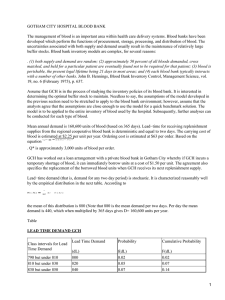

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/235264182 A model for the assessment of waste in job shop environments Article in International Journal of Operations & Production Management · August 2005 DOI: 10.1108/01443570510608619 CITATIONS READS 87 1,322 1 author: Ibrahim Rawabdeh University of Jordan 44 PUBLICATIONS 338 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: McGill Project View project All content following this page was uploaded by Ibrahim Rawabdeh on 30 January 2016. The user has requested enhancement of the downloaded file. The Emerald Research Register for this journal is available at www.emeraldinsight.com/researchregister The current issue and full text archive of this journal is available at www.emeraldinsight.com/0144-3577.htm IJOPM 25,8 A model for the assessment of waste in job shop environments 800 Industrial Engineering Department, University of Jordan, Amman, Jordan Ibrahim A. Rawabdeh Abstract Purpose – The paper aims to investigate the waste in a job shop environment and proposes an assessment method aimed at helping companies to identify root causes of waste. Design/methodology/approach – The seven wastes (overproducing; processing; inventory; transporting; producing defects; time waiting; and motion waste) and their relationships were explored. A waste matrix was developed to quantify in a percentage form the relationships among wastes and represents a probability that a certain type of waste will affect others or be affected by others. An assessment questionnaire was employed to allocate the source of waste and differentiate between the levels of waste. The waste matrix and the assessment questionnaire were incorporated in the assessment method to rank the existing waste in a job shop. Findings – The developed model serves as guidelines for simplifying the search of waste problems and identifies opportunities for waste elimination. A case study was conducted to validate the model; and the results of the assessment and the real situation concur. Research limitations/implications – This paper has investigated a method to allocate waste, quantify it and discuss the relationships among wastes without quantifying the potential savings. Further research should be done in order to investigate the level of reduction in effort and time as a result of implementing the method. Practical implications – The approach provides a method by which managers can identify the sources of waste, differentiate between the levels of waste and rank their significance. Originality/value – The simplicity of the matrix and the comprehensiveness of the questionnaire contribute to the achievement of accurate results in identifying the root causes of waste. The new model provides an insight into on where to concentrate effort by weighing the contributions of the different waste types. Keywords Waste minimization, Just in time, Assessment, Materials management Paper type Research paper International Journal of Operations & Production Management Vol. 25 No. 8, 2005 pp. 800-822 q Emerald Group Publishing Limited 0144-3577 DOI 10.1108/01443570510608619 Introduction International competition and customer demands are forcing radical changes to occur in manufacturing. As a result, companies worldwide that are realizing the importance of being part of the global market are searching for operational methods to increase their competitive power through the use of innovative production systems. Traditional manufacturing paradigms are being challenged and new manufacturing principles are being developed. Terms such as: lean manufacturing, world-class manufacturing, and agile manufacturing have emerged. Firms have given increased emphasis to delivering products, that are needed by customers, faster than their competition, and meeting or exceeding “best-in-class” quality requirements. As more manufacturers struggle with global markets, competition from low-cost countries and faltering home economies, the attention of many manufacturers has naturally turned to operational costs and waste reduction (Strategic Direction, 2004). The typical approach taken in the past when studying improvement opportunities, has been to focus on the manufacturing processes, or the value-added process steps (Conner, 2001). In an internal manufacturing context, there are three types of operation that can be categorized: non-value adding (NVA); necessary but non-value adding (NNVA); and value-adding (VA). The first of these is pure waste and involves unnecessary actions that should be eliminated (Hines and Rich, 1997). Invariably little attention was given to non-value-added activities such as storage and transportation. The result is that minimal effect is realized in overall lead time, improved quality and reduced cost. For instance, Conner (2001) reported that when lead-time was examined, the two percentages of value-added activities and non-value-added activities are found to be 5 and 95 per cent, respectively. When all energies are spent trying to improve the value-added component of the lead-time, then the improvement to lead-time would be only 2.5 per cent. An array of new systems aiming at improving production efficiency and maintaining a high level of quality, cost, and on-time delivery has been developed. Just-in-time (JIT), in particular, has attracted much attention during the past decade; and has been shown to yield increased efficiencies and performance excellence throughout an organization; and its successes are well documented (Daugherty et al., 1994). Many specific topics have been considered in the literature as elements for JIT; these being summarized into: quality control, work force preparation and waste elimination (Rawabdeh, 2001). JIT is an umbrella term for a number of techniques whose purpose is to improve product quality and reduce cost by eliminating all waste in the production system (Miltenburg, 2001). In the JIT philosophy, the principal focal point is the elimination of all waste within a system (Daugherty et al., 1994). Waste can be defined as anything other than the minimum amount of resources which are absolutely essential to add value to the product. Canel et al. (2000) defined waste as anything other than the minimum amount of equipment, materials, parts, space, and workers’ time, which are absolutely essential to add value to the product or service. In terms of cost, waste refers to any incurred costs such as inventory, set-up, scrap, and rework that do not add to the value of the product (Svensson, 2001). Flinchbaugh (2001) argued that any goal beyond delivering the right product to the right customer at the right time at the right price is waste. From the perception of end users, waste is internal and external resources that are consumed without adding value to the customers (Emiliani, 2001), i.e. if a customer is not willing to pay for them, then their existence is considered a waste. This means that the different types of wastes threaten many facets of performance of the company that customers may value. Hence their elimination has become an axiom. The use of waste elimination to drive competitive advantage inside organizations was pioneered by Toyota’s chief engineers, Taiichi Ohno and Sensei Shigeo Shingo (Hines and Rich, 1997), and was focused principally on productivity gains rather than improved quality. The rationale is that improved productivity leads to leaner operations that, in turn, exposes further waste and quality problems in the system. Indeed, lean production’s originators, by formulating the “operating problem” as an unceasing battle against waste (or muda in Japanese) were able to make it almost axiomatic that lean implied better (Lewis, 