- Ninguna Categoria

Firefighter Forcible Entry Door Training Manual

Anuncio

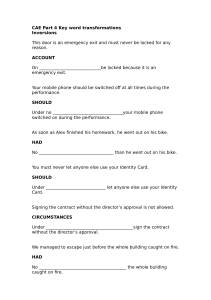

WHAT’S BEHIND…. THE GREEN DOOR? SEAN J. WILSON & SCOTT A. GARDNER SEARCH & DESTROY FIRE TRAINING, LLC SEARCH & DESTROY FIRE TRAINING, LLC SEAN J. WILSON & SCOTT A. GARDNER, LEAD INSTRUCTORS 5150 HAMPSHIRE DRIVE / SHELBY TWP., MI 48316 586-231-1478 [email protected] 2 SEARCH & DESTROY CONVENTIONAL FE DOOR What follows is a pictorial of our conventional forcible entry training door that we fabricated a few years ago. This is not so much of a ‘how-to’ as it is a ‘how-youmight’. Please forgive me as I don’t recall the exact step-by-step order in which we did things, but I’ll give measurements and put things in the rough chronology as best I can. We were certainly inspired by other props that were out there at the time. Ours is NOT the highest-tech or fanciest door around, nor does it have all the bells and whistles. It doesn’t have a baseball-bat swing cut-out or elegant hinge-springs ….but it is a more-than-serviceable conventional prop that has been extremely durable, fairly inexpensive, and simple enough that a couple of novices designed and built it from scratch with about $750 seed-money from our fire department’s training budget. This is for Chuck Olson, one of our friends who wanted to give our door a crack. I’m sure anybody out there who makes a stab at it can improve upon our work here. If you do develop your own door, whether you use any of our ideas or not, I’d love to see some pics! Email them to me at: [email protected] 3 PORTABILITY BY DESIGN One thing we intentionally designed our door to be, is PORTABLE. Working by myself, I can disassemble and load the door into the 6’ bed of my Chevy Colorado. I can also unload and assemble it by myself, though it’s MUCH easier with help. We teach a lot of off-site classes, so portability was something that was very important to us. However if you only intend to use this at your fire station with no intention of moving it, its components could be welded together more easily and with less drilling. 4 RAW MATERIALS – QUICK LIST, PART 1 Steel: • • • • • • • • • • • ¼” steel diamond-plate, 48” x 56” 3/16” steel plate, 18” x 30” 3/16” steel plate, 18” x 30” L-Bracket, bent to 1-7/8” at a right angle (see slide) 1/8” or 3/16” U-channel, 48” long, custom bent to 4” x 5” x 4” I.D. (see slide) 1/8” or 3/16” U-channel, 30” long, custom bent to 4” x 5” x 4” I.D. ¼” steel plate, 5” x 5”, quantity 2 ¼” steel plate, 5 x 10”, quantity 4 5” x 5” box steel, ¼” thick , 70” tall, quantity 2 6” x 6” box steel, ¼” thick, 8” tall, quantity 2 ¼” x 1” flat steel, 7-½” long, quantity 16 ¾” x 2” flat steel, 26” long 5 RAW MATERIALS – QUICK LIST, PART 2 Steel (continued): • • • • • • • • 1” x 1-½” box steel, 5” long, quantity 2 1” x 2” box steel, 2” long, quantity 1 1” x 2” box steel, 4” long, quantity 1 2” x 2” box steel, 2” long, quantity 1 2” x 2” box steel, 4” long, quantity 1 2” x 2” angle-iron, 24” long, quantity 2 1/8” or 3/16” steel cut into a trapezoid (see slide for dimensions) Round steel tubing (hollow), approximately 12” (should accept 7/16” Grade-8 bolt loosely) • Small diameter round steel rod (solid), approximately 36” long, Bolts: • • • • 7/16” x 3” Grade-8 bolts, quantity 15 7/16” x 4” Grade-8 bolts, quantity 12 7/16” x 6” Grade-8 bolts, quantity 4 3/8” x 6” Grade-8 bolts, quantity 6 6 RAW MATERIALS “Where the hell do I get all this friggin’ heavy-ass steel from?...Home Depot? Menard’s?” Your best bet is to find the local metal mart….in our case, it was a place called, uh, “Metal Mart”. What you need is the wholesale supplier to local welders and fabricators. They’ll likely also do custom cutting and bending. If it’s not one of your hang-outs already, I’m sure you can find the place in your area pretty quickly online. Failing that, stop in at your nearest welding shop and ask around. Also, if you don’t know how to weld, buddy up to the guy or guys on your department who do and get them to teach you, or better yet involve them in the project. Paying a welding shop to do this work for you can get pricey. At least in my area (Metro Detroit), the