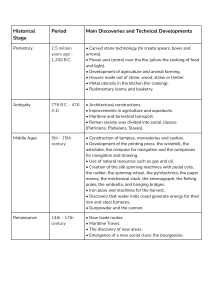

Carburizing Report: Methods, Theory, and Microstructures

Anuncio

1 Materia: Ciencia e Ingeniería de los Materiales Catedrático: Arturo Ortiz Mariscal Grupo: B Nombre de los integrantes: Axel Ricardo Martinez Sanchez Julio Cesar Saldivar Medellin Victor Manuel Ochoa Martinez Genaro de Jesus Zuñiga Cruz Arnulfo Zavala Guerrero 09/04/2024 Matamoros,Tamps. H. 2 Index introduction to carburizing................................................................................................... 3 Purpose.............................................................................................................................. 4 Solid carburized..................................................................................................................... 4 Simple introduction.............................................................................................................4 Process:............................................................................................................................. 5 Another types of carburizing...............................................................................................6 Carburizing Theory................................................................................................................ 8 The equilibrium state of a chemical reaction...................................................................... 8 Carburetion control factors................................................................................................. 9 The flow of carbon in iron................................................................................................... 9 Microstructures of Cemented Steels..................................................................................11 Martensite.........................................................................................................................11 Martensite Formation........................................................................................................11 Martensite Morphologies.................................................................................................. 12 Effect of Tempering.......................................................................................................... 13 Role of Transition Carbides.............................................................................................. 13 Conclusion............................................................................................................................15 3 introduction to carburizing Carburizing is a case-hardening process that adds carbon to the surface of various alloys, giving the material a hard outer layer that is resistant to wear, while retaining a softer and more ductile core that can better respond to stress without cracking. Processes like carburizing allow manufacturers to work with softer materials while still meeting the basic hardness requirements for an application. Although it does not add strength to the material, it does increase the hardness of the material's outer layer, making it more wear-resistant than it would otherwise be. This is achieved by diffusing carbon into the alloy's surface after manufacturing. In this thermal process, ferrous alloys are heated above their transformation temperature and exposed to a carbon-rich environment. Treatment temperatures range between 790 °C1040 °C. The diffusion of carbon into the part and subsequent cooling result in a piece with a hard, wear-resistant surface and a tough, impact-resistant core. Here the concept of the carburization process is shown. Here the concept of the carburization process is shown. Low carbon steel parts exposed to carbon-rich atmospheres, derived from a wide variety of sources, can be carburized at temperatures of 850 °C and higher. In the most primitive form of this process, the carbon source is so rich that the carbon solubility limit in austenite is reached on the steel surface and some carbides may form on the surface. The goal of current practice is to control the carbon content of the furnace atmosphere such that the final carbon concentration on the part's surface is below the solubility limit in austenite. . 4 Relationship between case depth and holding time Purpose The topic is of great importance because the practice of carburizing steel in the industry is an economic factor that adds high added value to a given metallurgical product; the significance of the generalization of this practice is obvious, as it would have considerable economic repercussions. The proper use of this process will result in obtaining a high-quality product with elevated physical properties, especially mechanical ones. It would be very extensive to try to list here the industrial applications of the process, however, in general, it is applied to machinery parts that are subjected to special working conditions, such as cams, camshafts, gears, pinions, bearings, screws, tools, etc. Solid carburized Simple introduction Carburization is a fundamental process in metallurgy that involves enriching the surface of a metal with carbon to improve its mechanical properties. This technique ancient has been used throughout history to strengthen materials and prolong their life useful in various industrial and engineering applications. The carburization process is carried out by different methods, ranging from exposure of the metal to a carbon-rich atmosphere up to immersion in liquids or application of carbonaceous solids at high temperatures. These methods allow the carbon infiltrates the surface of the metal, forming carbides that improve hardness, resistance to wear and corrosion resistance. The choice of carburizing method depends on factors such as the