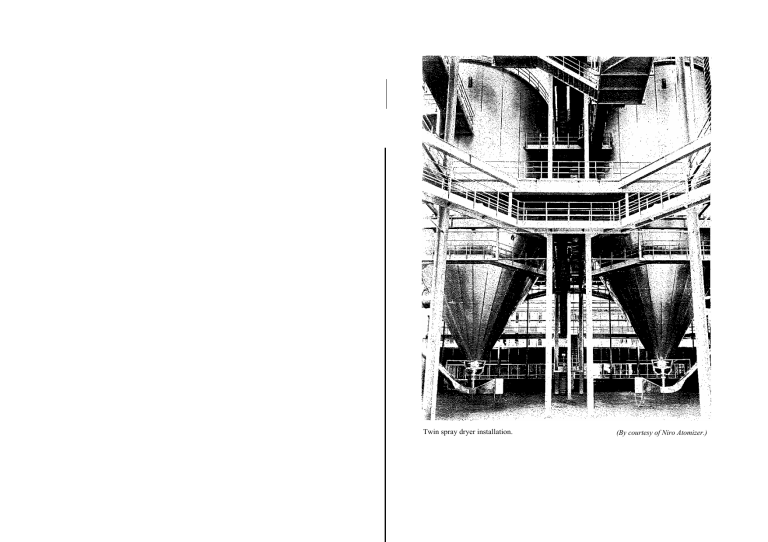

Twin spray dryer installation.

(By courtesy of Niro Atomizer.)

CHEMICAL AND PROCESS ENGINEERING SERIES

Spray Drying

An Introduction to Principles,

Operational Practice and Applications

K. MASTERS

LEONARD HILL BOOKS LONDON

AN INTERTEXT PUBLISHER

Published by

Leonard Hill Books

a division of

International Textbook Company Limited

158 Buckingham Palace Road, London SWI W9TR, and

24 Market Square, Aylesbury, Bucks

© K. Masters 1972

All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any

means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner.

First published 1972

ISBN 0 249 44093 8

c

Printed in Great Britain by J. W. Arrowsmith Ltd

To My Loving Wife, Ben to

for her patience and understanding during the many long

months of writing, and for her crowning the completion of

the book with a supreme gift, Caroline, a sister for Stephen.

Preface

The importance of spray drying, as illustrated by the rapid expansion

of spray drying facilities in all regions of industry, has not been reflected in

literary coverage of developments in industry: I have long felt a book

dealing specifically with the spray dryer operation is long overdue, In all

standard text books and handbooks on chemical and mechanical engineering, spray drying has been restricted to limited coverage under the section

headed 'Drying', and in most of these cases coverage consists of a few paragraphs following detailed handling of the more traditional drying operations,

for example, tray, rotary and drum drying. This, tdo';Carii be said of books

dealing specifically with drying where the text on spray rying is general in

nature. *

The true status of spray drying has not been truly voice

of applications being varied—ranging from low prodUction - rates,m the most

delicate pharmaceutical operations to high tonnage- Procinction :;:t1

inorganic chemicals. The purpose of this book is toprovide' a:sre erence

.,

medium covering spray drying principles, equiprnent, operatiOnat practice

and applications. By discussing these aspects in various degreeS Ofdetai

I hope to focus more attention on spray drying as a highly specialized

operation, fully established in many fields of inthistry.

The script has been prepared for both personnel associated with spray

drying and students of industrial drying. 1 have tried to relate the current

knowledge of the subject in practical terms, with worked examples to show

that theoretical principles, when backed up by practical experience, can be

often applied to predict, assess, and optimize spray dryer performance, to

* (a) Publications devoted solely to spray drying: see Marshall (35), Lykov and Lenochik

(478;) (b) recent publications containing chapters on spray drying: see Dombrowski and.

Munday (30), Williams-Gardner (376), Nonhebel and Moss (479); (c) literature reviews"on

spray drying: see Masters (I), McCormick (494).

ix

X PREFACE

select the most suitable dryer designs for a particular application, and to

show how limitations in existing designs can be rectified through equipment

modification. Theoretical models used to describe the spray dryer operation

are not discussed in detail. The majority of important equations are just

stated, and not derived. To those readers who wish to study aspects of spray

drying in greater depth, adequate references are given.

The choice of units for this book presented a difficult decision. In my

experience of spray drying installations, personnel concerned with their

operation do not use or have not as yet become familiar with the SI units

system due to become standard in the mid-seventies, Based upon the practical emphasis intended for the script I decided to maintain existing units,

joining in line with the latest editions of standard chemical and mechanical

engineering textbooks and handbooks. Many of these established books are

either American or English in Origin, thus based upon the British unit

systems. However, there are numerous personnel with spray drying interests

operating in areas using metric systems. As a compromise I have tried to

utilize both systems, by duplicating data where convenient, and by presenting

worked examples in either one set of units or the other, Perhaps this is far

from ideal, and I expect comment on this decision but I feel this approach

will familiarize the text to a greater number of people than had I used one

set of units throughout. Most people are familiar with both sets of units,

but feel more competent in one than the other, although they possess the

ability to convert units quickly.

Worked examples have been included in the text to illustrate use of

theoretical principles, empirical equations and operation of equipment.

Calculations throughout have been conducted using a slide rule or logarithmic tables, items that are readily available to personnel from management

to plant operator levels. Only in chapter 7 (example 7.4) dealing with droplet

motion in air was a computer used to eliminate the need to rework constantly

a given equation.

The writing of this book would not have been possible without the cooperation of the management of Aktieselskabet Niro Atomizer, Copenhagen,

(N.A.), and permission to use much of the pictorial material owned by N.A.

I wish to put on record my indebtedness to the late Dr. K. Nielsen, who as

Head of the Research and Development Department of N.A. encouraged

the commencement of the project, and who made available to me an extensive literature survey on spray drying.

I also wish to acknowledge the help of so many of my colleagues, whose

critique of the text proved so useful in the final preparation of the text for

the publisher. All I duly thank. Certain of my colleagues assisted so generously that special thanks are due ; Dr. S. Hovmand, Mr. M. Petersen,

for their assessment and suggestions in the first eleven chapters, Mr. Aa,

PREFACE xi

Moller for his opinions on atomization, Mr. M. Troldborg, whose experience

in the field of auxiliary equipment and operational practice I drew heavily

upon, Mr. J. Due Jensen for his unselfish assistance in tabulating patent

coverage of spray drying, Messrs. E. Houghton-Larsen, H. Justesen, and

J. Storm for their invaluable suggestions for improving the section on spray

drying operations, last but not least Mr. J. Pilegaard for the services of the

Information Department.

I wish to express my thanks to my wife and sister who assisted with the

preparation of the text, and to all the secretaries, who typed the text so well,

no mean task dealing with a tongue far removed from their native Danish.

My thanks also go to the ladies who assisted in preparing drawings, especially

Mrs. Lundgaard on whom the bulk of the work fell.

While acknowledging such assistance, I must emphasize that the interpretation of spray drying presented here is solely mine, and does not

necessarily agree with the official view of my employer (N.A.).

It is hoped that my handling of the script encourages greater use of the

spray drying operation and that, by providing a reference book, I have

helped fill the literature gap that exists as far as spray drying is concerned.

If these goals are achieved, the energies expended will be fully rewarded,

since there can be no disputing that spray drying today is a subject in its

own right.

Spray drying is a relatively new technique, but is already broad in scope.

The selection of material had to be a matter of personal choice. However,

to those readers who feel the text could be enhanced by clarification of any

part, or by further addition, I would be grateful to hear their suggestions.

