Determinacion de PFD

Anuncio

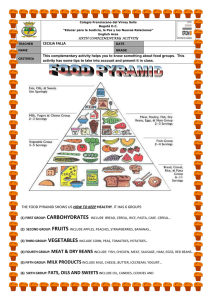

Risk Software S.A. de C.V.

Determinación de PFDavg (SIL) de

un Sistema Instrumentado de Seguridad (SIS)

Preparado para: Curso en Análisis de Riesgos y Seguridad Funcional

Preparado por: Victor Machiavelo Salinas

Risk Software SA de CV

www.risksoftware.com.mx

Risk Software S.A. de C.V.

1. Introducción

El valor de PFDavg (Probabilidad de Fallas Sobre Demanda Promedio) es utilizado en la Seguridad Funcional para determinar

el Nivel de Integridad de Seguridad -NIL- (Safety Integrity Level- SIL) que un Sistema Instrumentado de Seguridad -SIS- tiene

para una Función Instrumentada de Seguridad -FIS- dada.

La figura #1 nos muestra la relación que guarda un Sistema Instrumentado de Seguridad entre la relación (frecuencia) de

demandas (eventos/año) en que el SIS es requerido por el proceso dada una condición insegura y la relación (frecuencia) de

eventos indeseados finales (eventos/año) ocurridos dados la ineficiencia/falla/incapacidad, del SIS.

Relación de

Demandas

(D)

SIS

Relación de

Eventos

(H)

Figura #1

PFDavg = H/D = 1/(Factor de Reducción de Riesgos)

El nivel NIL/SIL, es una relación del valor numérico calculado de PFDavg para un SIS, donde incluimos a los elementos

sensores (presión, temperatura, Flujo, etc), al controlador lógico programable y a los elementos finales de control (válvulas,

motores, actuadores, etc).

El valor de la PFDavg Total para un SIS es la suma algebraica de la probabilidad de fallas sobre demanda promedio del

sensor mas la del controlador lógico mas la del elemento final de control como se muestra en la figura #2

Controlador

Logico

Sensor

Elementos

Finales

Figura #2

PFDavg Total = PFDS + PFDL + PFDEF

para realizar el calculo de la PFDavg de un sistema SIS, el estándar ANSI/ISA 84.01-2004 recomienda tres métodos:

1.

Ecuaciones Simplificadas (Diagramas de Bloques de Confiabilidad)

2.

Análisis de Arboles de Falla (FTA)

3.

Modelos de Markov.

El presente informe técnico se centra en el calculo de la PFDavg, utilizando los dos primeros métodos, los cuales son los mas

utilizados en la seguridad funcional, aclarando que los modelos de Markov son mas precisos y pueden modelar sistemas en

el tiempo, con secuencias y reparables.

Determinación de la PFDavg

1

Risk Software S.A. de C.V.

2. Falla de los Sistemas

Es necesario comprender la forma en que los sistemas y equipos fallan, debido a que las ecuaciones utilizadas para

determinar el valor de PFDavg depende directamente del mecanismo de falla de los sensores, controlador lógico y elementos

finales.

La figura #3 muestra los modos de falla que pueden tener los componentes de un SIS.

Modos de

Falla

Fallas Descubiertas

Relación de Paros en Falso

Fallas Cubiertas

Relación de Paros Peligrosos

λS = 1/MTBFsp

λD = 1/MTTF

Se debe vivir con

perdida de la producción

Paro de Planta o

Permanecer en Riesgo

Mientras se Repara

Detectadas

Por Diagnosticos

No Detectadas

Por Pruebas

manuales

El SIS esta Fuera

Durante las

Pruebas

Figura #3

Modos de Falla

MTBF = Mean Time Between Failures (Tiempo Medio Entre Fallas)

MTTF = Mean Time To Fail (Tiempo medio Para Fallar)

Modos de Falla Descubiertas:

Son conocidas también como fallas “Reveladas” debido a que estas fallas son conocidas en cuanto suceden, como ejemplo

tenemos la falla de la señal de un sensor cuando los cables que conducen la señal son cortados o bien la falla de la bobina

de una válvula solenoide.

Las fallas descubiertas normalmente generan una respuesta del sistema conocida como “Falla Segura” la consecuencia mas

común es una parada por emergencia del proceso. A esto se le conoce como “Relación de Disparos en Falso” en muchos

procesos esta condición es indeseada debido a que afecta directamente a la producción o a los tiempos de producción, en

procesos continuos como en la industria química o petrolera esta condición es muy costosa debido a que volver a iniciar los

procesos no es una tarea fácil ni rápida, en ciertos procesos esta condición también puede ser muy peligrosa, ya que parar

proceso inherentemente peligrosos donde se manejan grandes cantidades de materia y energía puede ocasionar condiciones

riesgosas para el personal, medio ambiente y bienes de las empresas.

La forma en que podemos evitar que esto ocurra es incrementando la tolerancia a falla en los sistemas y equipos (redundancia). La norma IEC-61511 en el punto 11.4 nos indica los mecanismos y niveles de tolerancia a falla para los sistemas SIS.

Determinación de la PFDavg

2

Risk Software S.A. de C.V.

Modos de Falla Cubiertas:

Las fallas cubiertas, son fallas peligrosas hasta que son detectadas y corregidas. El calculo de la PFDavg se basa en este tipo

de fallas. Típicamente las fallas cubiertas se manifiestas en dispositivos que tienen la función de generar o conducir al evento

final, como pueden ser los dispositivos de salida de las tarjetas del PLC, la bobina del relevador, el actuador de la válvula o

bien la lógica del controlador. El problema principal de estas fallas se presenta en dispositivos que no han sido operados por

periodos lagos de tiempo, tres tipos de condiciones se presentan en las fallas cubiertas:

1.

Fallas que pueden ser detectadas por auto diagnósticos.

2.

Fallas que pueden ser encontradas en un periodo de pruebas.

3.

Fallas que permanecen ocultas sin ser detectadas en el sistema hasta que se presenta una falla en demanda.

Cada una de estas fallas contribuyen al valor de PFDavg del SIS. Cada falla requiere un tratamiento diferente de calculo de

confiabilidad.

Las formulas para el calculo de sistemas basados en Auto diagnósticos, están generalmente referidas a controladores lógicos

programables ya que estos sistemas utilizan técnicas avanzadas de diagnósticos, en la mayoría de los sistemas cuando nos

referimos a “diagnósticos” no estamos refiriendo a la capacidad del sistema a realizar pruebas sin necesidad de intervención

del ser humano, estos diagnósticos que también son referidos como “activos” son pruebas funcionales del estado del sistema, como por ejemplo seria cambiar de estado la posición de las salidas de las tarjetas del controlador abrir/cerrar (On/Off)

para poder probar que el sistema tiene la capacidad de llevar al proceso a condición segura. Estas pruebas se realizan de

forma muy rápida generalmente en milisegundos, evitando que las pruebas sean en si mismas una condición peligrosa para el

proceso.

Cálculos:

El calculo de las fallas reveladas (llamadas también fallas seguras) es importante desde el punto de vista de la operación de

los procesos, la instalación de un sistema de seguridad es un proceso complicado y costoso, lo que menos deseamos es

que este sistema sea en si mismo quien genere una condición potencialmente inseguro o binen sea quien ocasiona perdidas

de producción o económicas. La selección de un sistema de seguridad sin tolerancia a fallas deberá ser cuidadosamente

evaluada desde el punto de vista de la seguridad y de la operación de los procesos, el diseño del sistema bajo el concepto

de ciclo de vida deberá incluir los costos de disparos en falso y los costos asociados a la tolerancia a fallas. las fallas relevadas también tienen dos componentes, fallas seguras detectables y fallas seguras no detectables. El echo de que ambas conduzcan a un paro seguro del proceso minimiza la necesidad de detallar cada una en una ecuación diferente.