going rate for welding is about $60/hour. 7 TOOLS LIST You’ll need a number of tools, including: • • • • • • • • • • Welder Drill press (bench-top is okay, but it must be bolted down) ½” corded drill ½” cobalt drill bit ½” airline drill bit (extra long bit) Large C-clamps Bench grinder Angle grinder Chop saw K12 rotary saw (optional, comes in handy if you plan on trimming the diamond plate yourself) • Table saw (for cutting dimensional lumber after the prop is built) 8 Top-Piece U-Channel NOMENCLATURE Upright (lock-side) Door-stop U-Channel Hinge (upright-side) Hinge (door-side) Wood-box (upright-side) Upright (hinge-side) Upright Support Handle Base 9 STAGE ONE: BASE & FRAME 10 DIAMOND-PLATE BASE The footprint we ended up with is rectangular, measuring 48” x 56” (¼” diamond plate). We cut the corners off, but that’s completely optional. Had we known what we’d need at the time, we could’ve saved quite a bit of money. Not being certain, we ended up buying a monstrous 5’ x 8’ sheet of diamond plate. We’ve used the leftover diamond plate for other projects, but you’ll do much better ordering it custom-cut to those dimensions and not have to cut it down yourself later. 11 UPRIGHT SUPPORTS, PART 1 The two 5” x 5” uprights are removable. They are ¼” thick steel. Order two pieces, each cut to 70”. Each upright is held in place by a 6” x 6” support welded to the diamond plate base. Use ¼” thick steel, have two pieces cut to 8” lengths. You could probably get away with smaller dimensional steel, say 4” x 4” uprights and 5” x 5” supports, if you wanted to save money and weight. 6” x 6” Steel 8” Tall 12 UPRIGHT SUPPORTS, PART 2 As I recall, initially we welded one support down pretty tightly, then just tack-welded the other very lightly so that it could be moved if necessary. I believe on our door, they ended up being 37” apart from edge to edge. That’s not to say yours has to be, but just to give you an idea. 13 SPACERS FOR THE UPRIGHTS The interior dimensions (I.D.) of the 6” x 6” upright supports are 5-1/2” x 5-1/2”. To take up the other half-inch, we welded two lengths of ¼” x 1” flat steel onto each side close to the corners. We used 7-½” lengths of flat steel (16 lengths total), and started the welds a half-inch off of the end of the 5” x 5” upright so that the welded flat steel pieces would not interfere with fitment by complicating insertion or pushing the upright up if it stuck out past the end of the upright and hit the diamond plate first when inserted into the support. As you can see in these pictures, we drilled out both the supports and the uprights to accept bolts to tighten everything, but we don’t even use them most of them the time. Quite frankly, the spacers do a pretty good job. I spray them with a little WD-40 every now and then so they slide in nicely. 5-­‐½” I.D. 14 U-CHANNEL TOP-PIECE We had a custom U-channel bent for us out of 1/8” steel, but 3/16” would also be fine if you want to go heavier. If portability is desirable for you, then a U-channel top-piece is the way to go. However, if this prop is going to be permanent-party in a corner of your apparatus bay forever, you could more easily just weld another piece of dimensional steel to your uprights. This U-channel is 48” long. 15 U-CHANNEL CUT-AWAY VIEW We had a custom U-channel bent for us. This U-channel is 48” long, and made from 1/8” or 3/16” steel. Interior dimensions are 4” x 5” x 4”. 4” 4” 5” 16 U-CHANNEL TOP-PIECE I’ll be damned if I remember how I drilled these out to match. I can’t remember if I clamped the upright and the U-channel together and drilled them out together, or if I just used a drilling template for each individually and was very careful in my measurement, and precise in my drilling. I drilled these out with a ½” airline bit, (extra long bit). We use 3/8” X 6” Grade-8 bolts and wing-nuts. It’s good to have a little play. I’m pretty sure I clamped them. 17 TRAPEZOID-BRACE We put a brace on the hinge-side upright-support. We decided to do only one so that it wouldn’t be a tripping hazard during evolutions. As it turns out, it’s really not that obtrusive. If I were you, I’d do one on each side just for what-the-hell. You can put one on the hinge-side early in the process, but I wouldn’t do the lock-side upright until everything is settled with the spacing of the uprights. 