K. Masters

Skovlunde

Denmark 1972

Contents

Preface

List of figures

List of tables

Introduction

ix

xxv

xxxiii

1

SECTION 1—BASIC PRINCIPLES, DEFINITIONS

I SPRAY DRYING FUNDAMENTALS

2 REPRESENTATION OF SPRAYS

2.1 Terminology

2.1.1 Droplet

2.1.2 Particle

2.1.3 Agglomerate

2.1.4 Size

2.1.5 Particle shape

2.1.6 Size distribution

2.1.7 Mean size

2.2 Methods of Data Presentation

2.2.1 Tabular form

2.2.2 Graphical form

(a) histograms

(b) size frequency curves

(c) cumulative plots

2.3 Analysis of data

2.3.1 Mean diameters

(a) most frequent diameter

(b) arithmetic mean diameter

11

23

23

23

23

23

25

25

25

25

26

27

27

27

27

28

28

28

29

29

X1V

CONTENTS

(c) geometric mean diameter

(d) harmonic mean diameter

(e) median diameter

2,3.2 Distribution functions

(a) normal distribution (Gaussian)

(b) log-normal distribution

(c) square root normal distribution

(d) empirical distribution functions

(i) Nukiyama–Tanasawa distribution

(ii) Rosin–Rammler distribution

(iii) upper limit function

2.3.3 Mean droplet diameter transformations

3 DRYING TERMS AND PRINCIPLES

3.1 Common Terms and Principles

3.2 Applying the Psychrometric Chart to the Spray Drying

Process

4 PERFORMANCE OF SPRAY DRYERS

4.1 Introduction

4.2 Heat and Mass Balances over Spray Dryers

4.3 Dryer Efficiency

4.4 Residence Time in Drying Chamber

5 EQUIPMENT INCORPORATED IN SPRAY DRYERS

5.1 Introduction

5.2 Passage of Air and Product through a Spray Dryer

5.3 Equipment Items Making up a Spray Dryer Layout

5.3.1 Equipment comprising the feed system

5.3.2 Atomizer

5.3,3 Equipment comprising the supply air system

5.3.4 Air disperser and drying chamber

5,3.5 Equipment for separation and recovery of product

from exhaust air

29

30

30

33

33

34

34

35

35

35

37

38

42

42

47

54

54

55

59

62

65

65

65

66

66

68

70

72

78

SECTION II—THE PROCESS STAGES OF SPRAY DRYING

6

ATOMIZATION

6.1 Introduction

6.2 Basic Mechanism of Atomization

6.3 Classification of Atomizers

6.4 Application of Basic Mechanisms to Commercial Atomizer

Conditions

6.5 Rotary Atomization

6.5.1 Introduction

6.5.2 Flat smooth disc atomization (vaneless)

87

87

87

91

92

93

93

93

6.6

CONTENTS

XV

(a) flow over smooth flat vaneless discs

(b) droplet size from smooth flat vaneless discs

6.5.3 Wheel atomization (atomizer wheels)

(a) introduction

(b) flow over a vaned wheel

(i) radial velocity

(ii) tangential velocity

(iii) resultant release velocity

(iv) angle of liquid release

(c) effect of operating variables on droplet size

(i) effect of liquid feed rate on droplet size

(ii) effect of peripheral speed on droplet size

(iii) effect of liquid viscosity on droplet size

(d) prediction of mean droplet diameter and spray size

distribution

(i) mean droplet diameter

(ii) size distribution

(iii) weight distribution of sprays

(e) atomizer wheel performance during spray drying

(i) air pumping effects

(ii) drying air entry

(iii) particle shape change

(f) atomizer design requirements

(i) atomizer drive

(ii) liquid distributor

(iii) atomizer wheels

(g) applications of atomizer wheels

6.5.4 Disc atomization (vaneless bowls, cups, plates)

(a) introduction

(b) fluid flow over vaneless discs

—radial velocity

—tangential velocity

(c) droplet size prediction

(d) performance of vaneless discs

(e) applications of vaneless discs

Nozzle Atomization

6.6.1 Introduction

6.6,2 Centrifugal pressure nozzle

(a) theoretical principles

(b) spray patterns

(c) fluid flow from centrifugal pressure nozzles

(d) nozzle operating characteristics

97

100

100

100

102

103

104

104

104

105

108

109

112

113

114

118

126

127

127

129

130

135

135

141

142

148

148

148

150

151

151

152

154

157

158

158

159

159

162

165

170

XV1

CONTENTS

(i) relation between flow rates, pressure and

density

(ii) spray angle

(iii) effect of operating variables on droplet size

—effect of capacity on droplet size

—spray angle and droplet size

—effect of pressure on droplet size

—effect of feed viscosity on droplet size

—effect of surface tension on droplet size

—effect of orifice size on droplet size

(iv) droplet size distribution

(e) prediction of nozzle performance

(f) prediction of mean droplet size of sprays from

centrifugal pressure nozzles

(g) nozzle operating features and nozzle applications

(h) nozzle assemblies for commercial use

6.6.3 Pneumatic (two-fluid) nozzle atomization

(a) theory

(b) design features

(c) droplet release and spray angle

(d) spray characteristics

(e) effect of variables on droplet size

(i) effect of air–liquid ratio

(ii) effect of relative velocity on droplet size

(iii) effect of viscosity on droplet size

(iv) effect of air density on droplet size

(f) prediction of mean droplet size

(i) Nukiyama–Tanasawa equation

(ii) Gretzinger–Marshall equation

(iii) Kim–Marshall equation

(iv) Kim–Marshall equation (three-fluid nozzle

atomizer)

(g) comparison between the spray characteristics of

two- and three-fluid nozzles

(h) pneumatic nozzle assemblies and their operation

(i) advantages and disadvantages of pneumatic

nozzles

(j) applications

6.6.4 Rotating pneumatic cup atomizers

(a) introduction

(b) effect of variables on droplet size

(c) prediction of mean droplet size

170

170

171

171

172

172

173

174

174

174

175.

182

188

193

196

196

197

199

200

201

201

202

202

202

202

206

211

217

221

221

222

227

228

229

229

231

232

CONTENTS

XVii

(d) prediction of droplet size distribution

6.7 Sonic Atomization

6.8 Atomizer selection

7 SPRAY-AIR CONTACT (MIXING AND FLOW)

7.1 Introduction

7.2 General Principles

7.3 Droplet Trajectory Characteristics

7.3.1 From rotary atomizers (atomizer wheels)

7.3.2 From nozzle atomizers

7.4 Droplet Moverhent in Drying Chambers

7.4.1 Droplet release velocities

7.4.2 Droplet deceleration

(a) from rotary atomizers

(b) from nozzle atomizers

7.4.3 Terminal velocity (spherical droplets)

7.4.4 Droplet movement : distance–time relationships

(a) droplet movement in non-rotating air

(i) motion from rotary atomizers

(ii) motion from nozzle atomizers

(b) droplet movement in rotating air

(i) large diameter chambers

(ii) small diameter chambers

7.4.5 Product deposition on chamber wall

(a) in small chambers

(b) in large chambers

8 DRYING OF DROPLETS/SPRAYS

8.1 Introduction

8.2 Evaporation of Pure Liquid Droplets

8.2.1 Evaporation of single droplets

(a) droplet evaporation under negligible relative

velocity conditions

(b) droplet evaporation under relative velocity

conditions

(c) evaporation under high air temperature conditions

8.2.2 Evaporation of sprays of pure liquid droplets

8.3 Evaporation of Droplets Containing Dissolved Solids

8.3.1 Evaporation of single droplets

(a) vapour pressure lowering effect

(b) effect of dried solid formation in droplets

(c) droplet evaporation times

8.3.2 Evaporation of sprays containing dissolved solids

8.4 Evaporation of Droplets Containing Insoluble Solids

233

234

235

241

241

247

249

249

251

251

251

252

252

253

256

261

261

261

267

271

271

273

274

275

276

279

279

281

282

282

284

293

297

302

302

302

303

305

309

310

XViii

CONTENTS

8.5

9

Drying in Media Other than Air

8.5.1 Drying in gases

8.5.2 Drying in superheated vapours

8.5.3 Drying in superheated steam

8.6 Dried Product Properties on Completion of Drying

8.6.1 Effect of operating variables on product properties

(particle size and bulk density)

(a) effect of feed rate

(b) effect of feed solids

(c) effect of feed temperature

(d) effect of surface tension

(e) effect of inlet drying temperature

(f) effect of spray/air contact velocity

8.6.2 Formation of hollow particles

8.7 Size Differences between Product before and after Drying

8.7.1 Procedures to predict dried particle size distribution

(a) graphical method

(b) mathematical method

8.8 Size Distributions of Wet Sprays and Resulting Dried

Particles

SEPARATION AND RECOVERY OF DRIED PRODUCT FROM AIR

9.1 Introduction

9.2 Selection of Equipment for Separating Powder from

Exhaust Drying Air

CONTENTS

313

314

314

315

316

11

316

316

316

316

317

318

319

319

319

320

320

320

322

324

324

327

10

CONTROL SYSTEMS

1 0, 1 Control System (based upon feed rate regulation)

