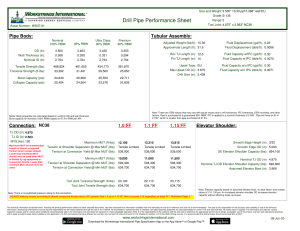

IM60011 Waterrflow De etector 2018 Editio on U‐Bolt Vaane Type Waterflow W Detector MODEL: IIM6001‐50//65/80/100 0/125/150//200 FLOW SENSITIVITY RANGE: R 4 ‐ 10 1 GPM(15‐‐38LPM) CONTACTT RATING: 8A@250VAC C,3A@24VD DC,2.5A@30 0VDC WORKING G PRESSUREE: 450PSI WORKING G TEMPEREETURE: 0℃ TO 49℃ COMPATIBLE PIPE: STEEL PIPE, SCHEDULE S 110~40 MAXIMUM SURGE:1 18FPS(5.5M/S) GENERALL INFOMATIION Waterflow w detectorrs are mounted to waater filled pipes in sprinkkler systemss. It is usedd on steel pip pe,schedulees 10 through 40, ssizes 50mm th hru 200mm (2” thru 8””). See Tab le 1 for detectors sizes. Waterflow w in the pipe deflects a vane, whhich triggers a switch usually u afte er a speciffied delay period. All waaterflow de etectos havve a pneumattically conttrolled mecchanical deelay mechanissm. Delays reset if the e flow of waater stops beffore the enttire delay has h elapsed.. All switches are actuatte when th he water fflow rate is 100gallons peer minute or o greater, but will not actuate iff the rate is less t han 4gallons per minutee. This instaallation mannual covers th he followingg waterflow w detectors for sprinkler. It can bee mounted in verticall or horizontaal position and suitab ble for inddoor and outdoor wet pip pe. Nom minal Pipe Size S Model DN500 2” IM6001‐5 0 DN655 2 2.5” IM6001‐6 5 DN800 3” IM6001‐8 0 DN1000 4” IM6001‐1000 DN1225 5” IM6001‐1225 DN1550 6” IM6001‐1550 DN2000 8” IM6001‐2000 Table 1: DETECTOR D SIZE S Corrosion n Protection n Fusion Bo onded Epoxxy Coated In nterior and d Exterior or Enamel Sppray Paint, Interior I and d Exterior. Installation NO OTE: Do not leave coverr off for an extended perriod of time. 1. These de evices mayy be mou unted on horrizontal or vertical v pipee. On horizo ontal pipe the ey shall be installed onn the top siide of the pip pe where th hey will bee accessible e. Be sure the ere is adeq quate clearaance for in nstallation and d remova al.See Figg.1 for mounting dim mensions. 2. The T device should nott be installed within 15ccm of a fittting which cchange the direction of the t waterflo ow or withiin 60cm of a valve or draain 3. Drain the system andd drill a ho ole in the Shanghai Iron Man Firre Fighting Eq quipment Co. ,ltd Room 716, 7F, No.100 0, Xiuyan Road d, Shanghai 2201315, China www.firefightingtool.com IM60011 Waterrflow De etector 2018 Editio on pipe. And d be sure th he hole is pe erpendiculaar to center off the pipe,ass show in Fiig.2. If the hhole is off cen nter, the vaane will bin nd against the inside waall of the pip pe. Use a ho ole saw in a slow w speed drrill to cut a hole of the proper diiameter, as show in Tab ble 2. 4. Removve burrs an nd sharp edges from the hole. Clean and rem move all scaale and foreeign matter ffrom the in nside of th he pipe foor a distance equal to the pipe diam meter on eitther side of th he hole. Cleaan the outside of the pipe to rremove dirtt,metal chip ps, and cuttting lubricant. 5. Roll th he vane so o that it maay be inserrted into the hole; do no ot bend or crease it. SSeat the gaskeet against the saddle and a mount the detector into the pip pe. Insert th he vane so tthat the e arrow on o the sadddle points in the dire ection of the waterrflow. The bushing sho ould fit insid de the hole in the pipe. 6. Install th he U‐bolt and tighten nuts alte ernately to ensure a uuniform seaal(see the Tab ble 2 for torque values)). 7. The T vane must m not ruub the inside of the pip pe or bind in any wayy. If the vaane binds, rem move the detector d annd correct the t cause beffore proceeding. 8. Ensure thatt the directtion of arro ow on the sad ddle point should be consistent with the dire ection of the waterflow w.See Fig.3. Notes: Remove e burrs from m edge of hole. Clean outt scale and foreign maatter from in nside wall of pipe p Fig.1 Mounting dimensions Fig.2 Mounting hole location Table 2 Main dimensions Pippe Wall thickness Nominaal Pipe Sizze No ominal Pipe e Size OD. Scheduule10 Scchedule40 mm DN50 DN65 DN80 DN100 DN125 DN150 DN200 mm m 60.3 7 73 88.9 11 14.3 14 41.3 16 68.3 21 19.1 mm 2.77 3.05 3.05 3.05 3.40 3.40 3.76 mm m 3.9 91 5.1 16 5.4 49 6.0 02 6.5 55 7.1 11 8.1 18 inch 2” 2.5” 3” 4” 5” 6” 8” inch 2.375 5 2.875 5 3.500 0 4.500 0 5.563 3 6.625 5 8.625 5 inch 00.109 0.12 0.12 1.12 00.134 00.134 00.148 Shanghai Iron Man Firre Fighting Eq quipment Co. ,ltd Room 716, 7F, No.100 0, Xiuyan Road d, Shanghai 2201315, China inch 0.154 0.203 0.216 0.237 0.258 0.280 0.322 L H mm 84 92 104 133 160 187 240 m mm 1188 2200 2220 2245 2272 2298 3350 mm U‐bolt Nuts Torque nm 32+2 2 40‐50 51+2 2 70‐95 Hole e Size www.firefightingtool.com IM60011 Waterrflow De etector 2018 Editio on Fig.3 Assembly diagram 2. A ground screw is provided with all waterflow de etectors. W When grou unding is req quired, clam mp wire withh screw in ho ole locatedd between n conduit enttrance holess. See Fig.5 Fig.5 Ground screw 3. If a secon nd conduitt entry is required, rem move the kn nockout pluug: Place sccrewdriver at inside i edge of kno ockouts, not in the cennter. Wiring 1.All mod del have two o SPDT swittches,one can be used to operatee a central station, w while the other contact iss used to operate o a loocal audible o or visual ann nunciator. Switch S contaacts COM and NO are closed when w waterr is flowing aand open when it is no ot. Connect the switches,, as shown in i Fig.4, dep pending on the applicatio on. Rettard Adjustment The e delay can be adjustedd by rotating the retard adjustm ment knob ffrom 0 to max m setting. To adjust the settting, turn th he adjustmeent knob clockwise to increase i the e delay, couunterclockw wise to deccrease it. Th he time dellay should be b set at thee minimum required to prevent p falsse alarms. Ma aintenance Inspect detecttors monthl y. If leak are e found, rep place the de etector. Fig.4 Electric connection Shanghai Iron Man Firre Fighting Eq quipment Co. ,ltd Room 716, 7F, No.100 0, Xiuyan Road d, Shanghai 2201315, China www.firefightingtool.com