18 TRAPEZOID-BRACE DIMENSIONS We had this trapezoid custom-cut for us. It’s 1/8” steel. I believe the bottom-side is 20” wide, the top-side is 5” wide, and the sides taper up to be 7” tall. 5” 7” 20” 19 STAGE TWO: THE DOOR 20 DOOR, PART 1 For our door, we chose a heavy, commercial-grade hollow-core metal door that we’d had donated to us from a local door and window company. The door is 36” wide, and we cut it down so that it is 48” tall. You could also consider fabricating your own door of the same dimensions out of box-steel and plate-steel. Just an idea. The door is reinforced by 2” x 2” angle-iron attached horizontally at the top and bottom, and by a 1/8” U-channel covering both sides and the edge the middle third of the door on the lock-side. The U-channel is formed by an L-bracket and a plate surrounding the door and then welded together where they meet. 48” tall 36” wide 21 DOOR, PART 2 We reinforced the top and bottom horizontal edges of the door with two pieces of 2” x 2” angle-iron. We cut our angle-iron down to 24”, you could go wider (up to full-width) if you’d like. 22 DOOR, PART 3 We created our own homemade U-channel to protect and reinforce the door by connecting two custom-made pieces. The first, an 1/8” steel plate measuring 18” x 30”. The second, an 1/8” steel plate bent into an L-bracket, with its face measuring 18” x 30”, and the small angle of the “L” bent to 1-7/8” I.D. (most doors are 1-3/4” thick). In retrospect, I would probably use 3/16” steel for both. 1-7/8” L-­‐Bracket 18” 23 DOOR, PART 4 We created our own homemade U-channel to protect and reinforce the door by connecting two custom-made pieces. The first, an 1/8” steel plate measuring 18” x 30”. The second, an 1/8” steel plate bent into an L-bracket, with its face measuring 18” x 30”, and the small angle of the “L” bent to 1-7/8” I.D. (most doors are 1-3/4” thick). In retrospect, I would probably use 3/16” steel for both. Drill out the plate L-bracket together for the best fitment upon installation onto the door. Use the plate as a template to mark the door, and drill out the door. Use ½” cobalt bit for all holes. Install plate and L-bracket using 7/16” x 3” Grade-8 bolts and hex nuts. Once installed, weld plate and bracket together. 1-7/8” 18” 24 WOOD-BOX, DOOR-SIDE, PART 1 For the door-side wood-box we used four-inch sections of 1” x 2” and 2” x 2” box steel welded on top of one another. The door-side won’t require the heavy reinforcement welds that the wood-box on the upright-side will, but make sure your welds are solid and full-length. Once assembled, we welded our wood-box smack dab in the middle of the door. That way you can make the door reversible later if you so choose. 25 WOOD-BOX, DOOR-SIDE, PART 2 There are some designs out there with wood-boxes high and low to simulate multiple locks. That is also a good design, and realistic for real-world forces. We decided to keep our prop at one wood-box for reasons of class cost, and we felt that this design allows us to teach about door-flex a little better. But again, that’s purely up to the fabricator, in this case, YOU. 26 WOOD-BOX, DOOR-SIDE, PART 2 If you intend to use only one set of wood-boxes (like our door), plan to put the door-side woodbox centered on the door. Plan accordingly for the upright-side wood-box. This will help to make the door reversible if you so choose. The wood-box should be mounted about 4” from the edge of the door. Wood-­‐box centered on door About 4” from the edge of the door 27 MULTIPLE WOOD-BOXES? HMMMMM… If you want to simulate multiple locks, use two sets of wood-boxes. Mount them so that they are equidistant from the top and bottom edge of the door. That is, mount them so that the top wood-box is the same distance from the top of the door as the bottom wood-box is from the bottom of the door. This will help to make the door reversible later if you so choose. Mount wood-­‐boxes same distance from top and boMom edge of door 28 WOOD-BOX, DOOR-SIDE, PART 3 Again, the wood-box on the door-side won’t require heavy reinforcement welding, but the reinforcement plate will pull away from the door slightly if it isn’t bolted down. Once the wood-box is welded onto the door, drill out holes in the plates and door above and below the wood-box. Use a ½” cobalt bit, and secure with 7/16” x 3” Grade-8 bolts. 