10.2 Control System (based upon heat input regulation)

10.3 Feed System Controls

10.3.1 Systems for rotary atomizers

10.3.2 Systems for nozzle atomizers

10.4 Interlocks

10.5 Fully Automatic Spray Dryers

10.5.1 Programmed start-up

10.5.2 Full automation of spray dryer and feed

pretreatment

10.6 Precaution Against Fire and Explosion

10.7 Control Systems for Preventing Fire/Explosion

Conditions in Deposit Formations

335

336

338

339

339

339

340

341

341

344

347

349

352

352

352

356

357

357

364

365

371

378

378

380

384

385

385

386

388

390

392

393

398

SECTION IV—SURVEY OF AUXILIARY EQUIPMENT

12

SECTION III—OPERATIONAL PRACTICE

OPERATIONAL MEASUREMENTS

11.1 Determination of Air Flow

11.1.., Supply air to dryer

11.1.2 Exhaust air leaving dryer

11.2 Measurement of Air Velocity in Ducts

11.2.1 Pitot tube measurement

11.2.2 Orifice/venturi measurements

11.2.3 Anemometer measurements

11.3 Determination of Powder Loading in Air Flows

11.3.1 Manual sampling

(a) cyclone probe (B.C.U.R,A.) method

(b) internal filter thimble method

(c) external filter thimble method

11.3.2 Continuous sampling

(a) light intensity methods

(b) electrostatic methods

(c) CEGRIT sampler

11.3.3 Determination of dried product losses from

mass balance techniques

11.3.4 Reducing powder losses from spray dryer

exhaust systems

11.4 Assessing Acoustic Environment (Noise Levels)

11.5 Measurement of Droplet and Particle Size

xix

SURVEY OF AUXILIARY EQUIPMENT

12.1 Air Heaters

12.1.1 Steam air heaters

12.1.2 Fuel oil air heaters

12.1.3 Gas air heaters

12.1.4 Electric air heaters

12.1.5 Liquid phase air heaters (thermal fluid heaters)

12,2 Fans

12.2.1 Fan requirements on a spray dryer layout

12.2.2 Fan parts and principles

12.2.3 Fan characteristics

12.2.4 Fan laws

12.2.5 Fan efficiency

12.2.6 Fan horsepower

12.2.7 Effect of altitude on fan performance

12.2.8 Fan mounting

12.2.9 Fan noise

401

401

401

404

406

406

406

407

408

408

410

411

414

415

418

418

418

XX

CONTENTS

CONTENTS

12.2.10 Fan selection

Mechanical Powder Separators

12.3.1 Dry collectors

(a) dry cyclones

(i) cyclone performance

(ii) overall cyclone efficiency

(iii) pressure drop over cyclones

(iv) cyclone layouts

(b) bag filters

(i) principles

(ii) bag filter designs

(iii) bag filter performance

(iv) pressure drop over bag filters

(v) bag filter fabrics

(vi) use of bag filters

(vii) bag filter layouts

(c) electrostatic precipitators

(i) principles

(ii) performance of electrostatic precipitators

(d) gravity settlers

12.3.2 Wet collectors

(a) wet scrubbers

(i) principles

(ii) wet scrubber designs

12.3.3 Powder removal from mechanical separators

(dry collectors)

(a) hoppers

(b) powder removal valves

12.4 Pneumatic Powder Conveying

12.4.1 Principles

12.4.2 Pneumatic conveying systems in practice

12.4.3 Operational difficulties with pneumatic

conveying systems

12.5 Pumps

12.5.1 Pump duties in spray dryers

12.5.2 Pump types and uses

12.6 Washing Equipment

12.3

419

419

420

420

422

424

427

431

432

432

432

435

436

436

436

437

437

437

438

439

440

440

440

443

445

445

445

451

451

455

456

458

458

460

460

SECTION V—APPLICATIONS OF SPRAY DRYING IN

INDUSTRY

13

14

APPLICATIONS OF SPRAY DRYING (A LITERATURE SURVEY)

APPLICATIONS IN THE CHEMICAL INDUSTRY

465

498

Plastics, Resins

14.1.1 Polyvinylchloride (P.V.C.)

14.1.2 Resins

14.1.3 SBR lattices

14.2 Ceramic Material

14.2.1 Wall tile and floor tile ceramics

14.2.2 Oxide ceramics

14.2.3 Plastic bodies

14.2.4 Glass

14.2.5 Carbides

14.3 Washing Powder

14.3.1 Heavy duty detergents

14.3.2 Light duty detergents

14.3.3 Soap powder

14.3.4 Soda products

14.3.5 Bleach powders

14.3.6 Optical brighteners

14.3.7 Perfumes for washing powder

14.4 Pesticides

14.4.1 Herbicides

14.4.2 Fungicides

14.4.3 Insecticides

14.5 Dyestuffs—Pigments

14.5.1 Titanium dioxide

14.5.2 Kaolin (china clay)

14.6 Fertilizers

14.6.1 Ammonium nitrate

14.6.2 Ammonium phosphate

14.6.3 Superphosphates

14.7 Mineral Ore Concentrates

14.7.1 Sulphide ores

14.7.2 Iron ores

14.7.3 Cryolite

14.8 Inorganic Chemicals

14.9 Organic Chemicals

14.10 New and/or Specialized Applications in the Chemical

Industry

14.10.1 Abrasives

14.10.2 Catalysts

14.10.3 Cement

14.10.4 Metal powders

14.10.5 Sodium carbonate

14.1

XXI

499

499

501

502

502

505

506

509

510

510

511

512

514

515

515.

517

517

518

518

520

521

521

521

522

523

526

526

528

530

533

535

535

537

537

537

538

539

539

540

542

543

xxii

15

CONTENTS

14.10.6 Sodium hydroxide

14.10.7 Titanium tetrachloride

APPLICATIONS IN THE FOOD INDUSTRY

15.1 Milk Products and Eggs

15.1.1 Milk products

(a) skim milk

(b) whole milk

(c) whey

(d) fat-enriched milk (milk replacer)

(e) sodium caseinate

(f) baby foods

(g) coffee/tea whiteners

(h) cheese

(i) ice-cream mix

(j) high fat powder for bakery use (also butter)

(k) buttermilk

15.1.2 Eggs

15.2 Beverages, Flavouring Compounds, Meats, Protein from

Vegetable Sources

15.2.1 Beverages

(a) instant coffee

(b) instant tea

15.2.2 Flavouring compounds

15.2.3 Meats

15.2.4 Edible protein from vegetable sources

(a) soya beans

(b) peanuts

(c) potato fruitwater

15.3 Fruits and Vegetables

15.3.1 Fruits

(a) tomatoes

(b) banana

(c) citrus fruits

(d) soft fruits

(e) other fruits

15.3.2 Vegetables

(a) beetroot

(b) asparagus

(c) peas

(d) mashed potato

15.4 Carbohydrates

15.4.1 Corn products

CONTENTS

543'

543

545

545

545

547

553

556

560

562

564

564

564

565

565

565

566

568

568

568

572

572

573

573

573

575

575

576

576

577

581

583

583

583

584

584

584

584

584

585

585

16

17

18

15.4.2 Wheat gluten

15.4.3 Sugar products

APPLICATIONS IN THE PHARMACEUTICAL-BIOCHEMICAL

INDUSTRY

16.1 Introduction

16.2 Enzymes

16.3 Antibiotics

16.4 Sera, Vaccines, Plasma and Substitutes

16,5 Micro-organisms

16.6 Yeast

16.6.1 Production of food yeast from sugar cane

molasses

16.6.2 Active yeast (brewers')

16.6.3 Barley powder

16.7 Vitamins

16.8 Pharmaceutical Gums

APPLICATIONS IN INDUSTRIES UTILIZING CHEMICALS FROM

TIMBER

17.1 Applications in the Tannin Industry

17.1.1 Manufacture of tannin from woods

17.1.2 Manufacture of tannin from barks

17.1.3 Manufacture of tannin from fruits

17.2 Applications in the Cellulose Industry

17,2.1 Concentrated sulphite waste liquor

17.2.2 Li gn osulphonates

APPLICATIONS IN THE OFFAL AND FISH INDUSTRIES

18.1 Spray Drying of Slaughterhouse By-products

18.1.1 Blood

18.1.2 Glands and tissues

18.1.3 Gelatin and glue

18.1.4 Excreta

18.2 Spray Drying of Fish Wastes

18.2.1 Stickwater (fish solubles)

18.2.2 Whole fish meal

18.2.3 Normal fish meal

18.2,4 Edible fish flour

18.2.5 Fish hydrolysates

SECTION VI—APPENDICES, NOMENCLATURE,

REFERENCES, INDEX

19 APPENDICES

A.1 Conversion Factors

XXiii

586

586

587

587

592

594

595

597

597

598

600

600

600

600

602

602

602

603

604

604

604

604

606

606

606

609

609

609

609

609

611

612

612

612

617

617

XXiV CONTENTS

A.2 Temperature Conversion Tables

A.3 Properties of Dry Air

A.4 Vapour Pressures of . Water

A.5 Psychometric Charts

1. Normal temperatures

2. Elevated temperatures

A.6 Humid Heat-Humidity Relation for Air-Water Vapour

System at Atmospheric Pressure

A.7 Temperature-Latent Heat of VaporizationTemperature Relation (Water)

