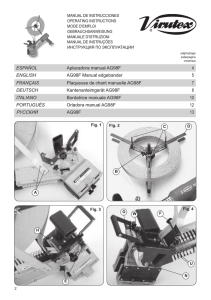

![[Colin Simmons, Dennis Maguire] Manual of engineer](http://s2.studylib.es/store/data/008795764_1-e307834f54630b81935f528d75fdb829-768x994.png)