29 STAGE THREE: THE HINGES 30 HINGES, PART 1 Our hinges are of a fairly simple design, at least when compared with the elaborately elegant type of hinges mounted on springs on some of the commercially-available doors. If you’d like some good plans for a spring-hinge design, check out FROZEN LEATHER TRAINING, they have a link to plans for their design. We decided to go this route for simplicity’s sake. The “give” in our prop when gapping it relies, not on springs, but on the muscle required to flex the door and the top-piece. We thought when building this prop that the door would be fairly strong, but sacrificial, and have to be changed every few classes. Three years and thousands of forces later, it’s a little warped but still in good shape. 31 HINGES, PART 2 The hinge-plates you see here are ¼” steel plate, and both measure 5” x 5”. Were I to do this again, I would make the door-side hinge-plate 5” high by 10” wide to allow for easier mounting of doors regardless of door-width. The hinges are the most complicated part for most of the FE door-props that you see. I don’t remember the EXACT order of assembly for these, but I will explain all that I remember about the process and provide ample pictures. Upright-side 5” x 5” Make door-side 5” x 10” 32 HINGES, PART 3 This is the basic design we settled on, though we ended up using rectangular steel box rather than square simply because it fit better. I don’t recall the exact size of the tubing we used for the actual hinges, but suffice it to say it’s thick steel, and its inner diameter is large enough for a 7/16” x 6” Grade-8 bolt to be dropped in VERY EASILY for use as a hinge-pin. In fact, we started off using the same length ½” Grade-8 bolt, but it was easier to line it up and drop it in with the smaller size. When you’re metal shopping, bring a 7/16” Grade-8 bolt with you to measure for I.D. The rectangular steel box is 1” x 1-½”. HINGE TUBING ¼” PLATE STEEL 33 HINGES, PART 4 The hinge tubing we measured to a 5” length, then cut into three equal parts (you do the math, that was years ago!). I seem to recall that we connected all three tube sections with the hinge-pin loosely, then welded each section to its respective hinge-plate. 34 HINGE-PINS 7/16” x 6” Grade-8 hex bolts. A nut should not be necessary. The hingetubing that you use should fairly thick steel, and of a large enough diameter that these hinge-pins drop in easily. On ours, a ½” bolt will fit in the tubing, but a little too snugly for easy “drop-in” insertion, so we use 7/16”. Keep it loose and easy to assemble. 35 HINGES, PART 5 Next, we fabricated the rest of the door-side hinge more or less according to our plans, and attached them to the door with 7/16” x 4” Grade-8 bolts. Again, I recommend using a wider door-side hinge-plate than we did so to have more flexibility with door-width if you need to change out the door down the road. 36 HINGES, PART 6 For mounting your hinges, mount them equidistant from the top and bottom of the door. That is, mount the top-hinge the same distance from the top of the door as the bottomhinge is from the bottom of the door. Again, this will aid in making the door reversible later if you so choose. The next few pages are all pics of the hinges, should you need them for reference. Mount hinges the same distance from the top and boMom edge of the door 37 38 39 40 41 42 43 Hinges separated, for a different view 44 Hinges separated, for a different view 45 46 47 48 HINGES, PART 6 As I recall, to mount the hinge-plates to the upright-side, we first installed both top and bottom door-side hinges to the door. Then we measured to get a ball-park idea of where the TOP upright-side hinge was going to be welded. Next, we connected the top upright-side hinge to the door-hinge and dropped the hinge-pin in. Finally, we used a floor-jack underneath the door to jack the door up into its proper position while steadying it with our hands. Once in place, we marked the spot, lowered the door, separated the hinge-plates, and welded the upright-side hinge-plate onto the upright. 