A.8 Liquid Flow over Vaned Atomizer Wheel

A.9 Thermal Conductivity of some Insulation Materials

A.10 Sieve Sizes

A.11 Particle Size Distributions of Standard Powder Grades

for Use when Optimizing Cyclone Product Loading

20 NOMENCLATURE

21 REFERENCES

22 hsTDEX

620

622

623

624

624

625

626

List of Figures

627

628

630

631

633

634

640

654

Frontispiece Twin spray dryer installation

0.1 The process stages of spray drying

0.2 Layouts of spray dryers and associated suspended particle

processing equipment involving atomization

0.3 Dried powder forms produced by spray drying

1.1 The features of the process stages involved in spray drying

1.2 Equipment involved in a standard spray dryer layout

1.3 Atomizers in operation

1.4 Product-air flow in spray dryers

1.5 Air temperature distributions in co-current and counter-current flow spray dryers

1.6 Product discharge from co-current flow spray dryers with a

rotary atomizer

2.1 Range of droplet/particle sizes obtained in spray drying

operations

2.2 Size distribution of droplets and particles

2.3 Droplet size distribution represented in histogram form

2.4 Frequency and cumulative curves showing mean droplet

diameter values in example 2.1

2.5 Log normal distribution on probability paper

2.6 Droplet size distribution of a centrifugal pressure nozzle

(grooved core swirl) conforming to a square root normal

distribution

2.7 Rosin-Rammier size distribution

2.8 Comparisons of log normal, square root normal and upper

li mit distributions for a centrifugal pressure nozzle

Size

data for example 2,2

2.9

3.1 Graphical relation between common drying terms

XXV

3

5

7

12

13

15

17

18

20

24

26

27

30

35

36

37

38

41

43

XXVI

LIST OF FIGURES

3.2 Two applications of the psychrometric chart in spray drying

3.3 Drying characteristics of droplets during spray drying

4.1 Effect of feed solids content on dryer heat load

4.2 Dryer data for calculation of heat and mass balances

4.3 Drying process represented in example 4.2

5.1 Product and air passage through a spray dryer

5.2 Spray dryer layouts with rotary and nozzle atomization

5.3 Feed system involving a feed preheater

5.4 Basic types of atomizers

5.5 Atomizer positioning in drying chamber

5.6 Co-current flow dryers

5.7 Air disperser types creating rotary air flow around atomizer

5.8 Counter-current flow dryer

5.9 Mixed flow dryers

5.10 Primary product discharge from drying chambers

5.11 Total product discharge from drying chambers

5.12 Drying chamber wall cooling

5.13 Equipment for separation and recovery of airborne powders

5.14 Dry product conveying systems on spray dryers

6.1 Ohnesorge chart showing liquid jet disintegration as a

function of Reynolds number

6.2 Classification of atomizers

6.3 Mechanisms of atomization

6.4 Mechanisms of atomization (represented photographically)

6.5 Atomization mechanism for rotating discs

6.6 Liquid flow to and from edge of atomizer wheel

6.7 Effect of feed rate on mean droplet size for atomizer wheel

6.8 Effect of atomizer wheel peripheral speed on mean droplet

size

6.9 Effect of atomizer wheel speed of rotation on mean droplet

size (aqueous sprays)

6.10 Effect of feed viscosity on wheel atomization

6.11 Curves for prediction of spray size distributions from

atomizer wheels after the Herring-Marshall relation

6.12 Size relationship between droplet and particle in example 6.4

6.13 Spray weight distribution from rotary atomizers

6.14 Air flow through vaned atomizer wheel due to air pumping

effects

6.15 Pressure distribution at vaned atomizer wheel due to air

pumping effects

6.16 Arrangement for supplying cool air to atomizer wheel

6.17 Positioning of rotary atomizer in relation to air disperser

LIST OF FIGURES

48

49-50

55

56

61

66

67

69

70

71

73

74

75

76

77

79

80

81

83

89

91

95

96

98

102

108

109

111

113

119

125

126

128

129

130

131

XXVii

6.18 Atomizer drives

136

6.19 Rotary atomizer drives for atomizer wheels

139

6.20 Rotary atomizer with variable speed control through a

fluid coupling

140

6.21 Spindle pressurizing

141

6.22 Positioning of liquid distributor with atomizer wheel

142

6.23 Liquid distributor designs

143

144

6.24 Designs of vaned atomizer wheels

6.25 Abrasive wear on vaned atomizer wheel

146

6.26 Atomizer wheel with bushings for abrasive and corrosive

147

feeds

6.27 Disc atomizer (plate type, multiLtier)

149

6.28 Disc atomizer (cup type)

149

155

6.29 Effect of feed rate on mean droplet size from disc atomizer

6.30 Effect of atomizer disc speed on mean droplet size

156

6.31 Effect of number of plate tiers of a disc atomizer on particle

size distribution

157

158

6.32 Size distributions from atomizer wheels and discs

6.33 Centrifugal pressure nozzles

160

6.34 Inserts for generating liquid rotation within centrifugal

161

pressure nozzles

161

6.35 Centrifugal pressure nozzle construction

162

6.36 Spray angle characteristics

6.37 Velocity diagram for liquid flow from a centrifugal pressure

166

nozzle

168

6.38 Variation of feed rate with square root of nozzle pressure

6.39 Feed rate, feed pressure, feed density ratios for centrifugal

pressure nozzles

171

6.40 Effect of variables (feed rate, feed viscosity) on Sauter mean

172

diameter

173

6.41 Effect of feed viscosity on spray droplet size distribution

6.42 Typical droplet size distribution of a centrifugal pressure

174

nozzle used in spray drying

175

6.43 Nozzles with tangential feed entry

176-7

6.44 Nozzle dimensioning relations after Doumas and Laster

6.45 Nozzle dimensioning relations after Dombrowski and Hasson 180-1

6.46 Range of orifice sizes per given nozzle body for optimum

189

atomization conditions

6.47 Performance of centrifugal pressure nozzles (rated on

192

aqueous feed) on 42 % TS skim milk concentrate

194

6.48 Positioning of nozzles in relation to air disperser

198

6.49 Designs of pneumatic nozzle heads

XXViii LIST OF FIGURES

6.50 Effect of nozzle operating variables on spray mean droplet

size

6.51 Nozzle designs used in pneumatic nozzle investigations

6.52 Nukiyama-Tanasawa plot for converging two-fluid nozzles

operating on aqueous feed

6.53 Nukiyama-Tanasawa distribution (a typical plot)

6.54 Gretzinger-Marshall plot for converging two-fluid nozzles

6.55 The Gretzinger-Marshall droplet size relation expressed as a

nomograph

6.56 Plot of film thickness against feed rate

6.57 Dimensions of nozzle design in example 6.15

6.58 Size distribution for two-fluid nozzle (after Kim-Marshall)

6.59 Piping connections for pneumatic nozzles

6.60 Feed systems for pneumatic nozzles (two-fluid)

6.61 Feed and air distribution rings for pneumatic nozzles

6.62 Two-fluid paste nozzle with screw feeder

6.63 Atomization mechanism for a pneumatic cup atomizer

6.64 Pneumatic cup atomizer head

6.65 Pneumatic cup atomizer and air disperser positioning in

drying chamber

6.66 Particle size distributions of rotary and nozzle atomizers

operating on silica and alumina based catalysts

6.67 Modifications of the atomizer drive to handle liquid, powder

or liquid-powder feeds

7.1 Air disperser for rotary atomizers (in co-current flow dryers)

7.2 Ceiling air disperser with rotary (vaned wheel) atomizer in

co-current flow dryer

7.3 Air disperser for nozzle atomizers in co-current flow dryers

7.4 Air disperser for counter-current flow dryers

7.5 Air dispensers and atomizers in mixed flow dryers

7.6 Plot of R f I pv 2 against Reynolds number for spherical particles

7.7 Plot for CD Re 2 against Re for spherical particles

7.8 Plot of drag coefficient against Reynolds number

7.9 Areas of likely wall impingement of partially dry product

in small dryers

7.10 Impingement area control by air disperser adjustment in

large dryers with rotary atomization

8.1 Drying rate curve

8.2 Configuration of droplet evaporating in high temperature

surroundings

8.3 Estimation of temperatures of droplets containing dissolved

solids

LIST OF FIGURES XXiX

203

204

207

208

211

212

214

217

220

223

224

225

226

230

231

232

236

239

243

244

245

246

247

250

257

260

277

278

280

295

302

Effect of crust properties on evaporation times

Characteristics of droplet undergoing drying (drying air

above boiling point)