Las fallas cubiertas (llamadas también peligrosas) como se muestra en la figura # 3 tienen dos componentes,

Determinación de la PFDavg

3

Risk Software S.A. de C.V.

1) Fallas peligrosas detectadas por auto diagnósticos, las cuales realizan el proceso de prueba y detección de errores y fallas

de forma automática, asociamos a estas fallas a las provocadas por los sistemas complejos como los controladores lógicos,

sin embargo en los últimos años algunos dispositivos de campo como sensores y actuadores de válvulas, han incorporado

altos niveles de auto diagnostico en su electrónica. Típicamente el tiempo de las pruebas con auto diagnósticos fluctúa entre

1 y 10 segundos.

2) Fallas peligrosas detectadas por pruebas manuales, son pruebas que no pueden ser realizadas por diagnósticos y es necesario que manualmente se realice la prueba y el diagnostico, típicamente el tiempo de estas pruebas es mucho menor

que el MTBF, este tipo de pruebas esta asociada a dispositivos de campo y elementos finales de control.

La figura #4 muestra la diferencia de pruebas requeridas para los diferentes dispositivos, existe una gran diferencia entre las

ecuaciones utilizadas para modelar el valor de PFDavg para sensores y elementos finales de control y las ecuaciones para

modelar a los controladores lógicos, no solo por que estos realizan sus pruebas de auto diagnostico, también debido a que

cada sistema puede contener diferentes dispositivos en diferentes configuraciones y numero (módulos de entradas y salidas,

fuentes de poder, procesadores, comunicaciones, etc).

Relación de

Demandas

(D)

Sensor

Controlador

Logico

Elementos

Finales

Pruebas

Manuales

Pruebas

Auto

Diagnosticos

Pruebas

Manuales

Relación de

Eventos

(H)

Figura #4

Requerimientos de Pruebas para Dispositivos

Las ecuaciones para modelar a los controladores lógicos programables han sido definidas a detalle en la norma IEC

61508-6.Edición 2.0 2010-04. También se cuentan con ecuaciones simplificadas para los controladores lógicos programables, que hacen mas fácil pero menos exacta la determinación del de la PFDavg.

Determinación de la PFDavg

4

" 27 "

ISA-TR84.00.02-2002 - Part 2

ISA-TR84.00.02-2002

- Part 2

" 28 "

ISA-TR84.00.02-2002 - Part 2

" 27 "

(Eq. No. 9)

$S =

ISA-TR84.00.02-2002 - Part 2

1

MTTF spurious

" 28 "

ISA-TR84.00.02-2002

- Part 22

ISA-TR84.00.02-2002

Part

28 the

" third term is the systematic er

The

second

term is the- common

cause term, "and

ISA-TR84.00.02-2002 - Part 2

The second -term

is2the

term,

Part

" 28

" and the third term is the systema

ISA-TR84.00.02-2002

- Part

2 common cause

" 27 ISA-TR84.00.02-2002

"

S

The above equations apply to elements with the same failure rates. If elements with different fa

S

DD

SNOTE

(Eq.

(Eq.No.

No.9)10) $ =

STR

=

$

+

$

+

$

F

ISA-TR84.00.02-2002

- Part

2 (See

28the

" with

"thethird

MTTF spurious

The second

term is

the

common

cause

and

is theIfsystematic

erro

appropriate

adjustments

must

beequations

made

ISA-TR84.00.02-2002,

Partterm

5 for rates.

method).

NOTE

The

above

apply

toterm,

elements

same

failure

elements with diffe

1oo1

1

S S S

1

appropriate

adjustments

must

be

made

(See

ISA-TR84.00.02-2002,

Part 5 for method).

Where

$ =is the safe or spurious failure rate for the component,

(Eq. No.

9)

(Eq.

No. 9) $ $ =

1oo1

spurious

The

second

term is the common

causewith

term,

and

the third

term

is the systematic

er

MTTF spurious

NOTE

The process

above equations

apply

the taken

same failure

rates.

If elements

with different

MTTF

SIS

industry

typically

must be

of

service

to make

repairsfail

w

S

S in the

DD

- Part

2to elements

" 28 "outPart

(Eq. No.

10)

+DD $+DD

+ISA-TR84.00.02-2002

$

dangerous

detected

rate for theadjustments

component,

and

$ is theSTR

F

appropriate

must

be

made

(See

ISA-TR84.00.02-2002,

5

for

method).

(Eq.

No. 10)

STR

==$ S$+ $

$ SF failure

Risktaken

Software

S.A.

de

C.V.

SIS

the

process

industry

typically

must

be

out

of is

service

toadditional

make repa

The

second

terminredundancy

is

the

common

cause

term, is

and

the

third

term

the for

systematic

er

detected

unless

of

components

provided.

Accounting

1oo1

NOTE

The

above

equations

apply

to

elements

with

the

same

failure

rates.

If

elements

with

different

fa

1oo1

detected

unless redundancy

of components

provided. short

Accounting

additio

S

are

being

made

is typically

not considered

due to theisrelatively

repairfor

time.

C

is the

systematic

failure

rate

for

the component.

S $S$isF the

Where

safesafe

or

spurious

failure

rate

forrate

the

component,

adjustments

must

be

made

(See

ISA-TR84.00.02-2002,

Part

5

for

method).

S

DD failure

S appropriate

Where

is

the

safe

or

spurious

for

the

component,

$

are being

made

istypically

typically

notwith

considered

due of

torates.

the relatively

short

repair

tim

SIS in The

the above

process

industry

must

be

taken

out

service

to make

repairs

wh

(Eq. No. 10)

STR = $ + $ + $ F NOTE

equations

apply

to

elements

the

same

failure

If

elements

with

different

fa

systematic

error

are

handled

as

described

in

5.1.5.

Therefore,

the

equations

above

S

DD

S

DD

second

term

isandthe

common

causeas

term,

the

third

term

is thefor

systematic

systematic

error

areofishandled

described

in 5.1.5.

the

equationser

a

the equation

dangerous

the

component,

and

$ inis the

(Eq. No.The

10)second term

STR =is$detected

$ failure

+The

$rate

the+

dangerous

detected

failure

rate

term

the

third

term

the

detected

unless

redundancy

components

isand

provided.

Accounting

additional

fa

F for

appropriate

adjustments

must

be made

(See

ISA-TR84.00.02-2002,

Part

5Therefore,

for method).

DDS

the

following:

SIS

in

the

typically

must

be

taken

out

of

service

to

make

repairs

w

systematic $

error

rate

term.

The

dangerous

detected

failure

term process

isthe

included

inindustry

the spurious

trip calculation

is

the

dangerous

detected

failure

rate

for

the

component,

and

Where

is

the

safe

or

spurious

failure

rate

for

the

component,

$

following:

are

being

made

is

typically

not

considered

due

to

the

relatively

short

repair

time.

Co

3. Determinación

de lafailure

Relación

de

Disparos en Falso STR

S dangerous

when the detected

puts that channel

(ofcomponent.

a redundant system) or system (if it is nonfor the

S $ F is the safe systematic failure rate

detected

unless

redundancy

components

provided.

Accounting

forwith

additional

NOTE

The

above

equations

apply of

to elements

with theissame

failure rates.