2000). Thus the systematic elimination of waste is also a systematic assault on the factors underlying poor quality and fundamental managerial problems. From a practical perspective, waste can be categorized into seven categories: waste from overproducing; processing; inventory; Waste in job shop environments 801 IJOPM 25,8 802 transporting; producing defects; time waiting; and motion waste (Shingo, 1992; Imai, 1997; Emiliani, 2001; Flinchbaugh, 2001). The seven wastes can also be categorized into three main groups related to: man, machine and material by means of activities or conditions that affect the fourth, namely, money. The man-group contains the concepts of motion, waiting, and overproduction; the machine-group contains over-processing waste; and the material-group contains transportation, inventory and defects waste. However, man and material overlaps in overproduction waste, whilst machine and material overlaps in defect waste. Figure 1 shows this classification. There have been many applications concerning the use and importance of the waste elimination concept in different fields of industry. However, investigations have followed varying approaches. The objective of this paper is to introduce an innovative approach in developing an assessment model that supports categorisation of the types of waste in a job shop environment. This paper is organized as follows: first, a background on waste elimination is presented, followed by a review of relevant literature. Second, the developed model is explored and discussed showing the concepts of seven waste relationships, a relationship matrix, and waste assessment questionnaire. Third, the results of model implementation are presented and discussed in a case study context. Finally, conclusions are presented, followed by recommendations for future work. Background Elimination of waste is the corner-stone of a JIT system. It is acknowledged that the implementation of JIT is one of the major factors contributing to the success achieved in the international competitiveness of Japanese manufacturing firms in the last two decades (Wu, 2003). Studies have identified that JIT also helped companies improve their performance (Ahmad et al., 2004). JIT manufacturing systems consist of systematic allocation and reduction of wasteful practices at all levels of any organization. It can be argued that the philosophy underpinning waste identification and its elimination is the basis upon which the JIT concept is built (Karlson and Awstrom, 1996). Waste allocation and elimination have recently become an important subject of research. Numerous contemporary definitions focus on JIT as an approach to minimize waste in manufacturing and research has identified that the JIT manufacturing philosophy is dependant upon organizations continually seeking to improve their products and processes by eliminating waste (Monden, 1983; Toyoda, Figure 1. The three categories of waste (man, machine, materials) and its effect on money 1987; Chong et al., 2001; Swanson and Lankford, 1998; Canel et al., 2000; Yasin et al., 2004). The objectives of JIT are complex to interpret due to the lack of homogeneity in the literature. However, two objectives appear to be common denominators: a continuous search for waste reduction and to make only what is needed in a timely way (Svensson, 2001). However, the JIT production system is being adopted by many firms and companies worldwide, so increasingly companies (especially small and medium sized) in their continuous strive for excellence, have realized that JIT production systems could be a direction for future competitiveness and prosperity. It is a perspective on the continuing evolution towards world-class manufacturing (Rawabdeh, 2001). A systematic and continuous identification and elimination of waste can lead to increased efficiency, improved productivity and enhanced competitiveness. Generally, companies that work towards the elimination of waste in their manufacturing processes realize the following benefits: lower raw material stock and associated holding cost, reduced work-in-process, and lower finished goods inventories; higher levels of product quality; increased flexibility and ability to meet customer demands; lower overall manufacturing costs; and increased employees’ involvement (Chase et al., 1998; Canel et al., 2000). Emiliani (2001) reported that, fundamentally, poor competitiveness is caused by the existence of large amounts of waste. Reduction of these non-productive activities (waste) eventually saves time and allows more resources to be allocated to improving throughput and profitability. The principle of continuous improvement by waste elimination has been applied as an approach to improving the performance of a case production system (Ramaswamy et al., 2002). Evans and Jukes (2000) suggested that synchronization in the area of product development can be achieved through the four key steps of process standardization, knowledge sharing, alignment of existing practices, and continuous elimination of waste within the joint development cycles. In JIT terminology, standard operations and procedures endeavour to produce efficiently with the least amount of waste, using efficient rules and methods (Lim et al., 1999). The process of identifying waste activities, however, is not an easy task. The large number of parameters and overlap between different processes may cause waste activities to be concealed between other activities. Nevertheless, the mere consideration of waste reduction brings about an important focus on the subject. Moreover, the importance of the problem is usually underestimated, and the starting point of where and how to search for waste is unclear. An additional issue is, when there are interventions to eliminate one type of waste, this may result in other waste-types being negatively affected. Such factors make it difficult to consider removing what may be considered as waste activities. A number of approaches have been developed to explore waste-related issues. Kobayashi (1995) developed a system termed the practical program of revolutions in factories (PPORF). The approach uses a 20-key system that defines the meaning of excellence in twenty key areas related to quality, cost, and delivery. That system demonstrates how improvements in these areas collectively improve a company’s overall competitiveness. It presented a scoring method that measured the progress of the company through five levels, in each area. Waste elimination is key number thirteen in that approach. Imai (1997) developed what is called a continuous improvement or kaizen approach. The approach is based on three ground rules for the Waste in job shop environments 803 IJOPM 25,8 804 practice of kaizen: specifically, housekeeping, standardization, and waste elimination. It employs a process in which cross-functional teams systematically analyze processes to identify and eliminate waste. Imai reported that each kaizen event can yield a higher per cent in waste reduction compared to that sporadically achieved by batch-and-queue businesses. Investment analysts would be wise to participate in shop floor kaizen events and witness first-hand the elimination of waste and concomitant improvements in operating and financial performance (Emiliani, 2001). Brunet and New (2003) discussed the practical aspects of kaizen and concluded that it appears to be less of a stand-alone suite of techniques and practices, and more of an integral part of an overall system of operations planning. They reported that there remained good reasons for continuing to seek the transferable “core” of kaizen management ideas, especially as organizations across the world attempt to replicate the operational