8.6 Characteristics of droplet undergoing drying (drying air

below boiling point)

8.7 Temperature profile in example 8.4

8.8 Temperature of droplet undergoing evaporation in air and

superheated vapour

8.9 Effect of feed concentration on bulk density of spray dried

products

8.10 Effect of inlet drying air temperature on bulk density of

spray dried products

8.11 Graphical determination of size distribution of dried product

from that of wet spray

9.1 Product discharge from conical and flat chamber bases

9.2 Exhaust ducts layouts with primary product discharge from

conical chamber base

10.1 Outlet air temperature chart for dryer operation under

manual and automatic control

10.2 Control system A: outlet temperature control by regulation

of feed rate, inlet temperature control by regulation of

fuel combustion rate

10.3 Control system B: outlet temperature control by regulation

of fuel combustion rate, manual regulation of feed rate

10.4 Control system for pressure nozzles (control system A)

10.5 A combined block and schematic diagram for a fully

automated spray dryer

10.6 Automatic feed solids content measuring equipment used in

fully automatic spray drying plant in the dairy industry

10.7 Block diagrams for automatic control of combined

evaporator and spray dryer systems

11.1 Pitot tube with inclined manometer

11.2 Positions for velocity measurement by pitot tube in circular

duct (equal duct areas)

11.3 Positions for velocity measurement by pitot tube in

rectangular ducts (equal duct areas)

11.4 Pitot tube pressure difference (P D )-air velocity nomograph

11.5 Permissible positions in ducts for pitot tube measurements

and air sampling

11.6 Location of venturi and orifice meters in inlet drying air duct

11.7 Positions selected in spray dryer layout for various air flow

measurements illustrated in example 11.2

8.4

8.5

304

306

307

312

315

317

318

321

325

326

336

337

339

340

342

344

346

357

359

360

361

363

364

366

XXX LIST OF FIGURES

11.8 Inlet duct zoning for anemometer measurements in

example 12.2

367

11.9 Flow conditions at sampling nozzle

372

11.10 Effect of incorrect sampling rate on observed powder loading

in air stream

373

11.11 Basic layout for sampling powder laden air

373.

11.12 Velocity distributions and profiles existing in ductwork

arrangement

375

11.13 Layout of B.C.U.R.A. cyclone probe for sampling powder

laden air

378

11.14 Layout for measuring powder loadings in air flows using

the filter thimble sampler with orifice plate for sampling

rate control

382

11.15 Filter thimble sampler for measuring powder loadings in

air flow

383

11.16 Layout for measuring powder loadings in air flows using the

filter thimble sampler with gas meter for sampling rate

control

384

11.17 Layout for external filter thimble equipment

385

11.18 Measuring powder-air loadings by light intensity methods

386

11.19 Layout for sampling equipment based upon contact

electrification

387

11.20 The CEGRIT sampler for measuring powder loading in air

flows

389

11.21 Sound pressure level against frequency plot for assessing

acoustic environment of equipment

395

12.1 Relation between saturated steam pressure and temperature

402

12.2 Indirect air heaters

404

12.3 One- and two-fan spray dryer layouts

407

12.4 Principle parts of a centrifugal fan

409

12.5 Performance curves characteristics for radial, forward

curving, and backward curving blades

410

12.6 Fan performance chart for example 12.1

411

12.7 Relation between fan horsepower and installed fan motor

horsepower

415

12.8 Basic designs of industrial cyclones

421

12.9 Theoretical and actual grade efficiency curves

423

12.10 Grade efficiency curve for cyclones specified in example 12.7

424

12.11 Measuring pressure drop over a cyclone

427

12.12 Cyclone layout in parallel

431

12.13 Grade efficiency curve for a standard bag filter

432

12.14 Designs of bag filters

434

LIST OF FIGURES xxxi

12.15 Electrical power system for an electrostatic precipitator

438

12.16 Grade efficiency curve for a dry electrostatic precipitator

439

12.17 Gravity settler

440

12.18 Designs of wet scrubber

441

12.19 Grade efficiency curves for wet scrubbers

442

12.20 Hoppers

446

12.21 Powder removal valves

448-9

12.22 Vortex air-lock

451

12.23 Powder removal from cyclones, equipment in practice

452

12.24 Pneumatic conveying layouts

453

12.25 Determination of air rate and duct size for pneumatic

conveying

455

12.26 Classification of pumps

458

12.27 Feed system layouts

459

12.28 Automatic washing equipment

461

14.1 Examples of unit operations associated with wet preparation

as compared with spray drying process

502

14.2 Spray dryers for ceramic pressbody

503

14.3 Micro-photographs of pressbody

504

14.4 Particle size distributions of wall tile material produced by

atomizer wheel and pressure nozzle atomization

505

14.5 Spray dried steatite

506

14.6 Flow diagram for production of ferrite by spray drying

508

14.7 Flow diagram for preparation of spray dried jiggering bodies

510

14.8 Flow diagram for spray drying carbides in closed cycle

511

14.9 Flow diagram for spray drying of detergent formulations

516

14.10 A semi-closed cycle spray dryer for herbicides

520

14.11 Flow diagram for spray drying titanium dioxide

523

14.12 Flow diagram for producing kaolin by spray drying

524

14.13 High tonnage spray dryers on kaolin in Georgia, USA, each

producing 15-25 tons per hour

525

14.14 Production of ammonium nitrate prills by spray cooling

528

14.15 Flow diagram for production of mono-ammonium phosphate

by spray drying

529

14.16 Flow diagrams for the production of double superphosphate

fertilizers

532

14.17 De-watering operations for flotation concentrates

533

14.18 Flow diagram for spray drying flotation concentrates

534

14.19 Twin spray dryer complex in Western Australia, producing

536

bone dry nickel-concentrate

14.20 Flow diagram for manufacture of cement utilizing spray

541

drying

XXXii LIST OF FIGURES

15.1 Products derived from milk

15.2 Spray dryer layouts for dairy products

15.3 Forms of spray dried skim milk powder

15.4 Rewet instantizer (shown with agglomerating tube mounted)

15.5 Spray dryer with vibro-fluidizer for instant skim milk, whole

milk, milk replacer, ice-cream mix, cheese, cream powders

15.6 Processing stages in the spray drying of whey

15.7 Spray dryer producing non-caking whey powder

15.8 Flow diagram for the production of spray dried sodium

caseinate

15.9 Processing diagram for production of egg powders

15.10 Flow diagram for production of instant coffee powder by

spray drying

15.11 Process stages in the production of protein from vegetable

sources using spray drying

15.12 Flow diagram for the production of potato protein by spray

drying

15.13 Flow diagram for the production of tomato powder by spray

drying

15.14 Dehumidified enclosed band conveyor for cooling spray

dried tomato powder

15.15 Processing stages in production of banana powder by spray

drying

16.1 Single stage aseptic spray drying system

16.2 Two stage aseptic spray drying system

16.3 Flow diagram for aseptic spray drying plant with two-fluid

atomization

16.4 Spray dryer with rotary atomizer for aseptic drying

16.5 Flow diagram for the production of fodder yeast from

molasses

18.1 Stages in the processing of animal blood by spray drying

18.2 Flow diagram for the production of dried fish solids

A.5 Psychrometric charts for air-water vapour system at

atmospheric pressure

A.6 Humid heat-humidity relation for air-water vapour system

at atmospheric pressure

A.7 Latent heat of vaporization-temperature relation (water)