If elements

different faf

DD

systematic

error

are

handled

Where redundant) $in S$ais

the

safe

or spurious

failure

rate

the

component,

safe

(de-energized)

state. This

can

be done

either

automatically

or by humanas described in 5.1.5. Therefore, the equations above

is the

dangerous

detected

failure

rate

forfor

the

component,

and

SIS

in

the

process

industry

typically

must

be

taken

outrelatively

of

to make

repairs

1oo1

appropriate

adjustments

must

be

made

(See

ISA-TR84.00.02-2002,

Partservice

5 for method).

EcuacionesThe

para

la

determinación

de

la

Relación

de

Disparos

en

Falso

(Spurious

Trip

Rate

-STR).

1oo1

are

being

made

is

typically

not

considered

due

to

the

short

repair

time. wC

intervention.

If

dangerous

detected

failure

does

not

place

the

channel

or

system

into

a

safe

state,

this

$

is

the

safe

systematic

failure

rate

for

the

component.

second term

failure rate term and the third term is the

F in the equation is the dangerous detected

the following:

term

is

not

included

in

Equations

10

through

15.

detected

unless

redundancy

of

components

is

provided.

Accounting

for

additional

DD

S

systematic error

term.

Thesystematic

dangerous

detected

failure

term

is included

the spurious

tripand

calculation

systematic

error

are

handled

as described in 5.1.5.

Therefore,

the equations abovef

is isthe

detected

failure

rate

theincomponent,

$ $rate

thedangerous

safe

failure

rate

for"the

component.

27

ISA-TR84.00.02-2002

- Part

2

" for

when the detectedF dangerous failure puts that channel

(ofbeing

a redundant

system)

ortypically

system (if it is

non-considered

S

S

are

made

is

not

due

to

the

relatively

short

repairrepairs

time. w

C

SIS

in

the

process

industry

typically

must

be

taken

out

of

service

make

ComoThe

comentamos

conveniente

conocer

la(Eq.

relación

de

disparos

un sistema tendrá, estotonos

following:

second

the(de-energized)

equationes

isstate.

the

dangerous

detected

failure

rate

term

and

the en

third

termque

is $

the

1oo2 term

No.

STR

=

redundant)

inanteriormente

ainsafe

This canthe

be

done

either10a)

automatically

or10a)

by

human

(Eq.

No.

STR

=

$falso

1oo1

The

second

term

in term.

the equation

is

the

dangerous

detected

failure

rate

and

the

term

is

the

systematic

error

are

handled

as

described

in

5.1.5.

Therefore,

the

equations

above

intervention.

IfSdangerous

detected

failure

does detected

notdetected

place thefailure

channel

or term

system

into

a third

safein

state,

this

systematic

error

rate

The

dangerous

term

is

included

the

spurious

trip

calculation

unless

redundancy

of

components

is

provided.

Accounting

for

additional

f

$sistemas

isinterm.

the

safe

systematic

failure

rateterm

for isthe

permitirá seleccionar

basados

los

asociados

a disparar/parar

un procesos por la falla de alguno de los

Frate

S detected

DD

systematic

The

dangerous

included

the spurious trip calculation

term

isNo.

noterror

included

Equations

10

15.

[2puts

]channel

[,(of

]component.

(Eq.

11)

STR

= through

%puts

($en

+ $DDare

)costos

+failure

% ($S (of

+ $made

)1oo2

+ $SFisin typically

when when

the

detected

dangerous

failure

a redundant

system)

(if it is due

non- to the relatively short repair time. C

the

following:

being

considered

1oo1

the detected

dangerous failure

that that

channel

a redundant

system) or system

(ifnot

itor

is system

nonS

1oo2

componentes

instrumentado

de

seguridad:

1 isstate.

(Eq.

No.

10a)

STR

redundant)

in sistema

ainsafe

state.

This

can

beeither

done

either

automatically

or =

by$human

redundant)

aSsafe(de-energized)

(de-energized)

This

can

be

done

automatically

or by human

1oo2del

systematic

are

as

The

term

indangerous

the

equation

the term

dangerous

detected

failure

ratehandled

term

and

the described

third term is in

the5.1.5. Therefore, the equations above

term

is the

common

cause

and

the

third

term

is error

the

systematic

error

rate

term.

(Eq.intervention.

No.second

9)The second

=

$

intervention.

If

detected

failure

does

not

place

the

channel

or

system

into

a

safe

state,

this

If dangerous detected

failure does not place the channel or system into a safe state, this

spurious

systematic

error

rate

term.

The

dangerous

term

is

included

in

the

spurious

the

following:

S trip calculation

S

S

DD detected

S failure

DD

S

1oo1

term

is

not

included

in

Equations

10

through

15.

MTTF

[channel

No.

11)

STR = [210

% ($through

+ $ )] +

, % ($No.

+ $ 10a)

)]a+(Eq.

$ F No. 11a)

term is (Eq.

not

included

in Equations

15.

STR

S = 2%$

(Eq.

STR

== $

1oo3

when the

detected dangerous failure

puts that

redundant

system)

or system

(if$it is non-/ISA TR

(Eq.

STR

2Simplificada

%

1oo2No.(of11a)

Arquitectura

Ecuación

Compleja/ISA

TR

8402p2

Ecuación

1oo2

redundant)

in a safe

done

automatically

or by human

The second

term is(de-energized)

the common causestate.

termS andDD

the third

systematic

error

rate term.

Sis theDD

S

1oo1

1oo2

[,notterm

(Eq. No. 12)

STR = [3 %failure

($ + $This

)]+ can

%No.

(be

$place

+10a)

$ the

)]either

+channel

$SF

1oo1

8402p2

(Eq.

STR

= a$safe

1oo3

intervention.

If dangerous detected

does

or

system

into

state, this

1oo2

S

DD

S

DD

S

1oo3

]+1oo3

[, % ($No.

(Eq.

No.included

11)

STR = [210

% (through

$ + $ )15.

+ $ 11a)

)]+ $F

(Eq.

STR = 2 % $S

term is

not

in Equations

The second term is the common cause term

the third term is the

error

S and DD

S systematic

DD

S rate term.

(Eq. No.

11)

STR

=[3 %2($%S S+$$DD+)]$+DD

%10a)

$]+(Eq.

+S $ No. +12a)

$ F rate term.

S ,

(Eq.

STR = $ SSTRS = 3 % $S

[,third

(Eq.

No.1oo1

12)term is the common

STR

=cause

%+

($+No.

+S$DD

$systematic

second

is )the

error

(Eq.1oo2

No.The

10)

STR

= $term +and$the

$term

1oo2

F 11a)F

(Eq.

No.

STR

2oo2

1oo3No. 12a)

(Eq.

STR == 23%% $$S

The second

is thecommon

common cause

termterm

and the

third

term

is theterm

systematic

error

rate term. error rate term.

1oo3

The second

termterm

is the

cause

and

the

third

is

the

systematic

S

DD

(Eq. No. 13)S

STR = [2 % $S ($

% ($S DD

+ $DD )] +S$SF

DD)% MTTR ] + [,S2oo2

S

(Eq. No.

11) 1oo2

STR

= spurious

2 %S $S DD

++$$1oo2

+No.

,rate

%11a)

$for

+ $the

+ $F

Where

or

failure

component,

$ is the safe

2oo2

S

(Eq.

STR

== 23 %

$

1oo3

S

DD

S

[

]

[

]

(Eq.

No.

12)

STR

=

3

%

(

$

+

$

)

+

,

%

(

$

+

$

)

+

$

(Eq.

No.

12a)

STR

%

$

2oo2

F

1oo3 The second term is the common cause term and the

third term is the systematic error rate term. This

(Eq. No.1oo1

9)

$S =

" 27 "

1

MTTF1 spurious

" 27 "

[ (

)] [ (

)]

[ (

)] [ (

)]

[cause

]+ [,isfailures

(Eq.

