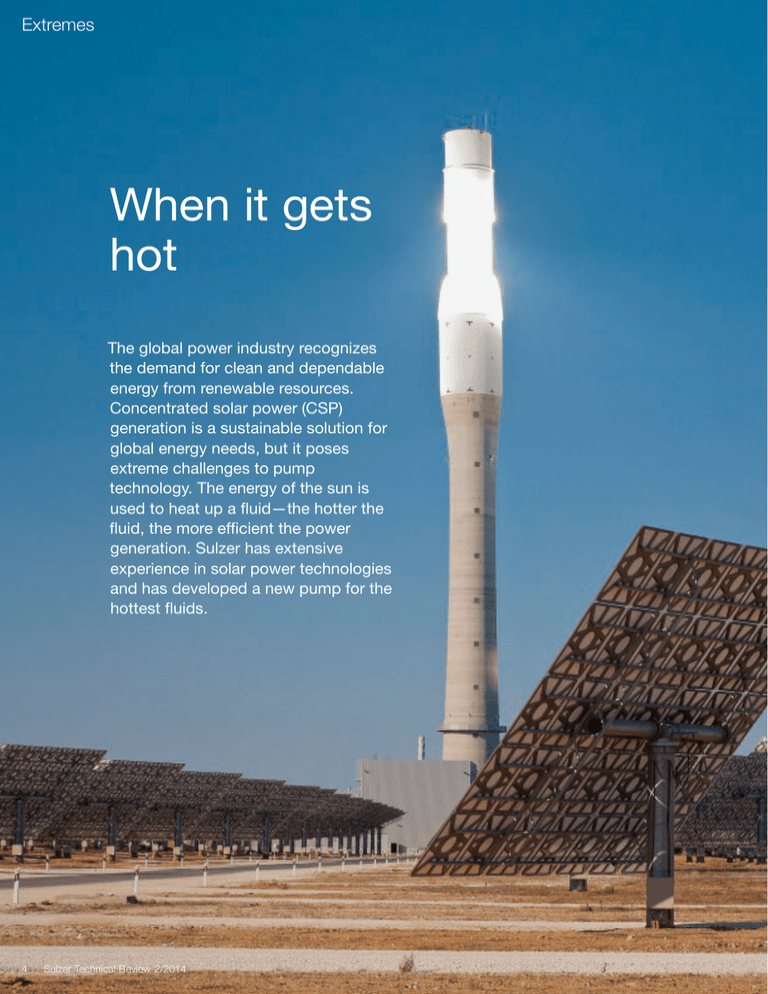

When it gets hot

Anuncio

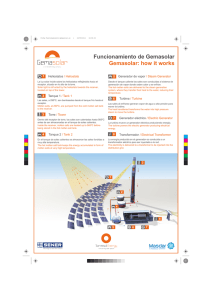

Extremes When it gets hot The global power industry recognizes the demand for clean and dependable energy from renewable resources. Concentrated solar power (CSP) generation is a sustainable solution for global energy needs, but it poses extreme challenges to pump technology. The energy of the sun is used to heat up a fluid—the hotter the fluid, the more efficient the power generation. Sulzer has extensive experience in solar power technologies and has developed a new pump for the hottest fluids. 4 Sulzer Technical Review 2/2014 Extremes Temperatures in modern steam power plants are getting hotter and hotter. The reason for that is simple: Thermal efficiency depends on steam pressure and temperature. Above a certain critical pressure, liquids directly become steam without boiling. For water, this happens at 374 °C and 220.6 bar. This is called supercritical steam. Operating a thermal power plant at steam conditions above this critical point increases the efficiency significantly. Supercritical steam has been used in coal-fired power plants for a long time. Now this trend is booming in concentrated solar power (CSP) plants as well. CSP plants concentrate solar radiation by using mirrors or lenses to heat up a working fluid (see Sulzer Technical Review 1/2012). The heated fluid drives a steam turbine to produce electricity. Today, the most widespread CSP technology is the parabolic trough system. Long, trough-shaped mirrors concentrate sunlight onto thermally efficient receiver tubes along the trough’s focal line. These tubes are filled with a heat transfer fluid, such as thermal oil, which is heated up by the sunlight. In order to avoid a degradation of the thermal oil, the temperatures need to be below 400 °C. A second type of CSP technology is the central tower system. This technology, which does not have thermal oil but molten salt as its primary heat transfer fluid, allows even higher temperatures and reaches better thermal efficiencies than parabolic trough plants. Circular arrays of flat, orientable mirrors (called heliostats) concentrate sunlight onto a tower-mounted thermal receiver that contains a heat transfer media. Benefits and challenges of molten salts Because of their high melting temperature and significant specific-heat capacity, molten salts are used in CSP plants more and more today as the primary heat transfer fluid and also for heat storage. The possibility of storing heat with molten salts brings great benefits. When a thermal storage reservoir of molten salts is integrated into a CSP plant, electricity can be generated even after the sun goes down. This way, the operation period can be extended by 6–8 hours. The molten-salt system consists of two huge tanks—one for the hot salt and one for the cold salt. Vertical pumps are mounted in the tanks to circulate the molten salt. The pumps can handle the temperature of 400 °C in the parabolic trough systems quite well. Such temperatures are common for pumps in the hydrocarbon processing industry as well. But the working temperature of central tower systems is in the range of 500–600 °C, which is an extreme condition for a pump. There are not many other fluids that are so hot. Sulzer Technical Review 2/2014 5 Extremes Sulzer has developed a new molten-salt circulation pump that meets these extreme requirements. It is a vertical mixed-flow pump with medium-to-high capacity and head. The pump is called SJT (VCN) and is an evolution of the existing VCN pumps. The VCN pumps have already been applied successfully to molten-salt heat storage in other industries. Now, Sulzer has adapted the pump design especially for the needs of the solar power industry. Dealing with extremes When dealing with extreme temperatures, one big challenge is the material growth. As the molten-salt circulation pumps are installed in large tanks, they need to be very long—usually in the range of 13–15 meters. The thermal expansion of such a long pump during operation is significant and has to be considered in the pump design. A second issue is the sealing. Because the molten salts are not compatible with any elastomer materials, the pump has to be free of any elastomer components. Therefore, it is not possible to seal the shaft with mechanical seals, which all use elastomer materials. The Sulzer engineers have developed a special sealing configuration by means of throttle bushing. The fluid pressure is