A.8 Liquid flow over vaned atomizer wheel

546

548

550

554

555

557

559

List of Tables

563

566

569

574

576

578

580

582

589

591

593

595

599

607

610

624-5

626

627

628

2.1 Calculation of mean diameters in example 2.1

2.2 Mean diameters based upon number, surface and volume

2.3 Distribution functions

2.4 Mean diameter transformation

2.5 Data for example 2,2

2.6 Calculation of Sauter mean diameter in example 2.2

5.1 Advantages and disadvantages of dry and wet powder

recovery

6.1 Prediction of droplet size following liquid jet disintegration

6.2 Droplet size prediction for smooth flat vaneless discs

6.3 Values of A = 0*(1) 2 ) 112

6.4 Values of radial velocity and liquid film thickness at edge of

vaned atomizer wheel (example 6.1)

6.5 Operating conditions covered by investigators in drawing

up equations (6.26-6.31) to predict spray characteristics

from atomizer wheels/discs

6.6 Effect of operating variables on droplet size from atomizer

wheels

6.7 Relation between mean droplet size and wheel speed for

different van loadings for low viscous feeds

6.8 Sauter mean diameter predicted from viscosity data (13, 42)

(figure 6.10) (a comparison with experimentally

determined values)

6.9 Relations to predict spray characteristics from atomizer

wheels

6.10 Comparison between experimental and predicted Sauter

mean droplet sizes

6.11 Values of constant in equation (6.30) for given dryer size

32

33

34

39

39

40

82

90

101

103

105

106

107

111

113

114

115

116

XXXiV

LIST OF TABLES

LIST OF TABLES

6.12 Range of operating variables applicable to curves A-E in

figure 6.11

6.13 Relations to predict droplet size from vaneless discs

6.14 Correlations to predict mean droplet size from centrifugal

pressure nozzles

6.15 Nozzle recommendation: enquiry form

6.16 Key to figure 6.48

6.17 Typical performance of internal mixing type nozzles

6.18 Correlations for predicting droplet size from converging

pneumatic nozzles

6.19 Experimental conditions covered by pneumatic nozzle

droplet size correlations

6.20 Relationship between dispersion coefficient, Sauter mean

diameter and slope of the Nukiyama-Tanasawa plot (6)

6.21 Values for example 6.15

6.22 Values for example 6.16

6.23 Comparison of predicted mean droplet sizes

6.24 Tabulated data showing pneumatic nozzle flexibility

6.25 Correlations for predicting droplet size from pneumatic cup

atomizers

6.26 Relation between Sauter mean diameter and maximum spray

droplet size

7.1 Relation between Reynolds Number (Re) and drag coefficient

(CD ) (for spherical droplet)

7.2 Spray trajectory relations for rotary atomizers

7.3 Values of K factor

7.4 Theoretical droplet trajectories in example 7.3 (from rotary

atomizer)

7.5 Theoretical droplet trajectories in example 7.4 (from nozzle

atomizer)

8.1 Proposals for the equation Nu (or Sh) = 2.0 + K(Re)x(Pr

or Sc)

9.1

117

153

11.1

205

11.2

206

11.3

11.4

209

215

219

220

228

233

12.1

12.2

12.3

12.4

12.5

12.6

13.1

234

13.2

249

251

255

14.1

267

14.2

15.1

16.1

16.2

270

286

Values of the integral f

in equation (8.23)

J C D Re l * 5

288

Fractional evaporation of aqueous droplets undergoing

decelerated motion in dry air (379°F)

8.4 Evaporation times for pure liquid droplets

8.5 Values of fl for different temperature driving forces

8.6 Spray evaporation history

8.7 Evaporation of aqueous droplets in atmospheres of air and

superheated steam

289

291

291

300

8.3

on

9.3

9.4

184-5

190

195

200

d(Re)

8.2

9.2

316

XXXV

Collection efficiency of primary separators on low and high

328

powder/air loadings

Suitability of powder-air separation equipment in spray

330

dryer installations

331

Relative costs of separation equipment in spray drying

Dimensions of separation equipment to handle 70 000 m 3 /hr

332

air at 80°C

Effect on Pd reading of pitot tube misalignment in the air

360

stream

Equipment for determination of powder loading in ducted

377

air flows

379

Efficiency of B.C. U R.A. cyclone

Available methods of measuring droplet size distribution of

397

sprays and particle size distribution of dried product

405

Efficiencies of indirect fuel oil air heaters

414

Typical fan efficiencies

425

Data for example 12.7

430

Dimensions of industrial and model cyclones

435

Recommended face velocities for bag filter designs

437

Properties of bag filter fabrics

Products suitable for suspended particle processing systems,

471-5

involving atomization

Recent patents and patent applications dealing with products

476-97

to which spray drying or spray cooling is applied

Particle size distribution of oxide ceramics according to

507

atomizer used

530

Methods of double superphosphate manufacture

553

Properties of ordinary and instant milk powders

594

Uses of spray dried enzymes

598

Relative compositions of fodder yeast and muscular protein

Introduction

Spray drying is by definition the transformation of feed from a fluid

state into a dried form by spraying the feed into a hot drying medium. It

is a one step continuous suspended particle processing operation. The

feed can be either a solution, suspension or paste. The resulting dried

product conforms to powders, granules or agglomerates, the form of which

depends upon the physical and chemical properties of the feed and the

dryer design and operation. Spray drying is a procedure which in many

industries meets dried product specifications most desirable for subsequent

processing or direct consumer usage. Intensive research and development

during the last two decades has resulted in spray drying becoming a highly

competitive means of drying a wide variety of products (1). The range of

product applications continues to expand so that today spray drying has

connections with many things that touch our daily lives. The extent of

this will become apparent during the course of this book.

Spray drying has moved into all major industries ranging from production

in the most delicate of conditions laid down in food and pharmaceutical

manufacture right through to the high-tonnage outputs within such heavy

chemical fields as mineral ores and clays. There are many products and

articles in use around us each day to exemplify the extensive usage of spray

drying. This is apparent if we consider just one aspect of common interest

to us all, namely our home living.

From foodstuffs to home fittings, spray drying has many associations.

Each product requires different powder requirements to be met during

manufacture. For example, the housewife may be concerned only with

the taste and price of the foodstuffs she buys and the quality of the household

aids she uses, but it is most likely one would find a wide range of foodstuffs,

equipment and fittings within her home having direct and indirect connections with the spray drying operation. Foodstuffs may well be instant

2

INTRODUCTION

coffee, coffee whitener, dried eggs, milk, soups, babyfoods, perhaps even

powdered cheese and fruits. These are examples of products with direct

connections. Spray dried foodstuffs appeal to the eye, retain nutritive

contents and are easy to use, through being readily dry mixed and reconstituted. This is irrespective of their dried forms which are highly diverse.

Milk powders can be in agglomerated (instant) form, whereas eggs, soup,

coffee whitener have powdery, and fruits granular, forms. Apart from dried

foodstuffs that are consumed directly, there are a variety of spray dried

products used in cuisine. Examples include condiments (garlic, pimento),

flavouring compounds, rennet, and ingredients in biscuits and cakes. Meat,

vegetables and fresh fruit are foodstuffs with indirect connections with spray

drying. Meat may be from a slaughtered animal reared on feeds based

upon spray dried skimmilk, whey or fat enriched milk (replacer). Whereas

appearance might not be so crucial here, particle size and consistency

must be conducive to animal digestion. All vegetables and fruit can be

connected with spray dried fertilizers and pesticides used in cultivation.

Here good spreading characteristics are the powder requirements, placing

emphasis on particle size distribution and moisture content of the powder.

Passing from foodstuffs to general household commodities, many examples

can be cited. Perhaps the best known spray drying application is household

detergents; but also spray dried soaps and other surface active agents

and optical brighteners are available. In the bathroom cabinet spray

dried pharmaceutical products, and even cosmetics, are likely to be found.

Pharmaceuticals, e.g. antibiotics, are produced under the most aseptic of

conditions as finely divided powders, which are often tableted prior to

marketing. The spray dried powder form is ideal for rapid assimilation

into the body organs. Many cosmetics rely on spray drying to provide

constituents in such articles as face powders and lipsticks. Applications

to home fittings and furnishings are also extensive. Wall tiling is formed

by pressing coloured spray dried clays. Paints contain spray dried pigments.