success of many Japanese firms. Lim et al. (1999) proposed a holistic framework that was formulated after careful consideration of Japanese corporate experience and practices. They used the 4Ms (man, machine, material and method) framework to help focus attention on potential areas that need to be addressed and improved. They recognized that the sources of waste often lie not simply in “hard” or “technical” operations, but reside within the soft drivers of these operations. Such soft issues need evaluation of how their role as supporting procedures and the format of documentation need to be engineered (or re-engineered), and so create efficient waste-less manufacturing operations. O’hEocha (2000) explored the practical use of the 5S technique for waste reduction in a manufacturing company. He demonstrated that the 5Ss were effective in improving the working environment and final performance, due primarily to the measured reductions in waste at the production level. The literature identifies that the concept of eliminating non-value activities, and reducing inventories, motions, defects, waiting and overproduction, is an essential part of a JIT manufacturing system. Although Japanese industries achieved substantial success by applying this concept, there have been few systematic methodologies that identify the procedural starting point for waste allocation. By adopting the principle of systematic waste elimination, this requires thinking and talking in the language of waste. The literature has not addressed the strength of relationships among all types of waste. There is little empirical work of a quantitative nature that adequately defines a comprehensive tool for waste elimination, and which will reduce types of wastes without negatively affecting other causes of waste. Methodology The proposed waste assessment model commences by articulating the definitions of each type of the seven wastes and their overlapping areas. A criterion was established to quantify the strength of direct relationships, thus leading to the creation of a waste matrix that classifies the strength of relationships using a scale ranging from very weak to very strong. Next, an assessment questionnaire was introduced. Within the context of a jobbing shop, it was possible to rank waste by combining the relationship matrix and the results of the assessment questionnaire. Seven wastes relationships All types of waste are inter-dependent, and each type has an influence on the others; and simultaneously is influenced by the others. For example, overproduction is regarded as the most serious waste as it gives rise to other types of waste (Kobayashi, 1995). Wu (2003) reported that over-production forces the plant to change the number in the work force, thus making standardization very difficult, that leads to quality problems and waste of competencies. Discussing the relationships among wastes is complex because the influence of each type on the others can appear directly or indirectly. The following discussion addresses the effect of each type of waste on the other six types. Each type of waste was abbreviated using its initial, (O: Over-production, I: Inventory, D: Defect, M: Motion, P: Process, T: Transportation, W: Waiting), and each relationship was assigned the symbol of underscore “_”. For instance, O_I indicates the direct effect of overproduction on inventory. Figure 2 shows which one is affecting, and is affected, by the others; Table I summarizes the explanation for the relationships. The different types of relationships and the nature of each type suggest that all these relationships are not of equal weights. The need to assign weights to relationships is justified by the need to know which type of waste contributes more to the wasteful activities on a shop floor. A measurement criterion based on a questionnaire was developed to quantify the strengths of waste relationships (see Table II). It consists of six questions and each answer has a specific weight ranging from zero to four. Several brainstorming sessions among specialists were held to Waste in job shop environments 805 Figure 2. Direct wastes relationship IJOPM 25,8 806 Overproduction O_I O_D O_M O_ T O_W Inventory I_O I_D I_M I_T Defects D_O D_I D_M D_T D_W Motion M_I M_D M_P M_W Transportation T_O T_I T_D T_M Table I. The explanation of waste relationships T_W Over-production consumes and needs large amounts of raw material causing stocking of raw material and producing more work-in-process that consume floor space, and are considered as a temporary form of inventory that has no customer (process) that may order it. When operators are producing more, their concern about the quality of the parts produced will decrease, because of the sense that there exists enough material to substitute the defects. Overproduction leads to non-ergonomic behavior, which leads to non-standardized working method with a considerable amount of motion losses. Over-production leads to higher transportation effort to follow the overflow of materials. When producing more, the resources will be reserved for longer times, thus other customer will be waiting and larger queues begin to form The higher level of raw materials in stores can push workers to work more, so as to increase the profitability of the company. Increasing inventory (RM, WIP, and FG) will increase the probability of become defected due to lack of concern and unsuitable storing conditions. Increasing inventory will increase the time for searching, selecting, grasping, reaching, moving, and handling. Increasing inventory sometimes block the available aisles, making a production activity more transportation time-consuming. Over-production behavior appears in order to overcome the lack of parts due to defects. Producing defective parts that need to be reworked means that increased levels of WIP exist in the form of inventory. Producing defects increases the time of searching, selection, and inspection of parts, not to mention that reworks are created which need higher training skills. Moving the defective parts to rework station will increase transportation intensity (back streams) i.e. wasteful transportation activities. Reworks will reserve workstations so that new parts will be waiting to be processed Non-standardized work methods lead to high amounts of work in process. Lack of training and standardization means the percentage of defects will increase. When jobs are non-standardized, process waste will increase due to the lack of understanding the available technology capacity. When standards are not set, time will be consumed in searching, grasping, moving, assembling, which result in an increase in part waiting parts. Items are produced more than needed based on the capacity of the handling system so as to minimize transporting cost per unit. Insufficient number of material handling equipment (MHE) leads to more inventory that can affect other processes. MHE plays a considerable role in transportation waste. Non-suitable MHE can sometimes damage items that end being defects. When items are transported anywhere this means a higher probability of motion waste presented by double handling and searching. If MHE is insufficient, this means that items will remain idle, waiting to be transported (continued) Process P_O P_I P_D P_M P_W Waiting W_O W_I W_D In order to reduce the cost of an operation per machine time, machines are pushed to operate full time shift, which finally results in overproduction. Combining operations in one cell will result directly to decrease WIP amounts because of eliminating buffers. If the machines are not properly maintained defects will be produced. New technologies of processes that lack training create the human