No.term

13)asDD

STR =14

2 %and

$ (15,

$term

+

$ and

)% third

MTTR

%term

($(Eq.

+can

$ No.

$13a)

equation,

well

as Equations

assumes

that

safe

be)] +

detected

on-line.

If safe

F

The second

is

the

the

third

is

the

systematic

error

term.

(Eq.

No.

11a)

STR

= rate

2 and

%

$ S = 2 % $S % MTTR

STR

The second

is

thecommon

common

cause

term

and the

term

therate

systematic

error

rate term.

is

dangerous

detected

failure

for

the

component,

$term

failures1oo3

can

only

bethe

detected

through testing

the12a)

testing

(orDD

inspection)

TI should

be $

S or inspection,

DD

S

S interval

1oo3

(Eq.

No.

STR

=

3

%

2

(Eq. No.

12)

STR = 3 % $ + $ 2oo2

+ , is%the$systematic

+ $ error

+ $rate

F term.STR

substituted

for MTTR.

The

second term

is the common cause term and the(Eq.

third term

This = 2 % $ S

No. 13a)

% MTTR

1oo3 2oo2

equation, as well as Equations 14 and 15, assumes that safe failures can be detected on-line. If safe

S

S

DD

S

[ (

DD

)] [ (

( )

2

S

S

)]

( )

$

STR

[ (

] [$ (+ $ )]+)] $

)(Eq.

STR =

= 32%% $($ ) % MTTR

(Eq. No. 12)

STR

= [3 % ($ + $ 2oo3

)]+ [No.

, % (13a)

STR = [6 % ($ )% ($ + $ )% MTTR ]+ [, % ($ + $ )]+ $

(Eq. No. 14a) STR = 3 %STR

= 6 % ($ ) % MTTR

(Eq. No. detected

12a)

The2oo2

second term in the equation is the dangerous

failure rate term and$the third term is the

2oo2

(Eq.

No.

13a)

STR

=

2

%

(

$

)) %% MTTR

The second term is the common [cause

term

and

the

third

term

is

the

systematic

error

rate

term.

2oo3

[,failure

($ ) ($ $ (Eq.

) No.] 14a)

($ $term

)] $ is included

systematic error

rate term. The dangerous

detected

trip calculation

2oo3

STR = in

6 %the

($spurious

MTTR

2oo3

S

1oo3

failures

through

testing or inspection,

the testing

(or

interval TI should be

2oo3 can only be

S 2

isdetected

the

safe

systematic

failure

rate

forSinspection)

S term

S

DD

DD component.

The second

is

the

common

cause

and

the

third

term

isthe

systematic

error rate term.

2oo2

F

S

(Eq.

No.

12a)

substituted

for

MTTR.

(Eq.

No. term

13)

STR

=

2

%

$

$

+

$

%

MTTR

+

,

%

$the

+ $SSF

S

DD

S $ +DD

2oo2

S

S

DD

S

DD

S

F

(Eq. No. 14)

F

2oo3

The

second term is the common cause term and the third term is the systematic error rate term. This

equation,

as

well

as

Equations

14

and

15,

assumes

that

safe

failures

can

be

detected

on-line.

If safe

S term,

DD

S

The second term is the common cause

the third term is the systematic

rate term.

(Eq. No.

14)

STR

= 6 % testing

% orS and

+inspection,

% MTTR

+ % S + DD + error

failures

can

only be detected

through

be

S

S

DD the testing (or inspection)

S Finterval

DD TI should

2oo4

No.

13) for MTTR.

STR = 2 %

+

+ %

+

+ SF

substituted

2oo2 % MTTR

2oo4

[

(

)

] [ (

S 2

S

S 2

S 2

)]

(Eq.

$ that

$ channel (of ,a redundant

$ $ system)

$

when

the The

detected

dangerous failure$ puts

or system

(if it is nonsecond term is the common cause term, and the third term is the systematic error rate term.

2oo2

2

2oo3

SS 2by human

redundant)

This

can

be

done

either

automatically

or

2oo3in a safe (de-energized) state. (Eq.

No.

13a)

STR

=

2

%

$

%

MTTR

3 (Eq. No.

14a) S is the

STR

6 term.

MTTR2

DD and

2

S 3 This

2oo4

The second

term

the third

error

rate

2oo4

(Eq. No.

15) is the common

STR = cause

12 % ($S term

MTTR

+ [,term

%(Eq.

($ +No.

$DD )]systematic

+ S$SF DDSTR

2oo4

=

S+ $ S ) %does

DD

S 12 % $into

intervention.

Ifwell

dangerous

detected

failure

not

place

the(15a)

channel

or

system

safe state, this

S 2 %aMTTR

(Eq. No.

13)

STR

=

2

%

(

$

$

)

%

MTTR

+

$

+

$

)

+

$

S$

S + DD

S, % DD

S detected

equation,

as

as

Equations

14

and

15,

assumes

that

safe

failures

can

be

on-line.

If

safe

F

(Eq.

No.

13a)

STR

=

2

%

$

%

MTTR

(Eq. No. 14)

STR = [6 % ($S )%DD

($ 3 + $ 15.

)% 2MTTR ]+ [S, % (DD$ + $ S )]+ $F

S 2

termfailures

is not

included

Equations

[

]

(Eq.

No.

15) be in

STR through

= [12 % (10

$ testing

+through

$ ) %or

MTTR

]

+

,

%

(

$

+

$

)

+

$

can

only

detected

inspection,

the

testing

(or

inspection)

interval

TI

should

be

(Eq.

STRS =3 6 % $ %2 MTTR

F

2oo4No. 14a)

2oo3

spurio

5.2.6

Combining

spurious

trip rates

for components to obtain SIS MTTF

(Eq.

No.

STR

=

12

$

%

MTTR

substituted

for

MTTR.

The second

term

is

thecommon

common cause

term,

and and

the

third

term

is15a)

the

systematic

error

rate %

term.

The

second

term

is

the

cause

term

the

third

term

is

the

systematic

error

rate

term.

This

S

λ1oo2

equation,

es la as

relación

fallas seguras

en assumes

falso

parathat

cada

2oo3

well asdeEquations

14 ando15,

safecomponente.

failures can be detected3 on-line. If safe

2 2 solver, and power supply portions are eva

2oo4

2oo4

S logic

Once

the (or

sensor,

2oo3

failures

can only be detected through testing or

inspection,

the

testing

interval

TI

should

be

spurious

(Eq.

No.

15a)

STR

=inspection)

12 STR

%final

$S =element,

(Eq.

No.

14a)

6%%MTTR

$for

% MTTR

spurious

5.2.6

Combining

spurious

trip

rates

components

to obtain

SIS MTTF

DD

for

the

SIS

being

evaluated

is obtained

as follows:

MTTF

substituted

for

MTTR.

λ es la relación de fallas peligrosas

detectadas

componente.

S 2

S

DD 3S

2para cada

S

DD

S DD

DD

S

S

[14a)

(Eq.

No. 15)

STR

= 12 %=($ 2+%$S $) %(Eq.

, %,

($ %+ $$ )]++ $$F S STR

S $ No.

DD+ +

(Eq.(Eq.

No.No.

11)14)

STR

+MTTR

+$DD

$ FS =+3$6S% $ %2 MTTR

spurious

STR

= 6 % $ % $(Eq.

+ $No.