49 50 HINGES, PART 7 For the BOTTOM hinge, we did more or less the same thing. We started by connecting the door-side hinge to the upright-side hinge with the hinge-pin. However, rather than jacking it up, we merely attached the door to the upright at the top hinge. From there, we manually held the door in its proper place to mark it, lowered the door, and welded the bottom upright-side hinge onto the upright. 51 52 STAGE FOUR: DOOR-STOP & WOOD-BOX 53 DOOR-STOP / WOOD-BOX U-CHANNEL, PART 1 We decided for our door-stop/wood-box area to create a semi-permanent piece that could be removed and re-created. Our thought was that this area was bound to take a beating and that it might be best to protect the 5” x 5” upright. For that reason, we ordered a second U-channel of the same dimensions as the top-piece U-channel, but not as long. Ours is 24”, but I would recommend making it 30” and centering the wood-box and door-stop on it vertically. 54 DOOR-STOP / WOOD-BOX U-CHANNEL, PART 2 I’m glad we did it, but this prop has held up rather well after thousands of forces. It’s in very good shape. I recommend using a U-channel to help your prop’s longevity, but if you wanted to weld your door-stop and wood-box directly to the upright itself, I think you could get away with it. 55 DOOR-STOP / WOOD-BOX U-CHANNEL, PART 3 We welded the U-channel high, low, and on the sides. Later we found it necessary to run two bolts thru the upright for additional support for the U-channel, one above and one below the wood-box. But that should be done later after mounting the wood-box. 7” 20” 56 DOOR-STOP, PART 1 For our door-stop we used a very beefy piece of flat steel measuring ¾” thick by 2” wide. These dimensions mimic perfectly the door-stop found on your average commercial steel jamb. This is a SOLID piece of steel. So it won’t be too close to some of the bolt-heads mounted on the door, order this door-stop cut to 26” and center it on the 30” U-channel. 57 DOOR-STOP, PART 2 If you use 5” x 5” for your uprights, mount your door-stop centered horizontally on the upright (not on the U-channel). Quite frankly, this is a good reason to use 5” x 5”. Not only is it easier to mount so that the door will be flush, but if you mount hinge-plates on either side of the hingeside upright, your door can be reversible. 58 WOOD-BOX, UPRIGHT-SIDE, PART 1 For the upright-side wood-box we used two-inch sections of 1” x 2” and 2” x 2” box steel welded on top of one another. There is a lot stress put on this side of the wood-box, so we reinforced it by welding some short sections of ¼” flat steel to the top and front of the wood-box. You can see the bottom side is not reinforced. Because we used that U-channel sleeve over the upright rather than just welding the wood-box directly onto the upright, we noticed some early distortion of the sleeve. To remedy this we just drilled a hole (using a ½” airline bit) above and below the wood-box thru the sleeve and upright. We secured the sleeve down tightly with two 7/16” x 6” Grade-8 bolts. If you don’t use a U-channel sleeve, you can skip this step. 59 WOOD-BOX, UPRIGHT-SIDE, PART 2 Obviously, you’ll weld the upright-side wood-box in-line horizontally with the door-side wood-box. Our upright-side wood-box ended up measuring 31-½” from the top of the upright, and 36” from the bottom of the upright. Just FYI. Yours will likely vary slightly. 