motion waste. When the technology used is unsuitable, setup times and repetitive downtimes will lead to higher waiting times. When a machine is waiting because its supplier is serving another customer, this machine may sometimes be forced to produce more, just to keep it running. Waiting means more items than needed at a certain point, whether they are RM, WIP, or FG. Waiting items may cause defects due to unsuitable conditions. Question (1) Does i produce j? Always Sometimes Rarely (2) What is the type of the relationship between i and j? As i increases j increases As i increases j reaches a constant level Random depends on conditions. (3) The effect of j due to i: Appears directly and clearly Needs time to appear Not often appears. (4) Eliminating the effect of i on j is achieved by: Engineering Methods Simple and direct Instructional solution (5) The effect of j due to i, mainly influences: Quality of products Productivity of resources Lead time Quality and productivity Productivity and lead time Quality and lead time Quality, productivity and lead time (6) In which degree does the effect of i on j increase manufacturing lead time? High degree Medium degree Low degree Note: i stands for any type of waste which has an effect on the other type of waste j Waste in job shop environments 807 Table I. Weight 4 2 0 2 1 0 4 2 0 2 1 0 1 1 1 2 2 2 4 4 2 0 Table II. The developed criteria for evaluating the strengths of waste relationships IJOPM 25,8 808 explore and answer the questions. The following steps show the analysis for developing relationship weightings. Table III illustrates an example of tabulating the results related to the relationship between over-production and inventory (O_I) and shows that if the answer to question number one is yes, then it is represented by the letter “a”, i.e. does i waste produce j waste, where i and j are types of waste? The same is applied for all questions about this particular relationship. Each answer was assigned a weight identified in the measurement criteria, and each number beside each character represents the weight of the answer. The weights of all answers of each relationship were added together, resulting in an overall summation. The summation was recorded in the column headed “Score”, where the score indicates the strength of each relationship. In order to distinguish different relationships, it was noted that higher scores represent stronger relationships and vice versa. The range of scores, based on the suggested method of evaluating the strengths of the wastes relationships, is found to be between (1) and (20), and it is divided into five equal intervals, each indicating a level of strength of a relationship (see Table IV). These steps are applied for each relationship resulting in total scores that were represented by symbols that related to the different types of relationship between each pair of waste types. The results are summarized in Table V. Waste relationship matrix The measurement criterion analysis was organized in a matrix titled waste relationship matrix (WRM). Each row indicates the effect of a certain waste on the other six wastes; similarly each column indicates to what extent a certain type of waste will be affected by others. The WRM is presented in Figure 3. The diagonal of the matrix was assigned with the highest relationship value, as, by default, each type of waste will have the ultimate relationship with itself. The waste matrix represents real relationships among wastes. The weightings of each row or column were totalled to obtain a score that represents the effect of a waste type on others or was affected by the others. This score is converted into a percentage to provide a more simplistic metric, as illustrated and Table III. The relationship between overproduction and inventory (O_I) Table IV. Range divisions of strength of direct relationship Question 1 2 3 4 5 6 Relationships Ans Wght Ans Wght Ans Wght Ans Wght Ans Wght Ans Wght Score O_I O_D a B 4 2 a c 2 0 a b 4 2 A B 2 1 f a 2 1 a c 4 0 18 6 Range Type of relationship Symbol 17 to 20 13 to 16 9 to 12 5 to 8 1 to 4 Absolutely necessary Especially important Important Ordinary closeness Unimportant A E I O U O_I O_D O_M O_T O_W I_O I_D I_M I_T D_O D_I D_M D_T D_W M_I M_D M_W M_P T_O T_I T_D T_M T_W P_O P_I P_D P_M P_W W_O W_I W_D Question Relationships Wght. 4 2 2 2 2 2 2 4 4 2 2 2 4 2 0 2 4 2 0 0 2 2 2 2 0 2 2 2 2 4 2 a b b b b b b a a b b b a b c b a b c c b b b b c b b b b a b 1 Ans. a c c a b c c b c b c c b a a b a b c b c c c b c a c a c a b Ans. 2 2 0 0 2 1 0 0 1 0 1 0 0 1 2 2 1 2 1 0 1 0 0 0 1 0 2 0 2 0 2 1 Wght. a b c b b a b b c a b a a b b b a a b b b c a b c a c b b a b Ans. 3 4 2 0 2 2 4 2 2 0 4 2 4 4 2 2 2 4 4 2 2 2 0 4 2 0 4 0 2 2 4 2 Wght. a b a b a a a a a c b b b b c a a c b b b c b a a a a a b a a Ans. 4 2 1 2 1 2 2 2 2 2 0 1 1 1 1 0 2 2 0 1 1 1 0 1 2 2 2 2 2 1 2 2 Wght. f a d f e e a e c e e e c e e g e d c f f e e e c a g e b g a Ans. 5 2 1 2 2 2 2 1 2 1 2 2 2 1 2 2 4 2 2 1 2 2 2 2 2 1 1 4 2 1 4 1 Wght. a c c b a b b c b c b b b b c a a b c c b c b c c c b b c a c Ans. 6 4 0 0 2 4 2 2 0 2 0 2 2 2 2 0 4 4 2 0 0 2 0 2 0 0 0 2 2 0 4 0 Wght. 18 6 6 11 13 12 9 11 9 9 9 11 13 11 6 15 18 11 4 6 9 4 11 9 3 11 10 12 6 20 8 Score A O O I E I I I I I I I E I O E A I U O I U I I U I I I O A O Relationship Waste in job shop environments 809 Table V. The relationship between different types of waste IJOPM 25,8 810 Figure 3. Waste relationship matrix (WRM) summarized in Figure 4. A scale of ten was chosen by dividing the right extreme by a factor of 2 for ease of use and comparative exposition. To validate the waste relationship matrix, and after reviewing the results, it was found that these findings concur with the literature in terms of the influence of the seven wastes on each other. Over-production waste was found to be dominating the other wastes with the highest percentage (16.8 per cent). It was reported that over-production was considered the most serious waste since it increases all the other types and has the maximum influence (Kobayashi, 1995). That is because it discourages a smooth flow of goods or services and is likely to inhibit quality and productivity (Hines and Rich, 1997). Producing more items than is immediately needed by the next station or market creates excess temporary inventories. This can be clearly recognized from the strong relationship between over-production and inventory. Over-production also tends to lead to excessive lead-times and increased storage. As a result, defects may not be detected sufficiently early (Imai, 1997). Due to over-production, motion waste is expected to rise by the same degree as that of defects. Additionally, material handling will be markedly increased, which results in waiting-waste being affected to a higher degree because goods are not moving and/or not being worked on. Conversely, the other wastes influence over-production by a lesser degree; which can be seen by the smaller percentage value (13.6 percent). Figure 4. Waste matrix values Excess inventory, i.e. inventory-waste, tends to increase lead-time, prevents rapid identification of problems and increases space requirements, thereby discouraging communication (Imai, 1997). In order to conduct effective purchasing, it is especially necessary to eliminate inventory-waste due to incorrect lead-times and due-dates (Barla, 2003). It is reported that removal of buffer stock is a major problem that should be addressed on the shop floor of small and medium size enterprises (Ramaswamy et al., 2002). It is found that inventory influences other wastes by 13.6 per cent. Inventory affects over-production, defects, motion, and transportation wastes by the same degree. Problems are hidden