type 5 of metal, the required properties and the specific application of the treated component. Therefore it is It is crucial to understand the different processes and their implications to obtain the results desired efficiently and effectively. Solid carburizing is a heat treatment method used to increase the carbon content on the surface of a metallic material, usually steel. This The process is carried out by exposing the metal to a solid source of carbon at high temperatures. During treatment, carbon diffuses into the metal surface, forming carbides. that increase hardness and wear resistance. Process: 1. Metal preparation: Before performing solid carburizing, it is important to clean and Prepare the metal surface to ensure uniform carbon diffusion. This can involve the removal of oxides and surface coatings through cleaning techniques chemical or mechanical 2. Exposure to solid carbon: Once prepared, the metal is placed in direct contact with a solid source of carbon, such as coal dust, graphite, animal bones, or compounds carbonaceous. The metal and carbon source are placed in a furnace or treatment chamber thermal and are heated to high temperatures, typically above 900 °C. 3. Carbon diffusion: As the metal is heated, the carbon in the solid source is diffuses on the surface of the metal. The elevated temperature allows the carbon atoms integrate into the crystalline structure of the metal, forming carbides in the surface layer 4. Controlled cooling: Once the diffusion stage is completed, the metal is cooled slowly in the oven to avoid stress and distortion. Controlled cooling allows the crystal structure to gradually stabilize, ensuring properties uniform mechanics throughout the piece. Solid carburizing is a versatile process used in tool manufacturing, machinery components and parts subject to abrasive wear. Provides a layer hardened surface with high wear resistance, while maintaining a tenacious core and resistant. However, it is important to note that the thickness of the carburized layer and The depth of carbon diffusion can vary depending on the time and temperature of treatment, as well as the composition of the base material. 6 Another types of carburizing Liquid carburizing is a process in which metal is immersed in a hot liquid rich in carbon, such as sodium cyanide, at high temperatures. The carbon in the liquid diffuses into the surface of the metal, forming carbides that increase hardness and resistance to wear. After immersion, the metal cools slowly and can receive additional treatments as necessary. This method is useful for treating complex shaped parts and provides a hardened surface layer to improve durability in high abrasion applications. Without However, strict safety measures must be followed due to the toxicity of the liquids. fuels. Gas carburizing is a heat treatment process in which the metal is exposed to a carbon-rich atmosphere at high temperatures. During this process, the atoms of carbon in the gas react with the metal, diffusing on its surface and forming carbides that increase hardness and wear resistance. This method is commonly used in industry to treat steel parts and provide them with a hardened surface layer. Is especially effective for complex shaped components and can be done in batches of pieces simultaneously. Gas carburizing offers excellent controllability of the process and can be adapted to achieve different depths of carburization according to the specific needs of the application. Vacuum carburizing is a process where the metal is placed in a vacuum environment controlled and exposed to carbon gas or vapor. This allows for more precise carburization and uniform, without contamination from other elements. It is useful for materials sensitive to oxygen and application ones that require high precision. Although it can be more expensive and requires equipment specialized, offers benefits such as precise process control and uniformity in the carburization. 7 Plasma carburizing is a process in which a carbon-enriched plasma is used to increase the carbon content on the surface of a metal. This is achieved by diffusion of carbon in the surface layer of the metal, forming carbides that increase its hardness and wear resistance. This method is fast, uniform and suitable for a variety metals, but requires specialized equipment and precise process control. Carburizing Theory The carburizing of steel can be explained from two fundamental concepts. The first is diffusion, influenced by the properties of iron and related to the movement of carbon in the iron itself; the second deals with the source that supplies the carbon and the transfer of carbon to the surface. Fick's first law.: describes diffusion under equilibrium conditions and is expressed mathematically by: Where D1 is the diffusion coefficient and j1 is the resulting flow gradient. Fick's second law: expresses the condition of diffusion disequilibrium where the concentration, at a point, changes with respect to time. 8 Carburizing is an imbalance process, that is, the gaseous components of the atmosphere are not completely in equilibrium with each other and the atmosphere is not in equilibrium with the steel being carburized. The equilibrium state of a chemical reaction The equilibrium state for chemical reaction The equilibrium state for chemical reactions can be represented by numerical constants, Kp, derived from the general expression. where Kp is called the "equilibrium constant", which is obtained from the values of the concentrations of the reactants and products of a chemical reaction. The subscript p indicates the dependence of the chemical reaction on pressure. T is the absolute temperature at which the reaction occurs. A and B are constants derived for the specific reaction. Carburetion control factors