31-­‐½” from the top of the upright 36” from the boMom of the upright 60 Wood-­‐box centered horizontally on the upright, not on the U-­‐channel 61 62 HOLY SHIT!....IT’S TEST-FORCE TIME! The moment of truth has arrived. I’ll say just two things: First, don’t get discouraged if there’s some part of your execution that needs tuning up. Our first set of hinges we made were far too light, and they bent drastically after just a few forces. I had a grumpy night and we went back to the drawing board the next day, a minor setback in the grand scheme of things. And secondly, the door may require a little “seasoning” before being put into service. Say, 20-30 forces to get everything warmed up. 63 STAGE FIVE: FINISHING TOUCHES 64 HANDLES This sucker’s heavy. Don’t let anyone tell you otherwise. We made our handles out of some small-diameter round stock. We put it in a bench vise and heated the areas we wanted bent with a small torch, and beat it into shape with a hand-sledge. Then cut the excess bottom pieces off with a chop-saw. Not too hard. The ones you see here are 7” wide. You could also go to a good auto spring shop and have a couple of shallow, wide U-bolts bent. Make sure your welds on these are good! You don’t want to be carrying the diamond plate and find out you did a lousy job on the one that’s over your foot. 65 WOOD “LOCKS”, PART 1 We use two sizes of dimensional lumber, each cut down to 12” lengths. For LIGHT RESISTANCE, we use 1” x 2” furring strips. For MEDIUM RESISTANCE, we use 2” x 2” furring strips. You can also use 2” x 3” or 2” x 4” dimensional lumber ripped in half (cheaper, but far more time-consuming to cut). For HEAVY RESISTANCE, we use a light piece and a medium piece together. 66 WOOD “LOCKS”, PART 2 The door-wedge pictured here (with blue tape) holds tension when using medium pieces alone. You’ll go thru several of these per training session. For tool-set practice, you can also use a bungee cord wrapped thru the woodboxes with a wedge tucked between the bungee and the door to maintain tension. We start off all of our classes that way so guys can get an idea of how the halligan needs to move thru the seam and past the door-stop (GAP-SET-FORCE). 67 U-CHANNEL TOP-PIECE We use wing-nuts on our U-channel. Hand-tight works just fine. 68 HINGE-PULL ATTACHMENT You’ve probably been wondering what the hell that apparatus mounted on the side of our door is. If you haven’t figured it out yet, it’s a hinge-pull prop. We have a separate PDF covering how to build this prop, contact us if you’d like a copy of it. It’s a fun add-on, and cheap to build (by comparison). 69 REVERSIBILITY BY DESIGN Because we have centered everything on the door and on the upright, this door is easily reversible by simply welding duplicate hinge-plates onto the opposite side of the hinge-side upright. You’ll flip the door upside-down and attach it that way. You’ll also need to put another wood-box on the opposite side of the lock-side upright. Minimal investment of time if you’ve got the welder warmed up already. Shoot, you could make all your hinge-plates and wood-boxes in one batch. This will enable you to diversify your training, and demonstrate the differences in technique required by the dimensions and physics of a halligan bar when forcing both left-handed and right-handed opening doors. 70 AWW, FER CRYIN’ OUT LOUD….PAINT IT! I’ve seen tons of FE props on-line that people didn’t like enough to paint. Look, you just spent the lion’s-share of a grand, and probably 200 man-hours on this thing…..don’t cheap out now. Spend another $30 on six cans of Rustoleum and protect your investment. Unless somebody backs over it with the ladder truck, this thing should outlast you by several decades. Even if you keep it inside year-round, it’s still likely going to get wet from the spray of washing the trucks if nothing else. So just paint it so it doesn’t rust shut in five years. 71 AND NOW…A WORD FROM OUR SPONSORS 72 AND NOW…A WORD FROM OUR SPONSORS 73 YOUR HOSTS, SCOTT & SEAN 74 YOUR HOSTS, SCOTT & SEAN 75 MR. PINK, LITTLE HELPER NINO, AND THULA 76 BUCK, BANANNON, AND THE SHERPA 77 “Avoid people who would belittle your ambitions. The small-minded will always do that. The truly great make us feel that we, too, can become great.” —Mark Twain 78 “WHY DOES EVERYBODY LAUGH WHENEVER I SAY ‘WOOD-BOX’…..” 79

Anuncio

Documentos relacionados

Descargar

Anuncio

Añadir este documento a la recogida (s)

Puede agregar este documento a su colección de estudio (s)

Iniciar sesión Disponible sólo para usuarios autorizadosAñadir a este documento guardado

Puede agregar este documento a su lista guardada

Iniciar sesión Disponible sólo para usuarios autorizados