by inventory (Hines and Rich, 1997), so that waste leads to inventory with the highest degree (18.4 per cent). Defect-waste is the bottom-line waste since it is a direct cost. When a defect occurs, rework may be required; otherwise the product will be scrapped. Generation of defects will not only waste material and labor resources, but it will also create material shortages, hinder meeting schedules, create idle time at subsequent workstations and extend the manufacturing lead-time. As a result, defects influence other wastes by the same degree as over-production (16.8 per cent). Defects have an effect on over-production, inventory, motion and waiting by the same degree; but they affect transportation by a higher level because of wasteful transportation activities due to rework and scrapped items. Defects are also affected by the other six wastes, indicating a comparatively high percentage (17.6 percent). Motion-waste involves poor ergonomics of production, where operators have to stretch, bend and pick up when such actions could be avoided. Such waste is likely to lead to poor productivity and, often, to quality problems (Hines and Rich, 1997). This can be clearly recognized from the matrix as it affects the other wastes by 15.2 per cent; whilst being influenced by other types of wastes (albeit by a lower level of 13.6 percent). Motion results in waiting by the highest level, while at the same time it leads to defects more strongly than any other type of waste. Also, it affects inventory and process-wastes by differing amounts. Transportation involves goods being moved around. Therefore, taken to an extreme argument, any movement in the factory could be viewed as a waste. In addition, double handling and excessive movements are likely to cause damage and deterioration, with the distance of communication between processes proportional to the time it takes to feed back reports of poor quality and to take corrective action (Hines and Rich, 1997). This is strong evidence that transportation has a major influence on defects and waiting. Transportation affects the other types of waste and is affected by them by the same level (12.0 percent). Inappropriate processing occurs in situations where overly complex solutions are found for simple procedures. It also occurs when machines are used inefficiently, so that poor quality goods will be produced (Imai, 1997). Process-waste affects other wastes by a percentage of 14.4 percent. However, it is influenced only by motion-waste, and hence the reason why it scores the lowest type of waste having an influence on others (6.4 per cent). One of the most wasteful manufacturing activities is waiting time (Fullerton and McWatters, 2001). It was found to have the highest percentage (18.4 per cent) in terms of its effect on the other wastes. Waiting-waste occurs whenever goods are not moving or being worked on and affects inventory and results in excessive work in process stocks (Hines and Rich, 1997). Waiting is the result of all types of waste, as it leads directly to increased manufacturing lead-time. However, the 11.2 per cent of the Waste in job shop environments 811 IJOPM 25,8 812 influence of the waiting-waste on the others derives principally from its impact on over-production, inventory and defects. Waste assessment questionnaire A waste assessment questionnaire was developed to allocate waste in a jobbing shop. Jobbing shops do not make the same product each day. Their business is likely to be “make-to-order”, with thousands of part numbers, and they can never accurately predict which part number will be in demand (Krajewski and Ritzman, 2002). In jobbing shops, machines are arranged into groups according to their general type of manufacturing process. Different parts, each requiring its own unique sequence of operations, can be routed through the respective departments in a sequential order. The assessment questionnaire consists of 68 different questions, which were introduced for the purpose of allocating waste. The assessment questions were introduced so that each question represents an activity, a condition or a behavior that may lead to a specific type of waste. Some questions are assigned a “From” note, which means that the question represents an existing type of waste that may lead to other wastes, with reference to the waste relationship matrix. Other questions are assigned a “To” note, which means that a question represents any existing type of waste that may have been caused by other types of waste. Each question has three answers and each answer was assigned a weight of: 1, 0.5 or zero. The questions were then categorized into four groups of man, machine, material and method since each question is related to one of these categories. A sample of the assessment questions is shown in Table VI. Upon development of the assessment model questionnaire, it was noted that each question led to a certain type of waste by a certain degree, depending on its answer. The final rank of wastes depended on the combination of answers. Because of this, an algorithm consisting of several steps was developed. It starts with counting the “From” and “To” questions of the same type of waste. Table VII shows the number of questions of each “From” or “To” type. Based on the Table VII classification, and utilizing the original weights of waste relationships in Table V, Table VIII is produced to simplify calculating the final score of existing waste types. The second step of the algorithm is to rearrange Table VIII and to remove the effect of variation of number of questions for each question type by dividing each weight in the row by the corresponding number of questions (Ni) for each question (see Table IX). Let W to be the weight of relationship and j the type of waste for each question number k, the values in each column under each type of wastes can be summed up to obtain a score based on equation (1) as follows: Sj ¼ K X W j;k Ni K¼1 for each type of waste j ð1Þ where: Sj is the score of the waste, and k ranges between 1 and 68. The third step is to remove the effect of the null answer. For each type of waste, which is represented by the waste columns, each cell that was assigned a weight was counted, where: Fj is the frequency (number) of cells that were assigned a weight other than 0, for each type of waste (j). The results for the frequency values (F) are shown in the bottom of Table IX. # Question Category (1): Man 1. Does the management transfer operators to various jobs and machines so that operations can be performed by all individuals? 2. Do supervisors provide the amount and quality of supervision needed? 3. Are hourly workers adequately supervised on evening shifts? 4. Are positive steps taken to raise hourly workers’ morale and work interest? Category (2): Material 8. Is vendor lead time available to production schedulers? 9. Are schedules checked for material availability before release to production? 10. Are parts received in unitized loads? 11. Does production planning give warehouse personnel sufficient advance notice of items and stock activity? 12. Are warehouse personnel notified in advance of planned inventory changes? 13. Is there any excessive accumulation of materials awaiting repair, rework, or return to vendors? 14. Do materials appear to be standing around piled up unnecessarily on the receiving platform? 15. Do production workers stand around waiting for materials to arrive? 16. Are materials moved more often than necessary? 17. Are delicate parts frequently damaged in transportation activities? Category (3): Machine 32. Are tests on the efficiency of the machines, standard to manufacturer’s specifications, periodically conducted? 