cast iron extension wings

Anuncio

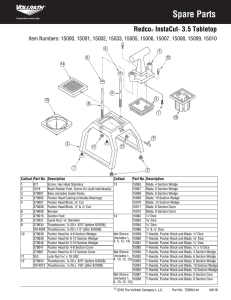

SawStop ® CAST IRON EXTENSION WINGS INSTALLATION INSTRUCTIONS The cast iron extension wings attach to the right and left sides of your contractor saw and replace the stamped metal extension wings. Notice that each cast iron extension wing has a beveled front edge. Position one of the extension wings next to the left side of the table and make sure the beveled edge is facing the front of the saw (see Fig. 1). Sa ¨ Co wSto ® ntr p act 10 make sure the beveled edge is facing the front of the saw !W A or Mode Sa Seria l No. w l No. CNS Elect C074 175 rical 01234 / Elect 5 115/2 ricida d / Élect 15/7.530 Volts 1 PhasAmps , 60 Hz ricité e SawSto p, LLC For 1.75 3500 HP RPM c ® www. 175370US sawst op.co m Made in Taiwan TCP RNIN your man own ual safet G befo y, 1. re read 2. Wear oper the Use eye ating instru opera the prote this ction hroug tion blade ction. saw. for guard 3. h sawin which 4. Keep and g. it can hands sprea 5. Use a be used,der for 6. Know push- out of includevery 7. Do nothow tostick the line when ing of 8. Neve perfo reduc requir the all r 9. Neve reach rm anye the saw Never try aroun operarisk ed. blade cartrid of r to . tion kickb 10. ge adjus test fired or over freeh ack. while t the the 11. Do not the and. Unplu try the positi brake saw blade on chang g to syste blade 12. ing the disab is of the m. . Do the saw le thespinn brake powe not brakebefor brakeing. 13. r supplconne cartrid e chang 14. Use the y. ct the ge ingsyste m. Do motor or the locati not bypas servic blade 15. ons. expos s switch direct ing. , ly to e to the Do not rain only a cabin put or when your et while use neces hands in damp the sary. bladeinside or is spinn under ing. neath ! AD VE Para su prop instru ia segu RTEN CIA cción 1. ridad ante , 2. Use las s de lea el Use gafas usar man separel dispo de ual la sierr peudaador sitivosegur de para de idad. a. 3. opera ser utilizacualqsegur Mantecione uier idad s da incluy Pour opera de 4. la cuchinga lasde serra la votre Utilice lla endo ción cuchi de mano r comp todaspara lla d’ins prop s fuera leto 5. neces una la sierra 1. la y truct re vara 6. Sepa ario. de o a las cual 2. Porte ion sécu de . través la trayec reduc empu Utilisez des avan rité, 7. No realic . ir el No jar t d’utillisez z le lunett toria cuand riesgo pongae ningu 3. type d'opé prote es le man de 8. cuchi o tournGarde rationcteurde sécur iser na del Nunclla. la mano la scie. uel opera retroc está 4. e. z les de . a alredeción eso. mains lameité. Utilise 9. freno trate de Nuncs. quel dor a mano à exper 5. néces z un pouss l’écar o detrá que a alzad t de 10. mient ajuste iment soit 6. Limitesaire. s de a. ras oir la lame z au le ar 11. No trate que la posic de 7. Ne travai la con Siem maxim fin la cuchi ión lorsqu el sistem de de Ne passellez pre de desco la cuchi passe um la ’elle desen lla del 8. lame. z pas a de necta está cartuc pas à la le risque si 12. mante lla, chufe de N’ess girandho votre volée No nerla.el cartuc r el sistem freina ayez de del la conec 9. bras . rejet. o. freno ge. jamai ho sierra 13. abast te a de freinN’aju antes s d'effe par-d Utiliceecimi el motor del freno stez freno essus 10. lorsqu jamai ento. ctuer , o de cambs. N’ess e direct 14. cuand el interr ou de s autou un No o está uptor ayezla lame la positi iar amen húme essai expon 11. freina r Débrage. pas tourn on te con 15. das. ga neces del du cartou de de No a la ario. bypas nchez neutre. la cartou circui un ponga 12. che lluvia t s solam gabin aliser de la scie priseNe branc frein, ete las mano o al le circui che de ente uso mient 13. de courahez ou avant en N'utili t de pas d’en de ras s dentr néces locali la cuchi o direct faire chang sez nt. zacio 14. sité. l’inter de emenl’entre er la lla ni debaj nes les Ne rupte gira. pas t le tien. lame, empla o del expos ur moteu 15. la de Ne ceme er by-pa rà mette nts a la une au-de ss humidpluie z qu'en ssouspas les es. et cas de mains ne pas de cabin à l’intér utilise et lorsqu r dans ieur e la on lame tourn e. ! AVERTIS SEME NT Fig. 1 The side of the extension wing next to the saw has four larger holes. Align those holes with the corresponding four threaded holes on the side of the saw table. Mount the extension wing to the table with four M8 lock washers and four M8 x 20 hex head screws (see Fig. 2), but do not tighten the screws. Repeat the same procedure to mount the other extension wing to the right side of the table. You must now level the extension wings and tighten the bolts. The instructions for that are in step 21 of the assembly instructions for your saw which are in the owner’s manual and on the assembly poster that came with your saw. M8 x 20 Hex Head Screw M8.2 x 15.4 Lock Washer Fig. 2 Cast Iron Extension Wing Parts List Description Part No. Qty. Cast Iron Extension Wing (includes hardware pack) CNS-07-017 1 Hardware Pack for Cast Iron Extension Wing CNS-07-258 1 Copyright SawStop, LLC. All Rights Reserved. SawStop is a registered trademark of SawStop, LLC. Updates of these instructions may be available at www.sawstop.com.