%Combining

MTTR

+

,spurious

%=$12+%

15a)

STR

$ logic

%F MTTR

5.2.6

trip

rates

for components

to supply

obtain SIS

MTTF

Once

the

sensor,

final

element,

solver,

and power

portions

are evaluat

2oo3

2oo4

S

STR

=

STR

+

STR

+

STR

+

STR

λ F

es la relación de fallas sistemáticas seguras para

cada

componente.

spurious

SIS

Si

Li

PSi + $

(Eq.

No. SIS

16) being evaluated

for the

is obtained

as Ai

follows:

MTTF

2oo4

second

termisisthe

the common

term,

and

the

third

term

is

the

systematic

error

rate

term.

TheThe

second

term

commoncause

cause

term

and

the

third

term

is

the

systematic

error

rate

term.

S

S

S solver, and power supply portions are spurious

Once

the

sensor,

trip

rates

for components

to obtain SIS MTTF evaluate

(Eq. No. 14)

STR = 6 % ($S )% ($5.2.6

+ $DDspurious

)Combining

% MTTR

+ final

,spurious

% ($element,

+ $DD

)S +logic

3$ F

2

El valor final de la relación de disparos en falso(Eq.

del

sistema

SIS

(utilizando

las% in

ecuaciones

simplificadas)

es follows:

laterm,

suma

de used

cadawhen systematic e

NOTE

The

last

term

the

equation,

theobtained

systematic

failure

is only

for

the

SIS

being

evaluated

is

as

MTTF

No.

15a)

STR

=

12

$

%

MTTR

2oo4

3 the user

individual

component

STRSTR

desires

toAiinclude

an

overall

value

for

the entire

STR

=

+

STR

+

STR

+

STR

$FS

Sand

2

1oo3

SIS

Si

Li

PSi +system.

(Eq.

No.

16)

elemento

del sistema:

No.

15a)

=element,

12 % $error

%

MTTR

The second

term is the common cause term, (Eq.

and

the

third

term isSTR

the

systematic

rate

term. and power supply portions are

Once

the

sensor,

final

logic

solver,

evaluat

spurious

S

spurious

3

SIS

being

evaluated

obtained

follows:

MTTF

2 for the

S

DD

S rates+foriscomponents

= +trip

STR

STR Ai + as STR

STR

5.2.6

Combining

spurious

to

obtain

MTTF

SIS

Si

Li + SIS

PSi + $F

(Eq.

No. 15)

STR = 12 % $S + $S DD

%DDMTTR

+ term

,

%SSTR

$

+DD

$

$

S the

(Eq.

No.

16)

S

F

1

2oo4

s

p

u

r

io

u

s

spurious

NOTE

The

last

in

the

equation,

systematic

failure

term,

is

only

used

when

systematic

error

ha

STR

= 12)

∑STRSensor + ∑STRCLP

(Eq.SISNo.

STR+ ∑STR

= 3 %EF$+ λ5.2.6

+F$

+ , % $ +spurious

$

+Mtrip

$TF Trates

Combining

to obtain SIS MTTF

F for components

= anS T

individual component STR and the user desires to include

overall

value for the entire system.

R

S

IS

(Eq. No.

17)element,

3

Once

the

sensor,

final

solver,STR

andAiterm,

power

supply

portions

evaluate

STR

= ) + $STR

+ is only

STR

STRare

$FS has

NOTE

The

in Sthe

equation,

the

systematic

failure

used

when

systematic

S

DD

2last term

DD

Slogic

SIS

Si +

Li +

PSi +error

(Eq.

No.

16)

(Eq.

No.

15) (Tiempo Medio

STR

=

12

%

(

$

+

$

)

%

MTTR

+

,

%

(

$

+

$

spurious

ElThe

valor

de

MTTF

Para

Fallar)

esta

dado

por:

F

Once

the

sensor,

final

element,

logic

solver,

and

power

supply

portions

are

evaluate

second term is the common cause term

and the

third

term

isand

the

error

rate

individual

component

STR

thesystematic

user

desires to

include

anterm.

overall

value for the entire system.

for the

SIS

being

evaluated

is

obtained

as follows:

MTTF

spurious The result is the MTTFspurious for the SIS.

1

s p u evaluated

r io u s

for the SIS being

is obtained

as follows:

MTTF

T Tequation,

F

NOTE The last termM

in the

the systematic

failure term, is only used when systematic error ha

=

M2oo2

TTF En Falso = 1/STRSIS

T1R S an

IS overall value for the entire system. S

individual

STR and=the

toSinclude

(Eq. No.component

17)

s p user

u r STR

io udesires

s

STR

+

STR

STR Li + STR PSi + $FS

Si=

Ai +

(Eq. No. 16)

M TSIST F

STR

=

STR

+

STR

STR Li + STR PSi + $F

SIS

Si

Ai +

S

T

R

S

IS

(Eq.

No.

16)

(Eq.

No. 17)

spurious S

S

the MTTF

(Eq. No. 13)

STR = 2 % $S $The

+ result

$DD %isMTTR

+ , % $for

+the

$DDSIS.

+ $SF

[[

((

] [

]

((

( )

( ) (

])]) [ (] [ ( )] )] (

( )

)

))

)

]

[ [ [ ( () (

[

] [

[ [( (

[

[

)

(NOTE

(# ] )

( )

)

)

#

#

)] [ ] [( (

]

)] )#

]

#

]

#

#

#

#

#

#

#

)

[

] [ (

)]

#

#

#

#

#

#

#

#

#

#

#

#

1

s p u r iothe

u ssystematic failure

The last term in the equation,

term, is only used when systematic error ha

M

Tand

Tequation,

Fthe user

spurious

= toSinclude

NOTE

The

last

termMTTF

in the

systematic

failure

term,

is only

when

systematic

The result

is the

forthe

the

SIS.

individual

component

STR

desires

an

overall

valueused

for the

entire

system. error ha

T

R

S

IS

(Eq. No.component

17)

individual

STR is

and

thesystematic

user desires to

include

anterm.

overall This

value for the entire system.

term

and the third term

the

error

rate

The second term is the common cause

equation, as well as Equations 14 and 15, assumes that safe failures

can be detected on-line. If safe

spurious

The result is the MTTF s p ufor

r io inspection)

uthe

s SIS. 1interval TI should be

failures can only be detected through testing or inspection, M

theTtesting

1

s p u(or

r io u s =

T

F

M TTF

= SS T

substituteddefor

MTTR.

Determinación

la PFDavg

(Eq. No. 17)

TR

R SS IS

IS

(Eq. No. 17)

2oo3

spurious

The result

result is

is the

the MTTF

MTTFspurious for

The

for the

the SIS.

SIS.

S

S

DD

S

DD

S

5

Risk Software S.A. de C.V.

ISA-TR84.00.02-2002

Part2 2

ISA-TR84.00.02-2002 - -Part

" 24

" 24

" "

4. Determinación de la Probabilidad de Falla Sobre Demanda

IfIfISA-TR84.00.02-2002

systematic

errors(functional

(functional

failures)

are

included

in the

calculations,

systematic

are

to to

be

included

the

calculations,

sep

- Part

2failures)

24

" be

" coninprueEcuaciones para la determinación de la Probabilidad de Fallas

Sobreerrors

Demanda

PFDavg

para

Sistemas

sub-system,

available,may

maybebeused

used

equations

above.

An alternate

a

sub-system, ififavailable,

in in

thethe

equations

above.