33. Is the workload for each machine predictable in sufficient detail? 34. Once a machine has been installed, is there follow-up to see if it performs according to specifications? 35. Is material-handling equipment capacity adequate to lift the heaviest jobs? Category (4): Method 44. Is warehouse space availability known in order to avoid blockage of warehouse aisles? 45. Is there a satisfactory drawing-numbering system that permits easy reference, storage and retrieval? 46 Is storage space used effectively for storage with the aid of racks and forklift trucks? 63. Do most of products flow in one direction? 64. Is there a group or committee, concerned with design, component, construction, drafting, and other forms of standardization? 65. Do work standards have specific and known objectives, such as component cost reduction, work simplifications, and inventory control? 66. Can work imbalances be forecast in time to adjust them? 67. Are work procedures screening out redundant or unnecessary work? 68. Are the results of quality control, product testing, and evaluation passed on to engineering? Type Waste in job shop environments To motion From motion From defects 813 From motion To waiting From waiting From transportation From inventory From inventory From defects From inventory From waiting To defects From defects From process To waiting From process From transportation To transportation From motion From waiting From motion From motion From motion From overproduction From process From defects Table VI. The assessment questions and types IJOPM 25,8 814 Table VII. Number of grouped assessment questions i 1 2 3 4 5 6 7 8 9 10 11 Ques. type Table VIII. The original weights as obtained from the WRM Man To motion From motion From defects From motion Material To waiting From waiting From transportation From inventory From inventory From defects From inventory From waiting To defects From defects Machine From process To waiting From process From transportation Method To transportation From motion From waiting From motion From motion From motion From overproduction From process From defects Type of question (i) No of questions (Ni) From overproduction From inventory From defects From motion From transportation From process From waiting To defects To motion To transportation To waiting 5 6 8 11 4 7 8 4 9 3 5 Question # O I D M T P W 1 2 3 4 4 0 6 0 6 4 6 4 6 8 10 8 10 10 6 10 2 0 8 0 6 6 0 6 0 10 6 10 8 9 10 11 12 13 14 15 16 17 8 4 2 6 6 6 6 4 2 4 0 10 4 10 10 6 10 10 4 6 6 4 6 6 6 10 6 4 6 10 10 0 2 6 6 6 6 0 2 8 6 0 10 6 6 8 6 0 10 6 6 0 0 0 0 0 0 0 0 6 10 10 6 0 0 6 0 10 6 4 32 33 34 35 6 8 6 2 2 0 2 4 6 6 6 6 6 10 6 2 0 6 0 10 10 6 10 0 6 10 6 6 44 45 46 63 64 65 66 67 68 Score 6 0 4 0 0 0 10 6 6 318 6 4 10 4 4 4 10 2 6 396 8 8 4 8 8 8 4 6 10 450 0 10 0 10 10 10 4 6 6 420 10 0 0 0 0 0 6 0 8 260 0 6 0 6 6 6 0 10 0 232 0 10 10 10 10 10 8 6 6 402 Ques. type #of ques.(Ni) Question # (K) Wo,k Wi,k Wd,k Wm,k Wt,k Wp,k Ww,k Man To motion From motion From defects From motion Material To waiting From waiting From transportation From inventory From inventory From defects From inventory From waiting To defects From defects Machine From process To waiting From process From transportation Method To transportation From motion From waiting From motion From motion From motion From overproduction From process From defects Score(Sj) Frequency(Fj) 9 11 9 11 1 2 3 4 0.44 0 0.67 0 1.11 0.36 0.67 0.36 0.44 0.73 1.11 0.73 0 0.91 0.67 0.91 0 0 0.89 0 0 0.55 0 0.55 1.11 0.91 0.67 0.91 5 8 3 6 6 9 6 8 2 9 8 9 10 11 12 13 14 15 16 17 0.8 0.5 0.67 1 1 0.67 1 0.5 1 0.67 2 1.25 1.33 1.67 1.67 0.67 1.67 1.25 2 0.67 0.8 0.5 2 1 1 1.11 1 0.5 3 1.11 0 0 0.67 1 1 0.67 1 0 1 0.67 0 0 3.33 1 1 0.89 1 0 5 0.89 0 0 0 0 0 0 0 0 0 0 2 1.25 2 0 0 0.67 0 1.25 3 0.67 7 5 7 3 32 33 34 35 0.86 0.8 0.86 0.67 0.29 2 0.29 1.33 0.86 0.8 0.86 2 0.86 0 0.86 0.67 0 0 0 3.33 1.43 0 1.43 0 0.86 2 0.86 2 3 11 8 11 11 11 5 7 8 44 45 46 63 64 65 66 67 68 0.67 0 0.5 0 0 0 2 0.86 0.75 45 49 1.33 0.36 1.25 0.36 0.36 0.36 2 0.29 0.75 70 68 2 0.73 0.5 0.73 0.73 0.73 0.8 0.86 1.25 70 68 0.67 0.91 0 0.91 0.91 0.91 0.8 0.86 0.75 49 54 3.33 0 0 0 0 0 1.2 0 1 49 28 0 0.55 0 0.55 0.55 0.55 0 1.43 0 21 26 2 0.91 1.25 0.91 0.91 0.91 1.6 0.86 0.75 76 61 Waste in job shop environments 815 Table IX. Division of Table VIII by Ni values and summary The next steps in the algorithm were completely dependent on answering the assessment questionnaire. As discussed previously, each question has three answers with assigned weights 1, 0.5 or zero. The obtained rows for each type of waste are multiplied by the weight of each answer, which is given the symbol Xk. For example, the number of questions in the “From Motion” in the Man-group of questions is 11 and the weight of question 2 with respect to defect waste is 8, and the answer to the question is b (X2 ¼ 0.5), this results in Wd,3 ¼ 0.5 * 8/11 (0.36). Table X Ans. Weight K Wo,1 Wi,2 Ws,3 Man Wm,4 1 0.5 0 1 2 3 0.44 0 0 1.11 0.18 0 0.44 0.36 0 0 0.45 0 Wt,5 Wp,6 Ww,7 0 0 0 0 0.27 0 1.11 0.46 0 Table X. Calculated weight values for each type of waste IJOPM 25,8 816 shows an example where rows are multiplied by the factor available in the “weights” column. The values in each column under each type of waste were summed to obtain the new score (sj), as in equation (2): sj ¼ K X XK £ K¼1 W j;k Ni for each type of waste ð2Þ j After the multiplication, the number of non-zero cells in each column was counted to obtain the frequency (fj) of a particular situation (i.e. a company). The rationale for this lies in the fact that sometimes the answer to a question will have a value that equals zero and sometimes there is a question that cannot indicate a relationship with a waste type and its value will also be zero. To obtain the initial indication factor of each type of waste, depending on the answers, equation (3) was applied separately for each type of waste: Yj ¼ sj f j £ Sj F j for each type of waste ð3Þ j where Yj is the initial indication factor of each type of waste. However, Yj only represents mathematical results, since each type of waste affects all other types by a certain percentage. The same is applied when considering how each type of waste is affected by others. In order to expedite this, the “From” and “To” percentages obtained from waste matrix values (Figure 4) are multiplied together to obtain the probability of their occurrence (Pj) (i.e. effect of overproduction ¼ 16.8 * 13.6 ¼ 228.48). To reflect the fact that the existence of each type of waste can affect others and at the same time be affected by others, Yj is multiplied by Pj to obtain the final waste factor (Yjfinal) as in equation (4): Y jfinal ¼ Y j £ P j ¼ sj f j £ £ Pj Sj F j for each type of waste j: ð4Þ As a result and based on the Yjfinal value of each waste, the types of waste were ranked in descending order. Case study A case study of a steel furniture company introduces the application of the proposed waste assessment model. The company is a medium-sized company with approximately 100 employees and working capital of $5M. The concept of “The seven wastes” and their interrelationships were introduced to the General Manager and Production Manager. The factory has a high-level of product mix. There are 24 main types of products in the plant categorized into four category groups: office furniture; storage systems; safes; and customized products. The company has a jobbing shop industrial environment. The flow of the materials into the factory is process oriented. The factory consists of a single floor, and the offices are on two levels. The available machines are either modern technology that depend on CNC or conventional manual types. Model implementation The implementation of the assessment model passed through several