Electrical insulation material is spray dried prior to pressing into parts for

electronics and electric power supplies. Also in the electronics field spray

dried ferrites enjoy wide use, being found in pressed form in telephones,

radio, television, etc. Many household aids are powered by an electric

motor with a ferrite rotor. All these pressing operations demand strict

particle size distributions that can be met by the spray drying operation.

No such survey of spray dried products in the home is complete without

mention of (a) plastics, as many household plastic utensils originate from a

manufacturing process that includes a spray drying stage; (b) fabrics, as

spray dried dyestuffs provide the vivid colours of furnishings and clothing;

(c) stationery, as spray drying provides many materials for printing while

spray dried kaolin is used in paper making itself ; (d) shoes, bags and leather

INTRODUCTION

3

wear as spray dried tannin is closely associated with the curing of leather ;

(e) starches, as the extensive processing of this, one of mankind's most

basic materials, often includes a spray drying stage. Spray dried starch

and its derivatives (sugar, syrup) are widely used in ice cream, confectionary,

desserts, jellies, preserves, frozen fruit, soft drinks. In non-food manufacture,

spray dried starch is used in textiles, papermaking, printing and adhesives.

Examples could go on, but the point has surely been made. The variety

of spray dried products illustrates the ability of spray drying equipment to

meet a wide range of powder product requirements.

Spray drying involves atomization of feed (hereafter aqueous unless

stated otherwise) into a spray, and contact between spray and the drying

medium (hereafter termed air unless stated otherwise) resulting in moisture

evaporation. The drying of the spray proceeds until the desired moisture

content in the dried particles is obtained, and the product is then recovered

from the air. These four stages are illustrated in figure 0.1.

I STAGE I

'ATOMIZATION

L

_J

IR

1

0

AIR

STAGE 2

SPRAY-AIR

LcONTACT

r

r

-

1

STAGE 4

DRIED

POWDER

RECOVERY

STAGE 3

!MOISTURE

EVAPORATION

FROM SPRAY

-

DRYING

CHAMBER

L

.1

U

L

Figure 0.1, The process stages of spray drying.

4

INTRODUCTION

INTRODUCTION

The word 'atomization' can be confusing initially. 'Atomization' has no

association with atoms and nuclear physics but covers the process of liquid

bulk break-up into millions of individual droplets forming a spray. The

energy necessary for this process is supplied by centrifugal, pressure, kinetic

or sonic effects. During spray—air contact, droplets meet hot air and a

rapid moisture evaporation takes place. If the spray drying plant is properly

designed the outcome will be dried particles suspended in the drying air,

from which an efficient particle removal is essential. Explaining the process

through viewing an actual installation can be unrewarding as the spray

drying operation cannot be separated into distinct processes for individual

viewing.

Any form of dryer provides means of moisture removal by the application

of heat to the feed product and control of the drying medium humidity. A

spray dryer is no exception. Heat is applied as a heated atmosphere and

evaporation is promoted by spraying the feed into this atmosphere. Humidity

control is by air flow and temperature regulation. Although the vast

majority of cases employ hot atmosphere to drive moisture from each

spray droplet, there are cases where the delicacy of the operation demands

that the drying medium is just warmed over atmospheric temperatures.

This is a variation of the basic spray drying concept, and is termed low

temperature spray drying. A further variation is to spray the product into

freezing air, whereupon the individual droplets are frozen for subsequent

moisture removal through sublimation under vacuum. This variation of

spray drying is termed spray freeze drying. Should the temperature of the

air permit only solidification of the spray droplets, the process is termed

spray cooling.

A still further variation is to utilize the chamber as a spray reactor. For

liquids that react chemically with a given gas to form a new compound, the

contacting of gas with liquid in an atomized state gives rise to fast reaction

rates because of the large surface area of the droplets. The process is termed

spray reaction.

The spray drying chamber need not only be used to produce dry products;

use as a spray concentrator has long been recognized. In fact the use of

drying and concentrating liquids by atomizing techniques can be traced

back to a one hundred year old patent (2). The historical background of

spray drying has been recently described by Hatfield (130).

While most of the spray drying operations utilize a drying medium of

air and exhaust the air to atmosphere (open cycle), there are cases where

an inert gas, e.g. nitrogen, is used as the drying medium instead of air. The

inert gas prevents risk of explosion where flammable or .explosive solvents

are involved. The inert gas is constantly re-used in the drying process

through re-cycling within a closed system. The evaporated liquid absorbed

5

into the drying gas in the drying chamber is recovered in a scrubber—

condenser system. Organic solvents and diluents can thus be evaporated

and recovered. For products that form potentially explosive powder—air

mixtures in the chamber of an open cycle drying system or where the exhaust

air contains pollutants or odours, the semi-closed drying system can be

used. In the former case, explosions are prevented by lowering the 0 2

content in the drying chamber by control of the combustion air to a direct

air heater and exhaust air bleed (see page 522). In the latter case the pollutants

and odours in the exhaust air bleed, which forms a small percentage of

dryer air requirement, are deactivated prior to atmospheric emission.

The spray drying layout and its possible modifications to closed cycle and

semi-closed spray drying, spray cooling, spray reaction and spray freeze

drying are illustrated in figure 0.2.

In introducing the subject, emphasis has been given to the ability of the

spray drying process to handle a wide range of products, and meet the

combustion

air

ine t gas

make-up

hot

heater

DRYING

CHAMB ER

DRYING

CHAMBER

p

A OPEN CYCLE

B CLOSED CYCLE

C

SEMI-CLOSED CYCLE

SPRAY DRYING

otIT.05ph0dC

air

COOLING

REACTION

FREEZING

CHAMBER

CHAMBER

CHAMBER

SPRAY COOLING

SPRAY REACTION

SPRAY FREEZING

KEY: f—feed, p--product, s—scrubber/condenser/cooler.

Figure 0.2. Layouts of spray dryers and associated suspended particle processing equipment

involving atomization.

6

INTRODUCTION

specifications laid down by diversified industries. Such range of application

has led to dryer designs becoming less standardized as each product has

to be treated individually and handled in specialized ways to meet the

dried product specifications. Whatever dryer design the product demands,

the advantageous features of spray drying are retained.

These advantages can be listed as :

(1) Continuous in operation.

(2) Adaptable to full automation.

(3) Dried product specifications met through dryer design and operational

flexibility.

(1) Required product form (particles as spheres, cenospheres, fines,

agglomerates) (figure 0.3).

(ii) Required product properties (dusty or dustless, degree of flowability,

wettability, etc., also see below).

(4) Applicable to both heat sensitive and heat resistant materials.

(5) Economic in operation.

Dried product specifications are related to the properties of :

(a) Particle size distribution. This governs product appearance, packing, and

subsequent processing requirements.

(b) Bulk density and particle density. This is closely related to packing

container requirements. Spray drying maintains constant product density

and eliminates the need for batch mixing to meet specified densities.

(c) Appearance. This is vital from the consumer angle.

(d) Moisture content. This governs powder quality, colour, flowability,

shelf life, packing and subsequent processing requirements.

(e) Friability. This is related to handling and packing.

(f) Dispersibility. This is related to rate of solubility on reconstitution.

(g) Colour, aroma, taste. This is related to overall powder quality.

(h) Activity. This is related to any heat degradation occurring with biochemical products.

Economic operation is closely associated with drying temperatures and

solids content in the feed. The higher the drying temperatures and solids

content, the greater the thermal efficiency' of the process. For example,

based on an ambient and outlet drying air temperature of 68°F (20°C) and

185°F (85°C), increase in inlet drying air temperature from 275°F (135°C)

to 1202°F (650°C) increases the overall dryer efficiency from about 44

to 90 Z. Increase in feed solids (for a given production rate) from 50 % to

60 % reduces the heat load by nearly 50 %. However, many spray dryers

operate at low feed solids and comparatively moderate drying temperatures

as these conditions are dictated by the feed properties. In these cases,

successful operation is based not so much on thermal efficiency but on the

ability of the process to dry delicate products without degradation.

INTRODUCTION

7

(a)

(b)

(c)

Figure 0.3. Dried-powder forms produced by spray drying. (a) Fine particles (dusty) (noninstant skim milk). (b) Spheres (Aluminium oxide). (c) Agglomerates (instant skim milk).