Instead of being developed formally from basic principles, the carburetion mechanism can be analyzed from the point of view of carbon flow, establishing the controlling factors.3 These factors can be divided for discussion into two distinct classifications: 1. Factors controlling the proportion of carbon in iron 2. Factors that influence the transfer of carbon to the iron surface The flow of carbon in iron Iron, when heated in the presence of carbon, forms a solid solution. A solid solution can be described as a solution of two or more components, such as solute and solvent, that share their atoms in their initial cells in the solid state. In other words, a solution can be defined as any phase whose composition can vary continuously within certain limits. Carburizing deals with the solid solution of carbon in austenite. The carbon content limits of this phase depend on temperature. The solid solution of carbon in gamma iron is an interstitial type of solid solution. As can be seen from the thermal equilibrium diagram of iron 9 and iron carbide, at a temperature below about 9101C (1183 K), pure iron occurs as a body-centered cubic (bcc) structure. Above 9101C (1183 K) there is a temperature range in which iron has a face-centered cubic (fcc) structure. Carbon, being an extremely small atom, can move into this hole to produce a solid solution of iron and carbon as shown. When iron has a bcc structure at lower temperatures, the interstices between the iron atoms become much smaller and, consequently, the solubility of carbon in bcc iron is relatively small. It shows the carburizing procedure in which a low-carbon iron (carbon-free iron) is maintained for several hours at a high temperature in contact with an atmosphere, such as natural gas, capable of providing carbon to the metal. The initial carbon content of the iron plate is zero at all distances from the surfaces. As the carbon atoms dissolve on the surface of the iron, they are free to diffuse further into the plate. The rate of carbon flux in austenite depends on the values of the diffusion coefficient and the characteristics of the concentration gradient. The diffusion coefficient is in turn a function of temperature and carbon concentration. Carbon diffusion proceeds from the highest concentration, developed from the supply source, to the lowest concentration. 10 Diffusion proceeds more rapidly along grain boundaries because this is a zone of crystalline imperfections.10 At the grain boundaries between two adjacent grains there is a transition zone that is not aligned with either grain as shown. Misalignment of the orientation of adjacent grains results in less efficient packing of atoms along the boundary. Therefore, the atoms along the boundary have a higher energy than those inside the grains. This higher energy of the boundary atoms is important for the nucleation of polymorphic phase changes and the lower atomic packing along the boundary favors atomic diffusion. Interstitials are the most prominent point defect that favors the diffusion of carbon in iron and steel. It arises when an additional atom is included within a crystal structure, especially if the atomic packing factor is low. Such an imperfection produces atomic distortion as shown, unless the interstitial atom is smaller than the rest of the atoms in the crystal. The interstitial mechanism moves atoms between neighboring atoms in the crystal structure shown. The interstitial atom has the same probability of moving in all six coordinate directions. If atoms change location, the 'energy ridges' must be overcome. Microstructures of Cemented Steels The microstructures of hardened case-hardened steels present high-carbon martensite on the surface and low-carbon martensite in the core. High-carbon martensite gradually transforms into lower-carbon martensite as distance from the surface increases. Lightly tempered martensite is the main microstructural constituent of properly casehardened steel. However, the morphology, quantity and properties of martensite vary depending on the distance from the surface. 11 Martensite Martensite is the dominant microstructural constituent in properly casehardened steel. It changes in morphology, quantity and properties depending on the distance from the surface. In addition to martensite, other microstructural constituents may be present, such as retained austenite, carbides of various origins, sizes and morphologies; inclusions; previous austenite grain boundaries embrittled by phosphorus segregation; microcracks; and surface oxides induced by processing. Compressive residual stresses produced during tempering are superimposed on the microstructures of the case. The core microstructures, depending on hardenability, can consist of quenched martensite, bainite or ferrite and pearlite. Martensite Formation The formation of martensite in carburized steels is a complex process that depends on the cooling rate. Under a slow or moderate cooling rate, carbon atoms can diffuse out of the austenite structure, allowing iron atoms to move slightly to form a body-centered cubic (bcc) structure. This transformation from austenite to ferrite is diffusion controlled and time dependent. With a further increase in the cooling rate, not enough time is allowed for the carbon to diffuse out of solution. Although some iron atoms move, the structure cannot become bcc as long as the carbon atom is trapped in solution. The microstructure. The resulting material is called martensite, which is formed from austenite by a diffusionless shear transformation. Quenching has the important function of providing cooling rates rapid enough to suppress competitive diffusion- controlled transformations of austenite. Martensite is a supersaturated solid solution of carbon trapped in a body- centered