reviews and improvements, following management’s comments about its nature, the requirement of being easy to understand and to implement. The answers and analysis of the assessment questions for the company are presented in Table XI. Table XII summarizes the assessment analysis and provides a rank of the different types of wastes. These results were presented to both the General Manager and Production Managers who explained that the factory’s three major problems were as follows: (1) Defects. Different types of defects existed among different departments in the company’s inbound supply chain. There were no standard procedures to deal with defective parts at that time. The company’s operators determined whether to report the defect so that other replacement parts are produced immediately Ans. Question # (K) Wo,k Wi,k Wd,k Wm,k Wt,k Wp,k Ww,k 1 2 3 4 0 0 0.333 0 0 0.182 0.333 0 0 0.364 0.556 0 0 0.455 0.333 0 0 0 0.444 0 0 0.273 0 0 0 0.455 0.333 0 8 9 10 11 12 13 14 15 16 17 0 0 0 1 0.5 0 0 0 0.5 0 0 0 0 1.667 0.833 0 0 0 1 0 0 0 0 1 0.5 0 0 0 1.5 0 0 0 0 1 0.5 0 0 0 0.5 0 0 0 0 1 0.5 0 0 0 2.5 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1.5 0 32 33 34 35 0.857 0 0 0 0.286 0 0 0 0.857 0 0 0 0.857 0 0 0 0 0 0 0 1.429 0 0 0 0.857 0 0 0 44 45 46 0 0 0 0 0.182 0 0 0.364 0 0 0.455 0 0 0 0 0 0.273 0 0 0.455 0 0 0.182 0 1 0.286 0.375 18 35 0 0.364 0 0.4 0.857 0.625 25 35 0 0.455 0 0.4 0.857 0.375 21 34 0 0 0 0.6 0 0.5 16 15 0 0.273 0 0 1.429 0 11 19 0 0.455 0 0.8 0.857 0.375 24 31 Waste in job shop environments 817 Man 0 0.5 0.5 0 Material 0 0 0 1 0.5 0 0 0 0.5 0 Machine 1 0 0 0 Method 0 0.5 0 0 0.5 0 0.5 1 0.5 Score (Sj) Frequency (Fj) 63 64 65 66 67 68 0 0 0 1 0.857 0.375 12 21 Table XI. Summary of the assessment analysis and a rank of the different types of wastes in the company IJOPM 25,8 818 before the setup of the previous machine is changed. This leads to hidden defective parts that are discovered later on, especially at the assembly station. This creates the need to produce additional parts to overcome the lack of parts caused by defects. Thus, the lead-time is increased. In addition, and based on the managers assumption that 100 per cent inspection is implemented through different processes, the inspection for both amount and quality received at each station was not set as a standard procedure. This also led to a late discovery of defects, and repetition of the problem. (2) Down-times and set-ups. The company experienced frequent downtimes due to machines malfunctioning. These malfunctionings were caused by lack of continuous checking of the machine running requirements and conditions of operations. No documented procedures were available to specify the status of machines in order to prevent down-times before their occurrence. (3) Over-production and inventory level. The level of inventory and the need for over-production was minimal. The company production system was based on make-to-order production. The results of implementing the waste assessment model show the following: . Managers’ opinions and assessment results do match, with regard to the defects problem. As the results show, defect-waste takes the first rank as a major waste (approximately same as motion waste) with 20.5 perent. . Although motion-waste is not considered or mentioned by the managers as a problem, the matrix shows that this type of waste can be the main cause of the defects waste since there is a direct relationship between motion-waste and producing defective parts. This type of waste is a significant issue but the managers were not aware of it. . Process-waste is ranked third. This agrees also with the managers’ perception of machine down-time being a problem. . Over-production-waste came in sixth position since the company’s policy depends on matching produced quantity with demand. This is also proven by the non-existence of excess finished products in a work-in-process form without a production order. . Transportation-waste was ranked as the waste that is least likely to exist, (which experience suggests is invariably the case), since the shop floor layout is designed on a straight-line flow pattern, and no back-stream flows are allowed. In addition, the factory has clear aisles for transportation with suitable distances, which reduces the need for excessive transportation. Table XII. The company assessment analysis Score (Yj) Pj Factor Final result (Yjfinal) Final result (%) Rank O I D M T P W 0.1126 228.48 25.76 10.1 6 0.1276 250.24 31.94 12.6 4 0.1762 295.68 52.10 20.5 2 0.2570 206.72 53.12 20.9 1 0.1683 144 24.23 9.5 7 0.3919 092.14 36.12 14.2 3 0.1515 206.08 31.21 12.3 5 . Inventory- and waiting-wastes came in the middle positions as minor wastes. These types of waste are usually incurred due to major waste, since inventory usually is performed intentionally to hide the problems of motion- and defect-waste. As deduced from the assessment model, the first major type of waste that is more likely to exist at the factory is motion-waste. The role of employees in producing defective parts can not be ignored since it is clear that defects are produced due to either process or operator problems. An investigation of the operators on the shop floor was carried out, and revealed that the majority of operators were involved with receiving, shipping, handling, storing and ergonomic activities. Both receiving and shipping activities of parts or products were not always located in standard places. Operators needed to walk to get the required parts, in addition to performing manual handling of materials which led to extra movement and a high probability of damaging the bases of the parts. Also, double handling of raw materials or finished goods was noticed where materials were loaded first on the floor and then reloaded on pallets and forklifts to be transported to the next station. Some tools, raw materials, and finished goods were not adequately sorted. Also, non-ergonomic actvities were observed in the form of unsuitable heights for both worker arms and backs, resulting in the need for arm stretching, and over bending. Moreover, the factory was suffering from high turnover of employees. This resulted in frequent hiring of employees, who subsequently remained in their job for short periods and which led to non-accountability of workers and lack of motivation. It is found that many of the employees had insufficient training before being given the responsibility of operating machines that resulted in them being unable to understand their workstation requirements. Also, most of the jobs were not standardized, i.e. the requirements of each job in terms of time, tools, and method were not documented. All these observations led to the conclusion that motion-waste did exist at the factory. It might be concluded, therefore, that the assessment results were thus satisfactory. Conclusions This paper presented a new model for performing an assessment of different types of waste in a jobbing shop environment. The model incorporates the following new features: wastes relationship, waste relationship matrix and assessment questionnaire. The developed model is dependent on categorizing waste into the well-known seven categories. Discussion covered the relationship amongst them, and provides the waste relationship matrix, which utilized the measurement of the strength levels of the relationships. It is argued that over-production-waste and defect-waste have the most significant impact on all other types of waste. Conversely, inventory waste is found to be highly affected by all others; while over-processing-waste is the least affected by others. This is because it is not connected to material-, or man-types of waste. All types of waste affect each