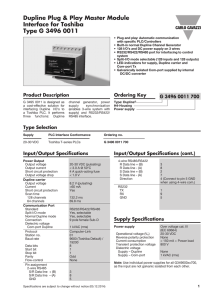

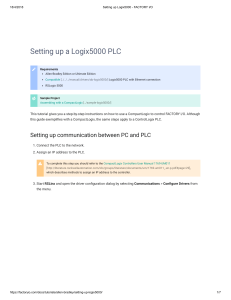

TECHNICAL SPECIFICATION: I2O WATER PUMP CONTROLLER General: One of the most common uses for VSD drives in water distribution networks is to control pumps to maintain a set delivery pressure.` I2O Water has developed a control system which uses the company’s web based pressure management application to enable VSD or PLC controlled pumps deliver the optimum pressure into the network to maintain adequate customer levels of service. The controller communicates via GPRS and local field service application using Bluetooth. The i2O pump controller monitors flow and delivery pressure from the pumping main and generates a set point signal fed to the VSD or PLC. All signals are analogue, 4-20mA, and need to be energised (6-24Volts). The VSD/PLC needs to be configured to perform a PID assessment comparing the set point to the actual measured pressure and to then adjust the speed of the pump(s) to match the two signals. The VSD/PLC needs to manage ‘out of range set point values’ generated from the i2O controller so the VSD/PLC software needs to perform a quality check on the signal. If an out of range signal is received then the VSD/PLC should revert to the internal set point value (4Bar). The out of range signal being <3.5 mA and >20.5 mA. The VSD/PLC software also needs to rate limit the effect of any change in set point signal received from the i2O controller to ensure that changes are applied in a steady controlled manner. For example the rate of change does not exceed 10% of the signal range. In normal flow modulating operation, the controller uses the flow input value to generate a real-time pump target pressure based on a control profile downloaded from the i2O server. The controller logs flow, manifold pressure and on-line status. Regular (at least daily) GPRS communications with the i2O server allows logged data to be uploaded and updated profiles to be downloaded. Specification: Mounting: Standard 35mm top-hat rail (EN50 022 x 15) Outer dimensions: 200 x 123.2 x 137.5 mm Device Inputs GPRS mobile network signal Power Supply: Input Voltage Range: 6 to 26V, 24V DC nominal, Fuse Trip Current: 1.5A, Fuse Holding Current: 750mA 4-20mA current loop for flow and manifold pressure: Opto isolated (floating), Type 2 (passive) 4-20mA loops requiring external energisation (6 to 26V DC). Impedance: ~160Ω, Max voltage burden: 6V Device Outputs 4-20mA current loop representing set point target pressure: Opto isolated (floating), Type 2 (passive) 4-20mA loops which requires an external energisation source. Impedance: ~140Ω, Max voltage burden: 6V, Isolation Voltage: 5kV RMS. PAGE 1 OF 2 COMMERCIAL IN CONFIDENCE © COPYRIGHT I2O WATER LIMITED Operation: When operating under normal conditions, the device expects the following inputs: Total Flow 4mA 20mA 15 bit Aggregated flow Manifold Pressure 4mA 20mA 15 bit Pressure at pump output manifold When operating under normal conditions, the device generates the following outputs: Pressure Demand POUT 4mA 20mA 14 bit Pressure demand output to VSD/PLC Watchdog WDG (Closed contact) Note that the pressure demand output rate-of-change is NOT limited It is left to the SCADA/PLC/VSD to limit the step response in the most appropriate way for any given pump set. Installation Examples: PAGE 2 OF 2 COMMERCIAL IN CONFIDENCE © COPYRIGHT I2O WATER LIMITED