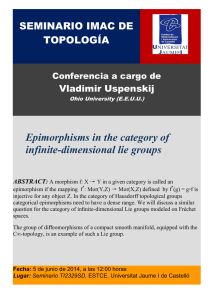

Cement seminars and courses 2014

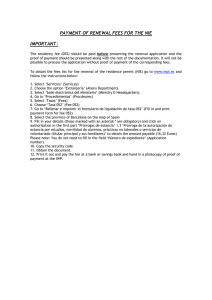

Anuncio