other by different weights. However, existing assessment models do not properly handle the weighing of the impact of these wastes. Most research efforts have focused on tools for elimination of waste but without being able to identify which type of waste causes an impact on the total generation of waste. Consequently, the model is anticipated to play a significant role in identifying waste as Waste in job shop environments 819 IJOPM 25,8 820 a first step to elimination, and in helping solve problems related to the operational environment of a jobbing shop. The waste relationship matrix clarifies the relationships among the different types of wastes. It provides an insight, in terms of weighing the contributions to the existence of certain types of waste. The importance of the matrix derives from the fact that it ranks the relationship quantitatively and classifies whether a certain type of waste affects or is affected by other types of waste. On the other hand, the waste relationship matrix (WRM) when integrated with the assessment questionnaire can help a company in allocating or identifying the source of waste and differentiating between the levels of waste and their effects on the performance of the company. It thereby enables it to rank the significance of the waste types that exist. The simplicity of the matrix and the comprehensiveness of the questionnaire contribute to the achievement of accurate results in terms of identifying the root causes of waste as seen in the case study. It has been noted that some of the waste cannot be observed and acknowledged by managers. The output of the model is a ranking for the existing waste in a jobbing shop. This is important for a large variety of companies, for which the articulated waste needs to be reduced or eliminated (based on their existence and the significant contribution to the total existing waste). It is expected that the developed assessment model will allow precise identification of waste generation. This has the advantage of providing a focus for managers, reducing effort and time and bringing about improved performance, in addition to quantifying the potential savings based on waste elimination. There are several interesting avenues for further research on this issue. One would be matching waste elimination tools with waste allocation tools and studying the allocation-elimination tools relationship. Another avenue would be to conduct a field study to collect empirical data for the implementation of the developed assessment model. Finally, it is also possible that this approach could be applied to the service sector, taking into consideration that the definitions of each type of waste may change due to specific requirements of the service sector. References Ahmad, A., Mehra, S. and Pletcher, M. (2004), “The perceived impact of JIT implementation on firms’ financial/growth performance”, Journal of Manufacturing Technology Management, Vol. 15 No. 2, pp. 118-30. Barla, S.B. (2003), “A case study of supplier selection for lean supply by using a mathematical model”, Logistics Information Management, Vol. 16 No. 6, pp. 451-9. Brunet, A.P. and New, S. (2003), “Kaizen in Japan: an empirical study”, International Journal of Operations & Production Management, Vol. 23 No. 12, pp. 1426-46. Canel, C., Rosen, D. and Anderson, E.A. (2000), “Just-in-time is not just for manufacturing: a service perspective”, Industrial Management & Data Systems, Vol. 100 No. 2, pp. 1-60. Chase, R.B., Aquilano, N.J. and Jacobs, R.F. (1998), Production and Operation Management Manufacturing and Services, Irwin, Homewood, IL. Chong, H., White, R.E. and Prybutok, V. (2001), “Relationship among organizational support, JIT implementation, and performance”, Industrial Management & Data Systems, Vol. 101 No. 6, pp. 273-81. Conner, G. (2001), Lean Manufacturing for the Small Shop, Society of Manufacturing Engineers (SME), Dearborn, MI. Daugherty, P.J., Rogers, D.S. and Spencer, M.S. (1994), “Just-in-time functional model: empirical test and validation”, International Journal of Physical Distribution & Logistics Management, Vol. 24 No. 6, pp. 20-6. Emiliani, M.L. (2001), “Redefining the focus of investment analysts”, The TQM Magazine, Vol. 13 No. 1, pp. 34-51. Evans, S. and Jukes, S. (2000), “Improving co-development through process alignment”, International Journal of Operations & Production Management, Vol. 20 No. 8, pp. 979-88. Flinchbaugh, J. (2001), “Beyond lean: building sustainable business and people success through new ways of thinking”, Center for Quality of Management Journal, Vol. 10 No. 2, pp. 37-50. Fullerton, R.R. and McWatters, C.S. (2001), “The production performance benefits from JIT implementation”, Journal of Operations Management, Vol. 19 No. 1, pp. 81-96. Hines, P. and Rich, N. (1997), “The seven value stream mapping tools”, International Journal of Operations & Production Management, Vol. 17 No. 1, pp. 46-64. Imai, M. (1997), Gemba Kaizen, a Common Sense, Low-Cost Approach to Management, McGraw-Hill, Inc., New York, NY. Karlson, C. and Awstrom, P. (1996), “Assessing changes towards lean production”, International Journal of Operations & Production Management, Vol. 16 No. 2, pp. 24-41. Kobayashi, I. (1995), Twenty Keys to Workplace Improvement, Productivity Press, Cambridge, MA. Krajewski, L.J. and Ritzman, L.P. (2002), Operations Management: Strategy and Analysis, 6th ed., Prentice-Hall, Upper Saddle River, NJ. Lewis, M.A. (2000), “Lean production and sustainable competitive advantage”, International Journal of Operations & Production Management, Vol. 20 No. 8, pp. 959-78. Lim, K.K., Ahmed, P.K. and Zairi, M. (1999), “Managing waste and looking beyond: the IMI approach”, The TQM Magazine, Vol. 11 No. 5, pp. 304-10. Miltenburg, J. (2001), “U-shaped production lines: a review of theory and practice”, International Journal of Production Economics, Vol. 70 No. 3, pp. 201-14. Monden, Y. (1983), Toyota Production System: Practical Approach to Production Management, Industrial Engineering and Management Press, Atlanta, GA. O’hEocha, M. (2000), “A study of the influence of company culture, communications and employee attitudes on the use of 5Ss for environmental management at Cooke Brothers Ltd”, The TQM Magazine, Vol. 12 No. 5, pp. 321-30. Ramaswamy, N.R., Selladurai, V. and Gunasekaran, A. (2002), “Just-in-time implementation in small and medium enterprises”, Work Study, Vol. 51 No. 2, pp. 85-90. Rawabdeh, I. (2001), “An investigation of the potential of implementing just-in-time in Jordan”, paper presented at the 7th International Conference on Production Engineering, Design and Control, Alexandria. Shingo, S. (1992), The Shingo Production Management System, Productivity Press, Cambridge, MA. Strategic Direction (2004), “Successful cost reduction methodologies”, Vol. 20 No. 4, pp. 31-3. Svensson, G. (2001), “Just-in-time: the reincarnation of past theory and practice”, Management Decision, Vol. 39 No. 10, pp. 866-79. Swanson, C.A. and Lankford, W.M. (1998), “Just-in-time manufacturing”, Business Process Management Journal, Vol. 4 No. 4, pp. 333-41. Waste in job shop environments 821 IJOPM 25,8 Toyoda, E. (1987), Toyota: First 50 Years in Motion, Kodansha International, Tokyo. Wu, Y.C. (2003), “Lean manufacturing: a perspective of lean suppliers”, International Journal of Operations & Production Management, Vol. 23 No. 11, pp. 1349-76. Yasin, M.M., Wafa, M. and Small, M.H. (2004), “Benchmarking JIT: an analysis of JIT implementations in the manufacturing service and public sectors”, Benchmarking: An International Journal, Vol. 11 No. 1, pp. 74-92. 822 Further reading Imai, M. (1991), Kaizen: The Key to Japan’s Competitive Success, McGraw-Hill, Inc., New York, NY. View publication stats