An alternate

appro

bas manuales.

value for

for functional

functionalfailure

failurefor

forthe

theentire

entire

SIF

and

add

term

as shown

in Eq

SIF

and

add

thisthis

term

as shown

in Equati

If systematic errors (functional failures) are to be included in the calculations, se

NOTE

Systematic

failures

are

rarely

modeled

for

SIF

Verification

calculations

due

the difficu

Systematic

failures

are

rarely

modeled

SIF

Verification

calculations

due

thetodifficulty

in

- Part 2 para sistemas

" 22 "

La Probabilidad de Fallas ISA-TR84.00.02-2002

Sobre Demanda

con pruebas

manuales,

esta

relacionada

generalmente

aabove.

los elesub-system,

if available,

may

be

usedforin

the

equations

Anto

alternate

app

effects

and

data

forfor

various

types

of systematic

failure.

However,

thesethe

fai

and

effects

andthe

thelack

lackoffailure

offailure

failurerate

rate

data

various

types

of systematic

failure.

However,

value

for

functional

for

the

entire

SIF

and

add

this

term

as

shown

in

Equa

ISA-TR84.00.02-2002

Part

2

24

"

"

mentos de campo, como son

sensores y elementos finales de control.

can

the

SIF

performance.

ForFor

thisthis

reason,

ANSI/ISA-84.01-1996,

IE

and

can result

resultininsignificant

significantimpact

the

SIF

performance.

reason,

ANSI/ISA-84.01-19

Equations for typical configurations:

ISA-TR84.00.02-2002

- impact

Part 2toto

" 24 "

provide aa lifecycle

design

andand

installation

concepts,

validation

and testing

provide

lifecycleprocess

processthat

thatincorporates

incorporates

design

installation

concepts,

validation

and tesc

NOTE

Systematic

failures

are

rarely

modeled

for SIF

Verification

duefailures.

to the difficulty

TI ) & D change.

TI

&

)

ISA-TR84.00.02-2002

- Part

2intended

24

" the

"

This

process

isis

intended

to to

support

the

reduction

incalculations

the

SIL Ve

This lifecycle

lifecycle

process

support

in systematic

the systematic

failures.

S

PFD avg = ($ DUentre

% + + pruebas

$ % change.

tiempo o intervalo

manuales

(TI),

que

tiene

como

objetivo

lareduction

identificación

yfailures.

errors

failures)

are

to betypes

included

in the

calculations,

separate

va

and

effects

and

the

lack(functional

of

failure

rate

data

for

various

of

systematic

failure.

However,

these

2 * '( F predominantly

2 If

*+ systematic

'

concerned

thethe

SIS

performance

related

to random

" 22 "

predominantly

concernedwith

withassessing

assessing

SIS

performance

related

to random

failures.

La base de estas ecuaciones es el

(Eq. No. 3)

1oo1

ISA-TR84.00.02-2002 - Part 2

If systematic errors (functional failures) are to be included in the calculations, separate

sub-system,

available,impact

may be

inperformance.

the equationsFor

above.

An alternate

approach is t

and

can result inif significant

to used

the SIF

this reason,

ANSI/ISA-84.01-1996,

localización de fallas peligrosas

en el$DUsistema

o elementos del sistema.

sub-system, if available, may be used in the equations above. An alternate approach i

where

is the undetected dangerous failure rate

Equations

for typical

Las ecuaciones

queconfigurations:

describen los

(Eq. No. 3)

value afor

functional

failure

the entiredesign

SIF and

this term

as shown

in Equation

1a in

provide

lifecycle

process

thatfor

incorporates

andadd

installation

concepts,

validation

and testing

Ifvalue

systematic

errors

(functional

failures)

are

to

beadd

included

in the

calculations,

separate

The

simplified

equations

the

terms

for

multiple

failures

during

com

for

functional

failurewithout

for

the

entire

SIF

and

this term

assystematic

shown

inrepair,

Equation

1aV

The

simplified

equations

the

terms

for

multiple

failures

during

repair,

change.

This

lifecycle

process

iswithout

intended

to support

the

reduction

in the

failures.

SIL

D

sub-system,

if available,

may

be

usedforinSIF

thefor

equations

above.

Antoalternate

approach

$ F is the dangerous systematic failure rate, and systematic

errors

reduce

toPeligrosas

following

use

incalculations

the

procedures

outlined

in 5.1

NOTE

Systematic

failures

are rarely

modeled

Verification

due

the difficulty

in assessing

predominantly

concerned

with

assessing

the SIS

performance

related

to

random

failures.

systematic

errors

reduce

tothe

the

following

for

use

in

the

procedures

outlined

in

sistemas

utilizan el componente

de Relación

de

Fallas

Sistemáticas.

value for functional failure for the entire SIF and add this term as shown in Equation 1a

and effects

and the lack

of failure

rate data

for various

types

of systematic

failure. due

However,

these failures

are

NOTE

Systematic

failures

are rarely

modeled

for SIF

Verification

calculations

to the difficulty

in assess

TI is the time interval between manual functional tests

of the component.

result

significant

impact rate

to the

SIFfor

performance.

For

reason, failure.

ANSI/ISA-84.01-1996,

61508,

and can

effects

andinthe

lack of failure

data

various types

of this

systematic

However, theseIEC

failures

a

1oo1

The

simplified

equations

without

the

terms

forFor

multiple

failures

during

repair,

com

TI failure

& DU TI- Part) 1 model

& theDsystematic

)1oo1

provide

aSystematic

lifecycle

process

that

design

and

concepts,

and

criteria,

and

NOTE

failures

areincorporates

rarely

modeled

for

SIF installation

Verification

calculations

due to

thetesting

difficulty

in asses

NOTE The equations in ISA-TR84.00.02-2002

as

an error

occurred

the

and

canthat

result

in during

significant

impact

to the

SIF

performance.

this

reason, validation

ANSI/ISA-84.01-1996,

IEC

615

PFD

=

$

%

+

$

%

specification, design,

in change.

the SIF component

being

susceptible

a

avgimplementation,

errors

reduce

to

following

for

use

in

the

procedures

outlined

in 5isa

This

lifecycle

process

is intended

support

thetypes

reduction

in the

systematic

SIL

Verification

( commissioning,+ or maintenance

( F that 2resulted

+butsystematic

and

effects

and

the

lack

oftofailure

ratethe

datato

for

various

of systematic

failure. failures.

However,

these

failures

provide

lifecycle

process

that

random failure. Some systematic failures do not2manifest themselves randomly,

exist

at time 0aand

remain failed

throughout

the incorporates design and installation concepts, validation and testing criteria,

1oo1

'

*

'

*

TI

predominantly

concerned

with

assessing

performance

related

random

failures.

mission time of the SIF. For example, if the valve actuator is specified improperly, leading

to

the inability

close

the valve

under

and

can

result

in

significant

impact

to thethe

SIF

performance.

For

thisinto

reason,

ANSI/ISA-84.01-1996,

IEC 615

change.

Thistolifecycle

process

is intended

toSIS

support

the reduction

the

systematic

failures. SIL Verificatio

DU

the process pressure that occurs during the hazardous event, then the average value as shown in the above equation is not

provide

a lifecycle

processwith

thatassessing

incorporates

and installation

concepts,

validation

predominantly

the design

SIS performance

related

to random

failures.and testing criteria,

applicable. In this event, the systematic failure would be modeled using $ % TI . When

modeling systematicconcerned

failures, the reader

DU

avg

change. This lifecycle process is intended to support the reduction in the systematic failures. SIL Verificatio

must determine which model is more appropriate for the type of failure being assessed.

(Eq.

No.

3a) selección,

PFD =implementación

$ % TI

Esta relación representa las fallas sistemáticas introducidas durante

diseño,

y mantenimiento de

1oo1el

(Eq.

