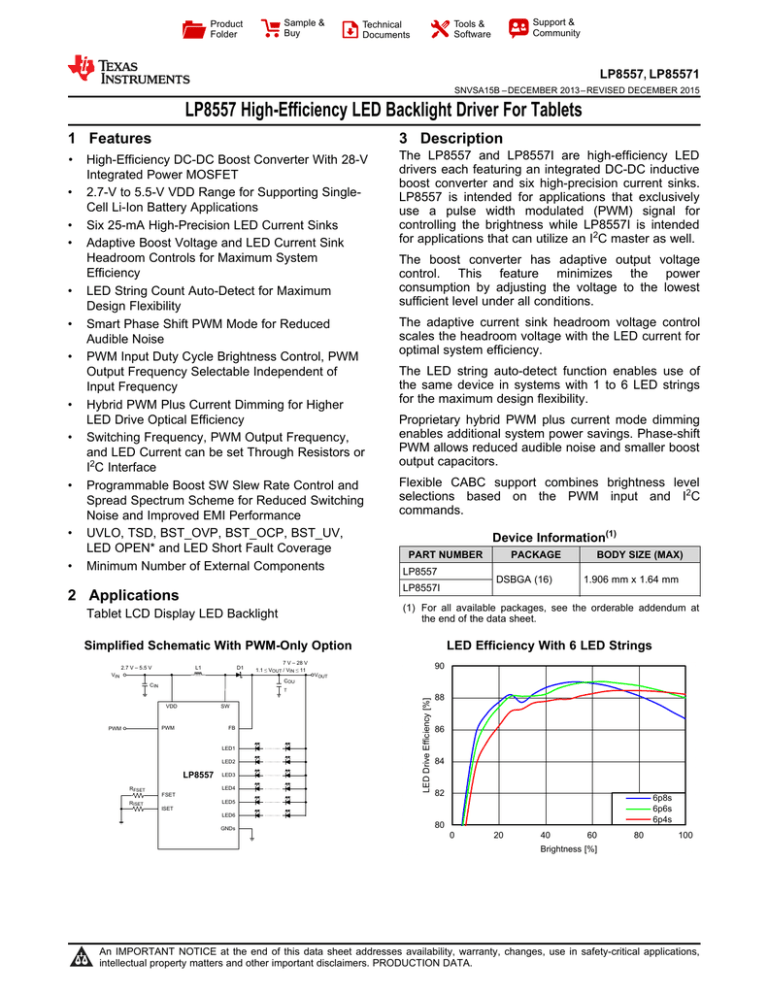

LP8557 and LP8557I - Texas Instruments

Anuncio