throttled, and the leakage is circulated internally back to the tank. A further important topic that Sulzer addressed is the risk of freezing. The molten salt freezes at 220 °C, which means that when it comes to contact with the environment, it becomes rock hard and blocks the pumps immediately. To avoid any contact of the fluid with the environment, the pump has to be selfdraining. Sulzer started developing the SJT (VCN) pump for concentrated solar power five years ago and managed to fulfill all the challenging requirements of this application. Now the pump is ready for field testing. After that, it will be available on the market. In addition to supplying molten-salt circulation pumps, Sulzer supports the solar power industry with a full product line of pumps. These include pumps for feed water, hot water circulation, condensate extraction, and cooling water, as well as main and auxiliary pumps for heat transfer oil. Contact: Miguel Angel Rivas [email protected] The SJT (VCN) pump incorporates the hydraulics from the SJT range. It is engineered to balance high efficiency, low submergence, and net positive suction head (NPSH) considerations. The maximum pressure is 60 bar (870 psi), and the maximum temperature is 600 °C (1100 °F). www.sulzer.com/SJT-VCN 6 Sulzer Technical Review 2/2014 Solar island Extremes Power island Solar receiver Hot salt tank Cooling tower Steam turbine Hot salt pump Generator Steam generator Condenser Heliostat field Central solar tower Deaerator Cold salt pump Cold salt tank Feedwater pump Condensate extraction pump Cooling water pump In central tower systems, heliostat fields heat up the molten salt. The molten salt is used as the primary heat transfer fluid and is also used to store heat. Sulzer supports this process with pumps for feed water, condensate extraction, cooling water, and molten salt circulation (hot salt pump, cold salt pump). Miguel Angel Rivas manages the Power Portfolio at Pumps Equipment and explains the idea behind the new SJT (VCN) pump. Central tower technology is a new and promising approach in the solar power industry. What are the key benefits? I believe that central tower technology is the future of concentrated solar power. Compared with parabolic troughs, the thermal efficiency is much higher, and the cost of installation is reasonably lower. In central tower systems, you could produce supercritical steam, which would make power generation more efficient and would reduce the mirror surface that you need to create the same amount of energy. A further advantage of the central tower system is that molten salts are more environmentally friendly than the thermal oils that circulate in the parabolic troughs. Thermal oil is an aggressive liquid, which is potentially polluting and flammable. By contrast, the molten salts are absolutely neutral. A further advantage of molten salts is that they can store energy. Why is that so important? The time when you can collect heat from the sun is not always the time of highest price or electricity consumption. That’s why having the option of storing the energy is very attractive. Then you can release the energy in the hours of peak electricity use. The possibility of storing energy in the form of heat makes concentrated solar power competitive with photovoltaic power. Photovoltaic systems have the advantage of generating energy at lower investment costs but they don’t have any storage options. But pumping molten salts is an extreme challenge… Yes, it’s like pumping melted rocks. The temperatures are extreme, and the risk of blocking the pump with solid particles is high. We developed the idea for our new SJT (VCN) pump five years ago, but our experience with molten salts goes back much further. We have manufactured pumps for molten salts for the past 45 years. Now, as new solar power technologies emerge, we are launching a pump that is tailored perfectly to the needs of the solar power industry. How is the central tower industry developing? The first central tower plant using molten salts in operation was Gemasolar in Spain. Now, many new projects are underway—especially in the US, Israel, Algeria, and South Africa. Many countries recognize that it’s imperative to have renewable power generation in order to reduce the greenhouse effect. In regions where there is high sun exposure, it’s obvious that solar power is an attractive option. That’s why we continually develop innovative solutions for the solar power market. Interview: Tünde Kirstein Sulzer Technical Review 2/2014 7