tetragonal (bct) structure, where two dimensions of the unit cell are equal, but the third is slightly expanded due to the trapped carbon. During carburization, carbon is introduced into the austenite, typically at a temperature of around 925°C. After carburization, martensite is produced by quenching. This martensite is reheated or quenched at low temperature (150– 180 °C) to produce low temperature quenched (LTT) martensite. This LTT martensite is the main component of the carburized microstructure that gives the desired properties to the carburized steel. Carburizing is applied to low-carbon steels that typically contain 0.2% by weight of C. The process introduces carbon to the surface of the steel, and the carbon diffuses into the low-carbon interior. Depending on the control of the atmosphere and the carburization temperature and time, surface carbon contents of 0.8% or more and carbon gradients over a range of distances or layer depths in the steel are produced. These carbon gradients have a profound influence on martensitic transformation, morphology and properties. The temperature at which martensite begins to form during quenching is designated as the martensite onset temperature, (Ms). As the carbon content increases, (Ms) decreases. 12 Martensite Morphologies Martensite that forms at low martensite initiation temperatures (Ms) has a plateshaped three-dimensional geometry, known as plate martensite. In the case of carburized low carbon Ni steels, the Adjacent martensite plates are not parallel, and under the optical microscope, the microstructure looks like a zigzagging series of needles or acicular shapes, which are actually cross sections of the martensite plates. After quenching, the plates are dark stained and surrounded by white-appearing retained austenite. The amount of martensite formed is determined solely by cooling below (Ms); Therefore, the lower (Ms) is, the lower the amount of martensite and the higher the amount of austenite retained after cooling to room temperature. In contrast to high-carbon regions, martensite that forms in medium- or low- carbon austenite assumes a completely different morphology. Martensite crystals appear to have a ribbon-shaped geometry: the crystals are relatively thin and flat, with a long dimension, and adjacent crystals form parallel to each other in stacks or packages like the following image. The high Ms temperature of low carbon austenite provides a much wider temperature range over which martensite can form during quenching, and therefore, there is little or no retained austenite in quenched low carbon lath martensites. At room temperature. With increasing carbon content, the amount of austenite retained in the martensitic lath microstructures increases, but the austenite is retained as thin films between the laths and is not resolved in the optical microscope. The carbon gradients introduced into the austenite by carburization result, after quenching, in a gradient of martensitic microstructure, ranging from plate martensite morphologies with large amounts of austenite Retained until martensitic ribbon microstructures. These gradients in the microstructure are directly related to the hardness and strength gradients produced by carburization. Although the features resolved in the optical microscope influence the hardness (especially the retained austenite, which coexists with the plate martensite in the case region), it is the carbon-dependent fine structure of the LTT martensite crystals that mainly determines the resistance gradients in carburized steels. Effect of Tempering Quenching of freshly quenched martensite at low temperatures results in the precipitation of very fine carbides to relieve carbon supersaturation. Low quenching temperatures of 150–180°C ensure that the precipitated carbides remain fine. Furthermore, the retained austenite remains stable at these low temperatures. Therefore, the only 13 microstructural changes produced by quenching occur at a very fine scale within the martensite plates. The carbides formed are not cementite, which is formed by quenching at higher temperatures, but transitional carbides. These transition carbides have been designated as epsilon carbides or eta carbides, depending on minor differences in their crystal structures and diffraction patterns. High dislocation densities, produced by the deformations that accompany subsequent martensitic and quenching transformations, are also associated with transition carbides. Role of Transition Carbides The carbon content in martensite determines the density of the transition carbide clusters after quenching. These carbide arrangements and associated dislocation substructures make deformation by sliding or dislocation movement difficult. As a result, the hardness and strength of LTT (low temperature quenching) martensite increase with increasing carbon content. This is illustrated in the following image, which shows the hardness of the freshly quenched martensitic microstructures and the LTT martensitic microstructures quenched between 150 and 180 °C. The increase in hardness is almost linear up to 0.8% C. At higher carbon contents, the rate of increase in hardness decreases due to greater amounts of retained austenite. Low temperature quenching reduces the hardness of freshly quenched martensite due to relief of carbon supersaturation and stress relief, but increases toughness. 14 Conclusion The topics discussed above were investigated and summarized in order to obtain a clear concept about the carburization processes, the importance they have and the effect of applying different ways of carburizing an alloy, in addition to knowing the quality-price relationship they have. with the industry and the high efficiency of these alloys despite having a low-cost carburization process.