acdcmodlib

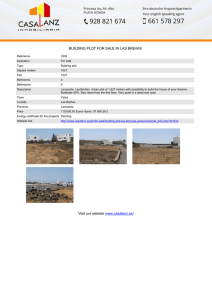

Anuncio