ALL FARM - GlobalG.A.P.

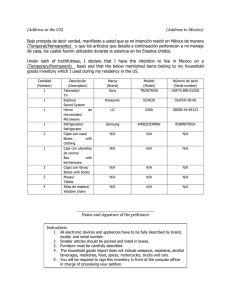

Anuncio