8

INTRODUCTION

• The book is divided into five sections. Section I contains five chapters

on basic principles and includes important definitions. Section II deals

with the process stages of spray drying, where individual chapters are

given to atomization, spray—air contact (mixing and flow), drying of sprays,

and dried product recovery. Section III, entitled 'Operational Practice',

describes control systems and common operational measurements. Section

IV briefly surveys some of the equipment used on spray dryers. Section V

concludes the book with descriptions of established, new or interesting

products that are spray dried nowadays. Products are classified according

to their induStry.

A literature survey, including recent patents covering spray drying

applications, is given at the beginning of section V (chapter 13).

Section I

BASIC PRINCIPLES, DEFINITIONS

1 Spray Drying Fundamentals

Spray drying consists of four process stages (figure 0.1):

(A) Atomization of feed into a spray.

(B) Spray—air contact (mixing and flow).

(C) Drying of spray (moisture evaporation).

(D) Separation of dried product from the air.

Each stage is carried out according to dryer design and operation, and,

together with the physical and chemical properties of the feed, determines

the characteristics of the dried product. The spray homogeneity following

atomization and the high rates of moisture evaporation (spray—air mixing

and flow) enable the temperature of the dry product to be considerably

lower than the drying air leaving the drying chamber. The product is thus

not subjected to high temperatures, and when separated from the drying

air is devoid of any heat degradation. The basic physical principle of

`evaporation causes cooling' is very pertinent to the operation.

Figure 1.1 shows diagrammatically what features each process stage has.

Figure 1.2 indicates the actual equipment involved to carry out each stage

in a standard layout, represented by a rotary atomizer, cyclone separators

and pneumatic product conveying. Feed is pumped from the product

feed tank (1) to the rotary atomizer (5). The atomizer is located within a

ceiling air disperser (12), through which drying air enters the drying chamber

(15). The air is drawn from atmosphere by a supply fan (8) and is steam

heated (10). Following the drying of the spray in the chamber, the majority

of dried product falls to the base of the chamber and enters a pneumatic

conveying system (20) via a powder offtake (18). Conveying air is filtered (19).

The product fines remain entrained in the air and pass (27) to cyclones (28)

for separation. The fines enter the pneumatic conveying system. Exhaust

air passes to atmosphere via the exhaust fan (31), Dried powder in the

SPRAY DRYING FUNDAMENTALS

BASIC PRINCIPLES, DEFINITIONS

pff

f7 d

ULLl

SPRAY EVAPORATION

;61,

SPRAY-AIR

L)

Figure 1.1. The features of the process stages involved in spray drying (shown diagrammatically).

PRODUCT SEPARATION

h,

oax

z

13

ao

Sti

FEED -ATOMIZATION

12

Equipment items

Feed system

1. Product feed tank.

2. Water feed tank for use during dryer

start-up and shut down.

3. Three way valve and filter.

4. Feed pump.

Atomizer system

5. Rotating vaned wheel atomizer.

6. Atomizer motor drive.

Supply air and spray-air contact system

7. Filter at drying air intake.

8. Air supply fan.

16. Insulated chamber wall.

17. Chamber pressure detector.

Product recovery system

18. Powder discharge unit at chamber base.

19. Filter at conveying air intake.

20. Pneumatic conveying system duct.

21. Transport cyclone.

22. Powder hopper.

23, Rotary valve.

24. Pneumatic conveying system exhaust

duct.

25. Conveying air fan (transport fan).

26. Outlet drying air temperature measuring

element.

27. Exhaust drying air duct.

28. Main powder recovery cyclone.

29. Rotary valve.

30. Exhaust air duct from cyclone.

31. Exhaust drying air fan.

32. Exhaust air flow damper.

33. Exhaust air stack.

34. Air hood.

35. Spray dryer control panel.

9. Air flow damper.

10. Air heater (here shown as a steam-air

heater).

11. Inlet drying air temperature measuring

element.

12. Air disperser.

13. Cooling air outlet (air disperser cooling),

14. Air disperser cooling fan.

15. Spray drying chamber.

Figure 1.2. Equipment involved in a standard spray dryer layout. (By courtesy of Niro

Atomizer.)

pneumatic transport system is collected at the base of the transport cyclone

(21). Instrumentation items include air temperature measurement (11) (26),

chamber pressure measurement (17) and dampers (9) (32) for adjustment

of air flows.

14

BASIC PRINCIPLES, DEFINITIONS

SPRAY DRYING FUNDAMENTALS

15

(A) Atomization of Feed into a Spray

The formation of a spray (atomization) and the contacting of the spray

with air are the characteristic features of spray drying. The selection and

operation of the atomizer is of supreme importance in achieving economic

production of top quality products. The atomization stage must create a

spray for optimum evaporation conditions leading to a dried product of

required characteristics.

Rotary atomizers and nozzles are used to form sprays. With rotary

atomizers centrifugal energy is utilized. There are two categories of rotary

atomizers : (a) atomizer wheels, (b) atomizer discs. Wheel designs are

available to handle feed rates up to tens of tons feed per hour. With nozzle

atomization, pressure, kinetic or (less common) sonic energy is utilized.

There is a wide range of nozzle sizes and designs to meet spray drying needs.

Feed capacities per nozzle are lower than per rotary atomizer, leading to

nozzle duplications to meet high feed rate requirements.

The selection of the atomizer depends upon the nature of the feed and

the desired characteristics of the dried product. In all atomizer types,

increased amounts of energy available for liquid atomization result in

sprays having smaller droplet sizes. If the available atomization energy is

held constant but the feed rate is increased sprays having larger droplet

sizes will, result. The degree of atomization depends also upon the fluid

properties of the feed material, where higher values of viscosity and surface

tension result in larger droplet sizes for the same amount of available

energy for atomization.

(i) Rotary Atomizers (Utilization of Centrifugal Energy)

Feed is introduced centrally on to a wheel or disc rotating at speed. The

feed flows outwards over the surface, accelerating to the periphery. Feed,

on leaving the periphery, readily disintegrates into a spray of droplets.

Rotary atomizers form a low pressure system. A wide variety of spray

characteristics can be obtained for a given product through combinations

of feed rate, atomizer speed and atomizer design. Designs of atomizer

wheels have vanes or bushings. Vanes are high, wide, straight or curved;

bushings circular or square. Vaned atomizer wheels are used in many and

varied industries, producing sprays of high homogeneity. Atomizer wheels

with bushings are used in more specialized fields, e.g., for handling abrasive

feeds. Wheels can be operated to produce sprays in the fine to medium

coarse size range (see figure 2.1). Peripheral velocities reach 550 ft/sec

(154 m/sec) in industry. Designs of disc include vaneless plates (discs),

cups, and inverted bowls. Discs are used to meet coarse spray requirements.

Rotary atomization is discussed in detail in chapter 6. The spray form

leaving a rotary atomizer (vaned wheel) is shown in figure 1.3(a). Rotary

atomizers are reliable, easy to operate and can handle varying loads.

(a)

(b)

Figure 1.3. Atomizers in operation. (a) Rotary atomizer (vaned wheel). (b) Nozzle atomizer

(pressure nozzle).

16

BASIC PRINCIPLES, DEFINITIONS

(ii) Pressure Nozzles (Utilization of Pressure Energy)

The feed concentrate is fed to the nozzle under pressure. Pressure energy

is converted to kinetic energy, and feed issues from the nozzle orifice as a

high-speed film that readily disintegrates into a spray as the film is unstable.

The feed is made to rotate within the nozzle resulting in cone shaped spray

patterns emerging from the nozzle orifice. Sprays from pressure nozzles

handling high feed rates are generally less homogeneous and coarser than

sprays from vaned wheels (see figure 2.1). At low feed rates spray characteristics from nozzles and wheels are comparable. Duplication of nozzles

allows fine sprays to be obtained in nozzle dryers, but nozzles are generally

used to form coarse particle powders having good free flowability. The

spray form leaving a pressure nozzle is shown in figure 1.3(b). Variation of

pressure gives control over feed rate and spray characteristics. Pressure

nozzles have operating pressures up to 10 000 p.s.i. (680 atm). Pressure

nozzles are described in detail in chapter 6.

(iii) Two-fluid Nozzles (Utilization of Kinetic Energy)

The feed concentrate and atomizing gas (usually air) are passed separately