at Work, September 1987 A Guide to Hazard and Operability Studies, Chemical lndusrries Association, 1985 Kletz, T. A., ‘Hazop and Hazon - Notes on the Identification and Assessment of Hazards’, IChemE, Rugby, ‘Nomenclature for Hazard and Risk Assessment in the Process Industries’ IChcmE, Rugby, 1985 Snamprogetti Ltd. ‘Internal Procedures Technical Information’, RISK 13 and 15 J. Loss Prev. Process Ind., 1988, Vol 7, April 109