3a) equations

PFDavg

= $ the terms

%2 for multiple failures during repair, common cau

TheNo.

simplified

without

where

$DU is the undetected dangerous failure rate

2

predominantly

concerned

with

assessing

the

SIS

performance

related

to random

failures.

los elementos de campo del

Sistema

Instrumentado

de

Seguridad.

systematic

errors

reduce

to

the

following

for

use

in the

procedures

outlined

in 5.1.1

throuc

The simplified equations without the terms for multiple

failures

during

repair,

common

1oo2

$ DF

TI for use in the procedures outlined in 5.1.1 thro

systematic errors reduce to the DU

following

1oo2

(Eq.

No.

3a) equations

PFDavgwithout

= $ the%terms for multiple failures during repair, common

The

simplified

1oo1

1oo2

2 for /ISA

systematic

errors

reduce

to

following

use inTR

the procedures outlined in 5.1.1 thr

Arquitectura

Ecuación

Compleja/ISA

TR 8402p2

EcuacióntheSimplificada

1oo1 &

&

TI 2 )

TI ) & D TI )

DU 2

2

DU 2

DU

DD

DU

]

" , ) % $ ) %manual

+ [(1 "functional

% MTTRof

% TI

+ (component.

, ) % $ % $ tests

, % $ % + + ( $F % +

TI

%

TI

$

avg = (((1between

+

TI is the timePFD

interval

the

DU

2

3 *

2 * = $ 8402p2

'

'

'

1oo2

(Eq. No.

3a) 2 * PFD

%$ DU % TI 2

1oo1

Equations for typical configurations:

(Eq.

No. 4a)

PFDavg

2TI

avg = DU

ISA-TR84.00.02-2002 - Part 2

" 23 "

(Eq.

No.

3a)

PFD

=

$

% 3

NOTE The equations in ISA-TR84.00.02-2002 - Part 1 model

failure

as(Eq.

an error

that

occurred

during

the =

No.

4a)

PFD

ISA-TR84.00.02-2002

-Consequently,

Part

2 avgavg

" 23 assumed

"the systematic

For simplification,

1-, is generally

to

be

one,

which

yields

conservative

results.

22

TI

TI

&

)

&

) resulted in the SIF component being susceptible to

specification, design, implementation,

commissioning,

a DUTI

DU toor maintenance

2

(Eq.

No.

5) = reduces

the

equation

1oo2No. 3a)

PFD

% + + ($ DF % that

(Eq. No. 3)

1oo1

1oo1

(Eq.

PFD

= $ DU$%the 3% TI

($manifest

+*

random failure. Some systematic failures avg

do not

but exist

at time 0 and remain

failed

throughout

avg

2 themselves

2randomly,

'

* '

1oo3

2

&

)

(Eq.

No.

4B)

& leading

) &No.

TI

TI1oo2

TI4a)

2

/to

)

PFD

=under

mission time

the5)SIF. For example,PFD

if the=valve

actuator

is specified improperly,

to close

the avg

valve

% (Eq.

$ %inability

-+ +the

(Eq.ofNo.

(($ ) %

+ + [($ ) % $ % "MTTR

23 " % TI ]+ ( , % 0 $ISA-TR84.00.02-2002

- Part 2

4 *event, then the

2shown

2 +* above equation is not DU 2

1 as1oo3

.* (' in the

'

DU

the process

during the

hazardous

average 'value

( $ DU) 2%3 3TI 2 3

where pressure$ that

is occurs

the undetected

dangerous

failure rate

1oo2

applicable. In this event, the systematic

failure

would

be

modeled

using

$

%

TI

.

When

modeling

systematic

failures,

the

reader

(Eq.

4a)

= $$DU %%TITI

3 No. 5) &

(Eq.

)multipleDUfailures

TIfor2 type

TInegligible

TI ) TI PFD

&2 isDU

) /No.

DU

& DU is3 more

)second=term

2for

&TIThis] +factor

)&$DF &for

TI

TI

The

during

repair.

typically

( DU

)3 3 2 3

) avg

must determine which

model

appropriate

the

being

DU

2 %assessed.

($DUaccounts

)2%%term

[MTTR

PFD

$ of %failure

$DD%

% MTTR

% short

1oo3

(' +error

+*%

($the )dangerous

)

% repair

+avgsystematic

%+rate,

+ the

%& ('0,term

%%TIsystematic

$&('The

$3DD

,fourth

$% $is(Eq.

$TI2DFterm.

PFDavg1oo2

$=DF(is

failure

and

third

is +the

common

causeTI

term and

the

-+No.

2/)+*No.

5a)

PFD

=

+ times.

(

+

(

+

)*

2

TI

(Eq.

4a)

PFD

=

2

&

)

avg

% TI

$

42oo2

avg

23 " % TI' ]+ ( ,1%ISA-TR84.00.02-2002

2 2 *

PFD

0 $ % 2-+ .+*($ %' - Part

'

* = (($ ) % 4 + + [($ ) % $ %" MTTR

$ DU ) 34% TI 2

(

2 .* '

2 *+

1

'

'

*

1oo2

1oo3

(Eq.

No.

5a)

PFD

=

3

TI is the time interval between manual functional tests of the component.

(Eq. No. 4a)

PFDavgavg=

where

MTTR is the mean time to repair

TI )

&

(Eq.

No. 5)

$ DU3 4% TI 3

(Eq. No. 6)

PFD = [$ % TI ] + [, % $ % TI ] + ($ % +

1oo3

2oo2

The second term accounts for multiple failures during repair. This

factor2 is

typically

negligible for short

'

*

3

NOTE

The

equations

in

ISA-TR84.00.02-2002

Part

1

model

the

systematic

failure

as

an

error

that

occurred

during

the

DD

(Eq. No.

4A)

The

second term accounts

fortimes.

multiple

during

repair.

factor

is(Eq.

typically

short = DU

repair

term

common

causefailure

termThis

and

theand

fourth term

is the systematic

error term.for

No.negligible

5a)

PFD

$failures

is dangerous

detected

rate,

&Theorthird

)is the that

&

avg ( $

TI

TI

2 beingTIsusceptible

/) &

) % 4TI 3

specification, design, implementation, commissioning,

resulted in the SIF component

to a)

)the

= term

% common

+ [(cause

% $ and%and

%term

%

%error

$ ismaintenance

$ ) term

,systematic

+systematic

PFD

MTTR

TIfourth

0 $ is

- term.

repair times.

The third term

is

the

the

term

the

The

term

third

is]+the

((common

+cause

1oo3

('$ % 2 +* the error term.

random failure. Some

systematic failures

dosecond

not manifest

themselves

randomly,

buttheexist

at

time

0('and

failed

throughout

2oo2

1oo3

2oo2

4 *

2 .+* No.

1remain

'

(Eq.

5a)

PFD

=

DU

DU 3

, fraction of

mission time of the SIF. For example, if the

improperly,

leading

tomore

the inability

to(Eq.

close

the

under system

failures that

impact

than one

channel

ofvalve

a redundant

No.

6a)

PFDavg

%)4 TI

2oo3valve actuator isisspecified

% TI 3

( $TI

avg = $

2

the process

during

the hazardous

event,

then the

average value as shown in the& above

is not

TIequation

(common

cause).

)

2oo2&pressure that occursDU

)

2 (Eq.

TI

TI

&

)

&

)

[, %modeling

No. 6)

PFD

= [DU

$%failures

% TI ]during

+DD

$ % TI ]systematic

+ (factor

$ % 2oo2

DUshortPFD

D

3

(Eq.

No.

5a)

=

+

(Eq.

No.would

7) termbe

The

second

accounts

forusing

multiple

repair. This

is

typically

negligible

for

applicable.

In

this

event,

the

systematic

failure

modeled

$

TI

.

When

failures,

the

reader

DU

avg $ % DU

2* + , %$

' % TI

PFD

= ( (1which

" ,model

) % is$more appropriate

%Thetimes.

+the

(type

1represents

"term

%cause

% MTTR

%forPFD

,is)the%multiple

$ assessed.

$ during

avg

+ The

TI 3

repair

third

common

term and

the fourth

is the

systematic

error term.

(Eq.

No.

term

failures

repair.

Thisterm

factor

is typically

negligible

short

(' 6a)

+ +avg

( F=( $$ 2 )+*4%%TI

must

determine

for

of failure

being

2oo2

3second

repair

times

(typically

less than

8 hours).

The

common

term.

term*is '

TI)) cause

TI ) The fourth 2

'

*

2oo3

&No.

& the

The

second

term

is theDU

common

cause

term and

thethird

thirdterm

term is

is

the

systematic

error

term.

TI

&

(Eq.

5a)

PFD

=

DU

D

(

)

(

)

+

%

PFD

=

$

%

TI

+

3

$

%

$

%

MTTR

%

TI

+

,

%

$

%

$

[

]

[

]

2oo2

the

systematic

error term.

PFD

% TI ] + [, % $ % TI ] + ('( $ F % (Eq.

2+*+ '(No. 26a)

*+

2oo2

avg = [$

1oo2(Eq. No. 6)

PFDavg = $ DU %4 TI

2oo3

2TI2oo2

' & 2oo3

*) No. 6a)

(Eq.

PFDavgavg= $ DU % TI2

1oo3

(Eq. No. 4A) systematic failure rate, and

is the dangerous

ISA-TR84.00.02-2002 - Part 2

" 22 "

3

DU 3

DU 2

DD

2

DU

D

F

avg

[(

3

DU 3

DU 2

]

DD

2

DU

D

F

avg

DU

DU

D

F

avg

3

DU 3

DU 2

DD

2

DU

D

F

avg

(

[

)

DU

DU

DU

2

DU

]

D

F

avg

2

DD

DU

D

F

avg

PFD

(Eq. No. 6)

[

[([(

[(

[(

[[

] [

]

]]

]

]

]]

)

)

)

[ [( ) ] ]

[( ) ]

[

]

[

]

[

]

(

= $DU % TI + , % $DU % TI + $D %

)

DU

)

2

(Eq.

7) term in the equation avg

(' F This

+* No.

TheNo.

second

represents multiple failures during repair.

is typically

(Eq. No. 4A)

2 factor

(Eq.

7a)

$

% TI

2oo2

avg = DU

negligible assumed

for short repair times.

The third

term is

the common

term.

The

fourth term is the

For simplification,

1-, is

generally

be

one,

which

conservative

results.PFD

Consequently,

The second term

is the

common

cause termtoand

the

third

term yields

is cause

the systematic

error

term.

(Eq.

No.

6a)

PFD

% TI

2oo3

systematic error term.

TI

TI )

avg = $

)

& term.

&

2oo3

ThePFD

second=term

third%term

is the

systematic

error

the equation reduces

to

($ is )the%common

(TI ) ] +cause

+

%

3$ term

% $ and% the

MTTR

TI ] +

,

%

$

%

$

[

[

(

2

DU 2

2

2 TI

*+ ) PFD

*+ '(& 7a)

& 2oo3 DU 2 TI2oo4

)

DU$

TI2 )No.

(Eq.

& '

D

avg= =

2oo3 + [(1 " , ) % $DU % $DD % MTTR % TI ] + , % $DU2oo4

(Eq.

No.

6a)

PFD

$

%

TI2 % TI

(

)

PFD2oo3

=

(

1

"

)

%

%

%

+

%

,

$

$

avg

avg

F

(

+

(

+

(

+

2

2oo3

2

DU

2

DU

No. 8)

3(Eq.second

2factor

'

*No.

'is typically

(Eq. No. 4B)'

The *

This

7a)

PFD = =$ $ % TI% TI

(Eq.

No.

7a) 2 * PFD

(Eq.

No. 7) term in the equation represents multiple failures during repair.(Eq.

DU

2

2

DU

DD

DU

avg

D

F

(

)

avgavg ( ( ) )

(Eq. No. 7)

TI ) &

TI )

&

DU 23

2oo4

2oo3

PFD = [( $ ) % ( TI ) ] + [4( $ ) % $ % MTTR % (TI ) ] +&(, % $ % TI+)+ (&$ % TI+ )

2oo4

) %%TI(TI2 )3

PFD

= (($$DU

*+No.

+'($8a)

%2 * +

PFD = [($ ) % (TI ) ] + [3$ % $ % MTTR % TI ] + ', % $(Eq.

% 2 No.

avg =

(Eq.

7a)

PFDavg

)

2oo4

2

2

For simplification, 1-, is generally assumed to be one, which yields conservative ('results.

Consequently,

*

*

'

2oo4TI ) &

TI )

&

the equation

reduces to

% +

PFD

% + + ($ TI

2

& DU= 2[($ TI)2 )% (TI )DU] + [3$DD % $ % MTTR % &TI ] + (',DU% $ (Eq.

TI

) 2No.

&* Combining

)2PFD

(Eq.

No.

7a)

($DU(DU$DU

) 2 )%3 TI

D

avg = =

* components’

'

3 PFDs

)3 SIF PFDavg

8a)

PFD

%

TIobtain

3(to

5.1.6

2oo4

(

)

[

]

PFD

=

%

$

+

$

%

$

%

%

+

,

%

$

%

+

$

%

MTTR

TI

avg

3

avg

F

(

+

)

(

)

(Eq. No. 4B)

(Eq.

No.

%

TI

TI

3

) &8a) TI ) +PFDavg = ($

&

(

+

(

DU

MTTR es

+ ($ % 2+ * PFD

= [( $ reparación

%2

$ * %No.

) % (TI ) ] + [4( $ ) % $ % MTTR

' % (TI ) ] + (', (Eq.

) % (TI )

' el tiempo3medio

* PFDpara

2'+* 8a)

2*

avg = ($

'

negligible for short repair times. The third term is the common cause term. The fourth term is the

3

3

2

DU 2

DD

DU

D

systematic errorDUterm.

avg

2oo4

DU

2

DU

2

2

DU

DD

DU

FD

F

avg

2

DU

D

F

The

equationrepresents

representsmultiple

multiple

failures

during

repair.

is typically

Thesecond

secondterm

term in

in the equation

failures

during

repair.

ThisThis

factorfactor

is typically

negligiblefor

forshort

short

The

third

is is

thethe

common

cause

The The

fourth

term term

is theDis the

negligible

times.

TheDU

third

term

common

cause

term.

2 term

3

2 term.

DU 3repair times.

DD

DU fourth

systematic

error term.

term.

avg

F

systematic

error

(Eq. No. 8)

avg

DD

DU

2oo4

Once

the sensor,

final element,

DU logic solver, and power supply (if applicable) port

For configurations other than those indicated above, see Reference 3 or ISA-TR84.00.02-2002

- Part 5.

2oo4

The second term in the equation

represents multiple failures during repair.5.1.6

This

is typically

components’

to obtain

SIF

PFDavg

(Eq.

No.Combining

8a)

PFD

%PFDs

TI

5.1.6factor

Combining

components’

to obtain

SIF PFD

avg = $

avg

the

SIF

beingPFDs

evaluated

is obtained

by summing

the individual

overall

PFD

The

terms

inThe

the equations

representing

common

causeTI

(Beta

factor term)

and

systematic

failuresterm

are for

avg

times.

third term

is&the

common

cause

term.

The fourth

is the

negligible

es& laDUfor

relación